Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesize and Composite Preparation

2.3. Characterization

3. Results and Discussion

3.1. Structure of Graphite Powders

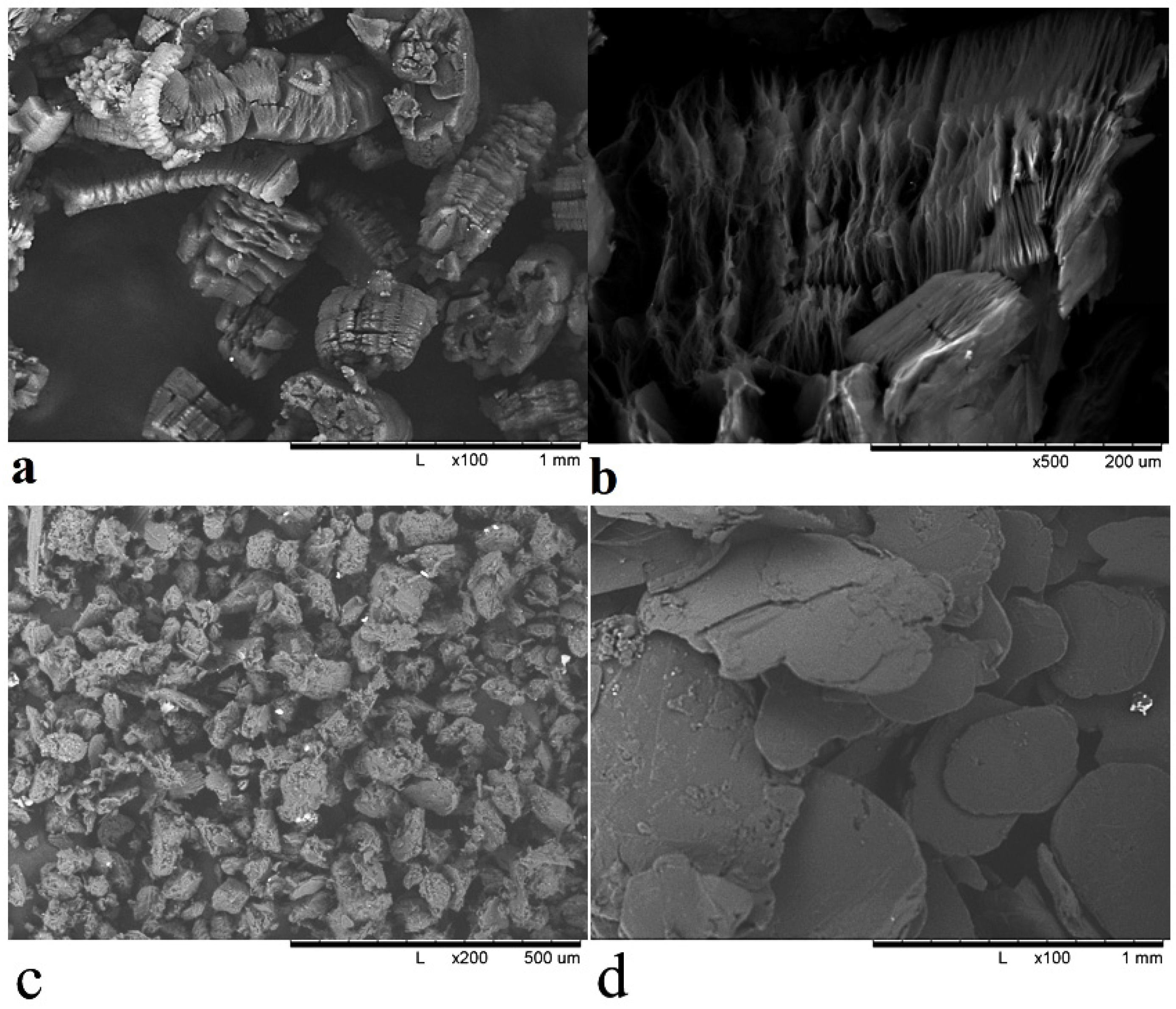

3.1.1. Morphology and Microstructure

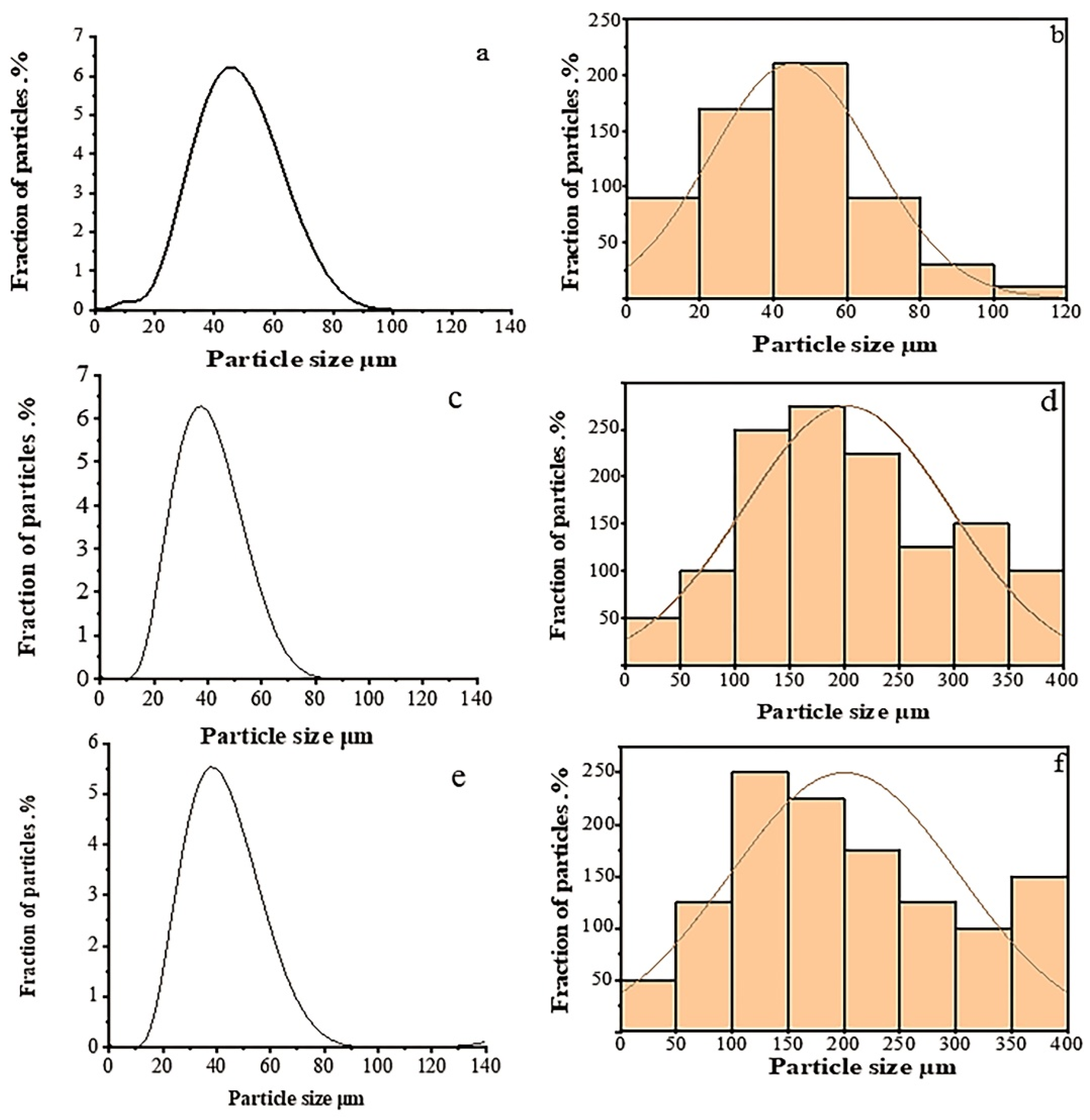

3.1.2. Particle Size Analysis

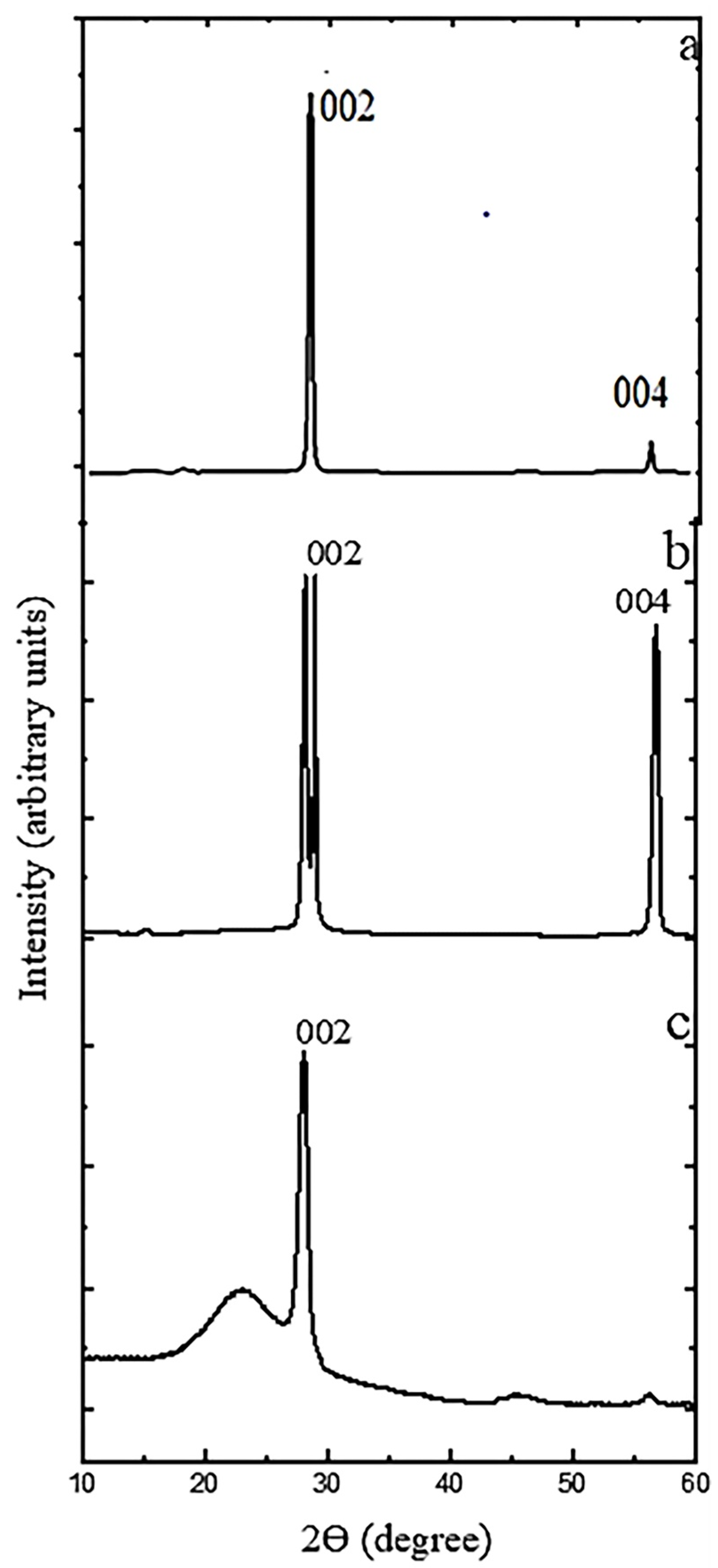

3.1.3. X-ray Diffraction

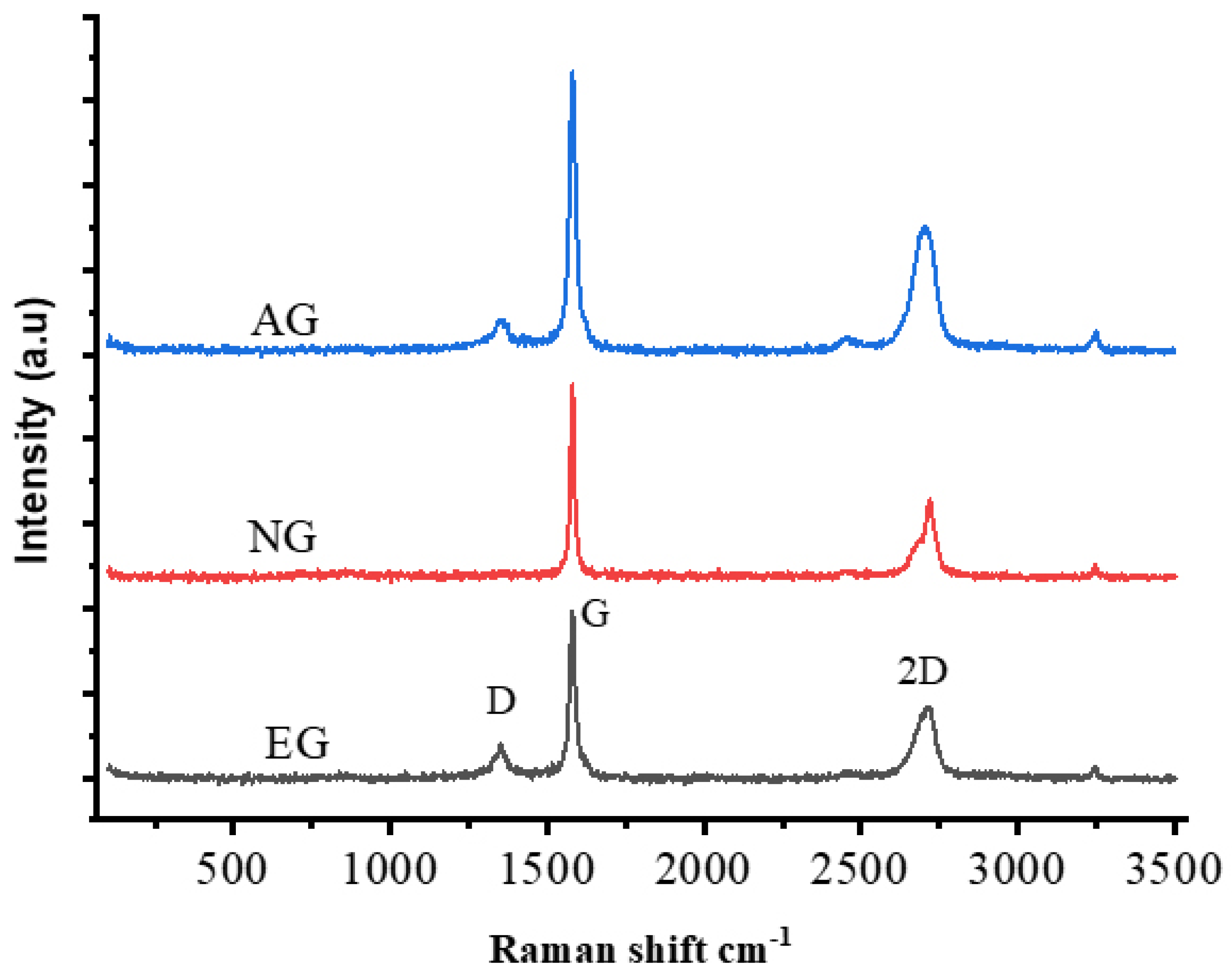

3.1.4. Raman Spectroscopy

3.1.5. Summary

3.2. Polysulfone-Based Composites

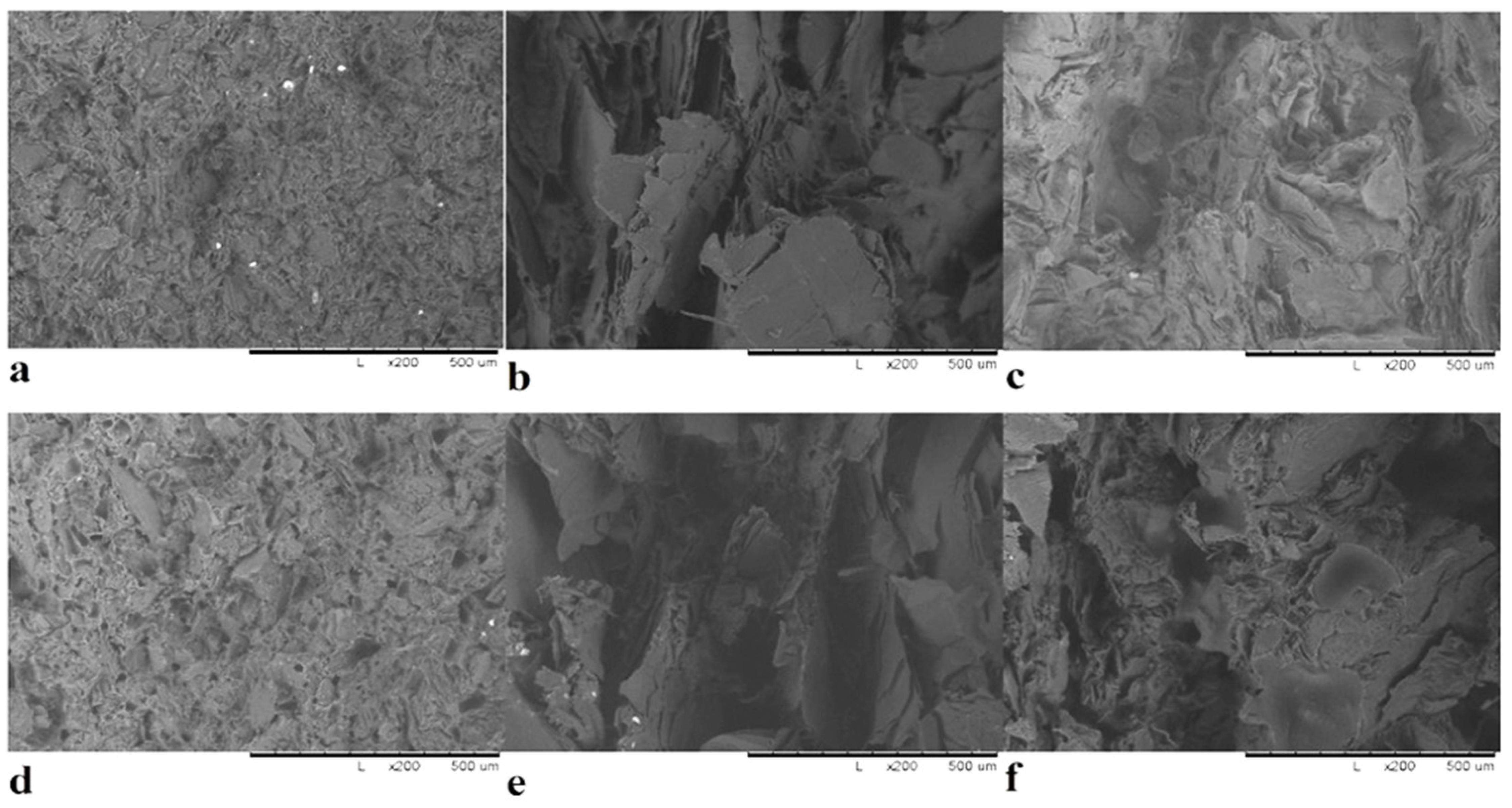

3.2.1. Microstructure

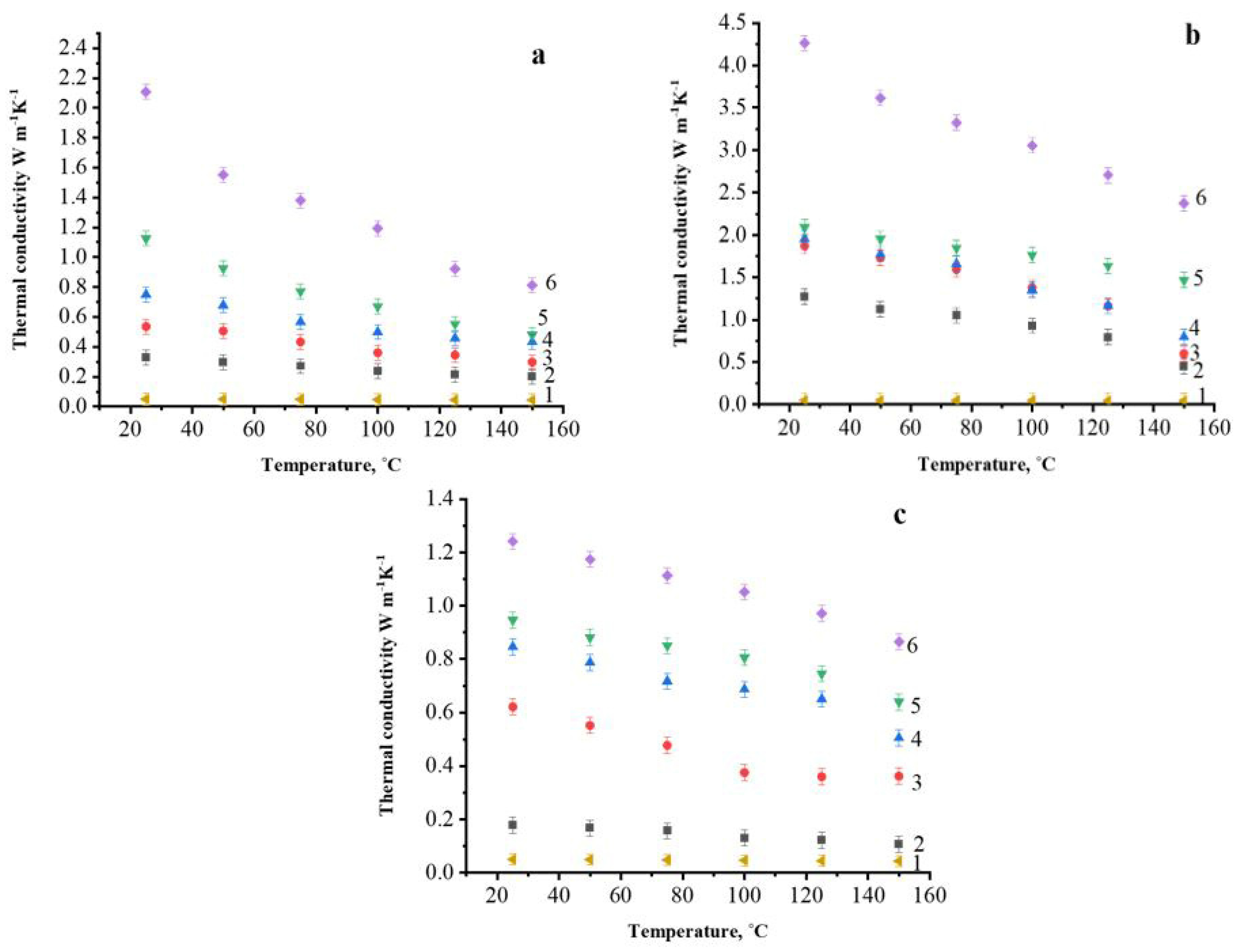

