The Influence of Ply Stacking Sequence on Mechanical Properties of Carbon/Epoxy Composite Laminates

Abstract

:1. Introduction

2. Materials and Methods

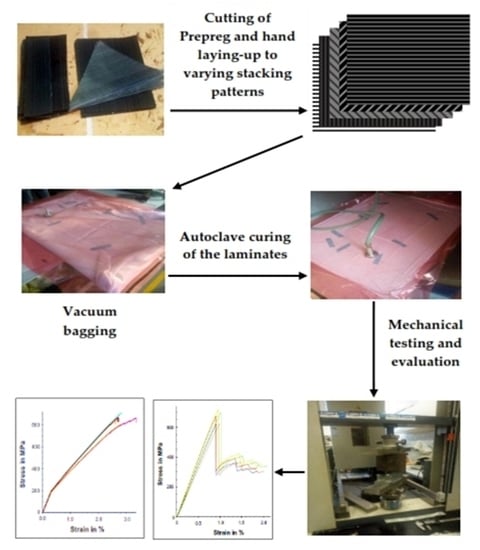

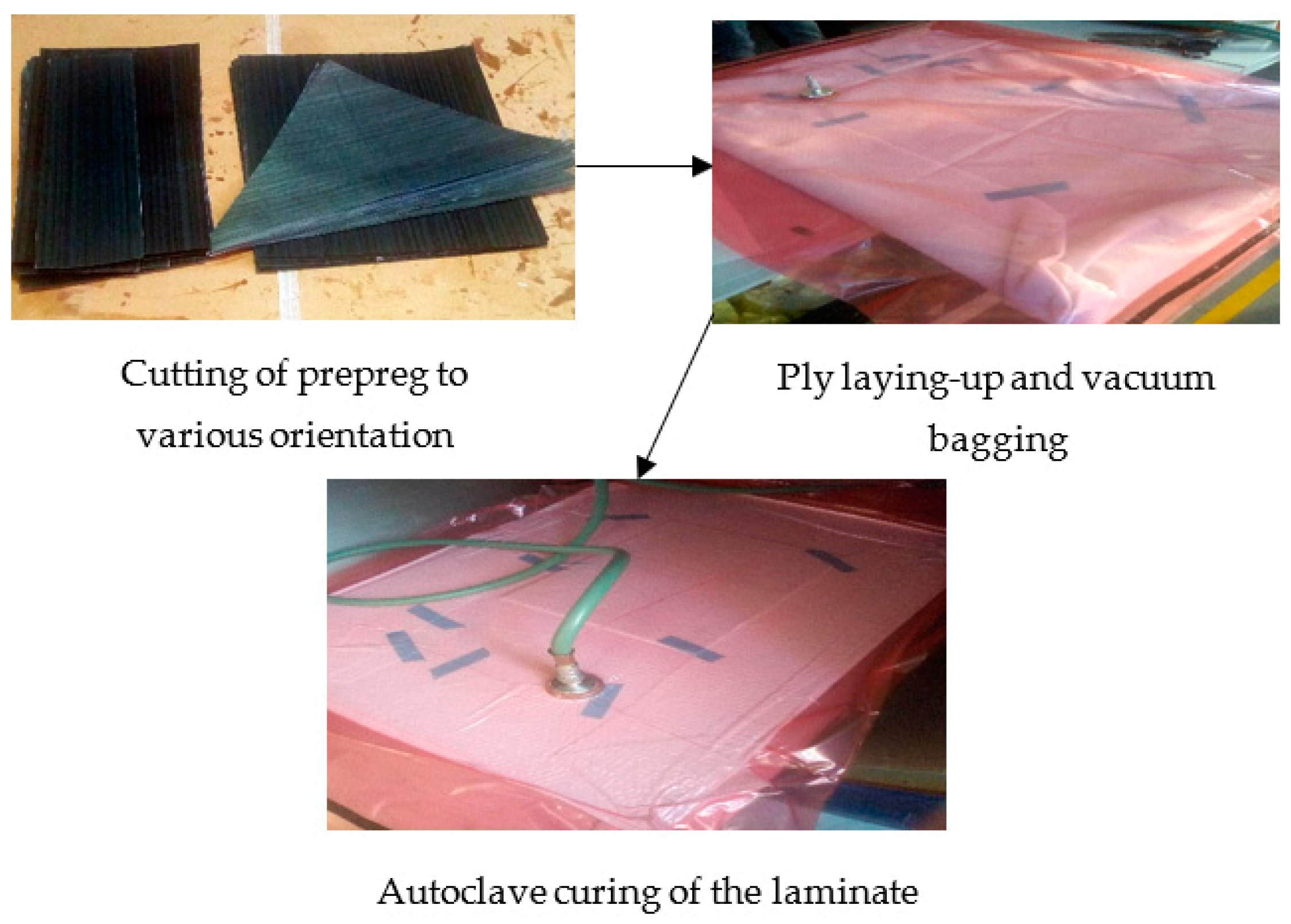

2.1. Preparation of the Specimen

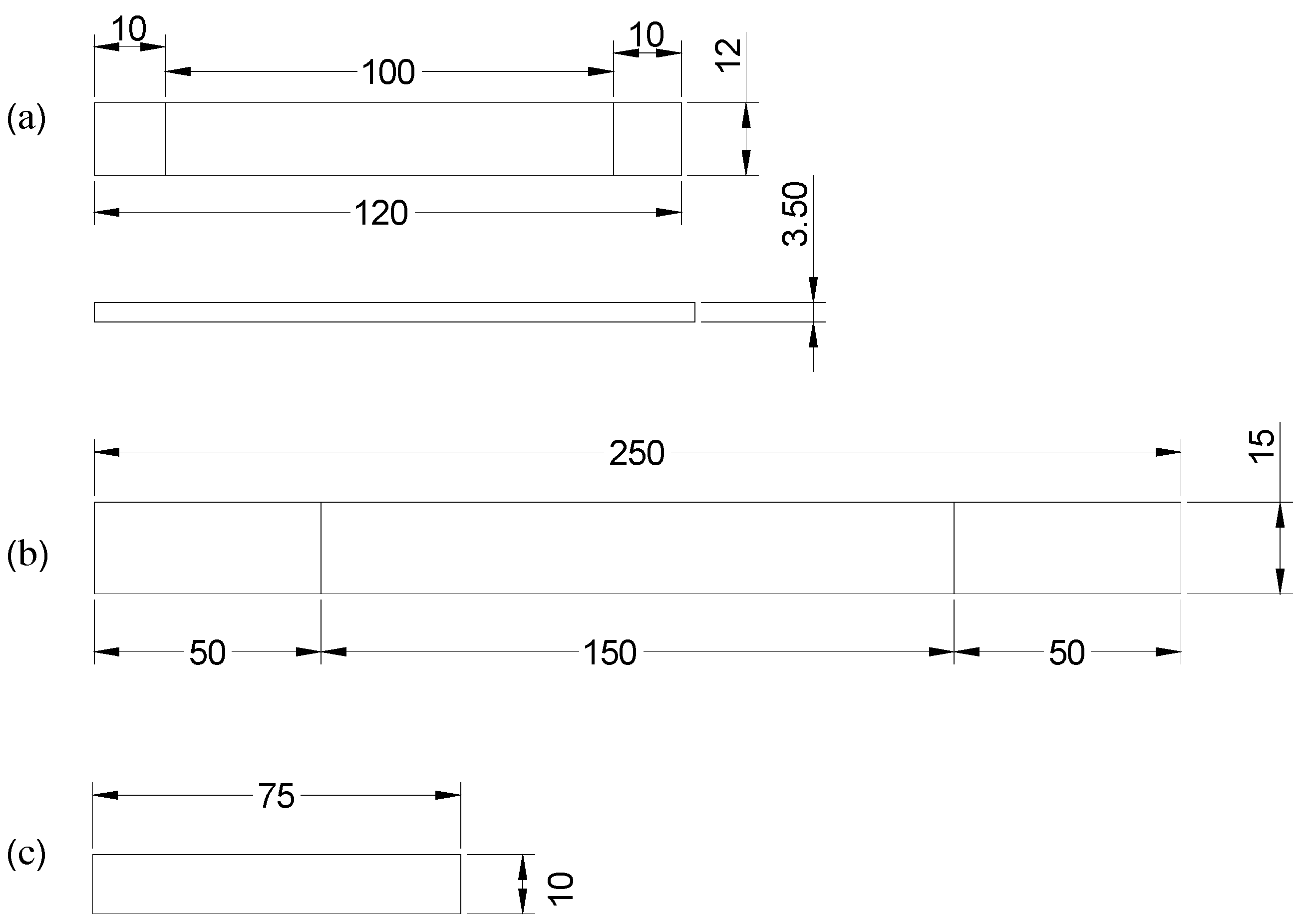

2.2. Mechanical Testing

2.3. Optical Microscopy

3. Results and Discussion

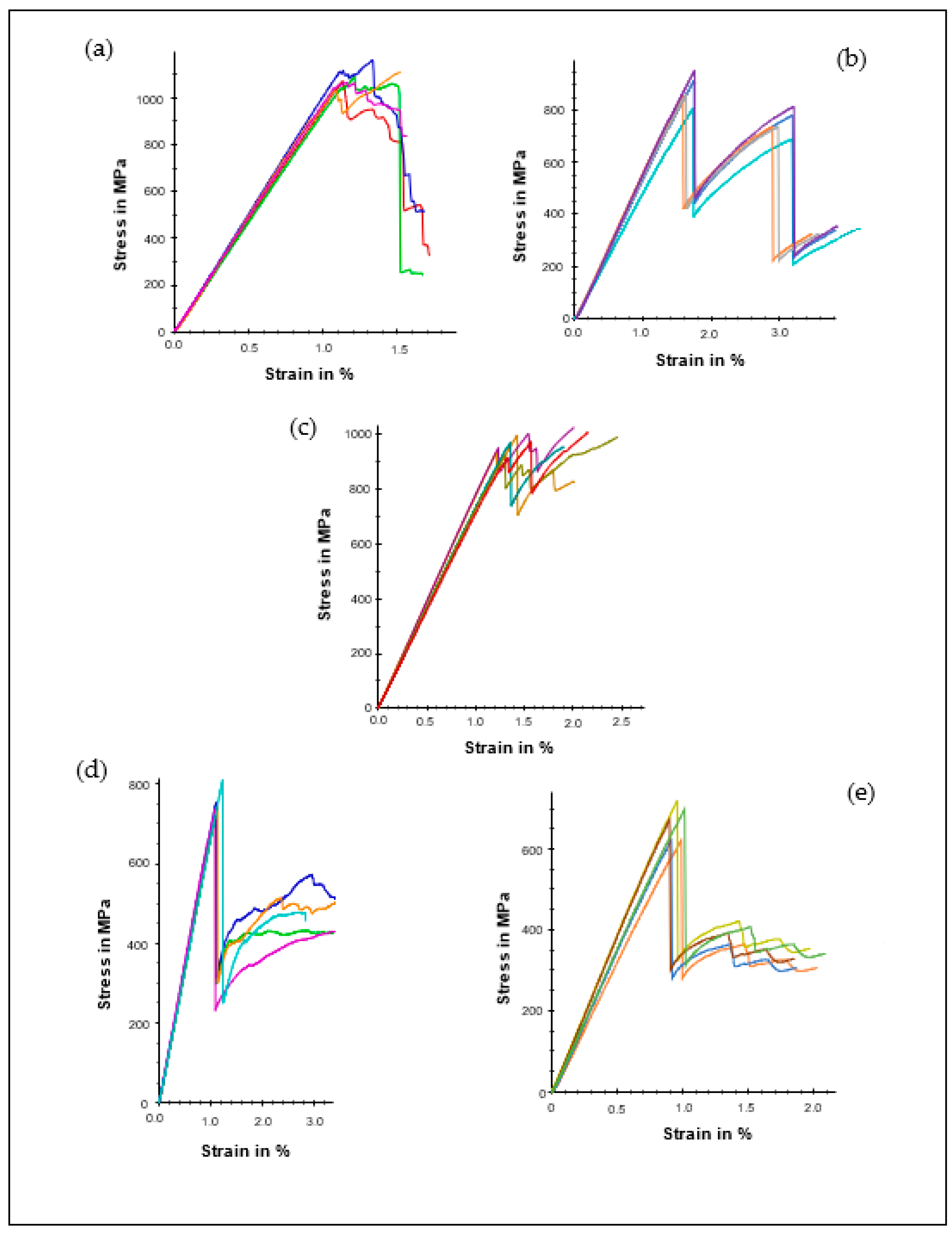

3.1. Flexural Properties

3.2. Tensile Properties

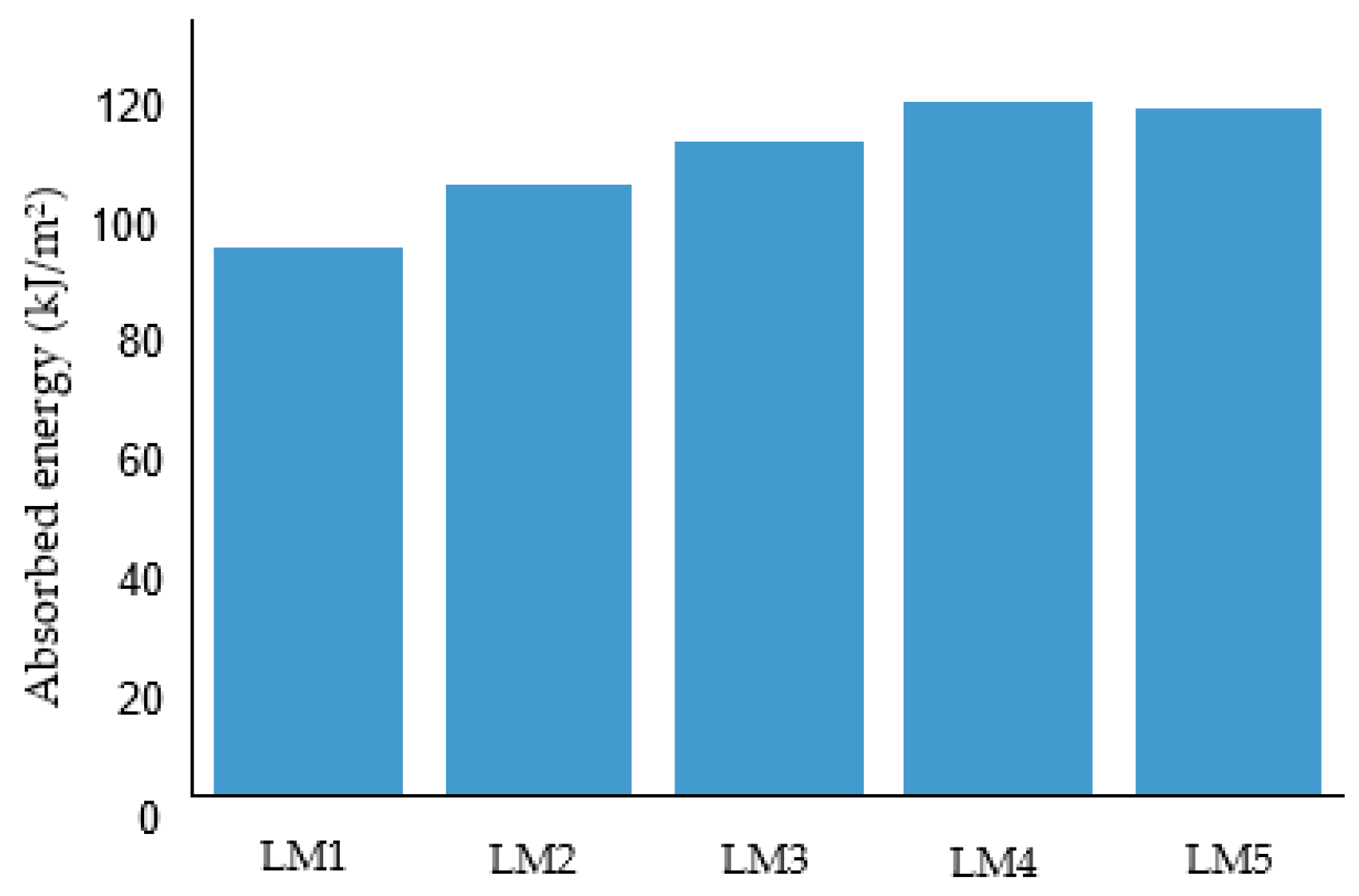

3.3. Charpy Impact Response

3.4. Failure Analysis

4. Conclusions

