A Multi-Attribute Decision-Making Model for the Selection of Polymer-Based Biomaterial for Orthopedic Industrial Applications

Abstract

:1. Introduction

2. Material and Methods

2.1. UHMWPE/MWCNTs Composites

2.1.1. Preparations

- UHMWPE resin powder having density d = 0.940 g cm−3

- Un-irradiated and γ-irradiated MWCNTs

- 99% pure acetone and methanol.

2.1.2. Irradiation and Labeling

- “P” represents the UHMWPE without any filler;

- “P-γCNTs” represent the UHMWPE composite with gamma irradiated MWCNTs;

- “P-CNTs” represent the UHMWPE composite with MWCNTs;

- “P-SP” represents the UHMWPE composite with Mg-silicate.

2.2. Structural Characterization

2.2.1. Fourier Transform Infrared (FT-IR) Analysis

2.2.2. Chemometric Analysis

3. Results and Discussions

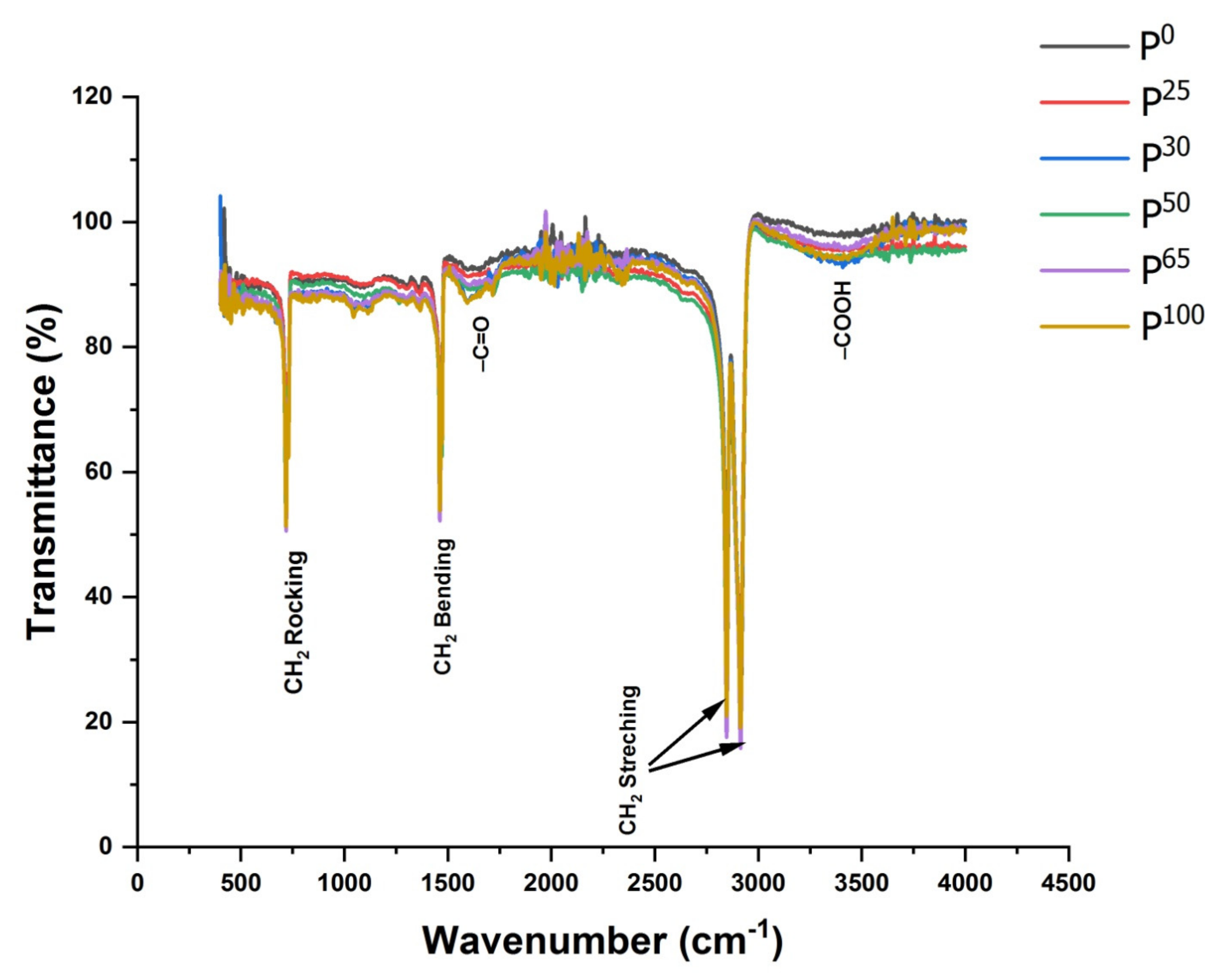

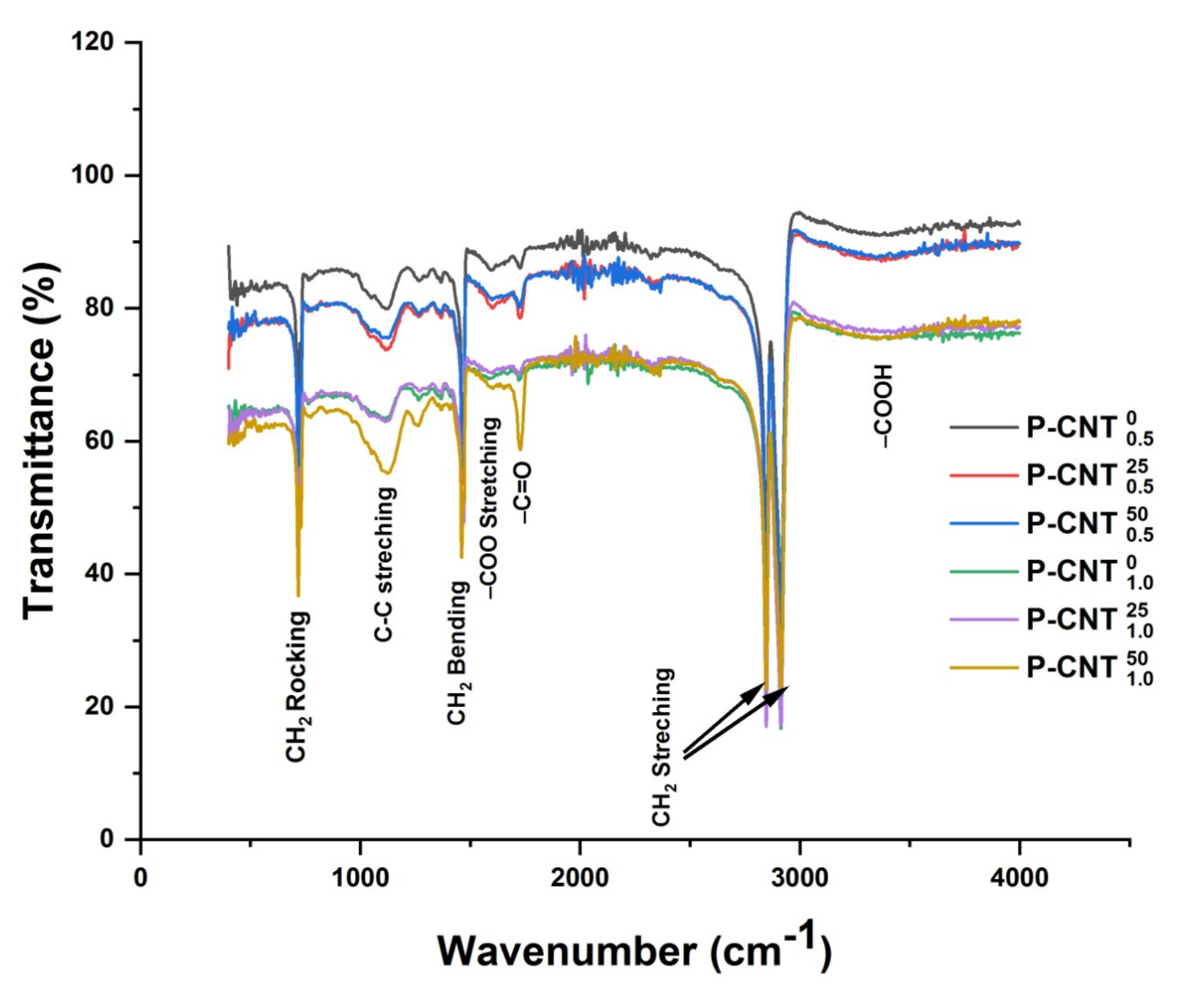

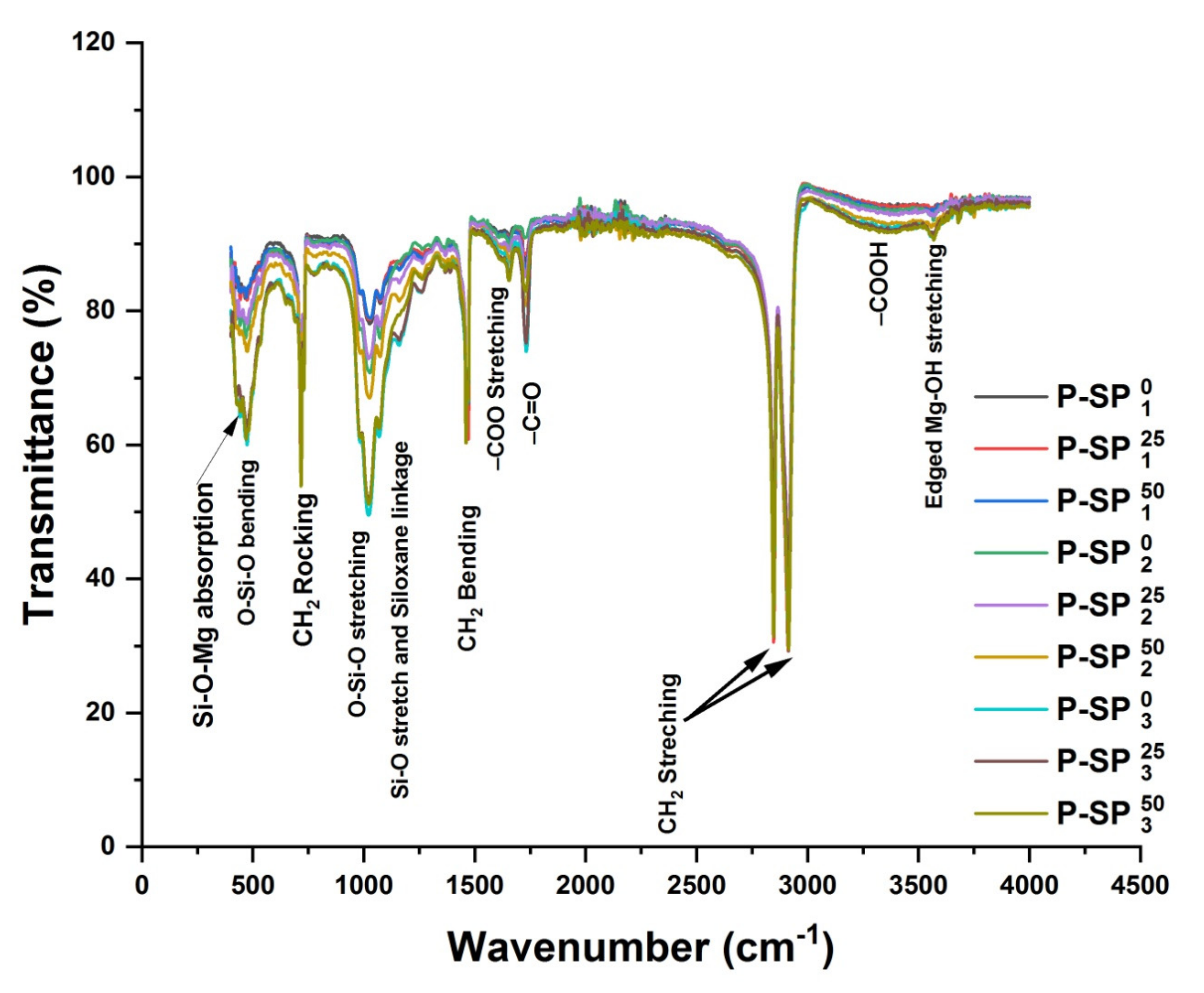

3.1. FTR Analysis

- Alteration in C–H bending and stretching (asymmetric and symmetric) absorption;

- Appearance of COO–, C–O stretching and C–C stretching absorption bands at 1596 cm−1, 1262 cm−1 and in the range of 1100–1000 cm−1, respectively;

- Appearance of absorption peaks because of carbonyl products (–C=O);

- Update in different stretching, contracting, and bending of PE chain (–CH2) because of addition of fillers and/or gamma irradiations;

