Thermomechanical Properties and Fracture Toughness Improvement of Thermosetting Vinyl Ester Using Liquid Metal and Graphene Nanoplatelets

Abstract

1. Introduction

2. Materials and Sample Preparation

2.1. Materials

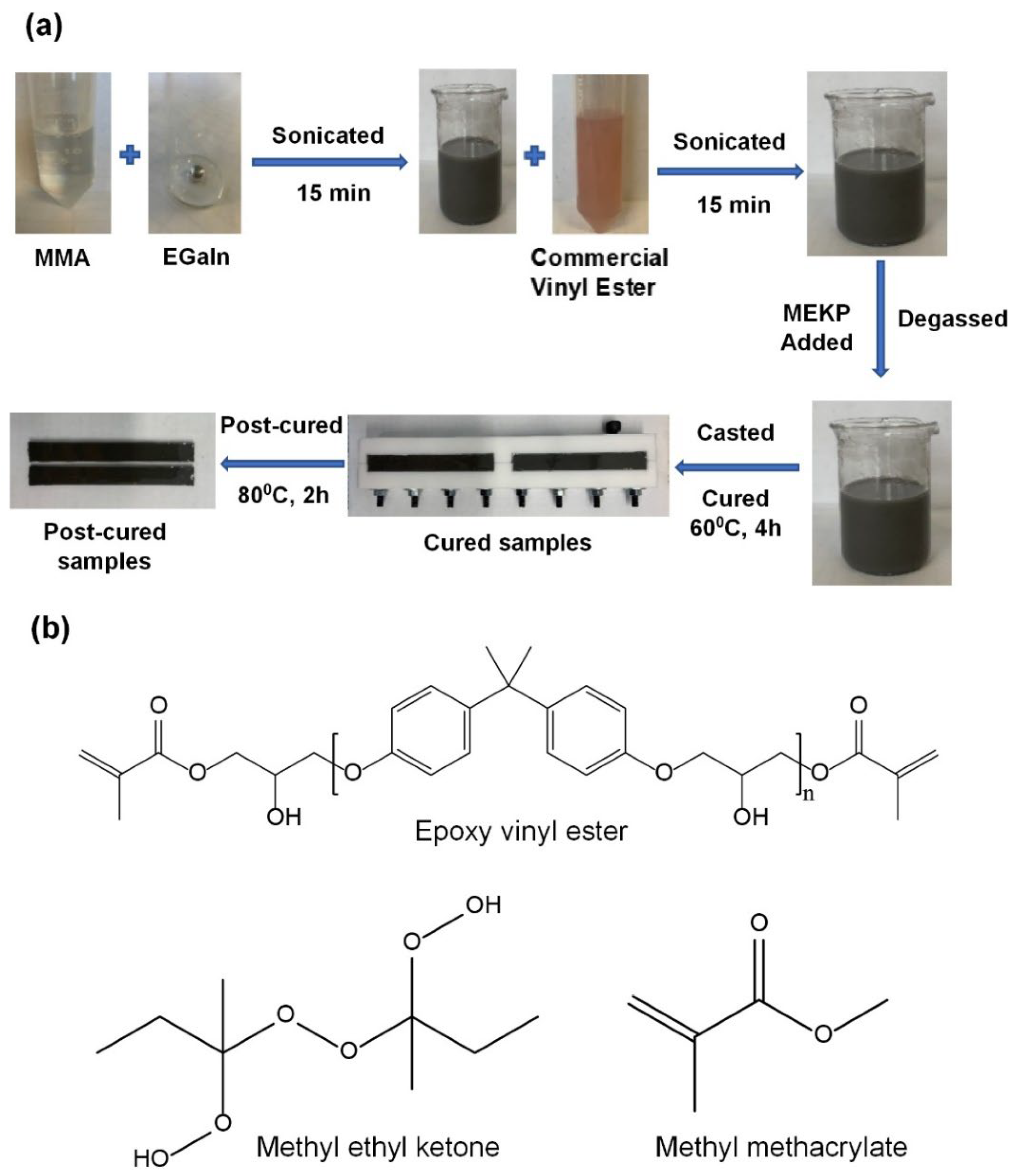

2.2. Preparation of EGaIn-Modified Comonomer Vinyl Ester Composites

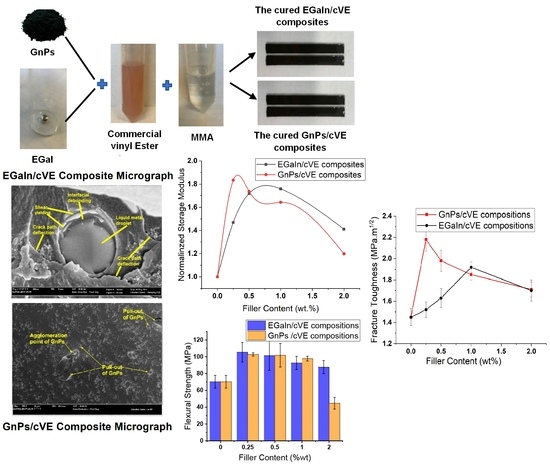

3. Results and Discussions

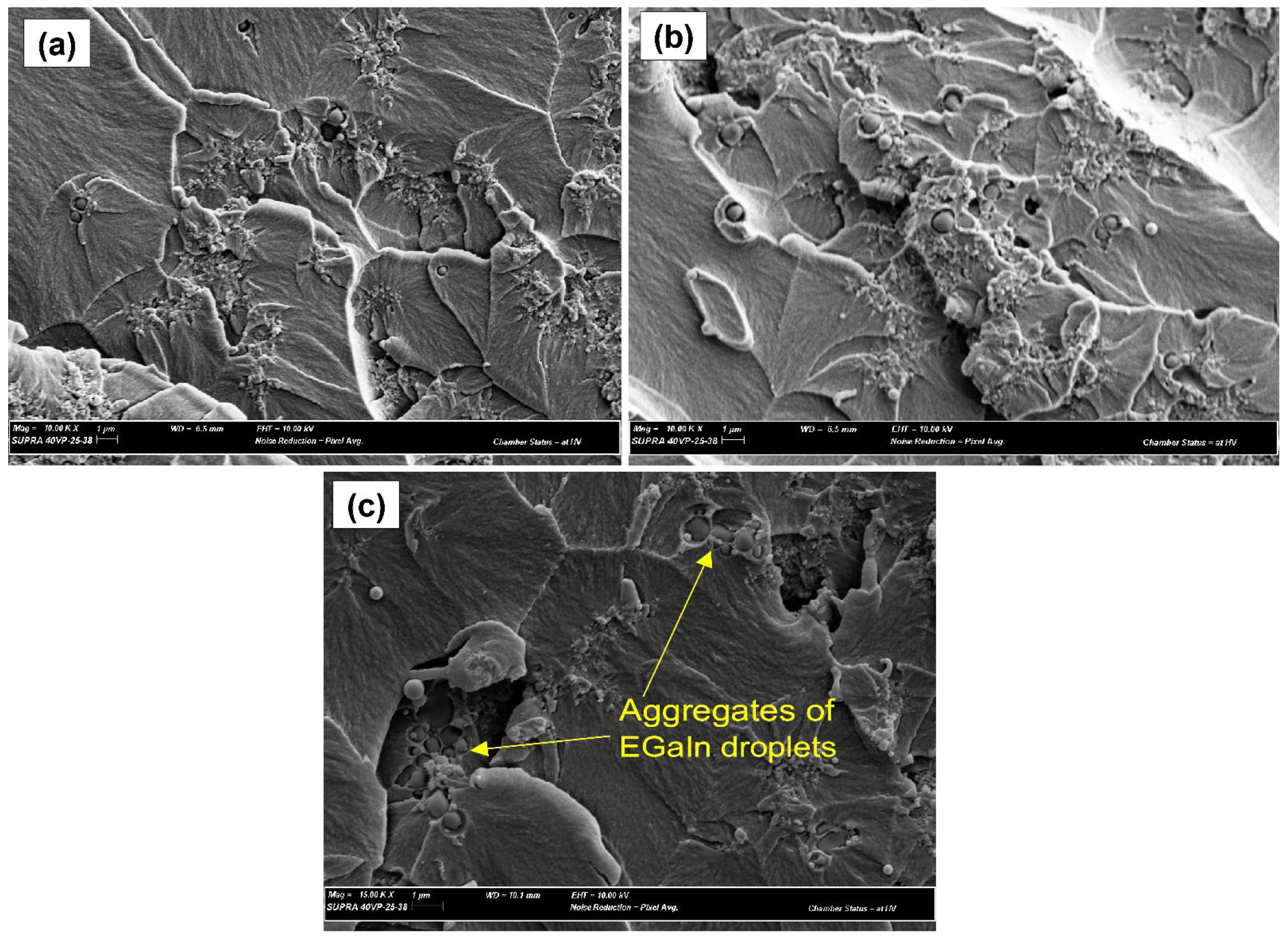

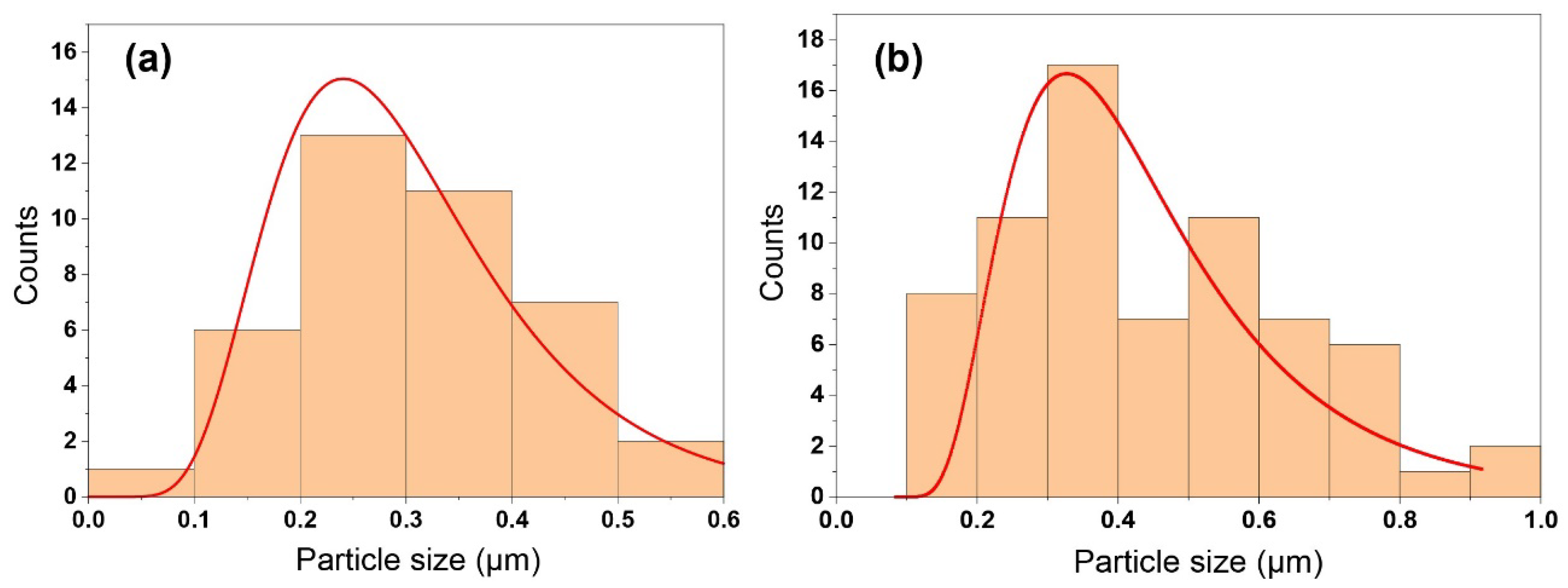

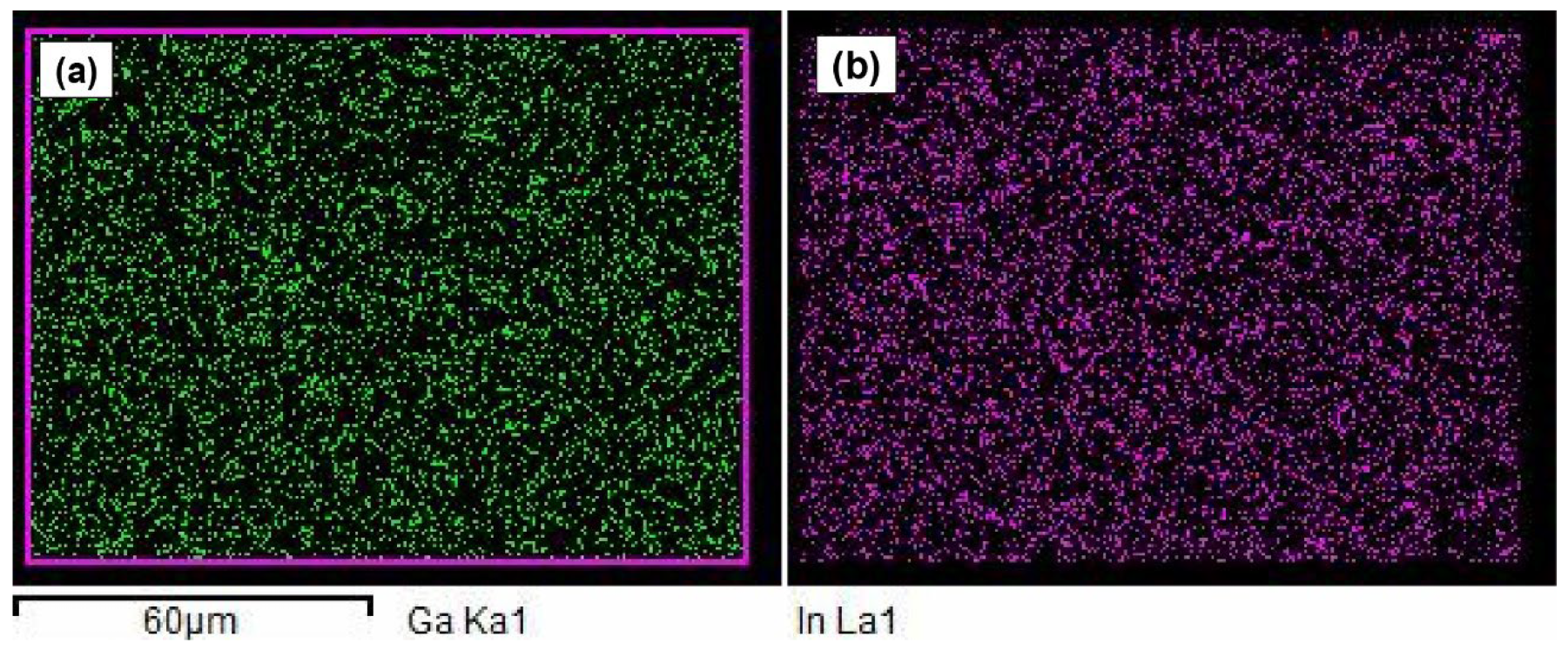

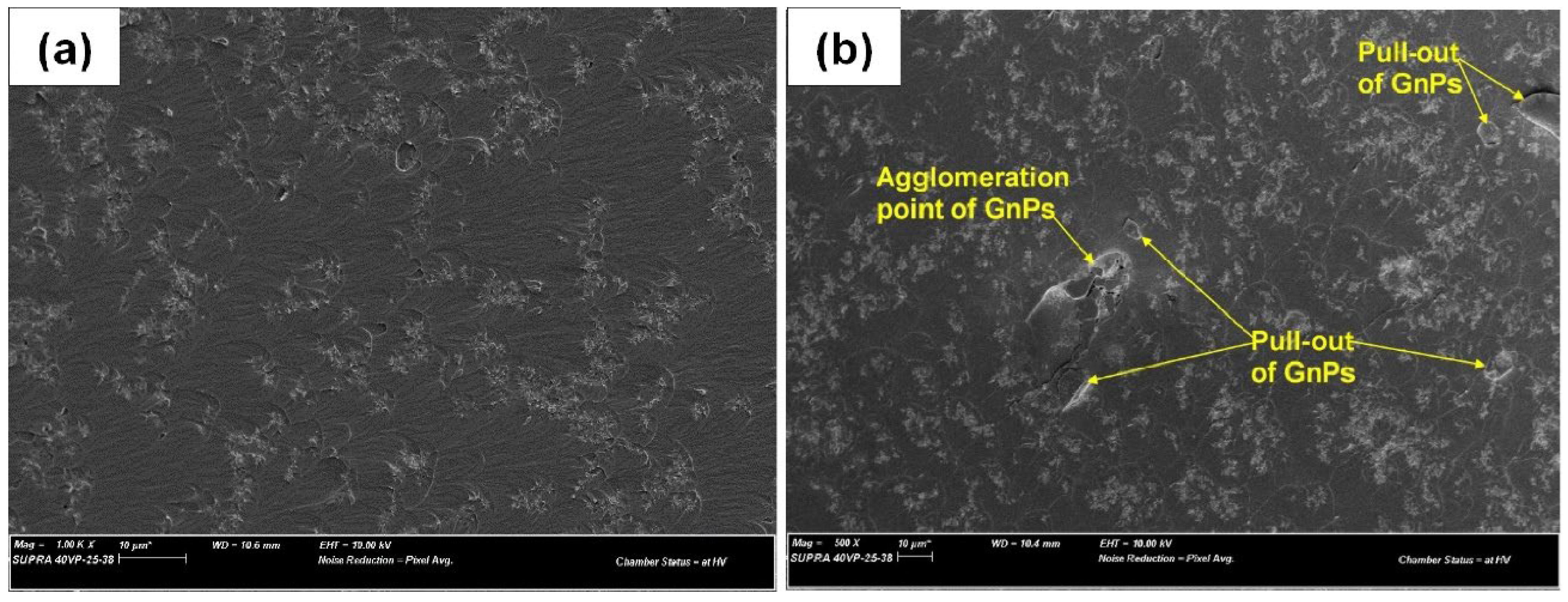

3.1. Morphological Observation

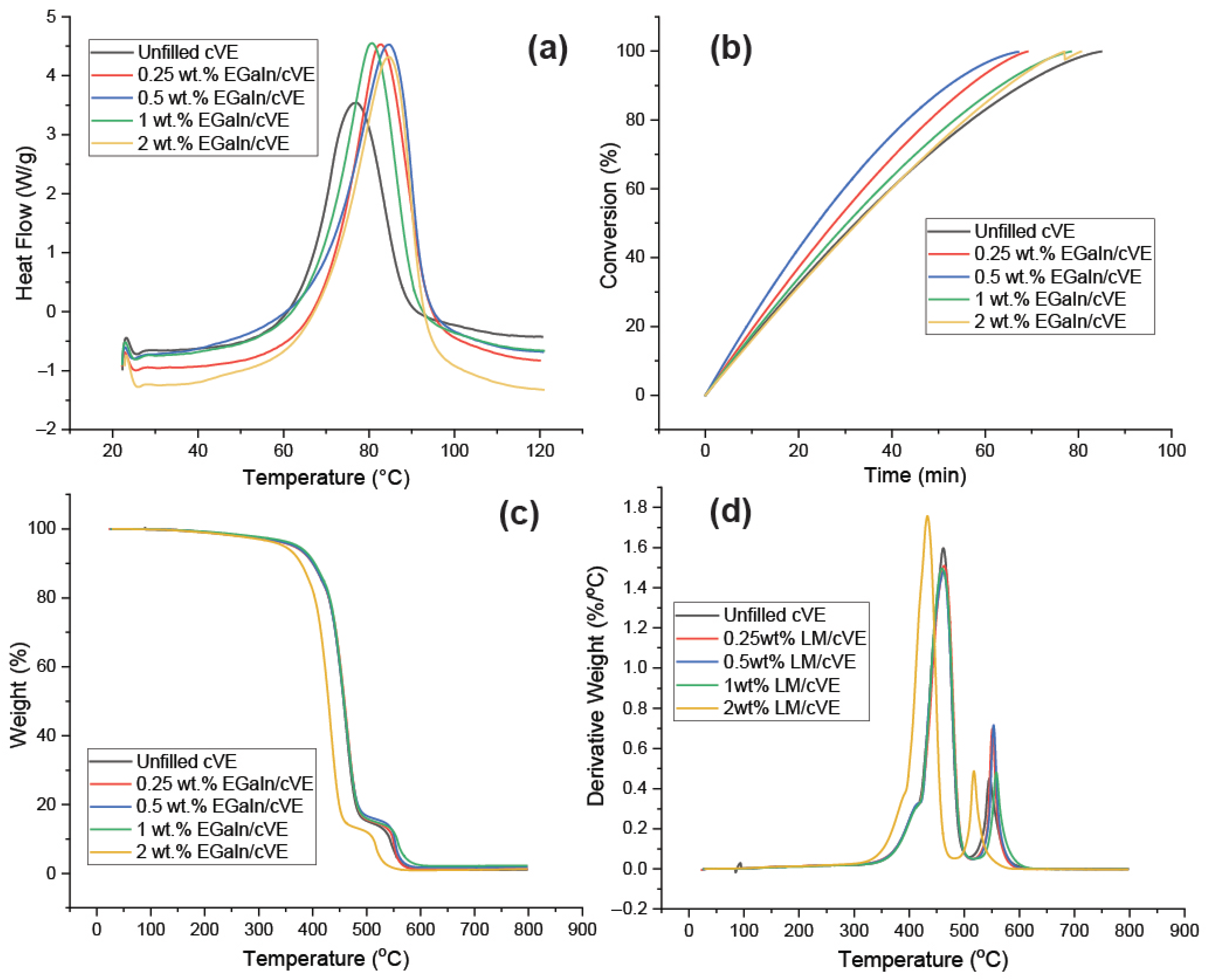

3.2. Thermal Analysis

3.3. Thermomechanical Analysis

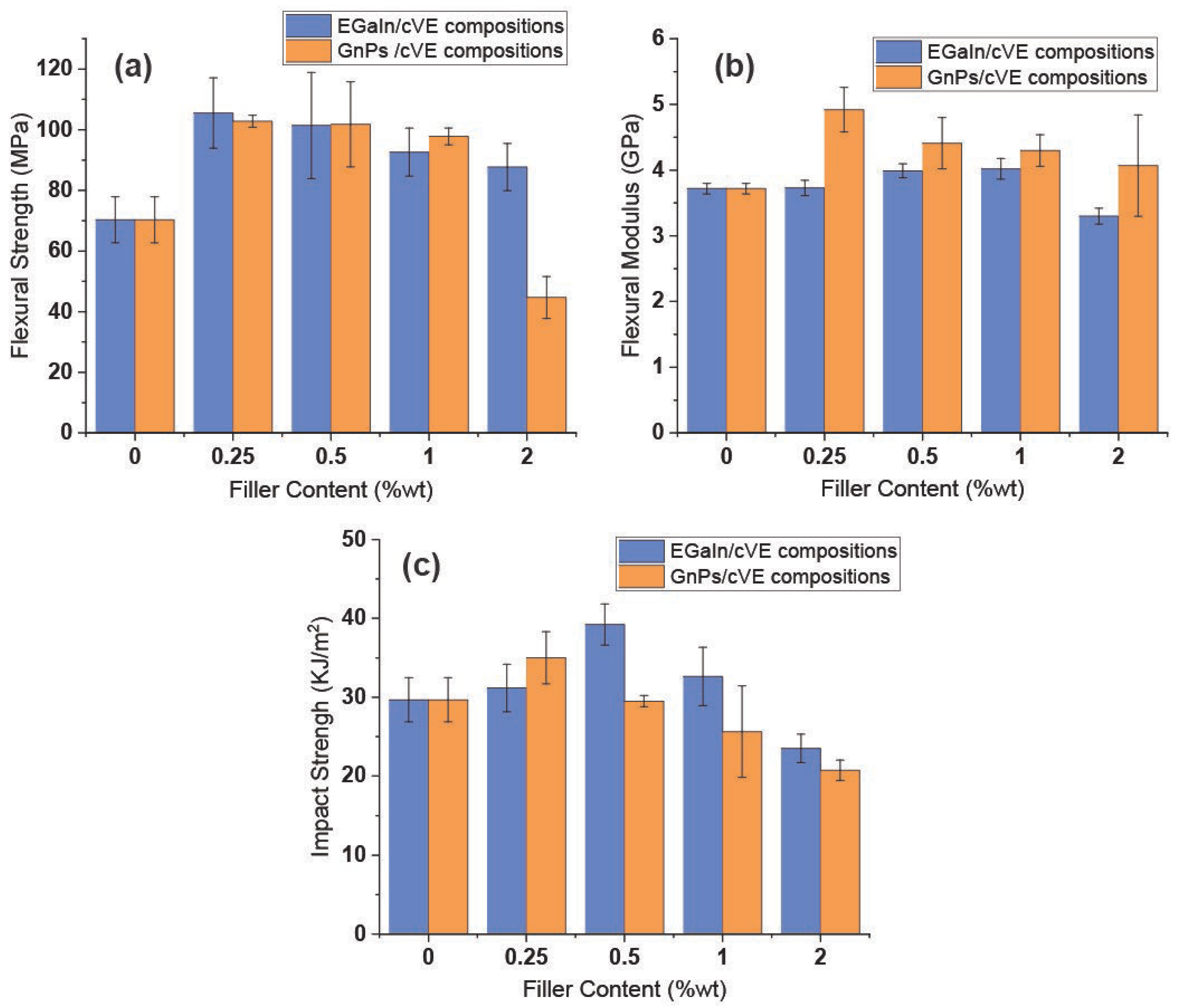

3.4. Mechanical Characteristic