- In flexural mode, unidirectional laminate demonstrated the highest flexural strength and modulus. However, it undergoes premature catastrophic failure.

- The unidirectional laminate (LM1) recorded the maximum tensile strength and modulus. This results from the alignment of the laminate ply orientation with the principal loading direction, which gives rise to the orthogonal behaviour of the composite. The carbon fibre also impacted the overall tensile properties due to the strong adhesive force between the carbon fibre and epoxy matrix, which provide high tensile properties to the laminate.

- The multidirectional quasi-isotropic laminates (LM4 and LM5) recorded the highest impact resistance due to high-impact energy.

- Microscopic analysis indicated that the laminates failed under flexural loading in typical matrix cracking, fibre pull-out, matrix debonding and delamination modes.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hallal, A.; Elmarakbi, A.; Shaito, A.; El-Hage, H. Overview of Composite Materials and Their Automotive Applications. In Advanced Composite Materials for Automotive Applications; John Wiley & Sons Ltd: Chichester, UK, 2013; pp. 1–28. [Google Scholar]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef] [Green Version]

- Teng, J.G.; Yu, T.; Fernando, D. Strengthening of steel structures with fiber-reinforced polymer composites. J. Constr. Steel Res. 2012, 78, 131–143. [Google Scholar] [CrossRef]

- Li, C.; Guo, R.; Xian, G.; Li, H. Effects of elevated temperature, hydraulic pressure and fatigue loading on the property evolution of a carbon/glass fiber hybrid rod. Polym. Test. 2020, 90, 106761. [Google Scholar] [CrossRef]

- Jayan, J.S.; Appukuttan, S.; Wilson, R.; Joseph, K.; George, G.; Oksman, K. An introduction to fiber reinforced composite materials. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–24. [Google Scholar]

- Dhakal, H.N.; MacMullen, J.; Zhang, Z.Y. Moisture measurement and effects on properties of marine composites. In Marine Applications of Advanced Fibre-Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 103–124. [Google Scholar]

- Parisi, F.; Menna, C.; Prota, A. Fabric-Reinforced Cementitious Matrix (FRCM) composites. In Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 199–227. [Google Scholar]

- Bencardino, F.; Nisticò, M. Evaluation of the maximum strain for different steel-FRCM systems in RC beams strengthened in flexure. Fibers 2022, 10, 67. [Google Scholar] [CrossRef]

