Versatile Polypropylene Composite Containing Post-Printing Waste

Abstract

:1. Introduction

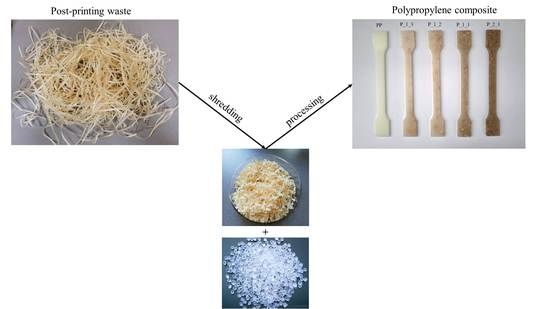

2. Materials and Methods

- Melt Flow Rate (230 °C/2.16 kg): 70 g/10 min.

- Density: 0.90 g/cm3.

- Tensile Stress at Yield: 28 MPa.

- Tensile Strain at Break: 30%.

- Tensile Strain at Yield: 5%.

- Charpy Impact Strength (Notched): 4 kJ/m2.

- Tensile Modulus: 1450 MPa.

- Melt temperature: 160 °C.

- Substance: 55 g/m2.

- Caliper: 49 µm.

- Tensile strength MD: 6.0 kN/m.

- Tensile strength CD: 2.3 kN/m.

- Transparency: 49%.

3. Results

4. Conclusions

- The total decrease in the melt flow rate after adding the greatest amount of filler, i.e., twice the volume excess of filler, was 2.2 g/10 min, which is 20% of the value of pure polypropylene.

- The greatest decrease in the tensile strength of polypropylene after adding the post-printing waste was 4.5 MPa, i.e., approx. 19% of the value of pure polymer. This result was obtained with the highest degree of filling of the composite.

- The obtained deformation drop was the same regardless of the volumetric content of the filler in the matrix. The applied post-printing waste reduces the elongation at maximum stress and elongation at break values to the level of approx. 5%, while the values for pure polypropylene were 8.1 and 35.9%, respectively.

- The total decrease in unnotched impact strength between the lowest and the highest content of post-printing waste was 6.4 kJ/m2, i.e., approx. 22%.

- The introduction of post-printing waste into the polypropylene matrix did not change the thermomechanical characteristics of the polymer.

- The degree of crystallinity of the tested materials decreased from 47.7% for pure polypropylene to 36.2% for the material containing a double excess of printing waste.

- The introduction of the post-printing waste into the matrix causes a reduction in thermal resistance, as the registered value of the 5% weight loss temperature decreased by 17 °C in relation to the value of pure polypropylene.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Das, O.; Babu, K.; Shanmugam, V.; Sykam, K.; Tebyetekerwa, M.; Neisiany, R.E.; Försth, M.; Sas, G.; Gonzalez-Libreros, J.; Capezza, A.J.; et al. Natural and Industrial Wastes for Sustainable and Renewable Polymer Composites. Renew. Sustain. Energy Rev. 2022, 158, 112054. [Google Scholar] [CrossRef]

- Bilitewski, B. The Circular Economy and Its Risks. Waste Manag. 2012, 32, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Stanchev, P.; Katsou, E.; Awad, S.; Fan, M. A Circular Economy Use of Recovered Sludge Cellulose in Wood Plastic Composite Production: Recycling and Eco-Efficiency Assessment. Waste Manag. 2019, 99, 42–48. [Google Scholar] [CrossRef]

- Demirbas, A. Waste Management, Waste Resource Facilities and Waste Conversion Processes. Energy Convers. Manag. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Amasuomo, E.; Baird, J. The Concept of Waste and Waste Management. J. Manag. Sustain. 2016, 6, 88. [Google Scholar] [CrossRef]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of Municipal Plastic and Wood Waste in Industrial Manufacturing of Wood Plastic Composites. Waste Biomass Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef] [Green Version]

