Soluble Poly(amide-imide)s from Diamide–Diamine Monomer with Trifluoromethyl Groups

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Measurements

2.3. Monomer Synthesis

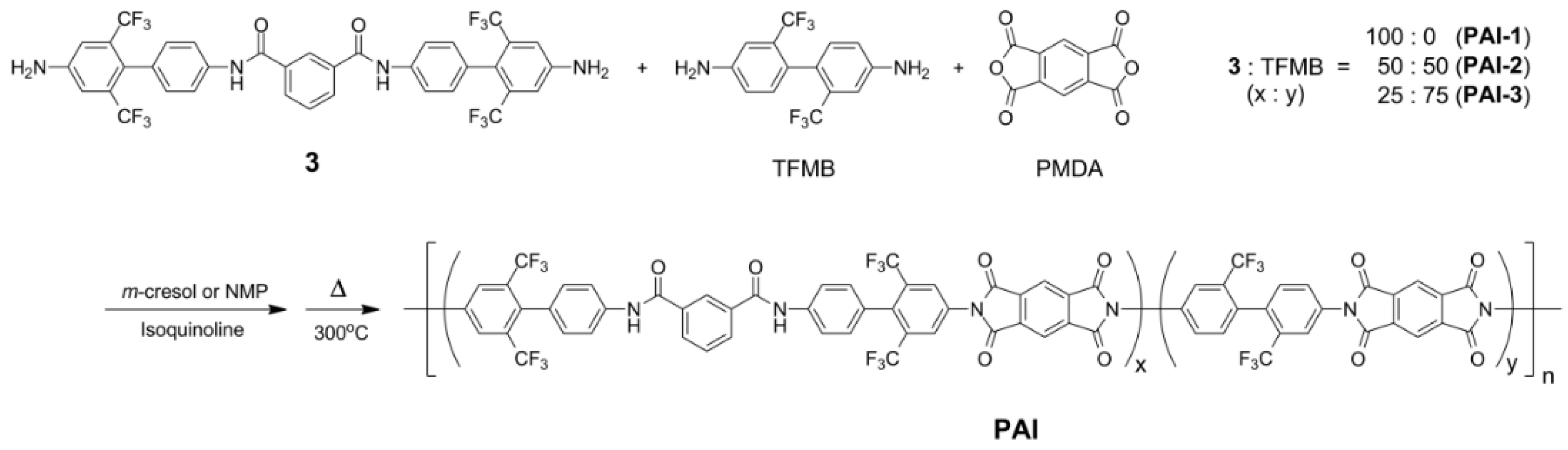

2.4. Polymerization

2.5. Preparation of Poly(amide-imide) Films

3. Results and Discussion

3.1. Monomer Synthesis

3.2. Polymerization

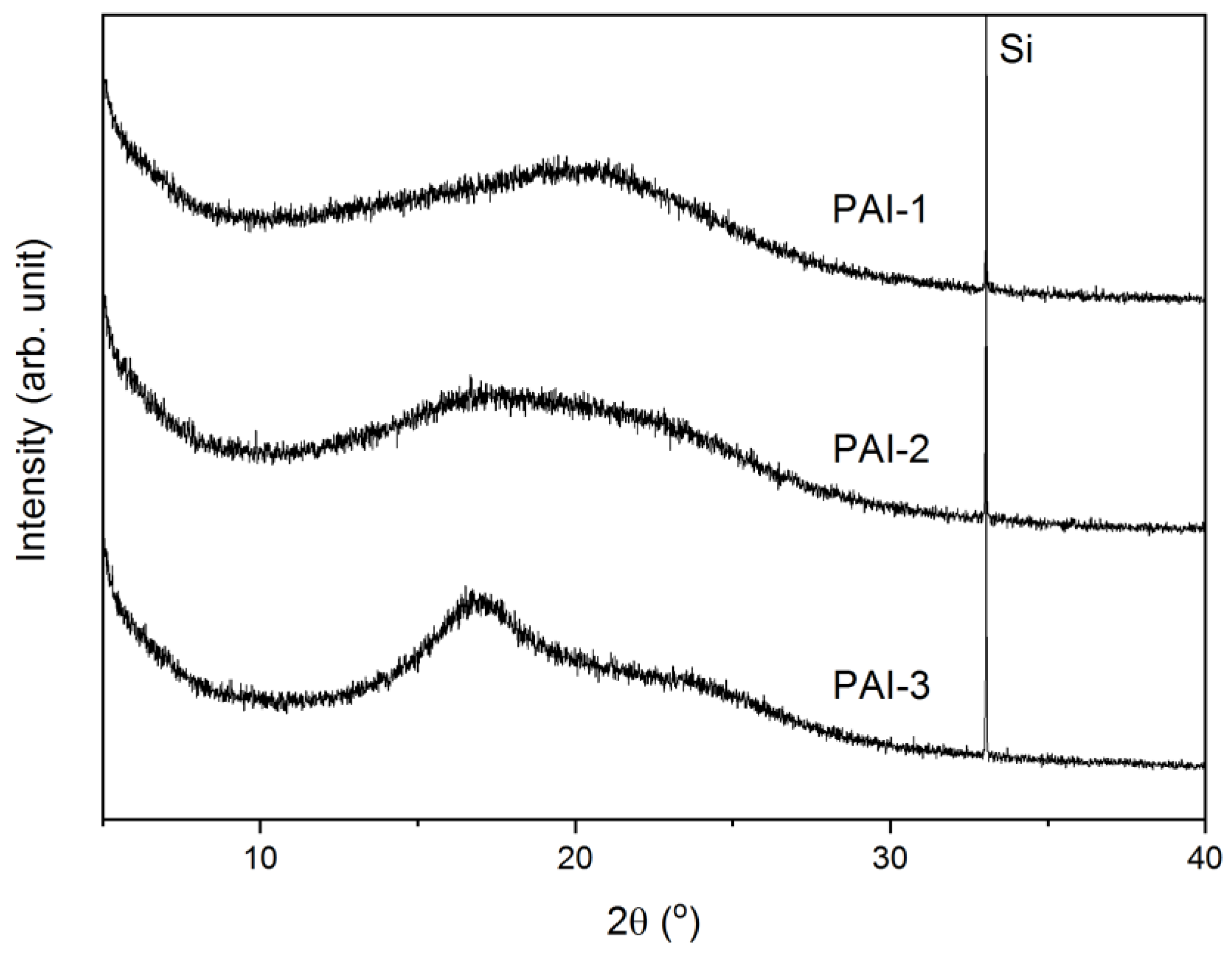

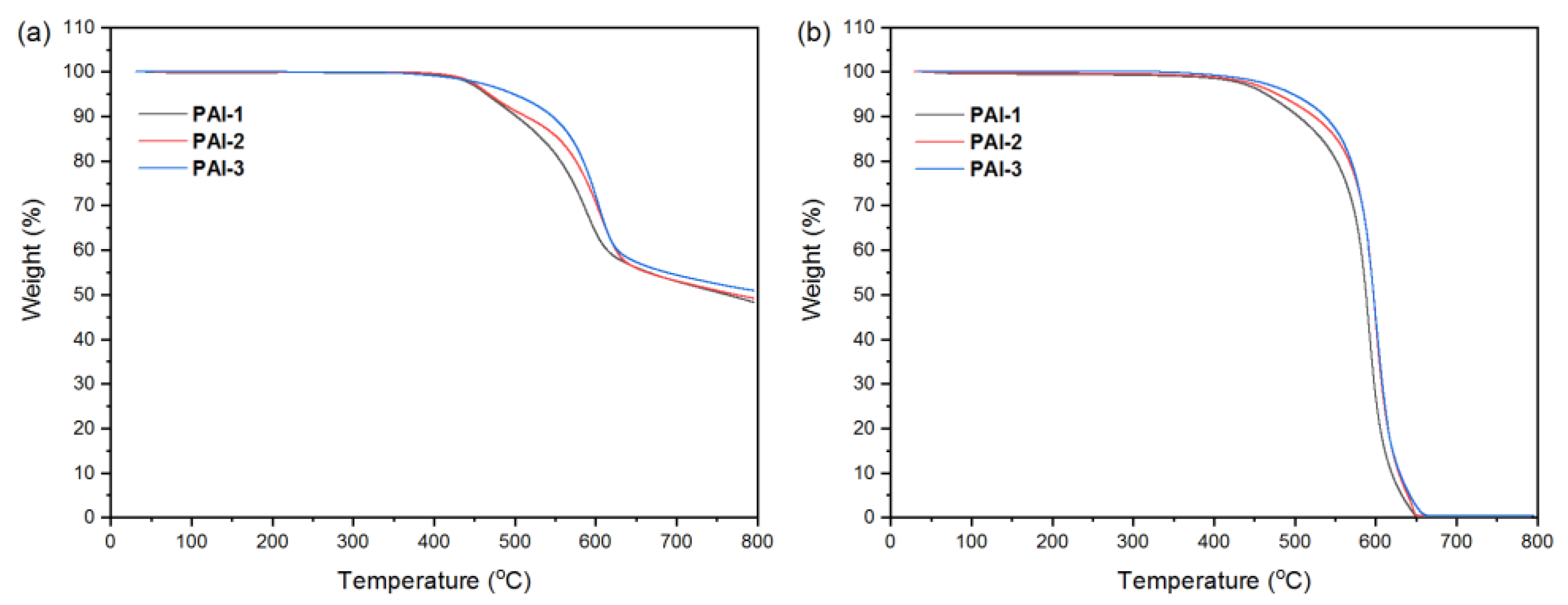

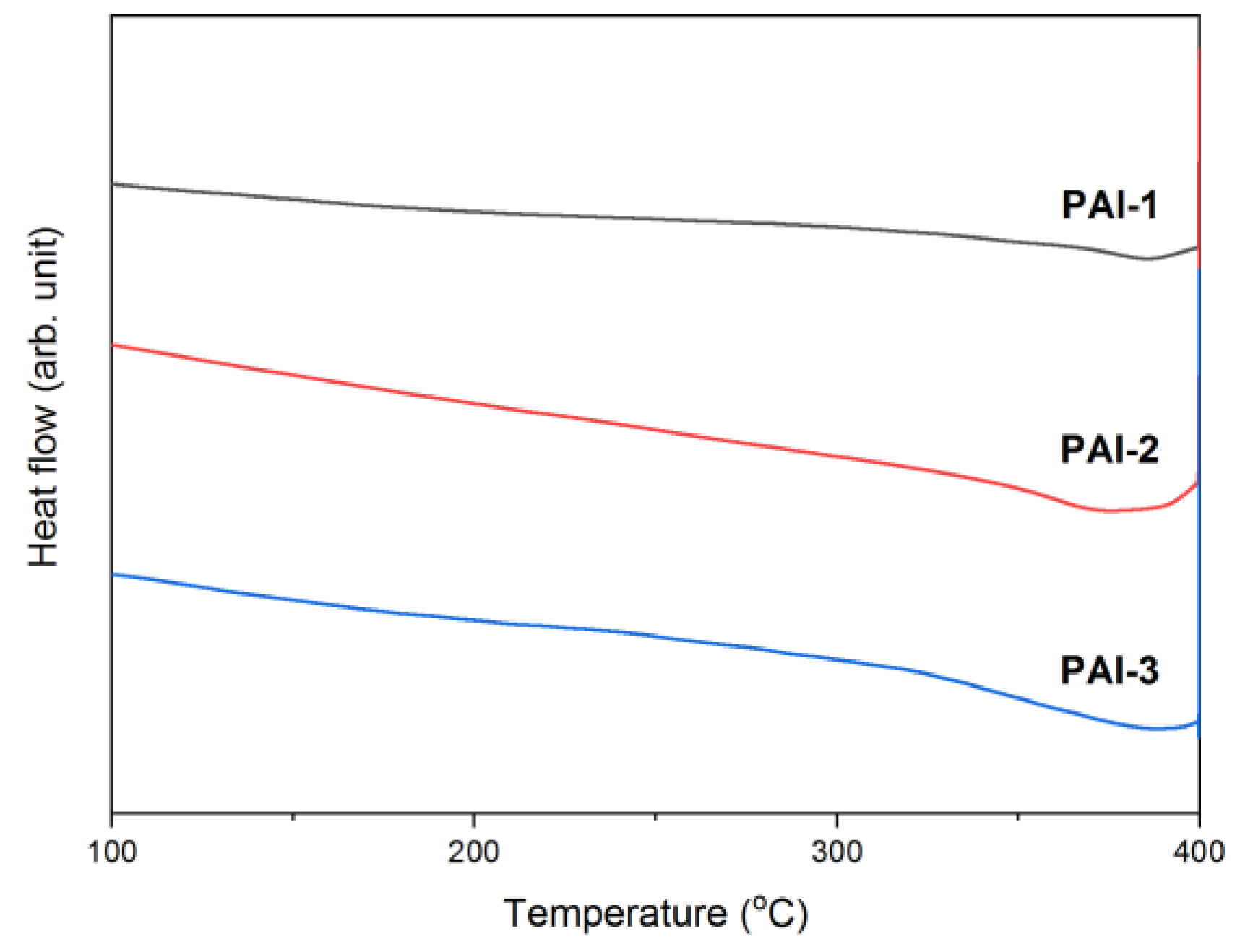

3.3. Polymer Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Malay, G.; Kash, M. Polyimides: Fundamentals and Applications, 1st ed.; Marcel, Dekker: New York, NY, USA, 1996. [Google Scholar]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Chung, I.S.; Kim, S.Y. Soluble Polyimides from Unsymmetrical Diamine with Trifluoromethyl Pendent Group. Macromolecules 2000, 33, 3190–3193. [Google Scholar] [CrossRef]

