Estimating the Relative Crystallinity of Biodegradable Polylactic Acid and Polyglycolide Polymer Composites by Machine Learning Methodologies

Abstract

:1. Introduction

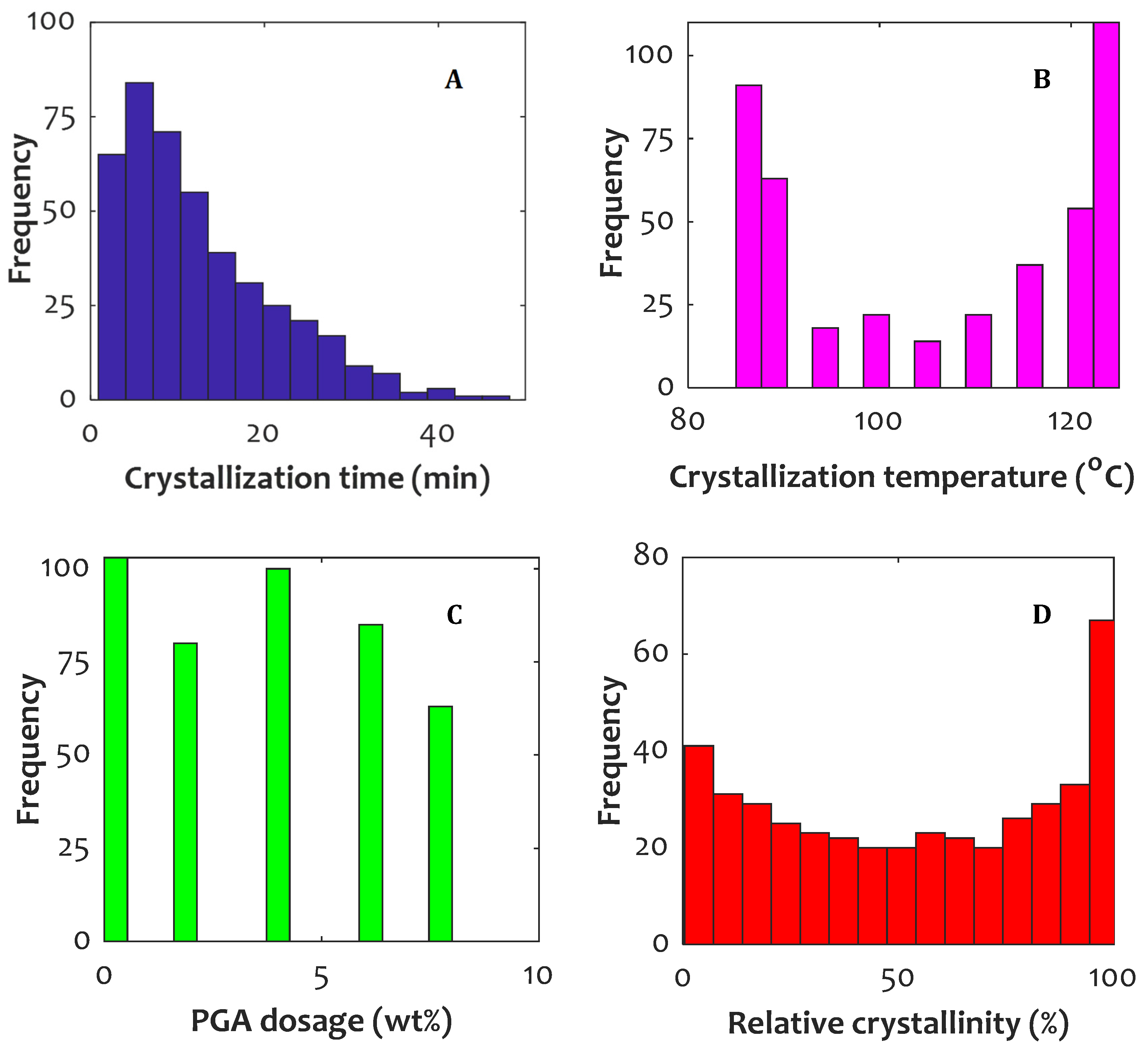

2. Materials and Experiments

3. Methodology

3.1. Artificial Neural Networks

3.2. Adaptive Neuro-Fuzzy Inference Systems

3.3. Least-Squares Support Vector Regression

