In Situ Characterization of the Reaction-Diffusion Behavior during the Gradient Interphase Formation of Polyetherimide with a High-Temperature Epoxy System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Optical Hot-Stage Microscopy Coupled with a Point Tracker Algorithm

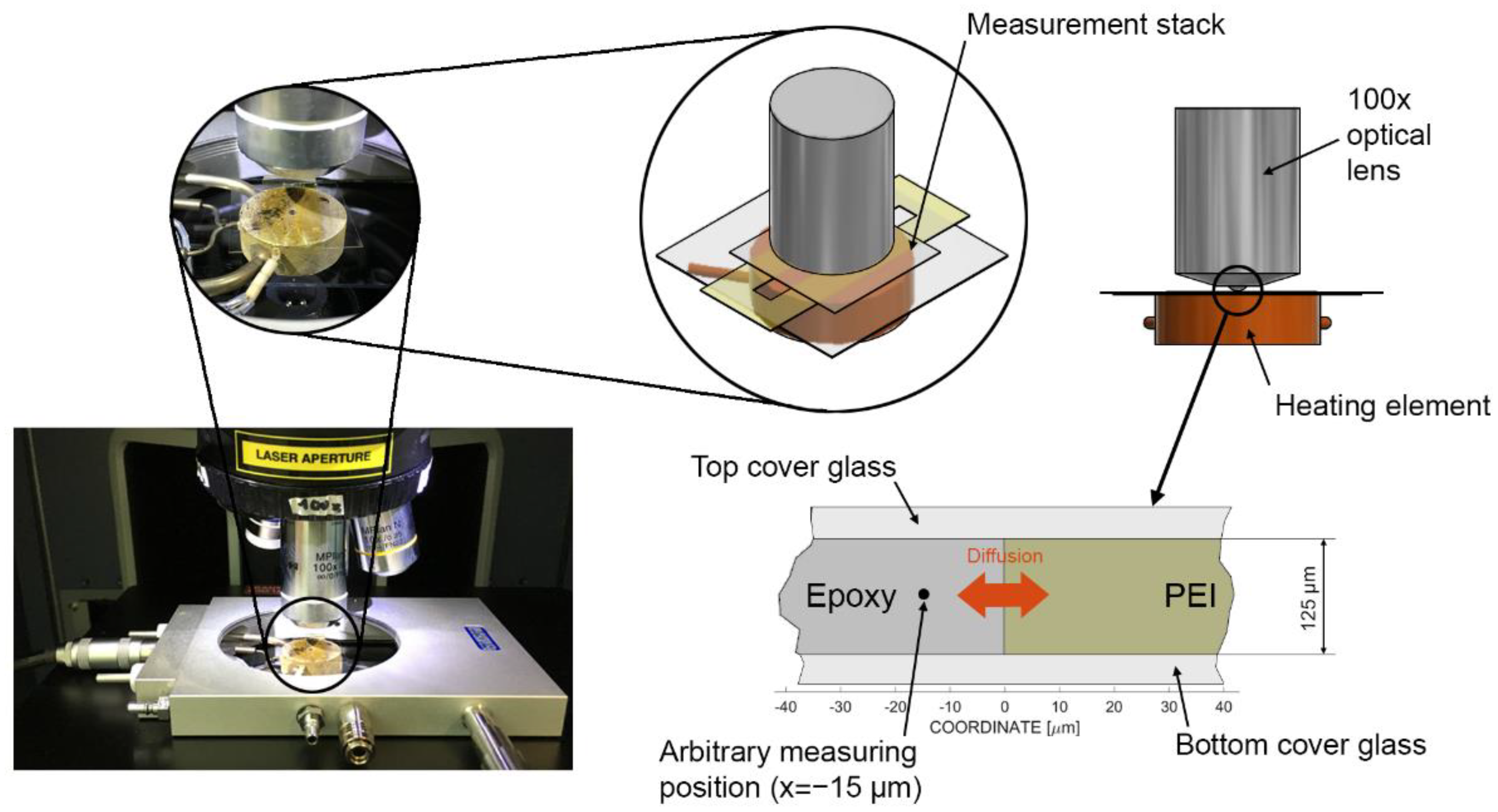

2.3. Raman Spectroscopy Coupled with In Situ Hot Stage Microscopy

3. Results

3.1. Mono and Multicomponent Diffusion Experiments with Optical Hot Stage Microscopy

3.2. Mono and Reactive Multicomponent Diffusion Experiments with Raman Spectroscopy

4. Discussion

4.1. Detailed Analysis of Reactive Multicomponent Diffusion from the Epoxy System into PEI

4.2. Comparison of Optical and Spectral Experimental Monocomponent Diffusion Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Starke, J. Carbon Composites in Automotive Structural Applications. Available online: https://cutt.ly/CteyLEP (accessed on 15 December 2021).

