Enhancing the In-Plane Behavior of a Hybrid Timber Frame–Mud and Stone Infill Wall Using PP Band Mesh on One Side

Abstract

:1. Introduction

2. Current Retrofitting Techniques for Village Buildings

- (1)

- FRP retrofitting technique

- (2)

- Steel strip retrofitting technique

- (3)

- Post-tensioned wire rope retrofitting technique

- (4)

- Fiber-reinforced cement composite retrofitting technique

- (5)

- Welded wire mesh and mortar retrofitting technique

- (6)

- Polypropylene (PP) band mesh and plastering mortar retrofitting technique

3. PP Band Mesh Retrofitting Method for Wood Frame Structures with Mud and Stone Infill Walls

4. Construction and Retrofitting Procedures

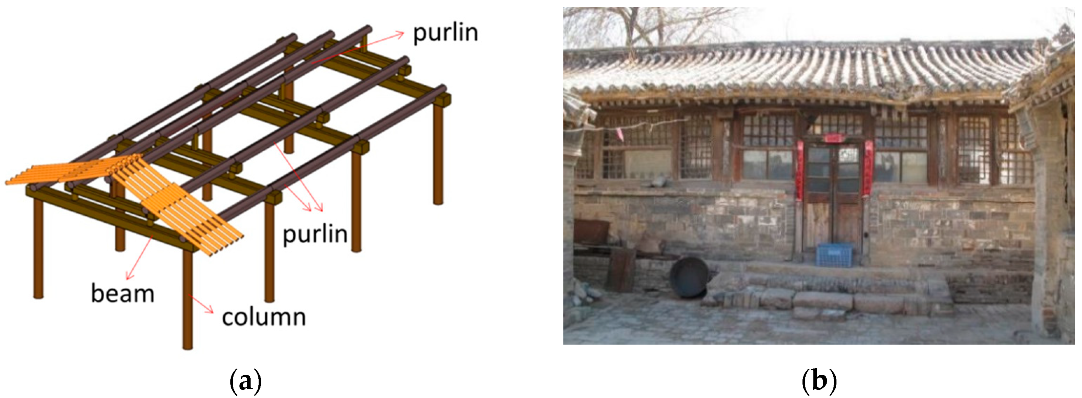

4.1. Timber Frame

4.2. Rubble Masonry Infill with Pebbles

4.3. Retrofitting Procedure

5. Experimental Program

5.1. Mechanical Properties of Materials

5.2. Test Setup and Loading Protocols

6. Result and Discussion

6.1. Experimental Phenomena of Strengthened Timber–Stone Hybrid Wall with PP Band Mesh

6.2. Hysteresis Curves

6.3. Idealized Equivalent Bilinear Curves

6.4. Stiffness Degradation Behavior

6.5. Energy Dissipation

7. Comparison with an Unreinforced Specimen with Irregular Rubble Infill

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xue, J.; Xu, D.; Ren, G.; Guo, R. Shake table test on seismic performance of column and tie wooden structure in traditional residence. Chin. Civ. Eng. J. 2019, 52, 5–14. (In Chinese) [Google Scholar] [CrossRef]

- Wang, H.; Shang, S.; He, F.; Huang, S.; Deng, T.; Liu, D. Shaking table tests of Chinese traditional wood building and light wood framed building. J. Build. Struct. 2012, 33, 138–143. (In Chinese) [Google Scholar] [CrossRef]

- Xue, J.; Xu, D.; Guo, R. Shaking table tests and contrastive analysis for column-and-tie wooden buildings with and without infills. J. Vib. Shock 2020, 39, 184–192. (In Chinese) [Google Scholar] [CrossRef]

- Xiong, H.; Wang, J.; Wu, L.; Chen, L. Experimental study on lateral resistance performance of Chuandou wooden frame structures. J. Build. Struct. 2018, 39, 122–129. (In Chinese) [Google Scholar] [CrossRef]

- Makarios, T.; Demosthenous, M. Seismic response of traditional buildings of Lefkas Island. Greece. Eng. Struct. 2006, 28, 264–278. [Google Scholar] [CrossRef]

- Ruggieri, N.; Tampone, G.; Zinno, R. Historical Earthquake-Resistant Timber Frames in the Mediterranean Area; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Meireles, H.; Bento, R.; Cattari, S.; Lagomarsino, S. A hysteretic model for “frontal” walls in Pombalino buildings. Bull. Earthq. Eng. 2012, 10, 1481–1502. [Google Scholar] [CrossRef]

