Polyurea Thickened Lubricating Grease—The Effect of Degree of Polymerization on Rheological and Tribological Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grease Synthesis

2.2. 1H NMR Analysis of the Polyurea Thickener

2.3. Penetrometer and NLGI Analysis

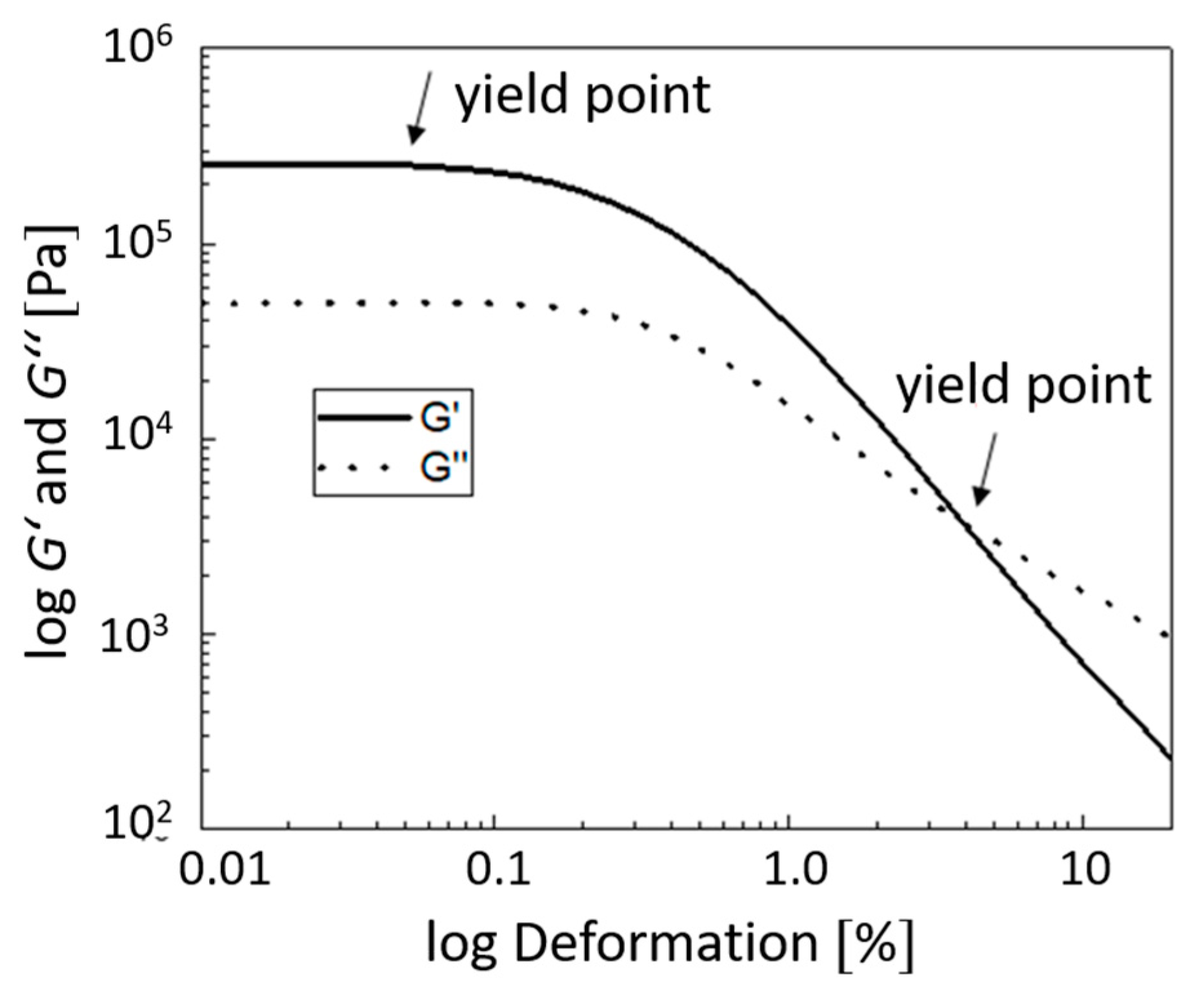

2.4. Rheology

2.5. Tribology

3. Results