- Meng, F.; Pickering, S.J.; Mckechnie, J. An Environmental Comparison of Carbon Fibre Composite Waste End-of-life Options. In Proceedings of the SAMPE Europe Conference 2018, Southampton, UK, 11–13 September 2018. [Google Scholar]

- Favaloro, M. Thermoplastic Composites in Aerospace–the Future Looks Bright. Available online: https://www.compositesworld.com/articles/thermoplastic-composites-in-aerospace-past-present-and-future (accessed on 15 December 2021).

- Farooq, U.; Teuwen, J.; Dransfeld, C. Toughening of Epoxy Systems with Interpenetrating Polymer Network (IPN): A Review. Polymers 2020, 12, 1908. [Google Scholar] [CrossRef] [PubMed]

- Hodgkin, J.H.; Simon, G.P.; Varley, R.J. Thermoplastic toughening of epoxy resins: A critical review. Polym. Adv. Technol. 1998, 9, 3–10. [Google Scholar] [CrossRef]

- Mimura, K.; Ito, H.; Fujioka, H. Improvement of thermal and mechanical properties by control of morphologies in PES-modified epoxy resins. Polymer 2000, 41, 4451–4459. [Google Scholar] [CrossRef]

- Turmel, D.-P.; Partridge, I. Heterogeneous phase separation around fibres in epoxy/PEI blends and its effect on composite delamination resistance. Compos. Sci. Technol. 1997, 57, 1001–1007. [Google Scholar] [CrossRef]

- Van Velthem, P.; Ballout, W.; Daoust, D.; Sclavons, M.; Cordenier, F.; Henry, E.; Dumont, D.; Destoop, V.; Pardoen, T.; Bailly, C. Influence of thermoplastic diffusion on morphology gradient and on delamination toughness of RTM-manufactured composites. Compos. Part A Appl. Sci. Manuf. 2015, 72, 175–183. [Google Scholar] [CrossRef]

- Farooq, U.; Heuer, S.; Teuwen, J.; Dransfeld, C. Effect of a Dwell Stage in the Cure Cycle on the Interphase Formation in a Poly(ether imide)/High Tg Epoxy System. ACS Appl. Polym. Mater. 2021. [Google Scholar] [CrossRef]

- Lipatov, Y.S.; Alekseeva, T.T. Phase-Separated Interpenetrating Polymer Networks, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 6–214. [Google Scholar] [CrossRef]

- Villegas, I.F.; Van Moorleghem, R. Ultrasonic welding of carbon/epoxy and carbon/PEEK composites through a PEI thermoplastic coupling layer. Compos. Part A Appl. Sci. Manuf. 2018, 109, 75–83. [Google Scholar] [CrossRef]

- Brauner, C.; Nakouzi, S.; Zweifel, L.; Tresch, J. Co-curing behaviour of thermoset composites with a thermoplastic boundary layer for welding purposes. Adv. Compos. Lett. 2020, 29. [Google Scholar] [CrossRef] [Green Version]

- Stavrov, D.; Bersee, H. Resistance welding of thermoplastic composites-an overview. Compos. Part A Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Villegas, I.F.; Benedictus, R. Investigation on energy director-less ultrasonic welding of polyetherimide (PEI)- to epoxy-based composites. Compos. Part B Eng. 2019, 173, 107014. [Google Scholar] [CrossRef]

- Deng, S.; Djukic, L.; Paton, R.; Ye, L. Thermoplastic–epoxy interactions and their potential applications in joining composite structures–A review. Compos. Part A Appl. Sci. Manuf. 2015, 68, 121–132. [Google Scholar] [CrossRef]