- Quitadamo, A.; Massardier, V.; Valente, M. Eco-Friendly Approach and Potential Biodegradable Polymer Matrix for WPC Composite Materials in Outdoor Application. Int. J. Polym. Sci. 2019, 2019, 3894370. [Google Scholar] [CrossRef]

- Teuber, L.; Osburg, V.S.; Toporowski, W.; Militz, H.; Krause, A. Wood Polymer Composites and Their Contribution to Cascading Utilisation. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Zajchowski, S.; Mirowski, J. Rheological Properties of Wood Polymer Composites at High Shear Rates. Polym. Test. 2016, 51, 58–62. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of Wood Fiber Esterification on Properties, Weatherability and Biodurability of Wood Plastic Composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Friedrich, D. Thermoplastic Moulding of Wood-Polymer Composites (WPC): A Review on Physical and Mechanical Behaviour under Hot-Pressing Technique. Compos. Struct. 2021, 262, 113649. [Google Scholar] [CrossRef]

- Essabir, H.; Hilali, E.; Elgharad, A.; El Minor, H.; Imad, A.; Elamraoui, A.; Al Gaoudi, O. Mechanical and Thermal Properties of Bio-Composites Based on Polypropylene Reinforced with Nut-Shells of Argan Particles. Mater. Des. 2013, 49, 442–448. [Google Scholar] [CrossRef]

- Laaziz, S.A.; Raji, M.; Hilali, E.; Essabir, H.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E.K. Bio-Composites Based on Polylactic Acid and Argan Nut Shell: Production and Properties. Int. J. Biol. Macromol. 2017, 104, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L. Rigid Polyurethane Foam Composites with Nut Shells. Polimery 2020, 65, 728–737. [Google Scholar] [CrossRef]

- Okonkwo, E.G.; Anabaraonye, C.N.; Daniel-Mkpume, C.C.; Egoigwe, S.V.; Okeke, P.E.; Whyte, F.G.; Okoani, A.O. Mechanical and Thermomechanical Properties of Clay-Bambara Nut Shell Polyester Bio-Composite. Int. J. Adv. Manuf. Technol. 2020, 108, 2483–2496. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel Engineered Wood and Bamboo Composites for Structural Applications: State-of-Art of Manufacturing Technology and Mechanical Performance Evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Lokesh, P.; Surya Kumari, T.S.A.; Gopi, R.; Loganathan, G.B. A Study on Mechanical Properties of Bamboo Fiber Reinforced Polymer Composite. Mater. Today Proc. 2020, 22, 897–903. [Google Scholar] [CrossRef]

- Adediran, A.A.; Akinwande, A.A.; Balogun, O.A.; Olasoju, O.S.; Adesina, O.S. Experimental Evaluation of Bamboo Fiber/Particulate Coconut Shell Hybrid PVC Composite. Sci. Rep. 2021, 11, 5465. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Zamani, M.H.; Estaji, S.; Tayouri, M.I.; Arjmand, M.; Jafari, S.H.; Nouranian, S.; Khonakdar, H.A. Mechanical Properties of Bamboo Fiber-Reinforced Polymer Composites: A Review of Recent Case Studies. J. Mater. Sci. 2022, 57, 3143–3167. [Google Scholar] [CrossRef]

- Agunsoye, J.O.; Isaac, T.S.; Samuel, S.O. Study of Mechanical Behaviour of Coconut Shell Reinforced Polymer Matrix Composite. J. Miner. Mater. Charact. Eng. 2012, 11, 774–779. [Google Scholar]

- Agunsoye, J.O.; Odumosu, A.K.; Dada, O. Novel Epoxy-Carbonized Coconut Shell Nanoparticles Composites for Car Bumper Application. Int. J. Adv. Manuf. Technol. 2019, 102, 893–899. [Google Scholar] [CrossRef]

- Nadzri, S.N.I.H.A.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Talib, A.R.A.; Jawaid, M.; Basri, A.A. A Comprehensive Review of Coconut Shell Powder Composites: Preparation, Processing, and Characterization. J. Thermoplast. Compos. Mater. 2020, 35, 2641–2664. [Google Scholar] [CrossRef]