- Dutu, A.; Ferreira, J.; Guerreiro, L.; Branco, F.; Goncalves, A.M. Timbered masonry for earthquake resistance in Europe. Mater. De Constr. 2012, 62, 615–628. [Google Scholar] [CrossRef] [Green Version]

- Langenbach, R. From “opus craticium” to the “Chicago frame”: Earthquake resistant traditional construction. Int. J. Archit. Herit. 2007, 1, 29–59. [Google Scholar] [CrossRef]

- Poletti, E.; Vasconcelos, G. Seismic behavior of traditional timber frame walls: Experimental results on unreinforced walls. Bull. Earthq. Eng. 2015, 13, 885–916. [Google Scholar] [CrossRef]

- Yasemin, D.A. Seismic resistance of traditional timber-frame hımış structures in Turkey: A brief overview. Int. Wood. Prod. J. 2017, 8, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Champagne, F.V.; Sieffert, Y.; Grange, S.; Polastri, A.; Daudeville, L. Experimental analysis of seismic resistance of timber-framed structures with stones and earth infill. Eng. Struct. 2014, 69, 102–115. [Google Scholar] [CrossRef]

- Dutu, A.; Niste, A.M.; Spatarelu, A.I.; Dima, D.I.; Kishiki, S. Seismic evaluation of Romanian traditional buildings with timber frame and mud masonry infills by in-plane static cyclic tests. Eng. Struct. 2018, 167, 655–670. [Google Scholar] [CrossRef]

- Cruz, H.; Pedro, J.; Stap, M.; Fronteira, A.M.D.; José, L.; Machado, S. The Use of FRP in the Strengthening of Timber Reinforced Masonry Load-Bearing Walls; Lourenço, P.B., Roca, P., Eds.; Historical Constructions: Guimarães, Portugal, 2001; pp. 847–856. [Google Scholar]

- Vasconcelos, G.; Poletti, E.; Salavessa, E.; Jesus, A.M.; Loureno, P.B.; Pilaon, P. In-plane shear behavior of traditional timber walls. Eng. Struct. 2013, 56, 1028–1048. [Google Scholar] [CrossRef]

- Poletti, E.; Vasconcelo, G. Seismic behavior of traditional half-timbered walls: Cyclic tests and strengthening solutions. J. Herit. Conserv. 2012, 32, 137–142. [Google Scholar]

- Ali, Q.; Schacher, T.; Ashraf, M.; Alam, B.; Naeem, A.; Ahmad, M.N.; Umar, M. In-plane behavior of full scale Dhajji Walls (Wooden Braced with Stone Infill) under quasi static loading. Earthq. Spectra 2012, 28, 835–858. [Google Scholar] [CrossRef]

- Ehsani, M.R. Strengthening of earthquake damaged masonry structures with composite materials. In Non-Metallic (FRP) Reinforcement for Concrete Structure, Proceedings of the Second International Rilem Symposium, London, UK, October 1995; E & FN Spon: London, UK, 1997; pp. 680–687. [Google Scholar]

- ElGawady, M.A.; Lestuzzi, P.; Badoux, M. Static cyclic response of masonry walls retrofitted with fiber-reinforced polymers. J. Compos. Constr. 2007, 11, 50–61. [Google Scholar] [CrossRef]

- Chagas, J.; Moita, G. Influence of fibre reinforced polymers in the rehabilitation of damaged masonry wallettes. Appl. Adhes. Sci. 2015, 3, 6. [Google Scholar] [CrossRef] [Green Version]

- Fam, A.; Musiker, D.; Kowalsky, M.; Rizkalla, S. In-plane testing of damaged masonry wall repaired with FRP. Adv. Compos. Lett. 2003, 11, 277–283. [Google Scholar] [CrossRef] [Green Version]

- Marcari, G.; Manfredi, G.; Pecce, M. Experimental behavior of masonry panels strengthened with FRP sheets. In Proceedings of the 6th Internaition Symposium on Fibre-Reinforced Polymer Reinforcement for Concrete Structures, Singapore, 8–10 July 2003; pp. 1209–1218. [Google Scholar] [CrossRef]

- Zhou, D.; Lei, Z.; Wang, J. In-plane behavior of seismically damaged masonry walls repaired with external BFRP. Compos. Struct. 2013, 102, 9–19. [Google Scholar] [CrossRef]

