Comparison of Dynamic Vibration Control Techniques by the GFRPU and/or LTMD System

Abstract

1. Introduction

2. Research Significance

3. Specimens

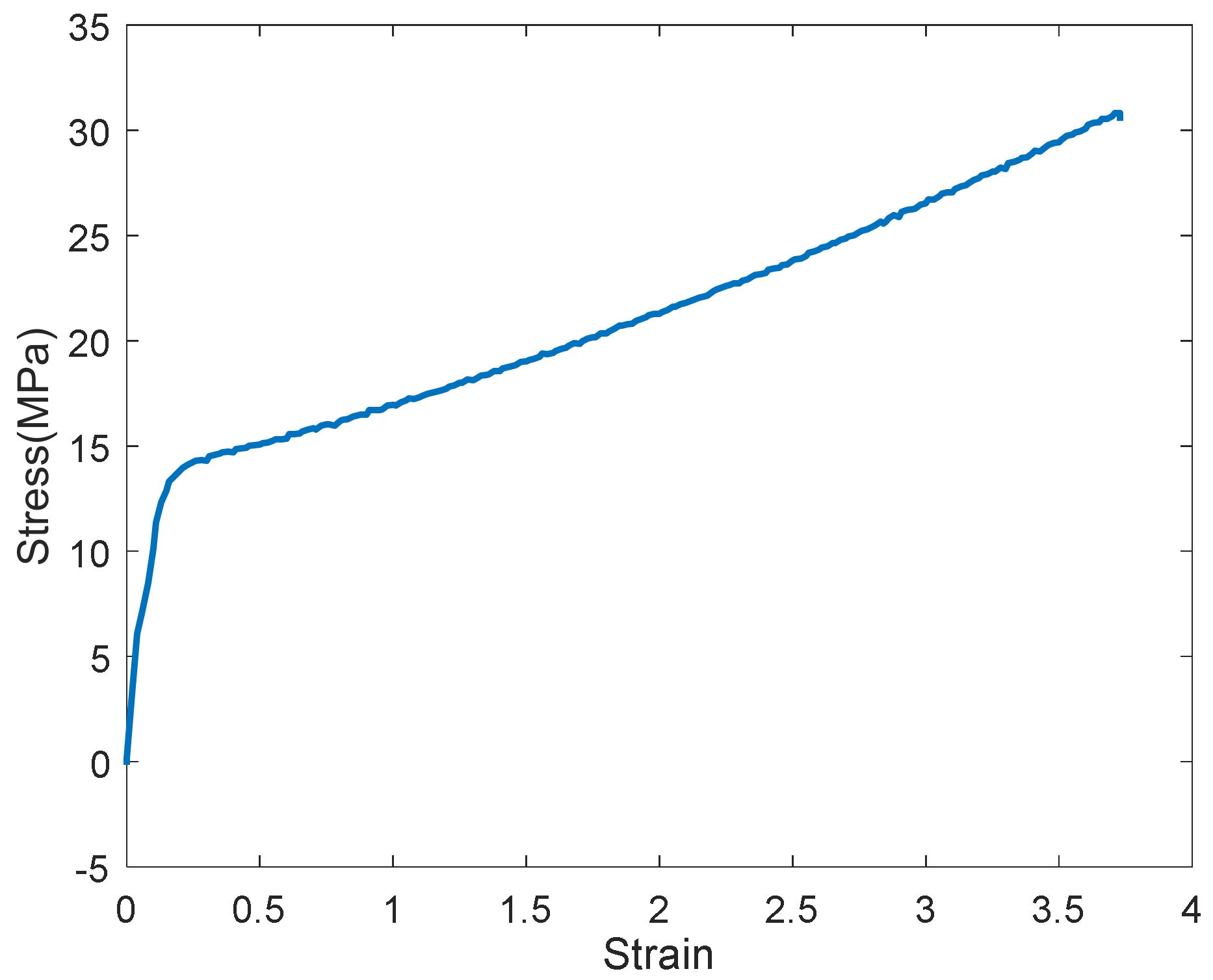

3.1. Materials

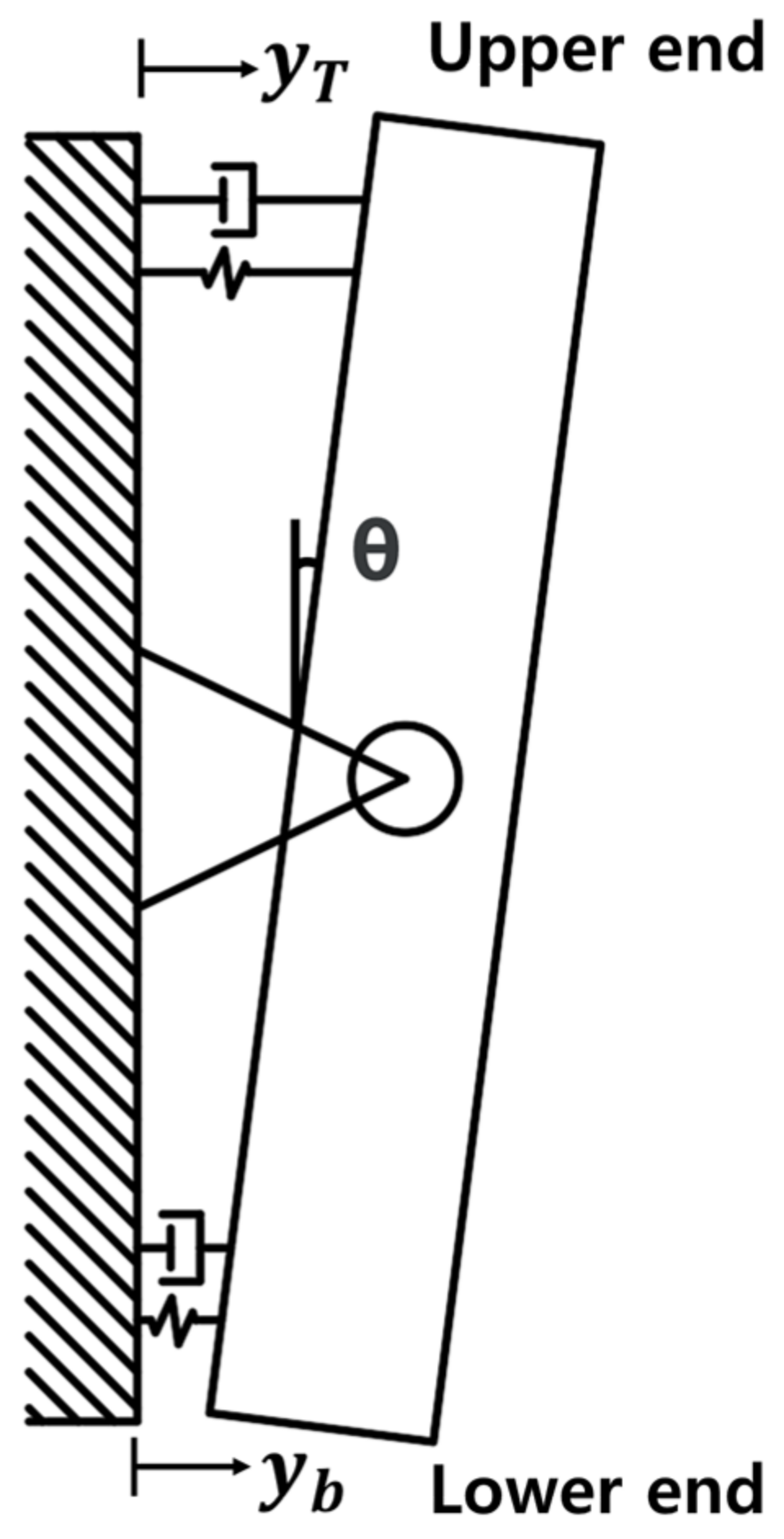

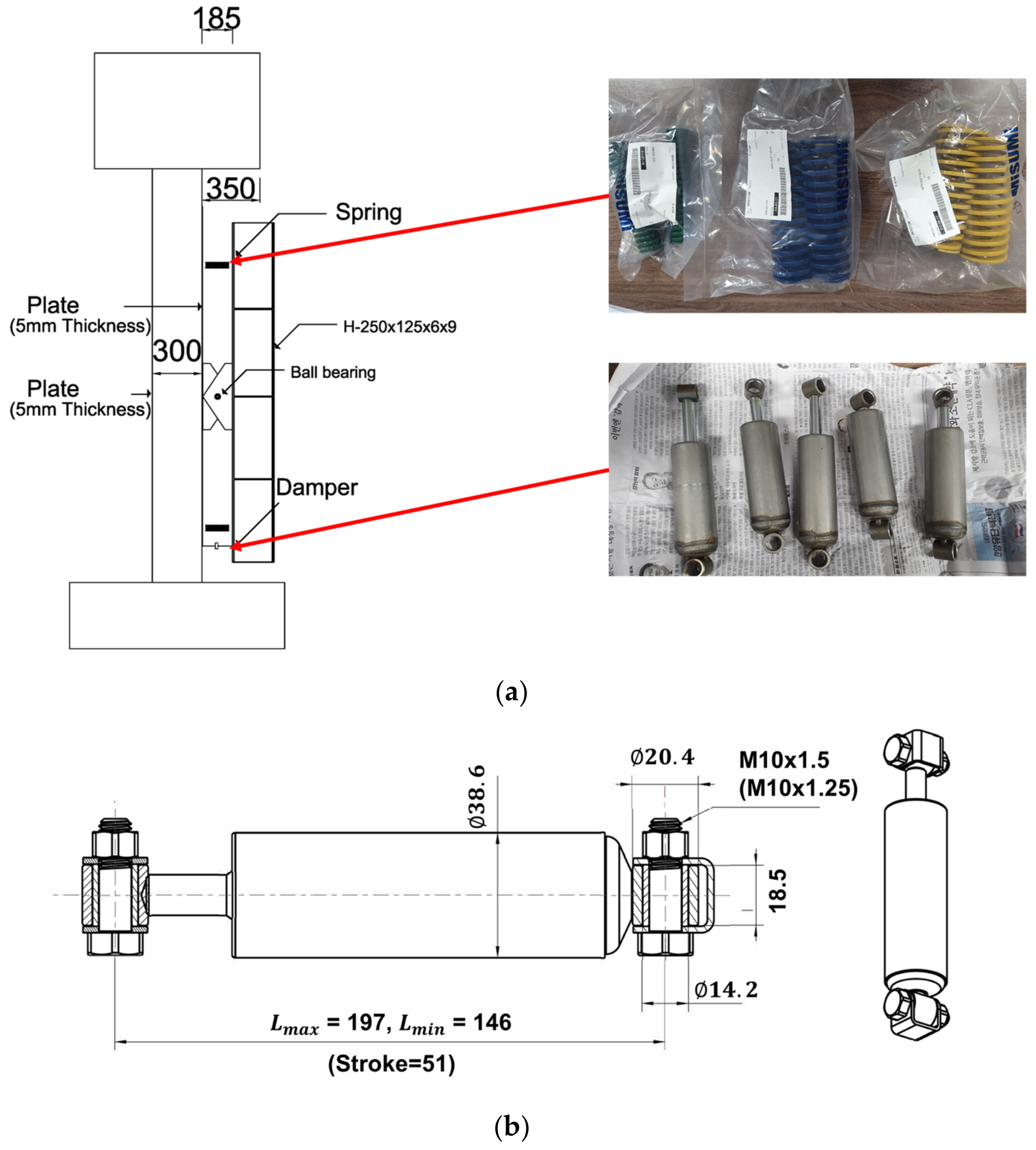

3.2. Specimens

3.3. Loading Instruments and Measurements

4. Experimental Results

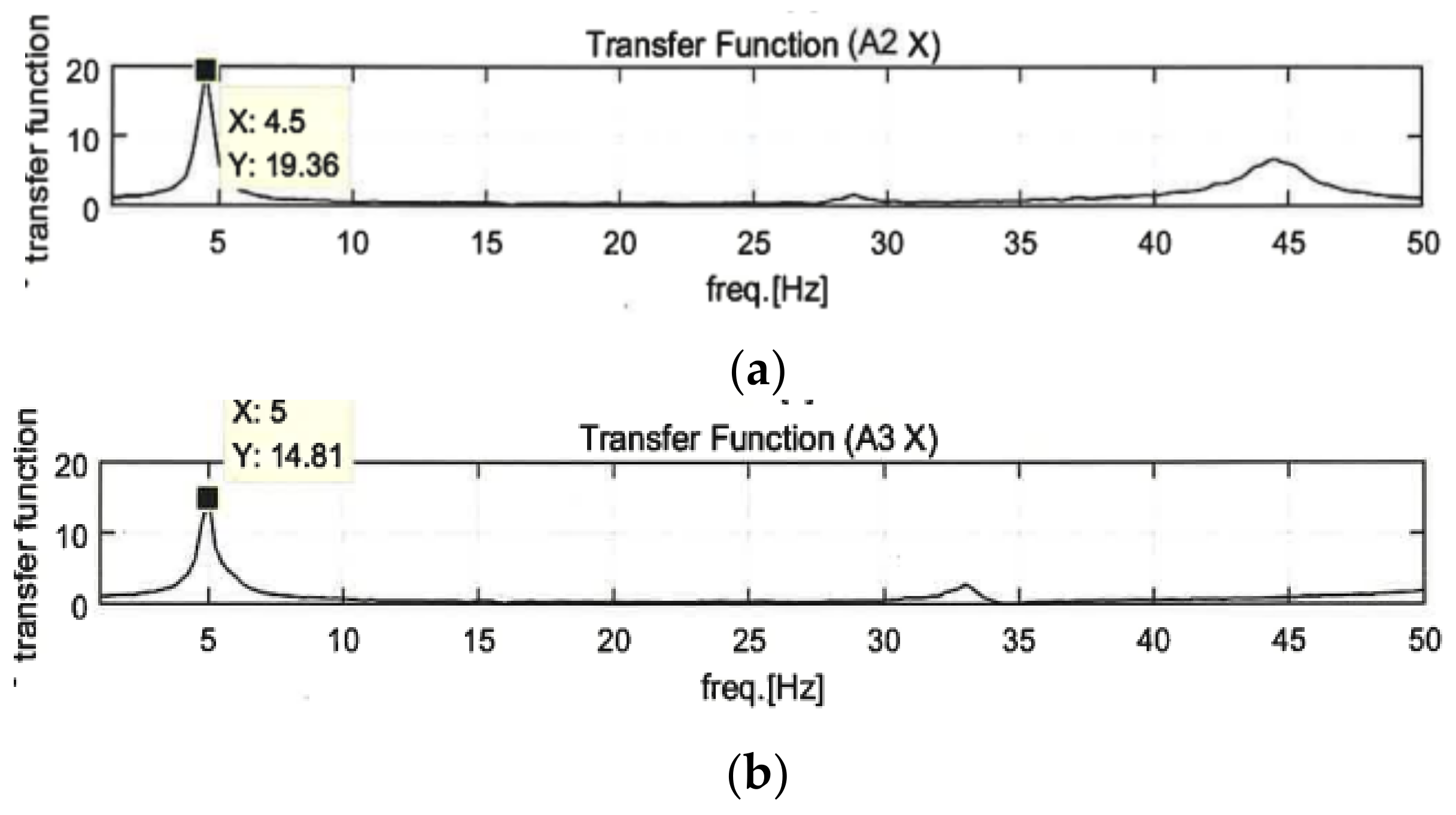

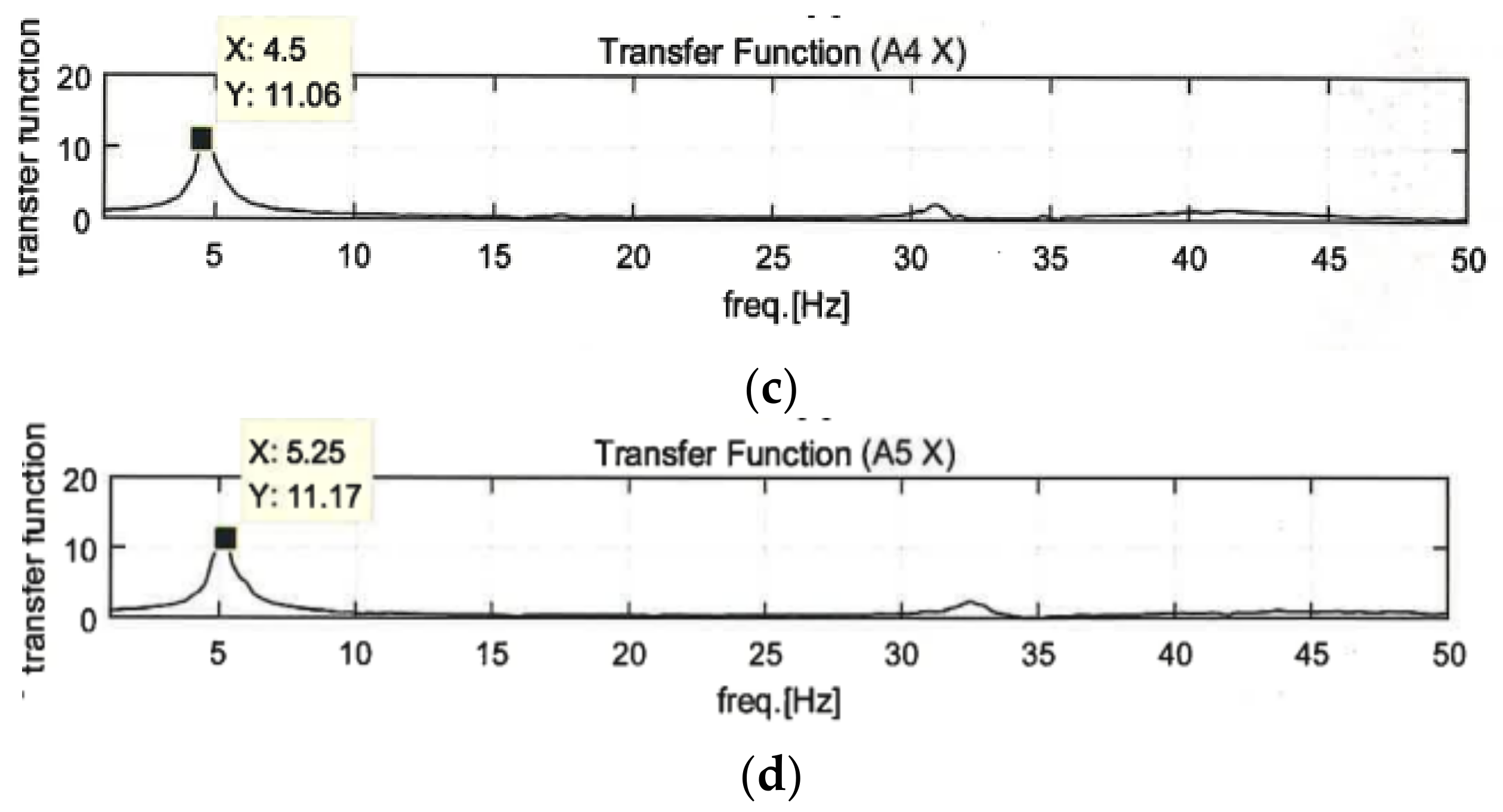

4.1. Natural Frequency of Specimen