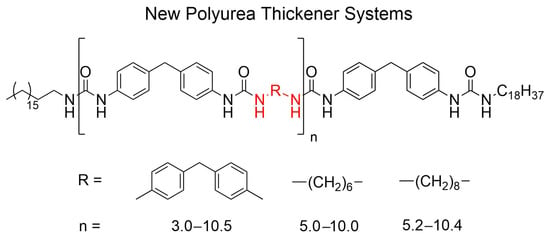

3.1. Synthesis of the Lubricants and Determination of the Molar Mass

3.2. NLGI Class Determination

3.3. Rheology

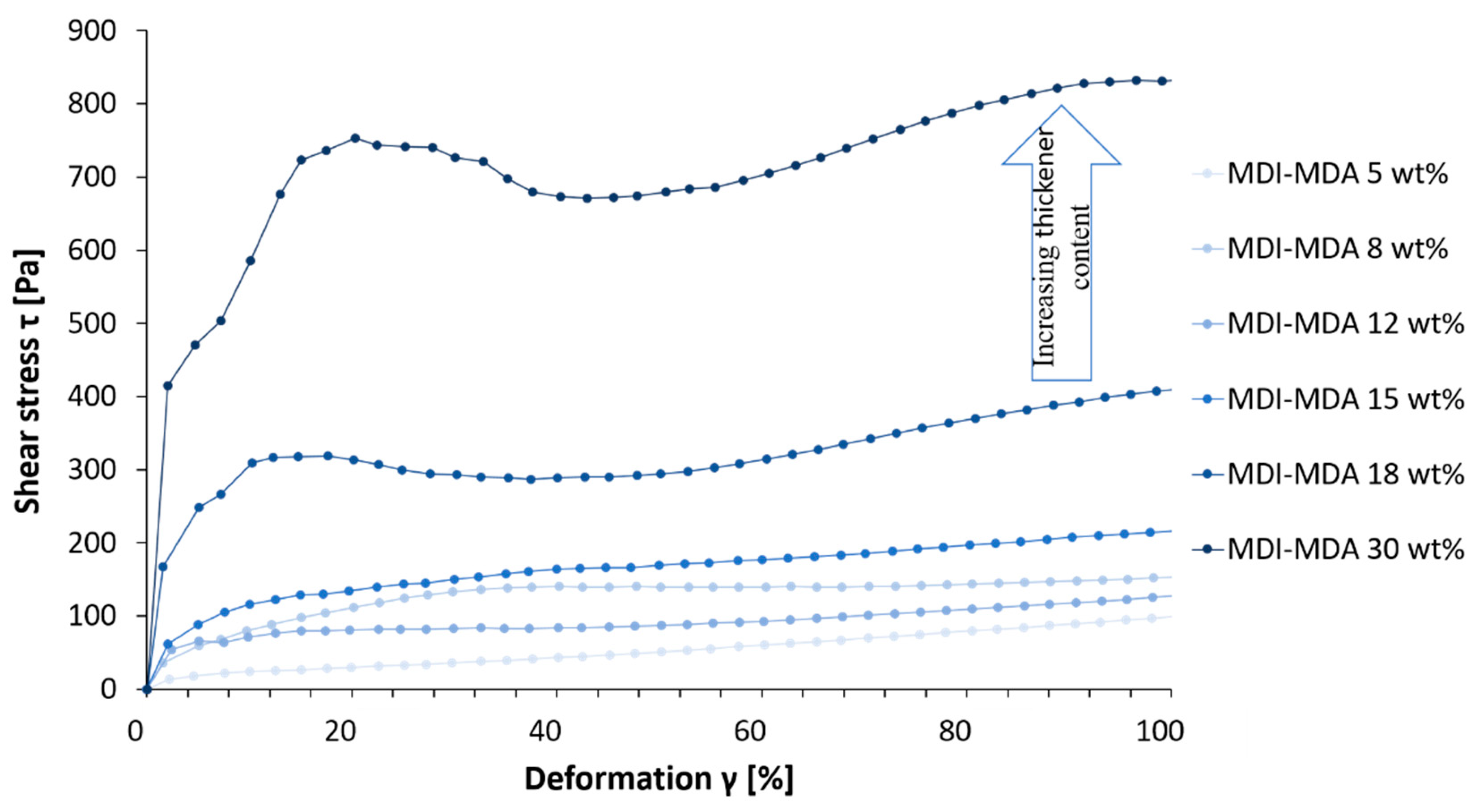

3.4. Tribology

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | DP a | Mn [kDa] b | MDI:MDA:Stearyl Amine c | MDI:MDA:Stearyl Amine d |

