A Systematic Investigation of Polymer Influence on Core Scale Wettability Aided by Positron Emission Tomography Imaging

Abstract

1. Introduction

2. Materials and Methods

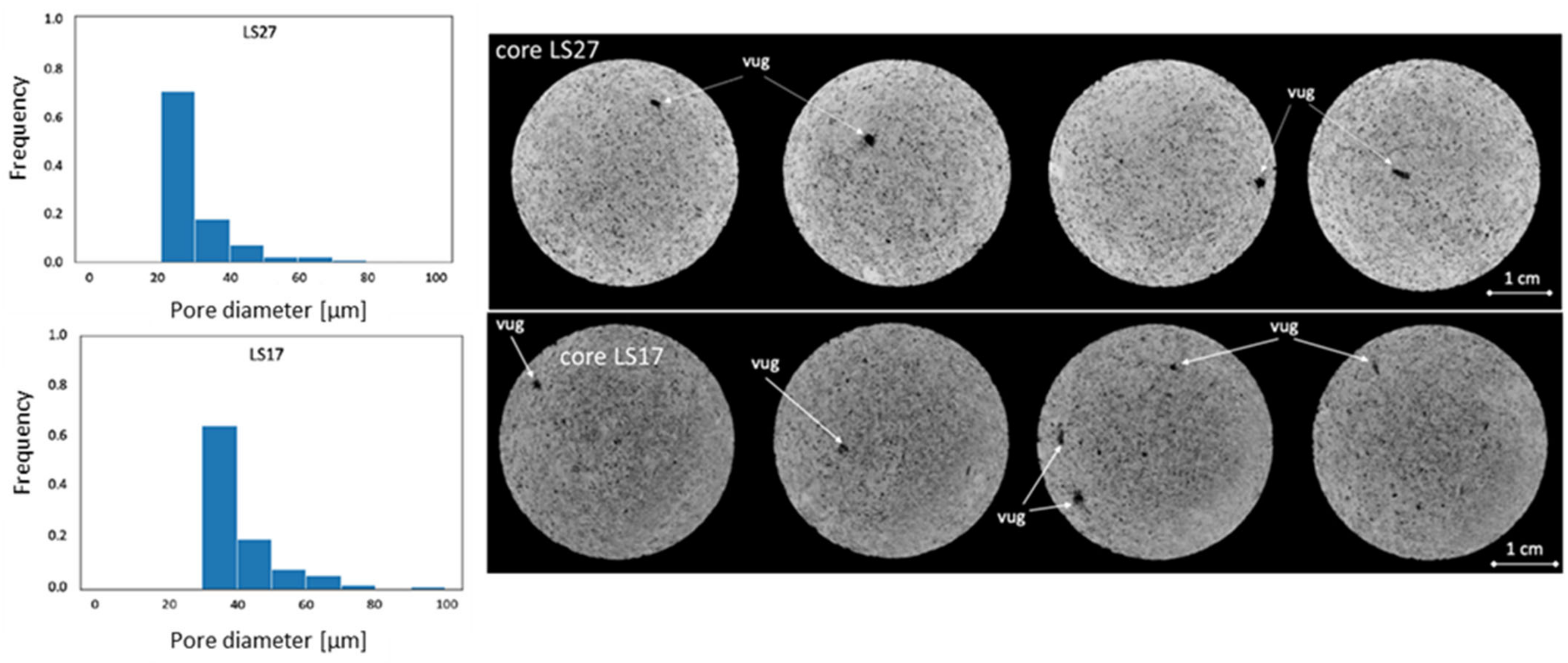

2.1. Core Preparations

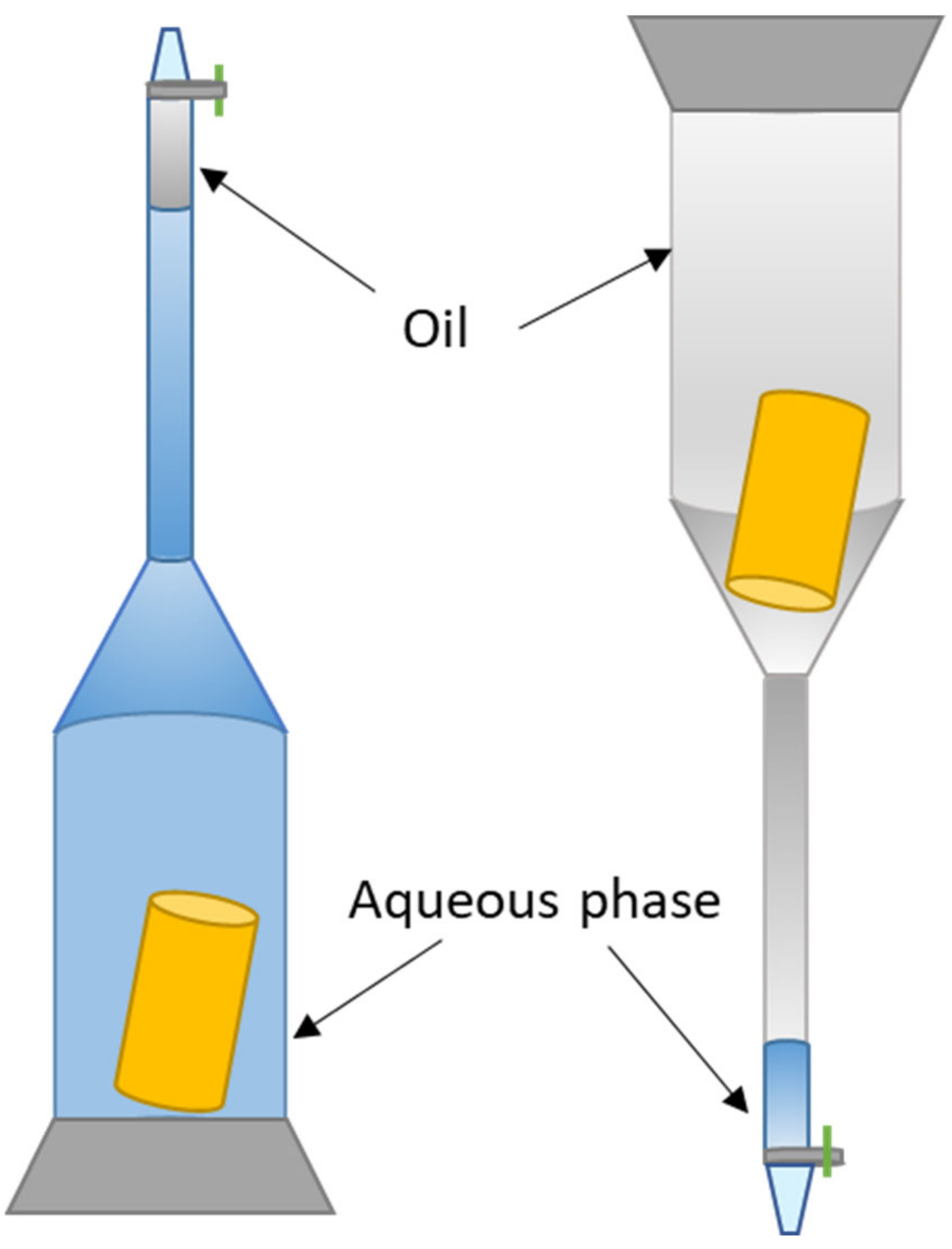

2.2. Wettability Alteration