- Appearance of absorption peaks because of some end products of peroxides such as ketones, and acids etc.

- Increase in absorbance for whole spectral range i.e., 400–4000 cm−1 on addition of MWCNTs, and this increase in absorbance is approximately 6% for composites having 0.5% of MWCNTs and 18% for composites containing 1.0% of MWCNTs.

- On addition of MWCNTs, appearance of absorption in region 900–1200 cm−1 with peak absorbance at 1100 cm−1 is quite evident. This peak belongs to C–C stretching absorption and it further increases with the concentration of MWCNTs and absorbed dose. The highest absorption in this region is observed for UHMWPE/MWCNTs nano composites containing 1.0% MWCNTs (by wt.) and irradiated with 50 kGy of gamma dose.

- On addition of MWCNTs and further irradiation, appearance of additional peak at 1262 cm−1 is observed which belongs to C–O stretching absorption. The trend of this peak is similar as that of C–C stretching absorption with respect to concentration of MWCNTs and gamma dose.

- Another peak at 1596 cm−1 is also observed for all samples on addition of MWCNTs. This peak belongs to –COO stretching absorption and follows the same trend as earlier.

- A significant increase in absorption in the region 1600–1800 cm−1 having peak absorbance at 1718 cm−1 is observed on irradiating the samples with gamma dose. The absorbance is higher for composite containing 1.0% of MWCNTs and irradiated with 50 kGy of gamma dose. This absorbance is due to C=O functional group and is used for assessing the degradation of polyethylene because of free radicals-induced oxidation chain reactions.

- In addition to this, polyethylene characteristics bands, i.e., –CH2 stretching, rocking, and bending vibrations also suffer modifications because of the addition of MWCNTs and irradiations.

- The increase of absorbance over the whole spectral range, i.e., from 400–4000 cm−1 for all UHMWPE/γMWCNTs samples is approximately 7% as opposite to UHMWPE/MWCNTs composites where the increase for absorbance is 18% for sample containing 1.0% of MWCNTs (see Figure 2).

- Most importantly, there is a significant reduction in absorbance for carbonyl-associated region, i.e., 1650–1850 cm−1 on further irradiating the composites with gamma dose. This reduction is higher for UHMWPE/γMWCNTs composite containing 1.0% of γMWCNTs and irradiated with 50 kGy of gamma dose thus revealing the free radical quenching potential of γMWCNTs.

- The absorbance due to C–C stretching absorption (from 900–1200 cm−1) is higher for UHMWPE/γMWCNTs composite containing 1.0% of γMWCNTs and irradiated with 50 kGy of gamma dose and seems to be negatively correlated with absorbance of carbonyl-associated region i.e., 1650–1850 cm−1.