- Mazzuca, P.; Firmo, J.P.; Correia, J.R.; Castilho, E. Influence of elevated temperatures on the mechanical properties of glass fibre reinforced polymer laminates produced by vacuum infusion. Constr. Build. Mater. 2022, 345, 128340. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P.; Poggi, C. Long-term behavior of PBO FRCM and comparison with other inorganic-matrix composites. Materials 2022, 15, 3281. [Google Scholar] [CrossRef] [PubMed]

- Yumnam, M.; Gupta, H.; Ghosh, D.; Jaganathan, J. Inspection of concrete structures externally reinforced with FRP composites using active infrared thermography: A review. Constr. Build. Mater. 2021, 310, 125265. [Google Scholar] [CrossRef]

- Katnam, K.B.; da Silva, L.F.M.; Young, T.M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Prog. Aerosp. Sci. 2013, 61, 26–42. [Google Scholar] [CrossRef]

- Nair, S.; Dasari, A.; Yue, C.; Narasimalu, S. Failure behavior of unidirectional composites under compression loading: Effect of fiber waviness. Materials 2017, 10, 909. [Google Scholar] [CrossRef]

- Rout, S.; Nayak, R.K.; Patnaik, S.C.; Yazdani Nezhad, H. Development of improved flexural and impact performance of kevlar/carbon/glass fibers reinforced polymer hybrid composites. J. Compos. Sci. 2022, 6, 245. [Google Scholar] [CrossRef]

- Khan, R.M.A.; Tabrizi, I.E.; Ali, H.Q.; Demir, E.; Yildiz, M. Investigation on interlaminar delamination tendency of multidirectional carbon fiber composites. Polym. Test. 2020, 90, 106653. [Google Scholar] [CrossRef]

- Habibi, M.; Selmi, S.; Laperrière, L.; Mahi, H.; Kelouwani, S. Experimental investigation on the response of unidirectional flax fiber composites to low-velocity impact with after-impact tensile and compressive strength measurement. Compos. B Eng. 2019, 171, 246–253. [Google Scholar] [CrossRef]

- Fotouhi, M.; Sadeghi, S.; Jalalvand, M.; Ahmadi, M. Analysis of the damage mechanisms in mixed-mode delamination of laminated composites using acoustic emission data clustering. J. Thermoplast. Compos. Mater. 2017, 30, 318–340. [Google Scholar] [CrossRef] [Green Version]

- Tan, R.; Xu, J.; Sun, W.; Liu, Z.; Guan, Z.; Guo, X. Relationship between matrix cracking and delamination in CFRP cross-ply laminates subjected to low velocity impact. Materials 2019, 12, 3990. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P. Damage resistance of carbon fibre reinforced epoxy laminates subjected to low velocity impact: Effects of laminate thickness and ply-stacking sequence. Polym. Test. 2017, 63, 530–541. [Google Scholar] [CrossRef]

- Mlyniec, A.; Korta, J.; Kudelski, R.; Uhl, T. The influence of the laminate thickness, stacking sequence and thermal aging on the static and dynamic behavior of carbon/epoxy composites. Compos. Struct. 2014, 118, 208–216. [Google Scholar] [CrossRef]

- Grigoriou, K.; Mouritz, A.P. Influence of ply stacking pattern on the structural properties of quasi-isotropic carbon-epoxy laminates in fire. Compos. Part A Appl. Sci. Manuf. 2017, 99, 113–120. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Mandal, P.; Rout, A.K.; Nayak, R.K. Effect of carbon/glass fiber symmetric inter-ply sequence on mechanical properties of polymer matrix composites. Procedia Manuf. 2018, 20, 530–535. [Google Scholar] [CrossRef]

- Kaboglu, C.; Eken, T.Y.; Yurekturk, Y. Impact performances and failure modes of glass fiber reinforced polymers in different curvatures and stacking sequences. J. Compos. Mater. 2022, 56, 1123–1138. [Google Scholar] [CrossRef]

