Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant

Abstract

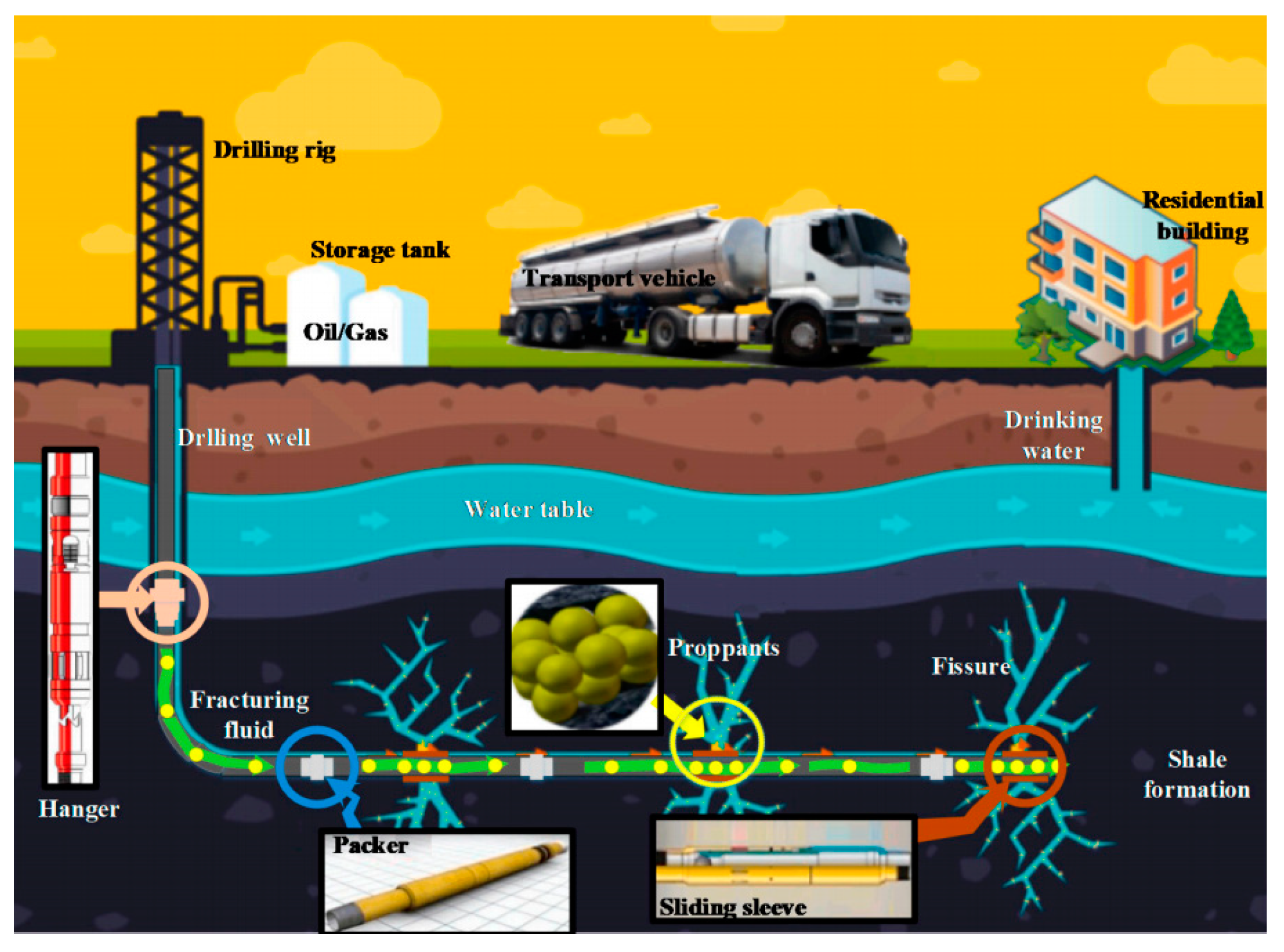

1. Introduction

2. Traditional High Density Proppant

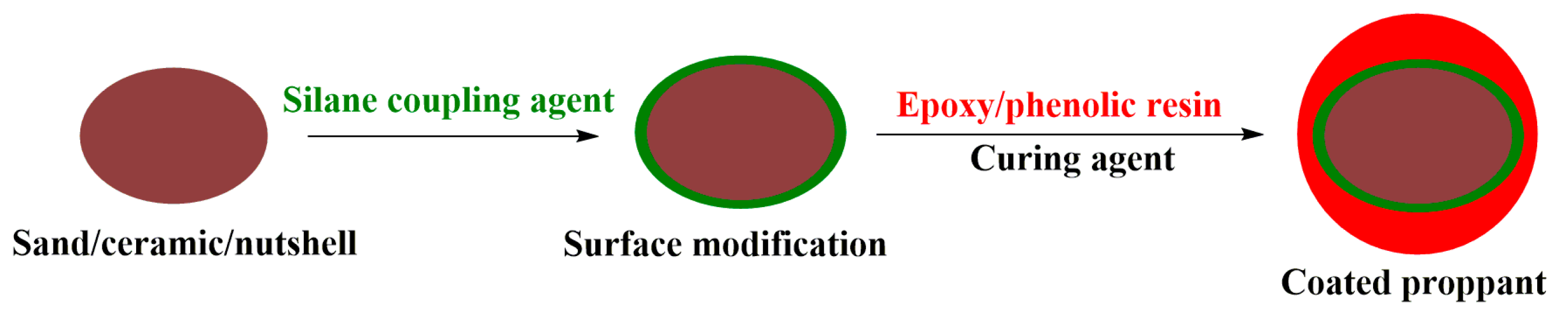

3. Polymers Used in the Proppant Coating

4. Application of Polymer in Coated Proppant

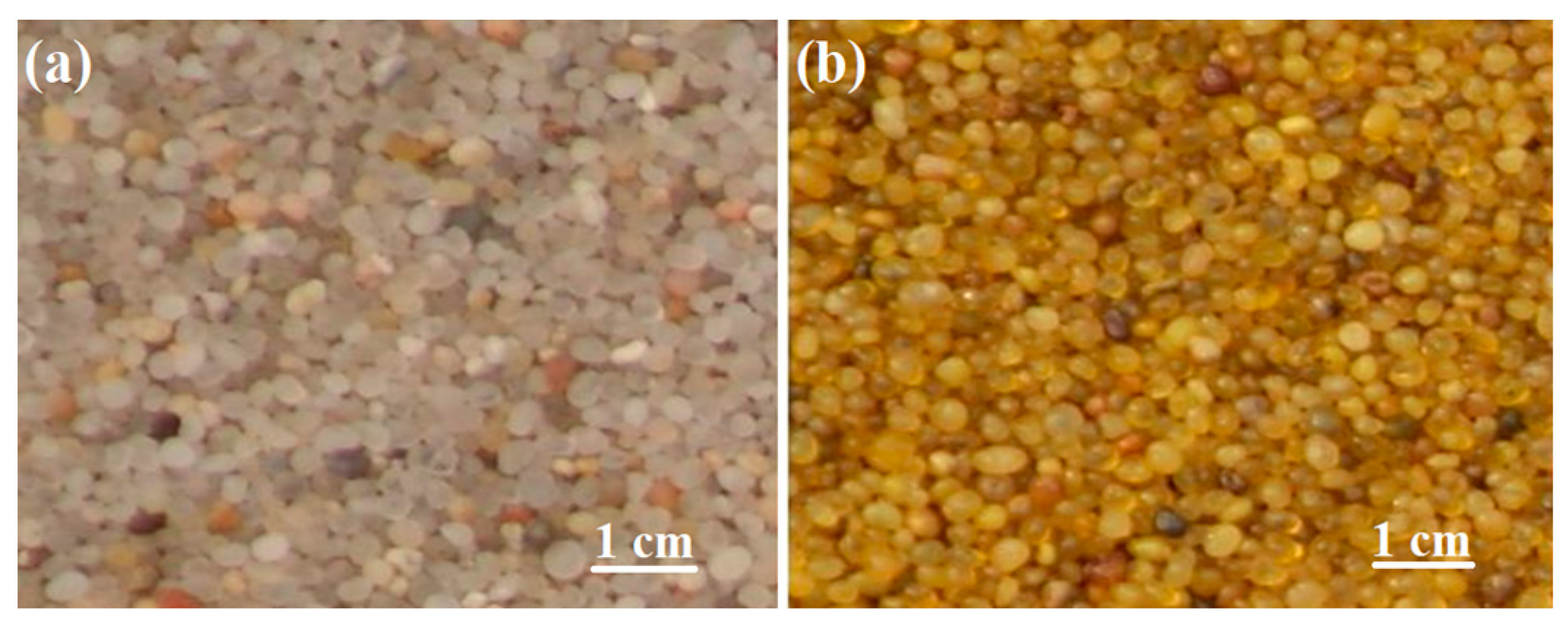

4.1. Polymer Coated Natural Sand Proppant

4.2. Polymer Coated Synthetic Ceramic Proppant

4.3. Polymer Coated Bio-Based Nutshell Proppant

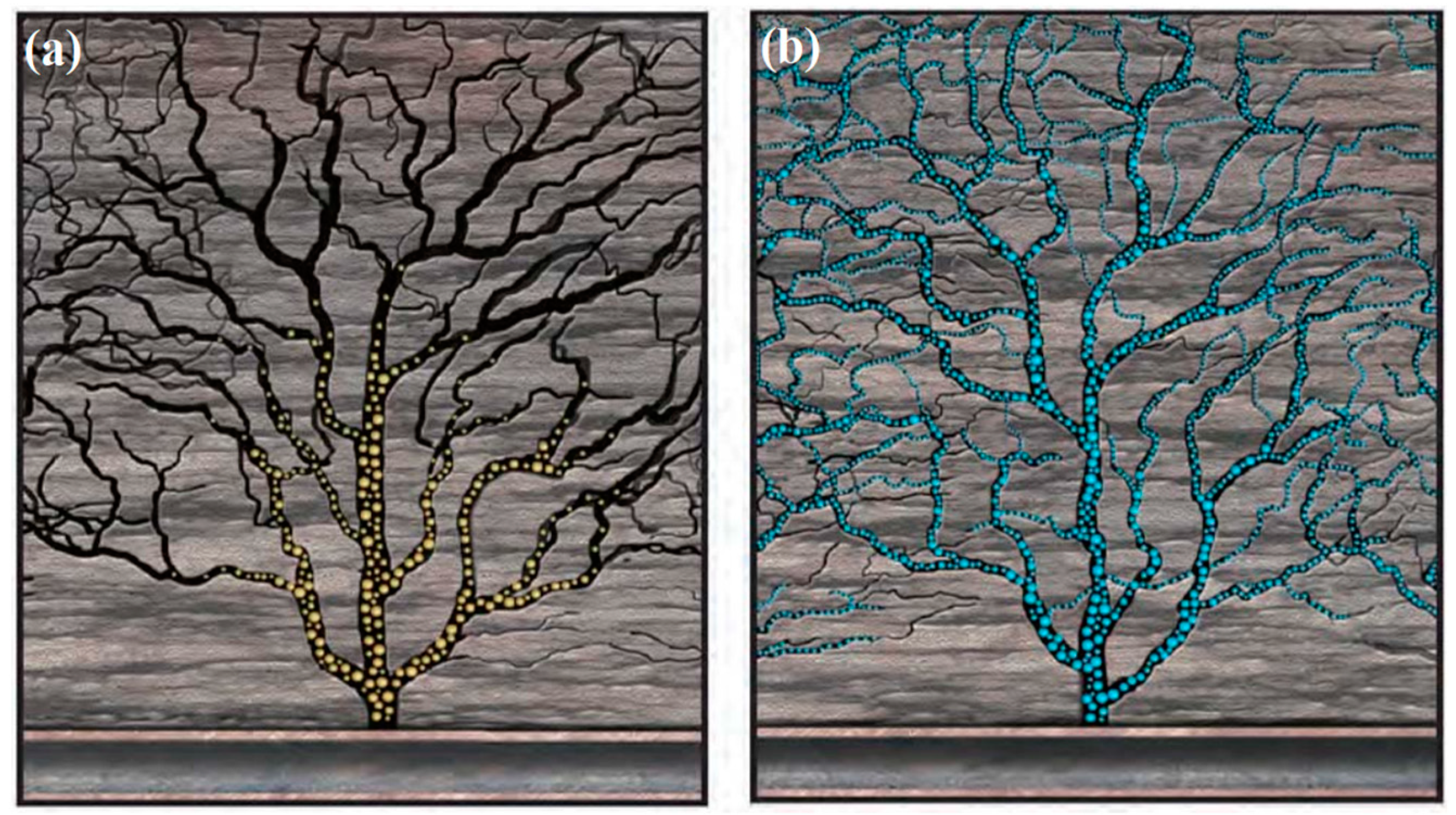

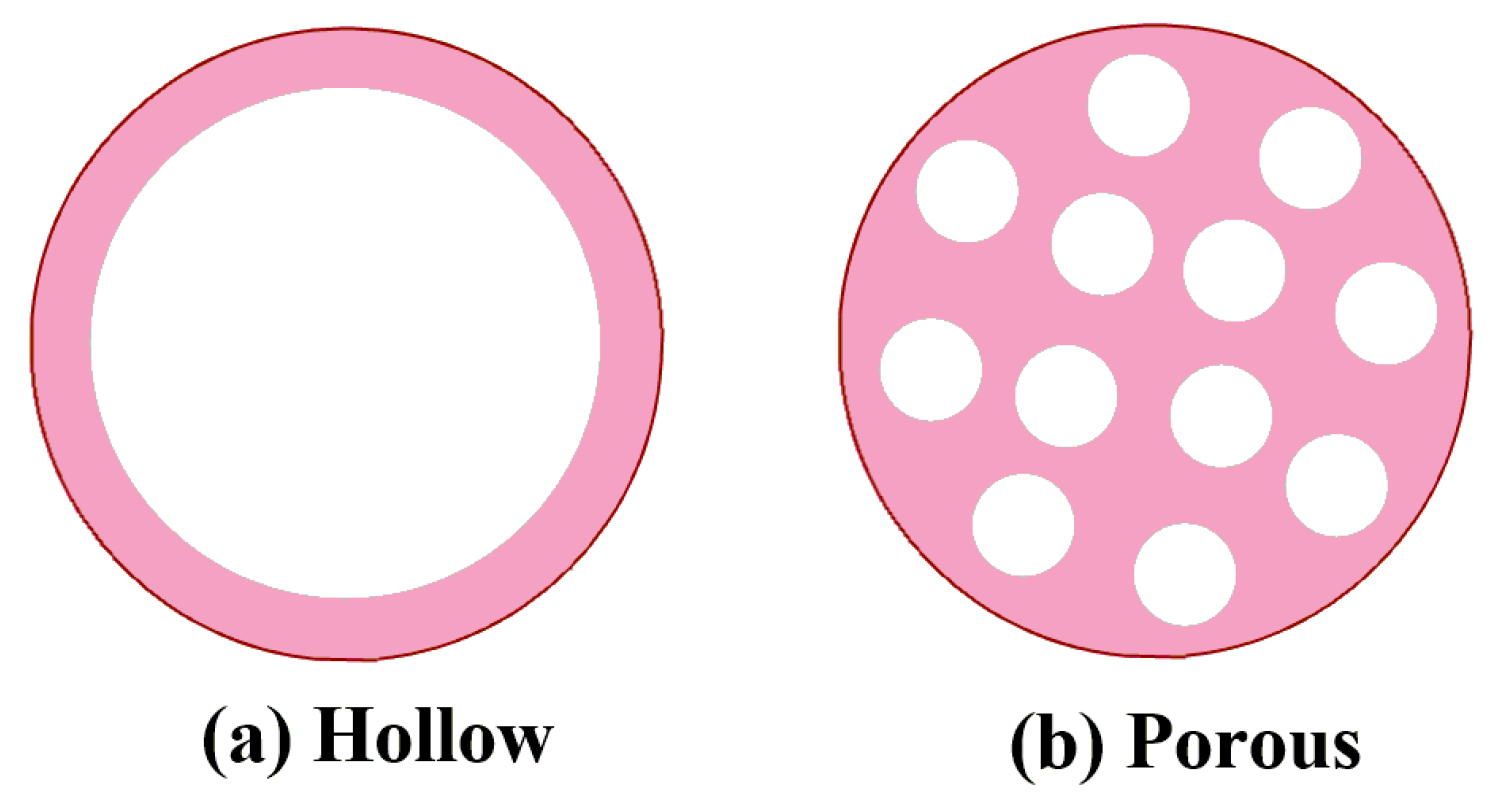

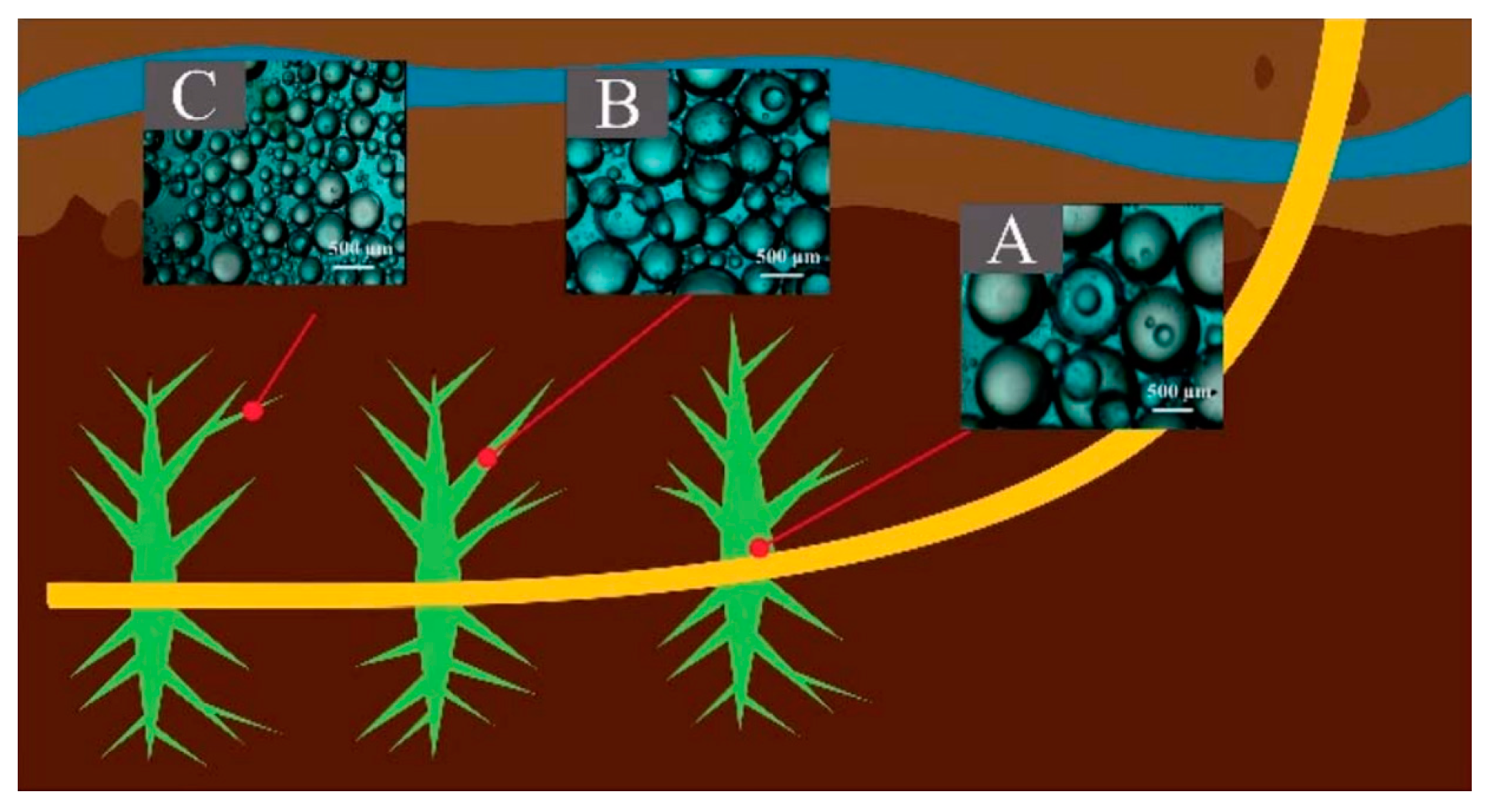

5. Polymer Composites Based Ultra-Low Density Proppant