|---|---|---|---|---|

| 1 | 3.0 (5.0) | 1.9 (2.8) | 1:0.50:0.50 | 773.7:306.5:416.6 |

| 2 | 4.0 (6.0) | 2.3 (3.2) | 1:0.60:0.40 | 666.3:316.7:287.0 |

| 3 | 5.5 (7.5) | 3.0 (3.9) | 1:0.69:0.31 | 551.4:302.4:182.7 |

| 4 | 7.0 (9.0) | 3.7 (4.7) | 1:0.75:0.25 | 470.4:279.5:126.6 |

| 5 | 8.0 (11.0) | 4.1 (5.5) | 1:0.80:0.20 | 393.3:249.3:84.7 |

| 6 | 10.5 (13.5) | 5.2 (6.6) | 1:0.84:0.16 | 326.4:217.2:56.2 |

| Sample | DP a | Mn [kDa] b | MDI:ODA:Stearyl Amine c | MDI:ODA:Stearyl Amine d |

|---|---|---|---|---|

| 1 | 5.0 (5.0) | 2.5 (2.5) | 1:0.50:0.50 | 856.9:247.0:461.4 |

| 2 | 5.5 (6.0) | 2.7 (2.9) | 1:0.60:0.40 | 740.6:256.1:319.0 |

| 3 | 6.0 (7.5) | 2.9 (3.5) | 1:0.69:0.31 | 618.7:253.2:200.0 |

| 4 | 7.2 (9.0) | 3.4 (4.1) | 1:0.75:0.25 | 526.3:227.5:141.7 |

| 5 | 9.5 (11.0) | 4.3 (4.9) | 1:0.80:0.20 | 441.1:203.4:95.0 |

| 6 | 10.0 (13.5) | 4.5 (5.9) | 1:0.84:0.16 | 367.0:177.7:63.3 |

| Sample | DP a | Mn [kDa] b | MDI:HDA:Stearyl Amine c | MDI:HDA:Stearyl Amine [mg] d |