4. Results and Discussion

4.1. Relevancy Analyses

4.2. Developing Machine Learning Methods

4.3. Selecting the Best Topology for Machine Learning Methods

4.4. Investigating the Effect of Activation Function on CFFNN Performances

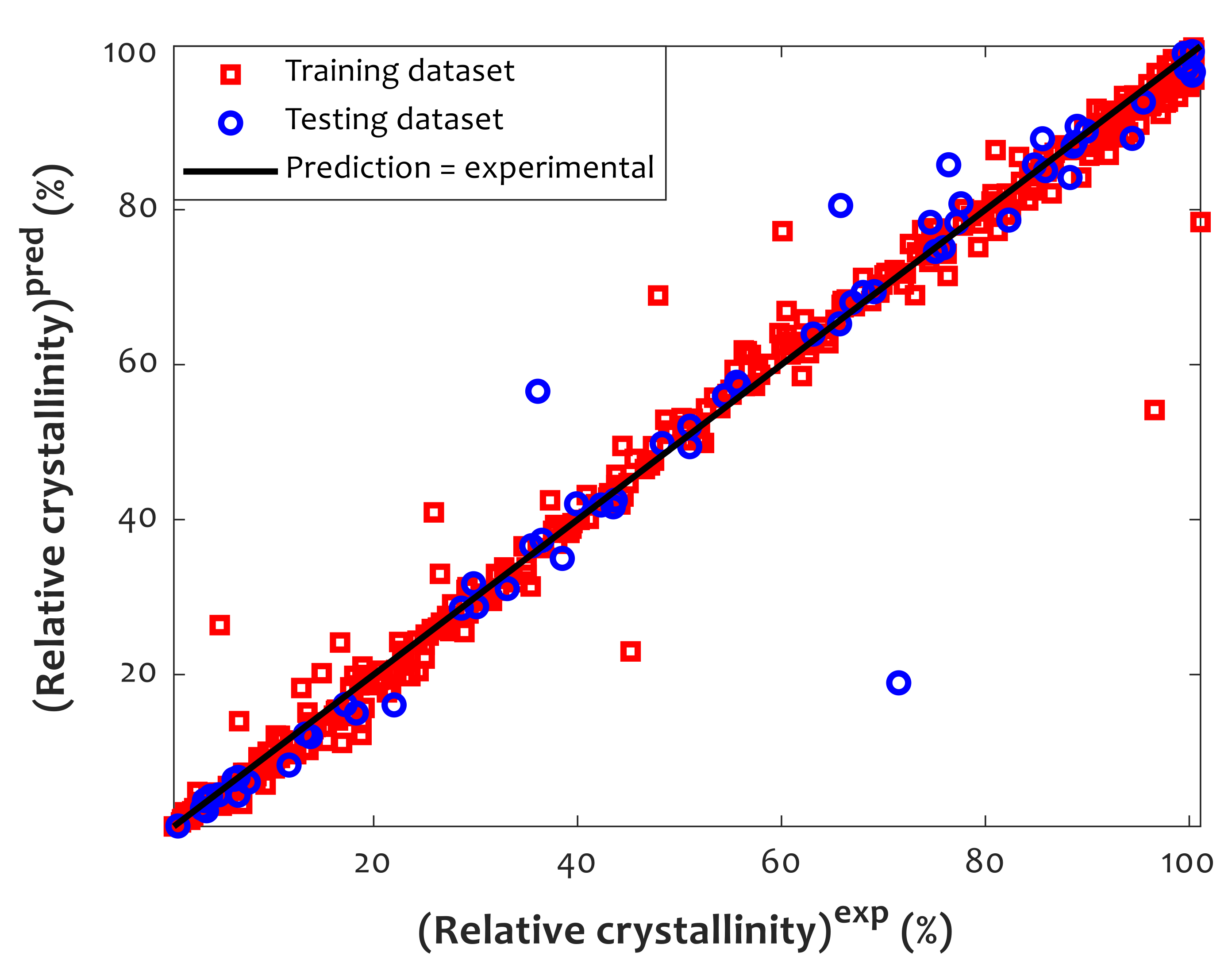

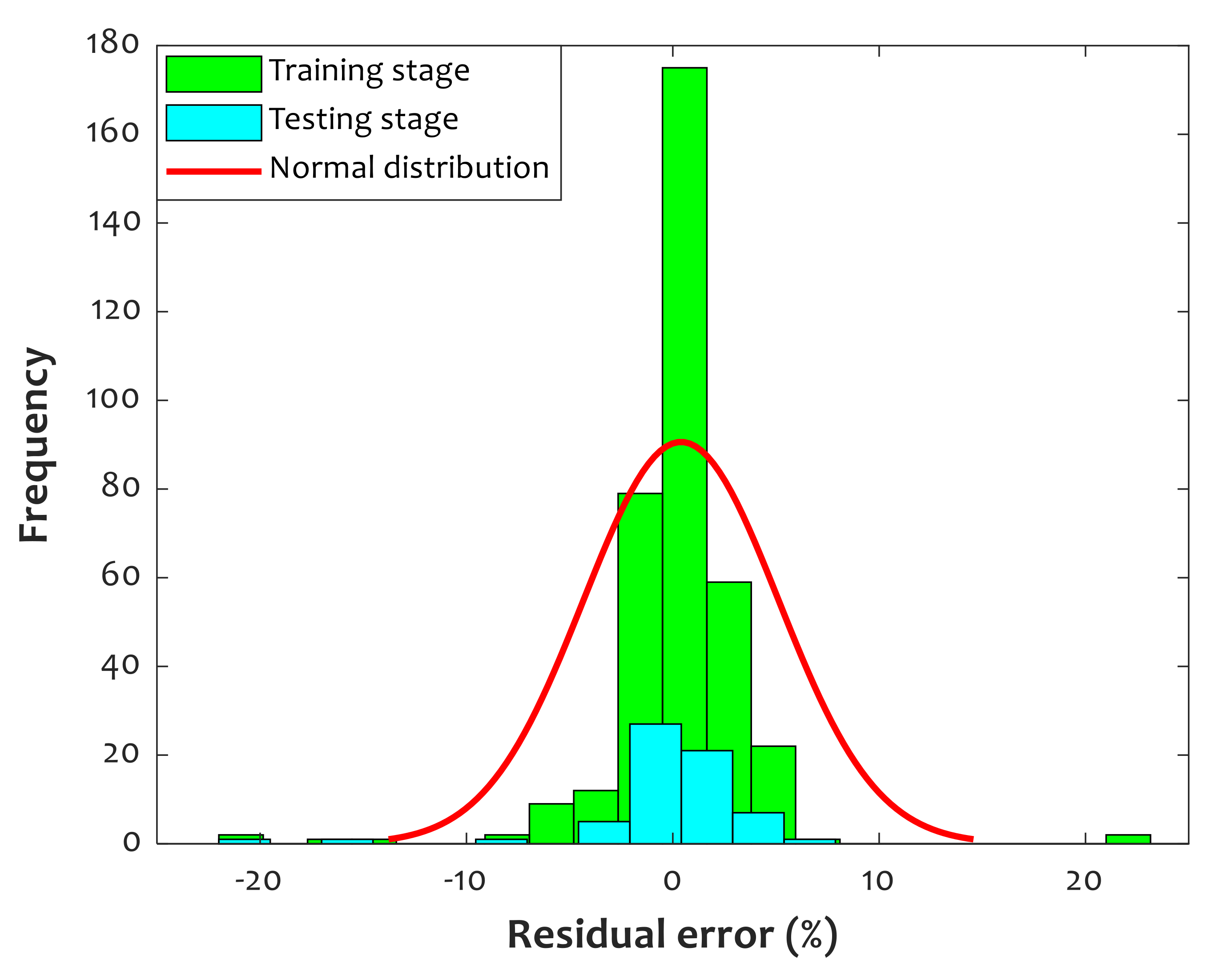

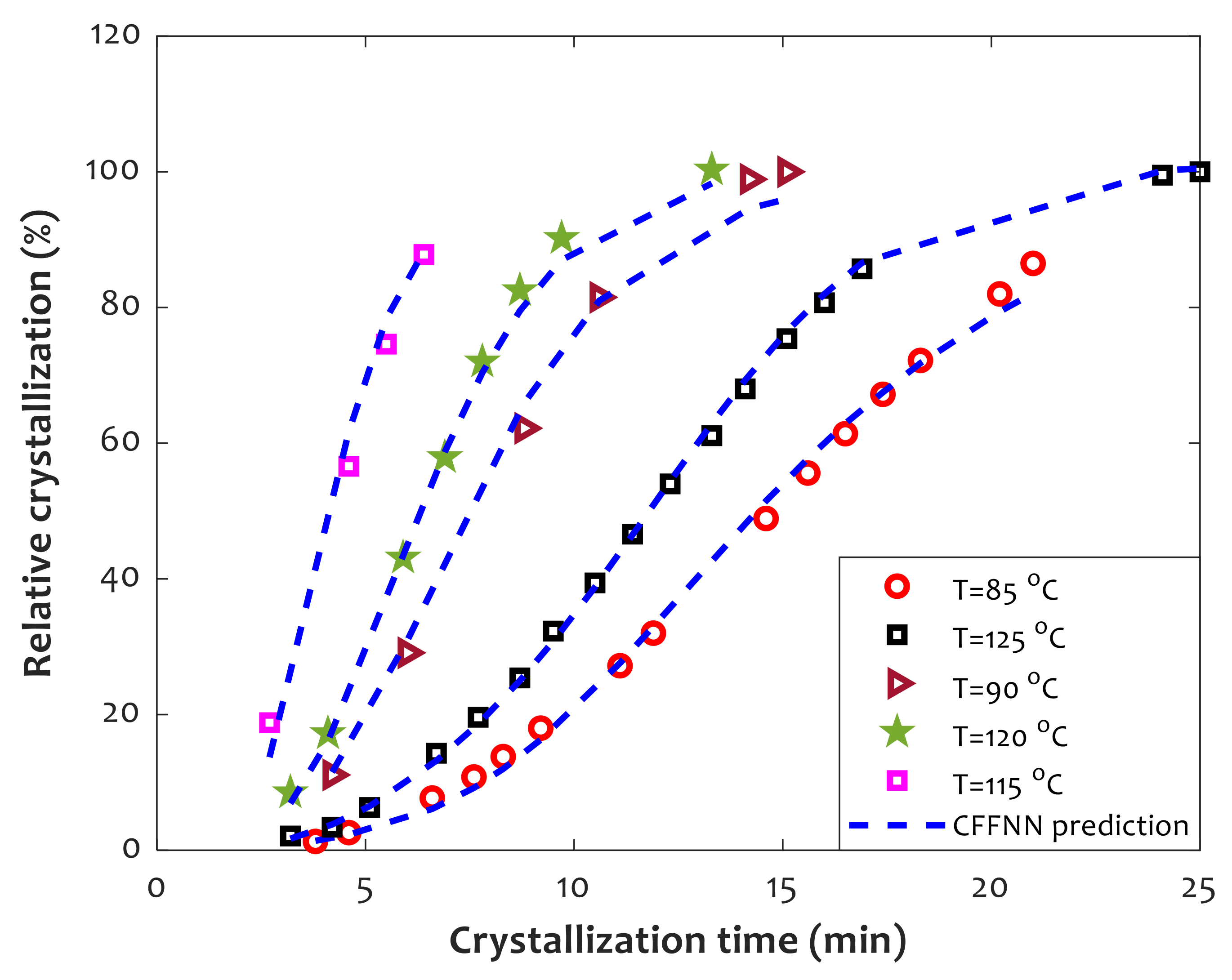

