Abstract

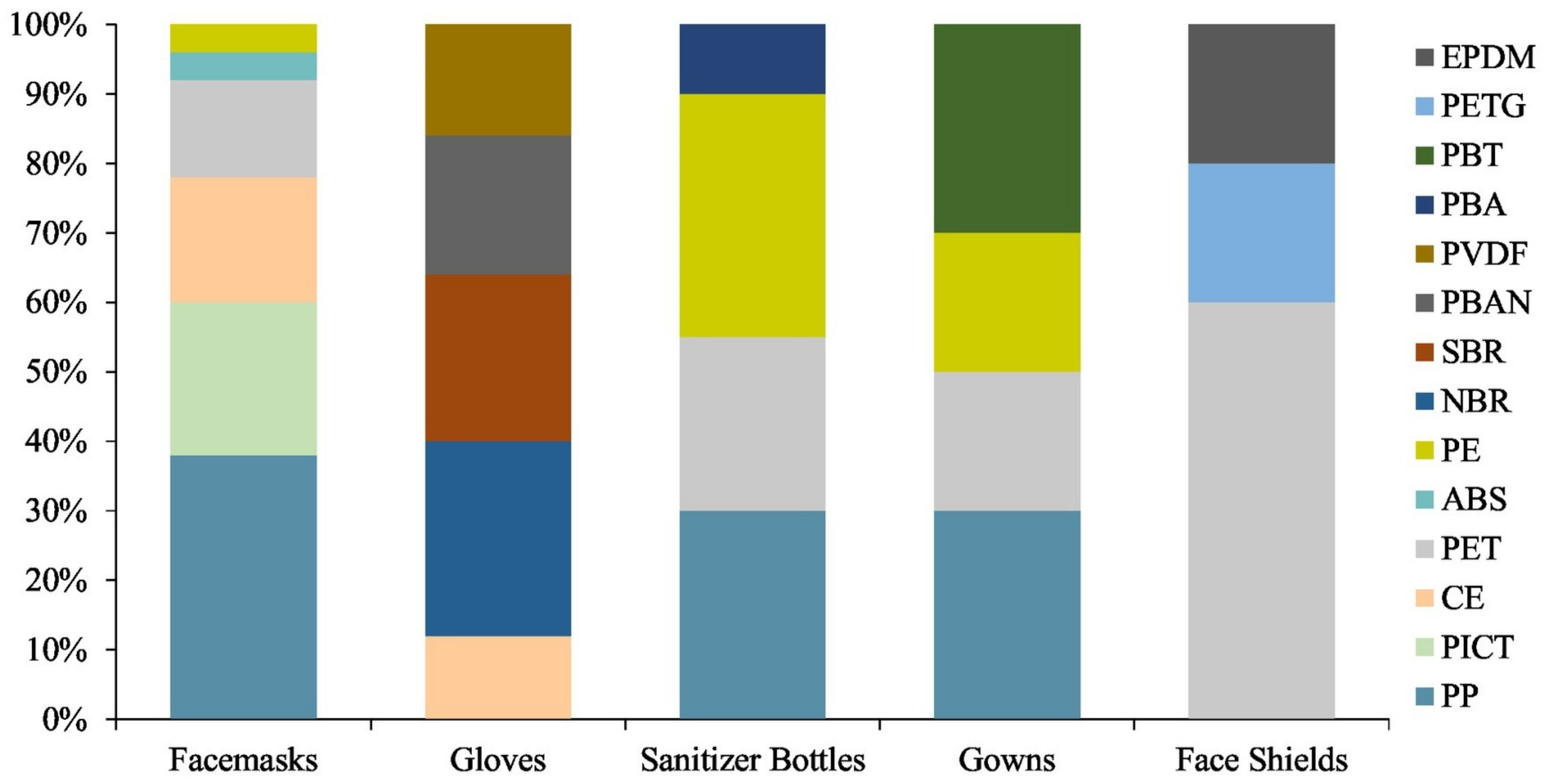

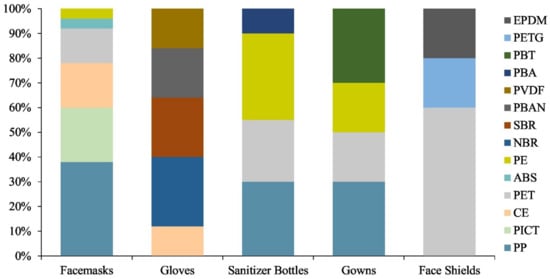

This article presents current possibilities of using polyester-based materials in hard and soft tissue engineering, wound dressings, surgical implants, vascular reconstructive surgery, ophthalmology, and other medical applications. The review summarizes the recent literature on the key features of processing methods and potential suitable combinations of polyester-based materials with improved physicochemical and biological properties that meet the specific requirements for selected medical fields. The polyester materials used in multiresistant infection prevention, including during the COVID-19 pandemic, as well as aspects covering environmental concerns, current risks and limitations, and potential future directions are also addressed. Depending on the different features of polyester types, as well as their specific medical applications, it can be generally estimated that 25–50% polyesters are used in the medical field, while an increase of at least 20% has been achieved since the COVID-19 pandemic started. The remaining percentage is provided by other types of natural or synthetic polymers; i.e., 25% polyolefins in personal protection equipment (PPE).

Keywords:

polyesters; medical applications; biomaterial; processing methods; properties; COVID-19; risks 1. Introduction

In addition to other types of polymeric materials, polyesters have found diverse uses in biomedical applications, such as controlled drug release systems [1,2,3,4,5], time-tailored implants, screws, prostheses, and different 3D structures including scaffolds for bone reconstruction and tissue engineering [6]. Various medical products containing polyesters are commercially available, while new ones are awaiting patents for placement on the market.