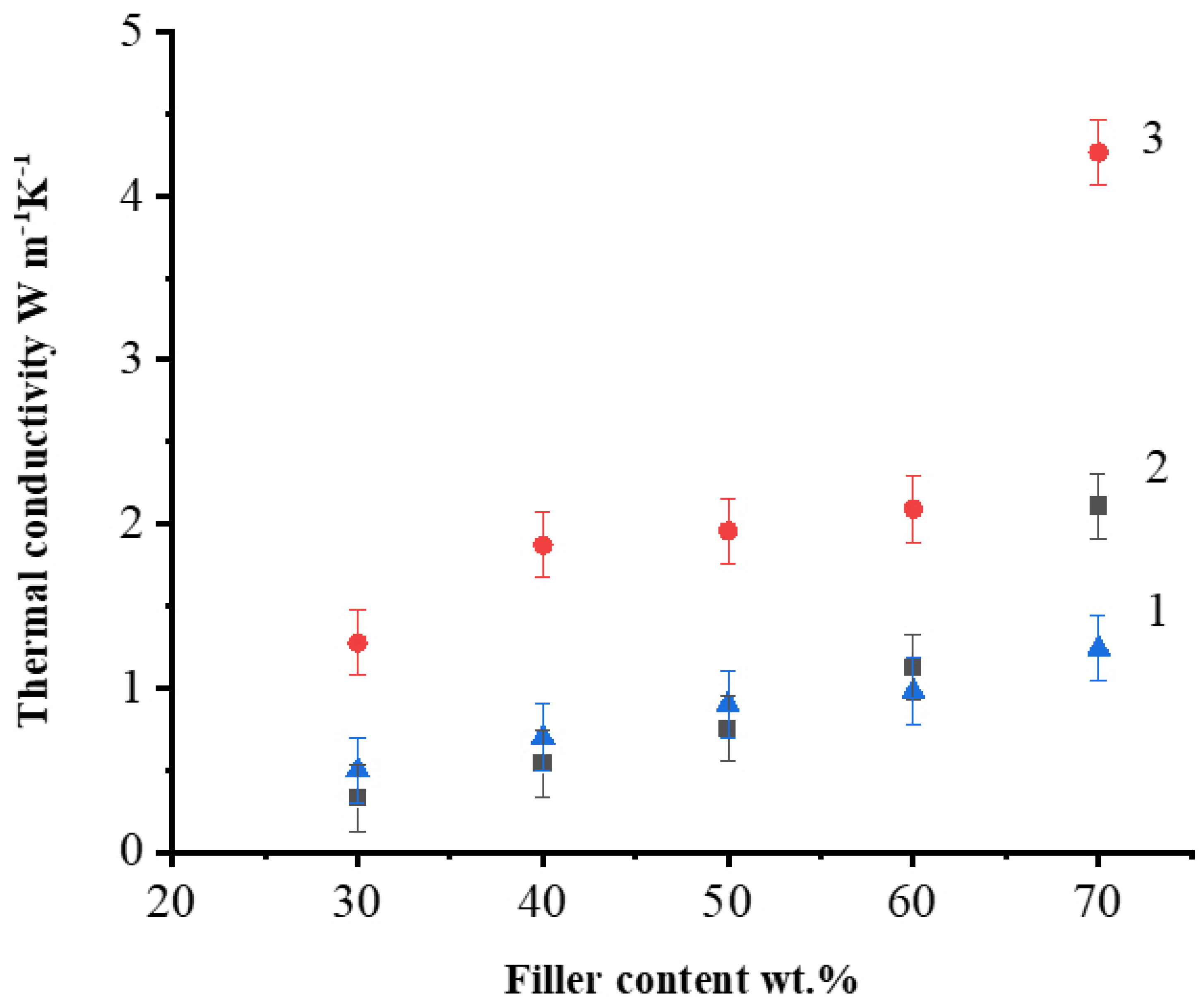

3.2.2. Thermal Conductivity

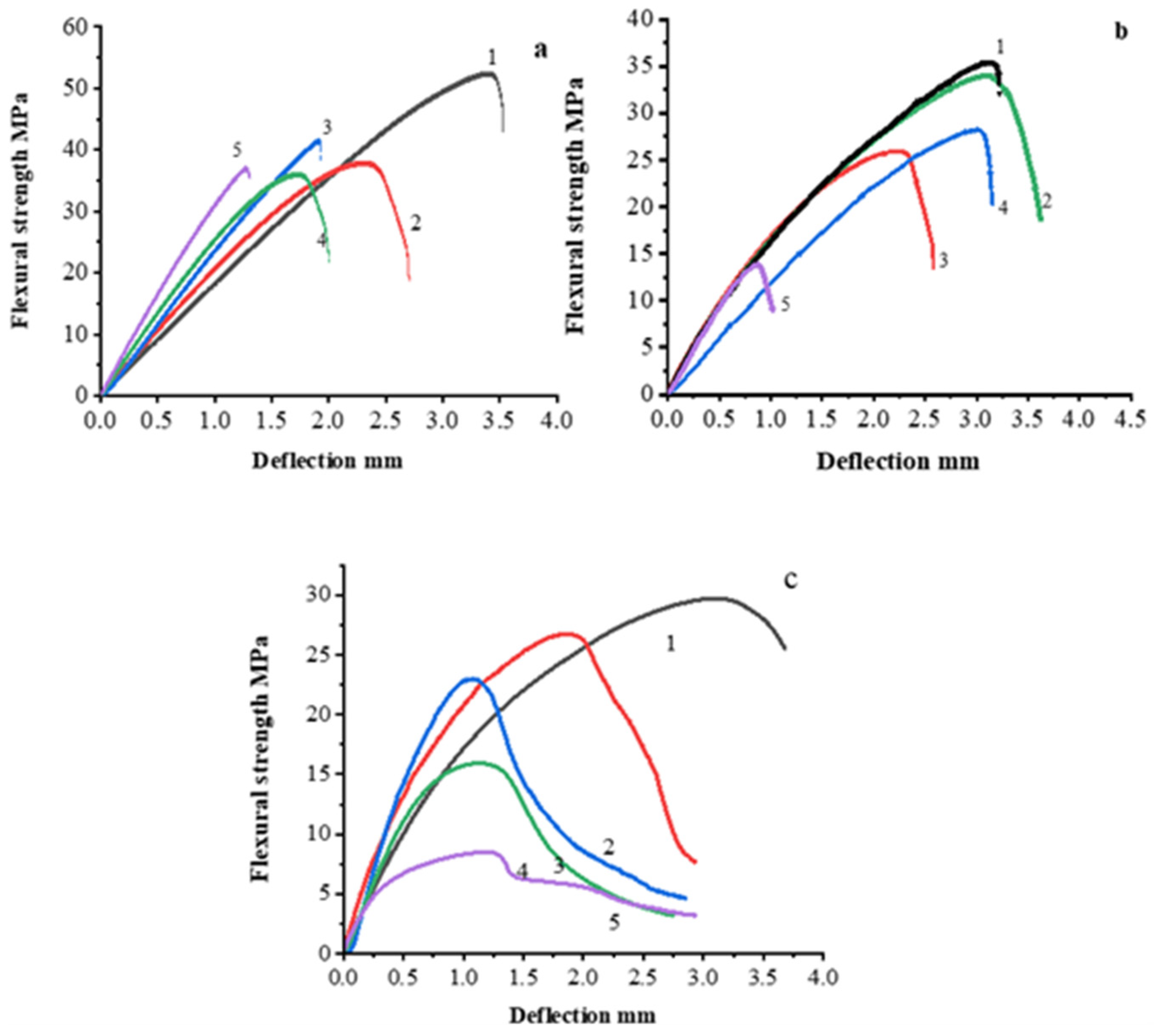

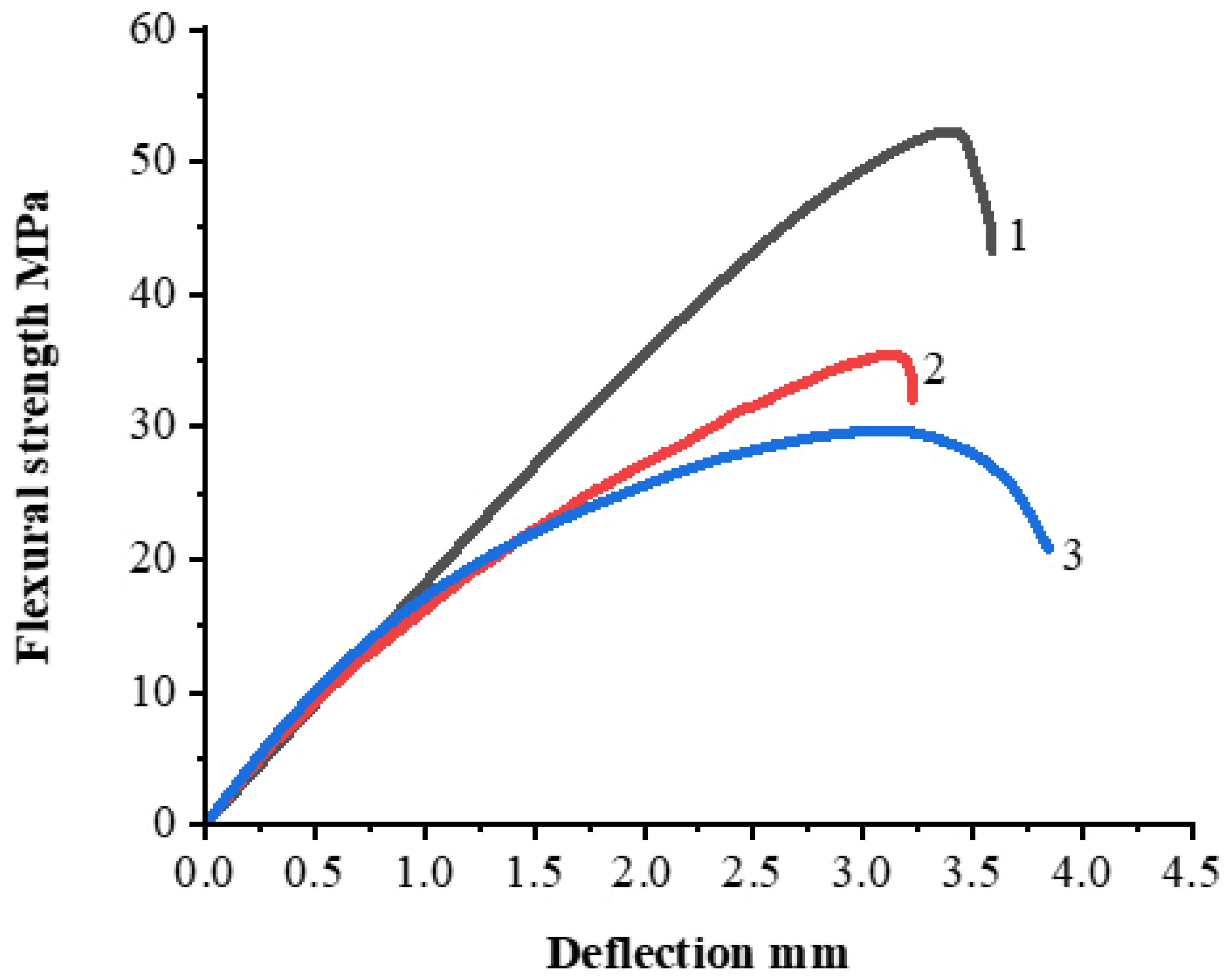

3.2.3. Mechanical Test

4. Summary and Conclusions

- Using solution-casting technology allows for the manufacturing of polysulfone-based composite with up to 70% filling of graphite particles and guarantees that they are distributed uniformly throughout the material. The produced press material can be used to manufacture products using the thermal pressing method, resulting in composites with a PSU matrix and a high filler content made from graphite materials;