- Singh, K. Mahesh effect of ply position switching in quasi-isotropic glass fibre reinforced polymer composite subjected to low velocity impact. Int. J. Damage Mech. 2022, 31, 665–693. [Google Scholar] [CrossRef]

- Giannis, S.; Hansen, P.L.; Martin, R.H.; Jones, D.T. Mode I Quasi–Static and Fatigue Delamination Characterisation of Polymer Composites for Wind Turbine Blade Applications. Energy Materials 2008, 3, 248–256. [Google Scholar] [CrossRef]

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6110; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Azmah Hanim, M.A. Partial replacement of glass fiber by woven kenaf in hybrid composites and its effect on monotonic and fatigue properties. Bioresources 2016, 11, 2665–2683. [Google Scholar] [CrossRef]

- Parmiggiani, A.; Prato, M.; Pizzorni, M. Effect of the fiber orientation on the tensile and flexural behavior of continuous carbon fiber composites made via fused filament fabrication. Int. J. Adv. Manuf. Technol. 2021, 114, 2085–2101. [Google Scholar] [CrossRef]

- Munikenche Gowda, T.; Naidu, A.C.B.; Chhaya, R. Some mechanical properties of untreated jute fabric-reinforced polyester composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 277–284. [Google Scholar] [CrossRef]

- El-Hacha, R.; Chen, D. Behaviour of hybrid FRP–UHPC beams subjected to static flexural loading. Compos. B Eng. 2012, 43, 582–593. [Google Scholar] [CrossRef]

- Bezazi, A.R.; el Mahi, A.; Berthelot, J.M.; Bezzazi, B. Flexural fatigue behavior of cross-ply laminates: An experimental approach. Strength Mater. 2003, 35, 149–161. [Google Scholar] [CrossRef]

- Sharma, A.; Daggumati, S. Computational micromechanical modeling of transverse tensile damage behavior in unidirectional glass fiber-reinforced plastic composite plies: Ductile versus brittle fracture mechanics approach. Int. J. Damage Mech. 2020, 29, 943–964. [Google Scholar] [CrossRef]

- Arteiro, A.; Catalanotti, G.; Melro, A.R.; Linde, P.; Camanho, P.P. Micro-mechanical analysis of the in situ effect in polymer composite laminates. Compos. Struct. 2014, 116, 827–840. [Google Scholar] [CrossRef] [Green Version]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Hadăr, A.; Baciu, F.; Voicu, A.-D.; Vlăsceanu, D.; Tudose, D.-I.; Adetu, C. Mechanical characteristics evaluation of a single ply and multi-ply carbon fiber-reinforced plastic subjected to tensile and bending loads. Polymers 2022, 14, 3213. [Google Scholar] [CrossRef] [PubMed]

- Ginzburg, D.; Pinto, F.; Iervolino, O.; Meo, M. Damage tolerance of bio-inspired helicoidal composites under low velocity impact. Compos. Struct. 2017, 161, 187–203. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Lin, Y.; Wu, J.A.; Zhang, Z.; Huang, Y.; Li, C.; Wang, M. Comparison of stacking sequence on the low-velocity impact failure mechanisms and energy dissipation characteristics of CFRP/Al hybrid laminates. Polym. Compos. 2022, 43, 5544–5562. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, G.; Qiu, S.; Han, Z.; Li, X.; Zhang, D. Exploration of energy absorption and viscoelastic behavior of CFRPs subjected to low velocity impact. Compos. B Eng. 2019, 165, 247–254. [Google Scholar] [CrossRef]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J. Effect of thermal ageing on the impact damage resistance and tolerance of carbon-fibre-reinforced epoxy laminates. Polymers 2019, 11, 160. [Google Scholar] [CrossRef] [Green Version]

- Evci, C. Thickness-dependent energy dissipation characteristics of laminated composites subjected to low velocity impact. Compos. Struct. 2015, 133, 508–521. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, K.K.; Sarkar, P. Impact damage on fibre-reinforced polymer matrix composite—A review. J. Compos. Mater. 2014, 48, 317–332. [Google Scholar] [CrossRef]

