Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate

Abstract

:1. Introduction

2. Experimental Setup

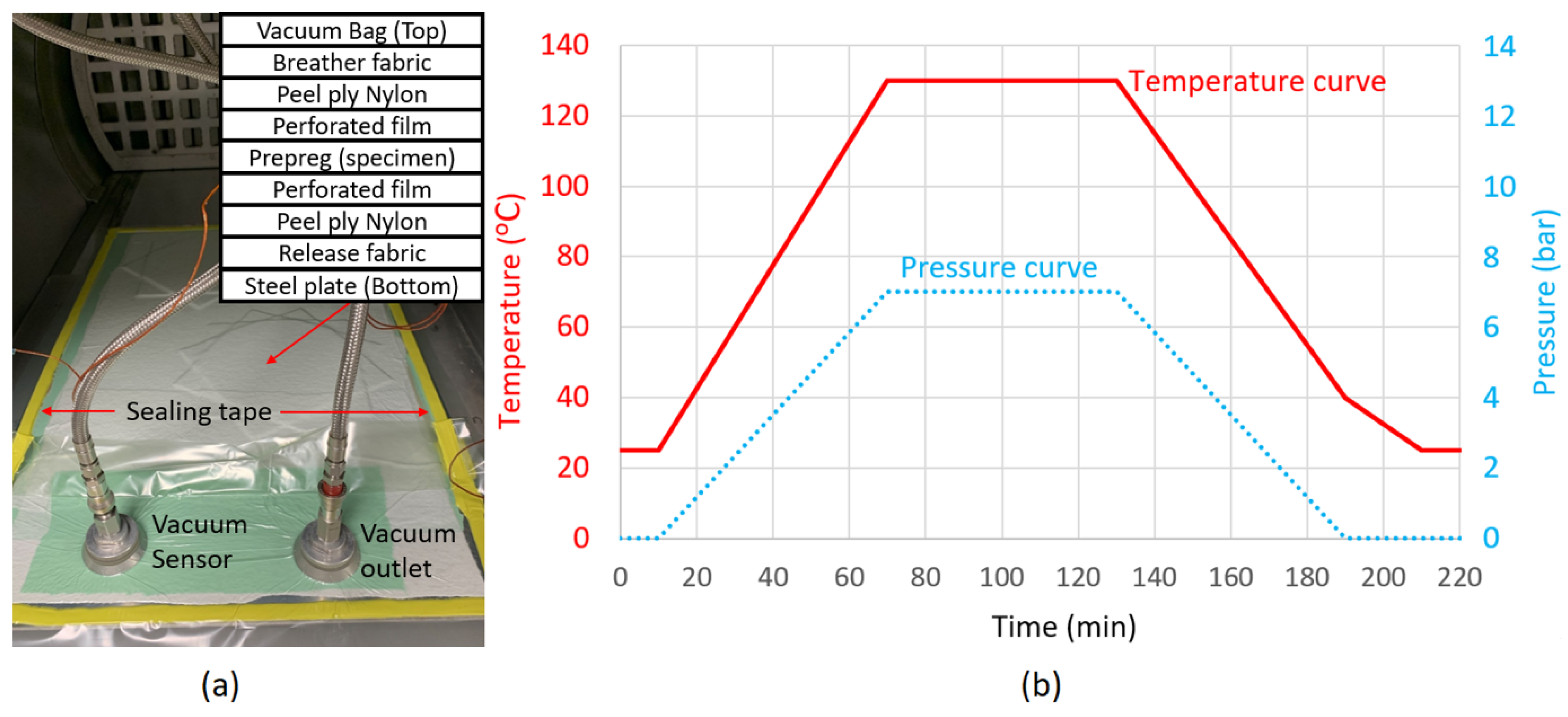

2.1. Fabrication Processes

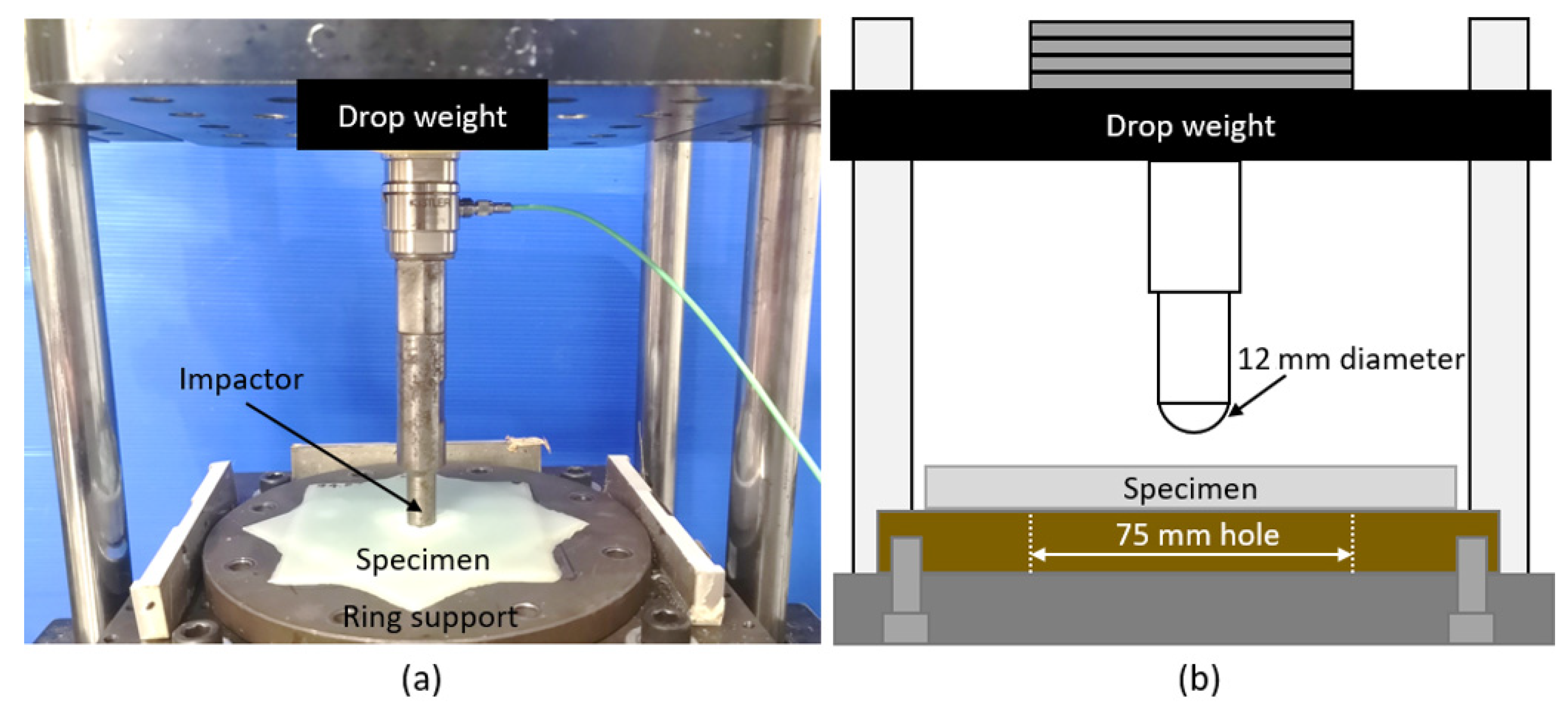

2.2. Perforation IMPACT Test

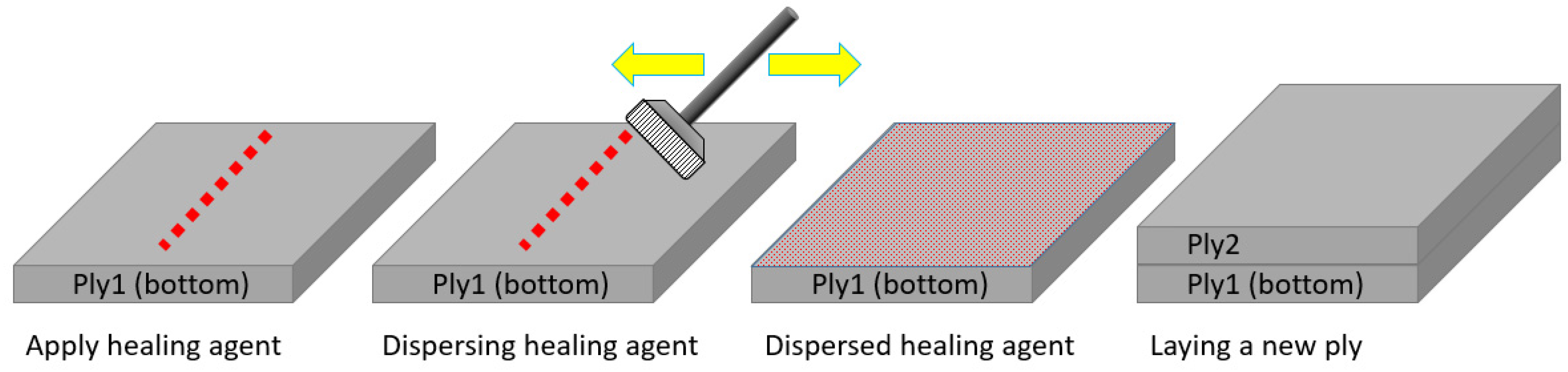

2.3. Fabrication Process of Healable Helicoidal GFRP Laminate

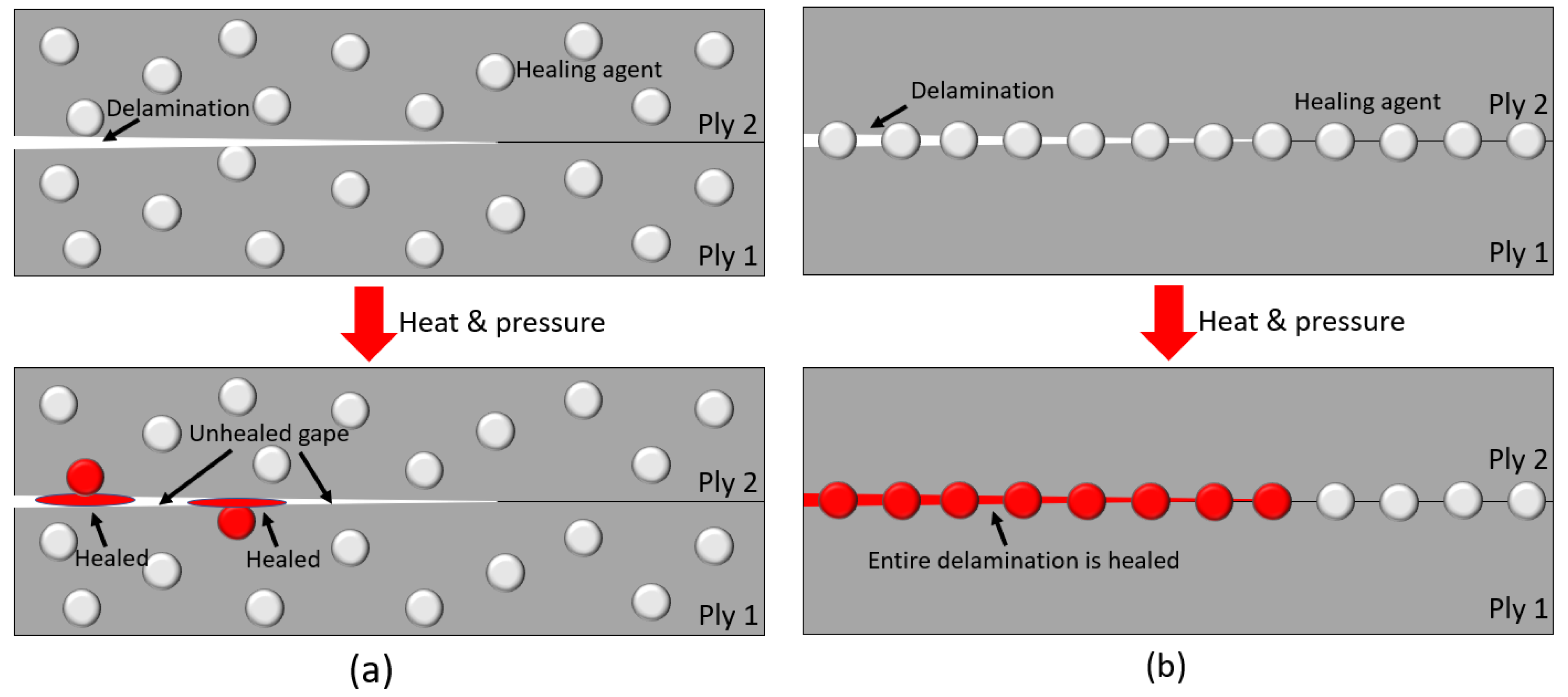

2.4. Impact and Healing of Helicoidal GFRP Laminate

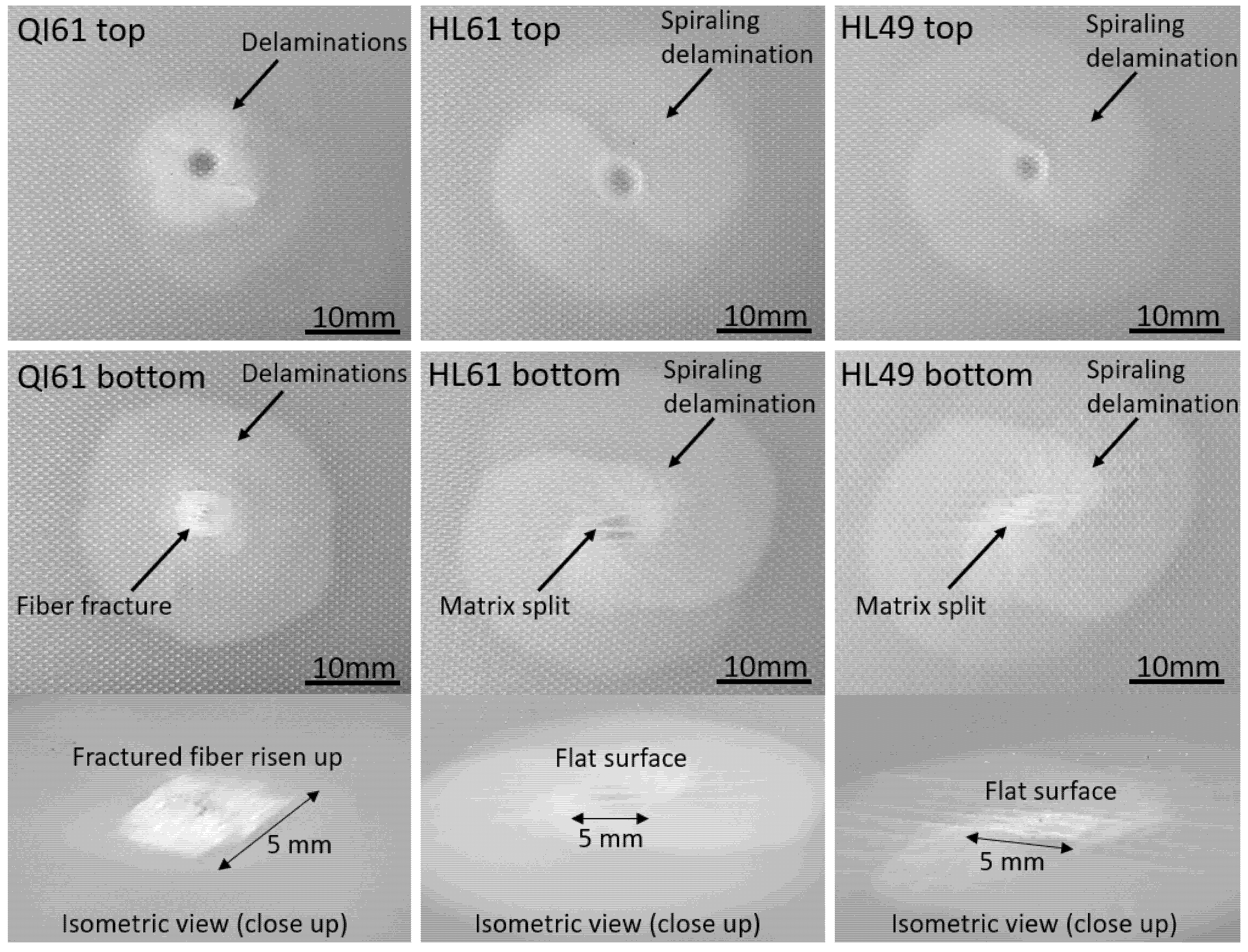

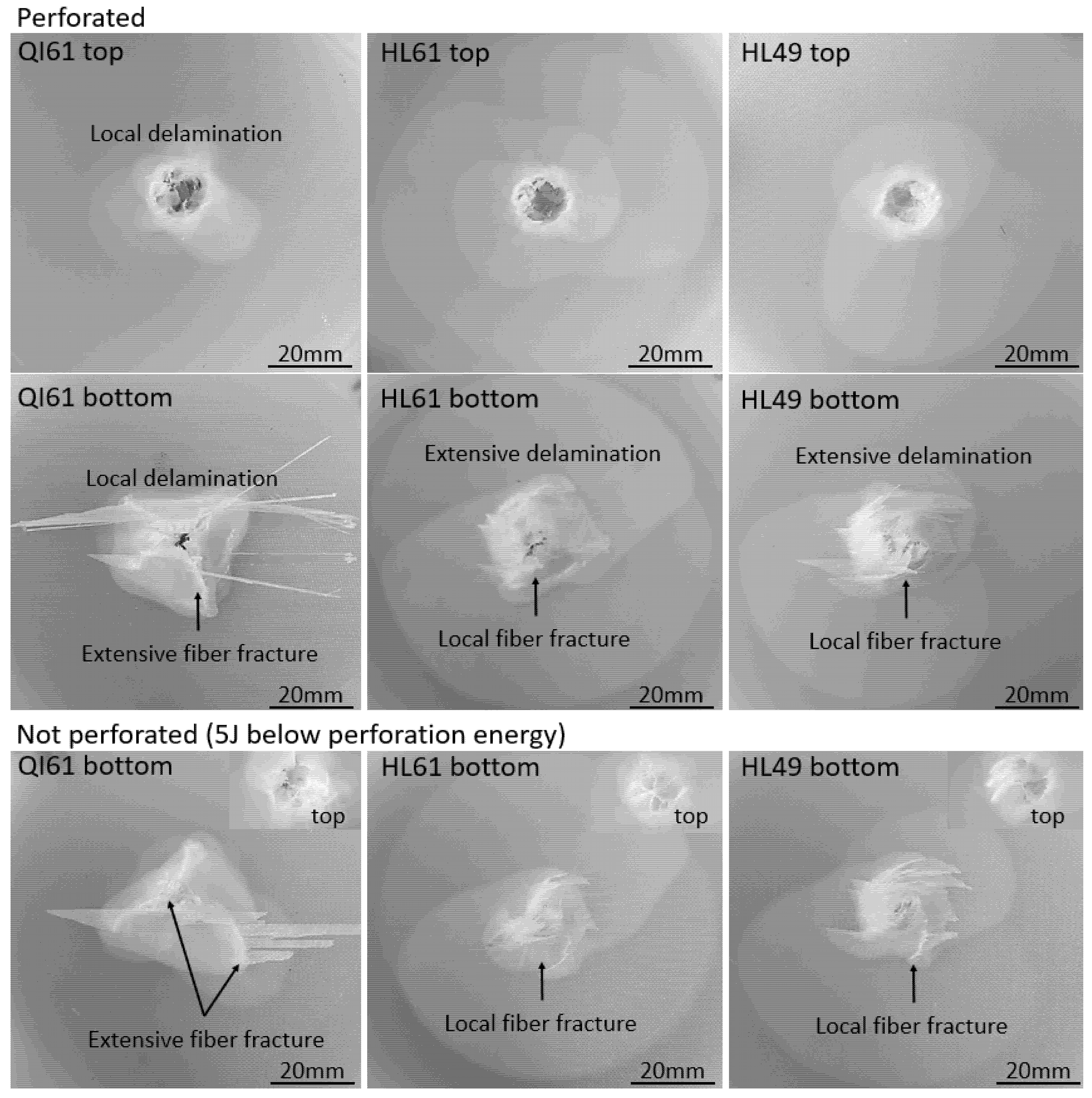

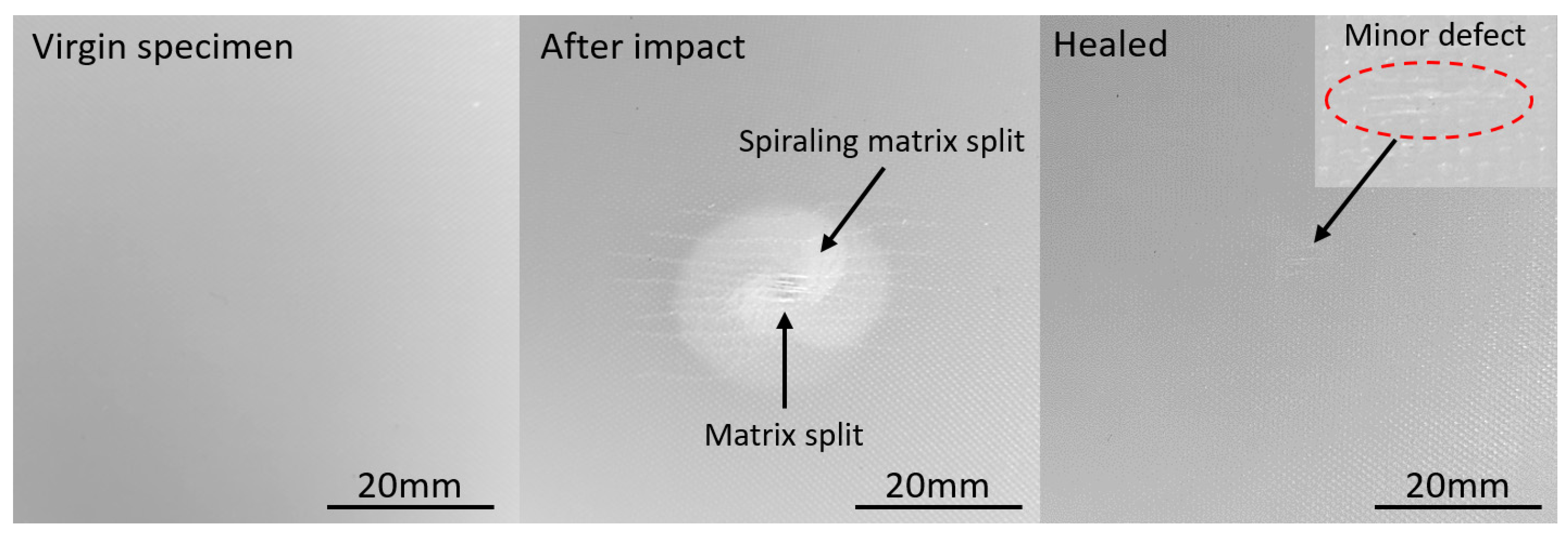

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomason, J.L. Glass fibre sizing: A