- Obasi, H.C.; Mark, U.C.; Mark, U. Improving the Mechanical Properties of Polypropylene Composites with Coconut Shell Particles. Compos. Adv. Mater. 2021, 30, 263498332110074. [Google Scholar] [CrossRef]

- Sundarababu, J.; Anandan, S.S.; Griskevicius, P. Evaluation of Mechanical Properties of Biodegradable Coconut Shell/Rice Husk Powder Polymer Composites for Light Weight Applications. Mater. Today Proc. 2021, 39, 1241–1247. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Volk, J. Physical, Chemical and Surface Properties of Wheat Husk, Rye Husk and Soft Wood and Their Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 480–488. [Google Scholar] [CrossRef]

- Arjmandi, R.; Hassan, A.; Majeed, K.; Zakaria, Z. Rice Husk Filled Polymer Composites. Int. J. Polym. Sci. 2015, 2015, 501471. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers and Textile Waste Fibers: Elaboration and Performances Evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef] [Green Version]

- Bisht, N.; Gope, P.C.; Rani, N. Rice Husk as a Fibre in Composites: A Review. J. Mech. Behav. Mater. 2020, 29, 147–162. [Google Scholar] [CrossRef]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.; Md Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymer 2021, 13, 2391. [Google Scholar] [CrossRef]

- Wilpiszewska, K.; Antosik, A.K. Effect of Grain Husk Microfibers on Physicochemical Properties of Carboxymethyl Polysaccharides-Based Composite. J. Polym. Environ. 2022, 30, 3129–3138. [Google Scholar] [CrossRef]

- Berger, C.; Mattos, B.D.; Amico, S.C.; de Farias, J.A.; Coldebella, R.; Gatto, D.A.; Missio, A.L. Production of Sustainable Polymeric Composites Using Grape Pomace Biomass. Biomass Convers. Biorefinery 2020, 12, 5869–5880. [Google Scholar] [CrossRef]

- Morinaga, H.; Haibara, S.; Ashizawa, S. Reinforcement of Bio-Based Network Polymer with Wine Pomace. Polym. Compos. 2021, 42, 2973–2981. [Google Scholar] [CrossRef]

- Aljnaid, M.; Banat, R. Effect of Coupling Agents on the Olive Pomace-Filled Polypropylene Composite. E Polym. 2021, 21, 377–390. [Google Scholar] [CrossRef]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly(Vinyl Chloride) Composites with Raspberry Pomace Filler. Polymer 2021, 13, 1079. [Google Scholar] [CrossRef]

- Hiremath, P.; Shettar, M.; Shankar, M.C.G.; Mohan, N.S. Investigation on Effect of Egg Shell Powder on Mechanical Properties of GFRP Composites. Mater. Today Proc. 2018, 5, 3014–3018. [Google Scholar] [CrossRef]

- Owuamanam, S.; Cree, D. Progress of Bio-Calcium Carbonate Waste Eggshell and Seashell Fillers in Polymer Composites: A Review. J. Compos. Sci. 2020, 4, 70. [Google Scholar] [CrossRef]

- Sakthi Balan, G.; Santhosh Kumar, V.; Rajaram, S.; Ravichandran Ramakrishnan, M.K. Investigation on Water Absorption and Wear Characteristics of Waste Plastics and Seashell Powder Reinforced Polymer Composite. J. Tribol. 2020, 27, 57–70. [Google Scholar]

- Vasanthkumar, P.; Balasundaram, R.; Senthilkumar, N.; Palanikumar, K.; Lenin, K.; Deepanraj, B. Thermal and Thermo-Mechanical Studies on Seashell Incorporated Nylon-6 Polymer Composites. J. Mater. Res. Technol. 2022, 21, 3154–3168. [Google Scholar] [CrossRef]

- Hayta, P.; Oktav, M. The Importance of Waste and Environment Management in Printing Industry. Eur. J. Eng. Nat. Sci. 2019, 3, 18–26. [Google Scholar]