- With the proposed technology, the thermal conductivity coefficient of a polysulfone-based material using natural graphite as a filler was increased to 4.26 W/m K while maintaining an acceptable degree of mechanical strength;

- Structural defect and the appearance of pores affected on both thermal and mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-Based Composites: An Indispensable Material for Present and Future Applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Wang, R.-M.; Zheng, S.R.; Zheng, Y.P. Polymer Matrix Composites and Technology; Science Press: Beijing, China, 2011; pp. 1–548. [Google Scholar]

- Sani, E.; Vallejo, J.P.; Cabaleiro, D.; Lugo, L. Functionalized graphene nanoplatelet-nanofluids for solar thermal collectors. Sol. Energy Mater. Sol. Cells 2018, 185, 205–209. [Google Scholar] [CrossRef]

- Selvakumar, N.; Biswas, A.; Krupanidhi, S.; Barshilia, H. Enhanced optical absorption of graphene-based heat mirror with tunable spectral selectivity. Sol. Energy Mater. Sol. Cells 2018, 186, 149–153. [Google Scholar] [CrossRef]

- Vaqueiro-Contreras, M.; Bartlam, C.; Bonilla, R.; Markevich, V.; Halsall, M.; Vijayaraghavan, A.; Peaker, A. Graphene oxide films for field effect surface passivation of silicon for solar cells. Sol. Energy Mater. Sol. Cells 2018, 187, 189–193. [Google Scholar] [CrossRef]