review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Zisimopoulos, D.A. Use of Fiber Reinforced Plastics in Ship Construction: A Study of SOLAS Regulation II-2/17 on Alternative Design and Arrangementsfor Fire Safety. 2016. Available online: https://dspace.lib.ntua.gr/xmlui/handle/123456789/42464 (accessed on 15 December 2021).

- Park, C.K.; Kan, C.D.S.; Hollowell, W.T.; Hill, S.I. Investigation of Opportunities for Lightweight Vehicles Using Advanced Plastics and Composites. 2012. Available online: https://trid.trb.org/view/1226276 (accessed on 15 December 2021).

- Katnam, K.; Da Silva, L.; Young, T. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Prog. Aerosp. Sci. 2013, 61, 26–42. [Google Scholar] [CrossRef]

- Ozdemir, N.G.; Zhang, T.; Hadavinia, H.; Aspin, I.; Scarpa, F. Glass fibre reinforced polymer composites toughened with acrylonitrile butadiene nanorubber. Compos. Part B Eng. 2016, 88, 182–188. [Google Scholar] [CrossRef] [Green Version]

- Ngah, S.A.; Taylor, A.C. Toughening performance of glass fibre composites with core–shell rubber and silica nanoparticle modified matrices. Compos. Part A Appl. Sci. Manuf. 2016, 80, 292–303. [Google Scholar] [CrossRef]

- Singh, K.K.; Nanda, T.; Mehta, R. Addition of nanoclay and compatibilized EPDM rubber for improved impact strength of epoxy glass fiber composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 263–271. [Google Scholar] [CrossRef]