- Zhou, D.; Zhou, S.; Lei, Z. In-Plane Shear Behaviors of Constrained Masonry Walls Externally Retrofitted with BFRP. J. Compos. Constr. 2016, 20, 04015059. [Google Scholar] [CrossRef]

- Tumialan, J.G.; Morbin, A.; Micelli, F.; Nanni, A. Flexural strengthening of URM walls with FRP laminates. In Proceedings of the 3rd International Conference on Composites in Infrastructure, San Francisco, CA, USA, 9–10 September 2003. [Google Scholar]

- Yu, W.; Ge, X.; Zhu, L. Experimental Study on Shaking Table Test of Adobe Building Model of Kashi, Xinjiang. Earthq. Resist. Eng. Retrofit. 2007, 29, 24–29. (In Chinese) [Google Scholar] [CrossRef]

- Jing, D.; Yan, J.; Cao, S. Experimental Study on Seismic Performance of Brick Masonry Infill Walls with Wood Frame Strengthened by Embedded Steel Bars and External Steel Plates. J. Hunan Univ. 2016, 43, 43–49. (In Chinese) [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Castori, G.; Molinari, A. Stainless steel strip–A proposed shear reinforcement for masonry wall panels. Constr. Build. Mater. 2019, 211, 594–604. [Google Scholar] [CrossRef]

- Farooq, S.H.; Shahid, I.; Llyas, M. Seismic performance of masonry strengthened with steel strips. KSCE J. Civ. Eng. 2014, 18, 2170–2180. [Google Scholar] [CrossRef]

- Darbhanzi, A.; Marefat, M.S.; Khanmohammadi, M. Investigation of in-plane seismic retrofit of unreinforced masonry walls by means of vertical steel ties. Constr. Build. Mater. 2014, 52, 122–129. [Google Scholar] [CrossRef]

- Wight, G.D.; Ingham, J.M.; Wilton, A.R. Innovative seismic design of a post-tensioned concrete masonry house. Can. J. Civ. Eng. 2007, 34, 1393–1402. [Google Scholar] [CrossRef]

- Wight, G.D.; Kowalsky, M.J.; Ingham, J.M. Shake table testing of posttensioned concrete masonry walls with openings. J. Struct. Eng. 2007, 133, 1551–1559. [Google Scholar] [CrossRef]

- Renle, M.A.; Lu, J.A.; Minjuan, H.A.; Cheng, F.B.; Feng, L.C. Experimental investigations on masonry structures using external prestressing techniques for improving seismic performance. Eng. Struct. 2012, 42, 297–307. [Google Scholar] [CrossRef]

- Yang, K.H.; Joo, D.B.; Sim, J.I.; Kang, J.H. In-plane seismic performance of unreinforced masonry walls strengthened with unbonded prestressed wire rope units. Eng. Struct. 2012, 45, 449–459. [Google Scholar] [CrossRef]

- Liu, H.; Yue, Y.; Han, M.; Tian, Y. Application of prestressed seismic retrofitting technology in strengthening and reconstruction of rural dilapidated residences. Build. Struct. 2020, 50, 6. (In Chinese) [Google Scholar] [CrossRef]

- Liu, H.; Han, M.; Lan, C.; Wang, T.; Tian, Y. Pseudo-dynamic test and quasi-static test of full-scale model of a two-story brick building retrofitted with prestressed tendons. Chin. Civ. Eng. J. 2016, 49, 44–63. (In Chinese) [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Karlos, K.; Papathanasiou, M. Textile reinforced mortar (TRM) versus FRP as strengthening material of URM walls: Out-of-plane cyclic loading. Mater. Struct. 2007, 40, 1081–1097. [Google Scholar] [CrossRef]

- Arisoy, B.; Ercan, E.; Demir, A. Strengthening of brick masonry with PVA fiber reinforced cement stucco. Constr. Build. Mater. 2015, 79, 255–262. [Google Scholar] [CrossRef]

- Lin, Y.W.; Wotherspoon, L.; Scott, A.; Ingham, J.M. In-plane strengthening of clay brick unreinforced masonry wallettes using ECC shotcrete. Eng. Struct. 2014, 66, 57–65. [Google Scholar] [CrossRef]

- Deng, M.; Dong, Z.; Yang, S.; Wang, L.; Zhou, T. Shaking table test on damaged masonry structure reinforced with high ductile concrete layer. Eng. Mech. 2019, 36, 10. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, T.; Liu, B.; Shi, Q.; Zhang, B. Seismic retrofitted experiment on the timber frame-cavity wall houses by shaking table test. World Earthq. Eng. 2019, 35, 17–26. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2019&filename=SJDC201901003&uniplatform=NZKPT&v=GiFigZwVyoM1UfsScn3CIrv7cmlvyuoujHnR9pRADpHoYzuoe19h4gdwOhUTntv0 (accessed on 12 January 2022). (In Chinese).