- Quan, D.; Alderliesten, R.; Dransfeld, C.; Tsakoniatis, I.; Benedictus, R. Co-cure joining of epoxy composites with rapidly UV-irradiated PEEK and PPS composites to achieve high structural integrity. Compos. Struct. 2020, 251, 112595. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Benedictus, R.; Villegas, I.F. On the sensitivity of the ultrasonic welding process of epoxy- to polyetheretherketone (PEEK)-based composites to the welding force and amplitude of vibrations. Compos. Part C Open Access 2021, 5, 100141. [Google Scholar] [CrossRef]

- Shi, H.; Sinke, J.; Benedictus, R. Surface modification of PEEK by UV irradiation for direct co-curing with carbon fibre reinforced epoxy prepregs. Int. J. Adhes. Adhes. 2017, 73, 51–57. [Google Scholar] [CrossRef]

- Vandi, L.J.; Hou, M.; Veidt, M.; Truss, R.; Heitzmann, M.; Paton, R. Interface diffusion and morphology of aerospace grade epoxy co-cured with thermoplastic polymers. In Proceedings of the 28th Congress of the International Council of the Aeronautical Sciences 2012, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Zweifel, L.; Brauner, C. Investigation of the interphase mechanisms and welding behaviour of fast-curing epoxy based composites with co-cured thermoplastic boundary layers. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106120. [Google Scholar] [CrossRef]

- Zweifel, L.; Brunner, J.; Brauner, C.; Dransfeld, C. Development of a resistance welding process for thermoset fiber composite components with co-cured thermoplastic boundary layer. In Proceedings of the European Conference of Composite Materials 2018, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Shi, H. Resistance Welding of Thermoplastic Composites: Process and Performance. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, November 2014. [Google Scholar] [CrossRef]

- Jongbloed, B.; Teuwen, J.; Benedictus, R.; Villegas, I.F. On differences and similarities between static and continuous ultrasonic welding of thermoplastic composites. Compos. Part B Eng. 2020, 203, 108466. [Google Scholar] [CrossRef]

- Teuwen, J.J.E.; Asquier, J.; Inderkum, P.; Masania, K.; Brauner, C.; Villegas, I.F.; Dransfeld, C. Gradient interphases between high Tg epoxy and polyetherimide for advanced joining processes. In Proceedings of the European Conference of Composite Materials 2018, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Lestriez, B.; Chapel, J.-P.; Gérard, J.-F. Gradient Interphase between Reactive Epoxy and Glassy Thermoplastic from Dissolution Process, Reaction Kinetics, and Phase Separation Thermodynamics. Macromolecules 2001, 34, 1204–1213. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L. Resistance welding of thermosetting composite/thermoplastic composite joints. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1603–1612. [Google Scholar] [CrossRef]

- Taylor, R.; Krishna, R. Multicomponent Mass Transfer; Wiley: New York, NY, USA, 1983. [Google Scholar]

- Edwards, D.A. Non-Fickian diffusion in thin polymer films. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 981–997. [Google Scholar] [CrossRef]

- Yaneva, J.; Dünweg, B.; Milchev, A. Non-Fickian interdiffusion of dynamically asymmetric species: A molecular-dynamics study. J. Chem. Phys. 2005, 122, 2041051–2041056. [Google Scholar] [CrossRef] [Green Version]

- Thomas, N.; Windle, A. A theory of case II diffusion. Polymer 1982, 23, 529–542. [Google Scholar] [CrossRef]

- Dumont, D.; Seveno, D.; De Coninck, J.; Bailly, C.; Devaux, J.; Daoust, D. Interdiffusion of thermoplastics and epoxy resin precursors: Investigations using experimental and molecular dynamics methods. Polym. Int. 2012, 61, 1263–1271. [Google Scholar] [CrossRef]

- Bruckbauer, P. Struktur-Eigenschafts-Beziehungen von Interphasen zwischen Epoxidharz und Thermoplastischen Funktionsschichten für Faserverbundwerkstoffe. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2018. [Google Scholar]

- Munz, M.; Sturm, H.; Stark, W. Mechanical gradient interphase by interdiffusion and antiplasticisation effect—Study of an epoxy/thermoplastic system. Polymer 2005, 46, 9097–9112. [Google Scholar] [CrossRef]

- van Overbeke, E.; Devaux, J.; Legras, R.; Carter, J.; McGrail, P.; Carlier, V. Phase separation in epoxy-copolyethersulphone blends: Morphologies and local characterisation by micro-Raman spectroscopy. Polymer 2003, 44, 4899–4908. [Google Scholar] [CrossRef]

