A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers

Abstract

:1. Introduction

2. Synthesis of PBS

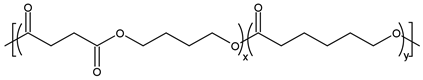

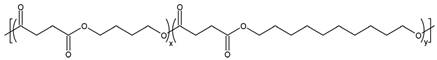

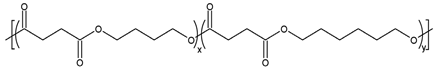

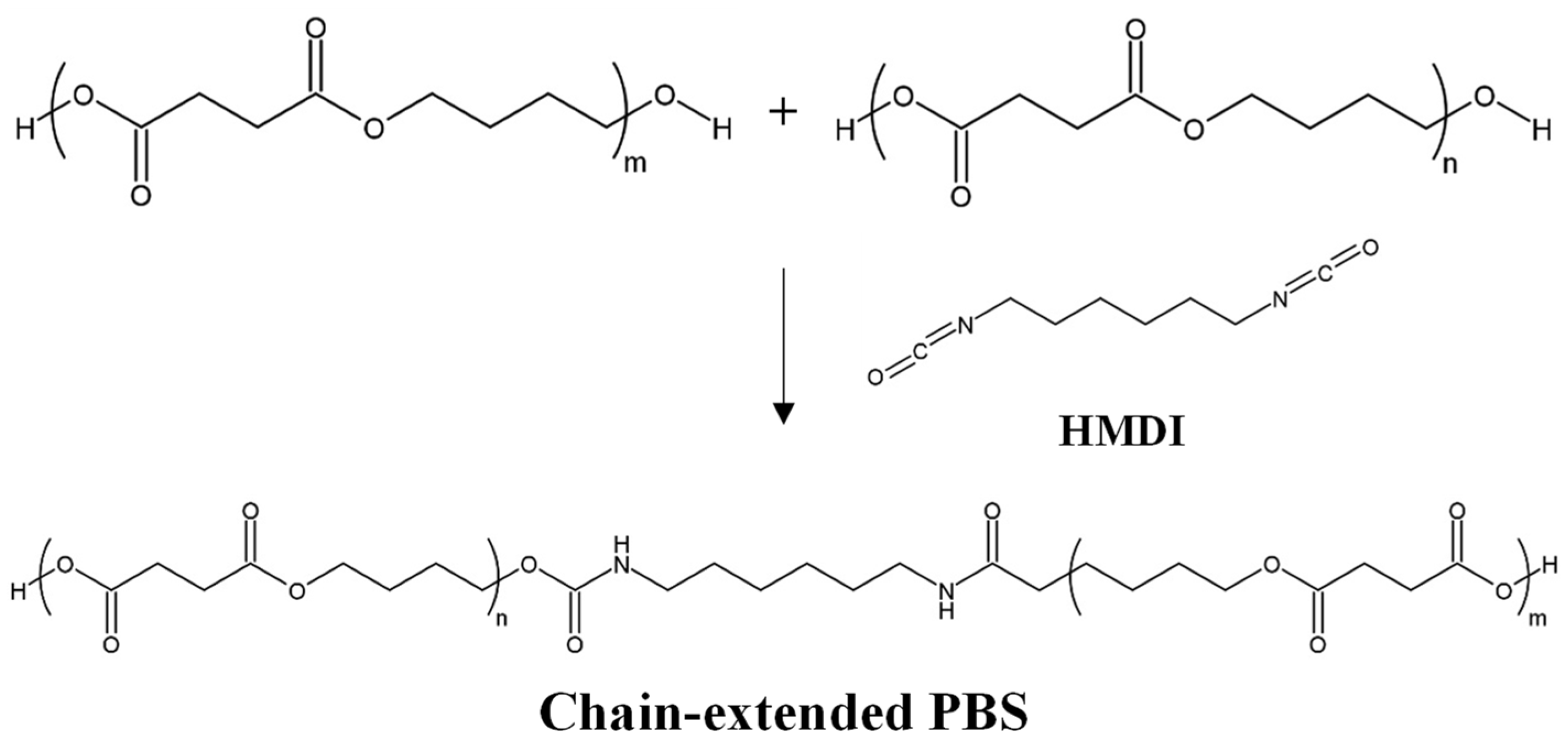

2.1. Petroleum-Based Synthesis: Transesterification Polymerization: Melt, Chain Extender, and Solution

2.2. Bio-Based Polymerization: Enzymatic Synthesis

3. PBS Copolyesters

3.1. Influence of the Preparation Conditions on the Molecular Weight

3.2. Enzymatic Synthesis for PBS-Based Copolyesters

3.3. Transesterification/ROP Reaction

3.4. Crystallization Behavior in PBS Copolyesters as Determined by DSC

3.5. Pseudo-Eutectic Point at Different Content, Comonomer Exclusion, and Isomorphism in PBS-Based Copolymers

3.6. Influence of the Comonomer Content in the Crystallinity

3.7. Effect of Comonomer Content on Mechanical Properties

4. PBS Nanocomposites: Modulation of Mechanical Properties

5. Barrier Properties

5.1. PBS-Based Copolymers

5.2. PBS-Based Nanocomposites

6. Biodegradation of PBS

6.1. Hydrolytic Degradation

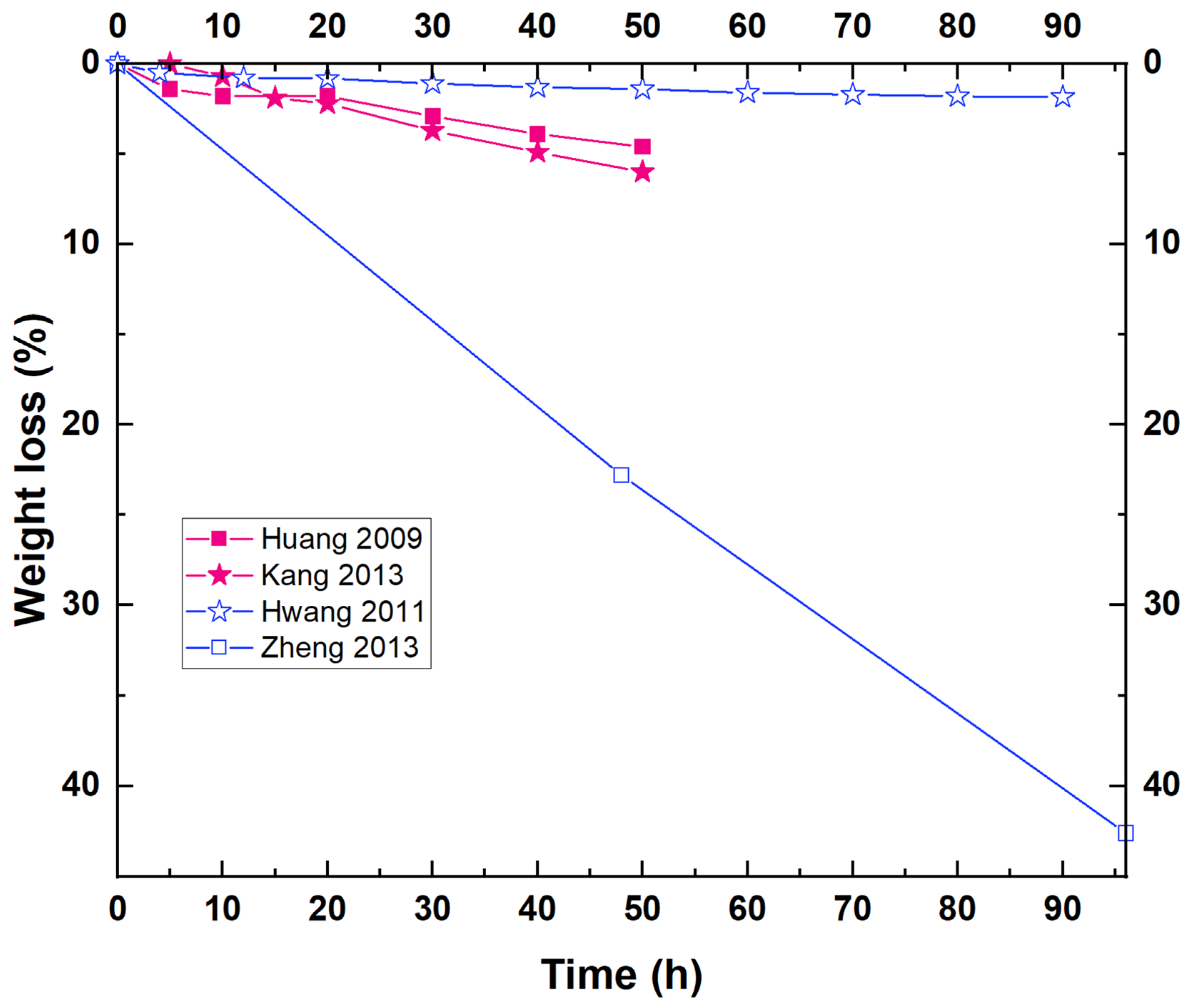

6.2. Enzymatic Degradation

6.3. PBS-Based Copolymers: Hydrolytic and Enzymatic Degradation

6.4. Biodegradation in Environmental Conditions

6.4.1. PBS Homopolymer and PBS-Based Copolymers

6.4.2. PBS-Based Biocomposites

7. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| Symbol/Acronym in the Text | Definition |

