An Experimental Investigation into Mechanical and Thermal Properties of Hybrid Woven Rattan/Glass-Fiber-Reinforced Epoxy Composites

Abstract

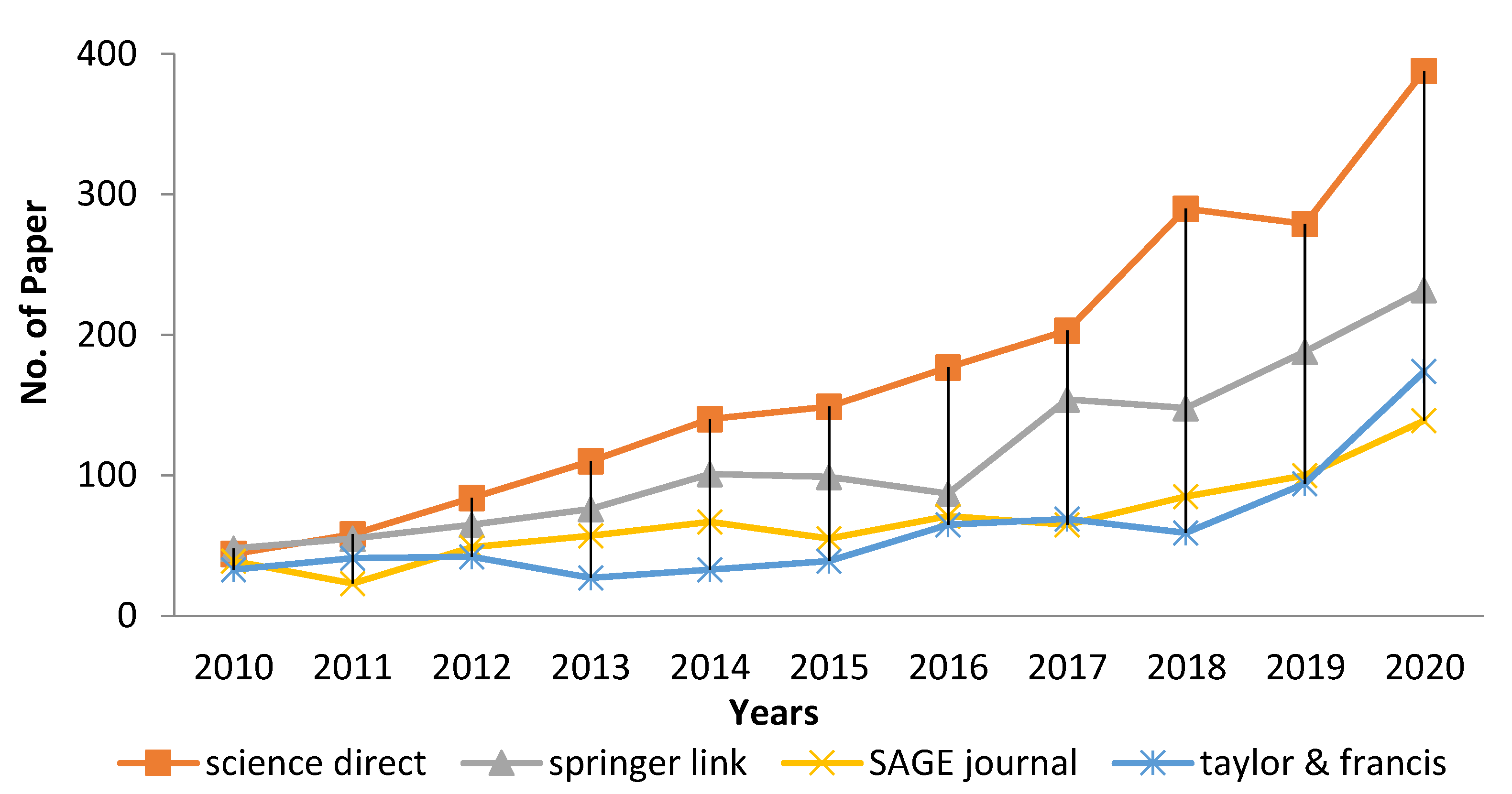

:1. Introduction

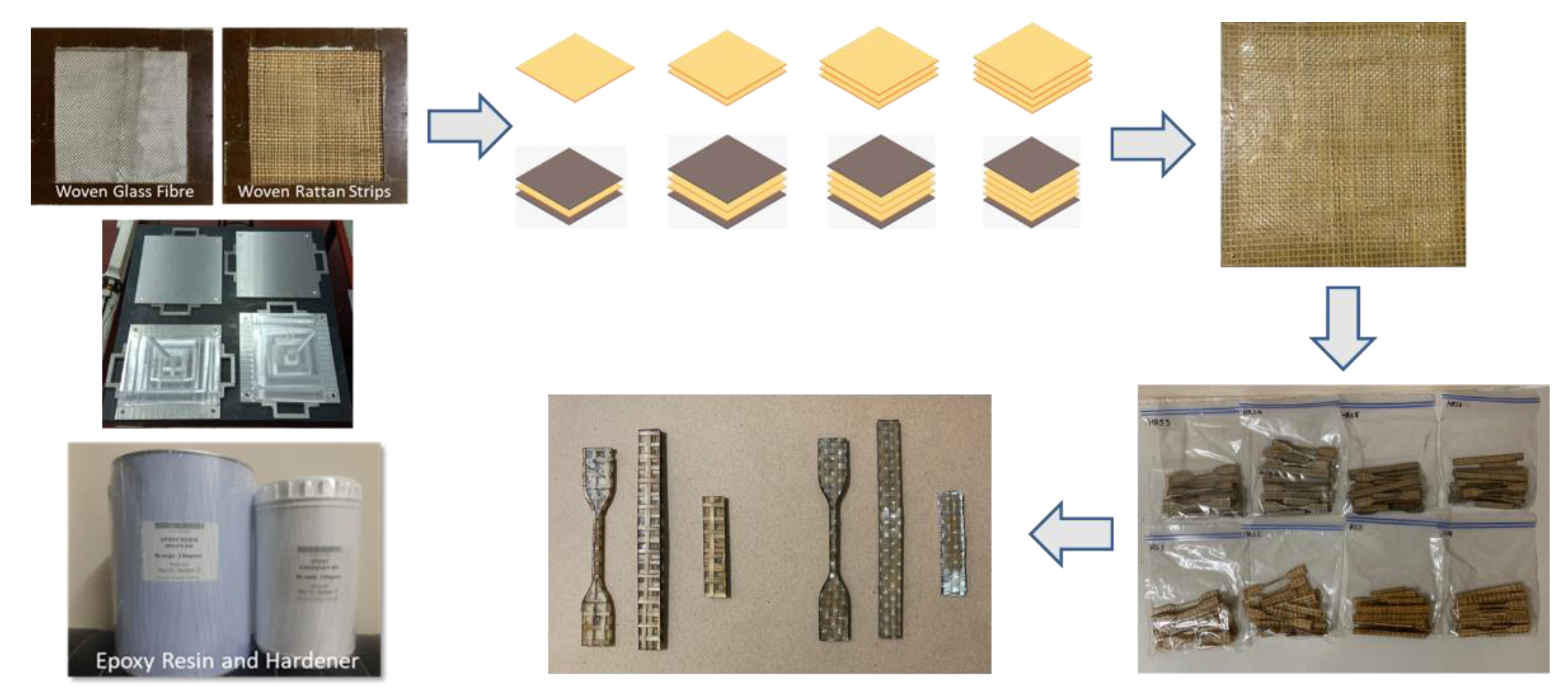

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Composite Laminates

2.3. Tensile Test

2.4. Flexural Test

2.5. Izod Impact Test

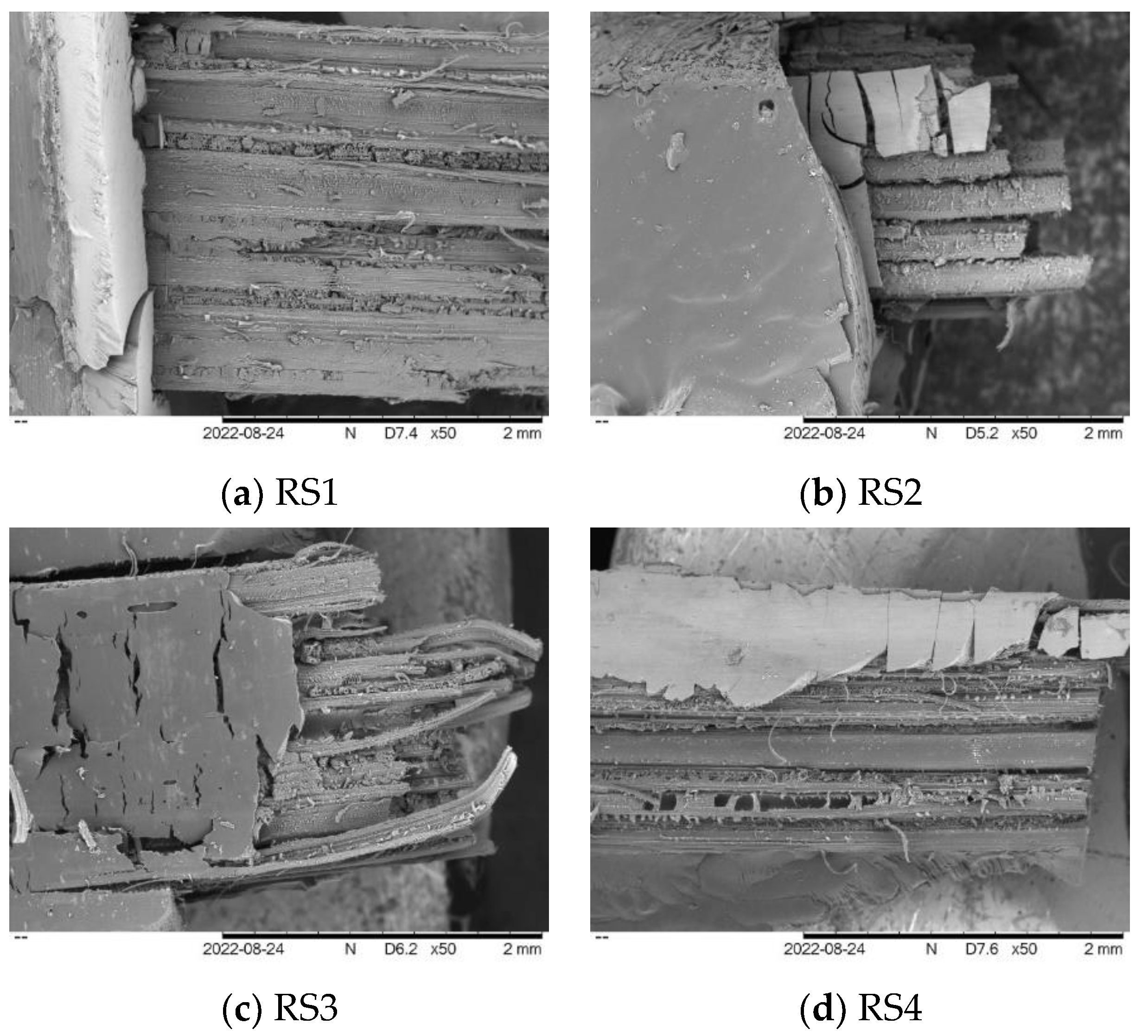

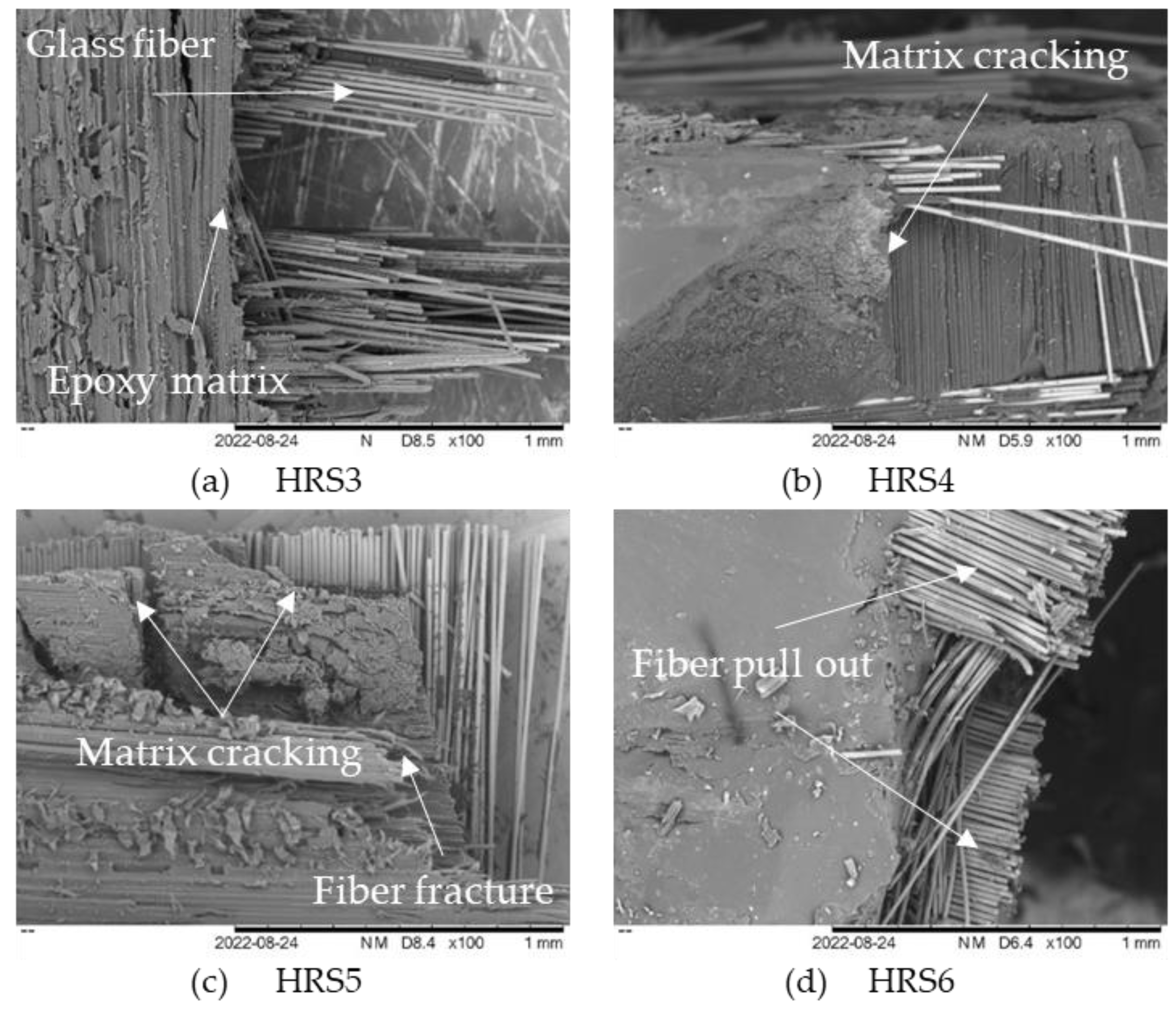

2.6. Scanning Electron Microscopy (SEM)

2.7. Thermogravimetric Analysis (TGA)

2.8. Differential Scanning Calorimetry (DSC)

3. Results and Discussion

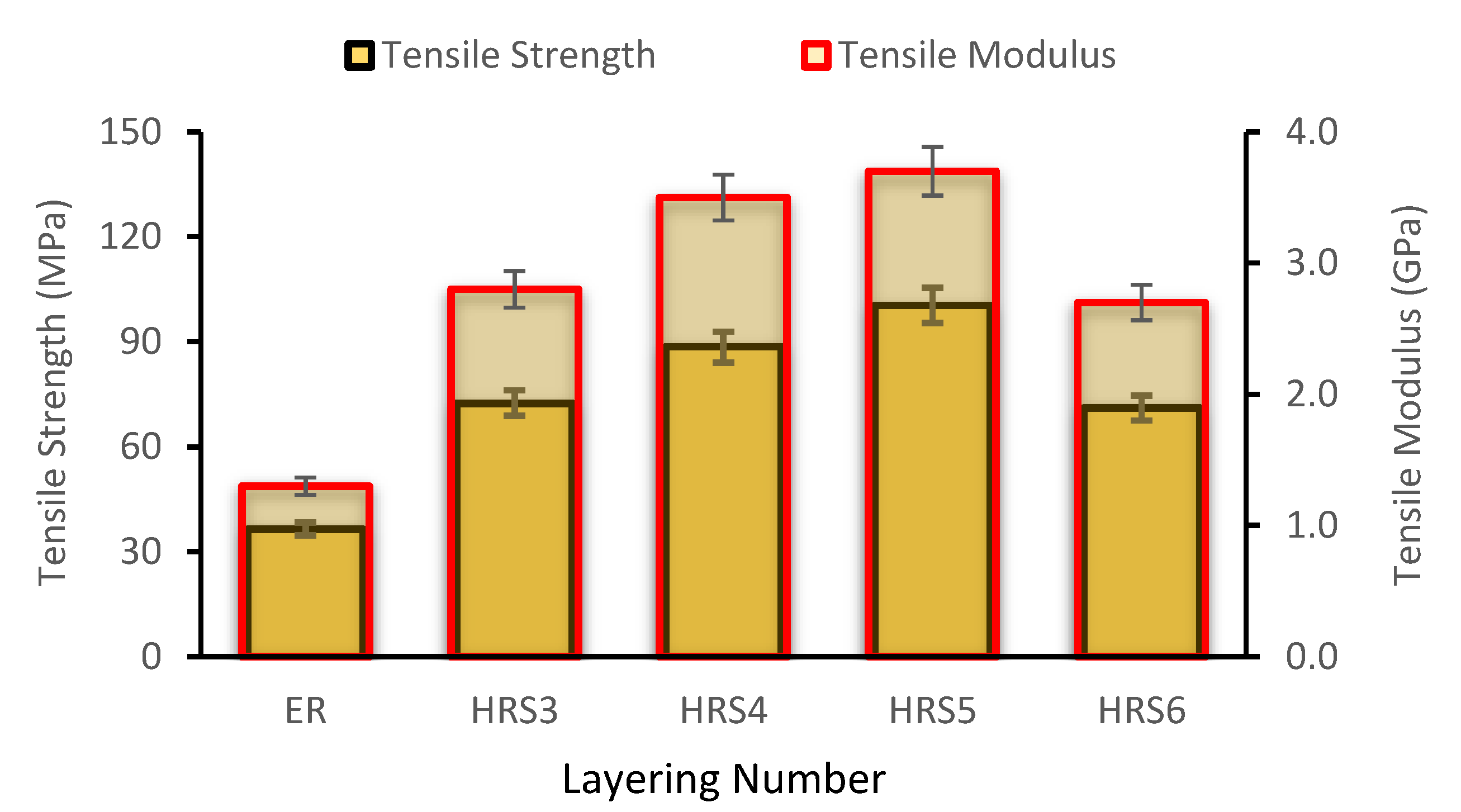

3.1. Tensile Properties

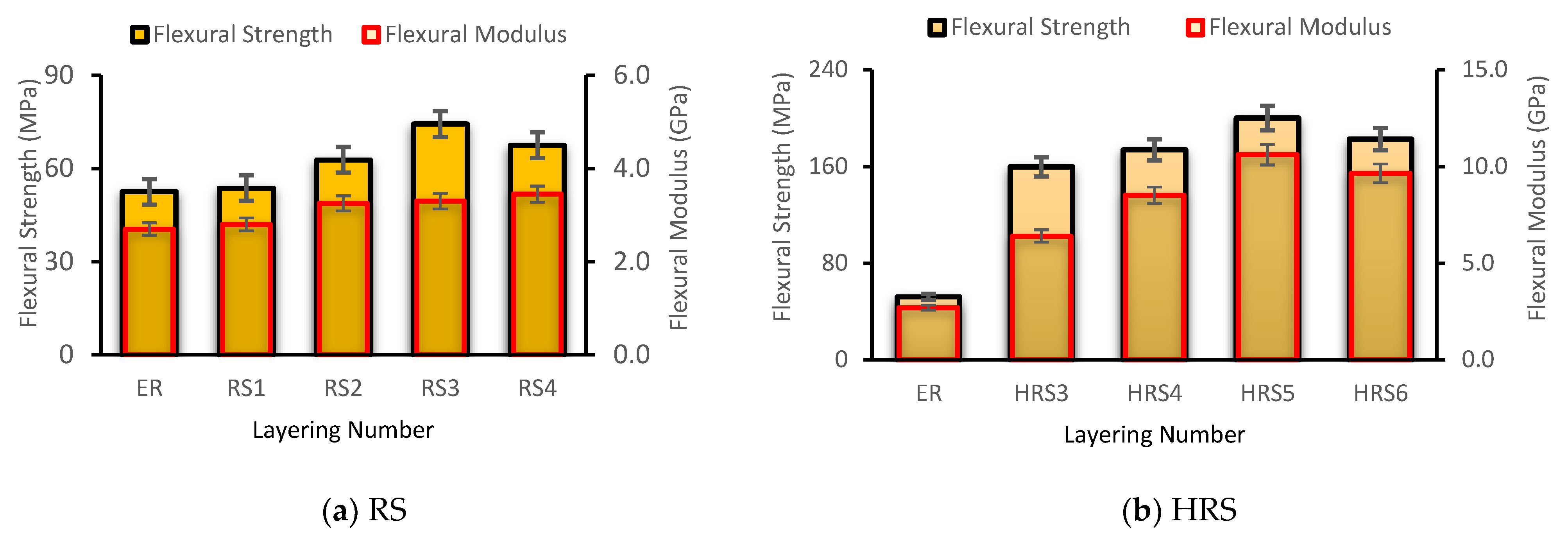

3.2. Flexural Properties

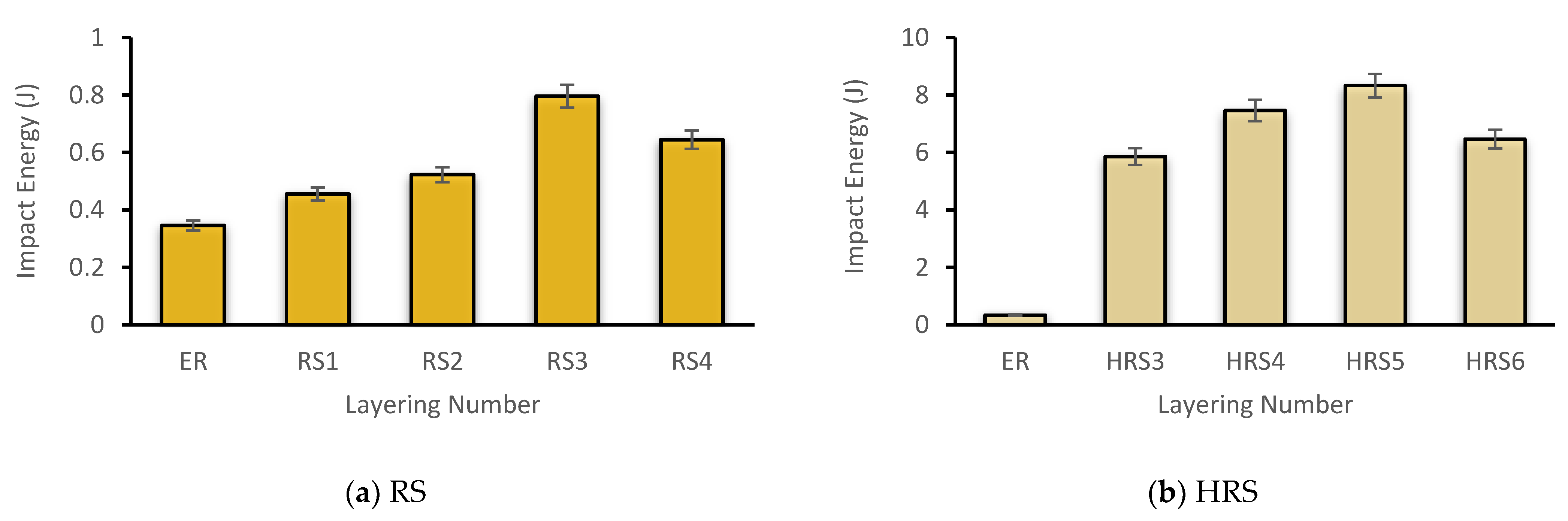

3.3. Impact Strength

3.4. Thermogravimetric Analysis

