Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

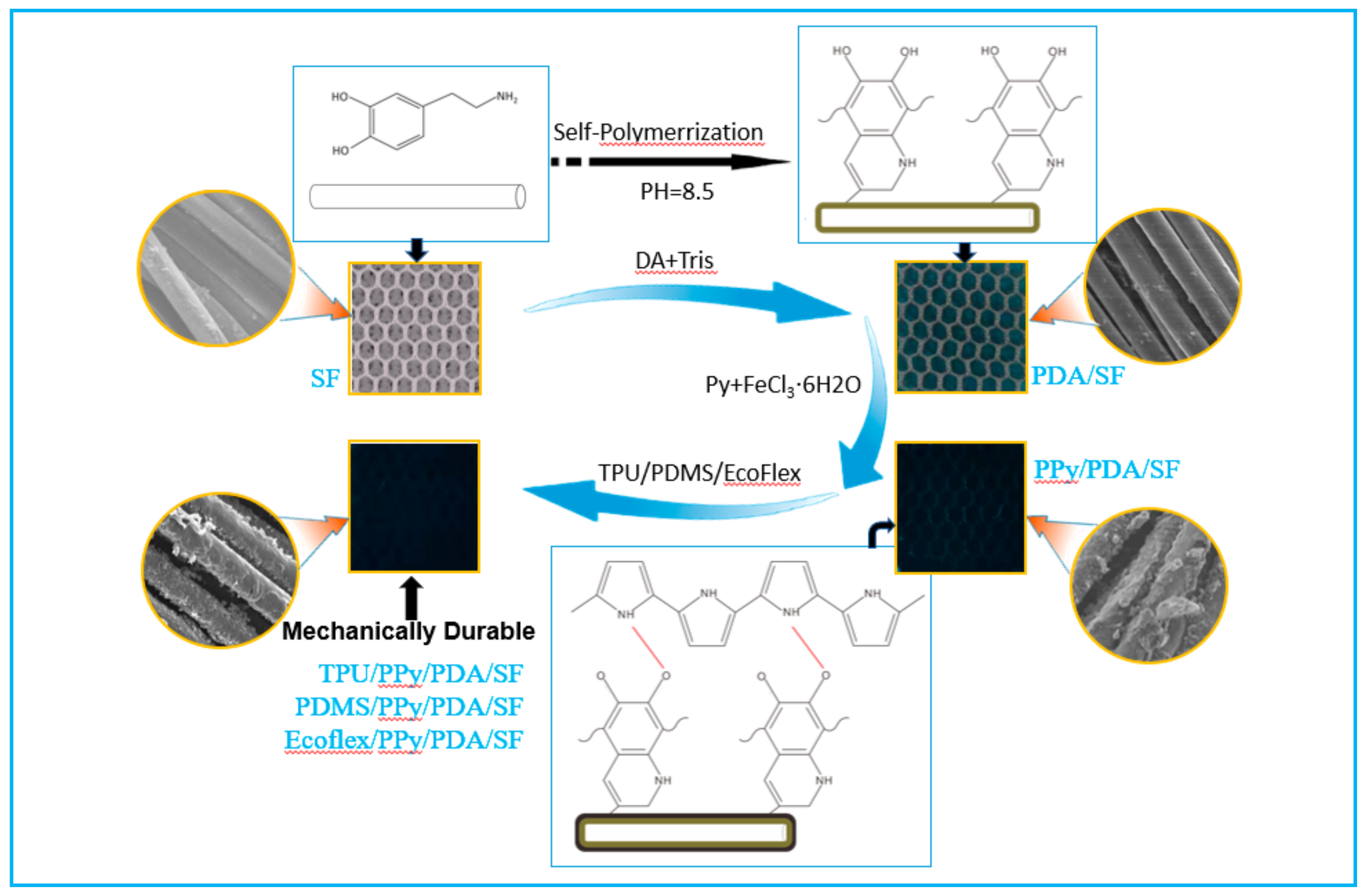

2.2. Fabrication of PPY/PDA/SF and TPU/PPY/PDA/SF

2.3. Characterization

3. Results and Discussion

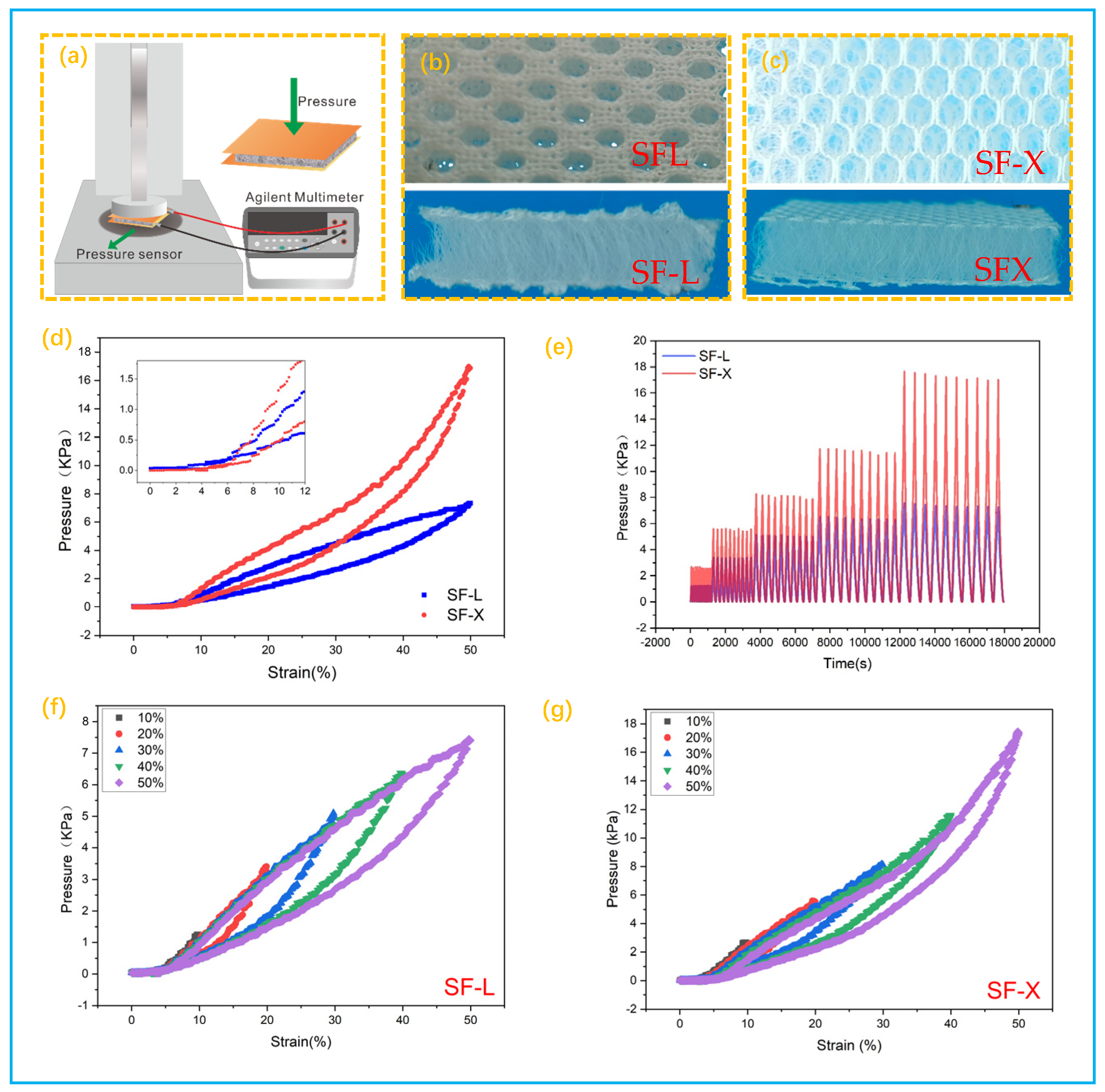

3.1. Mechanical Properties of SF

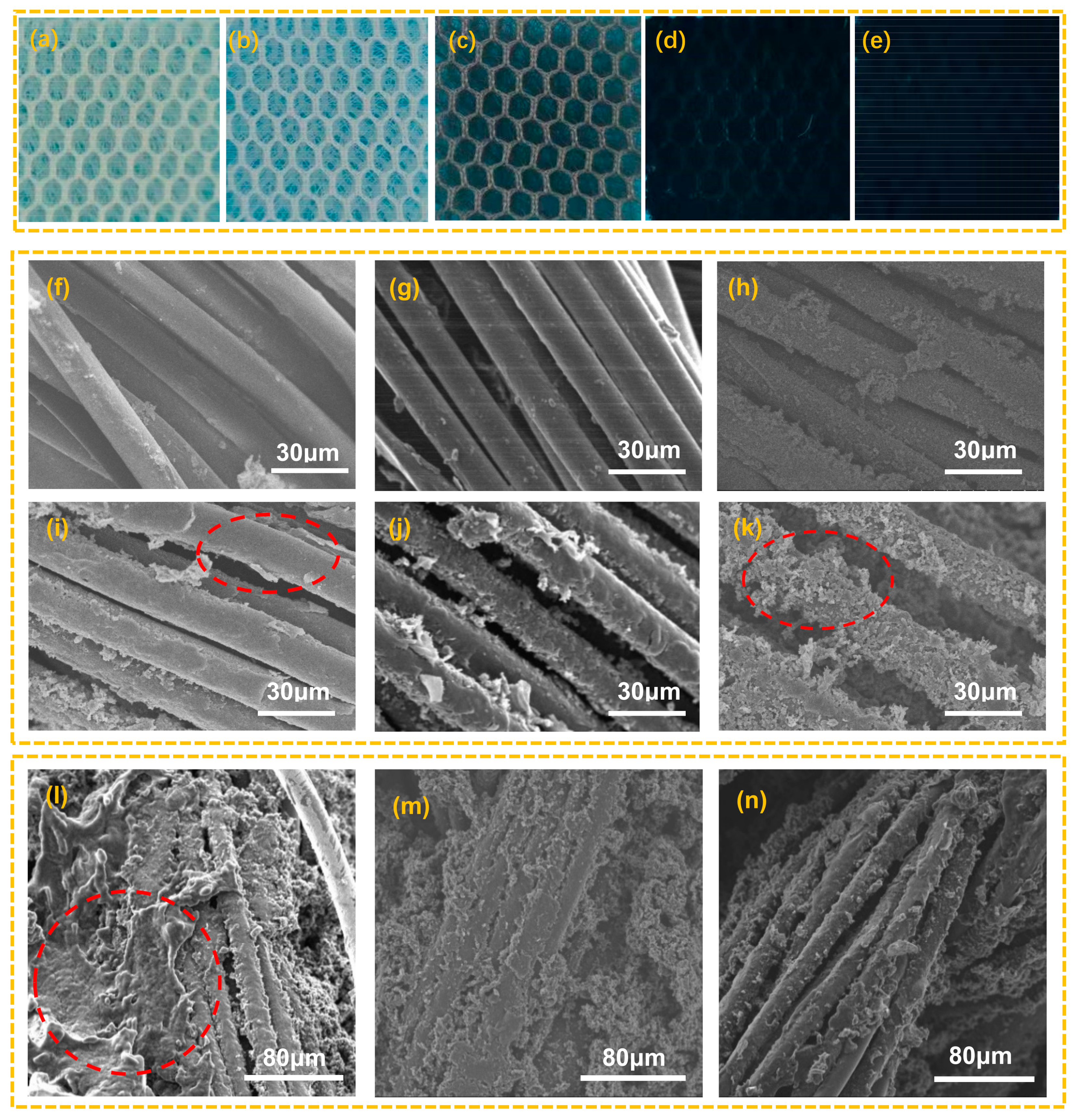

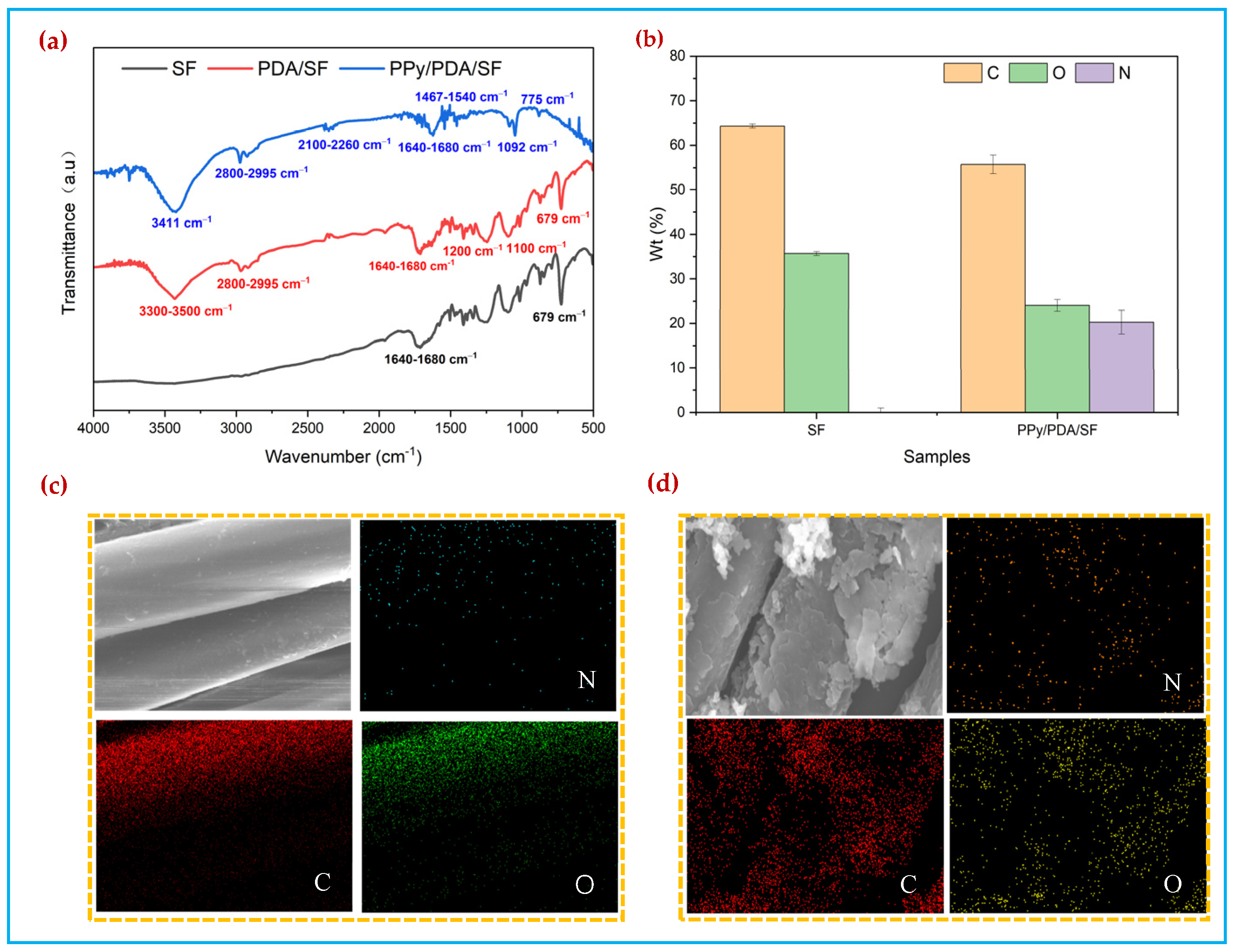

3.2. Coating Characterization

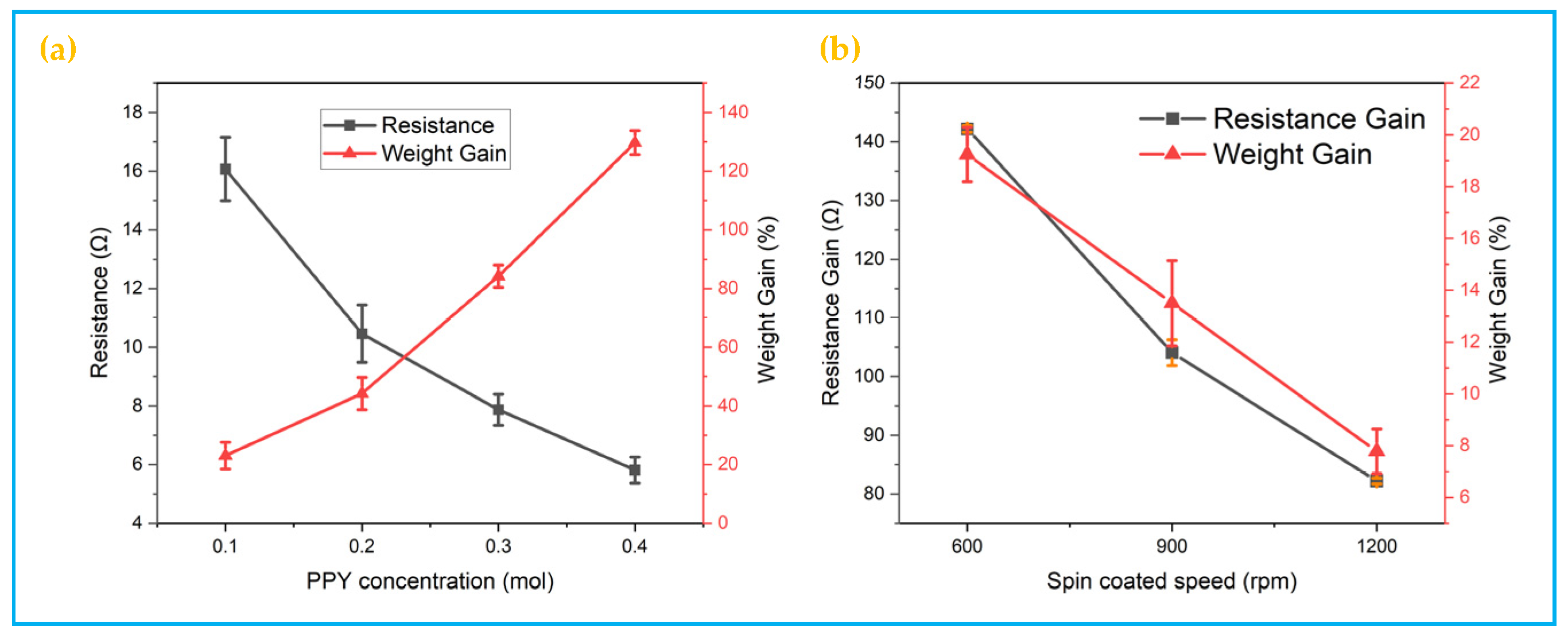

3.3. Electrical Conductivity

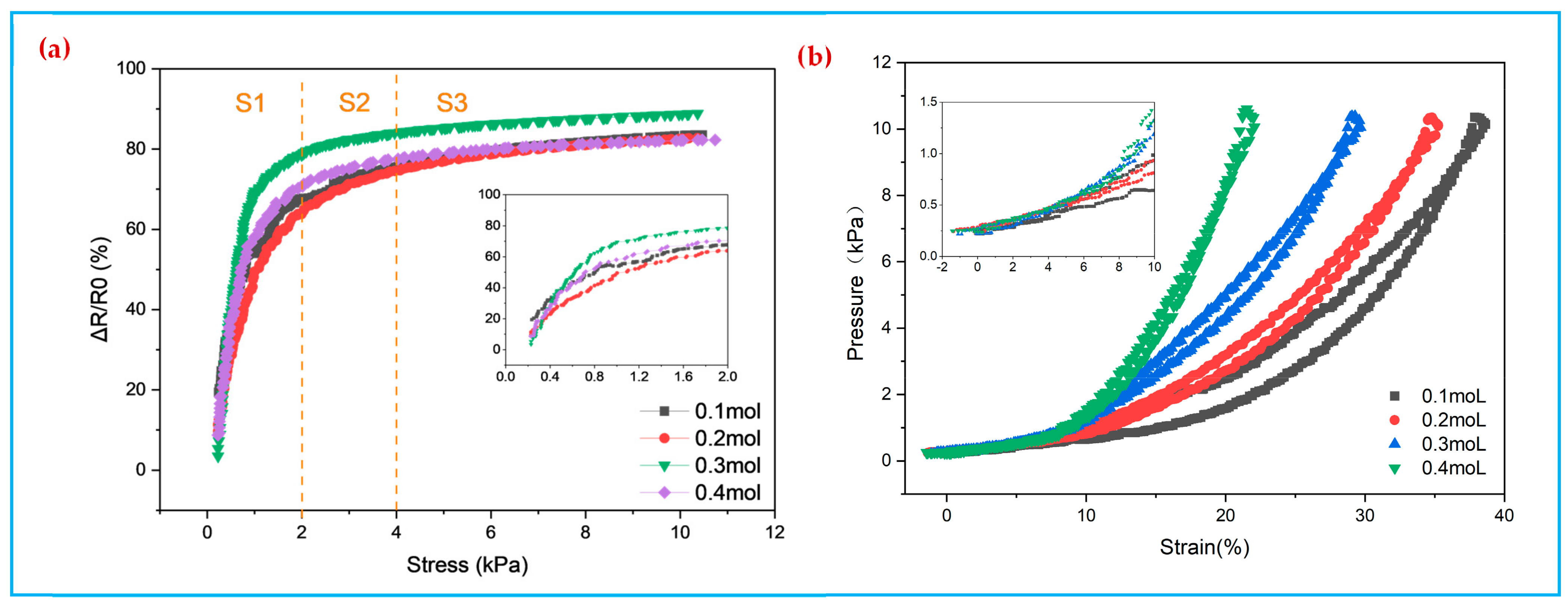

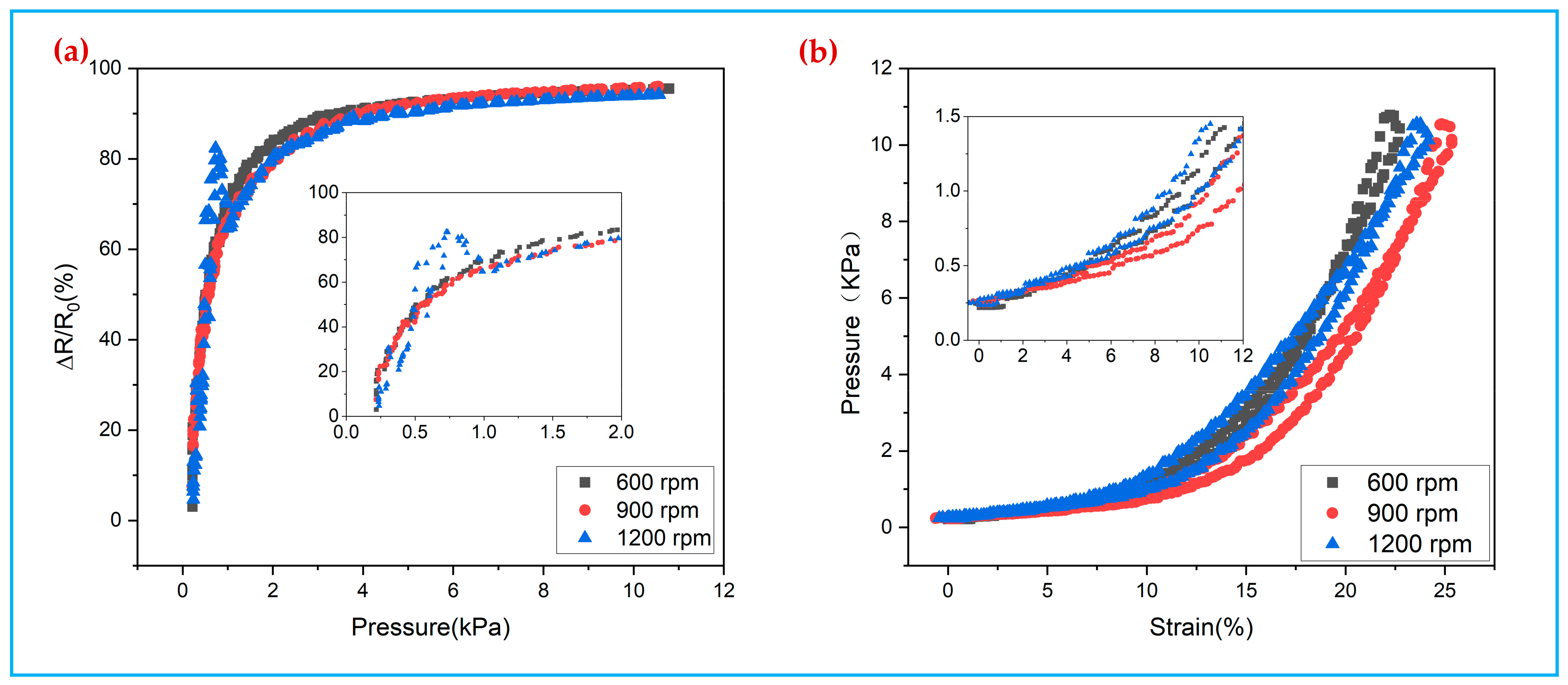