| Melting enthalpy | |

| Equilibrium melting enthalpy | |

| E | Young’s modulus |

| ε | Elongation at break |

| Weight fraction | |

| Mn | Number average molecular weight |

| Mw | Weight average molecular weight |

| Tc | Crystallization temperature |

| Tm | Melting temperature |

| Xc | Degree of crystallinity |

| AF | Abaca fiber |

| ASTM | American Society for Testing and Materials |

| BD | 1,4-butanediol |

| BS | Butylene succinate |

| C25A | Cloisite® 25A |

| CALB | Candida antarctica lipase B |

| CF | Cotton fiber |

| CGM | Corn gluten meal |

| CL | Caprolactone |

| CM | Canola meal |

| CNC | Cellulose nanocrystals |

| CO2P | Carbon dioxide permeability |

| DES | Diethyl succinate |

| DMAz | Dimethylazelate |

| DMS | Dimethyl succinate |

| DSC | Differential scanning calorimetry |

| eROP | Enzymatic ring-opening polymerization |

| EVOH | Ethylene vinyl alcohol |

| FHT | Fluorohectorite |

| HA | Hydroxyapatite |

| HDPE | High-density polyethylene |

| HMDI | Hexamethylene diisocyanate |

| INF | Isora nanofibers |

| ISO | International Standardization Organization |

| JF | Jute fiber |

| KFP | Konjac fly powders |

| LCP | Liquid crystal polymer |

| LDPE | Low-density polyethylene |

| MCC | Microcrystalline cellulose |

| MDI | Methylene diphenyl diisocyanate |

| MMT | Montmorillonite |

| MW | Molecular weight |

| NCC | Nanocrystalline cellulose |

| NFC | Nanofibrillated cellulose |

| NR | Natural rubber |

| O2P | Oxygen permeability |

| OMLS | Organically modified layered silicate |

| OMMT | Organically modified montmorillonite |

| OPMF | Oil palm mesocarp fibers |

| PAN | Polyacrylonitrile |

| PBF | Poly(butylene fumarate) |

| PBMS | Poly(butylene 2-methylsuccinate) |

| PBS | Poly(butylene succinate) |

| PBSu | Poly(butylene succinate) |

| PBT | Polybutylene terephthalate |

| PcBS | Poly(cis-butene succinate) |

| PCL | Poly(ε-caprolactone) |

| PDMS | Polydimethylsiloxane |

| PE | Polyethylene |

| PEG | Poly (ethylene glycol) |

| PEMA | Poly (ethyl methacrylate) |

| PET | Poly (ethylene terephthalate) |

| PGA | Poly(glycolide) |

| PHAs | Polyhydroxyalkanoates |

| PHB | Polyhydroxybutyrate |

| PHBV | Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) |

| PHS | Poly(hexamethylene succinate) |

| PLA | Poly(lactic acid) |

| PMP | Polymethylpentene |

| PP | Polypropylene |

| PPO | Polyphenylene oxide |

| PPS | Poly(propylene succinate) |

| PRHB | Poly((r)-3-hydroxybutyrate) |

| PS | Polystyrene |

| PSF | Pistachio shell flour |

| PTFE | Polytetrafluoroethylene |

| PTMS | Poly(tetramethylene succinate) |

| PTMSP | Poly(1-trimethylsilyl-1-propyne) |

| PVA | Polyvinyl alcohol |

| PVC | Polyvinyl chloride |

| PVDC | Polyvinylidene chloride |

| PVDF | Polyvinylidene fluoride |

| rCell | Recycled cellulose |

| RHF | Rice husk flour |

| RT | Room temperature |

| RWP | Rubberwood powders |

| SA | Succinic acid |

| SAP | Saponite |

| SG | Switchgrass |

| SM | Soy meal |

| SNC | Starch nanocrystals |

| SRF | Sugarcane rind fiber |

| TNBT | Titanium (IV) butoxide |

| TTIP | Titanium (IV) isopropoxide |

| ULDPE | Ultra-low-density polyethylene |

| UVA | Ultraviolet A |

| WAXS | Wide Angle X-ray Scattering |

| WF | Wood flour |

| Copolymers cited within the review. | |

| Acronym in the Text | Definition and Chemical Structure |

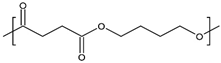

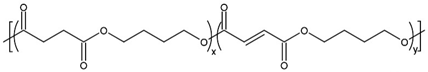

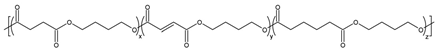

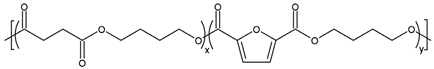

| PBS-co-PBF | Poly(butylene succinate-co-butylene fumarate) |

| PBS-ran-PBA | Poly(butylene succinate-ran-butylene adipate) |

| PBS-ran-PBAz | Poly(butylene succinate-ran-butylene azelate) |

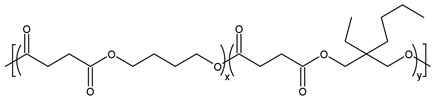

| PBS-ran-PBEPS | Poly(butylene succinate-ran-2-butyl-2-ethyl-propylene succinate) |

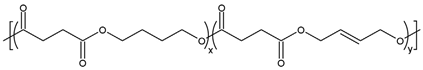

| PBS-ran-PBF | Poly(butylene succinate-ran-butylene fumarate) |

| PBS-ran-PBF-ran-PBA | Poly(butylene succinate-ran-butylene fumarate-ran-butylene adipate) |

| PBS-ran-PBFur | Poly(butylene succinate-ran-butylene furanoate) |

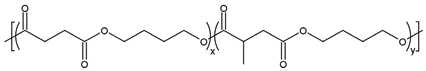

| PBS-ran-PBMS | Poly(butylene succinate-ran-butylene 2-methylsuccinate) |

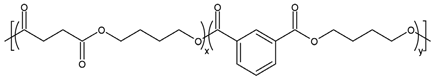

| PBS-ran-PBT | Poly(butylene succinate-ran-butylene terephthalate) |

| PBS-ran-PcBS | Poly(butylene succinate-ran-cis-butene succinate) |

| PBS-ran-PCL | Poly(butylene succinate-ran-ε-caprolactone) |

| PBS-ran-PDMSu | Poly(butylene succinate-ran-decamethylene succinate) |

| PBS-ran-PHS | Poly(butylene succinate-ran-hexamethylene succinate) |

| PBS-ran-PIS | Poly(butylene succinate-ran-isosorbide succinate) |

| PBS-ran-PNS | Poly(butylene succinate-ran-neopenthyl succinate) |

| PBS-ran-PPS | Poly(butylene succinate-ran-propylene succinate) |

| PBS-ran-PTDGS | Poly(butylene succinate-ran-thiodiethylene glycol succinate) |

References

- Plastics Europe. Plastics—The Facts 2019: An Analysis of European Plastics Production, Demand and Waste data; Plastics Europe: Brussels, Belgium, 2019. [Google Scholar]

- Plastics Europe. Plastics—The Facts 2021: An Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussels, Belgium, 2021. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 19–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A review on properties and application of bio-based poly(butylene succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef] [PubMed]

- Chinthapalli, R.; Skoczinski, P.; Carus, M.; Baltus, W.; De Guzman, D.; Käb, H.; Raschka, A.; Ravenstijn, J. Biobased Building Blocks and Polymers—Global Capacities, Production and Trends, 2018–2023. Ind. Biotechnol. 2019, 15, 237–241. [Google Scholar] [CrossRef]

- Chen, G.Q.; Patel, M.K. Plastics derived from biological sources: Present and future: A technical and environmental review. Chem. Rev. 2012, 112, 2082–2099. [Google Scholar] [CrossRef] [PubMed]

- Jambeck, J.R.; Ji, Q.; Zhang, Y.-G.; Liu, D.; Grossnickle, D.M.; Luo, Z.-X. Plastic waste inputs from land into the ocean. Science 2015, 347, 764–768. [Google Scholar] [CrossRef] [PubMed]

- ten Brink, P.; Schweitzer, J.-P.; Watkins, E.; Janssens, C.; De Smet, M.; Leslie, H.; Galgani, F. Circular economy measures to keep plastics and their value in the economy, avoid waste and reduce marine litter. Econ. Discuss. Pap. 2018, 3, 15. [Google Scholar]

- Abhilash, M.; Thomas, D. Biopolymers for Biocomposites and Chemical Sensor Applications. In Biopolymer Composites in Electronics; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 405–435. ISBN 9780081009741. [Google Scholar]

- Zini, E.; Scandola, M. Green Composites: An Overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Kumar, G.; Kim, D.S.; Mulla, S.I.; et al. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Market Data 2019. Global Production Capacities of Bioplastics 2019–2024; European Bioplastics: Berlin, Germany, 2019; Available online: https://www.european-bioplastics.org/wp-content/uploads/2019/11/Report_Bioplastics-Market-Data_2019_short_version.pdf (accessed on 30 January 2022).