|---|---|---|---|---|

| 1 | 5.2 (5.0) | 2.4 (2.4) | 1:0.50:0.50 | 907.6:210.7:488.7 |

| 2 | 6.0 (6.0) | 2.7 (2.7) | 1:0.60:0.40 | 786.1:219.0:338.6 |

| 3 | 7.3 (7.5) | 3.2 (3.3) | 1:0.69:0.31 | 658.2:217.0:212.7 |

| 4 | 8.0 (9.0) | 3.5 (3.8) | 1:0.75:0.25 | 560.9:195.3:151.0 |

| 5 | 8.8 (11.0) | 3.8 (4.6) | 1:0.80:0.20 | 470.9:174.9:101.4 |

| 6 | 10.4 (13.5) | 4.4 (5.5) | 1:0.84:0.16 | 392.3:153.0:67.6 |

| Thickener | DP | M [kDa] | Penetration [mm] | NLGI-Class |

|---|---|---|---|---|

| MDI-MDA | 10.5 | 5.2 | 266 | 2 |

| 8.0 | 4.1 | 253 | 3 | |

| 7.0 | 3.7 | 250 | 3 | |

| 5.5 | 3.0 | 227 | 3 | |

| 4.0 | 2.3 | 222 | 3 | |

| 3.0 | 1.9 | 180 | 4 | |

| MDI-ODA | 10.0 | 4.5 | 385 | 0 |

| 9.5 | 4.3 | 365 | 0 | |

| 7.2 | 3.4 | 357 | 0 | |

| 6.0 | 2.9 | 339 | 1 | |

| 5.5 | 2.7 | 338 | 1 | |

| 5.0 | 2.5 | 331 | 1 | |

| MDI-HDA | 10.4 | 4.4 | 385 | 0 |

| 8.8 | 3.8 | 370 | 0 | |

| 8.0 | 3.5 | 367 | 0 | |

| 7.3 | 3.2 | 356 | 0 | |

| 6.0 | 2.7 | 340 | 1 | |

| 5.2 | 2.4 | 325 | 1 |

| Sample | DP | Mn [kDa] | τF [Pa] a | γy [%] a | Polymer [wt%] b | γF [%] |

|---|---|---|---|---|---|---|

| 1 | 3.0 | 1.9 | 740 | 0.2 | 13 | 9 |

| 2 | 4.0 | 2.3 | 620 | 0.3 | 18 | 20 |

| 3 | 5.5 | 3.0 | 541 | 0.3 | 12 | 21 |

| 4 | 7.0 | 3.7 | 493 | 0.3 | 8 | 30 |

| 5 | 8.0 | 4.1 | 439 | 0.4 | 13 | 34 |

| 6 | 10.5 | 5.2 | 216 | 0.4 | 5 | 43 |

| Sample | DP | Mn [kDa] | τF [Pa] a | γy [%] a | Polymer [wt%] b | γF [%] |

|---|---|---|---|---|---|---|

| 1 | 5.0 | 2.5 | 104 | 0.2 | 5 | 3 |

| 2 | 5.5 | 2.7 | 114 | 0.2 | 20 | 27 |

| 3 | 6.0 | 2.9 | 114 | 0.2 | 15 | 36 |

| 4 | 7.2 | 3.4 | 119 | 0.3 | 7 | 55 |

| 5 | 9.5 | 4.3 | 124 | 0.4 | 18 | 68 |

| 6 | 10.0 | 4.5 | 227 | 0.5 | 12 | 83 |

| Sample | DP | Mn [kDa] | τF [Pa] a | γy [%] a | Polymer [wt%] b | γF [%] |

|---|---|---|---|---|---|---|

| 1 | 5.2 | 2.4 | 190 | 0.2 | 17 | 3 |

| 2 | 6.0 | 2.7 | 112 | 0.2 | 17 | 26 |

| 3 | 7.3 | 3.2 | 111 | 0.3 | 14 | 31 |

| 4 | 8.0 | 3.5 | 87 | 0.4 | 8 | 49 |

| 5 | 8.8 | 3.8 | 76 | 0.5 | 13 | 54 |

| 6 | 10.4 | 4.4 | 70 | 0.5 | 7 | 94 |

| DP | Polymer [wt%] a | τF [Pa] | γF [%] |

|---|---|---|---|

| 2 | 5 | 721 | 8 |

| 2 | 8 | 619 | 9 |

| 2 | 12 | 683 | 9 |

| 2 | 15 | 521 | 9 |

| 2 | 18 | 875 | 8 |

Appendix B

References

- Mang, T.; Dresel, W. Lubricants and Lubrication, 2nd ed.; WILEY-VCH: Weinheim, Germany, 2007. [Google Scholar]

- Bartz, W.J.; Dresel, W.; Hubmann, A.; Kotal, P.; Lehmann, B.; Möller, U.J.; Müller, J.; Nemack, C.; Pelzer, E.; Peschk, G.; et al. Biologisch Schnell Abbaubare Schmierstoffe und Arbeitsflüssigkeiten; Band 402; Expert Verlag: Böblingen, Germany, 1993; ISBN 3-8169-0810-1. [Google Scholar]

- Bollmann, W.; Spreadborough, J. Action of Greaphite as a Lubricant. Nature 1960, 186, 29–30. [Google Scholar] [CrossRef]

- Asao, M.; Mikami, H. Solid Lubricant for Bearings Comprising a Mixture Containing a Lubricating Grease and Polyethylene Powder. U.S. Patent 5804536A, 8 September 1998. [Google Scholar]

- Scott, D.; Blackwell, J.; McCullagh, P.J.; Mills, G.H. Composite materials for rolling bearing cages. Wear 1970, 15, 257–269. [Google Scholar] [CrossRef]

- Lyadov, A.S.; Maksimova, Y.M.; Shakhmatova, A.S.; Kirillov, V.V.; Parenago, O.P. Urea (Polyurea) Greases. Russ. J. Appl. Chem. 2018, 91, 885–894. [Google Scholar] [CrossRef]