4.5. Analyzing the Performance of the CFFNN Model

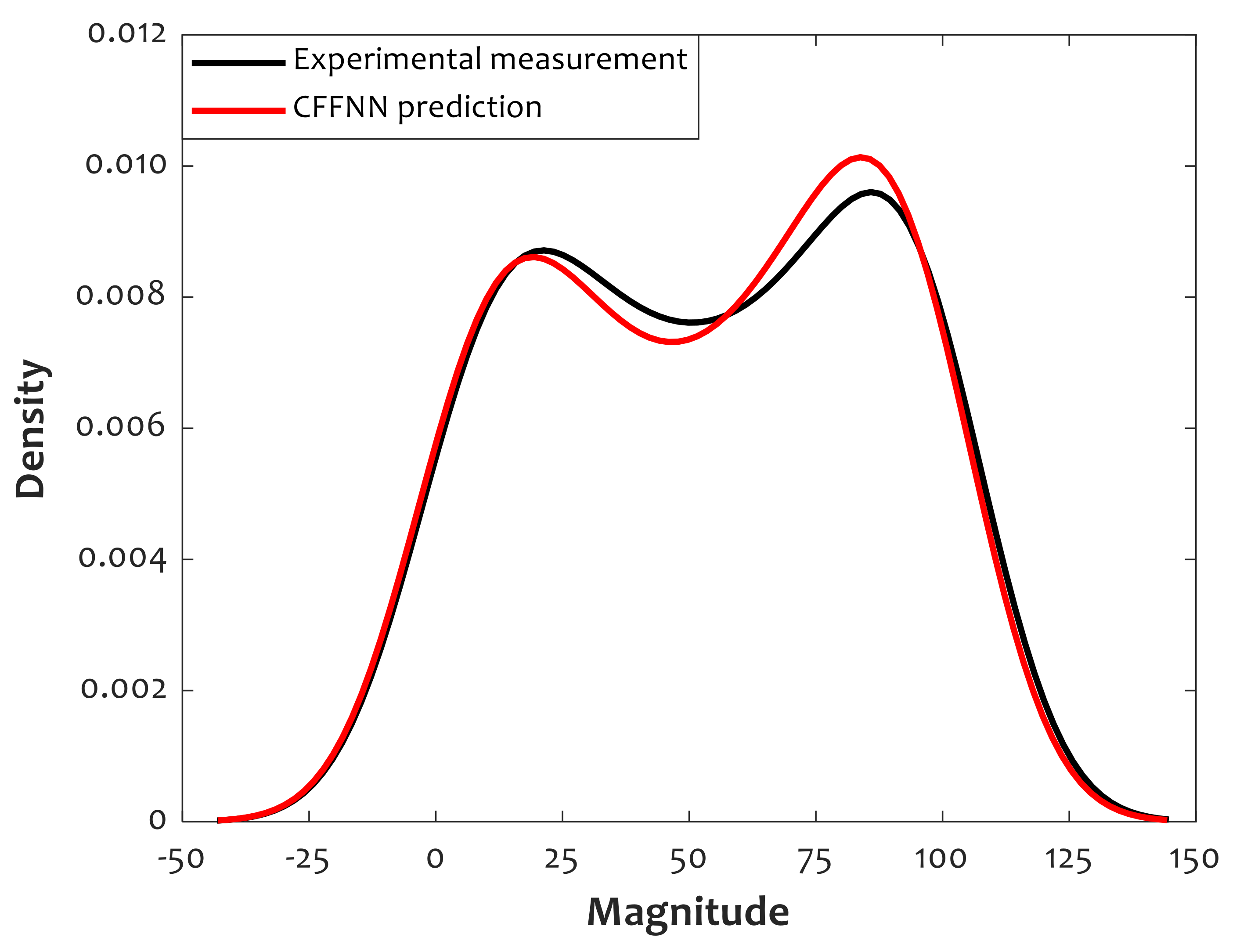

4.6. Checking the Validity of Experimental Data

4.7. Monitoring the Effect of Influential Features on Relative Crystallinity

4.8. Transferability of the Proposed Model

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puppi, D.; Chiellini, F. Biodegradable Polymers for Biomedical Additive Manufacturing. Appl. Mater. Today 2020, 20, 100700. [Google Scholar] [CrossRef]

- Iqbal, N.; Khan, A.S.; Asif, A.; Yar, M.; Haycock, J.W.; Rehman, I.U. Recent concepts in biodegradable polymers for tissue engineering paradigms: A critical review. Int. Mater. Rev. 2019, 64, 91–126. [Google Scholar] [CrossRef] [Green Version]