- Ratshoshi, B.K.; Farzad, S.; Görgens, J.F. Techno-economic assessment of polylactic acid and polybutylene succinate production in an integrated sugarcane biorefinery. Biofuels Bioprod. Biorefining 2021, 15, 1871–1887. [Google Scholar] [CrossRef]

- Ioannidou, S.M.; Ladakis, D.; Moutousidi, E.; Dheskali, E.; Kookos, I.K.; Câmara-Salim, I.; Moreira, M.T.; Koutinas, A. Techno-economic risk assessment, life cycle analysis and life cycle costing for poly(butylene succinate) and poly(lactic acid) production using renewable resources. Sci. Total Environ. 2022, 806, 150594. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Richter, G.M.; Mwabonje, O.N.; Qi, A.; Patel, M.K.; Woods, J. Novel integrated agricultural land management approach provides sustainable biomass feedstocks for bioplastics and supports the UK’s “net-zero” target. Environ. Res. Lett. 2021, 16, 014023. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review in memory of our beloved colleague and friend Dr. Lara Finelli. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Sander, M. Biodegradation of Polymeric Mulch Films in Agricultural Soils: Concepts, Knowledge Gaps, and Future Research Directions. Environ. Sci. Technol. 2019, 53, 2304–2315. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Kumar Thakur, V.; Barkane, A.; Beluns, S. Bio-Based Poly (Butylene Succinate): Recent Progress, Challenges and Future Opportunities. Eur. Polym. J. 2021, 161, 110855. [Google Scholar] [CrossRef]

- Larrañaga, A.; Lizundia, E. A review on the thermomechanical properties and biodegradation behaviour of polyesters. Eur. Polym. J. 2019, 121, 109296. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sionkowska, A. Current research on the blends of natural and synthetic polymers as new biomaterials: Review. Prog. Polym. Sci. 2011, 36, 1254–1276. [Google Scholar] [CrossRef]

- Soccio, M.; Dominici, F.; Quattrosoldi, S.; Luzi, F.; Munari, A.; Torre, L.; Lotti, N.; Puglia, D. PBS-based green copolymer as efficient compatibilizer in Thermoplastic inedible Wheat Flour/Poly (Butylene Succinate) Blends. Biomacromolecules 2020, 21, 3254–3269. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Song, M.; Xu, Y.; Wang, W.; Wang, Z.; Zhang, L. Bio-based polyesters: Recent progress and future prospects. Prog. Polym. Sci. 2021, 120, 101430. [Google Scholar] [CrossRef]

- Safari, M.; Otaegi, I.; Aramburu, N.; Guerrica-Echevarria, G.; Martínez de Ilarduya, A.; Sardon, H.; Müller, A.J. Synthesis, structure, crystallization and mechanical properties of isodimorphic PBS-ran-PCL copolyesters. Polymers 2021, 13, 2263. [Google Scholar] [CrossRef] [PubMed]

- Sandoval, A.J.; Fernández, M.M.; Candal, M.V.; Safari, M.; Santamaria, A.; Müller, A.J. Rheology and Tack Properties of Biodegradable Isodimorphic Poly(butylene succinate)-Ran-Poly(ε-caprolactone) Random Copolyesters and Their Potential Use as Adhesives. Polymers 2022, 14, 623. [Google Scholar] [CrossRef] [PubMed]

- Burk, M.J.; Van Dien, S.J.; Burgard, A.; Niu, W. Compositions and Methods for the Biosynthesis of 1,4-Butanediol and Its Precursors. U.S. Patent US8067214 B2, 29 November 2011. [Google Scholar]

- Díaz, A.; Katsarava, R.; Puiggalí, J. Synthesis, properties and applications of biodegradable polymers derived from diols and dicarboxylic Acids: From Polyesters to poly(ester amide)s. Int. J. Mol. Sci. 2014, 15, 7064–7123. [Google Scholar] [CrossRef] [Green Version]

- Tserki, V.; Matzinos, P.; Pavlidou, E.; Vachliotis, D.; Panayiotou, C. Biodegradable aliphatic polyesters. Part I. Properties and biodegradation of poly(butylene succinate-co-butylene adipate). Polym. Degrad. Stab. 2006, 91, 367–376. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Pavlidou, E.; Panayiotou, C. Biodegradable aliphatic polyesters. Part II. Synthesis and characterization of chain extended poly(butylene succinate-co-butylene adipate). Polym. Degrad. Stab. 2006, 91, 377–384. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.-H. Microbial succinic acid, its polymer poly(butylene succinate), and applications. In Plastics from Bacteria: Natural Functions and Applications; Springer: Berlin/Heidelberg, Germany, 2010; Volume 14, pp. 347–388. ISBN 978-3-642-03286-8. [Google Scholar]

- Xu, J.; Guo, B.H. Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef] [PubMed]

- Luyt, A.S.; Malik, S.S. Can biodegradable plastics solve plastic solid waste accumulation? In Plastics to Energy: Fuel, Chemicals, and Sustainability Implications; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 403–423. ISBN 9780128131404. [Google Scholar]

- Zhu, Q.Y.; He, Y.S.; Zeng, J.B.; Huang, Q.; Wang, Y.Z. Synthesis and characterization of a novel multiblock copolyester containing poly(ethylene succinate) and poly(butylene succinate). Mater. Chem. Phys. 2011, 130, 943–949. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, X.; Du, Z.; Li, H.; Yu, K. Preparation and characterization of chain extended Poly(butylene succinate) foams. Polym. Eng. Sci. 2015, 55, 988–994. [Google Scholar] [CrossRef]

- Fujimaki, T. Processability and properties of aliphatic polyesters, “BIONOLLE”, synthesized by polycondensation reaction. Polym. Degrad. Stab. 1998, 59, 209–214. [Google Scholar] [CrossRef]

- Huang, C.Q.; Luo, S.Y.; Xu, S.Y.; Zhao, J.B.; Jiang, S.L.; Yang, W.T. Catalyzed chain extension of poly(butylene adipate) and poly(butylene succinate) with 2,2′-(1,4-phenylene)-bis(2-oxazoline). J. Appl. Polym. Sci. 2010, 115, 1555–1565. [Google Scholar] [CrossRef]

- Zhao, J.B.; Li, K.Y.; Yang, W.T. Chain extension of polybutylene adipate and polybutylene succinate with adipoyl- and terephthaloyl-biscaprolactamate. J. Appl. Polym. Sci. 2007, 106, 590–598. [Google Scholar] [CrossRef]

- Zhao, J.B.; Wu, X.F.; Yang, W.T. Synthesis of aliphatic polyesters by a chain-extending reaction with octamethylcyclotetrasilazane and hexaphenylcyclotrisilazane as chain extenders. J. Appl. Polym. Sci. 2004, 92, 3333–3337. [Google Scholar] [CrossRef]

- Ishii, M.; Okazaki, M.; Shibasaki, Y.; Ueda, M.; Teranishi, T. Convenient synthesis of aliphatic polyesters by distannoxane-catalyzed polycondensation. Biomacromolecules 2001, 2, 1267–1270. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, Z.; Liu, Q.; Wang, Z.; Jin, J. Synthesis and Biodegradation of Aliphatic Polyesters from Dicarboxylic Acids and Diols. J. Appl. Polym. Sci. 2003, 90, 982–990. [Google Scholar] [CrossRef]

- Jie, S. Synthesis and Characterization of High Relative Molecular Mass Poly(butylene succinate). Fine Chem. 2007, 24, 117. [Google Scholar]

- Azim, H.; Dekhterman, A.; Jiang, Z.; Gross, R.A. Candida antarctica lipase B-catalyzed synthesis of poly(butylene succinate): Shorter chain building blocks also work. Biomacromolecules 2006, 7, 3093–3097. [Google Scholar] [CrossRef]

- Debuissy, T.; Pollet, E.; Avérous, L. Enzymatic Synthesis of a Bio-Based Copolyester from Poly(butylene succinate) and Poly((R)-3-hydroxybutyrate): Study of Reaction Parameters on the Transesterification Rate. Biomacromolecules 2016, 17, 4054–4063. [Google Scholar] [CrossRef]

- Ciulik, C.; Safari, M.; Martínez de Ilarduya, A.; Morales-Huerta, J.C.; Iturrospe, A.; Arbe, A.; Müller, A.J.; Muñoz-Guerra, S. Poly(butylene succinate-ran-ε-caprolactone) copolyesters: Enzymatic synthesis and crystalline isodimorphic character. Eur. Polym. J. 2017, 95, 795–808. [Google Scholar] [CrossRef] [Green Version]