- Teng, C.C.; Ma, C.C.M.; Lu, C.H.; Yang, S.Y.; Lee, S.H.; Hsiao, M.C.; Yen, M.Y.; Chiou, K.C.; Lee, T.M. Thermal conductivity and structure of non-covalentfunctionalized graphene/epoxy composites. Carbon 2011, 49, 5107–5116. [Google Scholar] [CrossRef]

- Hofmann, D.; Thomann, R.; Mülhaupt, R. Thermoplastic SEBS Elastomer Nanocomposites Reinforced with Functionalized Graphene Dispersions. Macromol. Mater. Eng. 2017, 303, 1700324. [Google Scholar] [CrossRef]

- Alemour, B.; Badran, O.; Hassan, M.R. A Review of Using Conductive Composite Materials in Solving Lightening Strike and Ice Accumulation Problems in Aviation. J. Aerosp. Technol. Manag. 2019, 11, 1019. [Google Scholar] [CrossRef]

- Gao, W.; Majumder, M.; Alemany, L.B.; Narayanan, T.N.; Ibarra, M.A.; Pradhan, B.K.; Ajayan, P.M. Engineered Graphite Oxide Materials for Application in Water Purification. ACS Appl. Mater. Interfaces 2011, 3, 1821–1826. [Google Scholar] [CrossRef]

- Gohil, S.V.; Suhail, S.; Rose, J.; Vella, T.S.; Nair, L. Polymers and Composites for Orthopedic Applications. In Materials and Devices for Bone Disorders; Bose, S., Bandyopadhyay, A., Eds.; Elsevier/Academic Press: Amsterdam, The Netherlands, 2016; pp. 349–403. [Google Scholar] [CrossRef]