3.5. Differential Scanning Calorimetry (DSC)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, K.S.; Vijayarangan, S.; Kumar, A. Low Velocity Impact Damage Characterization of Woven Jute—Glass Fabric Reinforced Isothalic Polyester Hybrid Composites. J. Reinf. Plast. Compos. 2007, 26, 959–976. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef] [PubMed]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical Properties of Banana/Kenaf Fiber-Reinforced Hybrid Polyester Composites: Effect of Woven Fabric and Random Orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Rajesh, M.; Pitchaimani, J. Mechanical Properties of Natural Fiber Braided Yarn Woven Composite: Comparison with Conventional Yarn Woven Composite. J. Bionic Eng. 2017, 14, 141–150. [Google Scholar] [CrossRef]

- Tezara, C.; Hadi, A.E.; Siregar, J.P.; Muhamad, Z.; Hamdan, M.H.M.; Oumer, A.N.; Jaafar, J.; Irawan, A.P.; Rihayat, T.; Fitriyana, D.F. The Effect of Hybridisation on Mechanical Properties and Water Absorption Behaviour of Woven Jute/Ramie Reinforced Epoxy Composites. Polymers 2021, 13, 2964. [Google Scholar] [CrossRef] [PubMed]

- Tezara, C.; Zalinawati, M.; Siregar, J.P.; Jaafar, J.; Hamdan, M.H.M.; Oumer, A.N.; Chuah, K.H. Effect of Stacking Sequences, Fabric Orientations, and Chemical Treatment on the Mechanical Properties of Hybrid Woven Jute–Ramie Composites. Int. J. Precis. Eng. Manuf. -Green Technol. 2022, 9, 273–285. [Google Scholar] [CrossRef]

- Misnon, M.I.; Islam, M.M.; Epaarachchi, J.A.; Lau, K.T. Analyses of Woven Hemp Fabric Characteristics for Composite Reinforcement. Mater. Des. 2015, 66, 82–92. [Google Scholar] [CrossRef]