- Safari, M.; Martínez De Ilarduya, A.; Mugica, A.; Zubitur, M.; Muñoz-Guerra, S.; Müller, A.J. Tuning the Thermal Properties and Morphology of Isodimorphic Poly[(butylene succinate)- ran-(ε-caprolactone)] Copolyesters by Changing Composition, Molecular Weight, and Thermal History. Macromolecules 2018, 51, 9589–9601. [Google Scholar] [CrossRef]

- Pérez-Camargo, R.A.; Fernández-D’Arlas, B.; Cavallo, D.; Debuissy, T.; Pollet, E.; Avérous, L.; Müller, A.J. Tailoring the structure, morphology, and crystallization of isodimorphic poly(butylene succinate-ran-butylene adipate) random copolymers by changing composition and thermal history. Macromolecules 2017, 50, 597–608. [Google Scholar] [CrossRef]

- Mincheva, R.; Delangre, A.; Raquez, J.M.; Narayan, R.; Dubois, P. Biobased polyesters with composition-dependent thermomechanical properties: Synthesis and characterization of poly(butylene succinate-co-butylene azelate). Biomacromolecules 2013, 14, 890–899. [Google Scholar] [CrossRef] [PubMed]

- Díaz, A.; Franco, L.; Puiggalí, J. Study on the crystallization of poly(butylene azelate-co-butylene succinate) copolymers. Thermochim. Acta 2014, 575, 45–54. [Google Scholar] [CrossRef]

- Pérez-Camargo, R.A.; Liu, G.; Cavallo, D.; Wang, D.; Müller, A.J. Effect of the crystallization conditions on the exclusion/inclusion balance in biodegradable poly(butylene succinate-ran-butylene adipate) copolymers. Biomacromolecules 2020, 21, 3420–3435. [Google Scholar] [CrossRef] [PubMed]

- Tan, B.; Bi, S.; Emery, K.; Sobkowicz, M.J. Bio-based poly(butylene succinate-co-hexamethylene succinate) copolyesters with tunable thermal and mechanical properties. Eur. Polym. J. 2017, 86, 162–172. [Google Scholar] [CrossRef]

- Sisti, L.; Totaro, G.; Marchese, P. PBS makes its entrance into the family of biobased plastics. In Biodegradable and Biobased Polymers for Environmental and Biomedical Applications; Scrivener Publishing: Berverly, MA, USA, 2016; pp. 225–286. ISBN 9781119117360. [Google Scholar]

- Pérez-Camargo, R.A.; Arandia, I.; Safari, M.; Cavallo, D.; Lotti, N.; Soccio, M.; Müller, A.J. Crystallization of isodimorphic aliphatic random copolyesters: Pseudo-eutectic behavior and double-crystalline materials. Eur. Polym. J. 2018, 101, 233–247. [Google Scholar] [CrossRef]

- Pan, P.; Inoue, Y. Polymorphism and isomorphism in biodegradable polyesters. Prog. Polym. Sci. 2009, 34, 605–640. [Google Scholar] [CrossRef]

- Safari, M.; Mugica, A.; Zubitur, M.; Martínez De Ilarduya, A.; Muñoz-Guerra, S.; Müller, A.J. Controlling the Isothermal Crystallization of Isodimorphic PBS-ran-PCL Random Copolymers by Varying Composition and Supercooling. Polymers 2020, 12, 17. [Google Scholar] [CrossRef] [Green Version]

- Arandia, I.; Mugica, A.; Zubitur, M.; Arbe, A.; Liu, G.; Wang, D.; Mincheva, R.; Dubois, P.; Müller, A.J. How composition determines the properties of isodimorphic poly(butylene succinate-ran-butylene azelate) random biobased copolymers: From single to double crystalline random copolymers. Macromolecules 2015, 48, 43–57. [Google Scholar] [CrossRef] [Green Version]

- Arandia, I.; Mugica, A.; Zubitur, M.; Iturrospe, A.; Arbe, A.; Liu, G.; Wang, D.; Mincheva, R.; Dubois, P.; Müller, A.J. Application of SSA thermal fractionation and X-ray diffraction to elucidate comonomer inclusion or exclusion from the crystalline phases in poly(butylene succinate-ran-butylene azelate) random copolymers. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 2346–2358. [Google Scholar] [CrossRef]

- Arandia, I.; Mugica, A.; Zubitur, M.; Mincheva, R.; Dubois, P.; Müller, A.J.; Alegría, A. The Complex Amorphous Phase in Poly(butylene succinate-ran-butylene azelate) Isodimorphic Copolyesters. Macromolecules 2017, 50, 1569–1578. [Google Scholar] [CrossRef] [Green Version]

- Arandia, I.; Zaldua, N.; Maiz, J.; Pérez-Camargo, R.A.; Mugica, A.; Zubitur, M.; Mincheva, R.; Dubois, P.; Müller, A.J. Tailoring the isothermal crystallization kinetics of isodimorphic poly (butylene succinate-ran-butylene azelate) random copolymers by changing composition. Polymer 2019, 183. [Google Scholar] [CrossRef]

- Safari, M.; Leon Boigues, L.; Shi, G.; Maiz, J.; Liu, G.; Wang, D.; Mijangos, C.; Müller, A.J. Effect of Nanoconfinement on the Isodimorphic Crystallization of Poly(butylene succinate- ran-caprolactone) Random Copolymers. Macromolecules 2020, 53, 6486–6497. [Google Scholar] [CrossRef]

- Yu, Y.; Wei, Z.; Liu, Y.; Hua, Z.; Leng, X.; Li, Y. Effect of chain length of comonomeric diols on competition and miscibility of isodimorphism: A comparative study of poly(butylene glutarate-co-butylene azelate) and poly(octylene glutarate-co-octylene azelate). Eur. Polym. J. 2018, 105, 274–285. [Google Scholar] [CrossRef]

- Yu, Y.; Wei, Z.; Zheng, L.; Jin, C.; Leng, X.; Li, Y. Competition and miscibility of isodimorphism and their effects on band spherulites and mechanical properties of poly(butylene succinate-co-cis-butene succinate) unsaturated aliphatic copolyesters. Polymer 2018, 150, 52–63. [Google Scholar] [CrossRef]

- Yu, Y.; Wei, Z.; Zhou, C.; Zheng, L.; Leng, X.; Li, Y. Miscibility and competition of cocrystallization behavior of poly(hexamethylene dicarboxylate)s aliphatic copolyesters: Effect of chain length of aliphatic diacids. Eur. Polym. J. 2017, 92, 71–85. [Google Scholar] [CrossRef]

- Schäfer, M.; Yuan, S.; Petzold, A.; Pérez-Camargo, R.A.; Müller, A.J.; Thurn-Albrecht, T.; Saalwächter, K.; Schmidt-Rohr, K. Asymmetric Co-unit Inclusion in Statistical Copolyesters. Macromolecules 2021, 54, 835–845. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Bikiaris, D.N. Synthesis, cocrystallization, and enzymatic degradation of novel poly(butylene-co-propylene succinate) copolymers. Biomacromolecules 2007, 8, 2437–2449. [Google Scholar] [CrossRef]

- Debuissy, T.; Sangwan, P.; Pollet, E.; Avérous, L. Study on the structure-properties relationship of biodegradable and biobased aliphatic copolyesters based on 1,3-propanediol, 1,4-butanediol, succinic and adipic acids. Polymer 2017, 122, 105–116. [Google Scholar] [CrossRef]

- Kluge, M.; Bikiaris, D.N.; Robert, T. Enhancing the properties of poly(propylene succinate) by the incorporation of crystallizable symmetrical amido diols. Eur. Polym. J. 2019, 120, 109195. [Google Scholar] [CrossRef]

- Debuissy, T.; Pollet, E.; Avérous, L. Synthesis and characterization of biobased poly(butylene succinate-ran-butylene adipate). Analysis of the composition-dependent physicochemical properties. Eur. Polym. J. 2017, 87, 84–98. [Google Scholar] [CrossRef]

- Ye, H.M.; Wang, R.D.; Liu, J.; Xu, J.; Guo, B.H. Isomorphism in poly(butylene succinate-co-butylene fumarate) and its application as polymeric nucleating agent for poly(butylene succinate). Macromolecules 2012, 45, 5667–5675. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, Z.; Wu, S.; Li, C.; Zhang, D.; Xiao, Y. Novel poly(butylene fumarate) and poly(butylene succinate) multiblock copolymers bearing reactive carbon-carbon double bonds: Synthesis, characterization, cocrystallization, and properties. Ind. Eng. Chem. Res. 2013, 52, 6147–6155. [Google Scholar] [CrossRef]

- Wei, X.W.; Huang, G.; Wang, J.; Meng, X.; Zhou, Q.; Ye, H.M. Tailoring crystallization of random terpolyester: Combination of isodimorphism and isomorphism. Macromolecules 2020, 53, 8918–8927. [Google Scholar] [CrossRef]