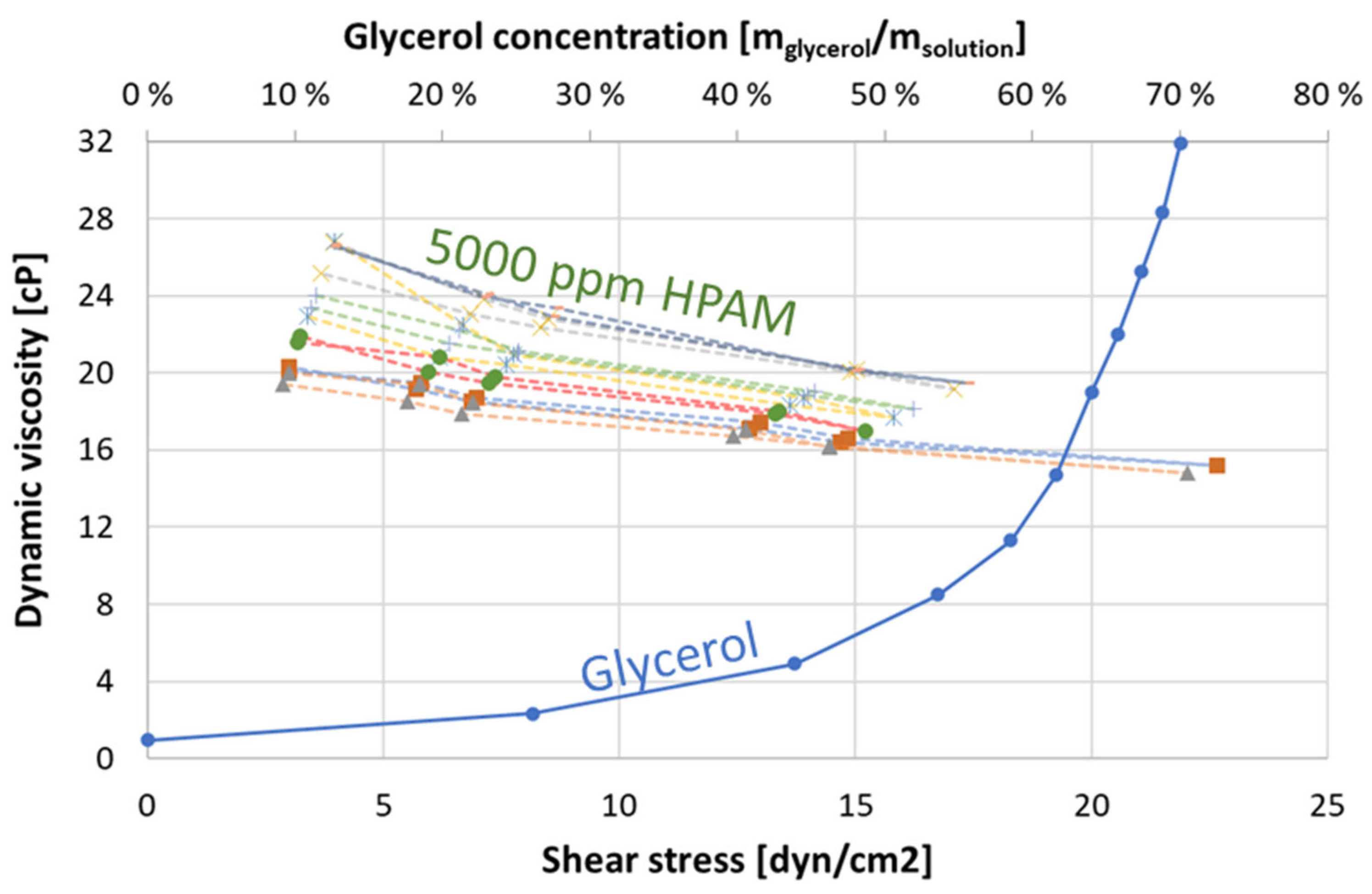

2.3. Imbibing Fluids

2.4. PART 1: Core Scale Evaluation of Wetting Stability

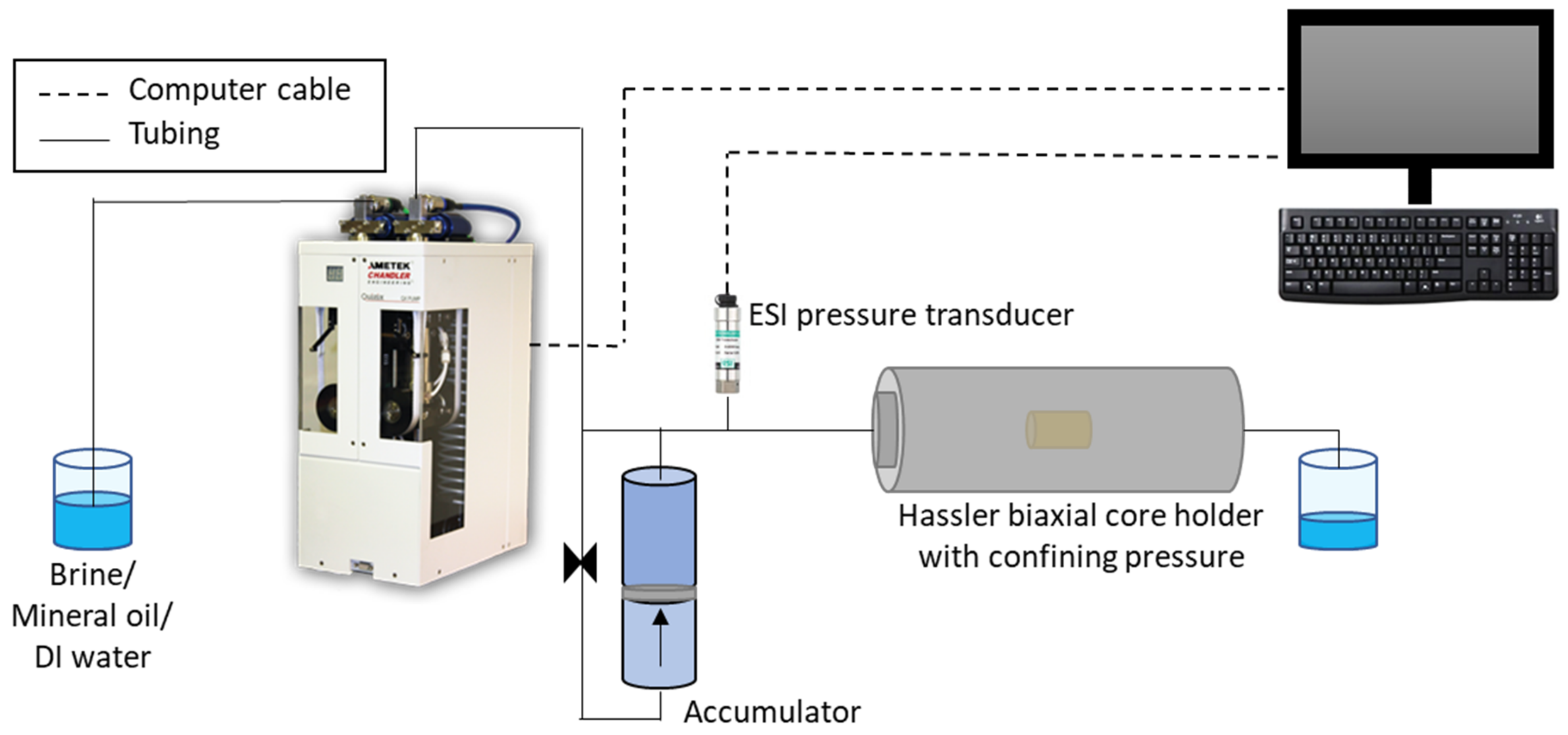

2.5. PART 2: In Situ Visualization of Viscous Displacements in Oil-Wet Limestone

3. Results

3.1. PART 1: Core Scale Evaluation of Wetting Stability