- Azlin, M.N.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ilyas, R.A. Thermal Stability, Dynamic Mechanical Analysis and Flammability Properties of Woven Kenaf/Polyester-Reinforced Polylactic Acid Hybrid Laminated Composites. Polymers 2022, 14, 2690. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A. Cellulosic/Synthetic Fibre Reinforced Polymer Hybrid Composites: A Review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Adesina, O.T.; Jamiru, T.; Sadiku, E.R.; Ogunbiyi, O.F.; Beneke, L.W. Mechanical Evaluation of Hybrid Natural Fibre–Reinforced Polymeric Composites for Automotive Bumper Beam: A Review. Int. J. Adv. Manuf. Technol. 2019, 103, 1781–1797. [Google Scholar] [CrossRef]

- Dong, C. Review of Natural Fibre-Reinforced Hybrid Composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Concept Selection of Car Bumper Beam with Developed Hybrid Bio-Composite Material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- Muthalagu, R.; Murugesan, J.; Kumar, S.S.; Babu, B.S. Tensile Attributes and Material Analysis of Kevlar and Date Palm Fibers Reinforced Epoxy Composites for Automotive Bumper Applications. Mater. Today Proc. 2021, 46, 433–438. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact Behaviour of Hybrid Composites for Structural Applications: A Review. Compos. B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and Interfacial Properties of Unidirectional Flax/Glass Fiber Reinforced Hybrid Composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical Properties of Hybrid Kenaf/Glass Reinforced Epoxy Composite for Passenger Car Bumper Beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.A.; Jawaid, M.; Iqbal, M. Development of Kenaf-Glass Reinforced Unsaturated Polyester Hybrid Composite for Structural Applications. Compos. B Eng. 2014, 56, 68–73. [Google Scholar] [CrossRef]