- Wei, X.W.; Yang, L.L.; Li, Y.; Meng, X.; Cai, L.H.; Zhou, Q.; Ye, H.M. Asymmetrical formation of isomorphism in the crystalline/crystalline blend of poly(butylene succinate) and poly(butylene fumarate). Polymer 2021, 235. [Google Scholar] [CrossRef]

- Poussard, L.; Mecheri, A.; Mariage, J.; Barakat, I.; Bonnaud, L.; Raquez, J.M.; Dubois, P. Synthesis of oligo(butylene succinate)-based polyurethanes: Influence of the chemical structure on thermal and mechanical properties. J. Renew. Mater. 2014, 2, 13–22. [Google Scholar] [CrossRef]

- Jamaluddin, N.; Razaina, M.T.; Ishak, Z.M. Mechanical and Morphology Behaviours of Polybutylene (succinate)/Thermoplastic Polyurethaneblend. Procedia Chem. 2016, 19, 426–432. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Jeon, H.; Jegal, J.; Kim, J.H.; Yang, H.; Park, J.; Oh, D.X.; Hwang, S.Y. Trans crystallization behavior and strong reinforcement effect of cellulose nanocrystals on reinforced poly(butylene succinate) nanocomposites. RSC Adv. 2018, 8, 15389–15398. [Google Scholar] [CrossRef] [Green Version]

- Then, Y.Y.; Ibrahim, N.A.; Zainuddin, N.; Chieng, B.W.; Ariffin, H.; Zin Wan Yunus, W.M. Effect of 3-aminopropyltrimethoxysilane on chemically modified oil palm mesocarp fiber/poly(butylene succinate) biocomposite. BioResources 2015, 10, 3577–3601. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Manepalli, P.H.; Zhu, L.; Narayan-Sarathy, S.; Alavi, S. Morphological, barrier and mechanical properties of films from poly(butylene succinate) reinforced with nanocrystalline cellulose and chitin whiskers using melt extrusion. J. Polym. Res. 2019, 26, 1–10. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Wibooranawong, S.; Naknaen, P. Antimicrobial food packaging prepared from poly(butylene succinate) and zinc oxide. Meas. J. Int. Meas. Confed. 2016, 93, 442–448. [Google Scholar] [CrossRef]

- Zainal Abidin, A.S.; Yusoh, K.; Jamari, S.S.; Abdullah, A.H.; Ismail, Z. Surface functionalization of graphene oxide with octadecylamine for improved thermal and mechanical properties in polybutylene succinate nanocomposite. Polym. Bull. 2018, 75, 3499–3522. [Google Scholar] [CrossRef]

- Ludueña, L.N.; Fortunati, E.; Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Puglia, D.; Manfredi, L.B.; Pracella, M. Preparation and characterization of polybutylene-succinate/poly(ethylene-glycol)/cellulose nanocrystals ternary composites. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Planellas, M.; Sacristán, M.; Rey, L.; Olmo, C.; Aymamí, J.; Casas, M.T.; Del Valle, L.J.; Franco, L.; Puiggalí, J. Micro-molding with ultrasonic vibration energy: New method to disperse nanoclays in polymer matrices. Ultrason. Sonochem. 2014, 21, 1557–1569. [Google Scholar] [CrossRef]

- Henke, L.; Zarrinbakhsh, N.; Endres, H.J.; Misra, M.; Mohanty, A.K. Biodegradable and Bio-based Green Blends from Carbon Dioxide-Derived Bioplastic and Poly(Butylene Succinate). J. Polym. Environ. 2016, 25, 499–509. [Google Scholar] [CrossRef]

- Phua, Y.J.; Chow, W.S.; Mohd Ishak, Z.A. Reactive processing of maleic anhydride-grafted poly(butylene succinate) and the compatibilizing effect on poly(butylene succinate) nanocomposites. Express Polym. Lett. 2013, 7, 340–354. [Google Scholar] [CrossRef]

- He, L.; Song, F.; Li, D.F.; Zhao, X.; Wang, X.L.; Wang, Y.Z. Strong and Tough Polylactic Acid Based Composites Enabled by Simultaneous Reinforcement and Interfacial Compatibilization of Microfibrillated Cellulose. ACS Sustain. Chem. Eng. 2020, 8, 1573–1582. [Google Scholar] [CrossRef]

- Dai, X.; Qiu, Z. Synthesis and properties of novel biodegradable poly(butylene succinate-co-decamethylene succinate) copolyesters from renewable resources. Polym. Degrad. Stab. 2016, 134, 305–310. [Google Scholar] [CrossRef]

- Jacquel, N.; Saint-Loup, R.; Pascault, J.P.; Rousseau, A.; Fenouillot, F. Bio-based alternatives in the synthesis of aliphatic-aromatic polyesters dedicated to biodegradable film applications. Polymer 2015, 59, 234–242. [Google Scholar] [CrossRef]

- Genovese, L.; Lotti, N.; Gazzano, M.; Siracusa, V.; Dalla Rosa, M.; Munari, A. Novel biodegradable aliphatic copolyesters based on poly(butylene succinate) containing thioether-linkages for sustainable food packaging applications. Polym. Degrad. Stab. 2016, 132, 191–201. [Google Scholar] [CrossRef]

- Ojijo, V.; Sinha Ray, S. Processing strategies in bionanocomposites. Prog. Polym. Sci. 2013, 38, 1543–1589. [Google Scholar] [CrossRef]

- Ojijo, V.; Sinha Ray, S. Nano-biocomposites based on synthetic aliphatic polyesters and nanoclay. Prog. Mater. Sci. 2014, 62, 1–57. [Google Scholar] [CrossRef]

- Shirali, H.; Rafizadeh, M.; Afshar Taromi, F.; Jabbari, E. Fabrication of in situ polymerized poly(butylene succinate-co-ethylene terephthalate)/hydroxyapatite nanocomposite to fibrous scaffolds for enhancement of osteogenesis. J. Biomed. Mater. Res.-Part A 2017, 105, 2622–2631. [Google Scholar] [CrossRef] [PubMed]

- Joy, J.; Jose, C.; Varanasi, S.B.; Mathew, L.P.; Thomas, S.; Pilla, S. Preparation and characterization of poly(butylene succinate) bionanocomposites reinforced with cellulose nanofiber extracted from Helicteres isora plant. J. Renew. Mater. 2016, 4, 351–364. [Google Scholar] [CrossRef]

- Saeed, U.; Nawaz, M.A.; Al-Turaif, H.A. Wood flour reinforced biodegradable PBS/PLA composites. J. Compos. Mater. 2018, 52, 2641–2650. [Google Scholar] [CrossRef]

- Chen, Z.; Gan, L.; Chang, P.R.; Liu, C.; Huang, J.; Gao, S. Cost Reduction and Mechanical Enhancement of Biopolyesters Using an Agricultural Byproduct from Konjac Glucomannan Processing. ACS Sustain. Chem. Eng. 2017, 5, 6498–6506. [Google Scholar] [CrossRef]

- Brody, A.L. Packaging of Foods. Encycl. Food Microbiol. Second Ed. 2014, 2, 1017–1027. [Google Scholar] [CrossRef]

- Li, S.L.; Wu, F.; Yang, Y.; Wang, Y.Z.; Zeng, J.B. Synthesis, characterization and isothermal crystallization behavior of poly(butylene succinate)-b-poly(diethylene glycol succinate) multiblock copolymers. Polym. Adv. Technol. 2015, 26, 1003–1013. [Google Scholar] [CrossRef]

- Robeson, L.M. Polymer Membranes. In Polymer Science: A Comprehensive Reference; Elsevier B.V.: Amsterdam, The Netherlands, 2012; Volume 8, pp. 325–347. ISBN 9780080878621. [Google Scholar]

- Puchalski, M.; Szparaga, G.; Biela, T.; Gutowska, A.; Sztajnowski, S.; Krucińska, I. Molecular and supramolecular changes in polybutylene succinate (PBS) and polybutylene succinate adipate (PBSA) copolymer during degradation in various environmental conditions. Polymers 2018, 10, 251. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Satti, S.M.; Shah, A.A. Polyester-based biodegradable plastics: An approach towards sustainable development. Lett. Appl. Microbiol. 2020, 70, 413–430. [Google Scholar] [CrossRef] [PubMed]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Mohd Nurrazi, N.; Isma, T.; Lee, C.H. Effect of empty fruit brunch reinforcement in polybutylene-succinate/modified tapioca starch blend for agricultural mulch films. Sci. Rep. 2020, 10, 1166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lagarón, J.-M. Multifunctional and Nanoreinforced Polymers for Food Packaging; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780081017074. [Google Scholar]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Lotti, N.; Munari, A.; Dalla Rosa, M. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Giacinti Baschetti, M.; Minelli, M. Test methods for the characterization of gas and vapor permeability in polymers for food packaging application: A review. Polym. Test. 2020, 89, 106606. [Google Scholar] [CrossRef]

- Massey, L.K. Permeability Properties of Plastics and Elastomers: A Guide to Packaging and Barrier Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003; Volume 92, ISBN 1884207979. [Google Scholar]