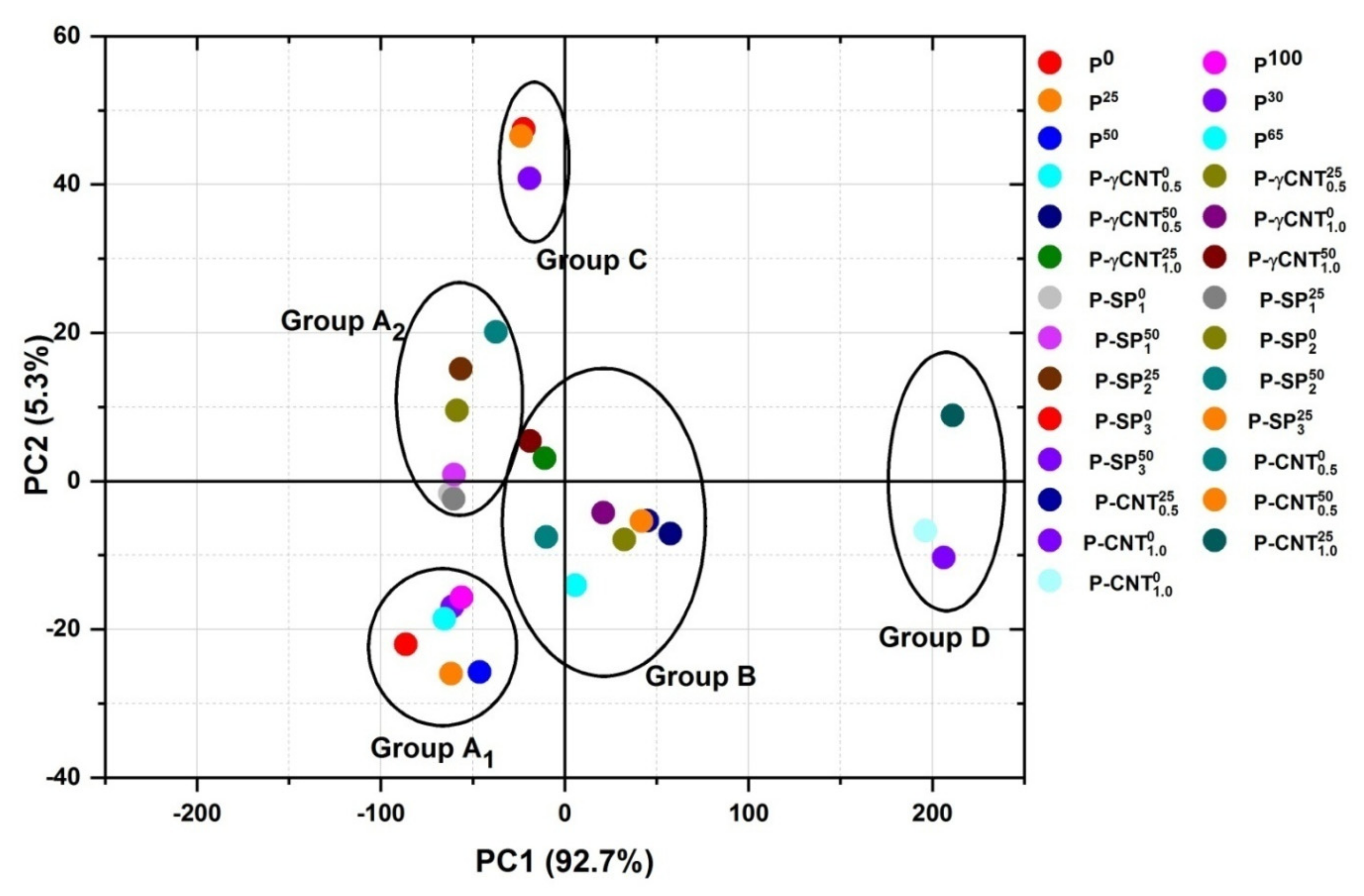

3.2. Chemometrics Studies

3.2.1. Hierarchy Cluster Analysis (HCA)

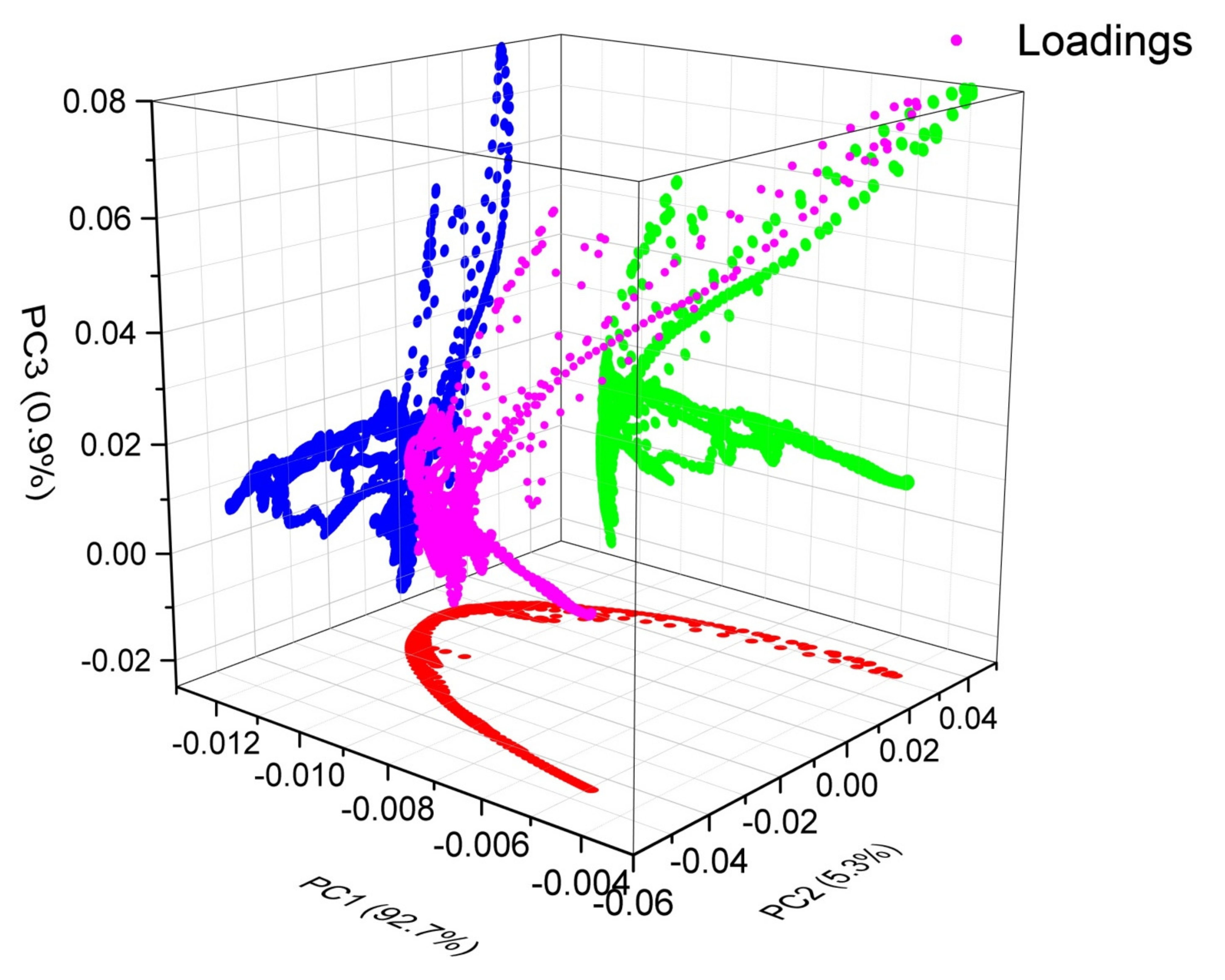

3.2.2. Principal Component Analysis (PCA)

4. Conclusions

- PC-1 is found to be responsible for explaining the variance in polyethylene characteristics bands because of addition of fillers;

- PC-2 is responsible for explaining the variance in IR spectra because of radiation-induced oxidation and cross linking reactions;

- PC-3 quantifies the variance because of IR active bands of MWCNTs and the end products of oxidation reactions i.e., hydro peroxide regions.

5. Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gursal, S.A.; Khurshid, M.S.; Saif-ur-Rehman, M.; Minhas, A.S.; Yasin, T.; Mehboob, N.; Mehmood, M.S. Investigating the effect of adding CdO nano particles on neutron shielding efficacy of HDPE. Radiat. Phys. Chem. 2020, 177, 109145. [Google Scholar]

- Mehmood, M.S.; Tabasam, M.; Ahmed, M.; Idris, A.; Yasin, T.; Ikram, M. Mueller matrix polarimetry for characterization of E-Beam irradiated Uhmwpe. Radiat. Phys. Chem. 2020, 166, 108503. [Google Scholar] [CrossRef]

- Serbaya, S.H.; Abualsauod, E.H.; Basingab, M.S.; Bukhari, H.; Rizwan, A.; Mehmood, M.S. Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application. Polymers 2022, 14, 47. [Google Scholar] [CrossRef]

