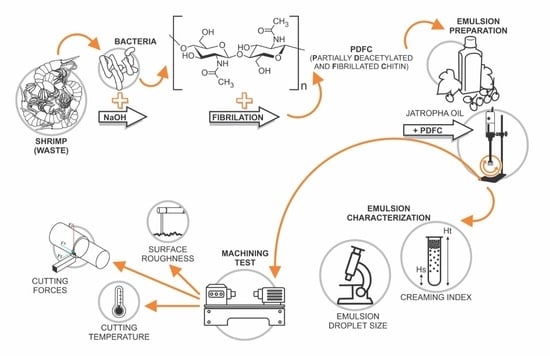

Partially Deacetylated and Fibrillated Shrimp Waste-Derived Chitin as Biopolymer Emulsifier for Green Cutting Fluids—Towards a Cleaner Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chitin Production and Emulsions Preparation

2.2. Machining Testing

2.3. Statistical Analysis

3. Results and Discussion

3.1. Characterization of the Formulated Emulsions

3.2. Machining Performance

3.2.1. Cutting Forces

3.2.2. Cutting Temperatures

3.2.3. Surface Finish

3.2.4. Chip Formation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, S.H.; Yang, C.; Ayaril, N.; Szekely, G. Solvent-Resistant Thin-Film Composite Membranes from Biomass-Derived Building Blocks: Chitosan and 2,5-Furandicarboxaldehyde. ACS Sustain. Chem. Eng. 2022, 10, 998–1007. [Google Scholar] [CrossRef]

- Pohling, J.; Dave, D.; Liu, Y.; Murphy, W.; Trenholm, S. Two-Step Demineralization of Shrimp (Pandalus Borealis) Shells Using Citric Acid: An Environmentally Friendly, Safe and Cost-Effective Alternative to the Traditional Approach. Green Chem. 2022. [Google Scholar] [CrossRef]

- Alammar, A.; Hardian, R.; Szekely, G. Upcycling Agricultural Waste into Membranes: From Date Seed Biomass to Oil and Solvent-Resistant Nanofiltration. Green Chem. 2022, 24, 365–374. [Google Scholar] [CrossRef]

- Chen, H.; Chen, S.; Fan, D.; Wang, Y. Preparation and Characterization of a Robust, High Strength, and Mildew Resistant Fully Biobased Adhesive from Agro-Industrial Wastes. ACS Appl. Polym. Mater. 2021, 3, 5197–5206. [Google Scholar] [CrossRef]

- Barikani, M.; Oliaei, E.; Seddiqi, H.; Honarkar, H. Preparation, and Application of Chitin and Its Derivatives: A Review. Iran. Polym. J. 2014, 23, 307–326. [Google Scholar] [CrossRef]

- Ling, S.; Chen, W.; Fan, Y.; Zheng, K.; Jin, K.; Yu, H.; Buehler, M.J.; Kaplan, D.L. Biopolymer Nanofibrils: Structure, Modeling, Preparation, and Applications. Prog. Polym. Sci. 2018, 85, 1–56. [Google Scholar] [CrossRef]

- Hall, G.M.; Barrera, C.H.; Shirai, K. Alternative Methods for Chitin and Chitosan Preparation, Characterization, and Application. In Handbook of Chitin and Chitosan; Elsevier: Amsterdam, The Netherlands, 2020; pp. 225–246. [Google Scholar]

- Perrin, E.; Bizot, H.; Cathala, B.; Capron, I. Chitin Nanocrystals for Pickering High Internal Phase Emulsions. Biomacromolecules 2014, 15, 3766–3771. [Google Scholar] [CrossRef]

- Bai, L.; Huan, S.; Xiang, W.; Liu, L.; Yang, Y.; Nugroho, R.W.N.; Fan, Y.; Rojas, O.J. Self-Assembled Networks of Short and Long Chitin Nanoparticles for Oil/Water Interfacial Superstabilization. ACS Sustain. Chem. Eng. 2019, 7, 6497–6511. [Google Scholar] [CrossRef]