- Don, R.C.; Gillespie, J.W., Jr.; McKnight, S.H. Bonding Techniques for High Performance Thermoplastic Compositions. US Patent 5643390A; filed 4 May 1995, and issued 1 July 1997,

- Baij, L.; Hermans, J.J.; Keune, K.; Iedema, P.D. Time-Dependent ATR-FTIR Spectroscopic Studies on Solvent Diffusion and Film Swelling in Oil Paint Model Systems. Macromolecules 2018, 51, 7134–7144. [Google Scholar] [CrossRef]

- Elabd, Y.A.; Baschetti, M.G.; Barbari, T.A. Time-resolved Fourier transform infrared/attenuated total reflection spectroscopy for the measurement of molecular diffusion in polymers. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2794–2807. [Google Scholar] [CrossRef]

- Skourlis, T.P.; McCullough, R.L. Measurement of diffusivity of a liquid diamine in solid epoxies using attenuated total reflectance infrared spectroscopy (FTIR-ATR). J. Appl. Polym. Sci. 1994, 52, 1241–1248. [Google Scholar] [CrossRef]

- Rajagopalan, G.; Gillespie, J.; McKnight, S. Diffusion of reacting epoxy and amine monomers in polysulfone: A diffusivity model. Polymer 2000, 41, 7723–7733. [Google Scholar] [CrossRef]

- Rajagopalan, G. Diffusion of Reacting Thermosets into Thermoplastics. Ph.D. Thesis, University of Delaware, Delaware, NV, USA, 1998. [Google Scholar]

- Guerrero-Pérez, M.O.; Patience, G.S.; Bañares, M.A. Experimental methods in chemical engineering: Raman spectroscopy. Can. J. Chem. Eng. 2020, 99, 97–107. [Google Scholar] [CrossRef]

- Hess, C. New advances in using Raman spectroscopy for the characterization of catalysts and catalytic reactions. Chem. Soc. Rev. 2021, 50, 3519–3564. [Google Scholar] [CrossRef]

- Kaur, H.; Rana, B.; Tomar, D.; Kaur, S.; Jena, K.C. Fundamentals of ATR-FTIR Spectroscopy and Its Role for Probing In-Situ Molecular-Level Interactions. In Modern Techniques of Spectroscopy: Basics, Instrumentation, and Applications; Singh, D.K., Pradhan, M., Materny, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; Volume 13, pp. 3–37. [Google Scholar]

- De Luca, A.C.; Rusciano, G.; Pesce, G.; Caserta, S.; Guido, S.; Sasso, A. Diffusion in Polymer Blends by Raman Microscopy. Macromolecules 2008, 41, 5512–5514. [Google Scholar] [CrossRef]

- Mestl, G. In situ Raman spectroscopy–a valuable tool to understand operating catalysts. J. Mol. Catal. A Chem. 2000, 158, 45–65. [Google Scholar] [CrossRef]

- Huntsman Technical Data Sheet for Araldite MY 0610 Trifunctional Resin. Available online: https://adhesives.specialchem.com/product/p-huntsman-araldite-my-0610 (accessed on 15 December 2021).

- Cugnoni, J.; Amacher, R.; Kohler, S.; Brunner, J.; Kramer, E.; Dransfeld, C.; Smith, W.; Scobbie, K.; Sorensen, L.; Botsis, J. Towards aerospace grade thin-ply composites: Effect of ply thickness, fibre, matrix and interlayer toughening on strength and damage tolerance. Compos. Sci. Technol. 2018, 168, 467–477. [Google Scholar] [CrossRef]

- Sabic PEI ULTEM RESIN 1000. Available online: https://www.sabic.com/en/products/specialties/ultem-resins/ultem-resin (accessed on 15 December 2021).

- MATLAB—Tracking and Motion Estimation. Available online: https://ch.mathworks.com/help/vision/tracking-and-motionestimation.html (accessed on 15 December 2021).

- Shi, J.; Tomasi, C. Good features to track. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 21–23 June 1994. [Google Scholar]

- MATLAB—Documentation vision.PointTracker. Available online: https://www.mathworks.com/help/vision/ref/vision.pointtracker-system-object.html (accessed on 15 December 2021).