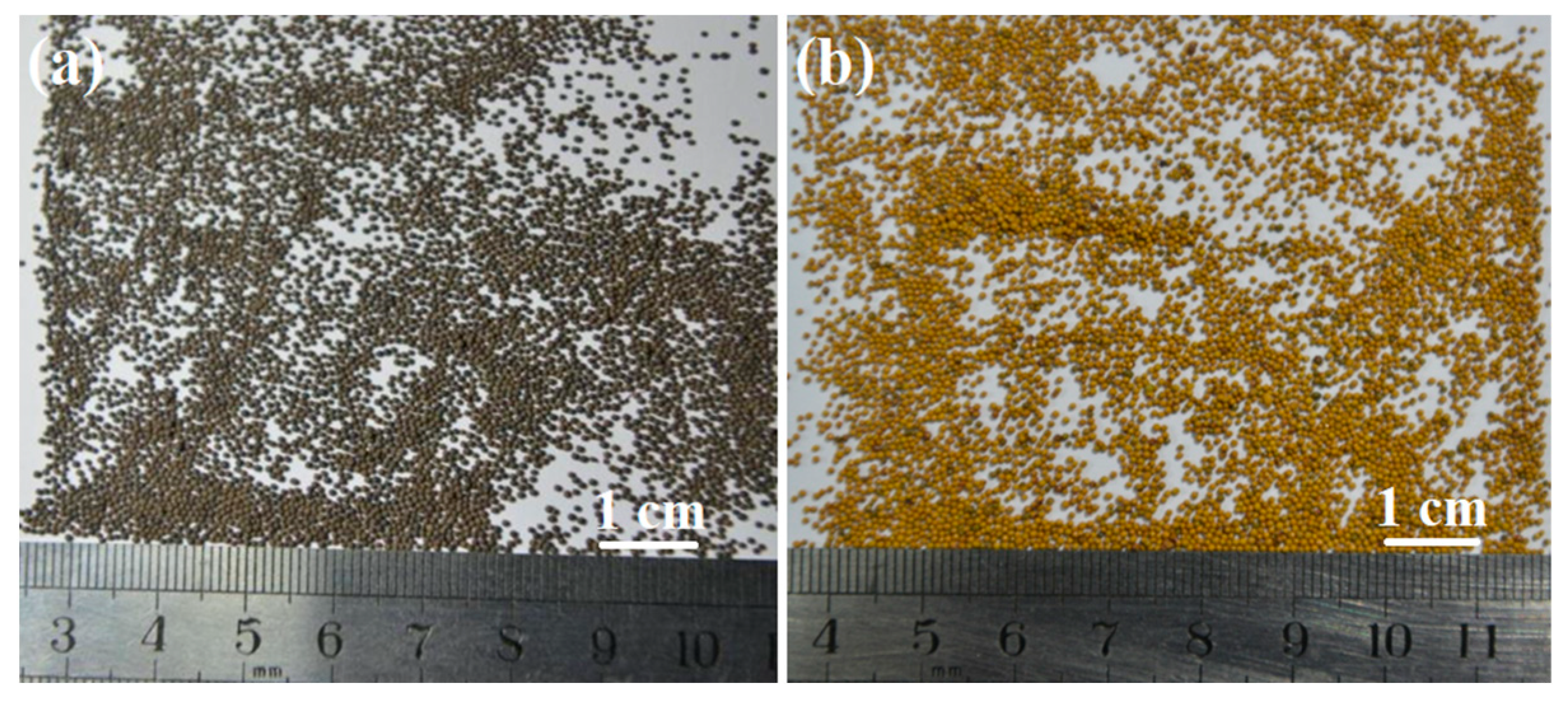

5.1. Ultra-Low Density Proppant Based on Polystyrene

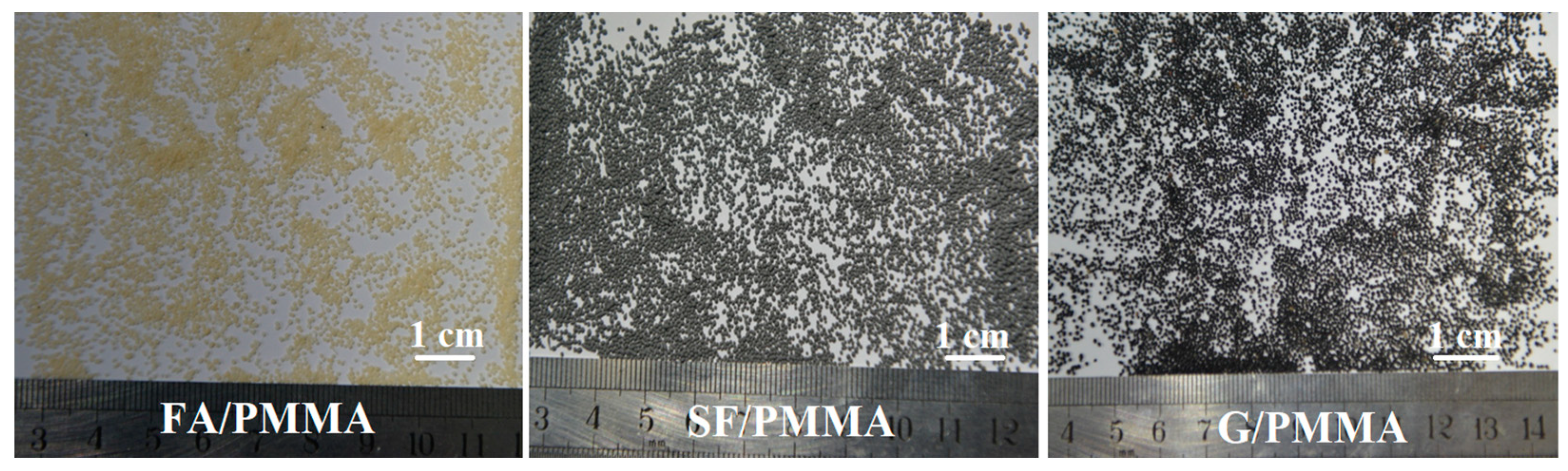

5.2. Ultra-Low Density Proppant Based on Polymethyl Methacrylate

| Samples | Apparent Density (g·cm−3) | Crushing Rate (%) | Acid Solubility (%) | Turbidity (FTU) | Sphericity and Roundness | Ref. |

|---|---|---|---|---|---|---|

| A151/PMMA | 1.08 | 6.3/69 MPa | / | / | >0.9 | [59] |

| PB/PMMA | 1.02 | 5 min/69 MPa | / | / | >0.9 | [60] |

| G/PMMA | 1.06 | 3.0/69 MPa | 0.08 | 35 | >0.9 | [61] |

| CB/PMMA | 1.23 | 2.44/69 MPa | 0.08 | 33 | >0.9 | [62] |

| SF/PMMA | 1.16 | 2.2/69 MPa | 2 | / | >0.9 | [63] |

