Selective Solvolysis of Bio-Based PU-Coated Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PU Coatings

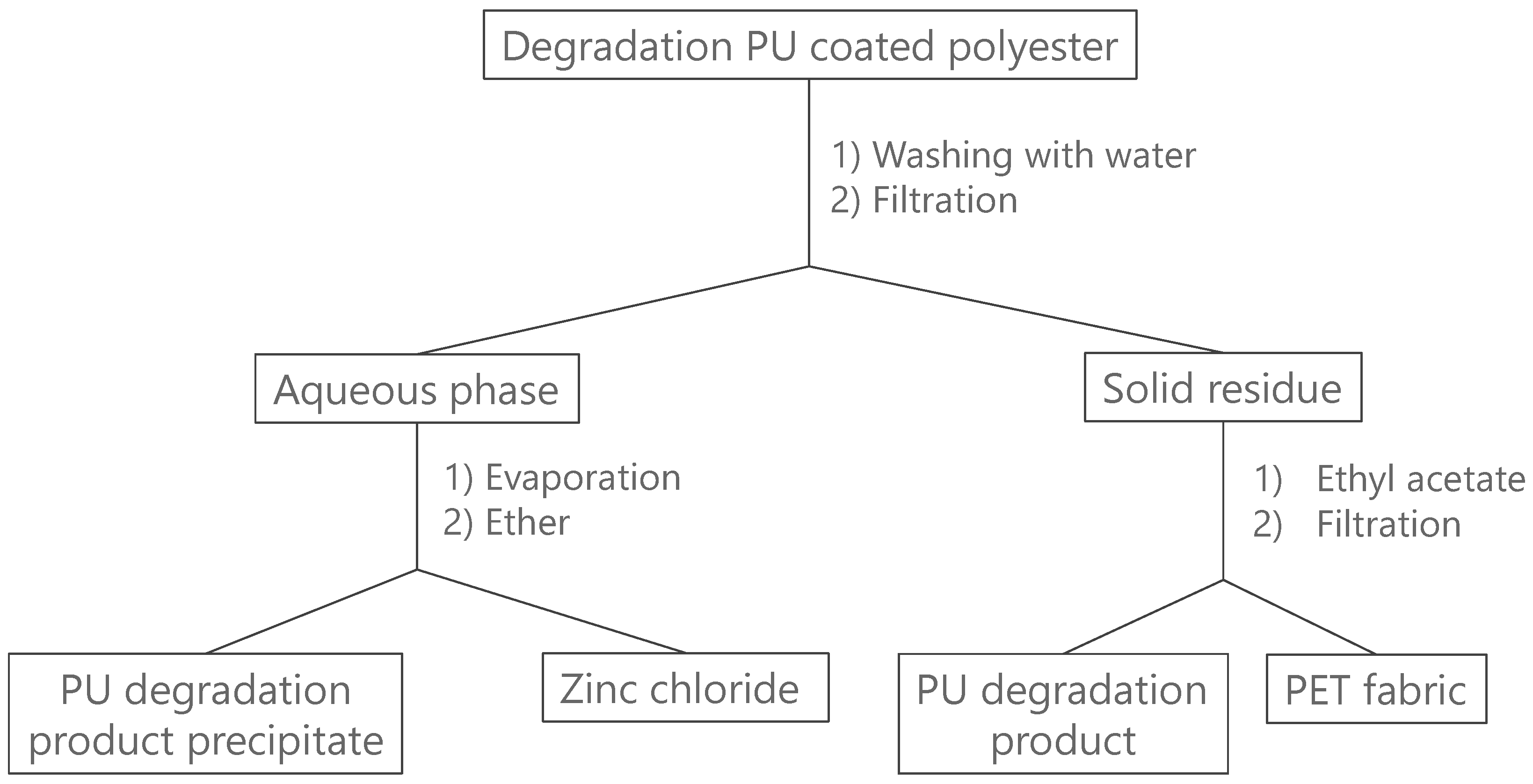

2.3. Degradation of PU-Coated Textile

2.4. Characterization

3. Results

3.1. Structural Characterization of Bio-Based PU Coating