- Raza, F.; Zafar, H.; Zhu, Y.; Ren, Y.; Ullah, A.; Khan, A.U.; He, X.; Han, H.; Aquib; Boakye-Yiadom, K.O.; et al. A Review on Recent Advances in Stabilizing Peptides/Proteins upon Fabrication in Hydrogels from Biodegradable Polymers. Pharmaceutics 2018, 10, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lai, W.-F.; Huang, E.; Lui, K.-H. Alginate-based complex fibers with the Janus morphology for controlled release of co-delivered drugs. Asian J. Pharm. Sci. 2021, 16, 77–85. [Google Scholar] [CrossRef]

- Lai, W.-F.; Wong, W.-T. Use of graphene-based materials as carriers of bioactive agents. Asian J. Pharm. Sci. 2020, 16, 577–588. [Google Scholar] [CrossRef]

- Bahador, F.; Foroutan, R.; Esmaeili, H.; Ramavandi, B. Enhancement of the chromium removal behavior of Moringa oleifera activated carbon by chitosan and iron oxide nanoparticles from water. Carbohydr. Polym. 2021, 251, 117085. [Google Scholar] [CrossRef]

- Nemati, F.; Jafari, D.; Esmaeili, H. Highly efficient removal of toxic ions by the activated carbon derived from Citrus limon tree leaves. Carbon Lett. 2021, 31, 509–521. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Yang, F.; Tang, Y. Janus particles with pH switchable properties for high-efficiency adsorption of PPCPs in water. Solid State Sci. 2021, 119, 106702. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q.; Yuan, H.; Luo, K.; Li, J.; Hu, W.; Pan, Z.; Xu, M.; Xu, S.; Levchenko, I.; et al. Comparative study of photocatalysis and gas sensing of ZnO/Ag nanocomposites synthesized by one- and two-step polymer-network gel processes. J. Alloys Compd. 2021, 868, 158723. [Google Scholar] [CrossRef]

- Tsuji, H.; Takai, H.; Fukuda, N.; Takikawa, H. Non-Isothermal Crystallization Behavior of Poly(L-lactic acid) in the Presence of Various Additives. Macromol. Mater. Eng. 2006, 291, 325–335. [Google Scholar] [CrossRef]

- Dobreva, T.; Pereña, J.; Pérez, E.; Benavente, R.; García, M. Crystallization behavior of poly(L -lactic acid)-based ecocomposites prepared with kenaf fiber and rice straw. Polym. Compos. 2010, 31, 974–984. [Google Scholar] [CrossRef]

- Chen, H.; Ma, C.; Bai, W.; Chen, N.; Xiong, C. Isothermal Crystallization and Melting Behavior of Composites Composed of Poly(L-lactic Acid) and Poly(glycolic Acid) Fibers. J. Macromol. Sci. Part B 2014, 53, 1715–1725. [Google Scholar] [CrossRef]

- Mandelkern, L. Crystallization of Polymers: Volume 2, Kinetics and Mechanisms; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Piorkowska, E.; Rutledge, G.C. Handbook of Polymer Crystallization; John Wiley & Sons: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Liu, L.; Xu, Y.; Pan, Y.; Xu, M.; Di, Y.; Li, B. Facile synthesis of an efficient phosphonamide flame retardant for simultaneous enhancement of fire safety and crystallization rate of poly (lactic acid). Chem. Eng. J. 2021, 421, 127761. [Google Scholar] [CrossRef]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos. Sci. Technol. 2009, 69, 1187–1192. [Google Scholar] [CrossRef]

- Ghanbari, S.; Vaferi, B. Prediction of degree of crystallinity for the LTA zeolite using artificial neural networks. Mater. Sci. 2017, 35, 486–495. [Google Scholar] [CrossRef] [Green Version]

- Crawford, C.B.; Quinn, B. Physiochemical properties and degradation. In Microplastic Pollutants; Elsevier: Amsterdam, The Netherlands, 2017; pp. 57–100. [Google Scholar]

- Balani, K.; Verma, V.; Agarwal, A.; Narayan, R. Physical, Thermal, and Mechanical Properties of Polymers. Biosurfaces 2015, 329–344. [Google Scholar] [CrossRef]

- Murthy, N.S. Experimental Techniques for understanding polymer crystallization. In Crystallization in Multiphase Polymer Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 49–72. [Google Scholar]

- Ming, Y.; Zhou, Z.; Hao, T.; Nie, Y. Molecular simulation of polymer crystallization under chain and space confinement. Phys. Chem. Chem. Phys. 2021, 23, 17382–17391. [Google Scholar] [CrossRef]

- Rahman, T.; Al-Ishaq, F.A.; Al-Mohannadi, F.S.; Mubarak, R.S.; Al-Hitmi, M.H.; Islam, K.R.; Khandakar, A.; Hssain, A.A.; Al-Madeed, S.; Zughaier, S.M.; et al. Mortality Prediction Utilizing Blood Biomarkers to Predict the Severity of COVID-19 Using Machine Learning Technique. Diagnostics 2021, 11, 1582. [Google Scholar] [CrossRef]

- Rahman, T.; Khandakar, A.; Hoque, E.; Ibtehaz, N.; Bin Kashem, S.; Masud, R.; Shampa, L.; Hasan, M.M.; Islam, M.T.; Al-Maadeed, S.; et al. Development and Validation of an Early Scoring System for Prediction of Disease Severity in COVID-19 Using Complete Blood Count Parameters. IEEE Access 2021, 9, 120422–120441. [Google Scholar] [CrossRef]