- Yang, C.-P.; Hsiao, S.-H.; Yang, H.-W. Organosoluble optically transparent poly(ether imide)s based on atert-butylhydroquinone bis(ether anhydride). Macromol. Chem. Phys. 2000, 201, 409–418. [Google Scholar] [CrossRef]

- Choi, H.; Chung, I.S.; Hong, K.; Park, C.E.; Kim, S.Y. Soluble polyimides from unsymmetrical diamine containing benzimidazole ring and trifluoromethyl pendent group. Polymer 2008, 49, 2644–2649. [Google Scholar] [CrossRef]

- Kim, S.D.; Kim, S.Y.; Chung, I.S. Soluble and transparent polyimides from unsymmetrical diamine containing two trifluoromethyl groups. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 4413–4422. [Google Scholar] [CrossRef]

- Yi, L.; Huang, W.; Yan, D. Polyimides with side groups: Synthesis and effects of side groups on their properties. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 533–559. [Google Scholar] [CrossRef]

- O’Harra, K.; Kammakakam, I.; Devriese, E.; Noll, D.; Bara, J.; Jackson, E. Synthesis and Performance of 6FDA-Based Polyimide-Ionenes and Composites with Ionic Liquids as Gas Separation Membranes. Membranes 2019, 9, 79. [Google Scholar] [CrossRef] [Green Version]

- Dodda, J.M.; Bělský, P. Progress in designing poly(amide imide)s (PAI) in terms of chemical structure, preparation methods and processability. Eur. Polym. J. 2016, 84, 514–537. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Liaw, B.-Y. Synthesis and properties of new polyamides derived from 1,4-bis(4-aminophenoxy)-2,5-di-tert-butylbenzene and aromatic dicarboxylic acids. J. Polym. Sci. Part A Polym. Chem. 1998, 36, 1069–1074. [Google Scholar] [CrossRef]

- Do Lee, Y.; Kim, K.; OK, Y.; Kim, M.; Chang, J.-H. Syntheses and Characterizations of Colorless and Transparent Poly(amide imide) Copolymer. Polym. Korea 2016, 40, 298. [Google Scholar] [CrossRef] [Green Version]

- Yin, J.; Mao, D.; Fan, B. Copolyamide-Imide Membrane with Low CTE and CME for Potential Space Optical Applications. Polymers 2021, 13, 1001. [Google Scholar] [CrossRef]

- Hasegawa, M.; Ishigami, T.; Ishii, J.; Sugiura, K.; Fujii, M. Solution-processable transparent polyimides with low coefficients of thermal expansion and self-orientation behavior induced by solution casting. Eur. Polym. J. 2013, 49, 3657–3672. [Google Scholar] [CrossRef]

