Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System

Abstract

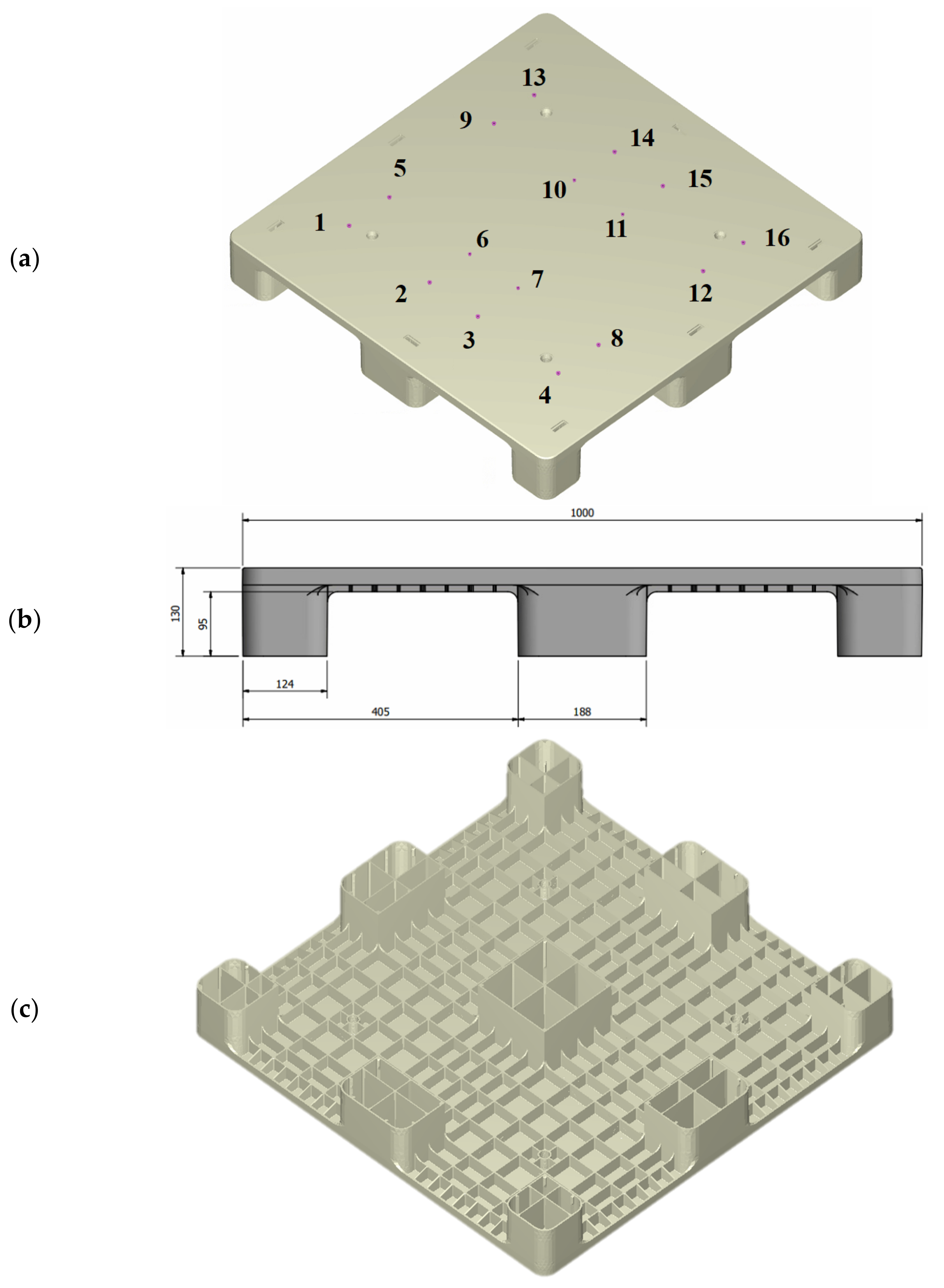

:1. Introduction

2. Experimental Setup and Software

3. Results and Discussion

3.1. Flow Front Comparison of Short Shot Testing

3.2. Flatness

3.3. Proposed Sequence of Valve Gate-Opening

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- SFS-EN ISO 445 Pallets for Materials Handling. Vocabulary. 2013. Available online: https://www.iso.org/standard/61915.html (accessed on 18 September 2021).