- Chowdhury, M.E.H.; Rahman, T.; Khandakar, A.; Al-Madeed, S.; Zughaier, S.M.; Doi, S.A.R.; Hassen, H.; Islam, M.T. An Early Warning Tool for Predicting Mortality Risk of COVID-19 Patients Using Machine Learning. Cogn. Comput. 2021, 1–16. [Google Scholar] [CrossRef]

- Kumar, S.; Ignacz, G.; Szekely, G. Synthesis of covalent organic frameworks using sustainable solvents and machine learning. Green Chem. 2021, 23, 8932–8939. [Google Scholar] [CrossRef]

- Hardian, R.; Liang, Z.; Zhang, X.; Szekely, G. Artificial intelligence: The silver bullet for sustainable materials development. Green Chem. 2020, 22, 7521–7528. [Google Scholar] [CrossRef]

- He, S.; Guo, F.; Zou, Q.; Ding, H. MRMD2.0: A Python Tool for Machine Learning with Feature Ranking and Reduction. Curr. Bioinform. 2021, 15, 1213–1221. [Google Scholar] [CrossRef]

- Al Omar, A.; Jamil, A.K.; Khandakar, A.; Uzzal, A.R.; Bosri, R.; Mansoor, N.; Rahman, M.S. A Transparent and Privacy-Preserving Healthcare Platform With Novel Smart Contract for Smart Cities. IEEE Access 2021, 9, 90738–90749. [Google Scholar] [CrossRef]

- Khandakar, A.; Chowdhury, M.E.H.; Gonzales, A., Jr.; Pedro, S.; Touati, F.; Emadi, N.A.; Ayari, M.A. Case Study to Analyze the Impact of Multi-Course Project-Based Learning Approach on Education for Sustainable Development. Sustainability 2020, 12, 480. [Google Scholar] [CrossRef] [Green Version]

- Rastogi, S.; Choudhary, S. Face Recognition by Using Neural Network. Acta Inform. Malays. 2019, 3, 7–9. [Google Scholar] [CrossRef]

- Gholami, E.; Vaferi, B.; Ariana, M.A. Prediction of viscosity of several alumina-based nanofluids using various artificial intelligence paradigms—Comparison with experimental data and empirical correlations. Powder Technol. 2018, 323, 495–506. [Google Scholar] [CrossRef]

- Esmaeili-Faraj, S.H.; Vaferi, B.; Bolhasani, A.; Karamian, S.; Hosseini, S.; Rashedi, R. Design of a Neuro-Based Computing Paradigm for Simulation of Industrial Olefin Plants. Chem. Eng. Technol. 2021, 44, 1382–1389. [Google Scholar] [CrossRef]

- Mahmoodi, F.; Darvishi, P.; Vaferi, B. Prediction of coefficients of the Langmuir adsorption isotherm using various artificial intelligence (AI) techniques. J. Iran. Chem. Soc. 2018, 15, 2747–2757. [Google Scholar] [CrossRef]

- Moghimihanjani, M.; Vaferi, B. A Combined Wavelet Transform and Recurrent Neural Networks Scheme for Identification of Hydrocarbon Reservoir Systems From Well Testing Signals. J. Energy Resour. Technol. 2021, 143, 013001. [Google Scholar] [CrossRef]

- Mousavi, N.S.; Vaferi, B.; Romero-Martínez, A. Prediction of Surface Tension of Various Aqueous Amine Solutions Using the UNIFAC Model and Artificial Neural Networks. Ind. Eng. Chem. Res. 2021, 60, 10354–10364. [Google Scholar] [CrossRef]

- Vaferi, B.; Eslamloueyan, R.; Ayatollahi, S. Application of Recurrent Networks to Classification of Oil Reservoir Models in Well-testing Analysis. Energy Sour. Part A Recover. Util. Environ. Eff. 2014, 37, 174–180. [Google Scholar] [CrossRef]

- Cybenko, G. Approximation by superpositions of a sigmoidal function. Math. Control. Signals, Syst. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- Karimi, M.; Aminzadehsarikhanbeglou, E.; Vaferi, B. Robust intelligent topology for estimation of heat capacity of biochar pyrolysis residues. Measurement 2021, 183, 109857. [Google Scholar] [CrossRef]

- Moosavi, S.R.; Vaferi, B.; Wood, D.A. Auto-characterization of naturally fractured reservoirs drilled by horizontal well using multi-output least squares support vector regression. Arab. J. Geosci. 2021, 14, 545. [Google Scholar] [CrossRef]

- Suykens, J.A.K.; Van Gestel, T.; De Brabanter, J.; De Moor, B.; Vandewalle, J. Least Squares Support Vector Machines; World Scientific Publishing: Singapore City, Singapore, 2002. [Google Scholar]

- Keshtkar, Z.; Tamjidi, S.; Vaferi, B. Intensifying nickel (II) uptake from wastewater using the synthesized γ-alumina: An experimental investigation of the effect of nano-adsorbent properties and operating conditions. Environ. Technol. Innov. 2021, 22, 101439. [Google Scholar] [CrossRef]