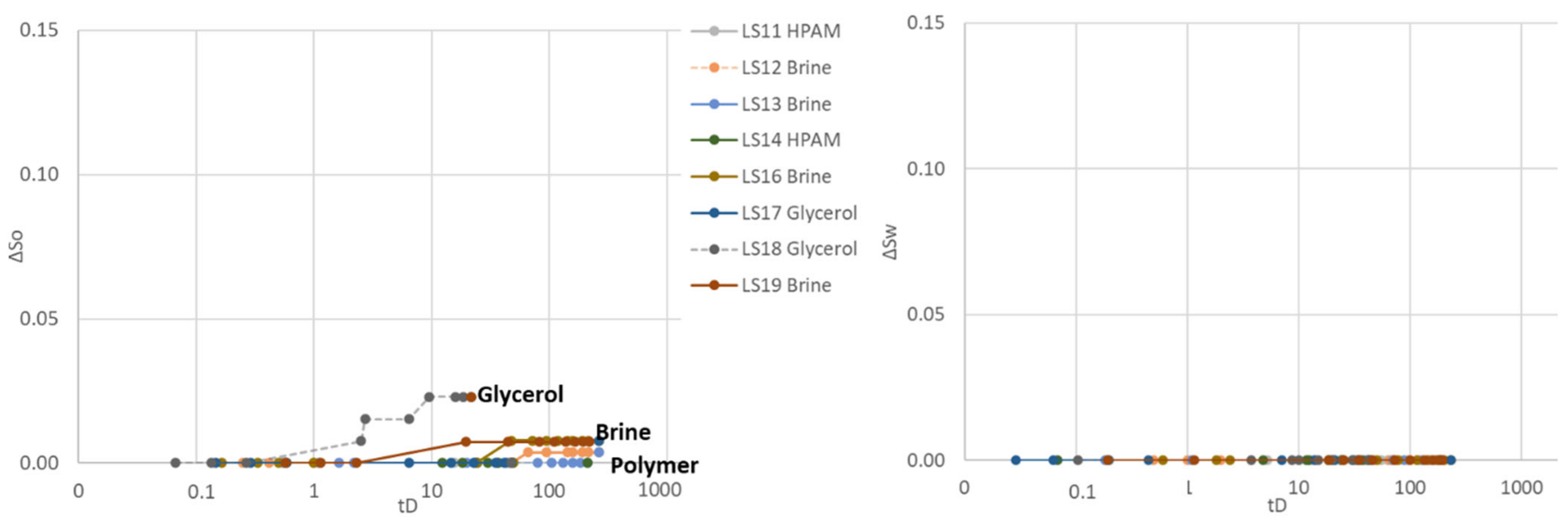

3.1.1. First Cycle (Brine/Oil)

3.1.2. Second Cycle

3.1.3. Third Cycle

3.1.4. Fourth Cycle

3.1.5. Fifth Cycle

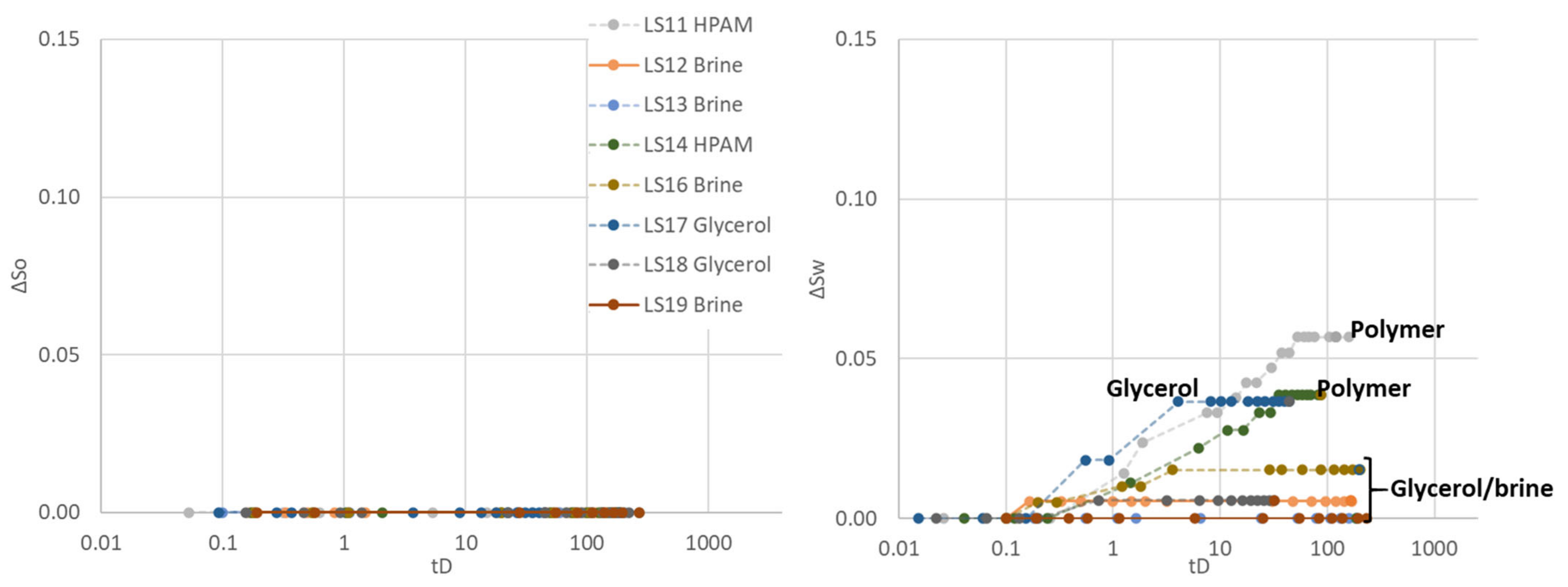

3.1.6. Estimating Wettability Alterations from Spontaneous Imbibition

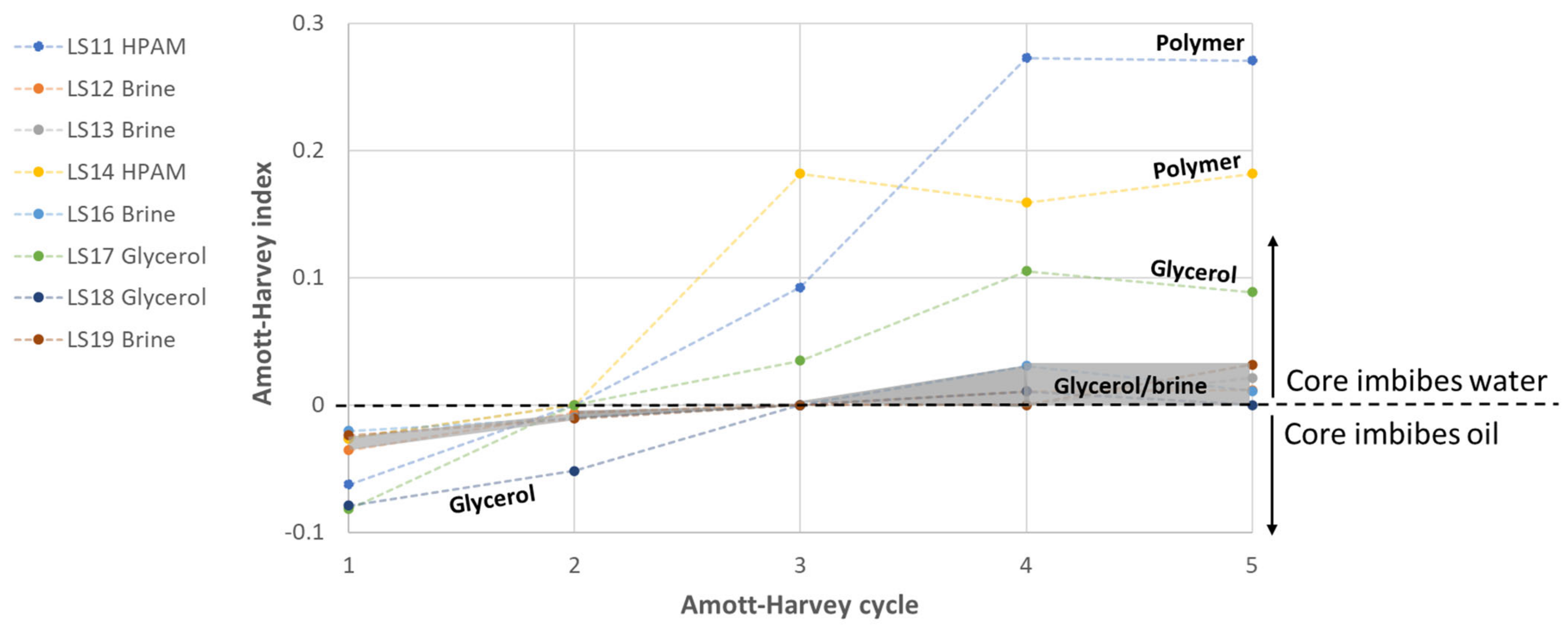