- Deviatkin, I.; Khan, M.; Ernst, E.; Horttanainen, M. Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability 2019, 11, 5750. [Google Scholar] [CrossRef] [Green Version]

- Edge Environment Pty Ltd Pallet Life Cycle Assessment and Benchmark. 2017. Available online: https://re-pal.com/wp-content/uploads/2019/03/Edge-Environment-Pallet-Life-Cycle-Assessment-and-Benchmark-Report.pdf (accessed on 18 September 2021).

- PlasticsEurope. Plastics–the Facts 2020: An Analysis of European Plastics Production, Demand and Waste Data. 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 17 September 2021).

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef]

- Gaxiola-Cockburn, R.; Martínez-Romero, O.; Elías-Zúñiga, A.; Olvera-Trejo, D.; Reséndiz-Hernández, J.E.; Soria-Hernández, C.G. Investigation of the Mechanical Properties of Parts Fabricated with Ultrasonic Micro Injection Molding Process Using Polypropylene Recycled Material. Polymers 2020, 12, 2033. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.-C.; Tai, C.-C. The effective factors in the warpage problem of an injection-molded part with a thin shell feature. J. Mater. Process. Technol. 2001, 110, 1–9. [Google Scholar] [CrossRef]

- Ozcelik, B.; Sonat, I. Warpage and structural analysis of thin shell plastic in the plastic injection molding. Mater. Des. 2009, 30, 367–375. [Google Scholar] [CrossRef]

- Wang, C.; Huang, M.; Shen, C.; Zhao, Z. Warpage prediction of the injection-molded strip-like plastic parts. Chin. J. Chem. Eng. 2016, 24, 665–670. [Google Scholar] [CrossRef]

- Cheng, C.D.; Tsai, H.H.; Liao, Y.L. Investigation of the Large-Scale Pallet by Recycled Polypropylene and the Sequential Valve Gate System during the Injection Molding. Adv. Polym. Technol. 2021, 2021, 19. [Google Scholar] [CrossRef]

- Kurt, M.; Saban Kamber, O.; Kaynak, Y.; Atakok, G.; Girit, O. Experimental investigation of plastic injection molding: Assessment of the effects of cavity pressure and mold temperature on the quality of the final products. Mater. Des. 2009, 30, 3217–3224. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Sorrentino, A.; Titomanlio, G. Mechanical Properties Distribution within Polypropylene Injection Molded Samples: Effect of Mold Temperature under Uneven Thermal Conditions. Polymers 2017, 9, 585. [Google Scholar] [CrossRef] [Green Version]

- Wilczyński, K.; Narowski, P. A Strategy for Problem Solving of Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2020, 12, 805. [Google Scholar] [CrossRef] [Green Version]

- Wilczyński, K.; Narowski, P. Simulation Studies on the Effect of Material Characteristics and Runners Layout Geometry on the Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2019, 11, 639. [Google Scholar] [CrossRef] [Green Version]

- Liparoti, S.; Speranza, V.; Titomanlio, G.; Pantani, R. Effect of Rapid Mold Heating on the Structure and Performance of Injection-Molded Polypropylene. Polymers 2020, 12, 341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, K.; Kim, Y.-S. Effect of Mold Temperature on Mechanical Properties of an Injection-Molded Part with Microfeatures. J. Polym. Eng. 2009, 29, 135–154. [Google Scholar] [CrossRef]

- Fang, M.L. Study of Eliminating Welding Line by Sequential Valve Gate in Hot Runner System. Master’s Thesis, Department of Mold and Die Engineering, National Kaohsiung University of Applied Science, Kaohsiung, Taiwan, 2006. [Google Scholar]

- Wu, Y.Y. Study on Strength of Welding Line Using Sequential Valve Gates. Master’s Thesis, Department of Mold and Die Engineering, National Kaohsiung University of Applied Science, Kaohsiung, Taiwan, 2009. [Google Scholar]

- Iwko, J.; Steller, R.; Wróblewski, R. Experimentally Verified Mathematical Model of Polymer Plasticization Process in Injection Molding. Polymers 2018, 10, 968. [Google Scholar] [CrossRef] [Green Version]

- Cardozo, D. Three models of the 3D filling simulation for injection molding: A brief review. J. Reinforced Plas. Compos. 2008, 27, 1963–1974. [Google Scholar] [CrossRef]