- Larbi, F.; García, A.; del Valle, L.J.; Hamou, A.; Puiggalí, J.; Belgacem, N.; Bras, J. Comparison of Nanocrystals and Nanofibers Produced from Shrimp Shell α-Chitin: From Energy Production to Material Cytotoxicity and Pickering Emulsion Properties. Carbohydr. Polym. 2018, 196, 385–397. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, J.; Chen, L.; Zhang, L. Chitin Nanofibrils to Stabilize Long-Life Pickering Foams and Their Application for Lightweight Porous Materials. ACS Sustain. Chem. Eng. 2018, 6, 10552–10561. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, R.; Feng, W.; Chen, Z.; Wang, T. High Internal Phase Pickering Emulsions Stabilized by Co-Assembled Rice Proteins and Carboxymethyl Cellulose for Food-Grade 3D Printing. Carbohydr. Polym. 2021, 273, 118586. [Google Scholar] [CrossRef]

- Bai, L.; Lv, S.; Xiang, W.; Huan, S.; McClements, D.J.; Rojas, O.J. Oil-in-Water Pickering Emulsions via Microfluidization with Cellulose Nanocrystals: 1. Formation and Stability. Food Hydrocoll. 2019, 96, 699–708. [Google Scholar] [CrossRef]

- Rao, D.N.; Srikant, R.R. Influence of Emulsifier Content on Cutting Fluid Properties. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf. 2006, 220, 1803–1806. [Google Scholar] [CrossRef]

- Srikant, R.R.; Rao, N.D.; Rao, P.N. Influence of Emulsifier Content in Cutting Fluids on Cutting Forces, Cutting Temperatures, Tool Wear, and Surface Roughness. Proc. Inst. Mech. Eng. Pt. J J. Eng. Tribol. 2009, 223, 203–209. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; El-Din, M.R.N.; Nermine, E.; Maysour, E.; Nasser, N.M. Investigation Factors Affecting Cutting Oil Formulations Prepared by Emulsifiers Based on Linear Alkyl Benzene and Oleic Acid-maleic Anhydride Esters. J. Dispers. Sci. Technol. 2008, 29, 740–747. [Google Scholar] [CrossRef]

- Leong, W.D.; Lam, H.L.; Ng, W.P.Q.; Lim, C.H.; Tan, C.P.; Ponnambalam, S.G. Lean and Green Manufacturing—A Review on Its Applications and Impacts. Proc. Integr. Optim. Sustain. 2019, 3, 5–23. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental Friendly Cutting Fluids and Cooling Techniques in Machining: A Review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Dilger, S.; Fluri, A.; Sonntag, H.-G. Bacterial Contamination of Preserved and Non-Preserved Metal Working Fluids. Int. J. Hyg. Environ. Health 2005, 208, 467–476. [Google Scholar] [CrossRef]

- Li, K.; Aghazadeh, F.; Hatipkarasulu, S.; Ray, T.G. Health Risks from Exposure to Metal-Working Fluids in Machining and Grinding Operations. Int. J. Occup. Saf. Ergon. 2003, 9, 75–95. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Application of Vegetable Oil-Based Metalworking Fluids in Machining Ferrous Metals—A Review. Int. J. Mach. Tools Manuf. 2012, 52, 1–12. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Developments in the Formulation and Application of Vegetable Oil-Based Metalworking Fluids in Turning Process. Int. J. Adv. Manuf. Technol. 2013, 67, 1765–1776. [Google Scholar] [CrossRef]

- Wickramasinghe, K.C.; Sasahara, H.; Rahim, E.A.; Perera, G.I.P. Green Metalworking Fluids for Sustainable Machining Applications: A Review. J. Clean. Prod. 2020, 257, 120552. [Google Scholar] [CrossRef]

- Srikant, R.R.; Rao, P.N. Use of Vegetable-Based Cutting Fluids for Sustainable Machining. In Sustainable Machining; Springer International Publishing: Cham, Switzerland, 2017; pp. 31–46. [Google Scholar]

- Katna, R.; Suhaib, M.; Agrawal, N. Nonedible Vegetable Oil-Based Cutting Fluids for Machining Processes—A Review. Mater. Manuf. Process. 2020, 35, 1–32. [Google Scholar] [CrossRef]