- Daryayehsalameh, B.; Nabavi, M.; Vaferi, B. Modeling of CO2 capture ability of [Bmim] [BF4] ionic liquid using connectionist smart paradigms. Environ. Technol. Innov. 2021, 22, 101484. [Google Scholar] [CrossRef]

- Khandakar, A.; Chowdhury, M.E.; Reaz, M.B.I.; Ali, S.H.M.; Hasan, A.; Kiranyaz, S.; Rahman, T.; Alfkey, R.; Bakar, A.A.A.; Malik, R.A. A machine learning model for early detection of diabetic foot using thermogram images. Comput. Biol. Med. 2021, 137, 104838. [Google Scholar] [CrossRef]

- Lu, S.X.; Zhou, Q.Z.; Fan, R. Analysis of the Relevancy between Energy Consumption and Environmental Pollution Based on Grey Theory. Adv. Mater. Res. 2012, 616–618, 1404–1408. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, G.; Wang, J.; Vaferi, B. Hydrogen solubility in aromatic/cyclic compounds: Prediction by different machine learning techniques. Int. J. Hydrogen Energy 2021, 46, 23591–23602. [Google Scholar] [CrossRef]

- Xie, J.; Liu, X.; Lao, X.; Vaferi, B. Hydrogen solubility in furfural and furfuryl bio-alcohol: Comparison between the reliability of intelligent and thermodynamic models. Int. J. Hydrogen Energy 2021, 46, 36056–36068. [Google Scholar] [CrossRef]

- Vaferi, B.; Lashkarbolooki, M.; Esmaeili, H.; Shariati, A. Toward artificial intelligence-based modeling of vapor liquid equilibria of carbon dioxide and refrigerant binary systems. J. Serb. Chem. Soc. 2018, 83, 199–211. [Google Scholar] [CrossRef] [Green Version]

- Karimi, M.; Vaferi, B.; Hosseini, S.; Olazar, M.; Rashidi, S. Smart computing approach for design and scale-up of conical spouted beds with open-sided draft tubes. Particuology 2021, 55, 179–190. [Google Scholar] [CrossRef]

- Ghanbari, S.; Vaferi, B. Experimental and theoretical investigation of water removal from DMAZ liquid fuel by an adsorption process. Acta Astronaut. 2015, 112, 19–28. [Google Scholar] [CrossRef]

- Wood, D.A.; Choubineh, A.; Vaferi, B. Transparent Open-Box Learning Network Provides Auditable Predictions: Pool Boiling Heat Transfer Coefficient for Alumina-Water-Based Nanofluids. J. Therm. Anal. Calorim. 2019, 136, 1395–1414. [Google Scholar] [CrossRef]

- Zhou, Z.; Davoudi, E.; Vaferi, B. Monitoring the effect of surface functionalization on the CO2 capture by graphene oxide/methyl diethanolamine nanofluids. J. Environ. Chem. Eng. 2021, 9, 106202. [Google Scholar] [CrossRef]

- Vaferi, B.; Eslamloueyan, R.; Ayatollahi, S. Automatic recognition of oil reservoir models from well testing data by using multi-layer perceptron networks. J. Pet. Sci. Eng. 2011, 77, 254–262. [Google Scholar] [CrossRef]

- Atashi, A.; Nazeri, N.; Abbasi, E.; Dorri, S.; Alijani-Z, M. Breast Cancer Risk Assessment Using adaptive neuro-fuzzy inference system (ANFIS) and Subtractive Clustering Algorithm. Multidiscip. Cancer Investig. 2017, 1, 20–26. [Google Scholar] [CrossRef] [Green Version]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl. Math. Model. 2015, 39, 1837–1852. [Google Scholar] [CrossRef]

- Hosseini, S.; Vaferi, B. Determination of Methanol Loss Due to Vaporization in Gas Hydrate Inhibition Process Using Intelligent Connectionist Paradigms. Arab. J. Sci. Eng. 2021, 1–9. [Google Scholar] [CrossRef]

- Lacour, C.; Massart, P.; Rivoirard, V. Estimator Selection: A New Method with Applications to Kernel Density Estimation. Sankhya A 2017, 79, 298–335. [Google Scholar] [CrossRef] [Green Version]

| Crystallization Time (min) | Crystallization Temperature (°C) | PGA Dosage (wt%) | Relative Crystallinity (%) | Numbers of Measurements |

|---|---|---|---|---|

| 0–50 | 90–125 | 0 | 0–100 | 103 |

| 0–40 | 85–125 | 2 | 0–100 | 80 |

| 0–35 | 85–125 | 4 | 0–100 | 100 |

| 0–35 | 85–125 | 6 | 0–100 | 85 |

| 0–25 | 85–125 | 8 | 0–100 | 63 |

| Index Value | Direction of Relevancy | Magnitude of Relevancy |

|---|---|---|

| −1 to < 0 | Indirect | Magnitude of indirect relationship increases from zero to −1 |

| 0 | No dependency | No dependency |

| <0 to +1 | Direct | Magnitude of direct relationship increases from zero to 1 |

| Machine Learning Method | Structural Property | Numbers of Model | |

|---|---|---|---|

| Fixed Property | Adjustable Property | ||

| MLPNN | Number of hidden layers, i.e., two [37] The activation function of the hidden layer, i.e., hyperbolic tangent [37] The activation function of the hidden layer, i.e., logistic [37] Training algorithm, i.e., Levenberg–Marquardt [51] | Number of hidden neurons | 200 |