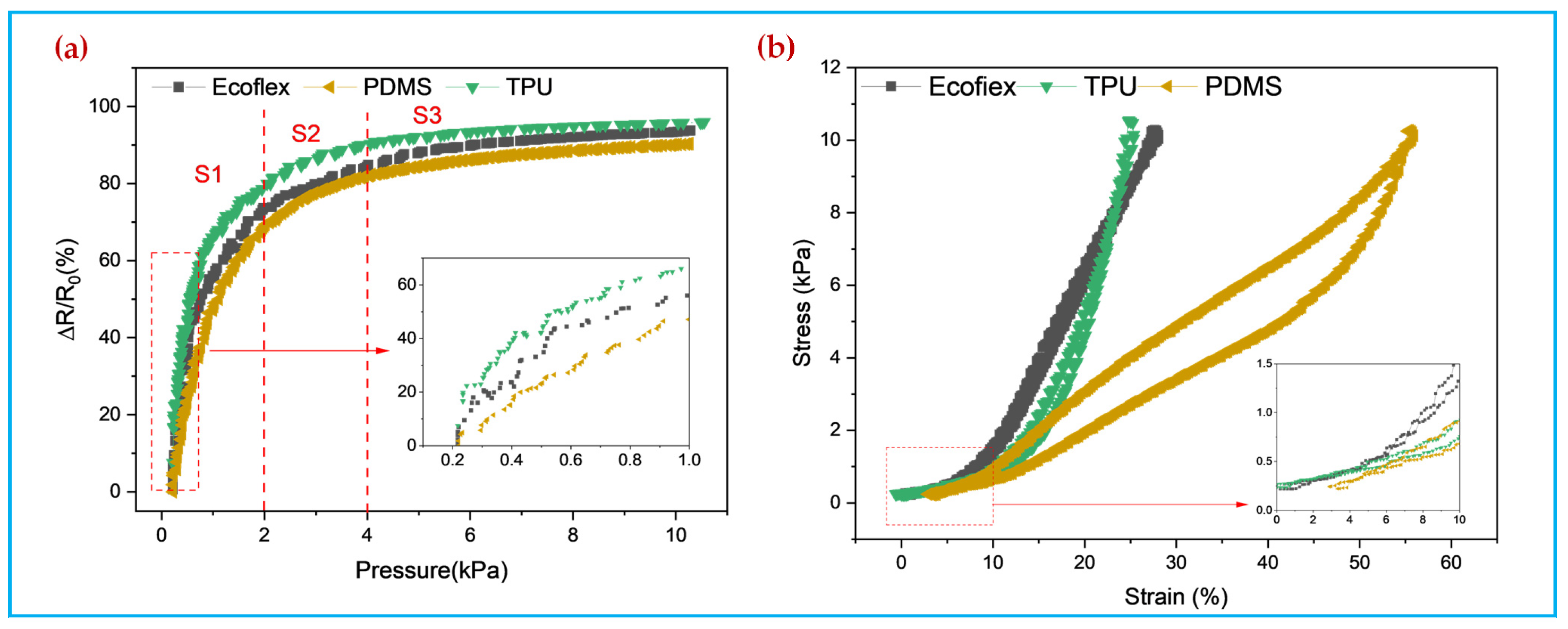

3.4. Pressure Sensing Characteristics of the PPy/PDA/SF Composite

3.5. Stability and Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar] [CrossRef]

- Melzer, M.; Kaltenbrunner, M.; Makarov, D.; Karnaushenko, D.; Karnaushenko, D.; Sekitani, T.; Someya, T.; Schmidt, O.G. Imperceptible magnetoelectronics. Nat. Commun. 2015, 6, 6080. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, Y.; Yin, R.; Zhao, Y.; Liu, H.; Zhang, D.; Shi, X.; Zhang, B.; Liu, C.; Shen, C. Conductive MXene/cotton fabric based pressure sensor