- Číhal, P.; Vopička, O.; Lanč, M.; Kludský, M.; Velas, J.; Hrdlička, Z.; Michalcová, A.; Dendisová, M.; Friess, K. Poly(butylene succinate)-cellulose triacetate blends: Permeation, pervaporation, sorption and physical structure. Polym. Test. 2018, 65, 468–479. [Google Scholar] [CrossRef]

- Guidotti, G.; Soccio, M.; Siracusa, V.; Gazzano, M.; Salatelli, E.; Munari, A.; Lotti, N. Novel Random PBS-Based Copolymers Containing Aliphatic Side Chains for Sustainable Flexible Food Packaging. Polymers 2017, 9, 724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I.; Romani, S.; Tylewicz, U.; Rocculi, P.; Rosa, M.D. Poly(lactic acid)-modified films for food packaging application: Physical, mechanical, and barrier behavior. J. Appl. Polym. Sci. 2012, 125, E390–E401. [Google Scholar] [CrossRef]

- McHugh, T.H.; Krochta, J.M. Sorbitol-vs Glycerol-Plasticized Whey Protein Edible Films: Integrated Oxygen Permeability and Tensile Property Evaluation. J. Agric. Food Chem. 1994, 42, 841–845. [Google Scholar] [CrossRef]

- Rudnik, E. Properties and Applications. In Compostable Polymer Materials; VCH: New York, NY, USA, 2019; pp. 49–98. ISBN 9781461361503. [Google Scholar]

- Okamoto, K.; Ray, S.S.; Okamoto, M. New poly(butylene succinate)/layered silicate nanocomposites. II. Effect of organically modified layered silicates on structure, properties, melt rheology, and biodegradability. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 3160–3172. [Google Scholar] [CrossRef]

- Charlon, S.; Follain, N.; Dargent, E.; Soulestin, J.; Sclavons, M.; Marais, S. Poly[(butylene succinate)-co-(butylene adipate)]-Montmorillonite Nanocomposites Prepared by Water-Assisted Extrusion: Role of the Dispersion Level and of the Structure-Microstructure on the Enhanced Barrier Properties. J. Phys. Chem. C 2016, 120, 13234–13248. [Google Scholar] [CrossRef]

- Dean, K.M.; Pas, S.J.; Yu, L.; Ammala, A.; Hill, A.J.; Wu, D.Y. Formation of Highly Oriented Biodegradable Polybutylene Succinate Adipate Nanocomposites: Effects of Cation Structures on Morphology, Free Volume, and Properties. J. Appl. Polym. Sci. 2009, 113, 3716–3724. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Effect of clay on thermal, mechanical and gas barrier properties of biodegradable poly(lactic acid)/poly(butylene succinate) (PLA/PBS) nanocomposites. Int. Polym. Process. 2009, 25, 5–14. [Google Scholar] [CrossRef]

- Petersen, K.; Nielsen, P.V.; Olsen, M.B. Physical and mechanical properties of biobased materials—Starch, polylactate and polyhydroxybutyrate. Starch/Staerke 2001, 53, 356–361. [Google Scholar] [CrossRef]

- Olabarrieta, I.; Forsström, D.; Gedde, U.W.; Hedenqvist, M.S. Transport properties of chitosan and whey blended with poly(ε-caprolactone) assessed by standard permeability measurements and microcalorimetry. Polymer 2001, 42, 4401–4408. [Google Scholar] [CrossRef]

- Bastarrachea, L.; Dhawan, S.; Sablani, S.S. Engineering Properties of Polymeric-Based Antimicrobial Films for Food Packaging. Food Eng. Rev. 2011, 3, 79–93. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, S.; Wang, P.; Wang, J. Synthesis of poly(butylene succinate) phosphorus-containing ionomers for versatile crystallization and improved thermal conductivity. Polymer 2018, 154, 258–271. [Google Scholar] [CrossRef]

- Cosquer, R.; Pruvost, S.; Gouanvé, F. Improvement of barrier properties of biodegradable polybutylene succinate/graphene nanoplatelets nanocomposites prepared by melt process. Membranes 2021, 11, 151. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Chen, J.B.; Zhang, Z.J.; Hsiao, B.S.; Zhong, G.J.; Chen, J.; Li, Z.M. From nanofibrillar to nanolaminar poly(butylene succinate): Paving the way to robust barrier and mechanical properties for full-biodegradable poly(lactic acid) films. ACS Appl. Mater. Interfaces 2015, 7, 8023–8032. [Google Scholar] [CrossRef]

- Messin, T.; Marais, S.; Follain, N.; Guinault, A.; Gaucher, V.; Delpouve, N.; Sollogoub, C. Biodegradable PLA/PBS multinanolayer membrane with enhanced barrier performances. J. Memb. Sci. 2020, 598, 1–11. [Google Scholar] [CrossRef]

- Messin, T.; Follain, N.; Guinault, A.; Sollogoub, C.; Gaucher, V.; Delpouve, N.; Marais, S. Structure and Barrier Properties of Multinanolayered Biodegradable PLA/PBSA Films: Confinement Effect via Forced Assembly Coextrusion. ACS Appl. Mater. Interfaces 2017, 9, 29101–29112. [Google Scholar] [CrossRef] [Green Version]

- Duan, R.T.; He, Q.X.; Dong, X.; Li, D.F.; Wang, X.L.; Wang, Y.Z. Renewable sugar-based diols with different rigid structure: Comparable investigation on improving poly(butylene succinate) performance. ACS Sustain. Chem. Eng. 2016, 4, 350–362. [Google Scholar] [CrossRef]

- Attallah, O.A.; Mojicevic, M.; Lanzagorta Garcia, E.; Azeem, M.; Chen, Y.; Asmawi, S.; Fournet, M.B. Macro and micro routes to high performance bioplastics: Bioplastic biodegradability and mechanical and barrier properties. Polymers 2021, 13, 2155. [Google Scholar] [CrossRef] [PubMed]

- Risse, S.; Tighzert, L.; Berzin, F.; Vergnes, B. Microstructure, rheological behavior, and properties of poly(lactic acid)/poly(butylene succinate)/organoclay nanocomposites. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Salehiyan, R.; Ray, S.S. Influence of Nanoclay Localization on Structure–Property Relationships of Polylactide-Based Biodegradable Blend Nanocomposites. Macromol. Mater. Eng. 2018, 303, 1–20. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, K.; Okamoto, M. Structure-property relationship in biodegradable poly(butylene succinate)/layered silicate nanocomposites. Macromolecules 2003, 36, 2355–2367. [Google Scholar] [CrossRef]

- Ilsouk, M.; Raihane, M.; Rhouta, B.; Meri, R.M.; Zicans, J.; Vecstaudža, J.; Lahcini, M. The relationship of structure, thermal and water vapor permeability barrier properties of poly(butylene succinate)/organomodified beidellite clay bionanocomposites prepared by in situ polycondensation. RSC Adv. 2020, 10, 37314–37326. [Google Scholar] [CrossRef]

- Saeng-on, J.; Aht-Ong, D. Compatibility of banana starch nanocrystals/poly(butylene succinate) bio-nanocomposite packaging films. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Preedanorawut, R.; Threepopnatkul, P.; Sittatrakul, A. Effect of zeolite types on properties of polybutylene succinate/polylactic acid films. IOP Conf. Ser. Mater. Sci. Eng. 2020, 773, 012026. [Google Scholar] [CrossRef]

- Gain, O.; Espuche, E.; Pollet, E.; Alexandre, M.; Dubois, P. Gas barrier properties of poly(ε-caprolactone)/clay nanocomposites: Influence of the morphology and polymer/clay interactions. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 205–214. [Google Scholar] [CrossRef]

- Follain, N.; Belbekhouche, S.; Bras, J.; Siqueira, G.; Chappey, C.; Marais, S.; Dufresne, A. Tunable gas barrier properties of filled-PCL film by forming percolating cellulose network. Colloids Surfaces A Physicochem. Eng. Asp. 2018, 545, 26–30. [Google Scholar] [CrossRef]

- Mao, L.; Wu, H.; Liu, Y.; Yao, J.; Bai, Y. Enhanced mechanical and gas barrier properties of poly(ε-caprolactone) nanocomposites filled with tannic acid-Fe(III) functionalized high aspect ratio layered double hydroxides. Mater. Chem. Phys. 2018, 211, 501–509. [Google Scholar] [CrossRef]

- Mohamed, R.M.; Yusoh, K. A Review on the Recent Research of Polycaprolactone (PCL). Adv. Mater. Res. 2015, 1134, 249–255. [Google Scholar] [CrossRef]

- Kunioka, M.; Ninomiya, F.; Funabashi, M. Biodegradation of poly(butylene succinate) powder in a controlled compost at 58 °C evaluated by naturally-occurring carbon 14 amounts in evolved CO2 based on the ISO 14855-2 method. Int. J. Mol. Sci. 2009, 10, 4267–4283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anankaphong, H.; Pentrakoon, D.; Junkasem, J. Effect of rubberwood content on biodegradability of poly(butylene succinate) biocomposites. Int. J. Polym. Sci. 2015, 2015, 19–21. [Google Scholar] [CrossRef] [Green Version]