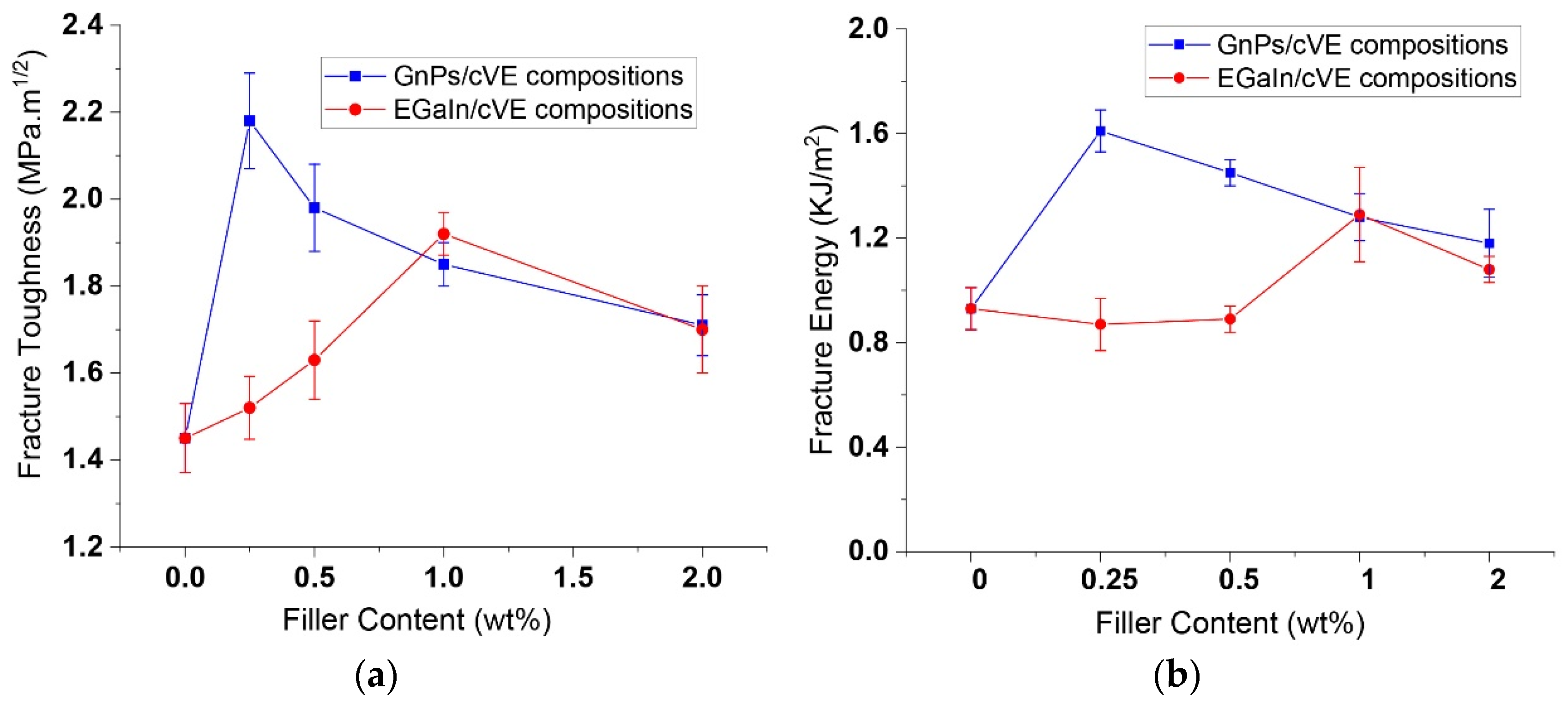

3.5. Fracture Toughness Analysis

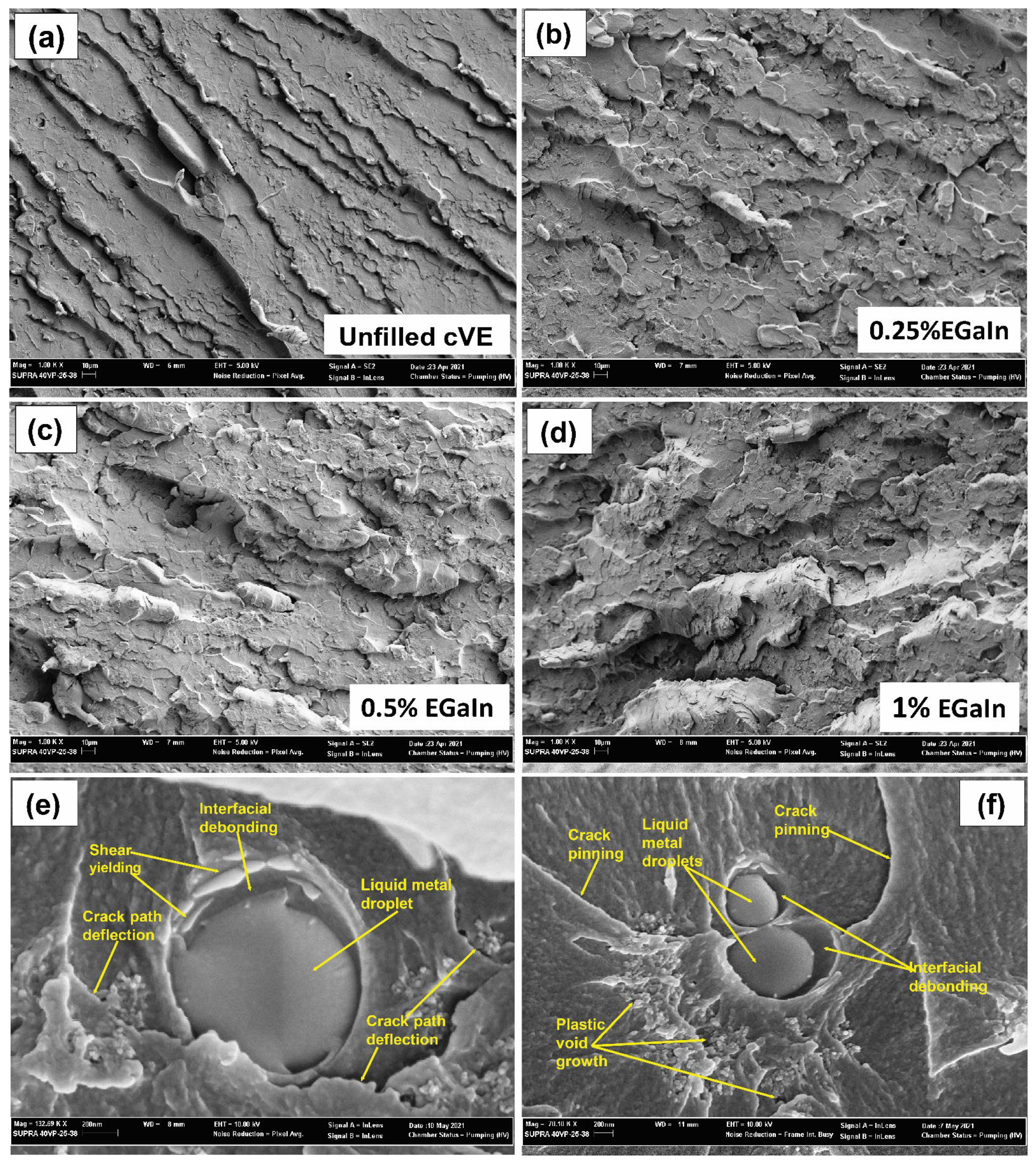

3.6. Fractography Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Atta, A.M.; El-Saeed, S.M.; Farag, R.K. New vinyl ester resins based on rosin for coating applications. React. Funct. Polym. 2006, 66, 1596–1608. [Google Scholar] [CrossRef]

- Banna, M.; Shirokoff, J.; Molgaard, J. Effects of two aqueous acidic solutions on polyester and bisphenol A epoxy vinyl ester resins. Mater. Sci. Eng. A 2011, 528, 2137–2142. [Google Scholar] [CrossRef]

- Kang, H.; Yoon, T.; Bump, M.; Riffle, J. Effect of solubility and miscibility on the adhesion behavior of polymer-coated carbon fibers with vinyl ester resins. J. Appl. Polym. Sci. 2001, 79, 1042–1053. [Google Scholar] [CrossRef]