| FA/PMMA | 1.05 | 3.0/69 MPa | 0.02 | 54 | >0.9 | [64] |

| FA/P(St-co-MMA) | 1.26 | 0.95/52 MPa | / | / | >0.9 | [72] |

| P(AN-co-VA) | 1.04 | 0.2/52 MPa | <1 | / | >0.9 | [9] |

6. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.B.; Zhang, M.; Yang, H.; Wang, D.G.; Ramos, M.A.; Hu, T.S.; Xu, Q. Friction challenge in hydraulic fracturing. Lubricants 2022, 10, 14. [Google Scholar] [CrossRef]

- Chen, B.; Barboza, B.R.; Sun, Y.N.; Bai, J.; Thomas, H.R.; Dutko, M.; Cottrell, M.; Li, C.F. A review of hydraulic fracturing simulation. Arch. Comput. Method E 2022, 29, 2113–2170. [Google Scholar] [CrossRef]

- Li, Q.S.; Xing, H.L.; Liu, J.J.; Liu, X.C. A review on hydraulic fracturing of unconventional reservoir. Petroleum 2015, 1, 8–15. [Google Scholar] [CrossRef]

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Poly. Sci. 2014, 131, 40735. [Google Scholar] [CrossRef]

- Danso, D.K.; Negash, B.M.; Ahmed, T.Y.; Yekeen, N.; Ganat, T.A. Recent advances in multifunctional proppant technology and increased well output with micro and nano proppants. J. Petrol. Sci. Eng. 2021, 196, 108026. [Google Scholar] [CrossRef]

- Michael, F.M.; Krishnan, M.R.; Li, W.G.; Alsharaeh, E.H. A review on polymer-nanofiller composites in developing coated sand proppants for hydraulic fracturing. J. Nat. Gas Sci. Eng. 2020, 83, 103553. [Google Scholar] [CrossRef]