- Ganesh Kumar, A.; Anjana, K.; Hinduja, M.; Sujitha, K.; Dharani, G. Review on plastic wastes in marine environment—Biodegradation and biotechnological solutions. Mar. Pollut. Bull. 2020, 150, 110733. [Google Scholar] [CrossRef]

- Iram, D.; Riaz, R.A.; Iqbal, R.K. Usage of potential micro-organisms for degradation of plastics. Open J. Environ. Biol. 2019, 4, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Brannigan, R.P.; Dove, A.P. Synthesis, properties and biomedical applications of hydrolytically degradable materials based on aliphatic polyesters and polycarbonates. Biomater. Sci. 2017, 5, 9–21. [Google Scholar] [CrossRef]

- Armentano, I.; Gigli, M.; Morena, F.; Argentati, C.; Torre, L.; Martino, S. Recent advances in nanocomposites based on aliphatic polyesters: Design, synthesis, and applications in regenerative medicine. Appl. Sci. 2018, 8, 1452. [Google Scholar] [CrossRef] [Green Version]

- Gualandi, C.; Soccio, M.; Govoni, M.; Valente, S.; Lotti, N.; Munari, A.; Giordano, E.; Pasquinelli, G.; Focarete, M.L. Poly(butylene/diethylene glycol succinate) multiblock copolyester as a candidate biomaterial for soft tissue engineering: Solid-state properties, degradability, and biocompatibility. J. Bioact. Compat. Polym. 2012, 27, 244–264. [Google Scholar] [CrossRef]

- Huang, A.; Peng, X.; Geng, L.; Zhang, L.; Huang, K.; Chen, B.; Gu, Z.; Kuang, T. Electrospun poly (butylene succinate)/cellulose nanocrystals bio-nanocomposite scaffolds for tissue engineering: Preparation, characterization and in vitro evaluation. Polym. Test. 2018, 71, 101–109. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, W.; Liu, Y. Synthesis and characterization of bio-based poly(butylene succinate-co-10-hydroxydecanoate). J. Elastomers Plast. 2018, 50, 325–338. [Google Scholar] [CrossRef]

- Sheikholeslami, S.N.; Rafizadeh, M.; Taromi, F.A.; Shirali, H.; Jabbari, E. Material properties of degradable Poly(butylene succinate-co-fumarate) copolymer networks synthesized by polycondensation of pre-homopolyesters. Polymer 2016, 98, 70–79. [Google Scholar] [CrossRef]

- Morales-Huerta, J.C.; Ciulik, C.B.; De Ilarduya, A.M.; Muñoz-Guerra, S. Fully bio-based aromatic-aliphatic copolyesters: Poly(butylene furandicarboxylate-co-succinate)s obtained by ring opening polymerization. Polym. Chem. 2017, 8, 748–760. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Gao, Z.; Wang, Z.; Su, T.; Yang, L.; Li, P. Enzymatic degradation of poly(butylene succinate) by cutinase cloned from Fusarium solani. Polym. Degrad. Stab. 2016, 134, 211–219. [Google Scholar] [CrossRef]

- Pan, W.; Bai, Z.; Su, T.; Wang, Z. Enzymatic degradation of poly(butylene succinate) with different molecular weights by cutinase. Int. J. Biol. Macromol. 2018, 111, 1040–1046. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Y.; Su, T.; Wang, Z. Effect of hydroxyl monomers on the Enzymatic degradation of poly(ethylene succinate), poly(butylene succinate), and poly(hexylene succinate). Polymers 2018, 10, 90. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.; Su, T.; Wang, Z. Comparison of poly(butylene succinate) biodegradation by Fusarium solani cutinase and Candida antarctica lipase. Polym. Degrad. Stab. 2019, 164, 55–60. [Google Scholar] [CrossRef]

- Li, S.L.; Wu, F.; Wang, Y.Z.; Zeng, J.B. Biobased Thermoplastic Poly(ester urethane) Elastomers Consisting of Poly(butylene succinate) and Poly(propylene succinate). Ind. Eng. Chem. Res. 2015, 54, 6258–6268. [Google Scholar] [CrossRef]

- Hwang, S.Y.; Jin, X.Y.; Yoo, E.S.; Im, S.S. Synthesis, physical properties and enzymatic degradation of poly (oxyethylene-b-butylene succinate) ionomers. Polymer 2011, 52, 2784–2791. [Google Scholar] [CrossRef]

- Yang, J.; Tian, W.; Li, Q.; Li, Y.; Cao, A. Novel biodegradable aliphatic poly(butylene succinate-co-cyclic carbonate)s bearing functionalizable carbonate building blocks: II. Enzymatic biodegradation and in vitro biocompatibility assay. Biomacromolecules 2004, 5, 2258–2268. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Li, C.; Zheng, L.; Zhang, D.; Guan, G.; Xiao, Y. Synthesis, characterization and properties of biodegradable poly(butylene succinate)-block-poly(propylene glycol)segmented copolyesters. Polym. Int. 2009, 58, 893–899. [Google Scholar] [CrossRef]

- Han, J.; Shi, J.; Xie, Z.; Xu, J.; Guo, B. Synthesis, properties of biodegradable poly(butylene succinate-co-butylene 2-methylsuccinate) and application for sustainable release. Materials 2019, 12, 1507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, Z.H.; Wang, C.L. Novel poly(butylenes succinate-block-1,3-propylene sebacate): Synthesis and enzymatic degradation. Adv. Mater. Res. 2013, 774–776, 569–572. [Google Scholar] [CrossRef]

- Kong, X.; Qi, H.; Curtis, J.M. Synthesis and characterization of high-molecular weight aliphatic polyesters from monomers derived from renewable resources. J. Appl. Polym. Sci. 2014, 131, 4–10. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Lawson, T.; Kanwal, A.; Miao, Z. Poly(butylene succinate-co-salicylic acid) copolymers and their effect on promoting plant growth. R. Soc. Open Sci. 2019, 6, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Nikolic, M.S.; Djonlagic, J. Synthesis and characterization of biodegradable poly(butylene succinate-co-butylene adipate)s. Polym. Degrad. Stab. 2001, 74, 263–270. [Google Scholar] [CrossRef]

- Song, D.K.; Sung, Y.K. Synthesis and characterization of biodegradable poly(1,4-butanediol succinate). J. Appl. Polym. Sci. 1995, 56, 1381–1395. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Dufresne, A.; Pinheiro, I.F.; Souza, D.H.S.; Gouveia, R.F.; Mei, L.H.I.; Lona, L.M.F. How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: A comprehensive review. Eur. Polym. J. 2018, 108, 274–285. [Google Scholar] [CrossRef]

- Scott, G. “Green” polymers. Polym. Degrad. Stab. 2000, 68, 1–7. [Google Scholar] [CrossRef]

- Nugroho, P.; Mitomo, H.; Yoshii, F.; Kume, T.; Nishimura, K. Improvement of processability of PCL and PBS blend by irradiation and its biodegradability. Macromol. Mater. Eng. 2001, 286, 316–323. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chemie-Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.S.; Yang, H.S.; Kim, H.J. Biodegradability and mechanical properties of agro-flour-filled polybutylene succinate biocomposites. J. Appl. Polym. Sci. 2005, 97, 1513–1521. [Google Scholar] [CrossRef]

- Huang, Z.; Qian, L.; Yin, Q.; Yu, N.; Liu, T.; Tian, D. Biodegradability studies of poly(butylene succinate) composites filled with sugarcane rind fiber. Polym. Test. 2018, 66, 319–326. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Barkane, A.; Sereda, A.; Gaidukova, G.; Grase, L.; Thakur, V.K.; Filipova, I.; Fridrihsone, V.; Skute, M.; et al. Bio-based poly(butylene succinate)/microcrystalline cellulose/nanofibrillated cellulose-based sustainable polymer composites: Thermo-mechanical and biodegradation studies. Polymers 2020, 12, 1472. [Google Scholar] [CrossRef]

- Calabia, B.P.; Ninomiya, F.; Yagi, H.; Oishi, A.; Taguchi, K.; Kunioka, M.; Funabashi, M. Biodegradable poly(butylene succinate) composites reinforced by cotton fiber with silane coupling agent. Polymers 2013, 5, 128–141. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.S.; Kim, H.J.; Lee, J.W.; Choi, I.G. Biodegradability of bio-flour filled biodegradable poly(butylene succinate) bio-composites in natural and compost soil. Polym. Degrad. Stab. 2006, 91, 1117–1127. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Yang, X. Biodegradability of poly(butylene succinate) (PBS) composite reinforced with jute fibre. Polym. Degrad. Stab. 2009, 94, 90–94. [Google Scholar] [CrossRef]

- Teramoto, N.; Urata, K.; Ozawa, K.; Shibata, M. Biodegradation of aliphatic polyester composites reinforced by abaca fiber. Polym. Degrad. Stab. 2004, 86, 401–409. [Google Scholar] [CrossRef]