Polyesters such as poly(lactic acid) (PLA), poly-L-lactide (PLLA), poly(ε-caprolactone) (PCL), poly(glycolic acid) (PGA), poly(lactic-glycolic acid) (PLGA) copolymers, or poly(hydroxyalkanoates) (PHA) are synthetic biodegradable polymers highly used in medical applications due to their wide range of custom properties, availability, tailoring capacity, cost-effectiveness, and easy processing. Since its development in 1932 by DuPont and the establishment of the first large production facility by Cargill Dow Polymers in 2001, PLA has experienced rapid growth, with a high potential to replace conventional petrochemical-based polymers in many medical applications. Before being produced on a larger scale, PLA was mainly used in medical applications due to its relatively high cost. Although most polyesters are synthesized from carbohydrate petroleum-based sources, alternative sustainable raw materials were found, with PLA, poly(hydroxybutyrate) (PHB), and partially bio-based polyethylene terephthalate (PET) being derived from renewable sources.

The polar characteristics of a polymer are among the most important properties to be considered in medical applications such as cell regeneration and tissue engineering, as variations in hydrophobicity lead to different interactions of scaffolds with cells and proteins (targeting cell attachment, spread, and viability in biological systems) [7]. From the medical point of view, the most important ones are inert nature and biocompatibility.

Polyester materials are widely studied for the development of biological tissue that can enable the restoration and maintenance of the functions of damaged human organs or tissues. This is due to the fact that esters, of which polyester materials are composed, exist naturally in the human body; i.e., fatty acids are energy sources and membrane constituents. They have biological activities that act to influence cell and tissue metabolism, function, and responsiveness to hormonal and other signals [8].

Tissue engineering can be considered an alternative to conventional more invasive surgical procedures when it comes to replacing or restoring damaged organ or tissue. The global market for tissue engineering was estimated at USD 9.9 billion in 2019, and is expected to register a compound annual growth rate (CAGR) of about 14.2% between 2020 and 2027 [9]. The main types of tissue engineering are cells, tissue-inducing substances, and scaffolds, which are basically cells combined with a type of matrix that can provide a physical support and allow the tissue growth. Adequate mechanical stiffness is required for polyesters such as PCL and PLA intended to be used as body tissues in order to prevent new-tissue deformation and overcome in vivo stresses [6,10].

The more conventional approaches are divided mainly into autografting and allografting. In order to introduce respective treatments, tissue is transplanted within the patient from one site to another or between two different patients. Both approaches have their drawbacks; i.e., anatomical restrictions, the risk of transferring diseases between the patients, and a possible rejection response from the patient’s immune system [11].

Polyesters are naturally biodegradable materials due to the fact that the ester bonds can be broken down by the means of hydrolysis or esterases, and in some cases, the degradation process can be undertaken by both of the factors. The hydrolytic degradation is one of the key features behind why these materials are of growing popularity when it comes to tissue-engineering studies, as they can be engineered to yield nontoxic products that are metabolized by the human body [12]. The ability to degrade in vivo is crucial for tissue-engineering applications, as there is need for a smooth and certain transition of functionality from the degrading polymeric scaffold to newly grown tissue. As time is very important in this process, it is possible to tailor the rate of the degradation by changing the chemical structure of the polymer or its additives [13].

There are two different mechanisms for polyester degradation that can affect the implementation of certain polymers: surface and bulk erosion. In surface erosion, the polymer maintains its bulk integrity, as the erosion is limited to the surface of the material. The device will reduce in its dimensions—the walls will become thinner; however, the core and its properties will remain intact. It is worth mentioning that as the degradation process is highly focused on the surface of the immersed material, the mass loss and dimensional stability is strictly proportional to the area of surface that is exposed to water. The other degradation mechanism, bulk erosion, occurs when the rate at which the water penetrates is much greater than the rate at which the polymer is being converted into water-soluble materials. The dimensions of the device may remain unaffected or even will increase with the volumetric water uptake; however, it will result in erosion throughout the material volume. This is a two-step process, as the molecular weight of the material is affected by its gradual decrease, as the properties of the material will tend to downgrade at a certain pace. After exceeding a critical value of the molecular weight with water penetrating, accompanied by the cleaving of the polymer chains, especially the hydrolytically unstable chemical bonds converting longer chains into water-soluble fragments, an enzyme-based attack occurs. Final mass loss is rapid, with a sudden release of degradation products, and then the material disintegrates completely [14].

In the case of surgical implant applications, polyesters are in the first generation of commercially available implants, therefore not many scientists have published new polyester blends and composites for such applications since 2016. Most of the literature available on the subject refers to clinical cases that compare those commercial products in a group of patients.

Wound-dressing materials should have important requirements related to their biocompatibility [15], wound healing [16], wound adhesion [17,18], maintenance of wound moisture [19,20], inhibition of the growth of bacteria [15,21,22], removal of excess exudates, and reductions in the dressing frequency [23,24].

Multiresistant infections, especially during the recent COVID-19 pandemic, have affected all of humanity from a variety of perspectives, including health issues, the socioeconomic crisis, and environmental concerns. Despite the economic shock that has affected many industries, the demand for polyester materials has shown great resilience. The use of PLA or PET for the manufacture of personal protective equipment (PPE) has received great consideration [25,26,27], with the polyester market being relieved of its worst consequences. The active integration of nanostructures into polyesters that self-sterilize against pathogens may provide a way to lower the transmission of viral infections. Given the recent growth in various infectious threats, the development of effective vaccination technologies containing novel vaccine delivery vehicles based on polyesters to immunize against various strains of viruses is in high demand. Sanitization is also highly necessary to prevent infection.