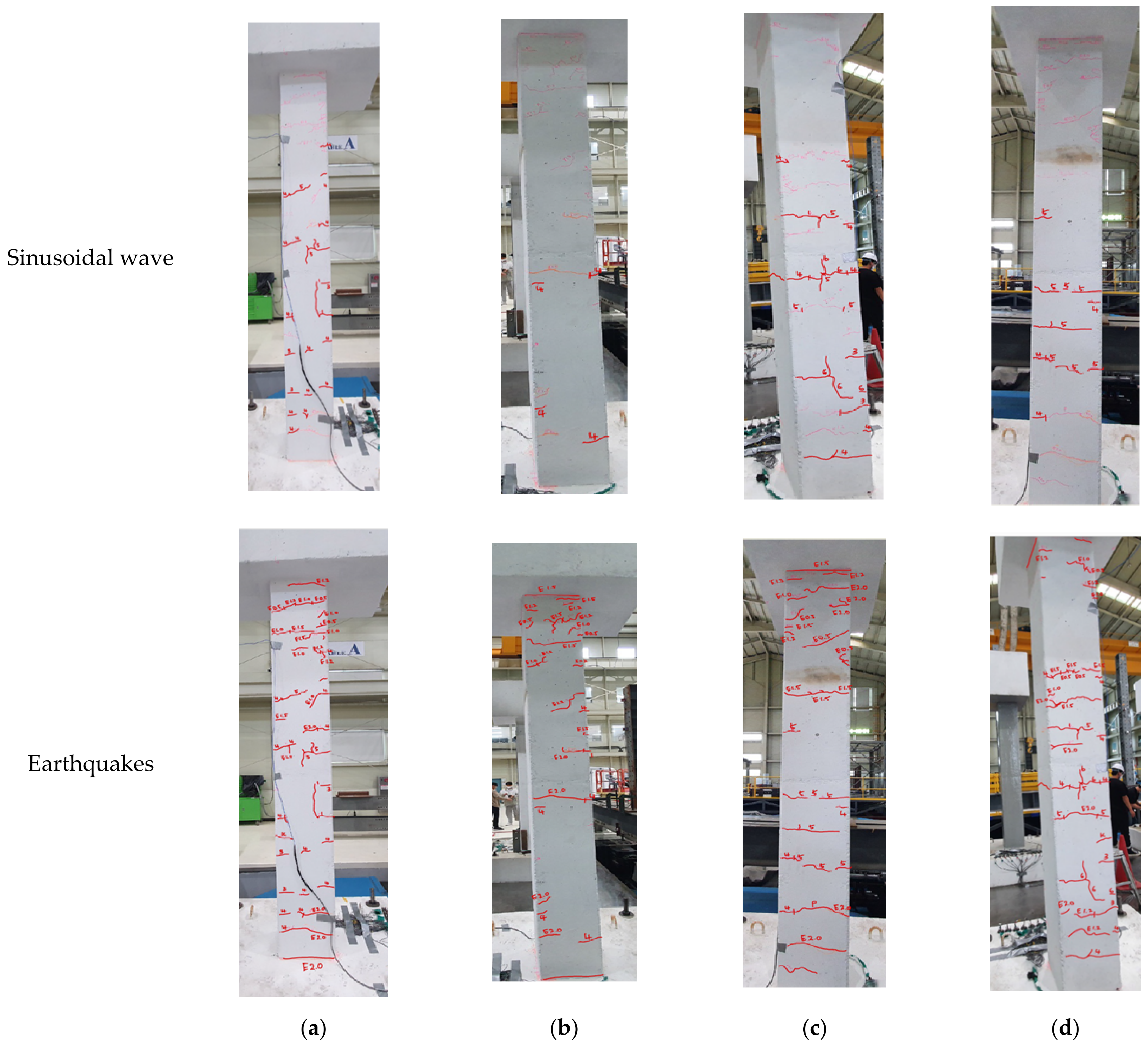

4.2. Deflected and Failure Modes

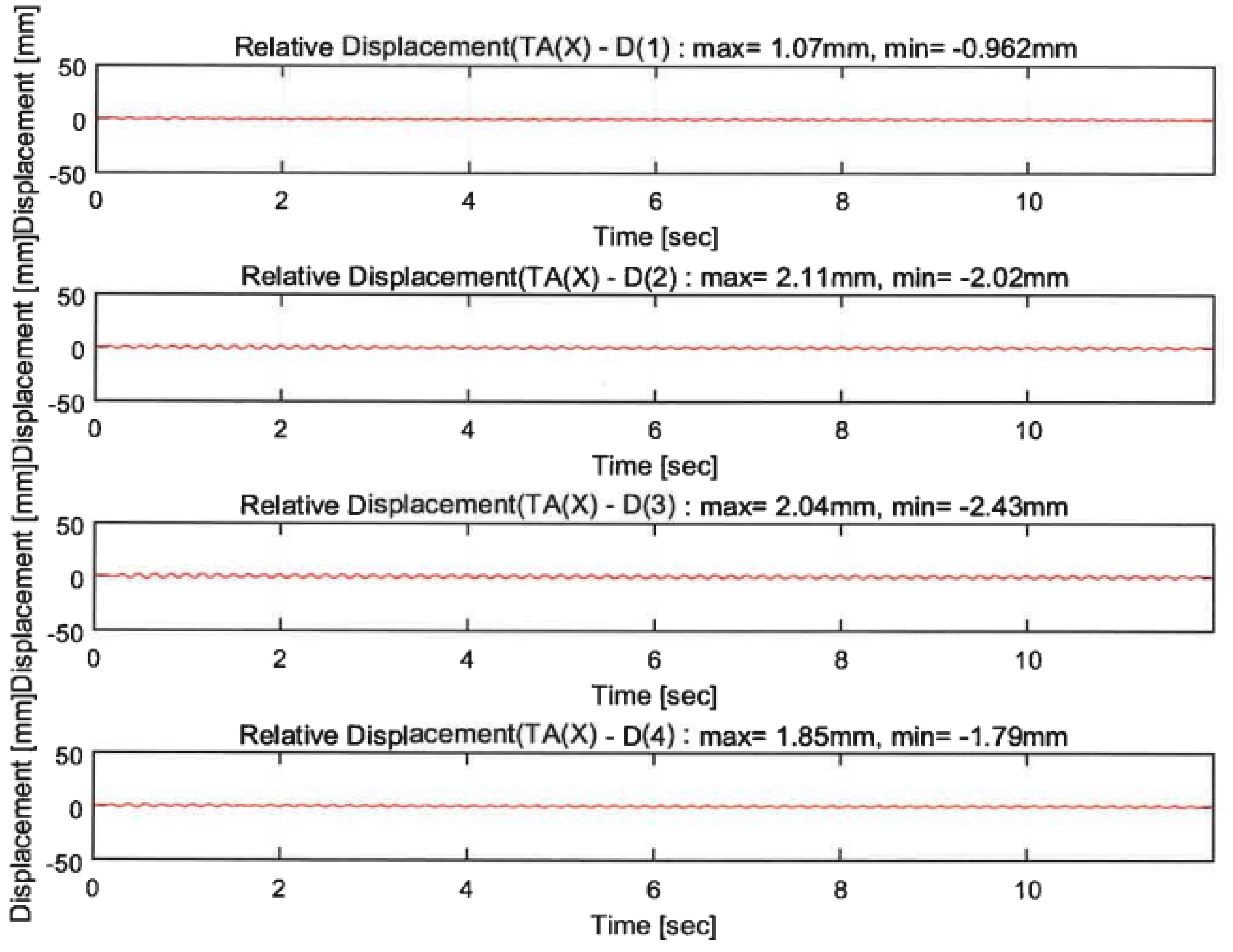

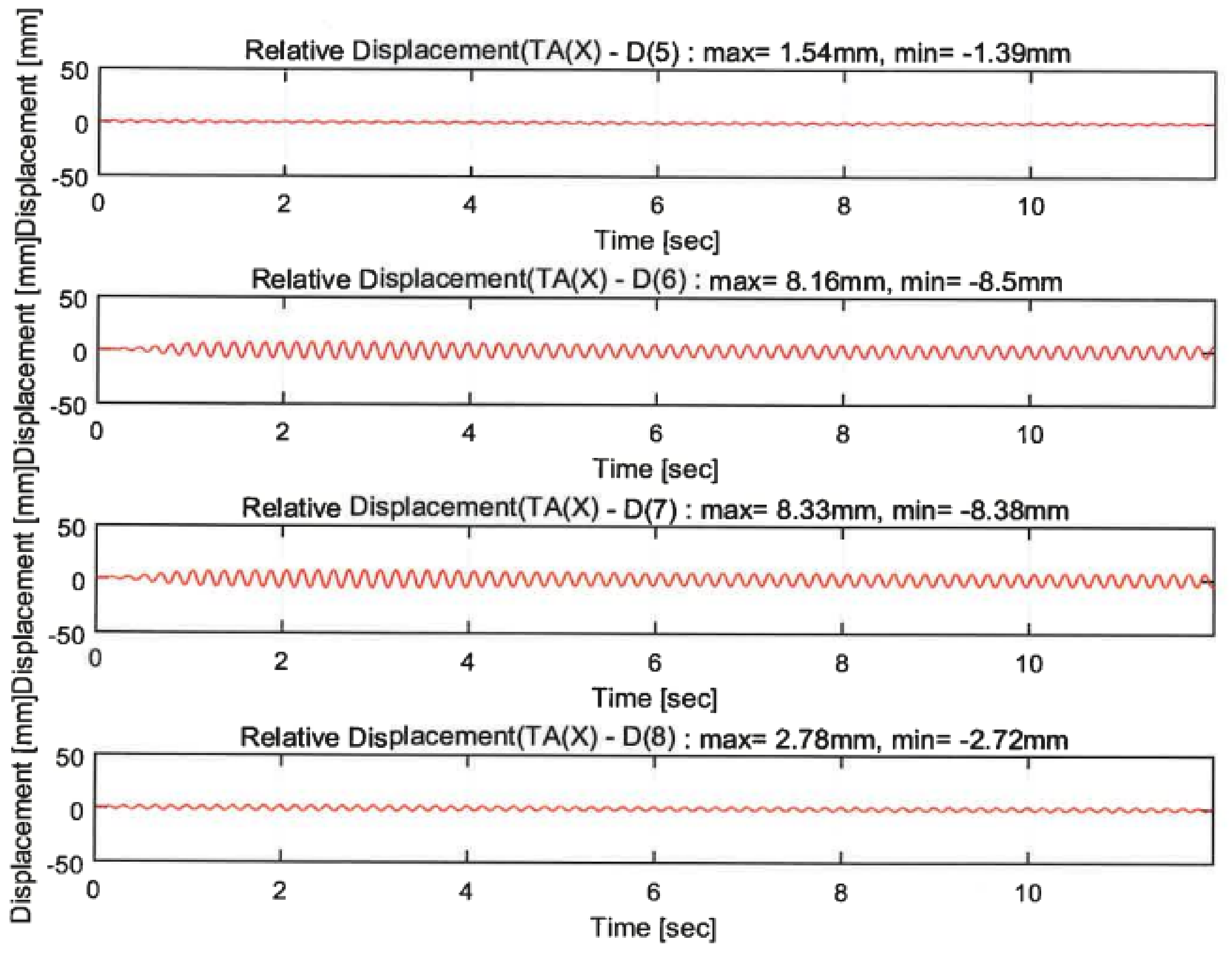

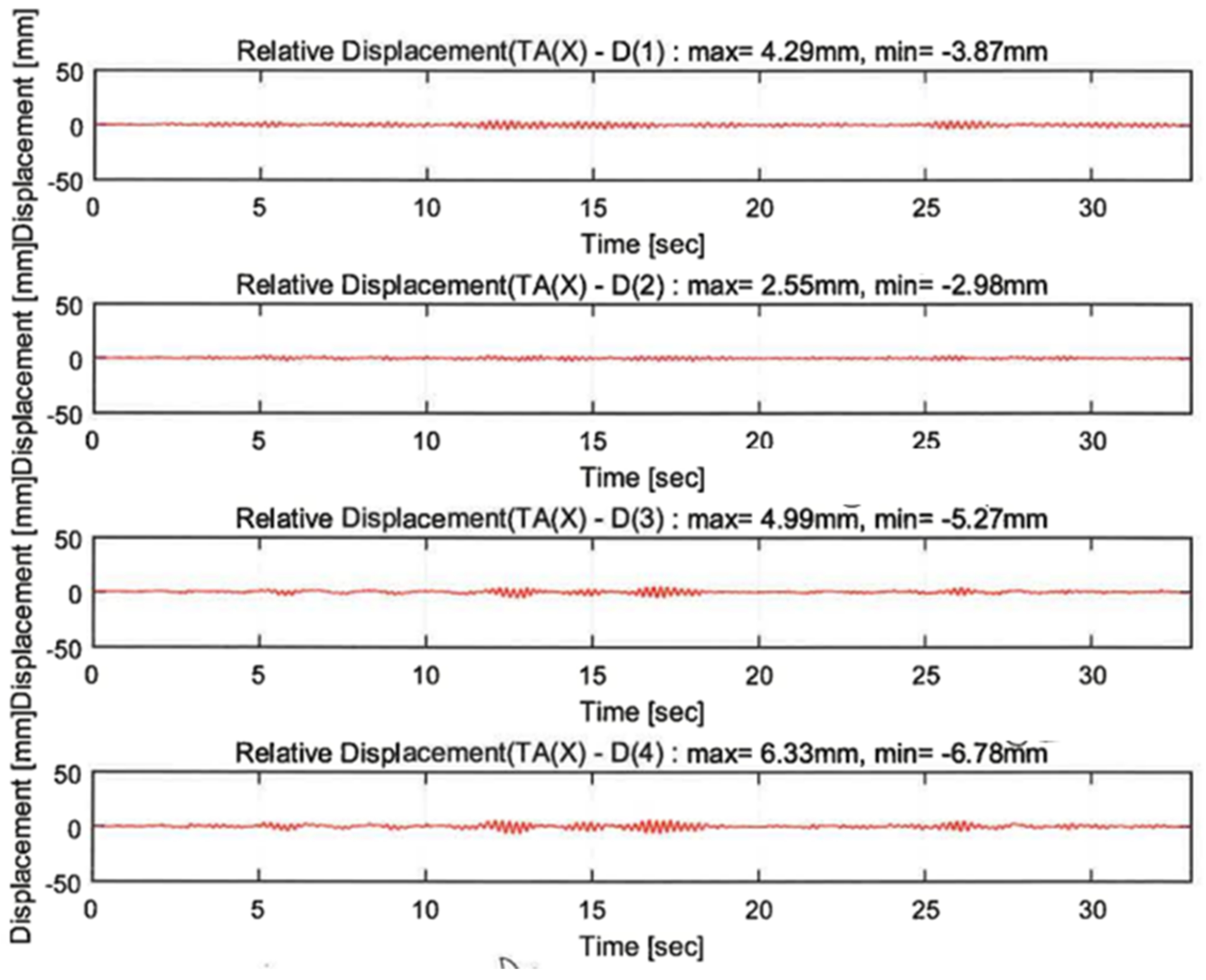

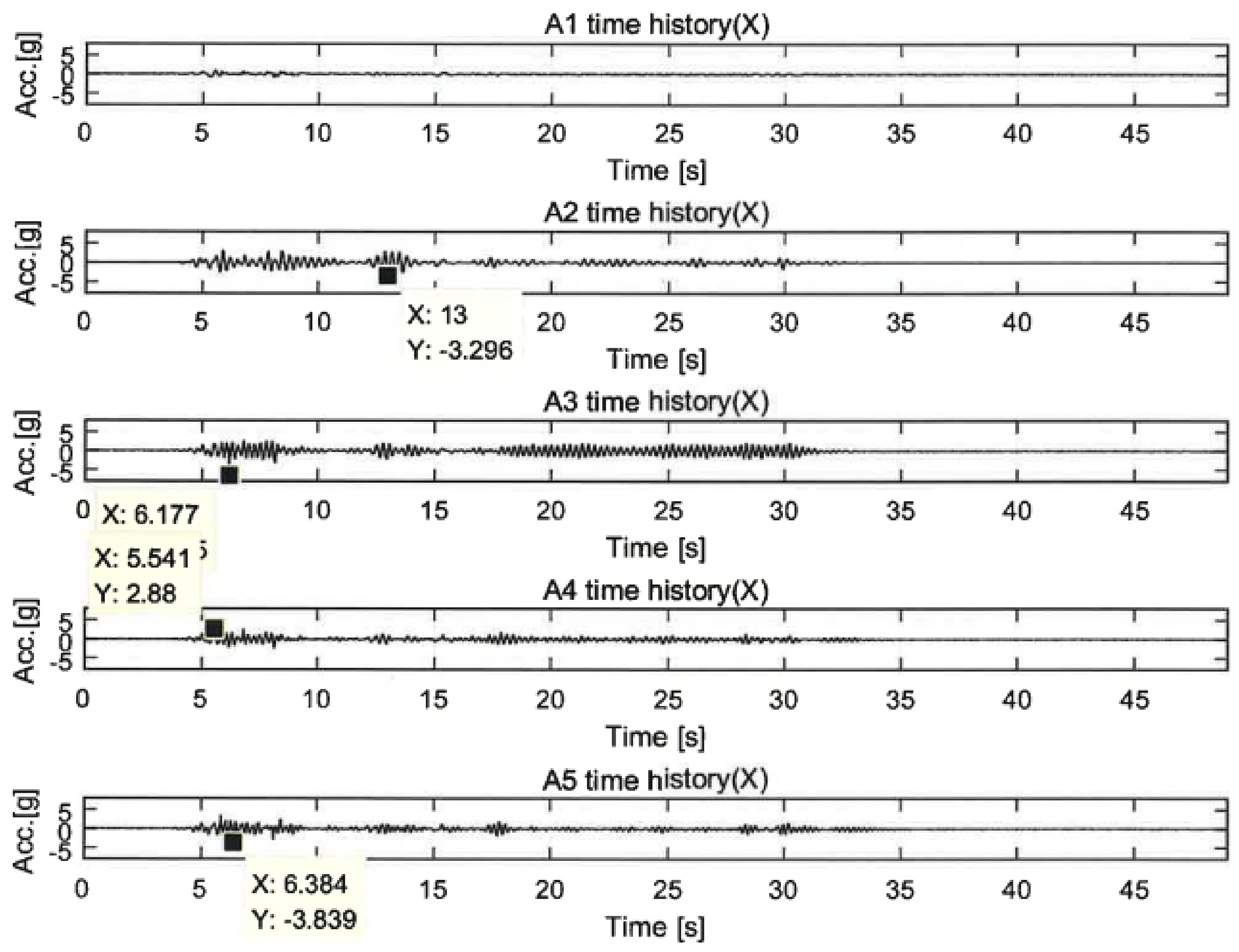

4.3. Dynamic Responses

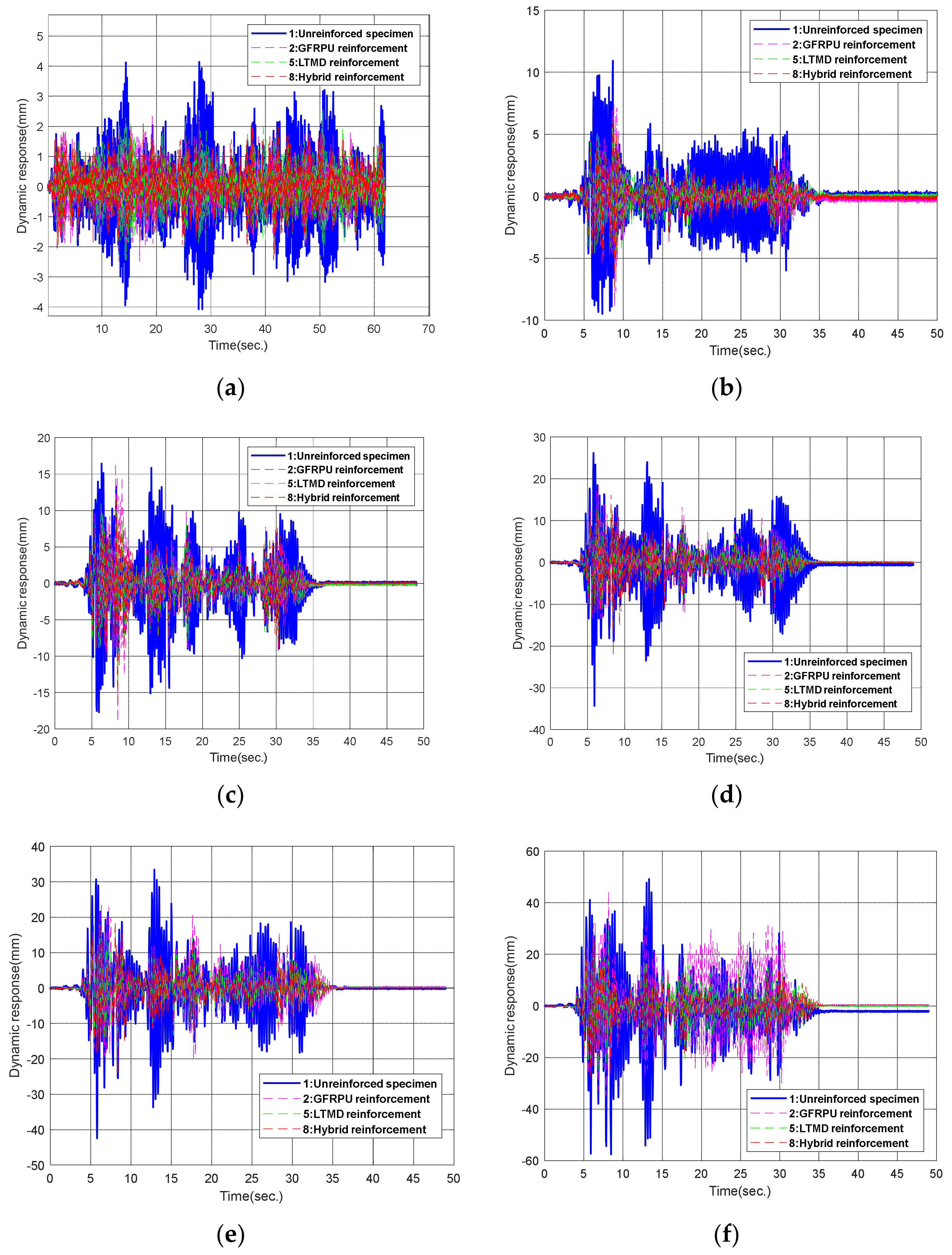

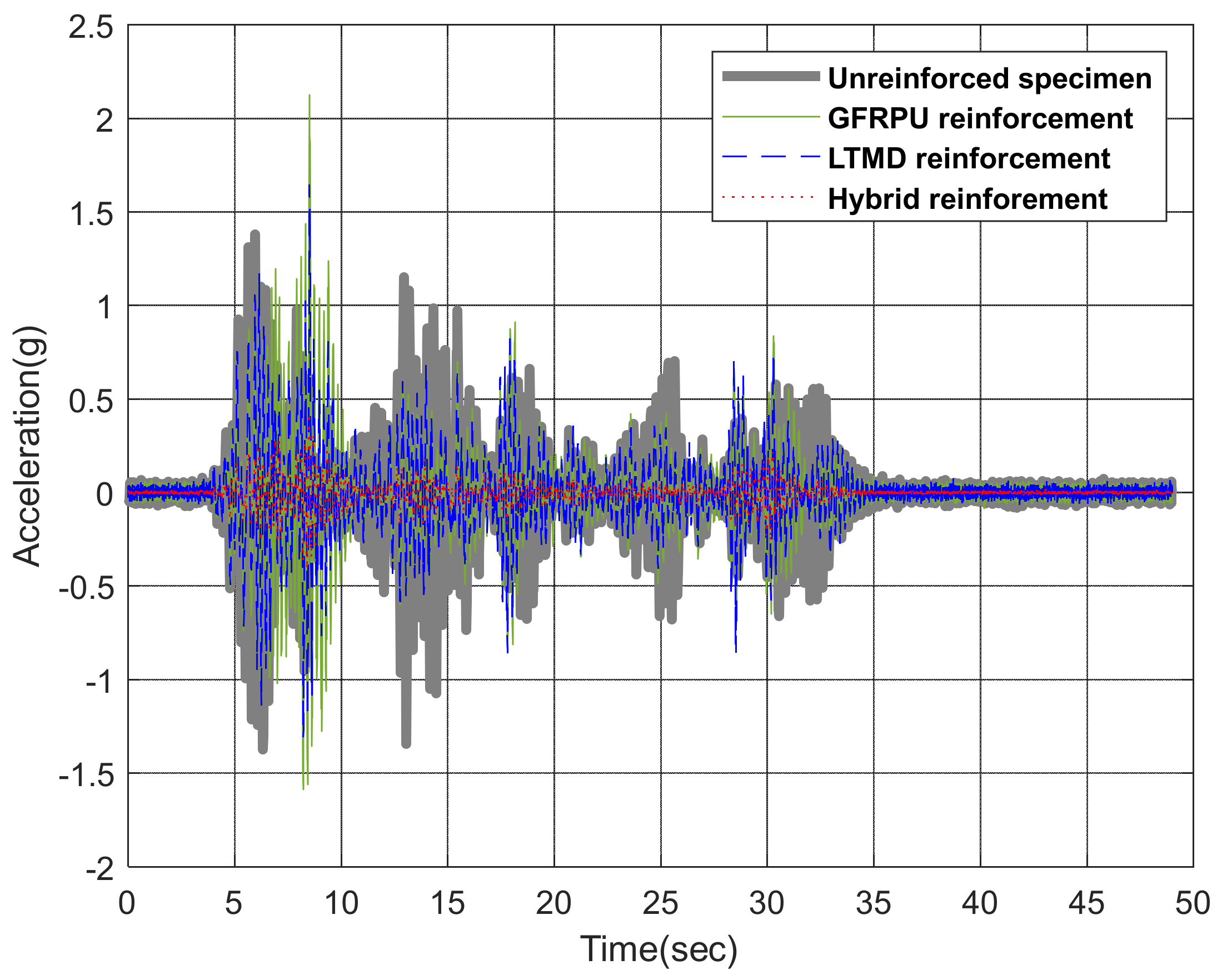

4.4. Control of Dynamic Responses

5. Conclusions

6. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FFT | fast Fourier transform |