- Peters, S.T. Handbook of Composites; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Afshar, A.; Liao, H.-T.; Chiang, F.-P.; Korach, C.S. Time-dependent changes in mechanical properties of carbon fiber vinyl ester composites exposed to marine environments. Compos. Struct. 2016, 144, 80–85. [Google Scholar] [CrossRef]

- Kandola, B.K.; Ebdon, J.R.; Zhou, C. Development of vinyl ester resins with improved flame retardant properties for structural marine applications. React. Funct. Polym. 2018, 129, 111–122. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Choudhury, M.I. Nanoscale characterization of glass flake filled vinyl ester anti-corrosion coatings. Coatings 2017, 7, 116. [Google Scholar] [CrossRef]

- Ehsani, M.; Khonakdar, H.A.; Ghadami, A. Assessment of morphological, thermal, and viscoelastic properties of epoxy vinyl ester coating composites: Role of glass flake and mixing method. Prog. Org. Coat. 2013, 76, 238–243. [Google Scholar] [CrossRef]

- Ambrogi, V.; Carfagna, C.; Giamberini, M.; Amendola, E.; Douglas, E. Liquid crystalline vinyl ester resins for structural adhesives. J. Adhes. Sci. Technol. 2002, 16, 15–32. [Google Scholar] [CrossRef]

- Levita, G.; De Petris, S.; Marchetti, A.; Lazzeri, A. Crosslink density and fracture toughness of epoxy resins. J. Mater. Sci. 1991, 26, 2348–2352. [Google Scholar] [CrossRef]