- Kim, S.D.; Lee, B.; Byun, T.; Chung, I.S.; Park, J.; Shin, I.; Ahn, N.Y.; Seo, M.; Lee, Y.; Kim, Y.; et al. Poly(amide-imide) materials for transparent and flexible displays. Sci. Adv. 2018, 4, eaau1956. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murad, A.R.; Iraqi, A.; Aziz, S.B.; Hi, H.; Abdullah, S.N.; Brza, M.A.; Abdulwahid, R.T. Influence of Fluorine Substitution on the Optical, Thermal, Electrochemical and Structural Properties of Carbazole-Benzothiadiazole Dicarboxylic Imide Alternate Copolymers. Polymers 2020, 12, 2910. [Google Scholar] [CrossRef]

- James, M. Engineering Thermoplastics: Properties and Applications, 1st ed.; Marcel, Dekker: New York, NY, USA, 1985. [Google Scholar]

- Chris, D.; Roger, R. Applied Plastics Engineering Handbook, 1st ed.; Myer, K., Ed.; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Patil, P.S.; Pal, R.R.; Salunkhe, M.M.; Maldar, N.N.; Wadgaonkar, P.P. Synthesis of aromatic poly(amide-imide)s from novel diimide-diacid (DIDA) containing sulphone and bulky pendant groups by direct polycondensation with various diamines. Eur. Polym. J. 2007, 43, 5047–5054. [Google Scholar] [CrossRef]

- Bai, L.; Zhai, L.; He, M.; Wang, C.; Mo, S.; Fan, L. Preparation of heat-resistant poly(amide-imide) films with ultralow coefficients of thermal expansion for optoelectronic application. React. Funct. Polym. 2019, 141, 155–164. [Google Scholar] [CrossRef]

- Javadi, A.; Shockravi, A.; Rafieimanesh, A.; Malek, A.; Ando, S. Synthesis and structure-property relationships of novel thiazole-containing poly(amide imide)s with high refractive indices and low birefringences. Polym. Int. 2015, 64, 486–495. [Google Scholar] [CrossRef]

- Li, W.; Qian, X.; Shi, H.; Zhou, W.; Cai, Y.; Liu, Y.; Shen, K. Synthesis and properties of novel soluble poly(amide-imide)s with different pendant substituents. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 3243–3252. [Google Scholar] [CrossRef]

- Özarslan, Ö.; Yilmaz, T.; Yildiz, E.; Fiedeldei, U.; Kuyulu, A.; Güngör, A. The preparation of perfectly alternating poly(amide-imide)s via amide unit containing new diamine. J. Polym. Sci. Part A Polym. Chem. 1997, 35, 1149–1155. [Google Scholar] [CrossRef]

- Hasegawa, M.; Watanabe, Y.; Tsukuda, S.; Ishii, J. Solution-processable colorless polyimides with ultralow coefficients of thermal expansion for optoelectronic applications. Polym. Int. 2016, 65, 1063–1073. [Google Scholar] [CrossRef]

- Matsuura, T.; Hasuda, Y.; Nishi, S.; Yamada, N. Polyimide derived from 2,2′-bis(trifluoromethyl)-4,4′-diaminobiphenyl. 1. Synthesis and characterization of polyimides prepared with 2,2′-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride or pyromellitic dianhydride. Macromolecules 1991, 24, 5001–5005. [Google Scholar] [CrossRef]

- Kim, S.D.; Ka, D.; Chung, I.S.; Kim, S.Y. Poly(arylene ether)s with Low Refractive Indices: Poly(biphenylene oxide)s with Trifluoromethyl Pendant Groups via a Meta-Activated Nitro Displacement Reaction. Macromolecules 2012, 45, 3023–3031. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, R.; Seo, M.; Lee, H.-S. Double-activated nucleophilic aromatic substitution polymerization by bis-ortho-trifluoromethyl groups to soluble para-poly(biphenylene oxide). Polymer 2020, 188, 122124. [Google Scholar] [CrossRef]

- Zhang, K.; Ishida, H. Smart Synthesis of High-Performance Thermosets Based on ortho-Amideâ-Imide Functional Benzoxazines. Front. Mater. 2015, 2. [Google Scholar] [CrossRef] [Green Version]