| FRF | frequency response function |

| GFRPU | glass fiber-reinforced polyurea |

| LTMD | lever-typed tuned mass damper |

| RC | reinforced concrete |

| SDOF | single degree of freedom |

| TMD | tuned mass damper |

References

- Den Hartog, J.P. Mechanical Vibration; McGraw-Hill: New York, NY, USA, 1956. [Google Scholar]

- Warburton, G.B.; Ayorinde, E.O. Optimum absorber parameters for simple systems. Earthq. Eng. Struct. Dyn. 1980, 8, 197–217. [Google Scholar] [CrossRef]

- Warburton, G.B. Optimum absorber parameters for viscous combinations of response and excitation parameters. Earthq. Eng. Struct. Dyn. 1982, 10, 381–401. [Google Scholar] [CrossRef]

- Sadek, F.; Mohraz, B.; Taylor, A.; Chung, R. A method of estimating the parameters of tuned mass dampers for seismic applications. Earthq. Eng. Struct. Dyn. 1997, 26, 617–635. [Google Scholar] [CrossRef]

- Abubakar, I.M.; Farid, B.J.M. Generalized Den Hartog tuned mass damper system for control of vibrations in structures. WIT Trans. Built Environ. 2009, 104, 185–193. [Google Scholar]

- Salvi, J.; Rizzi, E. A numerical approach towards best tuning of tuned mass dampers. Proc. ISMA 2012, 2012, 2419–2433. [Google Scholar]

- Lee, E.-T.; Eun, H.-C. Lever-type tuned mass damper for alleviating dynamic responses. Adv. Civ. Eng. 2019, 2019, 5824972. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, C.; Wang, X.; Wang, Y.; Wu, G.; Zhu, H.; Han, Z. Strengthening and converse strengthening effects of polyurea layer on polyurea-steel composite structure subjected to combined actions of blast and fragments. Thin Walled Struct. 2022, 178, 109527. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, W.; Lyu, P.; Yan, S.; Wang, X.; Ju, J. Polyurea for blast and impact protection: A review. Polymers 2022, 14, 2670. [Google Scholar] [CrossRef] [PubMed]

- Rotariu, A.; Bucur, F.; Toader, G.; Lupoae, M.; Sava, A.C.; Somoiag, P.; Matei, M.C. Experimental study on polyurea coating effects on deformation of metallic plates subjected to air blast loads. Mater. Plast. 2016, 53, 670–674. [Google Scholar]

- Remennikov, A.; Ngo, T.; Mohotti, D.; Uy, B.; Netherton, M. Experimental investigation and simplified modeling of response of steel plates subjected to close-in blast loading from spherical liquid explosive charges. Int. J. Impact Eng. 2017, 105, 78–89. [Google Scholar] [CrossRef]