- Uribe, B.B.; Chiromito, E.; Carvalho, A.; Arenal, R.; Tarpani, J. TEMPO-oxidized cellulose nanofibers as interfacial strengthener in continuous-fiber reinforced polymer composites. Mater. Des. 2017, 133, 340–348. [Google Scholar] [CrossRef]

- Luo, G.; Liu, G.; Chen, Y.; Liang, W.; Liu, G.; Niu, Y.; Li, G. High performance glass fiber reinforced polypropylene realized by reactive extrusion technology. Compos. Sci. Technol. 2018, 165, 198–205. [Google Scholar] [CrossRef]

- Weaver, J.C.; Milliron, G.W.; Miserez, A.; Evans-Lutterodt, K.; Herrera, S.; Gallana, I.; Mershon, W.J.; Swanson, B.; Zavattieri, P.; DiMasi, E.; et al. The Stomatopod Dactyl Club: A Formidable Damage-Tolerant Biological Hammer. Science 2012, 336, 1275–1280. [Google Scholar] [CrossRef] [Green Version]

- Bouligand, Y. Sur une architecture torsadee repandue dans de nombreuses cuticules d’arthropodes. C. R. Acad. Sci. 1965, 261, 3665–3668. [Google Scholar]

- Mencattelli, L.; Pinho, S.T. Ultra-thin-ply CFRP Bouligand bio-inspired structures with enhanced load-bearing capacity, delayed catastrophic failure and high energy dissipation capability. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105655. [Google Scholar] [CrossRef]

- Apichattrabrut, T.; Ravi-Chandar, K. Helicoidal Composites. Mech. Adv. Mater. Struct. 2006, 13, 61–76. [Google Scholar] [CrossRef]

- Grunenfelder, L.; Suksangpanya, N.; Salinas, C.; Milliron, G.; Yaraghi, N.; Herrera, S.; Evans-Lutterodt, K.; Nutt, S.; Zavattieri, P.; Kisailus, D. Bio-inspired impact-resistant composites. Acta Biomater. 2014, 10, 3997–4008. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Ren, Y.; Liu, Z.; Zhang, S.; Lin, Z. Low-velocity impact resistance behaviors of bio-inspired helicoidal composite laminates with non-linear rotation angle based layups. Compos. Struct. 2019, 214, 463–475. [Google Scholar] [CrossRef]

- Körbelin, J.; Goralski, P.; Kötter, B.; Bittner, F.; Endres, H.-J.; Fiedler, B. Damage tolerance and notch sensitivity of bio-inspired thin-ply Bouligand structures. Compos. Part C Open Access 2021, 5, 100146. [Google Scholar] [CrossRef]