- Pramoda, K.P.; Chung, T.S.; Liu, S.L.; Oikawa, H.; Yamaguchi, A. Characterization and thermal degradation of polyimide and polyamide liquid crystalline polymers. Polym. Degrad. Stab. 2000, 67, 365–374. [Google Scholar] [CrossRef]

- Hong, W.; Yuan, L.; Ma, Y.; Cui, C.; Zhang, H.; Yang, S.; Sun, W.-H. Resin Transfer Moldable Fluorinated Phenylethynyl-Terminated Imide Oligomers with High Tg: Structure-Melt Stability Relationship. Polymers 2021, 13, 903. [Google Scholar] [CrossRef]

- Hasegawa, M.; Hishiki, T. Poly(ester imide)s Possessing Low Coefficients of Thermal Expansion and Low Water Absorption (V). Effects of Ester-linked Diamines with Different Lengths and Substituents. Polymers 2020, 12, 859. [Google Scholar] [CrossRef] [Green Version]

- Ishige, R.; Masuda, T.; Kozaki, Y.; Fujiwara, E.; Okada, T.; Ando, S. Precise Analysis of Thermal Volume Expansion of Crystal Lattice for Fully Aromatic Crystalline Polyimides by X-ray Diffraction Method: Relationship between Molecular Structure and Linear/Volumetric Thermal Expansion. Macromolecules 2017, 50, 2112–2123. [Google Scholar] [CrossRef]

- Hasegawa, M. Development of Solution-Processable, Optically Transparent Polyimides with Ultra-Low Linear Coefficients of Thermal Expansion. Polymers 2017, 9, 520. [Google Scholar] [CrossRef]

- Wooten, F. Optical Properties of Solids, 1st ed.; Academic Press: New York, NY, USA, 1972; ISBN 9781483220765. [Google Scholar]