- Szafran, J.; Matusiak, A.; Rzeszut, K.; Jankowiak, I. Influence of polyurea coatings on low-longitudinal-reinforcement-ratio reinforced concrete beams subjected to bending. Materials 2022, 15, 2652. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.B.; Kim, J.H.J.; Choi, H.S.; Heo, G. Development and applicability evaluation of high performance polyurea for RC construction reinforcement. J. Korean Soc. Civ. Eng. 2010, 30, 169–176. [Google Scholar]

- Alizadeh, V.; Amirkhizi, A.V. Milled carbon fiber polyurea elastomeric composites. In Challenges in Mechanics of Time Dependent Materilas, Fracture, Failure and Damage Evolution; Springer: Cham, Switzerland, 2020; pp. 167–170. [Google Scholar]

- Anas, S.M.; Alam, M.; Umair, M. Experimental and numerical investigations on performance of reinforced concrete slabs under explosive-induced air-blast loading: A state-of-the-art review. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; pp. 428–461. [Google Scholar]

- Lee, T.-H.; Park, J.-H.; Yang, D.-H.; Lim, J.-H.; Bin, N. Material enhancements of newly developed stiff type polyurea for retrofitting of concrete structures. Case Stud. Constr. Mater. 2020, 17, e01431. [Google Scholar] [CrossRef]

- Greene, C.E.; Myers, J.J. Flexural and shear behavior of reinforced concrete members strengthened with a discrete fiber-reinforced polyuria system. J. Compos. Constr. 2013, 17, 108–116. [Google Scholar] [CrossRef]

- Carey, N.L.; Myers, J.J. Elastomeric systems with discrete fiber for infrastructure repair and rehabilitation. In Proceedings of the Structural Faults and Repair, Edinburgh, UK, 15–17 June 2010. [Google Scholar]

- Carey, N.L.; Myers, J.J. Discrete Fiber Reinforced Polymer Systems for Repair of Concrete Structures: Polyurea-Fiber Characterization Results; Special Publication 275; American Concrete Institute: Detroit, MI, USA, 2011; pp. 285–298. [Google Scholar]

- Song, J.-H.; Lee, E.-T.; Eun, H.-C. A study on the improvement of structural performance by glass fiber-reinforced polyurea (GFRPU) reinforcement. Adv. Civ. Eng. 2019, 2019, 2818219. [Google Scholar] [CrossRef]

- Song, J.-H.; Lee, E.-T.; Eun, H.-C. Shear Strength of Reinforced Concrete Columns Retrofitted by Glass Fiber Reinforced Polyurea. Civ. Eng. J. 2020, 6, 1852–1863. [Google Scholar] [CrossRef]

- Song, J.-H.; Eun, H.-C. Improvement of Flexural and Shear Strength of RC Beam Reinforced by Glass Fiber-Reinforced Polyurea (GFRPU). Civ. Eng. J. 2021, 7, 407–418. [Google Scholar] [CrossRef]

| 0% | 1% | 3% | 5% | 7% | |

|---|---|---|---|---|---|

| Average tensile strength (MPa) | 22.84 | 29.33 | 29.40 | 30.96 | 30.25 |

| Elongation at break (%) | 418 | 396 | 355 | 362 | 352 |

| 0% | 1% | 3% | 5% | 7% | |

|---|---|---|---|---|---|

| Elastic modulus (MPa) | 99.89 | 119.83 | 134.95 | 143.90 | 143.20 |

| Max. Loading | 60 ton |

| Table size | 5.0 m × 5.0 m |

| Control Axes | 3 DOF (Translational 2 axes, rotational 1 axis) |

| Max. Displacement | X-Axis = ± 300 mm, Y-Axis = ± 200 mm |

| Max. Velocity | H = 1000 m/s |

| Max. Acceleration at Bare Table | ±3.0 g |

| Frequency Range | (0.1~60) Hz |

| Excitation Mechanism | Electro-hydraulic Servo, 3 Variable Control |

| Control Software | MTS 469D, STEX Pro |

| Feedback Data Acquisition | 51 Channels (Sampling rate = 512 Hz) |

| Number of Specimens | Excitations |

|---|---|

| 1 | Random wave |

| 2~6 | Sinusoidal wave (3 Hz, 4.5 Hz, 6 Hz, 7.5 Hz, 9 Hz) |

| 7~13 | Earthquake (Kyungju and Pohang in Korea, El Centro (50%, 100%, 120%, 150%, 200%)) |

| D(1) Unreinforced | D(2) GFRPU | D(5) LTMD | D(8) Hybrid | |||||

|---|---|---|---|---|---|---|---|---|

| (+) | (−) | (+) | (−) | (+) | (−) | (+) | (−) | |

| 4.5 Hz sinusoidal wave (mm/%) | 9.97 | −9.75 | 3.32/ 66.7 | −3.23/ 66.9 | 4.67/ 53.2 | −4.94/ 49.3 | 2.84/ 71.5 | −2.78/ 71.5 |

| 6 Hz Sinusoidal wave (mm/%) | 1.07 | −0.962 | 2.11/ −97.2 | −2.02/ −110.0 | 1.54/ −43.9 | −1.39/ −44.5 | 2.78/ −160 | −2.72/ −182.7 |

| D(1) Unreinforced | D(2) GFRPU | D(5) LTMD | D(8) Hybrid | |||||

|---|---|---|---|---|---|---|---|---|

| (+) | (−) | (+) | (−) | (+) | (−) | (+) | (−) | |

| Random excitation (mm/%) | 4.29 | −3.87 | 2.55/ 40.6 | −2.98/ 23.0 | 2.96/ 31.0 | −2.83/ 26.9 | 2.63/ 38.7 | −2.84/ 26.6 |

| 200% El Centro (mm/%) | 50.8 | −56.2 | 43.5/ 14.4 | −35.8/ 36.3 | 30.1/ 40.8 | −25/ 55.2 | 27/ 46.9 | −27.3/ 51.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.-H.; Song, J.-H.; Jang, H.-S.; Roh, P.-S.; Eun, H.-C. Comparison of Dynamic Vibration Control Techniques by the GFRPU and/or LTMD System. Polymers 2022, 14, 4979. https://doi.org/10.3390/polym14224979

An J-H, Song J-H, Jang H-S, Roh P-S, Eun H-C. Comparison of Dynamic Vibration Control Techniques by the GFRPU and/or LTMD System. Polymers. 2022; 14(22):4979. https://doi.org/10.3390/polym14224979

Chicago/Turabian StyleAn, Jae-Hyoung, Jun-Hyeok Song, Hye-Sook Jang, Pil-Sung Roh, and Hee-Chang Eun. 2022. "Comparison of Dynamic Vibration Control Techniques by the GFRPU and/or LTMD System" Polymers 14, no. 22: 4979. https://doi.org/10.3390/polym14224979

APA StyleAn, J.-H., Song, J.-H., Jang, H.-S., Roh, P.-S., & Eun, H.-C. (2022). Comparison of Dynamic Vibration Control Techniques by the GFRPU and/or LTMD System. Polymers, 14(22), 4979. https://doi.org/10.3390/polym14224979