- Konnola, R.; Parameswaranpillai, J.; Joseph, K. Mechanical, thermal, and viscoelastic response of novel in situ CTBN/POSS/epoxy hybrid composite system. Polym. Compos. 2016, 37, 2109–2120. [Google Scholar] [CrossRef]

- Song, X.; Xu, S. Curing kinetics of pre-crosslinked carboxyl-terminated butadiene acrylonitrile (CTBN) modified epoxy blends. J. Therm. Anal. Calorim. 2016, 123, 319–327. [Google Scholar] [CrossRef]

- Tao, L.; Sun, Z.; Min, W.; Ou, H.; Qi, L.; Yu, M. Improving the toughness of thermosetting epoxy resins via blending triblock copolymers. RSC Adv. 2020, 10, 1603–1612. [Google Scholar] [CrossRef] [PubMed]

- Zeinedini, A.; Shokrieh, M.M.; Ebrahimi, A. The effect of agglomeration on the fracture toughness of CNTs-reinforced nanocomposites. Theor. Appl. Fract. Mech. 2018, 94, 84–94. [Google Scholar] [CrossRef]

- He, S.; Petkovich, N.D.; Liu, K.; Qian, Y.; Macosko, C.W.; Stein, A. Unsaturated polyester resin toughening with very low loadings of GO derivatives. Polymer 2017, 110, 149–157. [Google Scholar] [CrossRef]

- Peng, J.; Huang, C.; Cao, C.; Saiz, E.; Du, Y.; Dou, S.; Tomsia, A.P.; Wagner, H.D.; Jiang, L.; Cheng, Q. Inverse Nacre-like Epoxy-Graphene Layered Nanocomposites with Integration of High Toughness and Self-Monitoring. Matter 2020, 2, 220–232. [Google Scholar] [CrossRef]

- Vu, C.M.; Nguyen, L.T.; Phuc, B.T.; Tung, N.H.; Nguyen, D.D. Enhanced mode I interlaminar fracture toughness and mechanical properties of carbon fiber-filled vinyl ester resin-based composite by using both coal fly ash and nano-/micro-glass fiber. Polym. Bull. 2019, 77, 357–374. [Google Scholar]