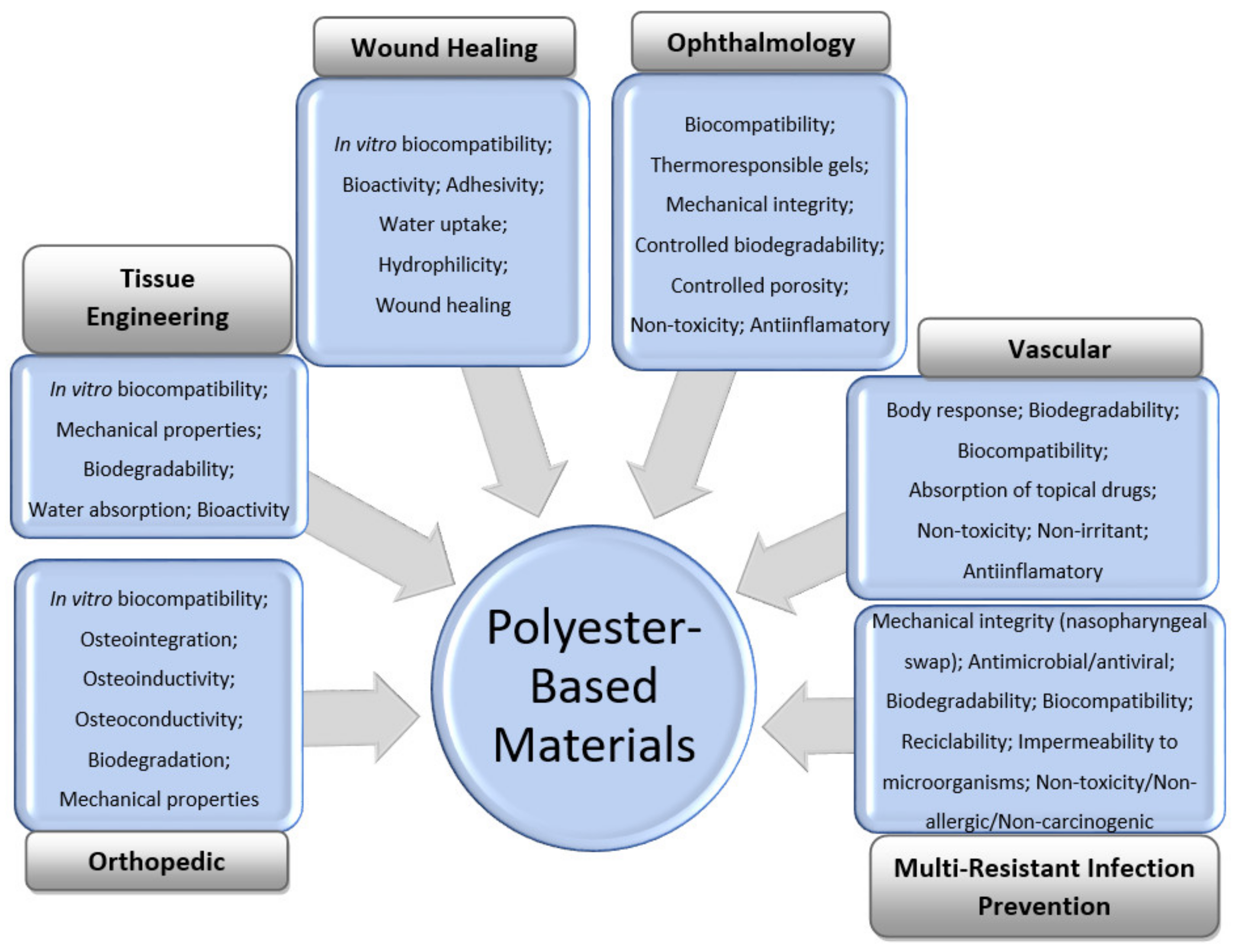

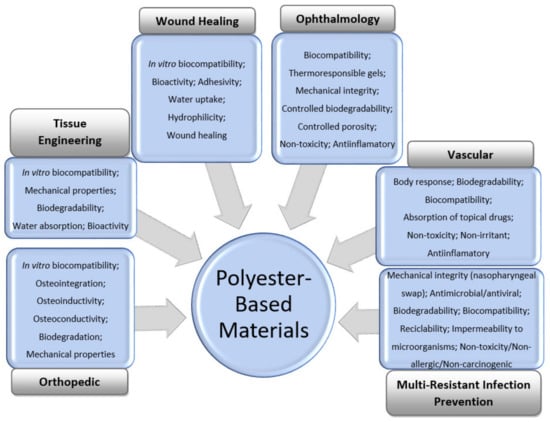

The general features of polyester-based materials used for orthopedic, tissue-engineering, wound-healing, vascular, and ophthalmology applications, as well as prevention of multiresistant infections, including during the COVID-19 pandemic, are shown in Figure 1.

Figure 1.

General requirements for the design of polyester-based materials for medical applications.

Neat polyesters can be combined with natural or synthetic materials to increase their bioactivities and obtain the desired properties for each medical application. The main recently designed formulations or composites containing polyesters, their manufacturing methods, and special features for the above-mentioned applications are summarized in this review.

2. Orthopedic Applications

Bone defects include trauma, bone infection, osteonecrosis, osteoporosis, bone tumors, and iatrogenic injury. Bone illnesses are expected to increase in the future due to population growth and aging. Therefore, there is a huge need for clear approaches that lead to bone healing. Bone treatment management involves autologous bone grafting, allogeneic grafting, xenografting from other species, or artificial bone-substitute materials [28,29]. Each option has advantages and disadvantages. Among all of them, autologous bone grafting provides an excellent healing capability, but is limited by the quantity of the donor site. Artificial bone-substitute materials represent an alternative to autologous and allogeneic bones, which are traditional options for patients to treat bone defects [28]. Researchers have developed innovative materials that are able to support the full repair of damaged bones.

The ideal bone-substitute material should be biodegradable in order to eliminate the need for a secondary surgery [30,31] and osteoconductive to promote bone regeneration [32,33,34]. The three-dimensional (3D) scaffold structure should have pore sizes larger than 100 µm and a highly interconnected pore structure to facilitate bone ingrowth, nutrient transport, and degradation of products in an acid–base balance. Polyester materials also should meet the rheological property requirements for printing; namely, the loss modulus (G″) should be greater than the storage modulus (G′) at the printing temperature (Tp), and the melt viscosity should be below 106 mPa·s to permit flow under applied pressure. The local microenvironment may influence the cell growth and bone repair, so it should be maintained at pH 7.2–7.4 [35]. Since the acidic degradation product of pure polyesters restrains the growth of cells or tissues, it is necessary to find new strategies for neutralization of the acidic condition that results from degradation of products. Finally, polyester biomaterials often require bioactivity to control cell function, including cell migration (infiltration), proliferation, and phenotype preservation or differentiation.