- Ramasubbu, R.; Madasamy, S. Fabrication of Automobile Component Using Hybrid Natural Fiber Reinforced Polymer Composite. J. Nat. Fibers 2022, 19, 736–746. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Maleque, M.A.; Hameedullah, M.; Suddin, M.N.; Ismail, N. A Note on the Conceptual Design of Polymeric Composite Automotive Bumper System. J. Mater. Process. Technol. 2005, 159, 145–151. [Google Scholar] [CrossRef]

- Olorunnishola, A.A.G.; Adubi, E.G. A Comparative Analysis of a Blend of Natural Jute and Glass Fibers with Synthetic Glass Fibers Composites as Car Bumper Materials. IOSR J. Mech. Civ. Eng. 2018, 15, 67–71. [Google Scholar]

- Maisuriya, V.; Jain, P.; Jariwala, H.; Badagha, D. Analysis of Unidirectional Aligned Banana and Glass Fibre Reinforced Polyester Composite for Tensile and Flexural Strength. J. Polym. Compos. 2020, 8, 49–61. [Google Scholar]

- Santhanam, V.; Dhanaraj, R.; Chandrasekaran, M.; Venkateshwaran, N.; Baskar, S. Experimental Investigation on the Mechanical Properties of Woven Hybrid Fiber Reinforced Epoxy Composite. Mater. Today Proc. 2021, 37, 1850–1853. [Google Scholar]

- Gujjala, R.; Ojha, S.; Acharya, S.K.; Pal, S.K. Mechanical Properties of Woven Jute–Glass Hybrid-Reinforced Epoxy Composite. J. Compos. Mater. 2014, 48, 3445–3455. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Kokan, S.J.; Raja, R.N.; Sathyanarayanan, R.; Elanchezhian, C.; Prasad, A.R.; Manickavasagam, V.M. Evaluation of Mechanical Properties of Abaca–Jute–Glass Fibre Reinforced Epoxy Composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Kumar, K.S.; Siva, I.; Rajini, N.; Jappes, J.T.W.; Amico, S.C. Layering Pattern Effects on Vibrational Behavior of Coconut Sheath/Banana Fiber Hybrid Composites. Mater. Des. 2016, 90, 795–803. [Google Scholar] [CrossRef]

- Bhoopathi, R.; Ramesh, M.; Deepa, C. Fabrication and Property Evaluation of Banana-Hemp-Glass Fiber Reinforced Composites. Procedia Eng. 2014, 97, 2032–2041. [Google Scholar] [CrossRef] [Green Version]

- Acharya, S.K. Soma Dalbehera Study on Mechanical Properties of Natural Fiber Reinforced Woven Jute-Glass Hybrid Epoxy Composites. Adv. Polym. Sci. Technol. 2014, 4, 1–6. [Google Scholar]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Effect of Layering Sequence and Chemical Treatment on the Mechanical Properties of Woven Kenaf–Aramid Hybrid Laminated Composites. Mater. Des. 2015, 67, 173–179. [Google Scholar] [CrossRef]

- Rajesh, M.; Singh, S.P.; Pitchaimani, J. Mechanical Behavior of Woven Natural Fiber Fabric Composites: Effect of Weaving Architecture, Intra-Ply Hybridization and Stacking Sequence of Fabrics. J. Ind. Text. 2018, 47, 938–959. [Google Scholar] [CrossRef]

- Elakhame, Z.U.; Alhassan, O.A.; Samuel, A.E. Development and Production of Brake Pads from Palm Kernel Shell Composites. Int. J. Sci. Eng. Res. 2014, 5, 735–744. [Google Scholar]

- Cionita, T.; Siregar, J.P.; Shing, W.L.; Hee, C.W.; Fitriyana, D.F.; Jaafar, J.; Junid, R.; Irawan, A.P.; Hadi, A.E. The Influence of Filler Loading and Alkaline Treatment on the Mechanical Properties of Palm Kernel Cake Filler Reinforced Epoxy Composites. Polymers 2022, 14, 3063. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Zhang, J. Tensile Properties of Natural and Synthetic Rattan Strips Used as Furniture Woven Materials. Forests 2020, 11, 1299. [Google Scholar] [CrossRef]

- Nath, A.; Kanjilal, T.; Bhattacharjee, C. Application of Bioactive Composite Green Polymer for the Development of Artificial Organs. In New Polymeric Composite Materials; Materials Research Forum LLC: Millersville, PA, USA, 2016. [Google Scholar]

- Abasolo, W.P. Properties of Rattan Cane as Basis for Determining Optimum Cutting Cycle of Cultivated Calamus Merrillii. J. Trop. For. Sci. 2015, 27, 176–188. [Google Scholar]

- Rachchh, N.V.; Ujeniya, P.S.; Misra, R.K. Mechanical Characterisation of Rattan Fibre Polyester Composite. Procedia Mater. Sci. 2014, 6, 1396–1404. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Zhao, R.; Xia, J.; Zhao, G.-L. Reinforcing Microwave Absorption Multiwalled Carbon Nanotube–Epoxy Composites Using Glass Fibers for Multifunctional Applications. Adv. Eng. Mater. 2020, 22, 1900780. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical Properties of Bamboo Fiber Bundle-Reinforced Bamboo Powder Composite Materials. Eur. J. Wood Wood Prod. 2022, 80, 263–275. [Google Scholar] [CrossRef]