- Czarny, R. Lubricating Greases; WNT Publishers: Warsaw, Poland, 2004. [Google Scholar]

- Mansot, J.L.; Terech, P.; Martin, J.M. Structural investigation of lubricating greases. Colloids Surf. 1989, 39, 321–333. [Google Scholar] [CrossRef]

- Swaken, E.A. Substituted ureas as grease thickeners. NLGI Spokesm. 1954, 18, 8–13. [Google Scholar]

- Lei, L.; Hongwei, S. Multi-steps synthesis and properties of tetraurea grease. Ind. Lubr. Tribol. 2011, 63, 453–455. [Google Scholar] [CrossRef]

- Anthony, C.; Achim, F. Polyurea grease safe and simple. Lubes Greases 2004, 10, 4–30. [Google Scholar]

- Kinoshita, H. Lubricants for rolling bearings. J. Jpn. Soc. Tribol. 1997, 42, 930–935. [Google Scholar]

- Endo, T.; Kimura, H.; Moriuchi, T.; Okada, M.; Yase, K. Structure Analyses of Urea Grease Thickener. J. Jpn. Soc. Tribol. 1990, 35, 343–348. [Google Scholar]

- Akabe, S.; Matsumoto, K.; Yamaguchi, K. Bearing Grease Composition for ABS Pump. U.S. Patent 5,846,916, 8 December 1998. [Google Scholar]

- Traise, T.P. Chemistry of polyurea grease thickeners. NLGI Spokesm. 1965, 29, 5–180. [Google Scholar]

- Dreher, J.L.; Carter, C.F. New polyurea greases. NLGI Spokesm. 1970, 33, 4–390. [Google Scholar]

- Sergeeva, A.V.; Danilov, A.M.; Doroshuk, A.P.; Soborov, Y.G. Lubricating greases based on polyurea. Chem. Technol. Fuels Oils 1986, 22, 575–577. [Google Scholar] [CrossRef]

- Kranz, K.; Scott, W.P. Manufacturing polyurea greases in the STRATCO contractor. NLGI Spokesm. 1993, 57, 199–205. [Google Scholar]

- Root, J. The world’s first fibrous polyurea grease. NLGI Spokesm. 1995, 58, 41–439. [Google Scholar]

- Shen, Z.; Geng, F.; Fan, X.; Shen, Z.; Wang, H. Effect of preparation process on elevated temperature tribological properties of composite polyurea grease. Ind. Lubr. Tribol. 2016, 68, 611–616. [Google Scholar] [CrossRef]

- Dai, X.Z.; Guo, P.; Hong, D.M.; Hui, J.D.; Hui, Z.M.; Geng, F. The effect of preparation and characterisation of polyurea grease. Mater. Res. Innov. 2015, 19, S5588–S5591. [Google Scholar] [CrossRef]

- El-Adly, R.A.; El-Naggar, A.Y.; Hussein, M.F.; Raafat, B.M. Investigation of some recycled oils as fluids for polyurea greases. Pet. Sci. Technol. 2019, 37, 1289–1297. [Google Scholar] [CrossRef]

- Tonkonogov, B.P.; Kilyakova, A.Y.; Shumakaeva, S.Z.; Vinokurov, V.A.; Safieva, R.Z.; Popova, O.V.; Parenago, O.P. Using of esters as dispersion medium of polyurea plastic greases. Izv. Vyss. Uchebnykh Zaved. Seriya Khimiya I Khimicheskaya Tekhnologiya 2019, 62, 73–78. [Google Scholar] [CrossRef]

- Lyadov, A.S.; Maksimova, Y.M.; Ilyin, S.O.; Gorbacheva, S.N.; Parenago, O.P.; Antonov, S.V. Specific Features of Greases Based on Poly-A-olefin Oils with Ureate Thickeners of Various Structures. Russ. J. Appl. Chem. 2018, 91, 1735–1741. [Google Scholar] [CrossRef]

- Garshin, M.V.; Porfiryev, Y.V.; Zaychenko, V.A.; Shuvalov, S.A.; Kolybelsky, D.S.; Gushchin, P.A.; Vinokurov, V.A. Effect of Base Oil Composition on the Low-Temperature Properties of Polyurea Greases. Pet. Chem. 2017, 57, 1177–1181. [Google Scholar] [CrossRef]