Usually, materials used to repair bone defects are metallic biomaterials [36,37], bioceramics [38,39], and natural and synthetic polymers [40,41]. Hydroxyapatite (HA; (Ca10(PO4)6(OH)2)) has been used as filler in polymer composites to improve the biocompatibility, mechanical strength, and porosity of biomaterials due to its similarity in structure and composition to bone and enamel, or to create polyester nanografts that impart the biodegradability and bioresorbability of polymers with their osteoconductivity, osteoinductivity, and osteointegration properties [42,43].

Naturally occurring polymers display inherent bioactivity, which is not the case for synthetic polymers [44]. Therefore, it is of great interest to design thermoplastic polyesters, such as PLA, PCL, PHA and thermoplastic polyurethane (TPU), for use as matrices in a wide range of bone applications.

2.1. Neat Polyesters

PLA is commercially used for pins for the foot, ankle, knee, and shoulder. PLLA and PDLA are two stereoisomers of PLA currently used in bone applications. PLLA is used for screws, washers, pins, rods, and plates used in cranial, oral, maxillofacial, plastic, and reconstructive surgeries, while blends of PLLA with HA, PLG, and PGA are employed for orthopedic fracture fixation devices [45]. Although the PLA absorbable reinforcement ligaments showed slow enzymatic degradation rates, they recorded high values as compared with the PLA synthesized in the laboratory, and were found entirely biocompatible according to the in vivo and in vitro hydrolysis in the human body [46,47]. While PLLA is degraded during 2–5 years in phosphate-buffered saline (PBS) (pH 7.4) at 37 °C, 2 months are needed for poly(D,L-lactic acid) (PDLLA) to lose its integrity, and 1 year under similar conditions for complete degradation. Currently, PLA composites are used in small load-bearing applications.

PCL has been widely used in the fabrication of 3D scaffolds in the field of bone-tissue engineering due to its advantages such as good biocompatibility, a slow degradation rate, released products that are less acidic in comparison to other polyesters, and its potential in load-bearing applications.

The chemical surface of a polyester-based material designed for orthopedic applications can be modified by associating with hydrophilic and hydrophobic polymers or mixing it with HA or halloysite nanotubes (HNTs), resulting in cell adhesion or enhancement of the mechanical properties. For example, Torres et al. [48] combined hydrophobic PCL with PLA and hydrophilic poly(2-hydroxyethyl methacrylate) (PHEMA) with ethyl methacrylate (EMA) and evaluated the effects of chemical surface modifications on cell viability, proliferation, and morphology. Higher cell viability was recorded for moderately hydrophobic surfaces within 3 days, while more hydrophilic surfaces reached advanced cell proliferation at prolonged culture periods. For moderated hydrophobic PCL/PLA material, the scanning electron microscopy (SEM) results showed round-shaped cells or cluster formations, with a monolayer of cells partially adhered to the polymeric surface, and improved cell viability with addition of HA and HNTs. Variations in wettability influenced the protein absorption on the surface of the biomaterial; for example, albumin easily adhered to the polyester surface due to the hydrophobic affinity.

PHAs are next-generation biomaterials isolated from bacterial sources designed for development on bone marrow cells and scaffolds for bone-tissue applications [33,49]. PHAs are highly biocompatible natural polyesters that degrade into water, carbon dioxide, and D-3-hydroxybutyric acid, a common metabolite that occurs in living organisms, avoiding the occurrence of inflammatory reactions developed in the case of other synthetic polyesters. PHB and poly(hydroxybutyrate-co-valerate) (PHBV) are the main homopolymer representants of the PHA family. PHB shows high mechanical strength, biocompatibility, and easy processability. The low narrow thermal processing window, lack of toughness, hydrophilicity, and bioactivity are the main drawbacks of PHA [50].

The long-term degradation of thermoplastic polyurethane (TPU) filaments in phosphate-buffered saline (PBS) and cell proliferation indicated that the polyurethanes (PUs) also are attractive polyester materials for bone-tissue applications [51].

Although pure polyesters are biodegradable and bioresorbable, without modifications they do not possess enough rigidity for resistance during implant insertion, and the degradative products can cause inflammatory reactions, so they cannot be used for orthopedic applications. These limitations of thermoplastic polyesters can be overcome by introducing bioactive ceramics such as HA, tricalcium phosphate (TCP), and bioactive glass (BG) [52,53,54]. The literature revealed that polyesters mixed with HA [55,56], PLA, and PGA mixed with BG [57,58] have been extensively studied as materials for orthopedic applications in terms of their processing, physicochemical, mechanical, and in vitro biological properties. Mixtures of polyesters with HA used for artificial bone substitute materials can show excessive hardness and brittleness, as well as the occurrence of foreign bodies, which cause an acidic microenvironment, and are dangerous to cell proliferation and bone regeneration. A strategy to prevent an acidic environment and an aseptic inflammation reaction was given by Kuo et al. [59]. Accordingly, the porous biodegradable structure based on β-TCP and poly(l-lactic-co-glycolic acid) (PLGA) was degraded 37% into smaller molecules during 60 days of accelerated testing [59]. The reaction during degradation was an acid–base neutralization due to the alkaline environment provided by the degradation product of TCP.

Even if PCL is incompatible with bioceramic materials, PCL/nano-HA electrospun fibers with improved mechanical characteristics were achieved by using a compatibilizer, such as PCL/poly(ethylene phosphoric acid) (PEPA) block-copolymer [60]. These nanocomposites showed that vancomycin was released against Staphylococcus aureus (S. aureus).

2.2. Manufacturing of Polyesters with Improved Functionalities

Different methods for fabrication of polyester-based materials for orthopedic applications are presented in Table 1.

Table 1.

Examples of modified polyesters obtained by different techniques for bone-tissue applications.