- Rizwan, A.; Saleem, M.; Serbaya, S.H.; Alsulami, H.; Ghazal, A.; Mehmood, M.S. Simulation of Light Distribution in Gamma Irradiated UHMWPE Using Monte Carlo Model for Light (MCML) Transport in Turbid Media: Analysis for Industrial Scale Biomaterial Modifications. Polymers 2021, 13, 3039. [Google Scholar] [CrossRef]

- Costa, L.; Bracco, P. Mechanisms of cross-linking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 467–487. [Google Scholar]

- Mehmood, M.S.; Sanawar, A.; Siddiqui, N.; Yasin, T. Quantification of silane grafting efficacy, weak IR vibration bands and percentage crystallinity in post e-beam irradiated UHMWPE. Polym. Bull. 2017, 74, 213–227. [Google Scholar] [CrossRef]

- Sharma, V.; Bose, S.; Kundu, B.; Bodhak, S.; Mitun, D.; Balla, V.K.; Basu, B. Probing the Influence of γ-Sterilization on the Oxidation, Crystallization, Sliding Wear Resistance, and Cytocompatibility of Chemically Modified Graphene-Oxide-Reinforced HDPE/UHMWPE Nanocomposites and Wear Debris. ACS Biomater. Sci. Eng. 2020, 6, 1462–1475. [Google Scholar] [CrossRef]

- Quan, J.; Wang, H.; Yu, J.; Wang, Y.; Zhu, J.; Hu, Z. UHMWPE/nanoparticle composite membrane for personal radiation shielding. Compos. Sci. Technol. 2021, 201, 108500. [Google Scholar] [CrossRef]

- Bistolfi, A.; Giustra, F.; Bosco, F.; Sabatini, L.; Aprato, A.; Bracco, P.; Bellare, A. Ultra-high molecular weight polyethylene (UHMWPE) for hip and knee arthroplasty: The present and the future. J. Orthop. 2021, 25, 98–106. [Google Scholar] [CrossRef]