| CFFNN | Number of hidden layers, i.e., two [37] The activation function of the hidden layer, i.e., hyperbolic tangent [37] The activation function of the hidden layer, i.e., logistic [37] Training algorithm, i.e., Levenberg–Marquardt [51] | Number of hidden neurons | 200 |

| RNN | Number of hidden layers, i.e., two [37] The activation function of the hidden layer, i.e., hyperbolic tangent [37] The activation function of the hidden layer, i.e., logistic [37] Training algorithm, i.e., scaled conjugate gradient [52] | Number of hidden neurons | 160 |

| LSSVR | Training algorithm, i.e., least-squares method [40] | Kernel function | 150 |

| ANFIS2 | Membership function, i.e., subtractive clustering [38,53] | Radius of cluster Training algorithm | 400 |

| ANFIS3 | Membership function, i.e., c-means clustering [54,55] | Number of clusters Training algorithm | 400 |

| Model | The Most Appropriate Characteristics | Collection | AAPD% | RAPE% | RMSE | R2 |

|---|---|---|---|---|---|---|

| MLPNN | Nine hidden neurons | Training | 11.13 | 7.38 | 4.95 | 0.988679 |

| Hyperbolic tangent and logistic | Testing | 6.25 | 5.37 | 2.38 | 0.997467 | |

| Levenberg optimization algorithm | Overall | 10.39 | 7.07 | 4.65 | 0.990062 | |

| CFFNN | Nine hidden neurons | Training | 8.74 | 6.68 | 4.54 | 0.990058 |

| Hyperbolic tangent and logistic | Testing | 9.42 | 7.28 | 5.32 | 0.990337 | |

| Levenberg optimization algorithm | Overall | 8.84 | 6.76 | 4.67 | 0.990082 | |

| RNN | Seven hidden neurons | Training | 10.92 | 9.81 | 4.00 | 0.992677 |

| Hyperbolic tangent and logistic | Testing | 11.07 | 13.76 | 9.14 | 0.966081 | |

| Scaled conjugate gradient algorithm | Overall | 10.94 | 10.44 | 5.12 | 0.988174 | |

| LSSVR | Gaussian kernel function | Training | 13.03 | 8.14 | 5.22 | 0.987382 |

| Testing | 14.13 | 8.78 | 4.33 | 0.992005 | ||

| Overall | 13.20 | 8.24 | 5.09 | 0.988064 | ||

| ANFIS2 | Hybrid optimization algorithm Cluster radius = 0.5 | Training | 8.54 | 5.27 | 4.41 | 0.991163 |

| Testing | 16.28 | 8.79 | 5.36 | 0.985432 | ||

| Overall | 9.71 | 5.74 | 4.57 | 0.990414 | ||

| ANFIS3 | Hybrid optimization algorithm Nine clusters | Training | 25.81 | 13.87 | 6.29 | 0.981923 |

| Testing | 19.01 | 18.39 | 7.78 | 0.971648 | ||

| Overall | 24.78 | 14.53 | 6.54 | 0.980306 |

| Hidden Layer | Output Layer | Training | Testing | Overall |

|---|---|---|---|---|

| Hyperbolic tangent | Logistic | 8.74 | 9.42 | 8.84 |

| Logistic | Logistic | 7.97 | 8.61 | 8.06 |

| Logistic | Hyperbolic tangent | 8.33 | 6.80 | 8.10 |

| Hyperbolic tangent | Hyperbolic tangent | 9.35 | 5.53 | 8.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Ayari, M.A.; Khandakar, A.; Chowdhury, M.E.H.; Uz Zaman, S.A.; Rahman, T.; Vaferi, B. Estimating the Relative Crystallinity of Biodegradable Polylactic Acid and Polyglycolide Polymer Composites by Machine Learning Methodologies. Polymers 2022, 14, 527. https://doi.org/10.3390/polym14030527

Wang J, Ayari MA, Khandakar A, Chowdhury MEH, Uz Zaman SA, Rahman T, Vaferi B. Estimating the Relative Crystallinity of Biodegradable Polylactic Acid and Polyglycolide Polymer Composites by Machine Learning Methodologies. Polymers. 2022; 14(3):527. https://doi.org/10.3390/polym14030527

Chicago/Turabian StyleWang, Jing, Mohamed Arselene Ayari, Amith Khandakar, Muhammad E. H. Chowdhury, Sm Ashfaq Uz Zaman, Tawsifur Rahman, and Behzad Vaferi. 2022. "Estimating the Relative Crystallinity of Biodegradable Polylactic Acid and Polyglycolide Polymer Composites by Machine Learning Methodologies" Polymers 14, no. 3: 527. https://doi.org/10.3390/polym14030527

APA StyleWang, J., Ayari, M. A., Khandakar, A., Chowdhury, M. E. H., Uz Zaman, S. A., Rahman, T., & Vaferi, B. (2022). Estimating the Relative Crystallinity of Biodegradable Polylactic Acid and Polyglycolide Polymer Composites by Machine Learning Methodologies. Polymers, 14(3), 527. https://doi.org/10.3390/polym14030527