The usual techniques for preparing modified polyesters for artificial bone-substitute materials involve 3D printing [51,61,65,66,72,74,75,76], thermally induced phase separation (TIPS) [32], salt leaching [32,69,79], solvent casting [33,35,77,79], electrospinning [60,64,70], copolymerization [31], and polycondensation [73].

The addition of silica aerogel to PCL has been reported to lead to biomaterial scaffolds obtained by the solvent-casting method with a stabilized environmental pH, enhanced cell viability, and osteogenic activity [35].

Macroporous PHBV films with hydroxyvalerate (HV) varying from 0 to 12 wt % were prepared by solvent casting using NaCl as a porogen for investigation of the effect of HV on the degradation of films and osteoblastic cell growth [33]. It was demonstrated that the PHBV film with a content of 12 wt % HV content could be used for orthopedic applications. The solvent-casting method was also used to obtain a potential bone scaffold material by mixing PCL with silica (SiO2) aerogels [35]. At a weight ratio of 1:0.5 between PCL and SiO2, the composite had a constant pH environment for up to 4 weeks, providing better NIH3T3 cell survival.

Scaffolds based on plasticized PHB and bacterial cellulose (BC) up to 2 wt % were prepared by melt-mixing and salt-leaching techniques and used for healing critical-size calvaria defects [69]. It was demonstrated that the smallest intraosseous defect was filled with new mature bone at 20 weeks postimplantation, due to the breaking of beta (1–4) glycosidic linkages in BC, which supported a progressive mineralization of scaffolds.

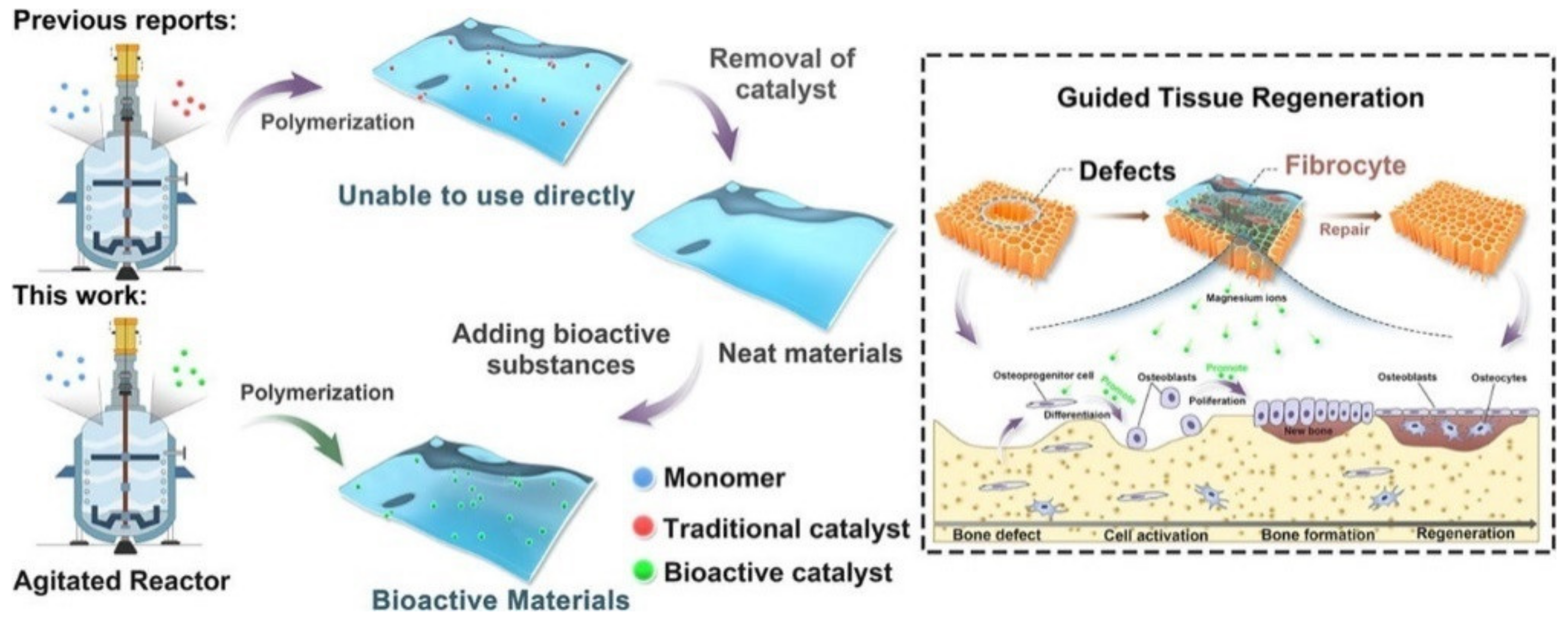

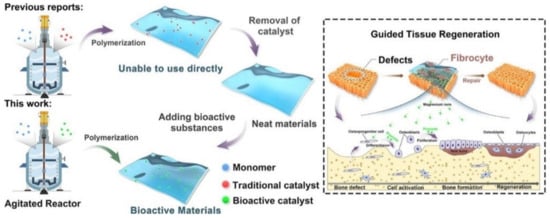

The copolymerization of poly(butylene succinate) (PBSu) with sebacic acid (SeA) in the presence of a magnesium catalyst formed in situ at a large scale is a new approach for the direct in-reactor engineering of bioactive polyesters without the use of a toxic catalyst [31] (Figure 2). First, PBSu was synthesized by two-stage esterification of succinic acid (SA) and 1,4-butanediol (BDO). It was proved that the low-cost bioactive polyester could be used to guide tissue regeneration, due to the higher degree of bone formation rate after 16 weeks as compared with a commercial PLA membrane. These features, together with cell proliferation, osteogenic activity, and anti-inflammatory properties of the PBSu/SeA composition, were assigned to magnesium ions.

Figure 2.

In-reactor engineering of bioactive aliphatic polyesters. Reproduced from [31] with permission from Elsevier.