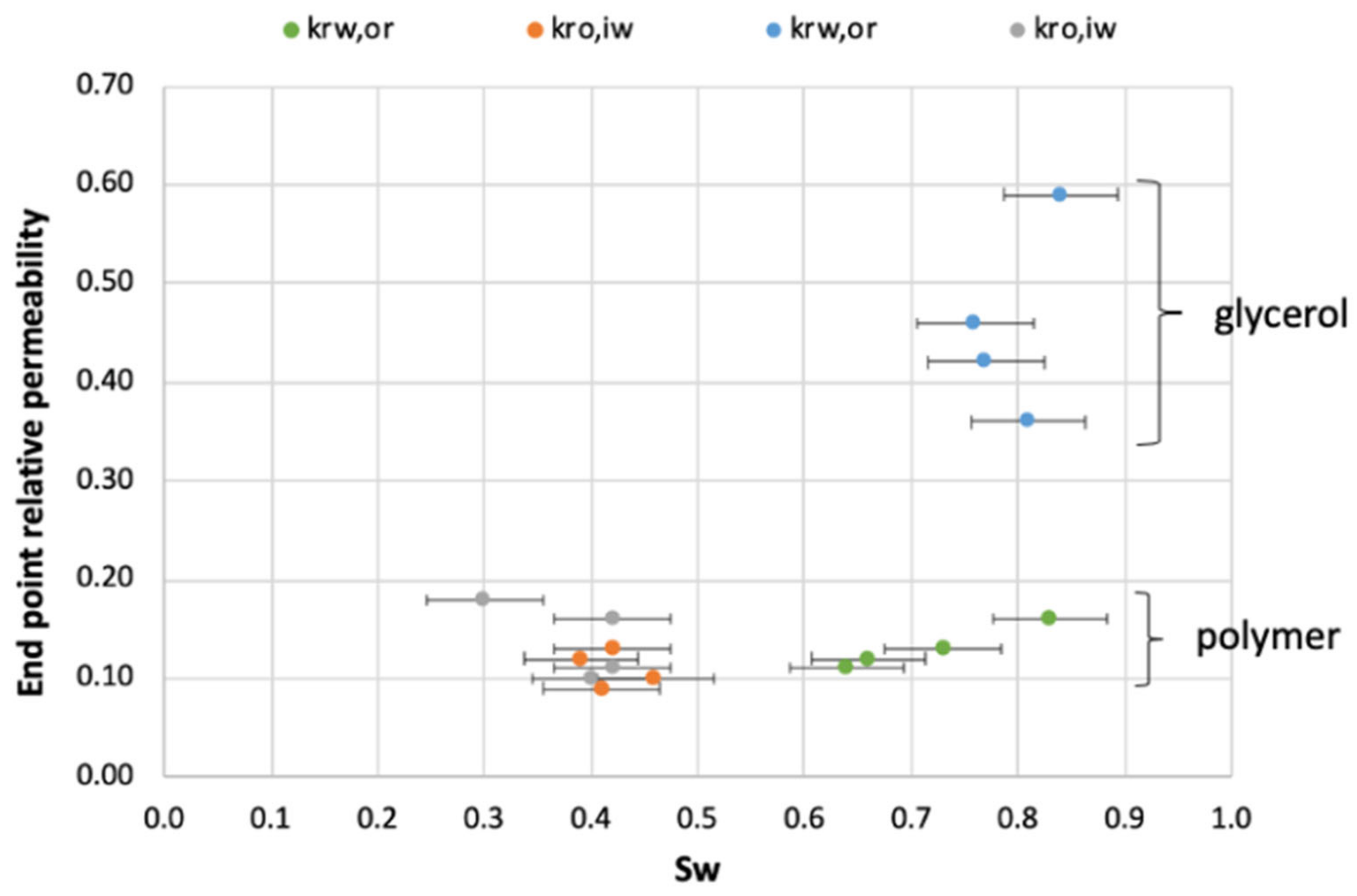

3.1.7. Observations of End-Point Relative Permeability

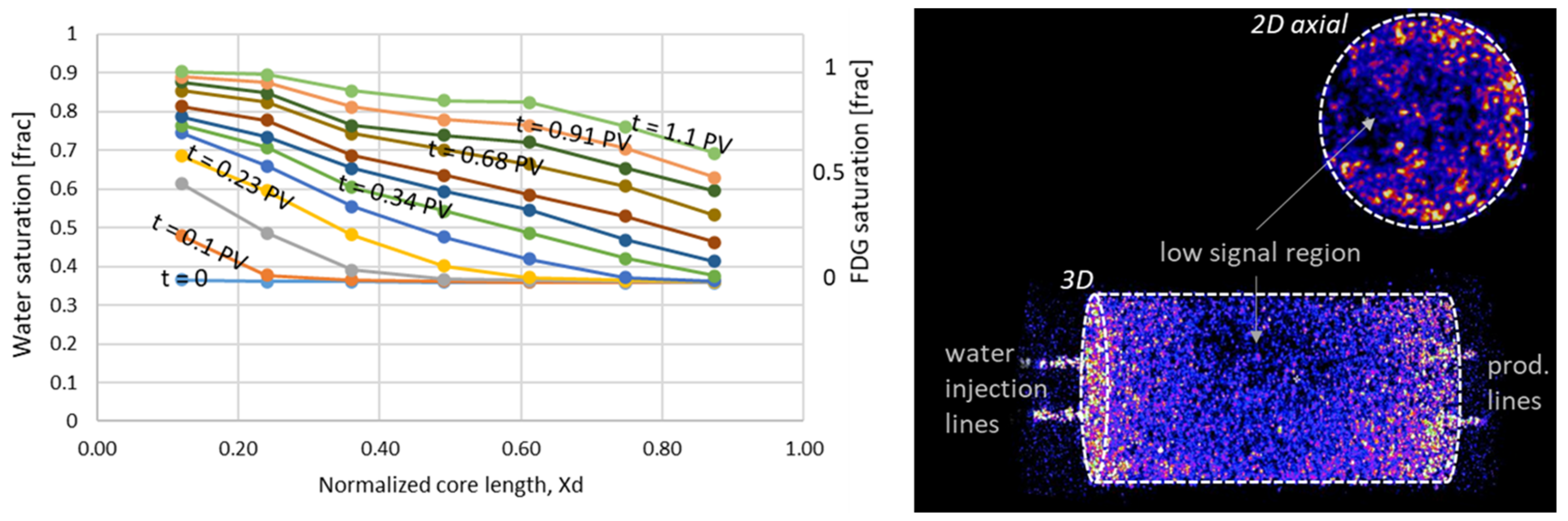

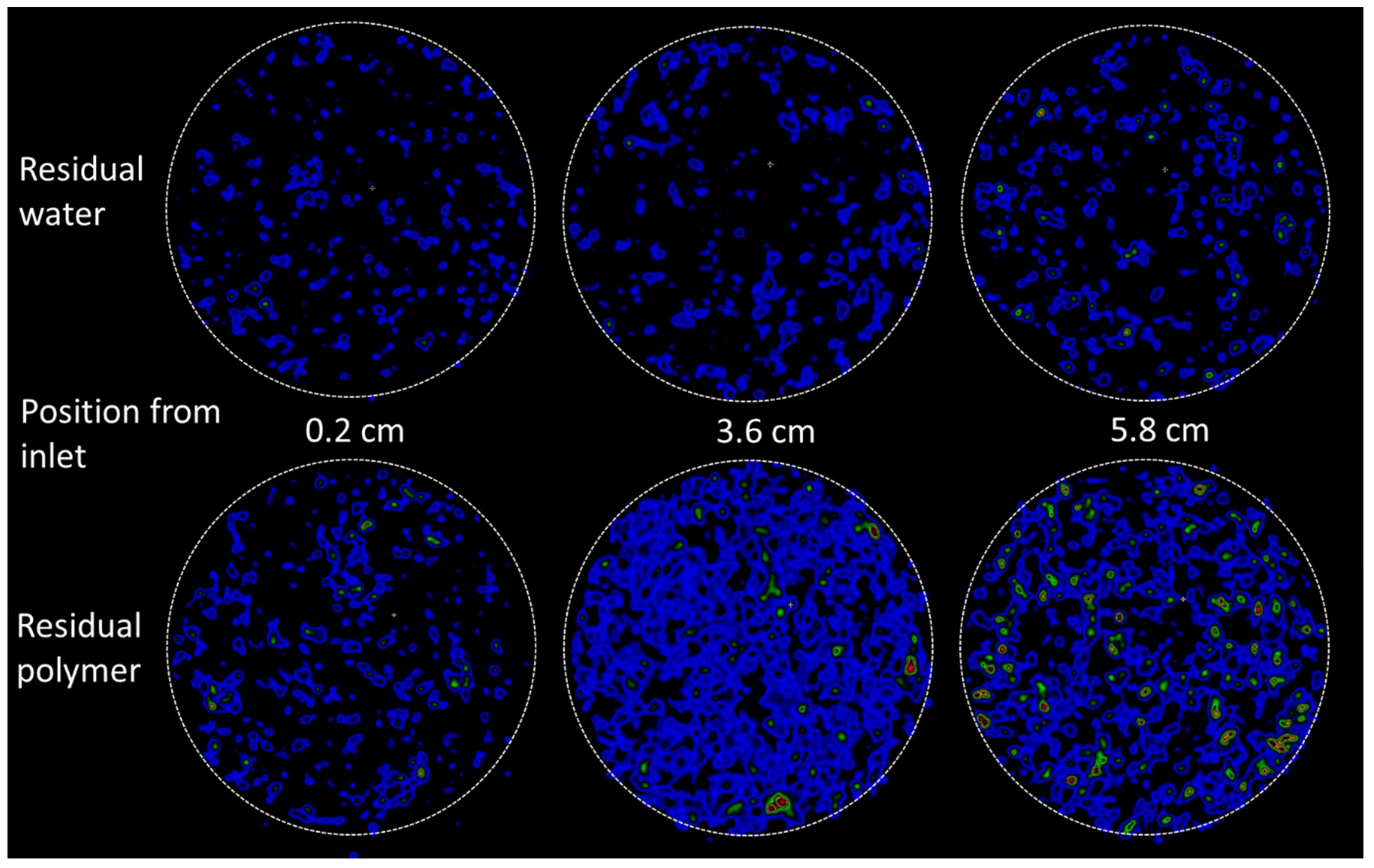

3.2. PART 2: In Situ Visualization of Viscous Displacements in Oil-Wet Limestone

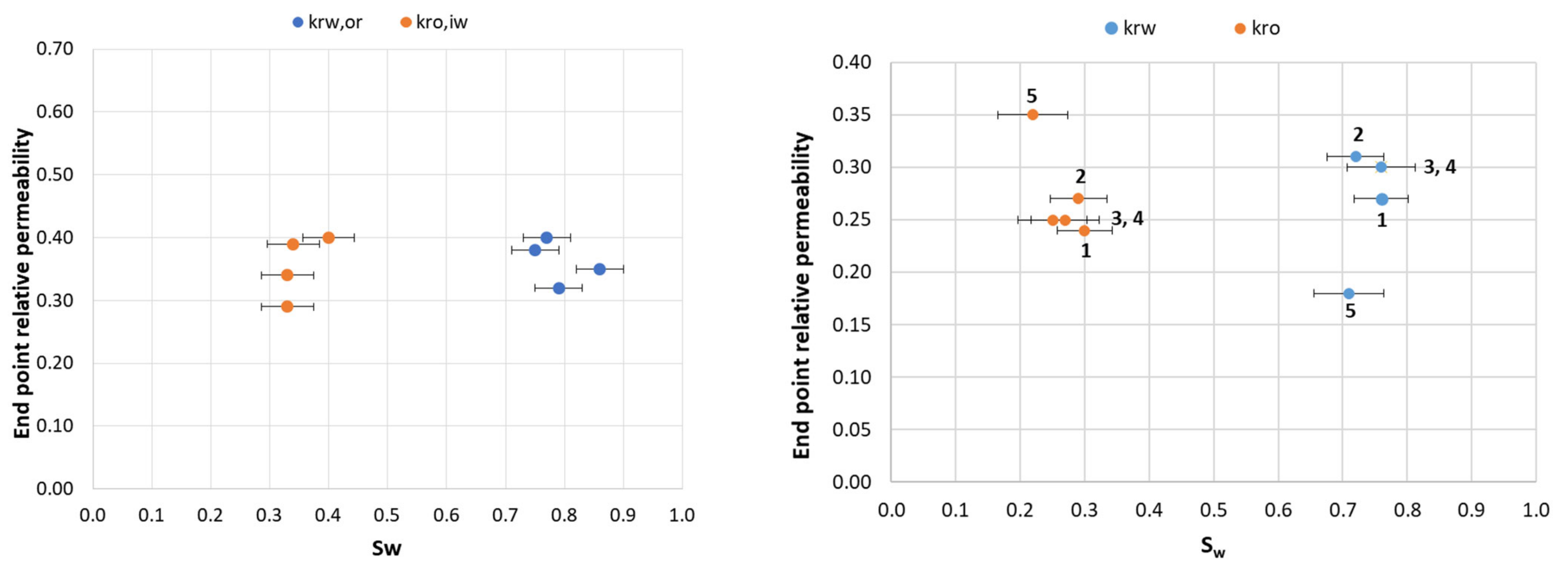