- Maghsoudlou, M.A.; Isfahani, R.B.; Saber-Samandari, S.; Sadighi, M. Effect of interphase, curvature and agglomeration of SWCNTs on mechanical properties of polymer-based nanocomposites: Experimental and numerical investigations. Compos. Part B Eng. 2019, 175, 107119. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Rong, M.; Zhang, M.; Ruan, W. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: A review. Mater. Sci. Technol. 2006, 22, 787–796. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Q.; Guo, M.; Wang, C.; Du, R.; Fu, Q. Study on the phase structures and toughening mechanism in PP/EPDM/SiO2 ternary composites. Polymer 2006, 47, 2106–2115. [Google Scholar] [CrossRef]

- Chan, C.-M.; Wu, J.; Li, J.-X.; Cheung, Y.-K. Polypropylene/calcium carbonate nanocomposites. Polymer 2002, 43, 2981–2992. [Google Scholar] [CrossRef]

- Kruenate, J.; Tongpool, R.; Panyathanmaporn, T.; Kongrat, P. Optical and mechanical properties of polypropylene modified by metal oxides. Surf. Interface Anal. 2004, 36, 1044–1047. [Google Scholar] [CrossRef]

- Bouhfid, N.; Raji, M.; Bensalah, M.-O. Functionalized graphene and thermoset matrices–based nanocomposites: Mechanical and thermal properties. In Functionalized Graphene Nanocomposites and Their Derivatives; Elsevier: Amsterdam, The Netherlands, 2019; pp. 47–64. [Google Scholar] [CrossRef]

- Dharmavarapu, P.; Reddy, M. Mechanical, low velocity impact, fatigue and tribology behaviour of Silane grafted aramid fibre and Nano-silica toughened epoxy composite. Silicon 2021, 13, 1741–1750. [Google Scholar] [CrossRef]

- Benight, S.J.; Wang, C.; Tok, J.B.; Bao, Z. Stretchable and self-healing polymers and devices for electronic skin. Prog. Polym. Sci. 2013, 38, 1961–1977. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. Liquid-phase metal inclusions for a conductive polymer composite. Adv. Mater. 2015, 27, 1928–1932. [Google Scholar] [CrossRef]

- Mei, S.; Gao, Y.; Deng, Z.; Liu, J. Thermally conductive and highly electrically resistive grease through homogeneously dispersing liquid metal droplets inside methyl silicone oil. J. Electron. Packag. 2014, 136, 011009. [Google Scholar] [CrossRef]

- Kalantar-Zadeh, K.; Tang, J.; Daeneke, T.; O’Mullane, A.P.; Stewart, L.A.; Liu, J.; Majidi, C.; Ruoff, R.S.; Weiss, P.S.; Dickey, M.D. Emergence of liquid metals in nanotechnology. ACS Nano 2019, 13, 7388–7395. [Google Scholar] [CrossRef]

- Ma, J.; Lin, Y.; Kim, Y.-W.; Ko, Y.; Kim, J.; Oh, K.H.; Sun, J.-Y.; Gorman, C.B.; Voinov, M.A.; Smirnov, A.I. Liquid metal nanoparticles as initiators for radical polymerization of vinyl monomers. ACS Macro Lett. 2019, 8, 1522–1527. [Google Scholar] [CrossRef]

- Bartlett, M.D.; Fassler, A.; Kazem, N.; Markvicka, E.J.; Mandal, P.; Majidi, C. Stretchable, high-k dielectric elastomers through liquid-metal inclusions. Adv. Mater. 2016, 28, 3726–3731. [Google Scholar] [CrossRef]

- Hohman, J.N.; Kim, M.; Wadsworth, G.A.; Bednar, H.R.; Jiang, J.; LeThai, M.A.; Weiss, P.S. Directing substrate morphology via self-assembly: Ligand-mediated scission of gallium–indium microspheres to the nanoscale. Nano Lett. 2011, 11, 5104–5110. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Genzer, J.; Li, W.; Qiao, R.; Dickey, M.D.; Tang, S.-Y. Sonication-enabled rapid production of stable liquid metal nanoparticles grafted with poly (1-octadecene-alt-maleic anhydride) in aqueous solutions. Nanoscale 2018, 10, 19871–19878. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, Y.; Genzer, J.; Dickey, M.D. Shape-transformable liquid metal nanoparticles in aqueous solution. Chem. Sci. 2017, 8, 3832–3837. [Google Scholar] [CrossRef]

- Tang, S.-Y.; Mitchell, D.R.G.; Zhao, Q.; Yuan, D.; Yun, G.; Zhang, Y.; Qiao, R.; Lin, Y.; Dickey, M.D.; Li, W. Phase Separation in Liquid Metal Nanoparticles. Matter 2019, 1, 192–204. [Google Scholar] [CrossRef]

- Kazem, N.; Hellebrekers, T.; Majidi, C. Soft multifunctional composites and emulsions with liquid metals. Adv. Mater. 2017, 29, 1605985. [Google Scholar] [CrossRef] [PubMed]

- Kazem, N.; Bartlett, M.D.; Majidi, C. Extreme toughening of soft materials with liquid metal. Adv. Mater. 2018, 30, 1706594. [Google Scholar] [CrossRef] [PubMed]

- Lou, Y.; Liu, H.; Zhang, J. Liquid Metals in Plastics for Super-Toughness and High-Performance Force Sensors. Chem. Eng. J. 2020, 399, 125732. [Google Scholar] [CrossRef]

- Jiménez-Suárez, A.; Prolongo, S. Graphene Nanoplatelets; MDPI: Basel, Switzerland, 2020; Volume 10, p. 1753. [Google Scholar]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Jang, B.Z.; Zhamu, A. Processing of nanographene platelets (NGPs) and NGP nanocomposites: A review. J. Mater. Sci. 2008, 43, 5092–5101. [Google Scholar] [CrossRef]

- Sengupta, R.; Bhattacharya, M.; Bandyopadhyay, S.; Bhowmick, A.K. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 2011, 36, 638–670. [Google Scholar] [CrossRef]

- Chung, D. A review of exfoliated graphite. J. Mater. Sci. 2016, 51, 554–568. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M. Effect of graphene nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog. Nat. Sci. Mater. Int. 2014, 24, 101–108. [Google Scholar] [CrossRef]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets–Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

- Cui, Y.; Kundalwal, S.; Kumar, S. Gas barrier performance of graphene/polymer nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef]

- Inuwa, I.; Hassan, A.; Wang, D.-Y.; Samsudin, S.; Haafiz, M.M.; Wong, S.; Jawaid, M. Influence of exfoliated graphite nanoplatelets on the flammability and thermal properties of polyethylene terephthalate/polypropylene nanocomposites. Polym. Degrad. Stab. 2014, 110, 137–148. [Google Scholar] [CrossRef]