- Ramanaiah, K.; Prasad, A.V.R.; Chandra Reddy, K.H. Mechanical and Thermo-Physical Properties of Fish Tail Palm Tree Natural Fiber–Reinforced Polyester Composites. Int. J. Polym. Anal. Charact. 2013, 18, 126–136. [Google Scholar] [CrossRef]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Hanim, M.A.A. Partial Replacement of Glass Fiber by Woven Kenaf in Hybrid Composites and Its Effect on Monotonic and Fatigue Properties. Bioresources 2016, 11, 2665–2683. [Google Scholar] [CrossRef]

- Irawan, A.P.; Sukania, I.W. Tensile Strength of Car Spoiler Product Based on ABS Plastic and Rattan Fiber Epoxy Composite Materials. In Proceedings of the 3rd Nommensen International Conference on Technology and Engineering 2019 (3rd NICTE), Nommensen HKBP University, Nommensen, Indonesia, 25–26 July 2019; Volume 725, p. 012040. [Google Scholar]

- Karthick, M.; Meikandan, M.; Kaliappan, S.; Karthick, M.; Sekar, S.; Patil, P.P.; Raja, S.; Natrayan, L.; Paramasivam, P. Experimental Investigation on Mechanical Properties of Glass Fiber Hybridized Natural Fiber Reinforced Penta-Layered Hybrid Polymer Composite. Int. J. Chem. Eng. 2022, 1–9. [Google Scholar] [CrossRef]

- Azlin, M.N.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S. Effect of Stacking Sequence and Fiber Content on Mechanical and Morphological Properties of Woven Kenaf/Polyester Fiber Reinforced Polylactic Acid (PLA) Hybrid Laminated Composites. J. Mater. Res. Technol. 2022, 16, 1190–1201. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-Friendly Bio-Composites Using Natural Rubber (NR) Matrices and Natural Fiber Reinforcements. In Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 249–283. [Google Scholar]

- Jegan, M.M.; Sathishkumar, T.P.; Anand, V.; Arun Ganesh, R.; Logesh Raja, C.; Mohanraj, K. Investigation of Fracture Behavior on Glass & Natural Fibre Reinforced Epoxy Composites. Int. J. Eng. Res. Technol. 2019, 7, 13–17. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.; Rejab, M.R.M.; Siregar, J.P.; Mohamad, Z.; Quanjin, M.; Mohammed, A.A. Mechanical Properties of Hybrid Glass Fiber/Rice Husk Reinforced Polymer Composite. Mater. Today Proc. 2020, 27, 1749–1755. [Google Scholar] [CrossRef]

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.-S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef]

- Hariharan, A.B.A.; Khalil, H.P.S.A. Lignocellulose-Based Hybrid Bilayer Laminate Composite: Part I-Studies on Tensile and Impact Behavior of Oil Palm Fiber-Glass Fiber-Reinforced Epoxy Resin. J. Compos. Mater. 2005, 39, 663–684. [Google Scholar] [CrossRef]

- Wang, R.; Tian, G.; Yang, S.; Wang, Y.; Jiang, Z. Tensile Properties of Single Rattan Fibers. Wood Fiber Sci. 2014, 46, 519–526. [Google Scholar]

- Suriani, M.J.; Rapi, H.Z.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M. Delamination and Manufacturing Defects in Natural Fiber-Reinforced Hybrid Composite: A Review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef]

- Selver, E.; Dalfi, H.; Yousaf, Z. Investigation of the Impact and Post-Impact Behaviour of Glass and Glass/Natural Fibre Hybrid Composites Made with Various Stacking Sequences: Experimental and Theoretical Analysis. J. Ind. Text. 2022, 51, 1264–1294. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on Mechanical Properties of Natural-Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Gowda, T.M.; Naidu, A.C.B.; Chhaya, R. Some Mechanical Properties of Untreated Jute Fabric-Reinforced Polyester Composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 277–284. [Google Scholar] [CrossRef]

- Sreekala, M.S.; George, J.; Kumaran, M.G.; Thomas, S. The Mechanical Performance of Hybrid Phenol-Formaldehyde-Based Composites Reinforced with Glass and Oil Palm Fibres. Compos. Sci. Technol. 2002, 62, 339–353. [Google Scholar] [CrossRef]

- Ho, M.; Lau, K. Design of an Impact Resistant Glass Fibre/Epoxy Composites Using Short Silk Fibres. Mater. Des. 2012, 35, 664–669. [Google Scholar] [CrossRef]

- Saha, N.; Banerjee, A.N.; Mitra, B.C. Tensile Behaviour of Unidirectional Polyethylene-Glass Fibres/PMMA Hybrid Composite Laminates. Polymer 1996, 37, 699–701. [Google Scholar] [CrossRef]

- Ma, W.; Elkin, R. Characterizations of Sandwich Structures. In Sandwich Structural Composites; CRC Press: Boca Raton, FL, USA, 2021; pp. 185–252. ISBN 100303537X. [Google Scholar]

- Megahed, M.; Ali-Eldin, S.S.; Abd El Moezz, S.M.; Abdalla, W.S. Synthesis of Developed Rice Straw Sheets and Glass Fiber-Reinforced Polyester Composites. J. Compos. Mater. 2020, 54, 3381–3394. [Google Scholar] [CrossRef]

- Jayabal, S.; Natarajan, U.; Sathiyamurthy, S. Effect of Glass Hybridization and Staking Sequence on Mechanical Behaviour of Interply Coir–Glass Hybrid Laminate. Bull. Mater. Sci. 2011, 34, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Ridzuan, M.J.M.; Majid, M.S.A.; Afendi, M.; Mazlee, M.N.; Gibson, A.G. Thermal Behaviour and Dynamic Mechanical Analysis of Pennisetum Purpureum/Glass-Reinforced Epoxy Hybrid Composites. Compos. Struct. 2016, 152, 850–859. [Google Scholar] [CrossRef]