- Chang, R.Y.; Yang, W.H. Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int. J. Numer. Meth. Fluids 2001, 37, 125–148. [Google Scholar] [CrossRef]

- Hua, S.; Zhang, S.; Cao, W.; Wang, Y.; Shao, C.; Liu, C.; Dong, B.; Shen, C. Simulation of Jetting in Injection Molding Using a Finite Volume Method. Polymers 2016, 8, 172. [Google Scholar] [CrossRef] [Green Version]

- Baldi-Boleda, T.; Sadeghi, E.; Colominas, C.; García-Granada, A. Simulation Approach for Hydrophobicity Replication via Injection Molding. Polymers 2021, 13, 2069. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers 2016, 8, 199. [Google Scholar] [CrossRef]

- Zink, B.; Szabó, F.; Hatos, I.; Suplicz, A.; Kovács, N.K.; Hargitai, H.; Tábi, T.; Kovács, J.G. Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers 2017, 9, 77. [Google Scholar] [CrossRef] [Green Version]

- Krebelj, K.; Krebelj, A.; Halilovič, M.; Mole, N. Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers 2021, 13, 138. [Google Scholar] [CrossRef]

- Huang, C.-T.; Chen, X.-W.; Fu, W.-W. Investigation on the Fiber Orientation Distributions and Their Influence on the Mechanical Property of the Co-Injection Molding Products. Polymers 2020, 12, 24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, C.-Y.; Hwang, S.-S.; Chen, S.-C.; Lai, M.-C. Effects of Injection Molding Process Parameters on the Chemical Foaming Behavior of Polypropylene and Polystyrene. Polymers 2021, 13, 2331. [Google Scholar] [CrossRef]

- Guerrier, P.; Tosello, G.; Kirstein Nielsen, K.; Hattel, J.H. Three-dimensional numerical modeling of an induction heated injection molding tool with flow visualization. Int. J. Adv. Manuf. Technol. 2016, 85, 643–660. [Google Scholar] [CrossRef] [Green Version]

- Guerrier, P.; Tosello, G.; Hattel, J.H. Flow visualization and simulation of the filling process during injection moulding. CIRP J. Manuf. Sci. Technol. 2017, 16, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Moayyedian, M.; Mamedov, A. Multi-objective optimization of injection molding process for determination of feasible moldability index. Procedia CIRP 2019, 84, 769–773. [Google Scholar] [CrossRef]

- Nian, S.C.; Wu, C.Y.; Huang, M.S. Warpage control of thin-walled injection molding using local mold temperatures. Int. Commun. Heat Mass Transf. 2015, 61, 102–110. [Google Scholar] [CrossRef]

- Fan, B.F.; Kazmer, D.O.; Bushko, W.C.; Theriault, R.P.; Poslinski, A.J. Warpage prediction of optical media. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 859–872. [Google Scholar] [CrossRef]

| Time (s) | Start | 1 | 2 | 3 | 5 | 6 | 8 |

| Gate (#) | #3, #5, #9, #13~16 | #8, #11 | #1, #10, #12 | #4 | #7 | #6 | #2 |

| Melt temperature (°C) | 250 |

| Curing temperature (°C) | 117 |

| Mold temperature (°C) | 50 |

| Fill rate (%) | 72 |

| Filling pressure (max) [MPa] | 40 |

| Filling time (s) | 9.3 |

| Packing time (s) | 3.0 |

| Packing pressure (%) | 70 |

| Cooling time (s) | 45 |

| Mold opening time (s) | 10 |

| Time (s) | Start | 2.2 | 5.42 | 5.46 | 5.5 | 5.85 | 5.88 | 6.04 |

| Gate (#) | #6, #7, #10, #11 | #2, #3, #14, #15 | #5 | #8, #12 | #9 | #1 | #4, #16 | #13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, H.H.; Liao, Y.L. Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System. Polymers 2022, 14, 616. https://doi.org/10.3390/polym14030616

Tsai HH, Liao YL. Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System. Polymers. 2022; 14(3):616. https://doi.org/10.3390/polym14030616

Chicago/Turabian StyleTsai, Hsi Hsun, and Yi Lin Liao. 2022. "Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System" Polymers 14, no. 3: 616. https://doi.org/10.3390/polym14030616

APA StyleTsai, H. H., & Liao, Y. L. (2022). Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System. Polymers, 14(3), 616. https://doi.org/10.3390/polym14030616