- Decker, M.; Price, A.; Khalili, A.; Klassen, R.; Walzak, M.J.; Teeter, M.; McCalden, R.; Lanting, B. The Impact of Free Radical Stabilization Techniques on in vivo Mechanical Changes in Highly Cross-Linked Polyethylene Acetabular Liners. Orthop. Res. Rev. 2021, 13, 113. [Google Scholar] [CrossRef]

- Bracco, P.; Oral, E. Vitamin E-stabilized UHMWPE for total joint implants: A review. Clin. Orthop. Relat. Res. 2011, 469, 2286–2293. [Google Scholar] [CrossRef]

- Saleem, M.; Rizwan, A. Development of Application Specific Intelligent Framework for the Optimized Selection of Industrial Grade Magnetic Material. Polymers 2021, 13, 4328. [Google Scholar] [CrossRef] [PubMed]

- Lan, R.-T.; Ren, Y.; Wei, X.; Tang, L.-Z.; Shah, N.A.; Xu, L.; Huang, S.-S.; Gul, R.M.; Xu, J.-Z.; Li, Z.-M. Synergy between vitamin E and D-sorbitol in enhancing oxidation stability of highly crosslinked ultrahigh molecular weight polyethylene. Acta Biomater. 2021, 134, 302–312. [Google Scholar] [CrossRef] [PubMed]

- Schwiesau, J.; Fritz, B.; Bergmann, G.; Reyna, A.L.P.; Schilling, C.; Grupp, T.M. Influence of radiation conditions on the wear behaviour of Vitamin E treated UHMWPE gliding components for total knee arthroplasty after extended artificial aging and simulated daily patient activities. J. Mech. Behav. Biomed. Mater. 2021, 122, 104652. [Google Scholar] [CrossRef]

- Han, J.; Duan, W.; Xia, Q.; Song, D. Diffusion behavior of vitamin-E in irradiation cross-linked GO/UHMWPE composites. Polym. Bull. 2021, 1–16. [Google Scholar] [CrossRef]

- Bakhsh, A.A. Gamma-Ray Modified Polymer/Clay Composites: Synthesis, Characterization, and Formulation Optimization Using Multivariate Calculus and Graph Theory. Energies 2021, 14, 2724. [Google Scholar] [CrossRef]

- Zavala, J.M.D.; Gutiérrez, H.M.L.; Segura-Cárdenas, E.; Mamidi, N.; Morales-Avalos, R.; Villela-Castrejón, J.; Elías-Zúñiga, A. Manufacture and mechanical properties of knee implants using SWCNTs/UHMWPE composites. J. Mech. Behav. Biomed. Mater. 2021, 120, 104554. [Google Scholar] [CrossRef] [PubMed]

- Mukhtar, S.S.; Mehmood, M.S.; Maqbool, S.A.; Ghafoor, B.; Baluch, M.A.; Siddiqui, N.; Yasin, T. Effect of γ-irradiation on the thermal properties of UHMWPE/MWCNTs nanocomposites: A comparative study of incorporating unmodified and γ-ray-modified MWCNTs. Bull. Mater. Sci. 2018, 41, 1–8. [Google Scholar] [CrossRef]

- Wright, T.; Astion, D.; Bansal, M.; Rimnac, C.; Green, T.; Insall, J.; Robinson, R. Failure of carbon fiber-reinforced polyethylene total knee-replacement components. A report of two cases. JBJS 1988, 70, 926–932. [Google Scholar] [CrossRef]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Chhetri, S.; Sarwar, A.; Steer, J.; Dhib, R.; Bougherara, H. Design of a bi-layer coating configuration on ultra-high molecular weight polyethylene (UHMWPE) fibre surface to derive synergistic response on interfacial bond strength. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106678. [Google Scholar] [CrossRef]

- Steinke, K.; Sodano, H.A. Enhanced interfacial shear strength in ultra-high molecular weight polyethylene epoxy composites through a zinc oxide nanowire interphase. Compos. Sci. Technol. 2022, 219, 109218. [Google Scholar] [CrossRef]

- Sreekanth, P.S.; Reddy, N.R.; Lahkar, M.; Subramani, K. Biocompatibility studies on MWCNTs reinforced ultra high molecular weight polyethylene nanocomposites. Trends Biomater. Artif. Organs 2013, 27, 1–9. [Google Scholar]

- Amurin, L.G.; Felisberto, M.D.; Ferreira, F.L.; Soraes, P.H.; Oliveira, P.N.; Santos, B.F.; Valeriano, J.C.; de Miranda, D.C.; Silva, G.G. Multifunctionality in ultra high molecular weight polyethylene nanocomposites with reduced graphene oxide: Hardness, impact and tribological properties. Polymer 2022, 240, 124475. [Google Scholar] [CrossRef]

- Naresh Kumar, N.; Yap, S.L.; Bt Samsudin, F.N.D.; Khan, M.Z.; Pattela Srinivasa, R.S. Effect of argon plasma treatment on tribological properties of UHMWPE/MWCNT nanocomposites. Polymers 2016, 8, 295. [Google Scholar] [CrossRef]

- Cui, D.; Tian, F.; Ozkan, C.S.; Wang, M.; Gao, H. Effect of single wall carbon nanotubes on human HEK293 cells. Toxicol. Lett. 2005, 155, 73–85. [Google Scholar] [CrossRef]