- Kyriacos, D. High-Temperature Engineering Thermoplastics. In Brydson’s Plastics Materials; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 545–615. [Google Scholar]

- Wu, N.; Che, S.; Li, H.-W.; Wang, C.-N.; Tian, X.-J.; Li, Y.-F. A review of three-dimensional graphene networks for use in thermally conductive polymer composites: Construction and applications. New Carbon Mater. 2021, 36, 911–926. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, H.; Fu, Q. Recent progress on thermal conductive and electrical insulating polymer composites. Compos. Commun. 2018, 8, 74–82. [Google Scholar] [CrossRef]

- Huang, X.; Zhi, C.; Lin, Y.; Bao, H.; Wu, G.; Jiang, P.; Mai, Y.-W. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R Rep. 2020, 142, 100577. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Qin, M.; Gao, L.; Li, Z.; Zhao, F.; Zhang, Z.; Lv, F.; Feng, W. Stress Controllability in Thermal and Electrical Conductivity of 3D Elastic Graphene-Crosslinked Carbon Nanotube Sponge/Polyimide Nanocomposite. Adv. Funct. Mater. 2019, 29, 1901383. [Google Scholar] [CrossRef]

- Qin, M.; Xu, Y.; Cao, R.; Feng, W.; Chen, L. Efficiently controlling the 3D thermal conductivity of a polymer nanocomposite via a hyperelastic double-continuous network of graphene and sponge. Adv. Funct. Mater. 2018, 28, 1805053. [Google Scholar] [CrossRef]

- Lewis, J.S.; Perrier, T.; Mohammadzadeh, A.; Kargar, F.; Balandin, A.A. Power Cycling and Reliability Testing of Epoxy-Based Graphene Thermal Interface Materials. C 2020, 6, 26. [Google Scholar] [CrossRef]

- Sudhindra, S.; Kargar, F.; Balandin, A.A. Noncured Graphene Thermal Interface Materials for High-Power Electronics: Minimizing the Thermal Contact Resistance. Nanomaterials 2021, 11, 1699. [Google Scholar] [CrossRef]

- Balandin, A.A. Phononics of Graphene and Related Materials. ACS Nano 2020, 14, 5170–5178. [Google Scholar] [CrossRef]

- Lewis, J.S.; Perrier, T.; Barani, Z.; Kargar, F.; Balandin, A.A. Thermal interface materials with graphene fillers: Review of the state of the art and outlook for future applications. Nanotechnology 2021, 32, 142003. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. Emerging trends in poly(methyl methacrylate) containing carbonaceous reinforcements—Carbon nanotube, carbon black, and carbon fiber. J. Plast. Film Sheeting 2020, 36, 409–429. [Google Scholar] [CrossRef]

- Zhang, S.M.; Lin, L.; Deng, H.; Gao, X.; Bilotti, E.; Peijs, T.; Zhang, Q.; Fu, Q. Synergistic effect in conductive networks constructed with carbon nanofillers in different dimensions. Express Polym. Lett. 2012, 6, 159–168. [Google Scholar] [CrossRef] [Green Version]

- Deng, H.; Skipa, T.; Bilotti, E.; Zhang, R.; Lellinger, D.; Mezzo, L.; Fu, Q.; Alig, I.; Peijs, T. Preparation of High-Performance Conductive Polymer Fibers through Morphological Control of Networks Formed by Nanofillers. Adv. Funct. Mater. 2010, 20, 1424–1432. [Google Scholar] [CrossRef]

- Wiemann, K.; Kaminsky, W.; Gojny, F.H.; Schulte, K. Synthesis and properties of syndiotactic poly(propylene)/carbon nanofiber and nanotube composites prepared by in situ polymerization with metallocene/MAO catalysts. Macromol. Chem. Phys. 2005, 206, 1472–1478. [Google Scholar] [CrossRef]

- Ray, M.; George, J.J.; Chakraborty, A.; Bhowmick, A.K. An Investigation of the Electromagnetic Shielding Effectiveness of Ethylene Vinyl Acetate Elastomer Reinforced with Carbon Nanofillers. Polym. Polym. Compos. 2010, 18, 59–65. [Google Scholar] [CrossRef]

- Marischal, L.; Cayla, A.; Lemort, G.; Campagne, C.; Devaux, E.; Éric, D. Influence of melt spinning parameters on electrical conductivity of carbon fillers filled polyamide 12 composites. Synth. Met. 2018, 245, 51–60. [Google Scholar] [CrossRef]

- Dorigato, A.; Brugnara, M.; Pegoretti, A. Novel polyamide 12 based nanocomposites for industrial applications. J. Polym. Res. 2017, 24, 96. [Google Scholar] [CrossRef]

- Pokharel, P.; Xiao, D.; Erogbogbo, F.; Keles, O.; Lee, D.S. A hierarchical approach for creating electrically conductive network structure in polyurethane nanocomposites using a hybrid of graphene nanoplatelets, carbon black and multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 161, 169–182. [Google Scholar] [CrossRef]

- Pech-Pisté, R.; Cen-Puc, M.; Balam, A.; May-Pat, A.; Avilés, F. Multifunctional sensing properties of polymer nanocomposites based on hybrid carbon nanostructures. Mater. Today Commun. 2020, 25, 101472. [Google Scholar] [CrossRef]

- Youn, C.; Gong, D.L.; Yeo, S.Y. Artificial hair filaments with improved flame retardancy. J. Appl. Polym. Sci. 2021, 138, 50341. [Google Scholar] [CrossRef]

- Wasi, A.M.; Soren, K.; Dey, B.; Khan, M.S.; Choudhury, A. Synergistic reinforcement effect of 3D graphene@multi-walled carbon nanotube hybrid nanofiller in enhancing the electrical, EMI-shielding, and mechanical properties of polyethersulfone. Int. J. Polym. Anal. Charact. 2021, 26, 754–771. [Google Scholar] [CrossRef]

- Kim, H.S.; Hyun, S.B.; Jaesang, Y.; Seong, Y.K. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef] [Green Version]

- Cho, E.C.; Huang, J.H.; Li, C.P.; Chang-Jian, C.W.; Lee, K.C.; Hsiao, Y.S.; Huang, J.H. Graphene-based thermoplastic composites and their application for LED thermal management. Carbon 2016, 102, 66–73. [Google Scholar] [CrossRef]