Another paper reported a polyester/HA graft synthesized by “graft-from” polymerization of D,L-lactide with HA in the presence of a tin(II)-2-ethylhexanoate catalyst, which was used as additive for commercial bone cement [42]. This ring-opening polymerization involved the growth of PDLLA on the hydroxyl groups of HA.

Nano fibrous synthetic scaffolds with diameters in the range of 400 to 500 nm showing antibacterial activity against S. aureus, cell proliferation, in vitro degradation, and mineralization were fabricated by the electrospinning method using an 8 wt/v % solution of PCL, HA, and ZnO [64]. It was shown that ZnO may act as a triggering molecule in mineralization of the scaffolds [64].

Recently, a protein-based growth factor, bone morphogenetic protein 2 (BMP2), was successfully dispersed in PCL and poly(lactide-co-glycolide)-co-poly(etherimide) (PLGA-PEI) polyesters in the presence of soybean lecithin (SL) to form a bioactive osteo-polyester scaffold (BOPSC), thus avoiding the implantation of exogenous stem cells or osteoblasts [30]. The optimized BOPSC showed a porosity of 83.42%; BMP2 capture efficiency of 95.35%; water uptake ratio of 850%; and proliferation, migration, and osteogenic differentiation of mouse adipose-derived mesenchymal stem cells (mADSCs), which successfully stimulated natural bone regeneration after 6 months of implantation in mice.

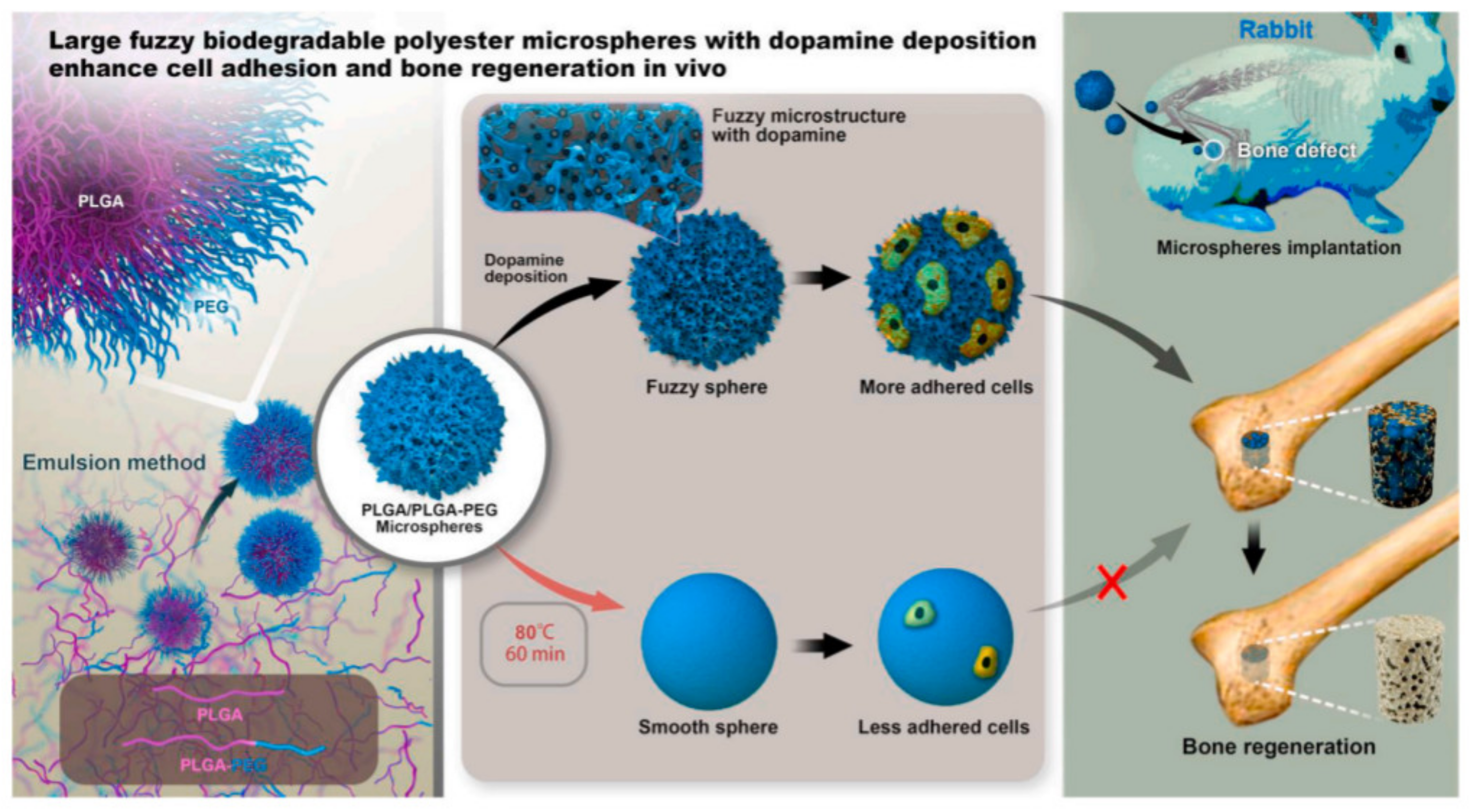

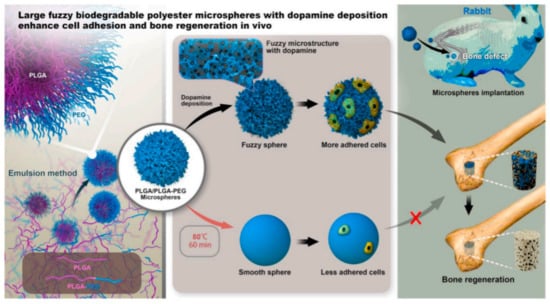

Poly(D,L-lactide-co-glycolide) (PLGA)/PLGA-b-poly(ethylene glycol) (PEG) microspheres with a diameter in the range of 50–100 μm were obtained through a facile and controllable emulsion process following the mechanism of interface instability [62]. The ratio of lactide and glycolide in these two polymers was 50:50. A series of microspheres with different surface structures were further prepared through annealing and dopamine deposition, and their efficiency in bone regeneration was evaluated in vivo (Figure 3).