- Pantarotto, D.; Briand, J.-P.; Prato, M.; Bianco, A. Translocation of bioactive peptides across cell membranes by carbon nanotubes. Chem. Commun. 2004, 16–17. [Google Scholar] [CrossRef]

- Abdul Samad, M. Recent Advances in UHMWPE/UHMWPE Nanocomposite/UHMWPE Hybrid Nanocomposite Polymer Coatings for Tribological Applications: A Comprehensive Review. Polymers 2021, 13, 608. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Kurtz, S.M. UHMWPE matrix composites. In UHMWPE Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 369–397. [Google Scholar]

- Mohammed, M.T. Nanocomposites in total hip joint replacements. In Applications of Nanocomposite Materials in Orthopedics; Elsevier: Amsterdam, The Netherlands, 2019; pp. 221–252. [Google Scholar]

- Patel, J.; Parikh, S.; Patel, S.; Patel, R.; Patel, P. Carbon Nanotube (CNTs): Structure, Synthesis, Purification, Functionalisation, Pharmacology, Toxicology, Biodegradation and Application as Nanomedicine and Biosensor: Carbon Nanotube (CNTs). J. Pharm. Sci. Med. Res. 2021, 1, 17–44. [Google Scholar] [CrossRef]

- Chen, Y.; Mitra, S. Fast microwave-assisted purification, functionalization and dispersion of multi-walled carbon nanotubes. J. Nanosci. Nanotechnol. 2008, 8, 5770–5775. [Google Scholar] [CrossRef]

- Safibonab, B.; Reyhani, A.; Golikand, A.N.; Mortazavi, S.; Mirershadi, S.; Ghoranneviss, M. Improving the surface properties of multi-walled carbon nanotubes after irradiation with gamma rays. Appl. Surf. Sci. 2011, 258, 766–773. [Google Scholar] [CrossRef]

- Kharisov, B.I.; Kharissova, O.V.; Leija Gutierrez, H.; Ortiz Méndez, U. Recent advances on the soluble carbon nanotubes. Ind. Eng. Chem. Res. 2009, 48, 572–590. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Wu, S.; Li, W. The effects of γ-irradiation dose on chemical modification of multi-walled carbon nanotubes. Nanotechnology 2005, 16, 2385. [Google Scholar] [CrossRef] [PubMed]

- Irfan, A.; Mehmood, M.N.; Mehmood, M.S.; Aziz, A.; Baluch, M.A.; Rizwan, M.; Yasin, T. A Potential Approach to Enhance the Seebeck Coefficient of UHMWPE by Using the Graphene Oxide. Non-Met. Mater. Sci. 2020, 2, 21–27. [Google Scholar] [CrossRef]

- Mehmood, M.; Khan, Y.; Yasin, T. Optical properties of UHMWPE-II: Photon distributions studies using Monte Carlo simulation. Radiat. Phys. Chem. 2019, 158, 103–108. [Google Scholar] [CrossRef]

- Eshaq, G.; Amer, M.; Khan, M.A.; Alothman, Z.A.; Sillanpää, M. A novel Sm doped Cr2O3 sesquioxide-decorated MWCNTs heterostructured Fenton-like with sonophotocatalytic activities under visible light irradiation. J. Hazard. Mater. 2022, 426, 127812. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Zhou, J.; Sun, P.; Peng, L.-M.; Zhang, Z. Analyzing Gamma-Ray Irradiation Effects on Carbon Nanotube Top-Gated Field-Effect Transistors. ACS Appl. Mater. Interfaces 2021, 13, 47756–47763. [Google Scholar] [CrossRef] [PubMed]

- Pandey, V.K.; Tan, C.M.; Kim, S.; Singh, P.; Sangwan, V.; Han, J.-W.; Meyyappan, M. Effect of 150 MeV protons on carbon nanotubes for fabrication of a radiation detector. Nanotechnology 2021, 32, 355501. [Google Scholar] [CrossRef]

- Bashir, M.; Mehmood, M.S.; Choudary, M.A.; Yasin, T.; Ahmad, I.; Tariq, M.; Noman-ul-Haq, M.; Asif, A.; Ikram, M. Analysis of pulse-laser-induced modifications on high-density polyethylene for laser processing of polyethylene. J. Russ. Laser Res. 2015, 36, 258–268. [Google Scholar] [CrossRef]

- Gul, A.; Mehmood, M.N.; Mehmood, M.S. Graph Theory and Matrix Approach (GTMA) Model for the Selection of the Femoral-Component of Total Knee Joint Replacement. Non-Met. Mater. Sci. 2021, 3, 1–9. [Google Scholar] [CrossRef]

- Hojati, S.; Khademi, H. Thermal behavior of a natural sepiolite from Northeastern Iran. J. Sci. Islamic Repub. Iran 2013, 24, 129–134. [Google Scholar]

- Ghafoor, B.; Mehmood, M.S.; Shahid, U.; Baluch, M.A.; Yasin, T. Influence of γ-ray modified MWCNTs on the structural and thermal properties of high-density polyethylene. Radiat. Phys. Chem. 2016, 125, 145–150. [Google Scholar] [CrossRef]