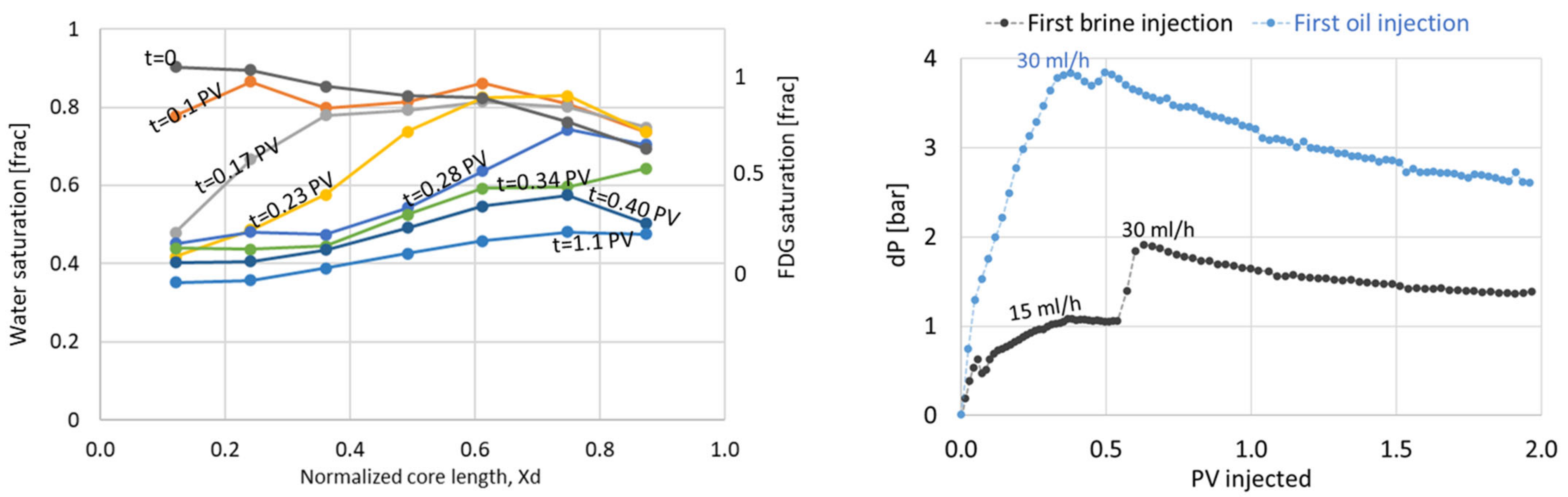

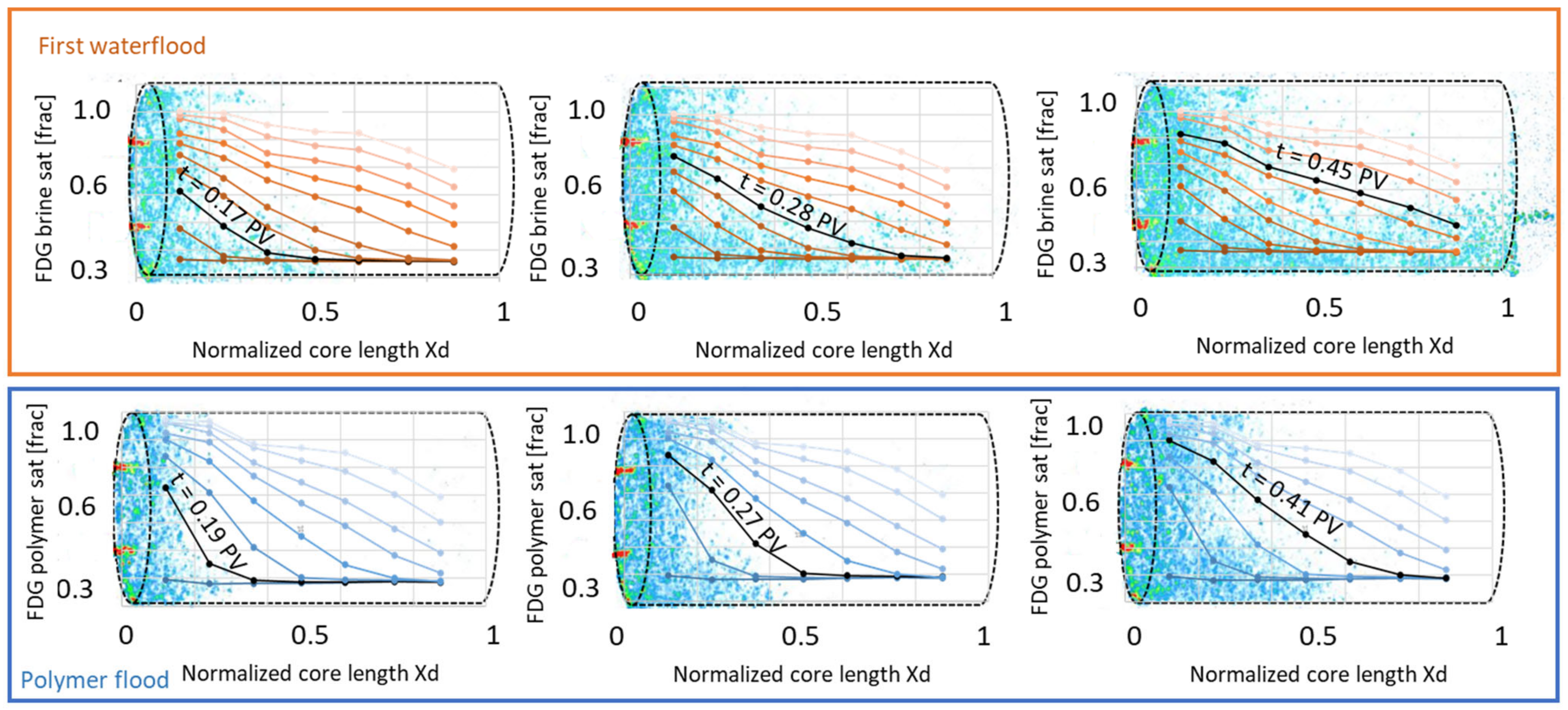

3.2.1. First Water and Oil Flood

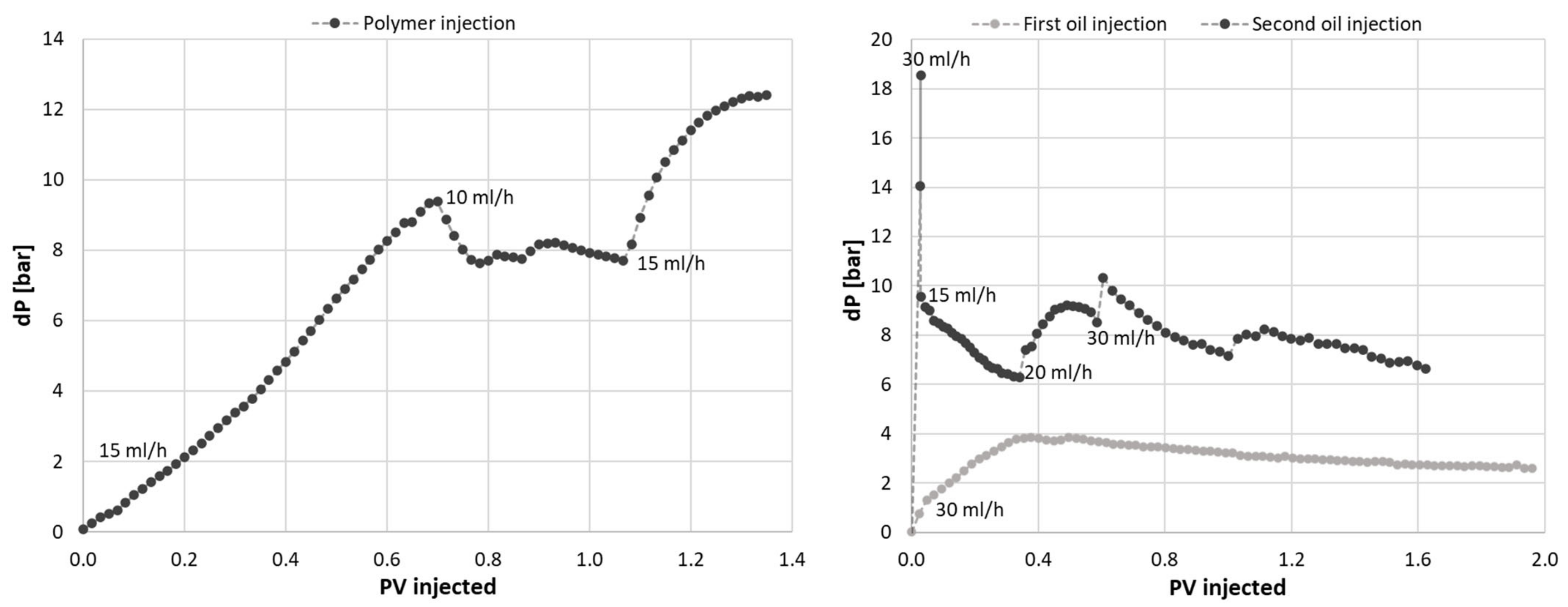

3.2.2. Polymer and Subsequent oil Flood

3.2.3. Water and Oil Flood after Polymer

4. Discussion

5. Conclusions

- Amott–Harvey cycles were used to qualitatively determine wetting change in polymer/mineral oil systems over time. Although the method has its weaknesses (especially around near-neutral wetting) the shift from oil-wet to water-wet conditions could be marked when the core plugs stopped spontaneously imbibing oil and started spontaneously imbibing water.