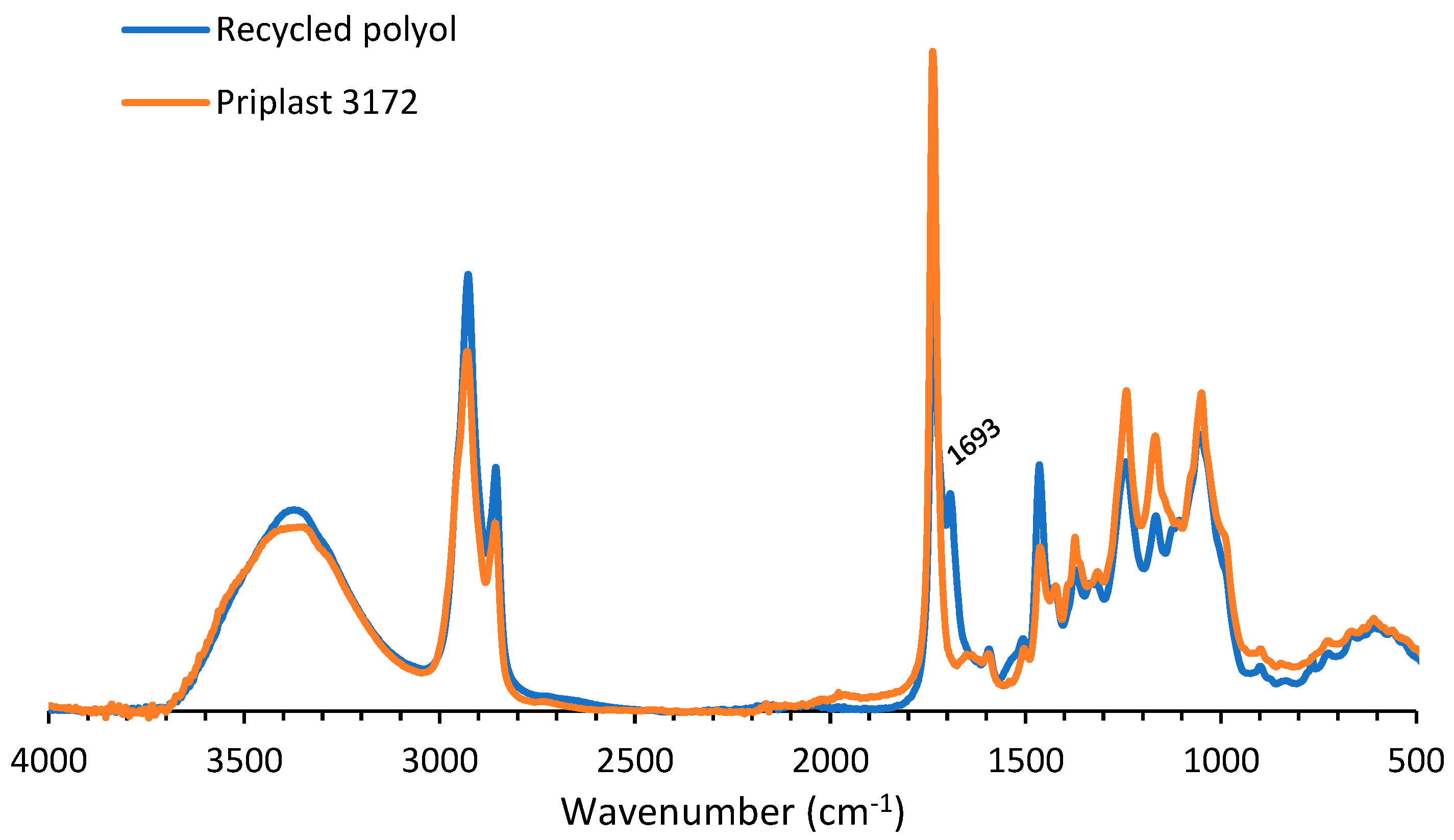

3.2. Characterization and Analysis of Degradation Products

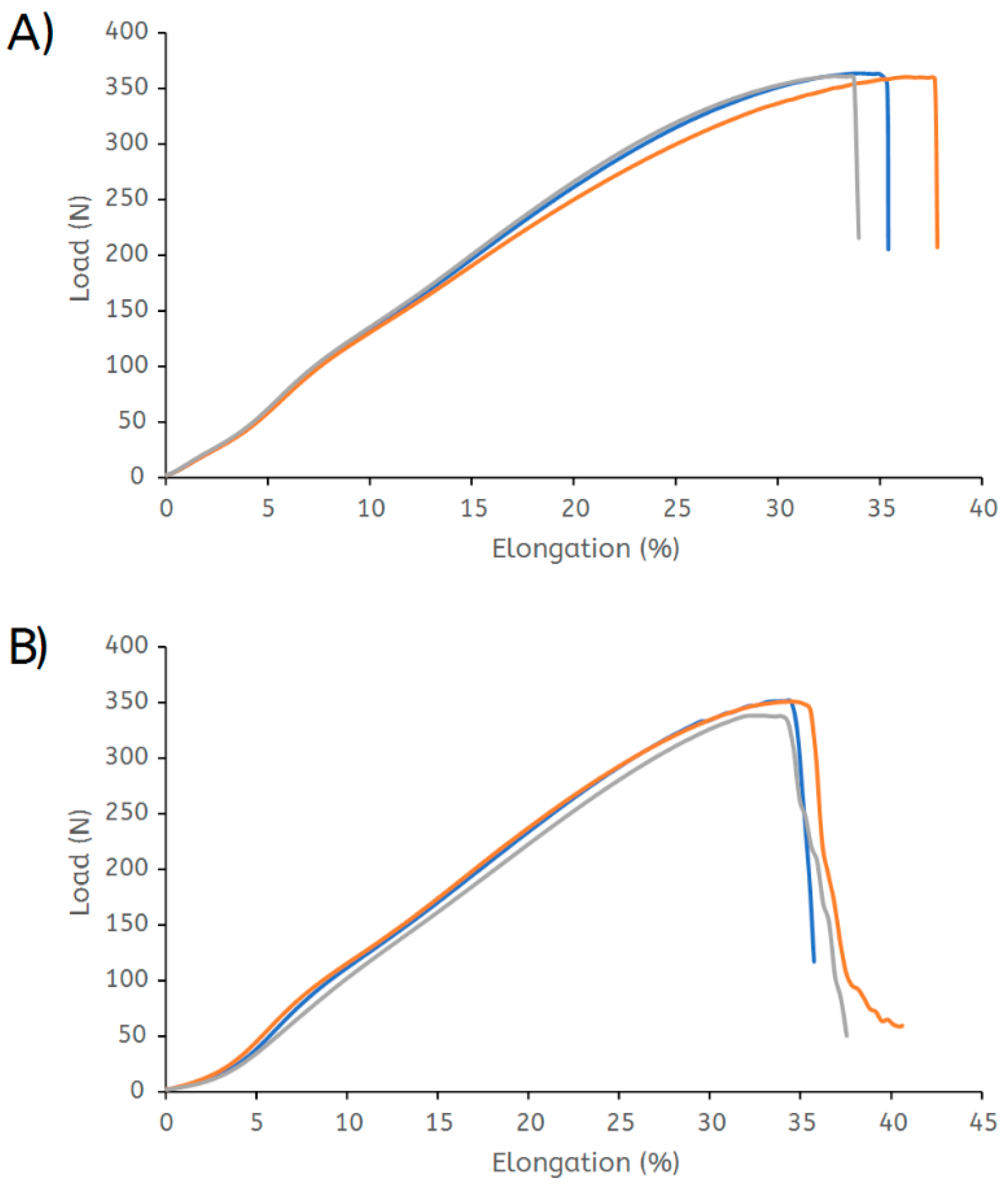

3.3. Characterization of Recycled Polyester

3.4. Thermal Degradation of Polyester

3.5. DSC Analysis of Polyester

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Analysis of the Most Appropriate Regulatory Management Option. Available online: https://echa.europa.eu/documents/10162/f96ae430-bfba-f349-36aa-fd9cc13c4f01 (accessed on 13 November 2022).