- Martínez-Morlanes, M.; Castell, P.; Martínez-Nogués, V.; Martinez, M.; Alonso, P.J.; Puértolas, J. Effects of gamma-irradiation on UHMWPE/MWNT nanocomposites. Compos. Sci. Technol. 2011, 71, 282–288. [Google Scholar] [CrossRef]

| Sample Code | UHMWPE Concentration by wt. (%) | Fillers Concentration by wt. (%) | Absorbed Dose (kGy) | ||

|---|---|---|---|---|---|

| MWCNTs | γMWCNTS | Mg-Silicate | |||

| P0 | 100 | – | – | – | 0 |

| P25 | 100 | – | – | – | 25 |

| P30 | 100 | – | – | – | 30 |

| P50 | 100 | – | – | – | 50 |

| P65 | 100 | – | – | – | 65 |

| P100 | 100 | – | – | – | 100 |

| P-γCNT0.50 | 99.5 | – | 0.5 | – | 0 |

| P-γCNT0.525 | 99.5 | – | 0.5 | – | 25 |

| P-γCNT0.550 | 99.5 | – | 0.5 | – | 50 |

| P-γCNT1.00 | 99.0 | – | 1.0 | – | 0 |

| P-γCNT1.025 | 99.0 | – | 1.0 | – | 25 |

| P-γCNT1.050 | 99.0 | – | 1.0 | – | 50 |

| P-CNT0.50 | 99.5 | 0.5 | – | – | 0 |

| P-CNT0.525 | 99.5 | 0.5 | – | – | 25 |

| P-CNT0.550 | 99.5 | 0.5 | – | – | 50 |

| P-CNT1.00 | 99.0 | 1.0 | – | – | 0 |

| P-CNT1.025 | 99.0 | 1.0 | – | – | 25 |

| P-CNT1.050 | 99.0 | 1.0 | – | – | 50 |

| P-SP10 | 99.0 | – | – | 1.0 | 0 |

| P-SP125 | 99.0 | – | – | 1.0 | 25 |

| P-SP150 | 99.0 | – | – | 1.0 | 50 |

| P-SP20 | 98 | – | – | 2.0 | 0 |

| P-SP225 | 98 | – | – | 2.0 | 25 |

| P-SP250 | 98 | – | – | 2.0 | 50 |

| P-SP30 | 97 | – | – | 3.0 | 0 |

| P-SP325 | 97 | – | – | 3.0 | 25 |

| P-SP350 | 97 | – | – | 3.0 | 50 |

| FTIR | Types and Origin of Vibrations | |||

|---|---|---|---|---|

| Band Position (cm−1) | ||||

| UHMWPE | UHMWPE Composites with MWCNTS | UHMWPE Hybrids with Magnesium Silicate | ||

| UHMWPE/MWCNTs | UHMWPE/γ-MWCNTs | |||

| – | – | – | 440 | Si–O–Mg absorption band [43] |

| – | – | – | 456 | O–Si–O bending vibrations [43] |

| 717 and 730 | 717 and 730 | 717 and 730 | 717 and 730 | –CH2 long chain rocking–deformation [44] |

| 910 | 910 | 910 | 910 | Vinyl (–CH=CH2) [12] |

| 963 | 963 | 963 | 963 | trans-vinylene, (–CH=CH–) [12] |

| – | – | – | 976, 1014, 1210 | O–Si–O stretching vibrations [43] |

| – | – | – | 1081 | Si–O stretch and Siloxane linkage [12] |

| – | 1100–900 | 1100–900 | – | C–C stretching absorption [44] |

| – | 1262 | 1262 | – | C–O stretching absorption [44] |

| 1305 | 1305 | 1305 | 1305 | PE amorphous band [44] |

| – | 1596 | 1596 | – | –COO stretching absorption |

| 1460 and 1470 | 1460 and 1470 | 1460 and 1470 | 1460 and 1470 | CH2 bending vibrations [44] |

| 1500–1700 | 1500–1700 | 1500–1700 | 1500–1700 | C=C estimation area [36] |

| 1650–1850 | 1650–1850 | 1650–1850 | 1650–1850 | Carbonyl estimation band [36] |

| 1896 | 1896 | 1896 | 1896 | PE crystalline band |

| 2849 and 2924 | 2849 and 2924 | 2849 and 2924 | 2849 and 2924 | –CH2 stretching vibrations – |

| 3000–3750 | 3000–3750 | 3000–3750 | 3000–3750 | Peroxide bond area [36] |

| – | – | – | 3536 | Edged Mg–OH stretching [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizwan, A.; Abualsauod, E.H.; Othman, A.M.; Serbaya, S.H.; Shahzad, M.A.; Hameed, A.Z. A Multi-Attribute Decision-Making Model for the Selection of Polymer-Based Biomaterial for Orthopedic Industrial Applications. Polymers 2022, 14, 1020. https://doi.org/10.3390/polym14051020

Rizwan A, Abualsauod EH, Othman AM, Serbaya SH, Shahzad MA, Hameed AZ. A Multi-Attribute Decision-Making Model for the Selection of Polymer-Based Biomaterial for Orthopedic Industrial Applications. Polymers. 2022; 14(5):1020. https://doi.org/10.3390/polym14051020

Chicago/Turabian StyleRizwan, Ali, Emad H. Abualsauod, Asem Majed Othman, Suhail H. Serbaya, Muhammad Atif Shahzad, and Abdul Zubar Hameed. 2022. "A Multi-Attribute Decision-Making Model for the Selection of Polymer-Based Biomaterial for Orthopedic Industrial Applications" Polymers 14, no. 5: 1020. https://doi.org/10.3390/polym14051020