- Borisenko, L.I.; Ishchuk, Y.L. Properties of polyurea greases on a synthetic base. Chem. Technol. Fuels Oils 2004, 40, 415–417. [Google Scholar] [CrossRef]

- Maksimova, Y.M.; Shakhmatova, A.S.; Ilyin, S.O.; Pakhmanova, O.A.; Lyadov, A.S.; Antonov, S.V.; Parenago, O.P. Rheological and Tribological Properties of Lubricating Greases Based on Esters and Polyurea Thickeners. Pet. Chem. 2018, 58, 1064–1069. [Google Scholar] [CrossRef]

- Ma, R.; Li, W.; Zhao, Q.; Zheng, D.; Wang, X. In Situ Synthesized Phosphate-based Ionic Liquids as High-Performance Lubricant Additives. Tribol. Lett. 2019, 67, 1–9. [Google Scholar] [CrossRef]

- Verma, D.K.; Kalyani; Jaiswal, V.; Rastogi, R.B. Tribological Studies of Some Quinoline Derivatives and Their Synergistic Interaction with Phosphate Ester. Tribol. Trans. 2019, 62, 283–294. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Chen, C. Fabrication of novel ionic liquids-doped polyaniline as lubricant additive for anti-corrosion and tribological properties. Tribol. Int. 2018, 120, 446–454. [Google Scholar] [CrossRef]

- Bai, T.; Geng, F. Investigate on the tribological properties of additives in tetra polyurea grease. IOP Conf. Ser. Earth Environ. Sci. 2018, 199, 032007. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, W. The tribological properties of the polyurea greases based on oil-miscible phosphonium-based ionic liquids. Lubr. Sci. 2018, 30, 16–22. [Google Scholar] [CrossRef]

- Hu, E.Z.; Xu, Y.; Hu, K.H.; Hu, X.G. Tribological properties of 3 types of MoS2 additives in different base greases. Lubr. Sci. 2017, 29, 541–555. [Google Scholar] [CrossRef]

- Gong, K.; Wu, X.; Zhao, G.; Wang, X. Tribological properties of polymeric aryl phosphates grafted onto multi-walled carbon nanotubes as high-performances lubricant additive. Tribol. Int. 2017, 116, 172–179. [Google Scholar] [CrossRef]

- Yan, J.; Zeng, H.; Liu, T.; Mai, J.; Ji, H. Tribological Performance and Surface Analysis of a Borate Calcium as Additive in Lithium and Polyurea Greases. Tribol. Trans. 2017, 60, 621–628. [Google Scholar] [CrossRef]

- Zaimovskaya, T.A.; Bordubanova, E.G.; Lyadov, A.S.; Parenago, O.P. Tribological Properties of Plastic Lubricants Infused with Molybdenum-Containing Additives. Chem. Technol. Fuels Oils 2016, 52, 1–8. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, X.; Zhao, G.; Wang, X. Tribological characteristics of bisphenol S bis(diphenyl phosphate) as a high-performance antiwear additive in lubricating greases at elevated temperature. Lubr. Sci. 2016, 28, 433–448. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, X.; Zhao, G.; Wang, X. Tribological characteristics of bisphenol AF bis(diphenyl phosphate) as an antiwear additive in polyalkylene glycol and polyurea grease for significantly improved lubrication. Appl. Surf. Sci. 2016, 363, 145–153. [Google Scholar] [CrossRef]

- Liu, L.; Sun, H.W. Impact of polurea structure on grease properties. Lubr. Sci. 2010, 22, 405–413. [Google Scholar] [CrossRef]

- Chae, T.U.; Ahn, J.H.; Ko, Y.S.; Kim, J.W.; Lee, J.A.; Lee, E.H.; Lee, S.Y. Metabolic engineering for the production of dicarboxylic acids and diamines. Metab. Eng. 2020, 58, 2–16. [Google Scholar] [CrossRef]

- Tullo, A. Covestro pursues biobased aniline. C&EN Glob. Enterpr. 2017, 95, 10. [Google Scholar]

- Winter, B.; Meys, R.; Bardow, A. Towards aromatics from biomass: Prospective Life Cycle Assessment of bio-based aniline. J. Clean. Prod. 2021, 290, 125818. [Google Scholar] [CrossRef]