with both high sensitivity and wide sensing range for human motion detection and E-skin. Chem. Eng. J. 2021, 420, 127720. [Google Scholar] [CrossRef]

- He, Y.; Zhao, L.; Zhang, J.; Liu, L.; Liu, H.; Liu, L. A breathable, sensitive and wearable piezoresistive sensor based on hierarchical micro-porous PU@CNT films for long-term health monitoring. Compos. Sci. Technol. 2020, 200, 108419. [Google Scholar] [CrossRef]

- Niu, X.; Gao, X.; Liu, Y.; Liu, H. Surface Bioelectric Dry Electrodes: A Review. Measurement 2021, 183, 109774. [Google Scholar] [CrossRef]

- Niu, X.; Wang, L.; Li, H.; Wang, T.; Liu, H.; He, Y. Fructus Xanthii-Inspired Low Dynamic Noise Dry Bioelectrodes for Surface Monitoring of ECG. ACS Appl. Mater. Interfaces 2022, 14, 6028–6038. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.; Xia, Q.; Zhou, K.; Yue, X.; Ren, M.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional flexible carbon black/polydimethylsiloxane piezoresistive sensor with ultrahigh linear range, excellent durability and oil/water separation capability. Chem. Eng. J. 2019, 372, 373–382. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yang, S.; Shi, X.; Zhang, D.; Shan, C.; Mi, L.; Liu, C.; Shen, C.; Guo, Z. Ultrasensitive and Highly Compressible Piezoresistive Sensor Based on Polyurethane Sponge Coated with a Cracked Cellulose Nanofibril/Silver Nanowire Layer. ACS Appl. Mater. Interfaces 2019, 11, 10922–10932. [Google Scholar] [CrossRef] [PubMed]

- Jayathilaka, W.A.D.M.; Qi, K.; Qin, Y.; Chinnappan, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S.; Thomas, S.W.; et al. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2019, 31, e1805921. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xu, B.; Gong, J.; Wen, J.; Hua, T.; Kan, C.-W.; Deng, J. Design of High-Performance Wearable Energy and Sensor Electronics from Fiber Materials. ACS Appl. Mater. Interfaces 2018, 11, 2120–2129. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Huang, Y.; Ng, W.S.; Liu, J.; Wang, Z.; Wang, Z.; Hu, H.; Zhi, C. 3D spacer fabric based multifunctional triboelectric nanogenerator with great feasibility for mechanized large-scale production. Nano Energy 2016, 27, 439–446. [Google Scholar] [CrossRef]