- When polymer was introduced to the cores oil spontaneous imbibition immediately stopped, and aqueous phase imbibition was observed during the following cycle; already imbibing more than four times the end-point volume of brine.

- After introduction of polymer to the core plugs, end point relative permeabilities for oil and water decreased, and the cores stopped spontaneously imbibing oil.

- This spontaneous imbibition study shows that wettability changed both quicker and towards stronger water-wet conditions with polymer solutions as the aqueous phase.

- PET imaging showed a continuously high presence of polymer in the core, also after oil flooding.

- The observations from our experimental work support polymer adsorption and entrapment as important mechanisms for apparent wettability change during and after polymer treatments.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Sandiford, B.B. Laboratory and Field Studies of Water Floods Using Polymer Solutions to Increase Oil Recoveries. J. Pet. Technol. 1964, 16, 917–922. [Google Scholar] [CrossRef]

- Willhite, G.P.; Zhu, H.; Natarajan, D.; McCool, C.S.; Green, D.W. Mechanisms Causing Disproportionate Permeability Reduction in Porous Media Treated with Chromium Acetate/HPAM Gels. SPE J. 2002, 7, 100–108. [Google Scholar] [CrossRef]

- Wei, B.; Romero-Zerón, L.; Rodrigue, D. Oil displacement mechanisms of viscoelastic polymers in enhanced oil recovery (EOR): A review. J. Pet. Explor. Prod. Technol. 2014, 4, 113–121. [Google Scholar] [CrossRef]

- Sheng, J. Modern Chemical Enhanced Oil Recovery: Theory and Practice; Gulf Professional Publishing: Burlington, MA, USA, 2011. [Google Scholar]

- Luo, H.; Al-Shalabi, E.W.; Delshad, M.; Panthi, K.; Sepehrnoori, K. A robust geochemical simulator to model improved-oil-recovery methods. SPE J. 2016, 21, 55–73. [Google Scholar] [CrossRef]

- Yin, H.; Wang, D.; Zhong, H. Study on flow behaviors of viscoelastic polymer solution in micropore with dead end. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Liang, B.; Jiang, H.; Li, J.; Chen, F.; Miao, W.; Yang, H.; Qiao, Y.; Chen, W. Mechanism Study of Disproportionate Permeability Reduction Using Nuclear Magnetic Resonance T2. Energy Fuels 2018, 32, 4959–4968. [Google Scholar] [CrossRef]

- Liang, B.; Jiang, H.; Li, J.; Seright, R.S.; Lake, L.W. Further insights into the mechanism of disproportionate permeability reduction. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Hatzignatiou, D.G.; Moradi, H.; Stavland, A. Polymer flow through water- and oil-wet porous media. J. Hydrodyn. 2015, 27, 748–762. [Google Scholar] [CrossRef]

- Barreau, P.; Bertin, H.; Lasseux, D.; Giénat, P.; Zaitoun, A. Water Control in Producing Wells: Influence of an Adsorbed-Polymer Layer on Relative Permeabilities and Capillary Pressure. SPE Reserv. Eng. 1997, 12, 234–239. [Google Scholar] [CrossRef]

- Askarinezhad RHatzignatiou, D.G.; Stavland, A. Associative polymers for disproportionate permeability reduction—Formation wettability effects. J. Pet. Sci. Eng. 2021, 206, 109060. [Google Scholar] [CrossRef]

- Elmkies, P.; Bertin, H.; Lasseux, D.; Murray, M.; Zaitoun, A. Further investigations on two-phase flow property modification by polymers: Wettability Effects. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 13–16 February 2001; p. 8. [Google Scholar]

- Grattoni, C.; Luckham, P.; Jing, X.; Norman, L.; Zimmerman, R. Polymers as relative permeability modifiers: Adsorption and the dynamic formation of thick polyacrylamide layers. J. Pet. Sci. Eng. 2004, 45, 233–245. [Google Scholar] [CrossRef]

- Hatzignatiou, D.G.; Moradi, H.; Stavland, A. Experimental investigation of polymer flow through water- and oil-wet berea sandstone core samples. In Proceedings of the SPE EAGE Annual Conference and Exhibition Incorporating SPE Europec, London, UK, 10–13 June 2013. [Google Scholar]

- Juarez-Morejon, J.L.; Bertin, H.; Omari, A.; Hamon, G.; Cottin, C.; Bourdarot, G.; Morel, D. Spontaneous imbibition as indicator of wettability change during polymer flooding. In Proceedings of the IOR 2017-19th European Symposium on Improved Oil Recovery, Stavanger, Norway, 24–27 April 2017; Volume 1, pp. 1–10. [Google Scholar]

- Tipura, L. Wettability Characterization by NMR T2 Measurements in Edwards Limestone. Master’s Thesis, University of Bergen, Bergen, Norway, 2008. [Google Scholar]

- Cobos, J.E.; Sandnes, M.; Steinsbø, M.; Brattekås, B.; Søgaard, E.G.; Graue, A. Evaluation of Wettability Alteration in Heterogeneous Limestone at Microscopic and Macroscopic Levels. J. Pet. Sci. Eng. 2021, 202, 108534. [Google Scholar] [CrossRef]

- Brattekås, B.; Fernø, M.A.; Haugen, M.; Føyen, T.; Steinsbø, M.; Graue, A.; Brekke, N.; Holm Adamsen, T.C.; Brekke Rygh, C.; Espedal, H. Of rats and rocks: Using pre-clinical PET imaging facilities in core analysis. In Proceedings of the Annual symposium of the Society of Core Analysts, Virtual, 13–16 September 2021. [Google Scholar]

- Graue, A.; Viksund, B.G.; Baldwin, B.A. Reproducible wettability alteration of low-permeable outcrop chalk. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 19–22 April 1998; p. 11. [Google Scholar]

- Fernø, M.A.; Torsvik, M.; Haugland, S.; Graue, A. Dynamic Laboratory Wettability Alteration. Energy Fuels 2010, 24, 3950–3958. [Google Scholar] [CrossRef]

- Graue, A.; Aspenes, E.; Bognø, T.; Moe, R.; Ramsdal, J. Alteration of wettability and wettability heterogeneity. J. Pet. Sci. Eng. 2022, 33, 3–17. [Google Scholar] [CrossRef]

- Foshee, W.C.; Jennings, R.R.; West, T.J. Preparation and Testing of Partially Hydrolyzed Polyacrylamide Solutions. In Proceedings of the SPE Annual Fall Technical Conference and Exhibition, New Orleans, LA, USA, 3–6 October 1976; Petroleum Society of Canada: Edmonton, AB, Canada, 1977. [Google Scholar]

- Fischer, H.; Morrow, N. Scaling of oil recovery by spontaneous imbibition for wide variation in aqueous phase viscosity with glycerol as the viscosifying agent. J. Pet. Sci. Eng. 2006, 52, 35–53. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, X.; Morrow, N.R. Influence of Fluid Viscosity on Mass Transfer Between Rock Matrix and Fractures. J. Can. Pet Technol. 1999, 38. [Google Scholar] [CrossRef]

- Juárez-Morejón, J.L.; Bertin, H.; Omari, A.; Hamon, G.; Cottin, C.; Morel, D.; Romero, C.; Bourdarot, G. A New Approach to Polymer Flooding: Effects of Early Polymer Injection and Wettability on Final Oil Recovery. SPE J. 2019, 24, 129–139. [Google Scholar] [CrossRef]

- Folgerø Sandnes, M. Wetting Stability of Aged Limestone in the Presence of HPAM Polymer—An Experimental Study. Master’s Thesis, University of Bergen, Bergen, Norway, 2020. [Google Scholar]

- Anderson, W.G. Wettability Literature Survey Part 5: The Effects of Wettability on Relative Permeabilit. SPE J. Pet. Technol. 1987, 39, 1453–1468. [Google Scholar] [CrossRef]