- Carothers, W.H. Polymers and polyfunctionality. Trans. Faraday Soc. 1936, 32, 39–49. [Google Scholar] [CrossRef]

- Jiang, X.; Zhu, X.; Arnold, A.A.; Kong, X.Z.; Claverie, J.P. Polyurea Structure Characterization by HR-MAS NMR Spectroscopy. Ind. Eng. Chem. Res. 2017, 56, 2993–2998. [Google Scholar] [CrossRef]

- Liaw, D.J.; Huang, H.P.; Hsu, P.N.; Chen, W.H. Synthesis and characterization of new highly soluble polyamides derived from α, α′-bis[3,5-dimethyl-4-(4-aminophenoxy)phenyl]-1,4-diisopropylbenzene. Polym. J. 2002, 34, 307–312. [Google Scholar] [CrossRef] [Green Version]

- Vafaei, S.; Fischer, D.; Jopen, M.; Jacobs, G.; Koenig, F.; Weberskirch, R. Investigation of Tribological Behavior of Lubricating Greases Composed of Different Bio-Based Polymer Thickeners. Lubricants 2021, 9, 80. [Google Scholar] [CrossRef]

- Mezger, T.G. Das Rheologie Handbuch: Für Anwedner von Rotations-und Oszillations-Rheometern, 2nd ed.; Vincentz: Hannover, Germany, 2006; Volume 2. [Google Scholar]

- Fleischmann, F. Ein Beitrag zur Bestimmung der Rheologischen Eigenschaften Selbstverdichtender Betone mit dem Kugel-Messsystem. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2014. [Google Scholar]

- Hiemenz, P.; Timothy, L.P. Polymer Chemistry, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Romo-Uribe, A. On the Molecular Orientation and Viscoelastic Behaviour of Liquid Crystalline Polymers: The Influence of Macromolecular Architecture. Source Proc. Math. Phys. Eng. Sci. 2001, 457, 207–229. [Google Scholar] [CrossRef]

- Piau, J.-M.; Dorget, M.; Palierne, J.-F. Shear elasticity and yield stress of silica-silicone physical gels: Fractal approach. J. Rheol. 1999, 43, 305–314. [Google Scholar] [CrossRef]

- Simic, V.; Bouteiller, L.; Jalabert, M. Highly Cooperative Formation of Bis-Urea Based Supramolecular Polymers. J. Am. Chem. Soc. 2003, 125, 13148–13154. [Google Scholar] [CrossRef]

- Calhoun, S.F. Antiwear and Extreme Pressure Additives for Greases Antiwear and Extreme Pressure Additives for Greases. ASLE Trans. 1960, 3, 208–214. [Google Scholar] [CrossRef]

- ASTM D5706-16: ASTM International. Standard Test Method for Determining Extreme Pressure Properties of Solid Bonded Films Using a High-Frequency, Linear-Oscillation (SRV) Test; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jopen, M.; Degen, P.; Henzler, S.; Grabe, B.; Hiller, W.; Weberskirch, R. Polyurea Thickened Lubricating Grease—The Effect of Degree of Polymerization on Rheological and Tribological Properties. Polymers 2022, 14, 795. https://doi.org/10.3390/polym14040795

Jopen M, Degen P, Henzler S, Grabe B, Hiller W, Weberskirch R. Polyurea Thickened Lubricating Grease—The Effect of Degree of Polymerization on Rheological and Tribological Properties. Polymers. 2022; 14(4):795. https://doi.org/10.3390/polym14040795

Chicago/Turabian StyleJopen, Max, Patrick Degen, Stephan Henzler, Bastian Grabe, Wolf Hiller, and Ralf Weberskirch. 2022. "Polyurea Thickened Lubricating Grease—The Effect of Degree of Polymerization on Rheological and Tribological Properties" Polymers 14, no. 4: 795. https://doi.org/10.3390/polym14040795

APA StyleJopen, M., Degen, P., Henzler, S., Grabe, B., Hiller, W., & Weberskirch, R. (2022). Polyurea Thickened Lubricating Grease—The Effect of Degree of Polymerization on Rheological and Tribological Properties. Polymers, 14(4), 795. https://doi.org/10.3390/polym14040795