- Carlos Alberto, P.J.; Sonia Karina, P.J.; Francisca Irene, S.A.; Adrielly Nahomee, R.Á. Waste Reduction in Printing Process by Implementing a Video Inspection System as a Human Machine Interface. Procedia Comput. Sci. 2021, 180, 79–85. [Google Scholar] [CrossRef]

- Medeiros, D.L.; Braghirolli, F.L.; Ramlow, H.; Ferri, G.N.; Kiperstok, A. Environmental Improvement in the Printing Industry: The Case Study of Self-Adhesive Labels. Environ. Sci. Pollut. Res. 2019, 26, 13195–13209. [Google Scholar] [CrossRef] [PubMed]

- Lanyi, F.J.; Wenzke, N.; Kaschta, J.; Schubert, D.W. On the Determination of the Enthalpy of Fusion of α-Crystalline Isotactic Polypropylene Using Differential Scanning Calorimetry, X-Ray Diffraction, and Fourier-Transform Infrared Spectroscopy: An Old Story Revisited. Adv. Eng. Mater. 2020, 22, 1900796. [Google Scholar] [CrossRef]

| Sample | Filler: Matrix Volume Ratio | Mass Concentration of Filler [wt.%] |

|---|---|---|

| PP | - | - |

| P_1_3 | 1:3 | 1.9 |

| P_1_2 | 1:2 | 2.5 |

| P_1_1 | 1:1 | 5.1 |

| P_2_1 | 2:1 | 10.3 |

| Sample | E’30 (MPa) | E’60 (MPa) | E’90 (MPa) | E’150 (MPa) |

|---|---|---|---|---|

| PP | 1225 | 759 | 416 | 132 |

| P_1_3 | 1207 | 782 | 432 | 142 |

| P_1_2 | 1247 | 779 | 431 | 142 |

| P_1_1 | 1326 | 791 | 443 | 143 |

| P_2_1 | 1194 | 744 | 426 | 148 |

| Sample | Cooling | Heating | |||

|---|---|---|---|---|---|

| Tc [°C] | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) | |

| PP | 124.5 | 97.4 | 163.7 | 98.8 | 47.7 |

| P_1_3 | 124.8 | 95.1 | 163.1 | 90.8 | 43.0 |

| P_1_2 | 119.0 | 80.1 | 161.5 | 85.6 | 40.3 |

| P_1_1 | 119.0 | 81.8 | 161.5 | 83.1 | 38.1 |

| P_2_1 | 118.4 | 80.8 | 161.4 | 83.2 | 36.2 |

| Sample | T5% (°C) | T50% (°C) | T95% (°C) | Tmax1 (°C) | Tmax2 (°C) |

|---|---|---|---|---|---|

| PP | 347.5 | 409.1 | 434.8 | - | 423.9 |

| P_1_3 | 344.8 | 440.5 | 465.4 | 353.6 | 450.1 |

| P_1_2 | 343.9 | 450.1 | 473.6 | 354.0 | 455.4 |

| P_1_1 | 340.0 | 440.7 | 467.9 | 356.5 | 450.8 |

| P_2_1 | 330.6 | 451.5 | 476.6 | 353.2 | 458.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moraczewski, K.; Karasiewicz, T.; Suwała, A.; Bolewski, B.; Szabliński, K.; Zaborowska, M. Versatile Polypropylene Composite Containing Post-Printing Waste. Polymers 2022, 14, 5335. https://doi.org/10.3390/polym14245335

Moraczewski K, Karasiewicz T, Suwała A, Bolewski B, Szabliński K, Zaborowska M. Versatile Polypropylene Composite Containing Post-Printing Waste. Polymers. 2022; 14(24):5335. https://doi.org/10.3390/polym14245335

Chicago/Turabian StyleMoraczewski, Krzysztof, Tomasz Karasiewicz, Alicja Suwała, Bartosz Bolewski, Krzysztof Szabliński, and Magdalena Zaborowska. 2022. "Versatile Polypropylene Composite Containing Post-Printing Waste" Polymers 14, no. 24: 5335. https://doi.org/10.3390/polym14245335