- Liang, F.; Sayed, M.; Muntasheri, G.; Chang, F.F.; Li, L.M. A comprehensive review on proppant technologies. Petroleum 2016, 2, 26–39. [Google Scholar] [CrossRef]

- Pangilinan, K.D.; Leon, A.C.; Advincula, R.C. Polymers for proppants used in hydraulic fracturing. J. Petrol. Sci. Eng. 2016, 145, 154–160. [Google Scholar] [CrossRef]

- Luo, Z.F.; Li, J.B.; Zhao, L.Q.; Zhang, N.L.; Chen, X.; Miao, W.J.; Chen, W.H.; Liang, C. Preparation and characterization of a selfsuspending ultra-low density proppant. RSC Adv. 2021, 11, 33083. [Google Scholar] [CrossRef]

- Wu, C.H.; Sharma, M.M. Effect of perforation geometry and orientation on proppant placement in perforation clusters in a horizontal well. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, Woodlands, TX, USA, 9–11 February 2016. [Google Scholar] [CrossRef]

- Gu, M.; Dao, E.; Mohanty, K.K. Investigation of ultra-light weight proppant application in shale fracturing. Fuel 2015, 150, 191–201. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Gharibi, A. Application of polymers for coating of proppant in hydraulic fracturing of subterraneous formations: A comprehensive review. J. Nat. Gas Sci. Eng. 2015, 24, 197–209. [Google Scholar] [CrossRef]

- Feng, Y.C.; Ma, C.Y.; Deng, J.G.; Li, X.R.; Chu, M.M.; Hui, C.; Luo, Y.Y. A comprehensive review of ultralow-weight proppant technology. Petrol. Sci. 2021, 18, 807–826. [Google Scholar] [CrossRef]

- Pei, Y.X.; Zhou, H.X.; Li, D.P.; Zhang, S.C.; Tian, F.C.; Zhao, L.Q. A novel unconventional reservoir fracturing method-liquid self-propping fracturing technology. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar] [CrossRef]

- Liao, Z.J.; Li, X.G.; Ge, L.; Yang, Z.Z.; Zhu, J.Y.; Xue, Q.; Wang, H. Lightweight proppants in unconventional oil and natural gas development: A review. Sustain. Mater. Tech. 2022, 33, e00484. [Google Scholar] [CrossRef]

- Hao, J.Y.; Hao, H.L.; Gao, Y.F.; Li, X.J.; Nin, M.; Wang, K.Y. Effect of sintering temperature on property of low-density ceramic proppant adding coal gangue. Mater. Sci. 2020, 26, 94–98. [Google Scholar] [CrossRef]

- El-Kader, M.A.; Abdou, M.I.; Fadl, A.M.; Rabou, A.A.; Desouky, O.A.; El-Shahat, M.F. Novel light-weight glass-ceramic proppants based on frits for hydraulic fracturing process. Ceram. Int. 2020, 46, 1947–1953. [Google Scholar] [CrossRef]

- Ren, Q.; Ren, Y.H.; Li, H.H.; Wu, X.L.; Bai, W.N.; Zheng, J.L.; Hai, O. Preparation and characterization of high silicon ceramic proppants using low grade bauxite and fly ash. Mater. Chem. Phy. 2019, 230, 355–361. [Google Scholar] [CrossRef]

- Roy, P.; Bertrand, G.; Coddet, C. Spray drying and sintering of zirconia based hollow powders. Powder Tech. 2005, 157, 20–26. [Google Scholar] [CrossRef]

- Rediger, R.; Petralla, J.; Aron, M.J.; Fennell, B.W. Increasing Buoyancy of Well Treating Materials. U.S. Patent 8,058,213, 15 November 2011. [Google Scholar]

- Zhang, W.M.; Li, C.; Ren, G.P.; Jie, J.L.; Gao, W.L. Study on precured resin coated sands. Acta Pet. Sin. 2006, 22, 75–80. (In Chinese) [Google Scholar]

- Xia, B.B. Preparation and Characterization of Resin Coated Sand Proppant Tougheded by Modified Carbon Nanotubes. Master’s Thesis, Xi’an University of Technology, Shanxi, China, 2017. [Google Scholar]

- Chen, T.; Wang, G.Z.; Gao, J.; Yang, Y.D.; Ma, R.; Lei, X.R.; Yan, C.J. Study on resin coated sand proppant used for oil production. Adv. Mater. Res. 2012, 524, 1910–1914. [Google Scholar] [CrossRef]

- Krishnan, M.R.; Aldawsari, Y.; Michael, F.M.; Li, W.G.; Alsharaeh, E.H. 3D-Polystyrene- polymethyl methacrylate/divinyl benzene networks-Epoxy-Graphene nanocomposites dual-coated sand as high strength proppants for hydraulic fracture operations. J. Nat. Gas Sci. Eng. 2021, 88, 103790. [Google Scholar] [CrossRef]

- Krishnan, M.R.; Aldawsari, Y.; Michael, F.M.; Li, W.G.; Alsharaeh, E.H. Mechanically reinforced polystyrene-polymethyl methacrylate copolymer-graphene and epoxy-graphene composites dual-coated sand proppants for hydraulic fracture operations. J. Nat. Gas Sci. Eng. 2021, 196, 107744. [Google Scholar] [CrossRef]

- Fu, L.P.; Zhang, G.C.; Ge, J.J.; Liao, K.L.; Jiang, P.; Pei, H.H.; Li, X.Q. Surface modified proppants used for porppant flowback control in hydraulic fracturing. Colloid Surf. A 2016, 507, 18–25. [Google Scholar] [CrossRef]

- Horadam, W.; Venkat, N.; Tran, T.; Bai, L.T.; Josyula, K.; Mehta, V. Leaching studies on novolac resin-coated proppants-performance, stability, product safety, and environmental health considerations. J. Appl. Poly. Sci. 2018, 135, 45845. [Google Scholar] [CrossRef]

- Ramlan, A.S.; Zin, R.M.; Bakar, N.F.; Othman, N.H.; Jarni, H.H.; Hussain, M.H.; Najib, N.I.; Zakran, M.Z. Characterisation of graphene oxide-coated sand for potential use as proppant in hydraulic fracturing. Arab. J. Geosci. 2022, 15, 1126. [Google Scholar] [CrossRef]

- Deng, H.; Gong, Y.S.; Luo, W.J.; Yan, C.J. Study on the preparation and performance of low-density and high strength coated ceramic proppants. Bull. Chin. Ceram. Soc. 2015, 34, 1193–1198. (In Chinese) [Google Scholar] [CrossRef]

- Xie, X.K.; Niu, S.X.; Zhang, T.; Wang, Z.; Miao, Y.; Gao, F. Preparation and properties of ceramic proppant whit ZnO as additive. Appl. Chem. Ind. 2020, 49, 1179–1182. (In Chinese) [Google Scholar] [CrossRef]

- Guo, Z.Y.; Yao, X.; Ma, X. Preparation and properties of porous mullite base low-density high-strength proppants. Petrol. Drill. Tech. 2013, 41, 39–43. (In Chinese) [Google Scholar] [CrossRef]

- Xu, Y.C. Preparation and Performance Evaluation of Low Density Proppant. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2016. [Google Scholar]

- Zhang, S.M.; So, L.L.; Faucher, S.; Xi, L. Polymer coating over solid particles with in situ thermal curing. Ind. Eng. Chem. Res. 2016, 55, 5574–5584. [Google Scholar] [CrossRef]