- Yin, H.; Gao, S.; Liao, C.; Li, C.; Cai, Z.; Xu, Y.; Liu, J. Self-assembly of 3D-graphite block infiltrated phase change materials with increased thermal conductivity. J. Clean. Prod. 2019, 235, 359–368. [Google Scholar] [CrossRef]

- Chung, S.; Kim, H.; Jeong, S.W. Improved thermal conductivity of carbon-based thermal interface materials by high-magnetic-field alignment. Carbon 2018, 140, 24–29. [Google Scholar] [CrossRef]

- Cobos, M.; De-La-Pinta, I.; Quindós, G.; Fernández, M.J.; Fernández, M.D. Synthesis, physical, mechanical, and antibacterial properties of nanocomposites based on poly (vinyl alcohol)/graphene oxide-silver nanoparticles. Polymers 2020, 12, 723. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.X.; He, Z.X.; Mo, D.C.; Lu, S.S. Thermal conductivity enhancement with different fillers for epoxy resin adhesives. Appl. Therm. Eng. 2014, 66, 493–498. [Google Scholar] [CrossRef]

- Lebedev, S.M.; Gefle, O.S. Evaluation of electric, morphological, and thermal properties of thermally conductive polymer composites. Appl. Therm. Eng. 2015, 91, 875–882. [Google Scholar] [CrossRef]

- Ye, C.M.; Shentu, B.Q.; Weng, Z.X. Thermal conductivity of high density polyethylene filled with graphite. J. Appl. Polym. Sci. 2006, 101, 3806–3810. [Google Scholar] [CrossRef]

- Wu, H.; Sun, X.; Zhang, W.; Zhang, X.; Lu, C. Effect of solid-state shear milling on the physico-chemical properties of thermally conductive low-temperature Expandable graphite/low-density polyethylene composite. Compos. Part A Appl. Sci. Manuf. 2013, 55, 27–34. [Google Scholar] [CrossRef]

- Wu, H.; Lu, C.; Zhang, W.; Zhang, X. Preparation of low-density polyethylene/low-temperature expandable graphite composites with high thermal conductivity by an in situ expansion melt blending process. Mater. Des. 2013, 52, 621–629. [Google Scholar] [CrossRef]

- Wang, Z.; Qi, R.; Wang, J.; Qi, S. Thermal conductivity improvement of epoxy composite filled with expanded graphite. Ceram. Int. 2015, 41, 13541–13546. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.B.; Yang, L.; Li, J.X.; Yang, L. Study on the preparation and properties of novolac epoxy/graphite composite bipolar plate for PEMFC. Int. J. Hydogen Energy 2010, 35, 3105–3109. [Google Scholar]

- Chukov, D.I.; Nematulloev, S.G.; Tcherdyntsev, V.V.; Torokhov, V.G.; Stepashkin, A.A.; Zadorozhnyy, M.Y.; Zherebtsov, D.D.; Sherif, G. Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics. Polymers 2019, 12, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Material | Shape | Scheme | Size | Crystalline Structure |

|---|---|---|---|---|

| AG | Nearly equiaxial |  | 20 to 60 µm | Defective crystalline graphite structure |

| NG | Flakes |  | D—200 to 500 µm h—15 to 20 µm | Perfect crystalline graphite structure |

| EG | Set of exfoliated flakes |  | D—200 to 500 µm w—100 to 300 µm h—35 to 50 nm | Defective crystalline graphite structure containing graphene layers |

| Composite | Filler Content | Thermal Conductivity W/m·K | Reference |

|---|---|---|---|

| LDPE/graphite | 10 vol.% | 6.5 | [38] |

| HDPE/graphite | 7 wt.% | 1.59 | [39] |

| LDPE/low-temperature Expandable graphite | 50 wt.% | 7.02 | [40] |

| LDPE/low-temperature Expandable graphite | 60 wt.% | 11.24 | [41] |

| Epoxy resin/graphite | 44.3 wt.% | 1.68 | [37] |

| Epoxy resin/graphite | 4.5 wt.% | 1.0 | [42] |

| Concentration wt.% | Maximum Flexural Strength MPa | Emodule GPa | Thermal Conductivity W·m−1·K−1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AG | NG | EG | AG | NG | EG | AG | NG | EG | |

| 30 | 52.3 ± 4.5 | 35.6 ± 4.6 | 29.7 ± 5.1 | 7.1 ± 0.7 | 9.1 ± 0.8 | 4.8 ± 5.9 | 0.3 ± 0.02 | 1.3 ± 0.06 | 0.2 ± 0.03 |

| 40 | 41.3 ± 4.3 | 28.3 ± 4.8 | 26.8 ± 4.3 | 5.7 ± 0.6 | 6.7 ± 0.6 | 3.9 ± 4.9 | 0.5 ± 0.03 | 1.8 ± 0.06 | 0.6 ± 0.04 |

| 50 | 41.4 ± 4.6 | 34.0 ± 5.3 | 23.0 ± 4.8 | 5.2 ± 0.5 | 5.9 ± 0.5 | 4.2 ± 5.8 | 0.7 ± 0.05 | 1.9 ± 0.07 | 0.8 ± 0.04 |

| 60 | 36.5 ± 4.5 | 33.1 ± 4.8 | 16.1 ± 5.6 | 4.6 ± 0.6 | 6.0 ± 0.9 | 3.4 ± 4.8 | 1.2 ± 0.09 | 2.1 ± 0.08 | 0.9 ± 0.05 |

| 70 | 36.9 ± 4.8 | 29.1 ± 5.7 | 12.0 ± 5.2 | 4.0 ± 0.3 | 4.9 ± 0.8 | 3.9 ± 4.7 | 2.1 ± 0.09 | 4.2 ± 0.09 | 1.2 ± 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammad, H.; Stepashkin, A.A.; Tcherdyntsev, V.V. Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites. Polymers 2022, 14, 399. https://doi.org/10.3390/polym14030399

Mohammad H, Stepashkin AA, Tcherdyntsev VV. Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites. Polymers. 2022; 14(3):399. https://doi.org/10.3390/polym14030399

Chicago/Turabian StyleMohammad, Hussam, Andrey A. Stepashkin, and Victor V. Tcherdyntsev. 2022. "Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites" Polymers 14, no. 3: 399. https://doi.org/10.3390/polym14030399

APA StyleMohammad, H., Stepashkin, A. A., & Tcherdyntsev, V. V. (2022). Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites. Polymers, 14(3), 399. https://doi.org/10.3390/polym14030399