- Anstey, A.; Muniyasamy, S.; Reddy, M.M.; Misra, M.; Mohanty, A. Processability and Biodegradability Evaluation of Composites from Poly(butylene succinate) (PBS) Bioplastic and Biofuel Co-products from Ontario. J. Polym. Environ. 2014, 22, 209–218. [Google Scholar] [CrossRef]

- Phua, Y.J.; Lau, N.S.; Sudesh, K.; Chow, W.S.; Mohd Ishak, Z.A. Biodegradability studies of poly(butylene succinate)/organo-montmorillonite nanocomposites under controlled compost soil conditions: Effects of clay loading and compatibiliser. Polym. Degrad. Stab. 2012, 97, 1345–1354. [Google Scholar] [CrossRef]

- Platnieks, O.; Sereda, A.; Gaidukovs, S.; Thakur, V.K.; Barkane, A.; Gaidukova, G.; Filipova, I.; Ogurcovs, A.; Fridrihsone, V. Adding value to poly(butylene succinate) and nanofibrillated cellulose-based sustainable nanocomposites by applying masterbatch process. Ind. Crops Prod. 2021, 169, 113669. [Google Scholar] [CrossRef]

- Platnieks, O.; Barkane, A.; Ijudina, N.; Gaidukova, G.; Thakur, V.K.; Gaidukovs, S. Sustainable tetra pak recycled cellulose/poly(butylene succinate) based woody-like composites for a circular economy. J. Clean. Prod. 2020, 270, 122321. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Arevalo, J.; Gomez-Caturla, J.; Garcia-Garcia, D.; Torres-Giner, S. Peroxide-induced synthesis of maleic anhydride-grafted poly(butylene succinate) and its compatibilizing effect on poly(butylene succinate)/pistachio shell flour composites. Molecules 2021, 26, 5927. [Google Scholar] [CrossRef] [PubMed]

| Family | Enzyme | Substrate | Experimental Conditions | Results | Reference |

|---|---|---|---|---|---|

| Cutinase | Fusarium solani | PBS films 30 × 10 × 0.1 mm3 | pH = 8.0 at 40 °C, 20 µg/mL | 100% weight loss in 6 h | [147] |

| Cutinase | Pichia pastoris | PBS films 30 × 10 × 0.5 mm3 | pH = 7.4 at 37 °C, 0.15 mg/mL | 100% weight loss in 12 h | [148] |

| Cutinase | Fusarium solani | PBS films 30 × 10 × 0.1 mm3 | pH = 7.4 at 37 °C, 10 mg/mL | 98.4% weight loss in 12 h | [149] |

| Cutinase | Fusarium solani | PBS films 30 × 10 × 0.5 mm3 | pH = 7.2 at 37 °C, 18 U/mL | ~100% weight loss in 26 h | [150] |

| Lipase | Candida antarctica (CALB) | PBS films 30 × 10 × 0.5 mm3 | pH = 7.2 at 45 °C, 18 U/mL | 95.1% weight loss in 26 h | [150] |

| Lipase | Candida rugosa | PBS films 10 × 10 × 0.5 mm3 | pH = 7.4 at 30 °C, 0.1 mg/mL | 2% weight loss after 7 weeks | [151] |

| Lipase | Pseudomonas cepacia | PBS films 20 × 30 × 0.3 mm3 | pH = 8.0 at 40 °C, 0.06 mg/mL | 2% weight loss after 90 h | [152] |

| Lipase | Candida antarctica (CALB) N435 | PBS films 30 × 10 mm2 | pH = 7.4 at 37 °C, 1.2 mg/mL | 1.8% weight loss after 90 h | [153] |

| Lipase | Porcine pancreas | PBS films 30 × 10 mm2 | pH = 7.4 at 37 °C, 0.8 mg/mL | 0.9% weight loss after 90 h | [153] |

| Lipase | Pseudomonas cepacia | PBS films 10 × 10 × 0.1 mm3 | pH = 6.86 at 45 °C, 0.22 mg/mL | 4.6% weight loss after 50 h | [154] |

| Lipase | Porcine pancreas | PBS film discs 10 × 10 × 0.2 mm3 | pH = 7.4 at 37 °C, 1 mg/mL | 21% weight loss after 30 days | [146] |

| Lipase | Pseudomonas fluorescens | PBS films 10 × 10 × 0.2 mm3 | pH = 7.3 at 37 °C, 2 mg/mL | No visible degradation after 300 h | [155] |

| Lipase | Pseudomonas cepacia | PBS films 10 × 10 × 0.1 mm3 | pH = 6.86 at 45 °C, 0.53 mg/mL | 100% weight loss after 288 h | [71] |

| Lipase | Pseudomonas cepacia | PBS film discs 20 × 20 × 0.05 mm3 | pH = 7.4 at 37 °C, 1 mg/mL | 6% weight loss after 50 h | [156] |

| Lipase | Rhizopus delemar and Pseudomonas cepacia | PBS film discs 50 × 50 × 2 mm3 | pH = 7.2 at 30 °C, 0.09 & 0.01 mg/mL | 2% weight loss after 360 h | [66] |

| Filler | Filler Content | Experimental Conditions | Results (Weight Loss) | Reference |

|---|---|---|---|---|

| Rubberwood powders (RWP) | 0–40 wt% | 60 days, no UV radiation, water control each 48 h | <1% (PBS) 2–10% (PBS/RWP) | [137] |

| Rice husk flour (RHF) and wood flour (WF) | 0–40 wt% | 4 months | 7% (PBS) 8–12% (PBS/RHF and PBS/WF) | [165] |

| Sugarcane rind fiber (SRF) | 0–15 wt% | 100 days, natural soil in cropland, water control each 24 h | 2.5% (PBS) 10–20% (PBS/SRF) | [166] |

| Microcrystalline cellulose (MCC) and nanofibrillated cellulose (NFC) | 0–40 wt% | 75 days, simulated compost, 58 °C, pH = 5.7–6.3, 50 wt% water content | 100% in 75–80 days (PBS) 100% in 65–70 days (PBS/MCC and PBS/NFC) | [167] |

| Cotton fiber (CF) | 0–40 wt% | Based on ISO 14855-2 100 days, 58 °C, 10 mL/min air flow | ~60% (PBS) ~90% (PBS/CF) | [168] |

| Rice husk flour (RHF) | 0–40 wt% | Based on ASTM D 6003-96 80 days, 30 °C, pH = 7, 50–60 wt% water content | ~12% (PBS) 13–18% (PBS/RHF) | [169] |

| Jute fiber (JF) | 0–30 wt% | 180 days, compost soil, 30 °C, constant water control | 31.4% (PBS) 47.3–62.5% (PBS/JF) | [170] |

| Abaca fiber (AF) | 10 wt% | 180 days, black soil and leaf mold for gardening, 25–30 °C, water control each 48 h | ~30% (PBS) ~50% (PBS/AF) | [171] |

| Soy, canola, and corn gluten meals (SM, CM, CGM) and switchgrass (SG) | 25 wt% | Based on ASTM D6400 200 days, 3 month-old compost, 58 °C, pH = 7–8, 50–55 wt% water content | ~95% (PBS) ~85% (PBS/SG) 90–95% (PBS/SM, PBS/CM and PBS/CGM) | [172] |

| Organically modified montmorillonite (OMMT) | 0–10 wt% | 180 days, natural compost, 30 °C, pH = 7.46, 60–70 wt% water content | ~9% (PBS) ~3.5–5% (PBS/OMMT) | [173] |

| Nanofibrillated cellulose (NFC) and recycled cellulose (rCell) | 0–15 wt% (PBS/NFC) 0–50 wt% (PBS/rCell) | 80 days, 58 °C, pH = 5.7–6.5, >50 wt% water content | ~80% (PBS) ~85–92% (PBS/NFC) 100% in 70 days (PBS/rCell) | [174,175] |

| Pistachio shell flour (PSF) | 0–30 wt% | Based on ISO 20200 112 days, compost, 58 °C, 55 % relative humidity | ~18% (PBS) ~14–17.5% (PBS/PSF) | [176] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peñas, M.I.; Pérez-Camargo, R.A.; Hernández, R.; Müller, A.J. A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers. Polymers 2022, 14, 1025. https://doi.org/10.3390/polym14051025

Peñas MI, Pérez-Camargo RA, Hernández R, Müller AJ. A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers. Polymers. 2022; 14(5):1025. https://doi.org/10.3390/polym14051025

Chicago/Turabian StylePeñas, Mario Iván, Ricardo Arpad Pérez-Camargo, Rebeca Hernández, and Alejandro J. Müller. 2022. "A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers" Polymers 14, no. 5: 1025. https://doi.org/10.3390/polym14051025

APA StylePeñas, M. I., Pérez-Camargo, R. A., Hernández, R., & Müller, A. J. (2022). A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers. Polymers, 14(5), 1025. https://doi.org/10.3390/polym14051025