- Ramesh, V.; Anand, P. Thermal Analysis of Kevlar/Basalt Reinforced Hybrid Polymer Composite. Mater. Res. Express 2021, 8, 115302. [Google Scholar] [CrossRef]

- Ferreira, M.V.F.; Neves, A.C.C.; de Oliveira, C.G.; Lopes, F.P.D.; Margem, F.M.; Vieira, C.M.F.; Monteiro, S.N. Thermogravimetric Characterization of Polyester Matrix Composites Reinforced with Eucalyptus Fibers. J. Mater. Res. Technol. 2017, 6, 396–400. [Google Scholar] [CrossRef]

- Shahinur, S.; Hasan, M.; Ahsan, Q.; Saha, D.K.; Islam, M. Characterization on the Properties of Jute Fiber at Different Portions. Int. J. Polym. Sci. 2015, 2015, 262348. [Google Scholar] [CrossRef] [Green Version]

- Lubis, M.A.R.; Handika, S.O.; Sari, R.K.; Iswanto, A.H.; Antov, P.; Kristak, L.; Lee, S.H.; Pizzi, A. Modification of Ramie Fiber via Impregnation with Low Viscosity Bio-Polyurethane Resins Derived from Lignin. Polymers 2022, 14, 2165. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Alothman, O.Y. Thermal Properties of Sugar Palm/Glass Fiber Reinforced Thermoplastic Polyurethane Hybrid Composites. Compos. Struct. 2018, 202, 954–958. [Google Scholar] [CrossRef]

- Braga, R.A.; Magalhaes, P.A.A., Jr. Analysis of the Mechanical and Thermal Properties of Jute and Glass Fiber as Reinforcement Epoxy Hybrid Composites. Mater. Sci. Eng. C 2015, 56, 269–273. [Google Scholar] [CrossRef] [PubMed]

- AlMaadeed, M.A.; Kahraman, R.; Khanam, P.N.; Madi, N. Date Palm Wood Flour/Glass Fibre Reinforced Hybrid Composites of Recycled Polypropylene: Mechanical and Thermal Properties. Mater. Des. 2012, 42, 289–294. [Google Scholar] [CrossRef]

- Sinha, E.; Rout, S.K. Influence of Fibre-Surface Treatment on Structural, Thermal and Mechanical Properties of Jute Fibre and Its Composite. Bull. Mater. Sci. 2009, 32, 65–76. [Google Scholar] [CrossRef]

- Bryś, A.; Bryś, J.; Ostrowska-Ligęza, E.; Kaleta, A.; Górnicki, K.; Głowacki, S.; Koczoń, P. Wood Biomass Characterization by DSC or FT-IR Spectroscopy. J. Therm. Anal. Calorim. 2016, 126, 27–35. [Google Scholar] [CrossRef]

| Properties | Epikote 828 | Rattan | E-Glass Fiber |

|---|---|---|---|

| Density (g/cm3) | 1.16 | 0.45 | 2.55–2.6 |

| Initial viscosity @ 25 °C (Pa s) | <10–12 | - | - |

| Modulus (GPa) | 3 | 4.97 | 72–85 |

| Tensile strength (MPa) | 60 | 41.97–121.5 | 1900–2050 |

| Elongation at break (%) | 4 | - | 1.8–4.8 |

| Glass transition (°C) | 155 | - | - |

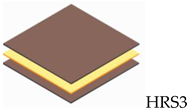

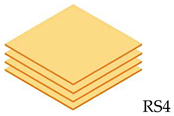

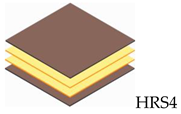

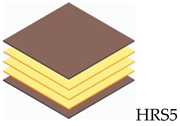

| Layering Number | Configuration Model and Label Code | |

|---|---|---|

| Rattan Strip | Hybrid Rattan Strip | |

| 1 |  | - |

| 2 |  | - |

| 3 |  |  |

| 4 |  |  |

| 5 | - |  |

| 6 | - |  |

| Temperature (°C) | Weight Loss (%) | ||

|---|---|---|---|

| Epoxy | HRS5 | RS3 | |

| 25–200 | 0.95 | 0.75 | 5.54 |

| 200–500 | 88.56 | 33.56 | 73.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irawan, A.P.; Anggarina, P.T.; Utama, D.W.; Najid, N.; Abdullah, M.Z.; Siregar, J.P.; Cionita, T.; Fitriyana, D.F.; Jaafar, J.; Hadi, A.E.; et al. An Experimental Investigation into Mechanical and Thermal Properties of Hybrid Woven Rattan/Glass-Fiber-Reinforced Epoxy Composites. Polymers 2022, 14, 5562. https://doi.org/10.3390/polym14245562

Irawan AP, Anggarina PT, Utama DW, Najid N, Abdullah MZ, Siregar JP, Cionita T, Fitriyana DF, Jaafar J, Hadi AE, et al. An Experimental Investigation into Mechanical and Thermal Properties of Hybrid Woven Rattan/Glass-Fiber-Reinforced Epoxy Composites. Polymers. 2022; 14(24):5562. https://doi.org/10.3390/polym14245562

Chicago/Turabian StyleIrawan, Agustinus Purna, Paula Tjatoerwidya Anggarina, Didi Widya Utama, Najid Najid, Mohd Zulkfly Abdullah, Januar Parlaungan Siregar, Tezara Cionita, Deni Fajar Fitriyana, Jamiluddin Jaafar, Agung Efriyo Hadi, and et al. 2022. "An Experimental Investigation into Mechanical and Thermal Properties of Hybrid Woven Rattan/Glass-Fiber-Reinforced Epoxy Composites" Polymers 14, no. 24: 5562. https://doi.org/10.3390/polym14245562