- Ginzburg, D.; Pinto, F.; Iervolino, O.; Meo, M. Damage tolerance of bio-inspired helicoidal composites under low velocity impact. Compos. Struct. 2017, 161, 187–203. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Singh, A.; Lee, H.; Tay, T.; Tan, V. The response of bio-inspired helicoidal laminates to small projectile impact. Int. J. Impact Eng. 2020, 142, 103608. [Google Scholar] [CrossRef]

- Ouyang, W.; Gong, B.; Wang, H.; Scarpa, F.; Su, B.; Peng, H.-X. Identifying optimal rotating pitch angles in composites with Bouligand structure. Compos. Commun. 2020, 23, 100602. [Google Scholar] [CrossRef]

- Chew, E.; Liu, J.; Tay, T.; Tran, L.; Tan, V. Improving the mechanical properties of natural fibre reinforced laminates composites through Biomimicry. Compos. Struct. 2021, 258, 113208. [Google Scholar] [CrossRef]

- Yang, F.; Yi, F.; Xie, W. The role of ply angle in interlaminar delamination properties of CFRP laminates. Mech. Mater. 2021, 160, 103928. [Google Scholar] [CrossRef]

- Liu, J.L.; Lee, H.; Tan, V. Effects of inter-ply angles on the failure mechanisms in bioinspired helicoidal laminates. Compos. Sci. Technol. 2018, 165, 282–289. [Google Scholar] [CrossRef]

- Liu, J.; Lee, H.; Kong, S.; Tan, V. Improving laminates through non-uniform inter-ply angles. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105625. [Google Scholar] [CrossRef]

- Plocher, J.; Mencattelli, L.; Narducci, F.; Pinho, S. Learning from nature: Bio-inspiration for damage-tolerant high-performance fibre-reinforced composites. Compos. Sci. Technol. 2021, 208, 108669. [Google Scholar] [CrossRef]

- Liu, J.L.; Lee, H.P.; Lai, K.S.; Tan, V.B.; Long, L.J. Bio-Inspired Laminates of Different Material Systems. J. Appl. Mech. 2019, 87, 031007. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Lee, H.; Tay, T.; Tan, V. Healable bio-inspired helicoidal laminates. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106024. [Google Scholar] [CrossRef]

- Czabaj, M.W.; Ratcliffe, J.G. Comparison of intralaminar and interlaminar mode I fracture toughnesses of a unidirectional IM7/8552 carbon/epoxy composite. Compos. Sci. Technol. 2013, 89, 15–23. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A.; Tsokanas, P.; Tsantzalis, S. Toughening and healing of composites by CNTs reinforced copolymer nylon micro-particles. Mater. Res. Express 2018, 52, 025305. [Google Scholar] [CrossRef]

- Pingkarawat, K.; Bhat, T.; Craze, D.A.; Wang, C.H.; Varley, R.J.; Mouritz, A.P. Healing of carbon fibre–epoxy composites using thermoplastic additives. Polym. Chem. 2013, 4, 5007–5015. [Google Scholar] [CrossRef]

- Selver, E.; Potluri, P.; Soutis, C.; Hogg, P. Healing potential of hybrid materials for structural composites. Compos. Struct. 2015, 122, 57–66. [Google Scholar] [CrossRef]

- Hayes, S.A.; Jones, F.R.; Marshiya, K.; Zhang, W. A self-healing thermosetting composite material. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1116–1120. [Google Scholar] [CrossRef]

- Meure, S.; Wu, D.Y.; Furman, S. Polyethylene-co-methacrylic acid healing agents for mendable epoxy resins. Acta Mater. 2009, 57, 4312–4320. [Google Scholar] [CrossRef]

- Meure, S.; Varley, R.J.; Wu, D.Y.; Mayo, S.; Nairn, K.; Furman, S. Confirmation of the healing mechanism in a mendable EMAA–epoxy resin. Eur. Polym. J. 2012, 48, 524–531. [Google Scholar] [CrossRef]

- Suksangpanya, N.; Yaraghi, N.A.; Kisailus, D.; Zavattieri, P. Twisting cracks in Bouligand structures. J. Mech. Behav. Biomed. Mater. 2017, 76, 38–57. [Google Scholar] [CrossRef] [PubMed]

- Hajikazemi, M.; McCartney, L.; Van Paepegem, W. Matrix cracking initiation, propagation and laminate failure in multiple plies of general symmetric composite laminates. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105963. [Google Scholar] [CrossRef]

- Hajikazemi, M.; Garoz, D.; Van Paepegem, W. Model to accurately predict out-of-plane shear stiffness reduction in general cracked laminates. Compos. Sci. Technol. 2019, 179, 88–96. [Google Scholar] [CrossRef]