Figure 3.

PLGA/PLGA-b-PEG microspheres obtained by interfacial instability of emulsion for bone adhesion in rabbit. Reproduced from [62] with permission from Elsevier.

Porous scaffolds obtained using a conventional porogen-leaching technique, as well as TIPS methods, have many drawbacks, including the use of organic solvents and poor control of the shape and interconnectivity of pores, while electrospinning mats exhibit small pores that limit cell infiltration and tissue ingrowth. The 3D-printing technique is an innovative strategy that allows the development of hard-tissue engineering for bone regeneration. The introduction of 5 wt % or 10 wt % of β-TCP into PCL has a good effect on the thermal stability, crystallinity, and rheological properties of PCL composites, which are easy to process for additive manufacturing via fused filament fabrication (FFF) [65].

Innovative scaffolds with a three-dimensional (3D) architecture were obtained by 3D melt extruding of PCL with 20 wt % chitosan [66] and coating of 3D-printed PCL scaffolds with HA and BG [72].

Poly(glycerol sebacate) (PGS) is a polyester synthesized from glycerin-3 and sebacic acid-2 that has received considerable attention in tissue-engineering applications [80]. PGS was modified by 3D-printing technology with nano-HA [32], PEG/TCP [81], PHB [82], PCL [83,84], poly(vinyl alcohol) (PVA) [85], and poly(acrylic acid) (PAA) [86] to obtain potential scaffolds for reconstruction of bone tissue, especially craniofacial bone. Among the characteristics of an ideal polyester for bone regeneration, there is increasing interest in the development of novel materials with antibacterial properties [87]. Silver nanoparticles (AgNPs), graphene oxide (GO) sheets, and ZnO are reinforcing fillers used in polyester formulations for avoiding infections in the orthopedic field. The content of an antibacterial agent in polyesters should be optimized, as the materials do not have toxic effect. PLA/HA/AgNPs nanocomposites containing up to 10 wt % antibacterial agent are considered noncytotoxic [87]. In addition, the introduction of natural resources such as diatoms [70] into polyesters enhanced the bioactivity of bone-tissue engineering.

3. Tissue Engineering

3.1. Polyesters with Improved Functionalities

Natural and synthetic polymeric materials have gained a decent amount of attention in recent years for tissue engineering. The conventional material groups such as metals, metal alloys, and ceramics are still in use due to their undeniable superiority in the field of mechanical properties; however, polymeric materials are gaining an increasing amount of attention. Selected polyester materials that present a potential for producing scaffolds and different biomedical applications are summarized in Table 2.

Table 2.

Properties of selected polyester materials and composites for tissue engineering.

Aliphatic polyesters such as PLA, PGA, PCL, and their composites have long been used for tissue engineering due to their good biocompatibility and biodegradability. Tuin et al. [99] reported a high-throughput process of (melt-blown, spun-bond, and carded) nonwoven manufacturing methods that were suitable for production of tissue engineering scaffolds from PLA.

Electroconductive composites or blends have also found applications in tissue engineering, as reported by Wang et al., who prepared a series of electrically conductive nanofibrous sheets with similar fiber diameters for cardiac-tissue engineering [88]. Further, the authors utilized these conductive nanofibrous sheets to develop a series of cardiomyocyte-based 3D bioactuators with spontaneous contraction motion, here exemplified by the conductive PLA/polyaniline (PANI) nanofibrous sheets with different PANI contents prepared by the electrospinning technique [88]. The obtained results have proven to be promising for this type of application, as the investigated 3D bioactuator continued beating spontaneously with regular contraction patterns after 21 days of culturing.

Cardiac-tissue-like patches are also an interesting approach, as reported by Cesur et al. [89], in which a randomly oriented PLA, PLA/PEG, and random and aligned PLA/PEG/collagen (PLA/PEG/COL) nanofiber patches were successfully produced by the electrospinning technique for myocardial tissue engineering, which is one of the promising treatment modalities for repairing damaged heart tissue in patients with heart failure. Interestingly, as reported, even a small amount of COL (1 wt %) in a PEG-plasticized PLA could increase the electrical conductivity by two orders of magnitude. Both randomly oriented and aligned fiber patches showed a therapeutic value in myocardial repair and tissue engineering, but the maximum cell viability rate was observed for aligned ones. Another interesting approach to treating cardiovascular diseases with surgical revascularization was presented by Jacob Hodge and Clay Quint, in which PGA-based scaffolds were investigated in terms of the response to a circumferential stretching on a tissue-engineered vessel obtained from an electrospun scaffold. What differentiated this work from other similar approaches was how the production of COL and cross-linking of COL fibers in relation to the mechanical properties of the engineered vessels was related to the mechanical stretching stimulation [92].

Research involving the use of PLA in a blend was investigated by Wrzecionek et al. [90], in which they synthesized poly(glycerol citrate) PGCit and further mixed it with PLA for creating porous nonwovens by electrospinning. The produced materials were tested for possible application in the field of tissue engineering. The addition of PGCit is a new approach; however, as authors pointed out, the obtained materials need further refinement before being extended to larger-scale medical applications [90].