- Craig, F.F. The reservoir engineering aspects of waterflooding. Monogr. Ser. Soc. Pet. Eng. AIME 1971. [Google Scholar]

| Core ID | Length ±0.01 [cm] | Diameter ±0.01 [cm] | Pore Volume ±0.01 [mL] | Porosity ±0.06 [%] | Permeability ±0.05 [mD] |

|---|---|---|---|---|---|

| LS11 | 6.80 | 3.80 | 21.16 | 27.44 | 45.88 |

| LS12 | 6.90 | 3.80 | 18.67 | 23.85 | 26.23 |

| LS13 | 6.90 | 3.80 | 20.42 | 26.09 | 35.06 |

| LS14 | 6.91 | 3.80 | 18.10 | 23.09 | 23.59 |

| LS16 | 6.71 | 3.80 | 19.72 | 25.92 | 33.74 |

| LS17 | 6.81 | 3.80 | 21.91 | 28.37 | 52.64 |

| LS18 | 6.69 | 3.80 | 17.41 | 22.95 | 21.49 |

| LS19 | 6.79 | 3.80 | 18.99 | 24.66 | 35.97 |

| LS27 | 6.91 | 3.80 | 17.65 | 22.52 | 18.48 |

| Core | Cycle1 | Cycle2 | Cycle3 | Cycle4 | Cycle5 |

|---|---|---|---|---|---|

| LS11 | Brine/oil | Polymer/oil | Polymer/oil | Polymer/oil | Polymer/oil |

| LS12 | Brine/oil | Brine/oil | Brine/oil | Brine/oil | Brine/oil |

| LS13 | Brine/oil | Brine/oil | Brine/oil | Brine/oil | Brine/oil |

| LS14 | Brine/oil | Polymer/oil | Polymer+ brine/oil | Polymer+ brine/oil | Polymer+ brine/oil |

| LS16 | Brine/oil | Brine/oil | Brine/oil | Brine/oil | Brine/oil |

| LS17 | Brine/oil | Glycerol/oil | Glycerol/oil | Glycerol/oil | Glycerol/oil |

| LS18 | Brine/oil | Glycerol/oil | Glycerol+ brine/oil | Glycerol+ brine/oil | Glycerol+ brine/oil |

| LS19 | Brine/oil | Brine/oil | Brine/oil | Brine/oil | Brine/oil |

| Inj. Fluid | PET Visualization | Inj. Rate [mL/h] | Water Saturation from [frac] to | |

|---|---|---|---|---|

| Brine | Signal from 18F-FDG labelled brine | 15, 30 | 0.36 | 0.79 |

| Oil | Implicit, displacing labelled brine | 30 | 0.79 | 0.38 |

| Polymer | Signal from 18F-FDG labelled polymer solution | 15, 10 | 0.38 | 0.82 |

| Oil | Implicit, displacing labelled polymer | 30, 15, 20, 30 | 0.82 | 0.36 |

| Brine | Signal from 18F-FDG labelled brine | 15, 10 | 0.36 | 0.71 |

| Oil | Implicit, displacing labelled brine | 15, 10, 15 | 0.71 | 0.36 |

| Core | LS11 | LS12 | LS13 | LS14 | LS16 | LS17 | LS18 | LS19 | |

|---|---|---|---|---|---|---|---|---|---|

| Cycle 1 | Aqueous phase | Brine | Brine | Brine | Brine | Brine | Brine | Brine | Brine |

| krw,or | 0.35 | 0.27 | 0.29 | 0.38 | 0.30 | 0.32 | 0.4 | 0.4 | |

| kro,iw | 0.4 | 0.24 | 0.25 | 0.34 | 0.30 | 0.39 | 0.29 | 0.29 | |

| Iw | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Io | 0.06 | 0.04 | 0.01 | 0.03 | 0.02 | 0.08 | 0.08 | 0.02 | |

| IAH | −0.06 | −0.04 | −0.01 | −0.03 | −0.02 | −0.08 | −0.08 | −0.02 | |

| Cycle 2 | Aqueous phase | Polymer | Brine | Brine | Polymer | Brine | Glycerol | Glycerol | Brine |

| krw,or | 0.16 | 0.31 | 0.27 | 0.23 | 0.31 | 0.59 | 0.61 | 0.27 | |

| kro,iw | 0.13 | 0.27 | 0.32 | 0.12 | 0.34 | 0.16 | 0.12 | 0.38 | |

| Iw | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Io | 0 | 0.01 | 0 | 0 | 0.01 | 0 | 0.05 | 0.01 | |

| IAH | 0 | −0.01 | 0 | 0 | −0.01 | 0 | −0.05 | −0.01 | |

| Cycle 3 | Aqueous phase | Polymer | Brine | Brine | Polymer/brine | Brine | Glycerol | Glycerol/brine | Brine |

| krw,or | 0.13 | 0.30 | 0.27 | 0.13 | 0.30 | 0.36 | 0.30 | 0.28 | |

| 0.01 * | 0.29 * | ||||||||

| kro,iw | 0.1 | 0.25 | 0.33 | 0.1 | 0.32 | 0.11 | 0.22 | 0.39 | |

| Iw | 0.09 | 0 | 0 | 0.18 | 0 | 0.04 | 0 | 0 | |

| Io | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| IAH | 0.09 | 0 | 0 | 0.18 | 0 | 0.04 | 0 | 0 | |

| Cycle 4 | Aqueous phase | Polymer | Brine | Brine | Polymer/brine | Brine | Glycerol | Glycerol/brine | Brine |

| krw,or | 0.12 | 0.30 | 0.27 | 0.11 | 0.31 | 0.42 | 0.45 | 0.28 | |

| 0.02 * | 0.35 * | ||||||||

| kro,iw | 0.09 | 0.26 | 0.28 | 0.11 | 0.31 | 0.1 | 0.27 | 0.38 | |

| Iw | 0.27 | 0.01 | 0 | 0.16 | 0.03 | 0.11 | 0.01 | 0 | |

| Io | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| IAH | 0.27 | 0.01 | 0 | 0.16 | 0.03 | 0.11 | 0.01 | 0 | |

| Cycle 5 | Aqueous phase | Polymer | Brine | Brine | Polymer/brine | Brine | Glycerol | Glycerol/brine | Brine |

| krw,or | 0.11 | 0.18 | 0.24 | 0.06 | 0.27 | 0.46 | 0.31 | 0.24 | |

| 0.02 * | 0.28 * | ||||||||

| kro,iw | 0.12 | 0.32 | 0.37 | 0.12 | 0.41 | 0.18 | 0.37 | 0.37 | |

| Iw | 0.27 | 0.01 | 0.02 | 0.18 | 0.01 | 0.09 | 0 | 0.03 | |

| Io | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| IAH | 0.27 | 0.01 | 0.02 | 0.18 | 0.01 | 0.09 | 0 | 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brattekås, B.; Sandnes, M.F.; Steinsbø, M.; Cobos, J.E. A Systematic Investigation of Polymer Influence on Core Scale Wettability Aided by Positron Emission Tomography Imaging. Polymers 2022, 14, 5050. https://doi.org/10.3390/polym14225050

Brattekås B, Sandnes MF, Steinsbø M, Cobos JE. A Systematic Investigation of Polymer Influence on Core Scale Wettability Aided by Positron Emission Tomography Imaging. Polymers. 2022; 14(22):5050. https://doi.org/10.3390/polym14225050

Chicago/Turabian StyleBrattekås, Bergit, Martine Folgerø Sandnes, Marianne Steinsbø, and Jacquelin E. Cobos. 2022. "A Systematic Investigation of Polymer Influence on Core Scale Wettability Aided by Positron Emission Tomography Imaging" Polymers 14, no. 22: 5050. https://doi.org/10.3390/polym14225050

APA StyleBrattekås, B., Sandnes, M. F., Steinsbø, M., & Cobos, J. E. (2022). A Systematic Investigation of Polymer Influence on Core Scale Wettability Aided by Positron Emission Tomography Imaging. Polymers, 14(22), 5050. https://doi.org/10.3390/polym14225050