- Montazerian, H.; Dalili, A.; Milani, A.; Hoorfar, M. Piezoresistive sensing in chopped carbon fiber embedded PDMS yarns. Compos. Part B Eng. 2019, 164, 648–658. [Google Scholar] [CrossRef]

- Ghahramani, P.; Behdinan, K.; Naguib, H.E. Development of piezoresistive PDMS/MWCNT foam nanocomposite sensor with ultrahigh flexibility and compressibility. J. Intell. Mater. Syst. Struct. 2021. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, T.K.; Varadarajan, K. Strong, stretchable and ultrasensitive MWCNT/TPU nanocomposites for piezoresistive strain sensing. Compos. Part B Eng. 2019, 177, 107285. [Google Scholar] [CrossRef]

- He, Y.; Ming, Y.; Li, W.; Li, Y.; Wu, M.; Song, J.; Li, X.; Liu, H. Highly Stable and Flexible Pressure Sensors with Modified Multi-Walled Carbon Nanotube/Polymer Composites for Human Monitoring. Sensors 2018, 18, 1338. [Google Scholar] [CrossRef] [Green Version]

- Mai, H.; Mutlu, R.; Tawk, C.; Alici, G.; Sencadas, V. Ultra-stretchable MWCNT–Ecoflex piezoresistive sensors for human motion detection applications. Compos. Sci. Technol. 2019, 173, 118–124. [Google Scholar] [CrossRef]

- Fortunato, M.; Bellagamba, I.; Tamburrano, A.; Sarto, M.S. Flexible Ecoflex(R)/Graphene Nanoplatelet Foams for Highly Sensitive Low-Pressure Sensors. Sensors 2020, 20, 4406. [Google Scholar] [CrossRef]

- Makireddi, S.; Shivaprasad, S.; Kosuri, G.; Varghese, F.V.; Balasubramaniam, K. Electro-elastic and piezoresistive behavior of flexible MWCNT/PMMA nanocomposite films prepared by solvent casting method for structural health monitoring applications. Compos. Sci. Technol. 2015, 118, 101–107. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Z.; Li, Y.; Sun, D.; Liu, X.; Pang, J.; Liu, H.; Zhou, W. Unsymmetrical Alveolate PMMA/MWCNT Film as a Piezoresistive E-Skin with Four-Dimensional Resolution and Application for Detecting Motion Direction and Airflow Rate. ACS Appl. Mater. Interfaces 2020, 12, 30896–30904. [Google Scholar] [CrossRef]

- Fernández, E.; Kurlyandskaya, G.V.; García-Arribas, A.; Svalov, A.V. Nanostructured giant magneto-impedance multilayers deposited onto flexible substrates for low pressure sensing. Nanoscale Res. Lett. 2012, 7, 230. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.W.; He, Y.; Qiao, J.T.; Niu, X.; Li, X.J.; Liu, H.; Liu, L. Highly Sensitive Interlocked Piezoresistive Sensors Based on Ultrathin Ordered Nanocone Array Films and Their Sensitivity Simulation. ACS Appl. Mater. Interfaces 2020, 12, 55169–55180. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.-H.; Liu, H.-Z.; Chen, S.; Dong, X.-C.; Wang, P.-P.; Liu, S.-Q.; Lin, Y.; Wei, Y.; Liu, L. Channel Crack-Designed Gold@PU Sponge for Highly Elastic Piezoresistive Sensor with Excellent Detectability. ACS Appl. Mater. Interfaces 2017, 9, 20098–20105. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Xu, T.; Onyilagha, O.; Fong, H.; Zhu, Z. Recent Advances in Flexible and Wearable Pressure Sensors Based on Piezoresistive 3D Monolithic Conductive Sponges. ACS Appl. Mater. Interfaces 2019, 11, 6685–6704. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xu, B. Novel highly sensitive and wearable pressure sensors from conductive three-dimensional fabric structures. Smart Mater. Struct. 2015, 24, 125022. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Patil, A.; Hou, C.; Zhu, S.; Fan, X.; Lin, H.; Yu, W.; Guo, W.; Liu, X.Y. All-Textile Electronic Skin Enabled by Highly Elastic Spacer Fabric and Conductive Fibers. ACS Appl. Mater. Interfaces 2019, 11, 33336–33346. [Google Scholar] [CrossRef] [PubMed]

- Rajan, T.P.; Sundaresan, S. Thermal comfort properties of plasma-treated warp-knitted spacer fabric for the shoe insole. J. Ind. Text. 2020, 49, 1218–1232. [Google Scholar] [CrossRef]

- Kumar, N.M.; Thilagavathi, G.; Periasamy, S. Development and characterization of warp knitted spacer fabrics for helmet comfort liner application. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Yu, S.; Dong, M.; Jiang, G.; Ma, P. Compressive characteristics of warp-knitted spacer fabrics with multi-layers. Compos. Struct. 2021, 256, 113016. [Google Scholar] [CrossRef]

- Chen, S. Low-Velocity Impact Properties of Polyurethane Composites Reinforced with Warp-Knit Spacer Fabric. AATCC J. Res. 2021, 8, 38–47. [Google Scholar] [CrossRef]