- Irie, M. Properties and Applications of Photoresponsive Polymers. Pure Appl. Chem. 1990, 62, 1495–1502. [Google Scholar] [CrossRef] [Green Version]

- Bertrand, O.; Gohy, J.-F. Photo-Responsive Polymers: Synthesis and Applications. Polym. Chem. 2017, 8, 52–73. [Google Scholar] [CrossRef]

- Sun, S.; Liang, S.; Xu, W.C.; Xu, G.; Wu, S. Photoresponsive Polymers with Multi-Azobenzene Groups. Polym. Chem. 2019, 10, 4389–4401. [Google Scholar] [CrossRef] [Green Version]

- Inui, T.; Yamanishi, K.; Sato, E.; Matsumoto, A. Organotellurium-Mediated Living Radical Polymerization (TERP) of Acrylates Using Ditelluride Compounds and Binary Azo Initiators for the Synthesis of High-Performance Adhesive Block Copolymers for on-Demand Dismantlable Adhesion. Macromolecules 2013, 46, 8111–8120. [Google Scholar] [CrossRef]

- Sato, E.; Yamanishi, K.; Inui, T.; Horibe, H.; Matsumoto, A. Acetal-Protected Acrylic Copolymers for Dismantlable Adhesives with Spontaneous and Complete Removability. Polymer 2015, 64, 260–267. [Google Scholar] [CrossRef]

- Fukamoto, Y.; Sato, E.; Okamura, H.; Horibe, H.; Matsumoto, A. Control of Adhesive Strength of Acrylate Polymers Containing 1-Isobutoxyethyl and Isobornyl Esters in Response to Dual Stimuli for Dismantlable Adhesion. Appl. Adhes. Sci. 2017, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Akiyama, H.; Kanazawa, S.; Okuyama, Y.; Yoshida, M.; Kihara, H.; Nagai, H.; Norikane, Y.; Azumi, R. Photochemically Reversible Liquefaction and Solidification of Multiazobenzene Sugar-Alcohol Derivatives and Application to Reworkable Adhesives. ACS Appl. Mater. Interfaces 2014, 6, 7933–7941. [Google Scholar] [CrossRef]

- June, S.M.; Suga, T.; Heath, W.H.; Lin, Q.; Puligadda, R.; Yan, L.; Dillard, D.; Long, T.E. Photoactive Polyesters Containing O-Nitro Benzyl Ester Functionality for Photodeactivatable Adhesion. J. Adhes. 2013, 89, 548–558. [Google Scholar] [CrossRef]

- Wang, Y.-Z.; Li, L.; Du, F.-S.; Li, Z.-C. A Facile Approach to Catechol Containing UV Dismantlable Adhesives. Polymer 2015, 68, 270–278. [Google Scholar] [CrossRef]

- Behrendt, G.; Naber, B.W. The Chemical Recycling of Polyurethanes (Review). J. Univ. Chem. Technol. Metall. 2009, 44, 3–23. [Google Scholar]

- Sánchez-Cadena, L.E.; Tersac, G.; Coqueret, X.; Gamiño-Arroyo, Z. Solvolysis of Acrylate-Urethane Coatings Cured by Electron-Beam and UV Radiation. Prog. Org. Coat. 2019, 136, 105268. [Google Scholar] [CrossRef]

- Miguel-Fernández, R.; Amundarain, I.; Asueta, A.; García-Fernández, S.; Arnaiz, S.; Miazza, N.L.; Montón, E.; Rodríguez-García, B.; Bianca-Benchea, E. Recovery of Green Polyols from Rigid Polyurethane Waste by Catalytic Depolymerization. Polymers 2022, 14, 2936. [Google Scholar] [CrossRef] [PubMed]

- Zahedifar, P.; Pazdur, L.; Vande Velde, C.M.L.; Billen, P. Multistage Chemical Recycling of Polyurethanes and Dicarbamates: A Glycolysis–Hydrolysis Demonstration. Sustainability 2021, 13, 3583. [Google Scholar] [CrossRef]