- Fan, F.; Li, F.X.; Tian, S.C.; Sheng, M.; Khan, W.; Shi, A.P.; Zhou, Y.; Xu, Q. Hydrophobic epoxy resin coated proppants with ultra-high self suspension ability and enhanced liquid conductivity. Petrol. Sci. 2021, 18, 1753–1759. [Google Scholar] [CrossRef]

- Neto, J.; Abrahao, T.; Prata, F.G.; Gomez, J.; Pedroso, C.A.; Martins, M.O.; Silva, D.N. Ultralightweight proppants: An effective approach to address problems in long horizontal gravel packs offshore brazil. SPE Drill. Complet. 2012, 27, 613–624. [Google Scholar] [CrossRef]

- Richards, A.R.; Brannon, H.D.; Wood, W.D. High strength, ultralight-weight proppant lends new dimensions to hydraulic fracturing application. SEP Prod. Oper. 2006, 21, 212–221. [Google Scholar] [CrossRef]

- Jia, X.N. Overview of the proppant development and prospect. Petrochem. Ind. Appl. 2017, 36, 1–6. (In Chinese) [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Gharibi, A. Characterization of agro-waste resources for potential use as proppant in hydraulic fracturing. J. Nat. Gas Sci. Eng. 2016, 36, 679–691. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Gharibi, A.; Jaafar, M.Z. Experimental characterization of a new high-strength ultra-lightweight composite proppant derived from renewable resources. J. Petrol. Sci. Eng. 2018, 170, 1038–1047. [Google Scholar] [CrossRef]

- Li, B.; Li, L.; Huang, Y.; Zhang, A.M. Preparation of resinified granulated walnut shell as fracturing proppant of ultralow density. Oilfield Chem. 2009, 26, 257–259. (In Chinese) [Google Scholar]

- Li, B.; Wang, Y.F.; Hu, Y.L.; Zhao, Z.C.; Shao, W.; Zhang, A.M. Study on a low-density fracturing fluid proppant. Oilfield Chem. 2011, 28, 371–375. (In Chinese) [Google Scholar]

- Huang, Y. Preparation of Phenolic Resin/Epoxy Resin Composite as Low Density Proppant. Master’s Thesis, Sichuan University, Chengdu, China, 2007. [Google Scholar]

- Huang, Y.; Gao, S.F.; Zhou, T.; Zhang, A.M. The study of phenolic resin/epoxy resin enwrapped and modified nutshell composite material. Polym. Mater. Sci. Eng. 2007, 23, 199–203. (In Chinese) [Google Scholar] [CrossRef]

- Gaurav, A.; Dao, E.K.; Mohanty, K.K. Evaluation of ultra-light-weight proppants for shale fracturing. J. Petrol. Sci. Eng. 2012, 92, 82–88. [Google Scholar] [CrossRef]

- Biswas, K.; Ghosh, S.; Basu, B. Ion-exchange resins and polypeptide supported catalysts: A critical review. Curr. Green Chem. 2020, 7, 40–52. [Google Scholar] [CrossRef]

- Davankov, V.A.; Sychov, C.S.; Ilyin, M.M.; Sochilina, K.O. Hypercrosslinked polystyrene as a novel type of high- performance liquid chromatography column packing material Mechanisms of retention. J. Chromatogr. A 2003, 987, 67–75. [Google Scholar] [CrossRef]

- Han, X.B.; Cheng, Q.X.; Bao, F.; Gao, J.; Yang, Y.D.; Chen, T.; Yan, C.J.; Ma, R. Synthesis of low-density heat-resisting polystyrene/graphite composite microspheres used as water carrying fracturing proppants. Polym. Plas. Technol. 2014, 53, 1647–1653. [Google Scholar] [CrossRef]

- Han, X.B. Preparation and Properties of Modified Polystyrene Microshperes Used as Ultra-Low Density Proppant. Master’s Thesis, Central China Normal University, Wuhan, China, 2015. [Google Scholar]

- Tan, X.T.; Duan, W.M.; Huang, D.; Zhang, T.L.; Zheng, C.C. Preparation of ultra-light density proppants and control of particle size and strength. Spec. Petrochem. 2022, 39, 23–27. (In Chinese) [Google Scholar]

- Ma, R.; Tang, W.; Hu, P.; Chen, T. Fabrication of low-density heat-resistance polystyrene/carbon black composite microspheres used as hydraulic fracturing proppant. Mater. Express 2019, 9, 150–158. [Google Scholar] [CrossRef]

- Han, X.B.; Kong, H.; Chen, T.; Gao, J.; Zhao, Y.; Sang, Y.N.; Hu, G.W. Effect of π–π stacking interfacial interaction on the properties of graphene/poly(styrene-b-isoprene-b-styrene) composites. Nanomaterials 2021, 11, 2158. [Google Scholar] [CrossRef]

- Han, X.B.; Chen, T.; Zhao, Y.; Gao, J.; Sang, Y.; Xiong, H.H.; Chen, Z.Y. Relationship between the microstructure and performance of graphene/polyethylene composites investigated by positron annihilation lifetime spectroscopy. Nanomaterials 2021, 11, 2990. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.; Bao, F.; Gao, J.; Chen, K.Y.; Hu, P.; Xu, L.; Fan, J.X. A Graphene Modified Ultra-Low Density Proppant and Preparation Method. CN Patent 1,068,336,01A, 13 June 2017. [Google Scholar]

- Tasque, J.E.; Vega, I.N.; Marco, S.; Raffo, P.A.; Accorso, N.B. Ultra-light weight proppant: Synthesis, characterization, and performance of new proppants. J. Nat. Gas Sci. Eng. 2021, 85, 103717. [Google Scholar] [CrossRef]

- Liang, T.; Yan, C.J.; Zhou, S.; Zhang, Y.H. Silica fume reinforced polystyrene-based composite particles used as ultra-light weight proppants in hydraulic fracturing. Mater. Res. Express 2017, 4, 115306. [Google Scholar] [CrossRef]

- Ma, R.; Bao, F.; Gao, J.; Chen, K.Y.; Hu, P.; Xu, L.; Fan, J.X. An Ion Cross-Linking Modified Ultra-Low Density Proppant and Preparation Method. CN Patent 1,067,533,20A, 30 December 2016. [Google Scholar]

- Ma, R.; Han, X.B.; Bao, F.; Gao, J.; Jiang, S.F.; Zhang, X.; Chen, K.Y.; Yan, C.J. Preparation and characterization of polymeric ultra-low-density proppants: Epoxy/phenolic resin-coated polystyrene/graphite microspheres. J. Polym. Mater. 2016, 33, 259–270. [Google Scholar]

- Ma, R.; Cheng, Q.X.; Bao, F.; Chen, T.; Gao, J.; Yan, C.J.; Wang, S.; Hu, J.L.; Tang, C.H. A Hydraulic Fracturing Proppant for Low Permeability Reservoir and Its Preparation Method. CN Patent 1,032,756,94B, 21 May 2013. [Google Scholar]

- Huang, D.; Wang, J.Y.; Niu, L.; Zheng, C.C. Preparation of low density, high-strength, strong hydrophobic particles (LHSPs) and its application as oil fracturing proppant. J. Disper. Sci. Techn. 2022, 1–8. [Google Scholar] [CrossRef]