- Srikant, R.R.; Ramana, V.S.N.V. Performance Evaluation of Vegetable Emulsifier Based Green Cutting Fluid in Turning of American Iron and Steel Institute (AISI) 1040 Steel—An Initiative towards Sustainable Manufacturing. J. Clean. Prod. 2015, 108, 104–109. [Google Scholar] [CrossRef]

- Aranday-García, R.; Román Guerrero, A.; Ifuku, S.; Shirai, K. Successive Inoculation of Lactobacillus Brevis and Rhizopus Oligosporus on Shrimp Wastes for Recovery of Chitin and Added-Value Products. Process Biochem. 2017, 58, 17–24. [Google Scholar] [CrossRef]

- McClements, D.J. Critical Review of Techniques and Methodologies for Characterization of Emulsion Stability. Crit. Rev. Food Sci. Nutr. 2007, 47, 611–649. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Gómez-Guarneros, M.; Pérez-González, J.; Godínez-Salcedo, J.G. Alteration of Lubricity of Jatropha Oil Used as Bio-Lubricant for Engines Due to Thermal Ageing. Renew. Energy 2020, 149, 1197–1204. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Pérez-González, J.; Marín-Santibáñez, B.M.; Lewis, R. Effects of Jatropha Lubricant Thermo-Oxidation on the Tribological Behaviour of Engine Cylinder Liners as Measured by a Reciprocating Friction Test. Wear 2019, 426–427, 910–918. [Google Scholar] [CrossRef]

- Martinez-Herrera, J. El piñón Mexicano: Una Alternativa Bioenergética Para México. Available online: http://www.revista.unam.mx/vol.8/num12/art88/dic_art88.pdf (accessed on 31 December 2021).

- Vysotsky, Y.B.; Kartashynska, E.S.; Vollhardt, D.; Fainerman, V.B. Surface pKa of Saturated Carboxylic Acids at the Air/Water Interface: A Quantum Chemical Approach. J. Phys. Chem. C Nanomater. Interfaces 2020, 124, 13809–13818. [Google Scholar] [CrossRef]

- Helgason, T.; Gislason, J.; McClements, D.J.; Kristbergsson, K.; Weiss, J. Influence of Molecular Character of Chitosan on the Adsorption of Chitosan to Oil Droplet Interfaces in an in Vitro Digestion Model. Food Hydrocoll. 2009, 23, 2243–2253. [Google Scholar] [CrossRef]

- Byers, J.P. Metalworking Fluids, 3rd ed.; Byers, J.P., Ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Abingdon, UK, 2017. [Google Scholar]

- Abdulhadi, H.A.; Aqida, S.N.; Ismail, I. Tool Failure in Die Casting. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Nune, M.M.R.; Chaganti, P.K. Performance Evaluation of Novel Developed Biodegradable Metal Working Fluid during Turning of AISI 420 Material. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–16. [Google Scholar] [CrossRef]

- ISO Standard No. 3685:1993Tool-Life Testing with Single-Point Turning Tools. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/9151.html(accessed on 16 December 2021).

- Kalpakjian, S. Manufacturing Engineering and Technology, 3rd ed.; Addison Wesley: London, UK, 1995. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar-Rosas, O.; Blanco, S.; Flores, M.; Shirai, K.; Farfan-Cabrera, L.I. Partially Deacetylated and Fibrillated Shrimp Waste-Derived Chitin as Biopolymer Emulsifier for Green Cutting Fluids—Towards a Cleaner Production. Polymers 2022, 14, 525. https://doi.org/10.3390/polym14030525

Aguilar-Rosas O, Blanco S, Flores M, Shirai K, Farfan-Cabrera LI. Partially Deacetylated and Fibrillated Shrimp Waste-Derived Chitin as Biopolymer Emulsifier for Green Cutting Fluids—Towards a Cleaner Production. Polymers. 2022; 14(3):525. https://doi.org/10.3390/polym14030525

Chicago/Turabian StyleAguilar-Rosas, Oscar, Stephany Blanco, Mariana Flores, Keiko Shirai, and Leonardo Israel Farfan-Cabrera. 2022. "Partially Deacetylated and Fibrillated Shrimp Waste-Derived Chitin as Biopolymer Emulsifier for Green Cutting Fluids—Towards a Cleaner Production" Polymers 14, no. 3: 525. https://doi.org/10.3390/polym14030525