- Jutrzenka Trzebiatowska, P.; Beneš, H.; Datta, J. Evaluation of the Glycerolysis Process and Valorisation of Recovered Polyol in Polyurethane Synthesis. React. Funct. Polym. 2019, 139, 25–33. [Google Scholar] [CrossRef]

- Simón, D.; Rodríguez, J.F.; Carmona, M.; Serrano, A.; Borreguero, A.M. Glycolysis of Advanced Polyurethanes Composites Containing Thermoregulating Microcapsules. Chem. Eng. J. 2018, 350, 300–311. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Norakankorn, C.; Pimpan, V. Chemical Recycling of Rigid Polyurethane Foam Scrap via Base Catalyzed Aminolysis. J. Met. Mater. Miner. 2002, 12, 19–22. [Google Scholar]

- Grdadolnik, M.; Drinčić, A.; Oreški, A.; Onder, O.C.; Utroša, P.; Pahovnik, D.; Žagar, E. Insight into Chemical Recycling of Flexible Polyurethane Foams by Acidolysis. ACS Sustain. Chem. Eng. 2022, 10, 1323–1332. [Google Scholar] [CrossRef]

- Moawed, E.A.; Kiwaan, H.A.; El-Zakzouk, S.K.; El-Sonbati, M.A.; El-Zahed, M.M. Chemical Recycling of Polyurethane Foam Waste and Application for Antibacterial and Removal of Anionic and Cationic Dyes. Brazilian J. Chem. Eng. 2022. [Google Scholar] [CrossRef]

- Watando, H.; Saya, S.; Fukaya, T.; Fujieda, S.; Yamamoto, M. Improving Chemical Recycling Rate by Reclaiming Polyurethane Elastomer from Polyurethane Foam. Polym. Degrad. Stab. 2006, 91, 3354–3359. [Google Scholar] [CrossRef]

- Liu, L.; Tang, L.; Wu, Y.; Ni, Y.; Zhu, Z. Degradation Process Investigation of Thermoplastic Polyurethane Elastomer in Supercritical Methanol. Polym. Degrad. Stab. 2013, 98, 2520–2528. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P.; Simón, D.; Rodríguez, J.F. Thermo-Chemical Decomposition Study of Polyurethane Elastomer Through Glycerolysis Route with Using Crude and Refined Glycerine as a Transesterification Agent. J. Polym. Environ. 2018, 26, 166–174. [Google Scholar] [CrossRef] [Green Version]

- Yan, Q.; Li, C.; Yan, T.; Shen, Y.; Li, Z. Chemically Recyclable Thermoplastic Polyurethane Elastomers via a Cascade Ring-Opening and Step-Growth Polymerization Strategy from Bio-Renewable δ-Caprolactone. Macromolecules 2022, 55, 3860–3868. [Google Scholar] [CrossRef]

- Wang, Y.; Song, H.; Ge, H.; Wang, J.; Wang, Y.; Jia, S.; Deng, T.; Hou, X. Controllable Degradation of Polyurethane Elastomer via Selective Cleavage of C O and C N Bonds. J. Clean. Prod. 2018, 176, 873–879. [Google Scholar] [CrossRef]

- Panowicz, R.; Konarzewski, M.; Durejko, T.; Szala, M.; Lazinska, M.; Czerwinska, M.; Prasula, P. Properties of polyethylene terephthalate (PET) after thermo-oxidative aging. Materials 2021, 14, 3833. [Google Scholar] [CrossRef] [PubMed]

- Wilhelm, C.; Gardette, J.L. Infrared Analysis of the Photochemical Behaviour of Segmented Polyurethanes: Aliphatic Poly(Ether-Urethane)S. Polymer 1998, 39, 5973–5980. [Google Scholar] [CrossRef]

- Irusta, L.; Fernandez-Berridi, M.J. Aromatic Poly(Ester-Urethanes): Effect of the Polyol Molecular Weight on the Photochemical Behaviour. Polymer 2000, 41, 3297–3302. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry; John Wiley & Sons, Ltd.: Chichester, UK, 2006; pp. 1–304. ISBN 9781351438384. [Google Scholar]