- Sy, B.L.; Fawaz, Z.; Bougherara, H. Damage evolution in unidirectional and cross-ply flax/epoxy laminates subjected to low velocity impact loading. Compos. Part A Appl. Sci. Manuf. 2018, 112, 452–467. [Google Scholar] [CrossRef]

- Giasin, K.; Dhakal, H.N.; Featheroson, C.A.; Pimenov, D.Y.; Lupton, C.; Jiang, C.; Barouni, A.; Koklu, U. Effect of fibre orientation on impact damage resistance of S2/FM94 glass fibre composites for aerospace applications: An experimental evaluation and numerical validation. Polymers 2021, 14, 95. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, L.; Pan, Z.; Zhang, B.; Hu, X. Effect of Off-Axial Angle on the Low-Velocity Impact Performance of Braided Laminates. Int J Mech Sci 2022, 216, 106967. [Google Scholar] [CrossRef]

- Grandidier, J.-C.; Casari, P.; Jochum, C. A fibre direction compressive failure criterion for long fibre laminates at ply scale, including stacking sequence and laminate thickness effects. Compos. Struct. 2012, 94, 3799–3806. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Khalkhali-Sharifi, S.S.; Shokrieh, M.M. Effect of ply stacking sequence on buckling behavior of e-glass/epoxy laminated composites. Comput. Mater. Sci. 2014, 89, 89–96. [Google Scholar] [CrossRef]

| Properties | SE84LV/HEC |

|---|---|

| Fibre density (g/cm3) | 1.8 |

| Resin content (%) | 35 ± 3 |

| Fibre volume fraction (%) | 55 |

| Fibre aerial weight (g/m2) | 400 |

| Prepreg thickness (mm) | 0.440 |

| Laminate Samples | ||||

|---|---|---|---|---|

| LM1 | LM2 | LM3 | LM4 | LM5 |

| Sample | Flexural | Tensile | ||

|---|---|---|---|---|

| LM1 | 1100 (37.6) | 98.40 (3.07) | 1220 (54.40) | 115.00 (3.32) |

| LM2 | 847 (131) | 46.70 (0.93) | 859 (37.70) | 62.90 (0.86) |

| LM3 | 999 (22.3) | 74.50 (3.20) | 808 (43.10) | 65.40 (1.00) |

| LM4 | 754 (32.7) | 67.00 (1.98) | 374 (15.00) | 42.70 (1.22) |

| LM5 | 674 (43.80) | 65.40 (3.05) | 362 (24.50) | 44.10 (1.05) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogunleye, R.O.; Rusnakova, S.; Zaludek, M.; Emebu, S. The Influence of Ply Stacking Sequence on Mechanical Properties of Carbon/Epoxy Composite Laminates. Polymers 2022, 14, 5566. https://doi.org/10.3390/polym14245566

Ogunleye RO, Rusnakova S, Zaludek M, Emebu S. The Influence of Ply Stacking Sequence on Mechanical Properties of Carbon/Epoxy Composite Laminates. Polymers. 2022; 14(24):5566. https://doi.org/10.3390/polym14245566

Chicago/Turabian StyleOgunleye, Raphael Olabanji, Sona Rusnakova, Milan Zaludek, and Samuel Emebu. 2022. "The Influence of Ply Stacking Sequence on Mechanical Properties of Carbon/Epoxy Composite Laminates" Polymers 14, no. 24: 5566. https://doi.org/10.3390/polym14245566

APA StyleOgunleye, R. O., Rusnakova, S., Zaludek, M., & Emebu, S. (2022). The Influence of Ply Stacking Sequence on Mechanical Properties of Carbon/Epoxy Composite Laminates. Polymers, 14(24), 5566. https://doi.org/10.3390/polym14245566