- Liang, C.; Luo, W.J.; Yan, C.J.; Zhou, Q.; Gao, Q.; Duan, P. Ultra-lightweight proppant synthesized from PMMA/pine bark composite: Low-cost material and outstanding properties. Chem. Let. 2016, 45, 994–996. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.X.; Yan, C.J.; Wang, H.Q.; Xu, Y.C.; Ma, R. Preparation of heat resisting poly(methyl methacrylate)/graphite composite microspheres used as ultra-lightweight proppants. J. Appl. Poly. Sci. 2015, 132, 41924. [Google Scholar] [CrossRef]

- Liang, T.; Yan, C.J.; Zhou, S.; Zhang, Y.H.; Yang, B.P. Carbon black reinforced polymethyl methacrylate (PMMA)-based composite particles: Preparation, characterization, and application. J. Geophys. Eng. 2017, 14, 1225–1232. [Google Scholar] [CrossRef]

- Wang, Y.X.; Chen, T.; Yan, C.J. Reinforced performances of polymethyl methacrylate/silica fume composite spherical particles used as ultra-lightweight proppants. J. Reinf. Plast. Comp. 2015, 34, 672–683. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Yan, C.J.; Chen, T.; Wang, Y.X. Ultra-lightweight composite proppants prepared via suspension polymerization. J. Comp. Mater. 2015, 50, 2823–2831. [Google Scholar] [CrossRef]

- Blond, D.; Barron, V.; Ruether, M.; Ryan, K.P.; Nicolosi, V.; Blau, W.J.; Coleman, J.N. Enhancement of modulus, strength, and toughness in poly(methyl methacrylate)-based composites by the incorporation of poly(methyl methacrylate)- functionalized nanotubes. Adv. Funct. Mater. 2006, 16, 1608–1614. [Google Scholar] [CrossRef]

- Kamonwanon, P.; Yodmongkol, S.; Chantarachindawong, R.; Thaweeboon, S.; Thaweeboon, B.; Srikhirin, T. Wear resistance of a modified polymethyl methacrylate artificial tooth compared to five commercially available artificial tooth materials. J. Prosthet. Dent. 2015, 114, 286–292. [Google Scholar] [CrossRef]

- Torres, J.M.; Stafford, C.M.; Vogt, B.D. Impact of molecular mass on the elastic modulus of thin polystyrene films. Polymer 2010, 51, 4211–4217. [Google Scholar] [CrossRef]

- Masood, M.T.; Guerrero, J.A.H.; Ceseracciu, L.; Palazon, F.; Athanassiou, A.; Bayer, I.S. Superhydrophobic high impact polystyrene (HIPS) nanocomposites with wear abrasion resistance. Chem. Eng. J. 2017, 322, 10–21. [Google Scholar] [CrossRef]

- Bhanvase, B.A.; Pinjari, D.V.; Gogate, P.R.; Sonawane, S.H.; Pandit, A.B. Synthesis of exfoliated poly(styrene-co-methyl methacrylate)/montmorillonite nanocomposite using ultrasound assisted in situ emulsion copolymerization. Chem. Eng. J. 2012, 181, 770–778. [Google Scholar] [CrossRef]

- Okamoto, M.; Morita, S.; Taguchi, H.; Kim, Y.H.; Kotaka, T.; Tateyama, H. Synthesis and structure of smectic clay/poly(methyl methacrylate) and clay/polystyrene nanocomposites via in situ intercalative polymerization. Polymer 2000, 41, 3887–3890. [Google Scholar] [CrossRef]

- Xu, J.S.; Ke, Y.C.; Zhou, Q.; Hu, X.L. In-situ encapsulating MMT intermediate particles by suspension polymerization of poly (methyl methacrylate-co-styrene): Preparation, tunable dispersion and properties. J. Polym. Res. 2013, 20, 196. [Google Scholar] [CrossRef]

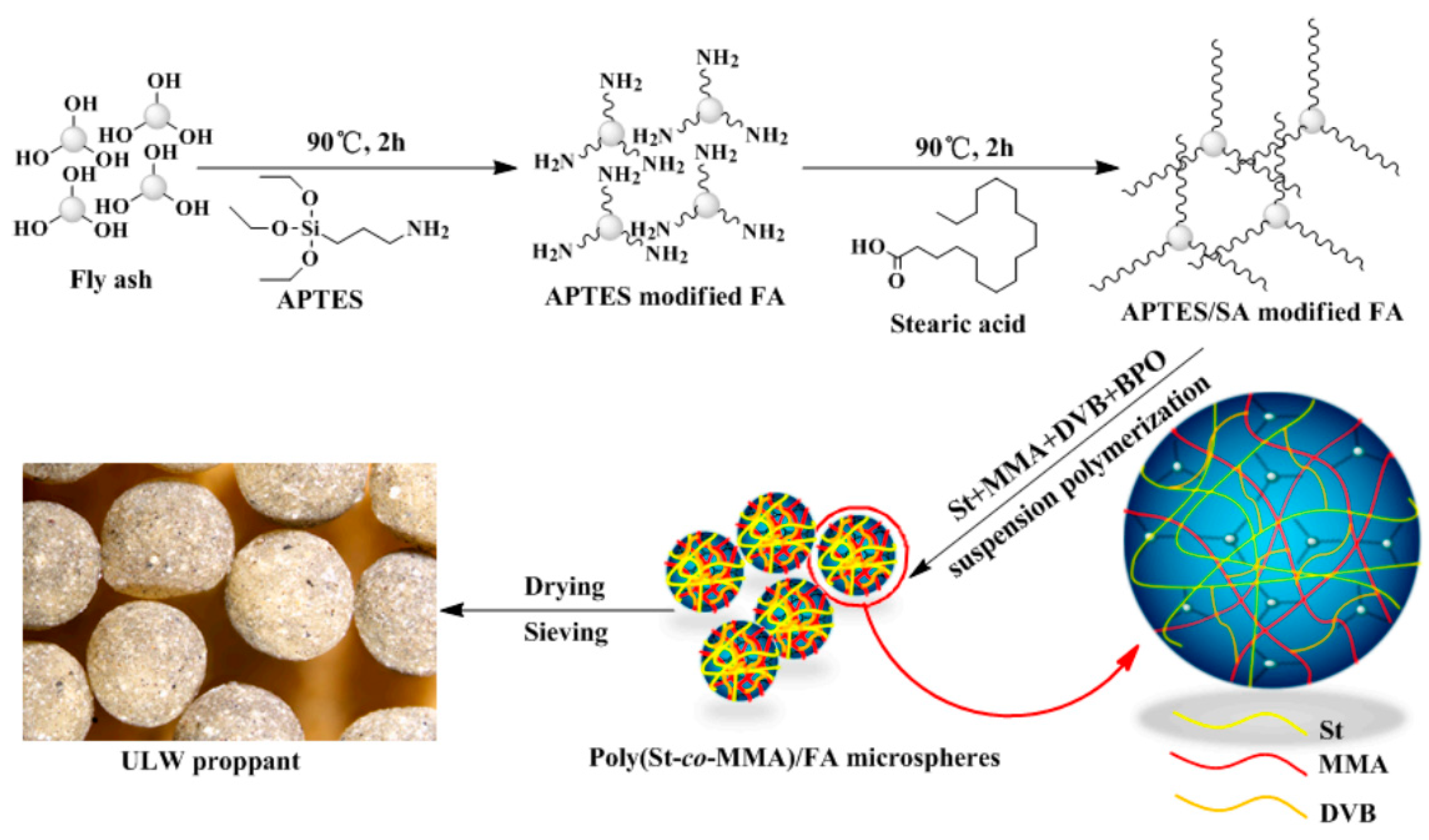

- Chen, T.; Sang, Y.N.; Zhou, Y.X.; Ji, L.D.; Han, X.B.; Hu, P.; Miao, P.P.; Gao, J.; Zhao, Y. Facile and controllable preparation of poly(St-co-MMA)/FA microspheres used as ultra-lightweight proppants. Materials 2021, 14, 7390. [Google Scholar] [CrossRef] [PubMed]