- Kaushiva, B.D.; McCartney, S.R.; Rossmy, G.R.; Wilkes, G.L. Surfactant Level Influences on Structure and Properties of Flexible Slabstock Polyurethane Foams. Polymer 2000, 41, 285–310. [Google Scholar] [CrossRef]

- Hu, J.; Chen, Z.; He, Y.; Huang, H.; Zhang, X. Synthesis and Structure Investigation of Hexamethylene Diisocyanate (HDI)-Based Polyisocyanates. Res. Chem. Intermed. 2017, 43, 2799–2816. [Google Scholar] [CrossRef]

- Holland, B.J.; Hay, J.N. The Thermal Degradation of Poly(Vinyl Acetate) Measured by Thermal Analysis-Fourier Transform Infrared Spectroscopy. Polymer 2002, 43, 2207–2211. [Google Scholar] [CrossRef]

- Pereira, A.P.D.S.; Silva, M.H.P.D.; Lima Júnior, É.P.; Paula, A.D.S.; Tommasini, F.J. Processing and Characterization of PET Composites Reinforced With Geopolymer Concrete Waste. Mater. Res. 2017, 20, 411–420. [Google Scholar] [CrossRef] [Green Version]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Sustaita-Rodríguez, J.M.; Medellín-Rodríguez, F.J.; Olvera-Mendez, D.C.; Gimenez, A.J.; Luna-Barcenas, G. Thermal Stability and Early Degradation Mechanisms of High-Density Polyethylene, Polyamide 6 (Nylon 6), and Polyethylene Terephthalate. Polym. Eng. Sci. 2019, 59, 2016–2023. [Google Scholar] [CrossRef]

- Włochowicz, A.; Eder, M. Distribution of Lamella Thicknesses in Isothermally Crystallized Polypropylene and Polyethylene by Differential Scanning Calorimetry. Polymer 1984, 25, 1268–1270. [Google Scholar] [CrossRef]

- Kong, Y.; Hay, J. Multiple Melting Behaviour of Poly(Ethylene Terephthalate). Polymer 2003, 44, 623–633. [Google Scholar] [CrossRef]

| PU | |

|---|---|

| Wavenumber (cm−1) | Corresponding Group |

| 765 | COO urethane (deformation vibration) |

| 1171 | C–O–C ester (elongation vibration) |

| 1244 | C–O–C urethane (elongation vibration) |

| 1465 | CH (deformation vibration) |

| 1527 | N–H and C–N amide |

| 1689 | C=O urethane (elongation vibration) |

| 1733 | C=O ester (elongation vibration) |

| 2856 | CH (elongation vibration) |

| 2929 | CH (elongation vibration) |

| 3389 | NH (elongation vibration) |

| Mn (kg/mol) | Mw (kg/mol) | Ð | |

|---|---|---|---|

| Virgin PET | 4.3 | 15.2 | 3.33 |

| Recycled PET | 4.9 | 18.2 | 3.68 |

| Tg (°C) | Tm (°C) | Xc (%) | |

|---|---|---|---|

| Virgin PET | 83 | 252 | 39 |

| Recycled PET | 80 | 253 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Smet, D.; Verjans, J.; Vanneste, M. Selective Solvolysis of Bio-Based PU-Coated Fabric. Polymers 2022, 14, 5452. https://doi.org/10.3390/polym14245452

De Smet D, Verjans J, Vanneste M. Selective Solvolysis of Bio-Based PU-Coated Fabric. Polymers. 2022; 14(24):5452. https://doi.org/10.3390/polym14245452

Chicago/Turabian StyleDe Smet, David, Jente Verjans, and Myriam Vanneste. 2022. "Selective Solvolysis of Bio-Based PU-Coated Fabric" Polymers 14, no. 24: 5452. https://doi.org/10.3390/polym14245452

APA StyleDe Smet, D., Verjans, J., & Vanneste, M. (2022). Selective Solvolysis of Bio-Based PU-Coated Fabric. Polymers, 14(24), 5452. https://doi.org/10.3390/polym14245452