- Kadam, S.B.; Singh, Y.; Bing, L. Strengthening of unreinforced masonry using welded wire mesh and micro-concrete—Behaviour under in-plane action. Constr. Build. Mater. 2014, 54, 247–257. [Google Scholar] [CrossRef]

- Shermi, C.; Dubey, R.N. In-plane behaviour of unreinforced masonry panel strengthened with welded wire mesh and mortar. Constr. Build. Mater. 2018, 178, 195–203. [Google Scholar] [CrossRef]

- Messali, F.; Meteili, G.; Plizzari, G.A. Experimental results on the retrofitting of hollow brick masonry walls with reinforced high performance mortar coatings. Constr. Build. Mater. 2017, 141, 619–630. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, S.; Chen, Y.; Liu, H. Seismic behavior of a retrofitted one-story four-bay masonry residential building in rural area of Beijing. J. Build. Struct. 2018, 39, 8. (In Chinese) [Google Scholar] [CrossRef]

- Kadam, S.B.; Singh, Y.; Li, B. Out-of-plane behaviour of unreinforced masonry strengthened using ferrocement overlay. Mater. Struct. 2015, 48, 3187–3203. [Google Scholar] [CrossRef]

- Navaratnarajah, S.; Meguro, K. Seismic retrofitting of non-engineering masonry houses using polypropylene band meshes. In Proceedings of the 2nd International Symposium on Advances in Civil and Environmental Engineering, Nanning, China, 22–24 May 2020. [Google Scholar]

- Mayorca, P.; Meguro, K. Efficiency of polypropylene bands for the strengthening of masonry structures in developing countries. In Proceedings of the 5th International Summer Symposium, Hongkong, China, 1–3 June 2008. [Google Scholar]

- Mayorca, P.; Meguro, K. Proposal of an Efficient Technique for Retrofitting Unreinforced Masonry Dwellings. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Sugijopranoto, A.; Triwiyono, A.; Priyosulistyo, H. Experimental Investigation on Pre-stressed Polypropylene-band. Procedia Eng. 2017, 171, 1341–1347. [Google Scholar] [CrossRef]

- Sathiparan, N.; Mayorca, P.; Neshali, K.N.; Guragain, R.; Meguro, K. Experimental study on unburned brick masonry wallettes retrofitted by PP-band meshes. Seisan Kenkyu 2006, 58, 121–124. [Google Scholar] [CrossRef]

- Sathiparan, N.; Mayorca, P.; Meguro, K. Parametric study on diagonal shear behavior of masonry wall retrofitted by PPband mesh. In Proceedings of the 26th Annual Conference of Japan Society for Natural Disaster Science, Sapporo, Japan, 26–31 May 2007. [Google Scholar]

- Sathiparan, N.; Mayorca, P.; Meguro, K. Shake Table Tests on One-Quarter Scale Models of Masonry Houses Retrofitted with PP-Band Mesh. Earthq. Spectra 2012, 28, 277–299. [Google Scholar] [CrossRef]

- Sathiparan, N. Effect of Roof and Diaphragm Connectivity on Dynamic Behaviour of the PP-band Retrofitted Adobe Masonry Structures. Period. Polytech. Civ. Eng. 2018, 62, 992–1000. [Google Scholar] [CrossRef] [Green Version]

- Sathiparan, N.; Meguro, K. Strengthening of adobe houses with arch roofs using tie-bars and polypropylene band mesh. Constr. Build. Mater. 2015, 82, 360–375. [Google Scholar] [CrossRef]

- Zhou, Q.; Yang, L.; Zhao, W. Experimental Analysis of Seismic Performance of Masonry Shear Wall Reinforced with PP-Band Mesh and Plastering Mortar under In-Plane Cyclic Loading. Adv. Civ. Eng. 2020, 2000, 4015790. [Google Scholar] [CrossRef]

- Banerjee, S.; Nayak, S.; Das, S. Enhancing the flexural behaviour of masonry wallet using PP band and steel wire mesh. Constr. Build. Mater. 2019, 194, 179–191. [Google Scholar] [CrossRef]

- JGJ/T70-2009; Standard for Test Method of Performance on Building Mortar. Shaanxi Provincial Building Research Institute: Shanxi, China, 2009. (In Chinese)

- GB/T 1040.1-2018; Plastics-Determination of Tensile Properties. State Administration for Market Regulation: Beijing, China, 2018. (In Chinese)

- ASTM2126-11; Standard Test Methods for Cyclic (Reversed) Load Test for Shear Resistance of Walls for Buildings. ASTM E2126: West Conshohocken, PA, USA, 2011.