- Hajikazemi, M.; McCartney, L.; Ahmadi, H.; Van Paepegem, W. Variational analysis of cracking in general composite laminates subject to triaxial and bending loads. Compos. Struct. 2020, 239, 111993. [Google Scholar] [CrossRef]

- Sebaey, T.; González, E.V.; Lopes, C.; Blanco, N.; Costa, J. Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of ply clustering. Compos. Struct. 2013, 106, 96–103. [Google Scholar] [CrossRef]

| Property | Value | Remarks |

|---|---|---|

| Ply thickness | 0.074 mm | |

| Ply areal density | 0.1475 kg/m2 | |

| Modulus (fiber direction), E1 | 61.6 GPa | ASTM D3039 |

| Modulus (Transverse direction), E2 | 11.8 Gpa | ASTM D3039 |

| Tensile strength (fiber direction), σ1t | 1146 Mpa | ASTM D3039 |

| Compressive strength (fiber direction), σ1c | 597 Mpa | ASTM D6641 |

| Tensile strength (transverse direction), σ2t | 38.5 Mpa | ASTM D3039 |

| Compressive strength (transverse direction), σ2c | 110 Mpa | ASTM D6641 |

| Interlaminar Mode I fracture toughness | 0.440 mJ/mm2 | ASTM D5528 |

| Interlaminar Mode II fracture toughness | 1.12 mJ/mm2 | ASTM D7905/D7905M |

| Intralaminar Mode I fracture toughness (transverse direction), | 0.751 mJ/mm2 | [27] |

| Inerlaminar shear strength | 69.5 Mpa | ASTM D2344 |

| Designation | Description | Laminate Area Density | Laminate Thickness | Weight Against QI61 | Configuration |

|---|---|---|---|---|---|

| QI61 | 61 ply quasi-isotropic | 9 kg/m2 | 4.5 mm | - | (0/90/45/−45)7/0/90/0/90/0/(−45/45/90/0)7 |

| HL61 | 61 ply helicoidal | 9 kg/m2 | 4.5 mm | 100% | 0/−12/−24/−36…/−720 |

| HL49 | 49 ply helicoidal | 7.2 kg/m2 | 3.6 mm | 80.3% | 0/−11.25/−22.5/−33.75…/−540 |

| HL46 | 46 ply helicoidal | 6.8 kg/m2 | 3.4 mm | 75.4% | 0/−12/−24/−36…/−540 |

| Designation | Specimen No. | Impact Energy (J) | Perforation |

|---|---|---|---|

| QI61 | 1 | 50 | No |

| 2 | 60 | No | |

| 3 | 70 | Yes | |

| 4 | 65 | No | |

| 5 | 68 | Yes | |

| 6 | 66 | No | |

| 7 | 67 | Yes | |

| 8 | 66 | Yes | |

| 9 | 61 | No | |

| HL61 | 1 | 80 | No |

| 2 | 100 | Yes | |

| 3 | 97 | No | |

| 4 | 98 | No | |

| 5 | 99 | Yes | |

| 6 | 98 | Yes | |

| 7 | 94 | No | |

| HL49 | 1 | 66 | Yes |

| 2 | 60 | No | |

| 3 | 65 | No | |

| 4 | 64 | No | |

| 5 | 66 | Yes | |

| 6 | 65 | No | |

| HL46 | 1 | 60 | No |

| 2 | 63 | Yes | |

| 3 | 61 | Yes | |

| 4 | 60 | Yes | |

| 5 | 59 | No | |

| 6 | 55 | No |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.L.; Mencattelli, L.; Zhi, J.; Chua, P.Y.; Tay, T.-E.; Tan, V.B.C. Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate. Polymers 2022, 14, 475. https://doi.org/10.3390/polym14030475

Liu JL, Mencattelli L, Zhi J, Chua PY, Tay T-E, Tan VBC. Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate. Polymers. 2022; 14(3):475. https://doi.org/10.3390/polym14030475

Chicago/Turabian StyleLiu, Jia Long, Lorenzo Mencattelli, Jie Zhi, Ping Yee Chua, Tong-Earn Tay, and Vincent Beng Chye Tan. 2022. "Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate" Polymers 14, no. 3: 475. https://doi.org/10.3390/polym14030475

APA StyleLiu, J. L., Mencattelli, L., Zhi, J., Chua, P. Y., Tay, T.-E., & Tan, V. B. C. (2022). Lightweight, Fiber-Damage-Resistant, and Healable Bio-Inspired Glass-Fiber Reinforced Polymer Laminate. Polymers, 14(3), 475. https://doi.org/10.3390/polym14030475