- Dittrich, B.; Wartig, K.-A.; Hofmann, D.; Mülhaupt, R.; Schartel, B. Flame retardancy through carbon nanomaterials: Carbon black, multiwall nanotubes, expanded graphite, multi-layer graphene and graphene in polypropylene. Polym. Degrad. Stab. 2013, 98, 1495–1505. [Google Scholar] [CrossRef]

- Liu, X.; Zou, Q.; Wang, T.; Zhang, L. Electrically conductive graphene-based biodegradable polymer composite films with high thermal stability and flexibility. Nano 2018, 13, 1850033. [Google Scholar] [CrossRef]

- Dang, M.T.K.; Nikzad, M.; Truong, K.V.; Masood, S.; Sbarski, I. A Co-monomer resin matrix design for processing of polymer concrete composites. In Proceedings of the ANTEC 2021: The Annual Technical Conference for Plastic Professionals, Online, 10–21 May 2021. [Google Scholar]

- Allen, T. Particle Size Measurement, 3rd ed.; Chapman and Hall: London, UK, 1981. [Google Scholar]

- Agrawal, S.; Mishra, A.; Rai, J. Effect of diluents on the decomposition behavior of vinyl ester resin. J. Appl. Polym. Sci. 2003, 87, 1952–1956. [Google Scholar] [CrossRef]

- Paran, S.M.R.; Naderi, G.; Javadi, F.; Shemshadi, R.; Saeb, M.R. Experimental and theoretical analyses on mechanical properties and stiffness of hybrid graphene/graphene oxide reinforced EPDM/NBR nanocomposites. Mater. Today Commun. 2020, 22, 100763. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, J.-J.; Han, C.-R.; Duan, J.-F. Keys to enhancing mechanical properties of silica nanoparticle composites hydrogels: The role of network structure and interfacial interactions. Compos. Sci. Technol. 2014, 95, 1–7. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; You, J.; Li, X.; Li, M.; Wu, X.; Li, C. Polymerization of moldable self-healing hydrogel with liquid metal nanodroplets for flexible strain-sensing devices. Chem. Eng. J. 2020, 392, 123788. [Google Scholar] [CrossRef]

- Idumah, C.I.; Obele, C.M. Understanding interfacial influence on properties of polymer nanocomposites. Surf. Interfaces 2021, 22, 100879. [Google Scholar] [CrossRef]

- Du, W.; Zhang, Z.; Su, H.; Lin, H.; Li, Z. Urethane-functionalized graphene oxide for improving compatibility and thermal conductivity of waterborne polyurethane composites. Ind. Eng. Chem. Res. 2018, 57, 7146–7155. [Google Scholar] [CrossRef]

- Li, W.; Leong, T.S.; Ashokkumar, M.; Martin, G.J. A study of the effectiveness and energy efficiency of ultrasonic emulsification. Phys. Chem. Chem. Phys. 2018, 20, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Cha, J.; Kim, J.; Ryu, S.; Hong, S.H. Comparison to mechanical properties of epoxy nanocomposites reinforced by functionalized carbon nanotubes and graphene nanoplatelets. Compos. Part B Eng. 2019, 162, 283–288. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Hsieh, T.; Kinloch, A.; Masania, K.; Taylor, A.; Sprenger, S. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Zappalorto, M.; Salviato, M.; Quaresimin, M. A multiscale model to describe nanocomposite fracture toughness enhancement by the plastic yielding of nanovoids. Compos. Sci. Technol. 2012, 72, 1683–1691. [Google Scholar] [CrossRef]

- Faber, K.T.; Evans, A.G. Crack deflection processes—I. Theory. Acta Metall. 1983, 31, 565–576. [Google Scholar] [CrossRef]

- Green, D.J.; Nicholson, P.S.; Embury, J.D. Fracture of a brittle particulate composite. J. Mater. Sci. 1979, 14, 1413–1420. [Google Scholar] [CrossRef]

- Jajam, K.C.; Tippur, H.V. Quasi-static and dynamic fracture behavior of particulate polymer composites: A study of nano-vs. micro-size filler and loading-rate effects. Compos. Part B Eng. 2012, 43, 3467–3481. [Google Scholar] [CrossRef]

- Wetzel, B.; Rosso, P.; Haupert, F.; Friedrich, K. Epoxy nanocomposites—Fracture and toughening mechanisms. Eng. Fract. Mech. 2006, 73, 2375–2398. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Friedrich, K.; Eger, C. Property improvements of in situ epoxy nanocomposites with reduced interparticle distance at high nanosilica content. Acta Mater. 2006, 54, 1833–1842. [Google Scholar] [CrossRef]

- ASTM D7028-07D-07; Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D5045-99; Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D256-06; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D7264/D7264M-07; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2015.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, T.K.M.; Nikzad, M.; Truong, V.K.; Masood, S.; Nguyen, C.K.; Sbarski, I. Thermomechanical Properties and Fracture Toughness Improvement of Thermosetting Vinyl Ester Using Liquid Metal and Graphene Nanoplatelets. Polymers 2022, 14, 5397. https://doi.org/10.3390/polym14245397

Dang TKM, Nikzad M, Truong VK, Masood S, Nguyen CK, Sbarski I. Thermomechanical Properties and Fracture Toughness Improvement of Thermosetting Vinyl Ester Using Liquid Metal and Graphene Nanoplatelets. Polymers. 2022; 14(24):5397. https://doi.org/10.3390/polym14245397

Chicago/Turabian StyleDang, Thanh Kim Mai, Mostafa Nikzad, Vi Khanh Truong, Syed Masood, Chung Kim Nguyen, and Igor Sbarski. 2022. "Thermomechanical Properties and Fracture Toughness Improvement of Thermosetting Vinyl Ester Using Liquid Metal and Graphene Nanoplatelets" Polymers 14, no. 24: 5397. https://doi.org/10.3390/polym14245397

APA StyleDang, T. K. M., Nikzad, M., Truong, V. K., Masood, S., Nguyen, C. K., & Sbarski, I. (2022). Thermomechanical Properties and Fracture Toughness Improvement of Thermosetting Vinyl Ester Using Liquid Metal and Graphene Nanoplatelets. Polymers, 14(24), 5397. https://doi.org/10.3390/polym14245397