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Architecture and Building Press: Beijing, China, 2015. (In Chinese)

- Shen, Y.; Yan, X.; Yu, P.; Liu, H.; Wu, G.; He, W. Seismic Resistance of Timber Frames with Mud and Stone Infill Walls in a Chinese Traditional Village Dwelling. Buildings 2021, 11, 580. [Google Scholar] [CrossRef]

| Specimen Label | Reinforcement Type | Infill Detail |

|---|---|---|

| W1 | Strengthened by PP band mesh (250 mm × 250 mm) and plastering mortar | Pebbles and irregular stones infilled with mud |

| W2 | Strengthened by PP band mesh (150 mm × 150 mm) and plastering mortar |

| Sample Label | Size (mm) | Elastic Modulus (GPa) | Ultimate Tensile Force (kN) | Ultimate Tensile Strength (MPa) | ||

|---|---|---|---|---|---|---|

| Lc | a0 | b0 | ||||

| A3 | 100 | 1 | 13 | 1.9 | 1.60 | 123 |

| A1 | 100 | 0.5 | 13.4 | 1 | 0.51 | 76 |

| A2 | 100 | 0.8 | 11 | 0.5 | 0.51 | 58 |

| A4 | 100 | 0.65 | 11.5 | 1.9 | 0.86 | 116 |

| A5 | 100 | 0.75 | 11.4 | 1.9 | 1.25 | 146 |

| Initial State | Yield Limit State | Strength Limit State | Failure Limit State | Ductility | |||||

|---|---|---|---|---|---|---|---|---|---|

| Loading Direction | Ke | Pyield | Dyield | Ppeak | Dpeak | Pu | Du | δ | |

| [kN/mm] | [kN] | [mm] | [kN] | [mm] | [kN] | [mm] | |||

| W1 | Positive | 9.06 | 15.96 | 1.76 | 17.24 | 5.14 | 13.79 | 30.42 | 17.2 |

| Negative | 12.15 | 18.57 | 1.53 | 20.06 | 9.98 | 16.05 | 37.16 | 24.3 | |

| Mean | 10.61 | 17.27 | 1.645 | 18.65 | 7.56 | 14.92 | 33.79 | 20.75 | |

| W2 | Positive | 20.58 | 27.23 | 2.26 | 30.1 | 5.00 | 24.08 | 16.49 | 7.30 |

| Negative | 17.37 | 24.59 | 2.37 | 25.92 | 9.52 | 20.74 | 31.78 | 13.4 | |

| Mean | 18.98 | 25.91 | 2.315 | 28.01 | 7.26 | 22.41 | 24.135 | 10.35 | |

| Label | Initial Stiffness [kN/mm] | Strength [kN] | ||||

|---|---|---|---|---|---|---|

| Positive | Negative | Mean | Positive | Negative | Mean | |

| W0 | 2.98 | 1.19 | 2.13 | 22.74 | 26.99 | 24.87 |

| W1 | 9.06 | 12.15 | 10.61 | 17.24 | 20.06 | 18.65 |

| W2 | 20.58 | 17.37 | 18.98 | 30.1 | 25.92 | 28.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Yan, X.; Liu, H.; Wu, G.; He, W. Enhancing the In-Plane Behavior of a Hybrid Timber Frame–Mud and Stone Infill Wall Using PP Band Mesh on One Side. Polymers 2022, 14, 773. https://doi.org/10.3390/polym14040773

Shen Y, Yan X, Liu H, Wu G, He W. Enhancing the In-Plane Behavior of a Hybrid Timber Frame–Mud and Stone Infill Wall Using PP Band Mesh on One Side. Polymers. 2022; 14(4):773. https://doi.org/10.3390/polym14040773

Chicago/Turabian StyleShen, Yinlan, Xingchen Yan, Hui Liu, Guofang Wu, and Wei He. 2022. "Enhancing the In-Plane Behavior of a Hybrid Timber Frame–Mud and Stone Infill Wall Using PP Band Mesh on One Side" Polymers 14, no. 4: 773. https://doi.org/10.3390/polym14040773