| Solvents | PAI-1 | PAI-2 | PAI-3 |

|---|---|---|---|

| NMP | ++ | ++ | + (gel on r.t.) |

| DMAc | ++ | ++ | + (gel on r.t.) |

| DMF | ++ | ++ | + (gel on r.t.) |

| DMSO | +− (gel on r.t.) | +− | − |

| m-cresol | − | − | − |

| THF | − | ++ | − |

| Anisole | − | − | − |

| Chloroform | − | − | − |

| Ethyl acetate | − | − | − |

| Acetone | − | − | − |

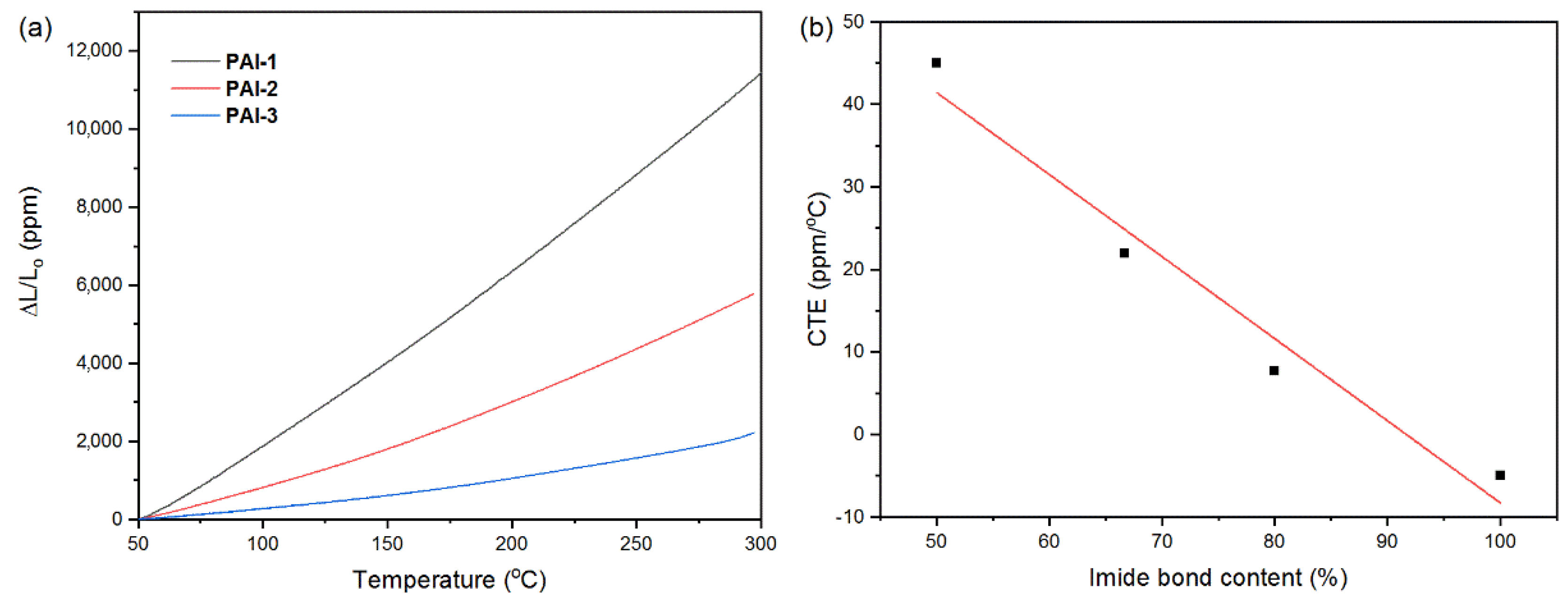

| Polymer Code | Td5 (°C) a | Tg (°C) b | CTE (ppm/°C) c | Char Yield (%) d | ||

|---|---|---|---|---|---|---|

| In N2 | In Air | 2nd Run | 3rd Run | |||

| PAI-1 | 465 | 464 | - e | 45.0 | 44.8 | 48 |

| PAI-2 | 468 | 478 | - e | 21.9 | 21.9 | 49 |

| PAI-3 | 498 | 497 | - e | 7.7 | 7.8 | 51 |

| Polymer Code | Cutoff Wavelength (nm) | Transmittance (%) | Film Thickness (μm) | |

|---|---|---|---|---|

| at 400 nm | at 550 nm | |||

| PAI-1 | 358 | 13.0 | 82.1 | ~25 |

| PAI-2 | 364 | 11.8 | 83.6 | ~25 |

| PAI-3 | 370 | 10.6 | 62.0 | ~15 |

| λ (nm) | Polymer Code | nTE a | nTM b | nav c | Δn d | ε e | d (μm) f |

|---|---|---|---|---|---|---|---|

| 633 | PAI-1 | 1.620 | 1.540 | 1.593 | 0.080 | 2.79 | 16.5 |

| PAI-2 | 1.627 | 1.533 | 1.596 | 0.094 | 2.80 | 20.9 | |

| PAI-3h | - | - | - | - | - | - | |

| 1310 | PAI-1 | 1.596 | 1.516 | 1.569 | 0.080 | 2.71 | 15.0 |

| PAI-2 | 1.596 | 1.512 | 1.568 | 0.084 | 2.70 | 20.6 | |

| PAI-3h | - | - | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Byun, T.; Kim, S.J.; Kim, S.Y. Soluble Poly(amide-imide)s from Diamide–Diamine Monomer with Trifluoromethyl Groups. Polymers 2022, 14, 624. https://doi.org/10.3390/polym14030624

Byun T, Kim SJ, Kim SY. Soluble Poly(amide-imide)s from Diamide–Diamine Monomer with Trifluoromethyl Groups. Polymers. 2022; 14(3):624. https://doi.org/10.3390/polym14030624

Chicago/Turabian StyleByun, Taejoon, Seong Jong Kim, and Sang Youl Kim. 2022. "Soluble Poly(amide-imide)s from Diamide–Diamine Monomer with Trifluoromethyl Groups" Polymers 14, no. 3: 624. https://doi.org/10.3390/polym14030624

APA StyleByun, T., Kim, S. J., & Kim, S. Y. (2022). Soluble Poly(amide-imide)s from Diamide–Diamine Monomer with Trifluoromethyl Groups. Polymers, 14(3), 624. https://doi.org/10.3390/polym14030624