- Gunasekara, D.S.W.; He, Y.; Fang, S.; Zhao, L.; Liu, H.; Liu, L. High-repeatability macro-porous sponge piezoresistive pressure sensor with polydopamine/polypyrrole composite coating based on in situ polymerization method. Appl. Phys. A 2020, 126, 789. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Kang, W.; He, Y.; Liu, W.; Liu, H.; Cheng, B. A novel flexible sensor for respiratory monitoring based on in situ polymerization of polypyrrole and polyurethane coating. RSC Adv. 2017, 7, 49576–49585. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Li, T.; Ren, H.; Peng, H.; Shiu, B.; Wang, Y.; Lou, C.; Lin, J. Dual-Shell Photothermoelectric Textile Based on a PPy Photothermal Layer for Solar Thermal Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 55072–55082. [Google Scholar] [CrossRef] [PubMed]

- Verpoorten, E.; Massaglia, G.; Pirri, C.; Quaglio, M. Electrospun PEO/PEDOT:PSS Nanofibers for Wearable Physiological Flex Sensors. Sensors 2021, 21, 4110. [Google Scholar] [CrossRef] [PubMed]

- Li, T.T.; Wang, Y.T.; Peng, H.K.; Zhang, X.F.; Shiu, B.C.; Lin, J.H.; Lou, C.W. Lightweight, flexible and superhydrophobic composite nanofiber films inspired by nacre for highly electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105685. [Google Scholar] [CrossRef]

- Luo, C.; Liu, N.; Zhang, H.; Liu, W.; Yue, Y.; Wang, S.; Rao, J.; Yang, C.; Su, J.; Jiang, X.; et al. A new approach for ultrahigh-performance piezoresistive sensor based on wrinkled PPy film with electrospun PVA nanowires as spacer. Nano Energy 2017, 41, 527–534. [Google Scholar] [CrossRef]

- Cheng, H.N.; Wang, B.; Tan, Y.S.; Yin, Y.J.; Wang, C.X. Low-Cost, Highly Sensitive, and Flexible Piezoresistive Pressure Sensor Characterized by Low-Temperature Interfacial Polymerization of Polypyrrole on Latex Sponge. Macromol. Mater. Eng. 2021, 306, 2000772. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.T.; Ren, H.T.; Sun, F.; Lin, Q.; Lin, J.H.; Lou, C.W. Tuning the gradient structure of highly breathable, permeable, directional water transport in bi-layered Janus fibrous membranes using electrospinning. RSC Adv. 2020, 10, 3529–3538. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, H.; Kassim, A.; Zainal, Z.; Yunus, W.M.M. Fourier transform infrared study of polypyrrole-poly(vinyl alcohol) conducting polymer composite films: Evidence of film formation and characterization. J. Appl. Polym. Sci. 2006, 100, 4107–4113. [Google Scholar] [CrossRef]

- Nicho, M.E.; Hu, H. Fourier transform infrared spectroscopy studies of polypyrrole composite coatings. Sol. Energy Mater. Sol. Cells 2000, 63, 423–435. [Google Scholar] [CrossRef]

- Tan, Y.; Ghandi, K. Kinetics and mechanism of pyrrole chemical polymerization. Synth. Met. 2013, 175, 183–191. [Google Scholar] [CrossRef]

- Fuensanta, M.; Martin-Martínez, J.M. Thermoplastic polyurethane pressure sensitive adhesives made with mixtures of polypropylene glycols of different molecular weights. Int. J. Adhes. Adhes. 2019, 88, 81–90. [Google Scholar] [CrossRef]

| Refs: No. | Materials | Method | Linear Range kPa | Highest Sensitivity (kPa−1) |

|---|---|---|---|---|

| [2] | MXene/cotton fabric | dip-coating and sandwiched between PDMS | 0–1.30 0–160 | 5.30 - |

| [3] | PU@CNT films | Solution modification | 0–3 kPa 0–16 kPa | 51.53 - |

| [6] | AgNWs/PU sponge | dip-coating and precompression treatment | - | 26.07 |

| [12] | PPy/PDMS | Oxidative polymerization | 0–1 | 19.32 |

| [15] | m-MWNT/PU | Solution modification | 0–63 | 4.282 |

| [29] | MPS | In situ polymerization of polypyrrole | 1 kPa 1–10 kPa | 10.69 ± 1.53 7.20 ± 2.46 |

| This Study | Space Fabric | In situ polymerization and spin-coating TPU | 0–2 kPa 2–4 kPa 4–10 kPa | 97.28 10.25 1.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Gao, X.; Wang, Y.; Niu, X.; Wang, T.; Liu, Y.; Qi, F.; Jiang, Y.; Liu, H. Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating. Polymers 2022, 14, 859. https://doi.org/10.3390/polym14050859

Wang X, Gao X, Wang Y, Niu X, Wang T, Liu Y, Qi F, Jiang Y, Liu H. Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating. Polymers. 2022; 14(5):859. https://doi.org/10.3390/polym14050859

Chicago/Turabian StyleWang, Xiujuan, Xiaoyu Gao, Yu Wang, Xin Niu, Tanyu Wang, Yuanjun Liu, Fangxi Qi, Yaming Jiang, and Hao Liu. 2022. "Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating" Polymers 14, no. 5: 859. https://doi.org/10.3390/polym14050859

APA StyleWang, X., Gao, X., Wang, Y., Niu, X., Wang, T., Liu, Y., Qi, F., Jiang, Y., & Liu, H. (2022). Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating. Polymers, 14(5), 859. https://doi.org/10.3390/polym14050859