- Tomasi, C.; Kanada, T. Detection and Tracking of Point Features; Technical Report CMU-CS-91-132; School of Computer Science, Carnegie Mellon University: Pittsburgh, PA, USA, 1991. [Google Scholar]

- Lucas, B.D.; Kanade, T. Iterative Image Registration Technique with an Application to Stereo Vision. In Proceedings of the 7th International Joint Conference on Artificial Intelligence, Vancouver, Canada, 24–28 August 1981. [Google Scholar]

- Vandenabeele, P.; Jehlicka, J.; Vítek, P.; Edwards, H. On the definition of Raman spectroscopic detection limits for the analysis of biomarkers in solid matrices. Planet. Space Sci. 2011, 62, 48–54. [Google Scholar] [CrossRef]

- Zięba-Palus, J.; Michalska, A. Photobleaching as a useful technique in reducing of fluorescence in Raman spectra of blue automobile paint samples. Vib. Spectrosc. 2014, 74, 6–12. [Google Scholar] [CrossRef]

- Fujita, H. Comments on free volume theories for plymer—Solvent systems. Chem. Eng. Sci. 1993, 48, 3037–3042. [Google Scholar] [CrossRef]

- Miller-Chou, B.A.; Koenig, J.L. A review of polymer dissolution. Prog. Polym. Sci. 2003, 28, 1223–1270. [Google Scholar] [CrossRef] [Green Version]

- Hein, R. Vorhersage und In-Situ Bewertung Fertigungsbedingter Deformationen und Eigenspannungen von Kompositen. Ph.D. Thesis, Deutsches Zentrum für Luft–und Raumfahrt e.V., Braunschweig, Germany, 2019. [Google Scholar]

- Khoun, L.; Hubert, P. Cure shrinkage characterization of an epoxy resin system by two in situ measurement methods. Polym. Compos. 2009, 31, 1603–1610. [Google Scholar] [CrossRef]

- Lyon, R.E.; Chike, K.E.; Angel, S.M. In situ cure monitoring of epoxy resins using fiber-optic Raman spectroscopy. J. Appl. Polym. Sci. 1994, 53, 1805–1812. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop, J.L.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Laser | 785 nm | Hole | 500 μm |

| Filter | 50% | Slit | 100 μm |

| Lens | x100 | Range | 600–2000 cm−1 |

| Accumulations | 2 | Acquisition time | 2 s |

| Grafting | 1200 (750 nm) | Delay time | 0 s |

| Total time | 3000 s | Time interval | 30 s |

| Autofocus mode | Off | Repetitive mode | Off |

| Temperature (°C) | Maximum Diffusion Length of PEI (μm) | Maximum Diffusion Length of Epoxy (μm) | Interphase Thickness after Diffusion (μm) | Time at Max. Diffusion (min) | Measured Interphase of Cured Samples (μm) [9,24] |

|---|---|---|---|---|---|

| 200 | 29.89 | 17.39 | 47.29 | 1.95 | 82.3 |

| 180 | 28.40 | 16.95 | 45.36 | 4 | 80.7 |

| 160 | 25.89 | 15.31 | 41.21 | 7.5 | 62.2 |

| 140 | 23.81 | 10.71 | 34.52 | 18 | 50.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zweifel, L.; Brauner, C.; Teuwen, J.; Dransfeld, C. In Situ Characterization of the Reaction-Diffusion Behavior during the Gradient Interphase Formation of Polyetherimide with a High-Temperature Epoxy System. Polymers 2022, 14, 435. https://doi.org/10.3390/polym14030435

Zweifel L, Brauner C, Teuwen J, Dransfeld C. In Situ Characterization of the Reaction-Diffusion Behavior during the Gradient Interphase Formation of Polyetherimide with a High-Temperature Epoxy System. Polymers. 2022; 14(3):435. https://doi.org/10.3390/polym14030435

Chicago/Turabian StyleZweifel, Lucian, Christian Brauner, Julie Teuwen, and Clemens Dransfeld. 2022. "In Situ Characterization of the Reaction-Diffusion Behavior during the Gradient Interphase Formation of Polyetherimide with a High-Temperature Epoxy System" Polymers 14, no. 3: 435. https://doi.org/10.3390/polym14030435

APA StyleZweifel, L., Brauner, C., Teuwen, J., & Dransfeld, C. (2022). In Situ Characterization of the Reaction-Diffusion Behavior during the Gradient Interphase Formation of Polyetherimide with a High-Temperature Epoxy System. Polymers, 14(3), 435. https://doi.org/10.3390/polym14030435