| Proppant | Bulk Density (g·cm−3) | Apparent Density (g·cm−3) |

|---|---|---|

| High density (HDP) | >1.8 | >3.35 |

| Intermediate density (IDP) | 1.65~1.80 | 3.00~3.35 |

| Low density (LDP) | 1.50~16.5 | 2.60~3.00 |

| Ultra-low density (ULDP) | <1.5 | <2.6 |

| Proppant | Natural Sand | Synthetic Ceramics |

|---|---|---|

| Apparent density (g·cm−3) | 2.5~2.7 | 3.3~3.6 |

| Crushing rate (%) | 36 | 13.5 |

| Acid solubility (%) | 5.5 | 6.9 |

| Turbidity (FTU) | 95 | 60 |

| Sphericity | 0.6 | 0.8 |

| Roundness | 0.6 | 0.8 |

| Cost | low | high |

| Polymer | Curing Temperature °C | Strength | Acid Resistance | Heat Resistance | Hydrophobic | Chemical Resistance |

|---|---|---|---|---|---|---|

| Epoxy resin | 66~204 | good | good | very good | good | good |

| Phenolic-aldehyde | 121~204 | good | good | very good | good | good |

| Urea-aldehyde | 121~204 | good | good | very good | good | good |

| Polyurethane | 99~121 | good | moderate | good | good | moderate |

| Vinyl resin | 100~149 | moderate | good | moderate | moderate | moderate |

| Polyester | 100~149 | moderate | moderate | moderate | moderate | moderate |

| Furan resin | 191 | bad | good | moderate | moderate | good |

| Polymer | Bulk Density (g·cm−3) | Crushing Rate (%) | Acid Solubility (%) | Turbidity (FTU) | Sphericity and Roundness | Ref. |

|---|---|---|---|---|---|---|

| Furan resin | 1.58 | 13/69 MPa | 0.49 | 30 | 0.8 | [21] |

| Resole resin | 1.57 | 3.9/69 MPa | 0.51 | 26 | 0.8 | |

| Novolak resin | 1.56 | 3.8/69 MPa | 0.50 | 28 | 0.8 | |

| Epoxy resin | 1.58 | 1.9/69 MPa | 0.18 | 24 | 0.8 | |

| CNT-Epoxy | / | 5.21/69 MPa | 2.83 | 24 | 0.8 | [22] |

| Epoxy/Phenolic | / | 1.6/52 MPa | / | / | 0.85 | [23] |

| (PS-PMMA-CG)- (epoxy-CG) | 1.35 | 9/69 MPa | / | / | 0.7 | [24] |

| (PS-PMMA/ DVB)-(Epoxy-CG) | 1.32 | 5/82 MPa | / | / | 0.7 | [25] |

| PFVP | The conductivity and flow back control ability was significantly improved | [26] | ||||

| Novolac resin | Leaching behavior under high temperature and strong acid was improved | [27] | ||||

| GO-KHS | 1.58 | 20/10 MPa | 0.7 | 55 | 0.8 | [28] |

| Polymer | Apparent Density (g·cm−3) | Crushing Rate (%) | Acid Solubility (%) | Turbidity (FTU) | Sphericity and Roundness | Ref. |

|---|---|---|---|---|---|---|

| Phenolic/Epoxy | 2.64 | 3.76/52 MPa | / | / | / | [29] |

| Epoxy | 2.27 | 1.16/69 MPa | / | / | / | [30] |

| Phenolic-Epoxy | 1.90 | 2.81/69 MPa | / | / | >0.9 | [31] |

| Epoxy | 1.03 | 17.01/55 MPa | / | 1.59 | >0.9 | [32] |

| Phenolic | / | 18/82 MPa | 4 | / | 0.9 | [33] |

| Epoxy | / | Hydrophobicity, suspension ability and conductivity improved | [34] | |||

| ULW-1.75 | 1.75 | Average porosity 50%, 56 MPa can be tolerated at 121 °C | [35,36] | |||

| Polymer | Apparent Density (g·cm−3) | Crushing Rate (%) | Acid Solubility (%) | Turbidity (FTU) | Sphericity and Roundness | Ref. |

|---|---|---|---|---|---|---|

| Coconut shell * | 1.22–1.33 | 2.12/55 MPa | 44 | 184 | 0.7 | [38] |

| Palm shell * | 1.16–1.19 | 4.22/55 MPa | 52 | 190 | 0.7 | |

| Walnut shell * | 1.14–1.25 | 7.0/55 MPa | 47 | 188 | 0.7 | |

| Epoxy | / | 0.16/55 MPa | 1.8 | 38 | 0.8 | [39] |

| Phenolic | 1.23 | 15/60 MPa | Conductivity increased from 41.8 to 113.4 μm2·cm | [40] | ||

| Phenolic | 1.24 | 14.8/60 MPa | / | / | 0.86 | [41] |

| Phenolic/Epoxy | / | No crack under 60 MPa, water adsorption significantly reduced | [42,43] | |||

| ULW-1.25 | 1.25 | 42 MPa can be tolerated at 79 °C | [35,36] | |||

| ULW-1.25 | 1.25 | Conductivity ability was obviously improved | 0.62 | [11,44] | ||

| Samples | Apparent Density (g·cm−3) | Crushing Rate (%) | Acid Solubility (%) | Sphericity and Roundness | Ref. |

|---|---|---|---|---|---|

| PS | 1.03 | 3.01/69 MPa | / | >0.9 | [49] |

| G/PS | 1.05 | 1.3/69 MPa | / | 0.94 | [47] |

| SiO2/PS | 1.07 | 3.0/69 MPa | / | 0.95 | [48] |

| CB/PS | 1.08 | 2.0/69 MPa | / | >0.9 | [50] |

| Graphene/PS | 1.05 | 0.45/52 MPa | / | 0.95 | [53] |

| CNT/PS | 1.05 | 1.7/138 MPa | 0.9 | 0.9 | [54] |

| SF/PS | 1.05 | 1.0/52 MPa | 1.75 | >0.9 | [55] |

| Metal/PS | 1.56 | 0.6/52 MPa | / | >0.9 | [56] |

| Coated-G/PS | 1.08 | 2.22/69 MPa | 0.11 | >0.9 | [48,57,58] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Gao, J.; Zhao, Y.; Liang, T.; Hu, G.; Han, X. Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant. Polymers 2022, 14, 5534. https://doi.org/10.3390/polym14245534

Chen T, Gao J, Zhao Y, Liang T, Hu G, Han X. Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant. Polymers. 2022; 14(24):5534. https://doi.org/10.3390/polym14245534

Chicago/Turabian StyleChen, Tao, Jie Gao, Yuan Zhao, Tian Liang, Guowen Hu, and Xiaobing Han. 2022. "Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant" Polymers 14, no. 24: 5534. https://doi.org/10.3390/polym14245534

APA StyleChen, T., Gao, J., Zhao, Y., Liang, T., Hu, G., & Han, X. (2022). Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant. Polymers, 14(24), 5534. https://doi.org/10.3390/polym14245534