The engineering of soft tissue as cartilage tissue was investigated by Chen et al. [100], who produced a 3D scaffold based on electrospun gelatin/PLA nanofibers. In addition, a process to cross-link a gelatin/PLA nanofibrous scaffold was realized by heating to a high temperature followed by water treatment (heat and water). The resulting scaffold exhibited a hierarchical cellular structure and a superabsorbent property [100]. The obtained materials had a relatively high compressive strength, and as tested, they could significantly repair the cartilage defects in rabbits. As stated before, different types of tissues can be grown using scaffolds. Thus, Grant et al. [10] proposed the first use of a sacrificial, transfected cell line to biofunctionalize an electrospun polymer scaffold for liver-tissue engineering. The authors decellularized the biofunctionalized scaffold and validated the platform using cells representative of the liver. Preliminary studies presented the development of a hepatic extracellular matrix–PLA hybrid composite that exerted a biological influence on liver cells, manipulating their microenvironment and resulting in alterations in their gene-expression profile, protein synthesis, and cell attachment and survival. Scaffolds for liver-tissue engineering manufactured from a PCL/chitosan (CS) composite were reported by Semnani et al. [94]. They produced the nanofiber by electrospinning. Subsequently, the mechanical properties, roughness parameters, regional anatomy, structure, hydrophilicity, and cell growth of epithelial liver mouse cells were considered for liver-tissue engineering. The measured properties were within specified limits, and the liver cells were completely infiltrated and attached to the scaffold after seven days. A similar approach was undertaken by Ghahremanzadeh et al. [95], in which the authors introduced two new galactosylation methods for modifying PCL/CS scaffolds. In the proposed procedure, chitosan powder was galactosylated and then blended with PCL, followed by the electrospinning technique. Two different methods were investigated: postgalactosylation treatment of already-produced PCL/CS by immersing the scaffold in the solution; and in situ galactosylation of chitosan performed simultaneously with a wet-electrospinning method [95]. An important area of the field of tissue engineering includes applications for bone-tissue recovery. A comparison between coaxial PCL-PLA/HA fibers and PCL-PLA scaffolds was investigated by Kareem et al. [101], in which the 2D and 3D PCL-PLA/HA scaffolds with core and shell structured fibers were produced using coaxial electrospinning. They reported that increasing the fiber alignment in the 3D scaffolds led to anisotropic mechanical behavior with reduced mechanical properties when tested across fiber orientations. The obtained structures showed a gradual reduction in their tensile properties after 12 weeks of immersion in simulated body fluid (SBF).

Composites based on PLA for tissue recovery were rarely investigated in recent years; however, Jiang et al. [91] proposed composite scaffolds with cubically interconnected pores fabricated using fused filament fabrication with two different types of iron-based particle fillers, including biocompatible stainless steel 316 L and pure iron. The 316 L steel was approved by the FDA as an implant material. According to the authors, the use of a specialized iron powder improved the dimensional accuracy and mechanical performance of the obtained scaffolds. The cell viability assay of the bone marrow cells cocultured with the 3D-printed scaffolds revealed superior cytocompatibility of the PLA/iron scaffolds compared with pure PLA scaffolds and PLA/316 L scaffolds.

Apart from cardiac or skin-tissue engineering as described above, production of other types of tissues, such as nerves for treating peripheral nerve injuries, are currently being investigated. Dehnavi et al. [96] presented an electrospun conduit based on PGA/collagen/bioglass nanocomposites. Nerve reconstruction requires a specific approach, therefore in this study, the obtained PLA/collagen composite reinforced with BG was used as a material for producing a guidance channel that allowed axonal growth from the proximal to distal stump.

The use of PGA-based scaffolds for manufacturing scaffolds in tissue engineering can be also applied in dental reconstruction, but not in terms of implants; rather, to endorse reconstruction of periodontal ligament tissue—specialized connective tissue that connects the cementum and alveolar bone. Wu et al. [102] investigated such application and found out that nonwoven PGA scaffolds provided effective structural support to promote the secretion of the extracellular matrix in periodontal (PDL) ligament tissue cells. Furthermore, the cell–PGA constructs implanted in nude mice formed such an engineered tissue with a well-developed blood supply. Thus, PGA scaffolds combined with PDL cells offer a strategy for complex periodontal tissue regeneration [102].

PHA-based materials present a broad range of mechanical properties, biodegradability, and biocompatibility that usually is obtained by microorganisms in a specific environment, depending on the level of nutrients. PHAs can be categorized based on two main criteria: firstly, based on the monomeric unit carbon atom number (3–5 carbon atoms—short chain length (scl; i.e., PHB), 6–14—medium chain length (i.e., poly(3-hydroxynonanoate) (PHN)), and 14 and more—long chain length); and secondly, based on their composition: homopolymers containing only one type of monomer unit, and heteropolymers composed of more than one type of monomer unit. Until now, the use of PHAs in tissue engineering was limited to hard tissues, mainly bone reconstruction [103,104,105]. This restriction was due to brittleness, a lack of bioactivity, a relatively high cost, and a slow degradation rate. Other applications have been quite limited to research purposes only. This is because, while genetically modified bacteria can provide a wide variety of modified polymers, the nature of microorganisms used (mainly inherited metabolic pathway) can result in end-product batch-to-batch variations, especially in terms of structure and composition. The efficiency of the production process with a low polymer concentration and high substrate cost must also be taken into account, as providing a large-scale production process is economically impracticable. Recent research in tissue engineering using PHAs has been mainly aimed at wound management [106,107], nerve regeneration [108], cardiac- and coronary-related tissue engineering, and bone reconstruction [49,105,109,110]. Due to relatively low market availability, only a few of more than 90 known PHAs are available. In terms of mechanical properties, the most elastic one is P4HB, while PHB is considered to be most rigid [111,112]. There are several papers describing the use of PHAs for soft-tissue replacement. Different methods of manufacturing PHA-based scaffolds were compared by Grande et al. [113]; namely, the conventional electrospinning of a PHB/gelatin/HA mixture and the combination of the electrospinning of a PHB/gelatin solution with the electrospraying of an HA dispersion. The obtained scaffolds exhibited a continuous cell proliferation, with a faster evolution of cell morphology for the gelatin-containing materials. A long-term biological investigation clearly demonstrated that the sprayed scaffold developed a high biomineralization rate [113]. Vascular tissue engineering involving the use of the PHB was investigated by Yao et al., in which they manufactured various films using solution-casting and electrospinning methods [97,113].

Another group of materials that is not discussed here but presents very promising results in terms of tissue-engineering applications are hydrogels, as they are quite similar to biological tissues in terms of their mechanical and chemical properties; present good water absorption, and most importantly, are generally biocompatible [114,115].

3.2. Manufacturing Methods

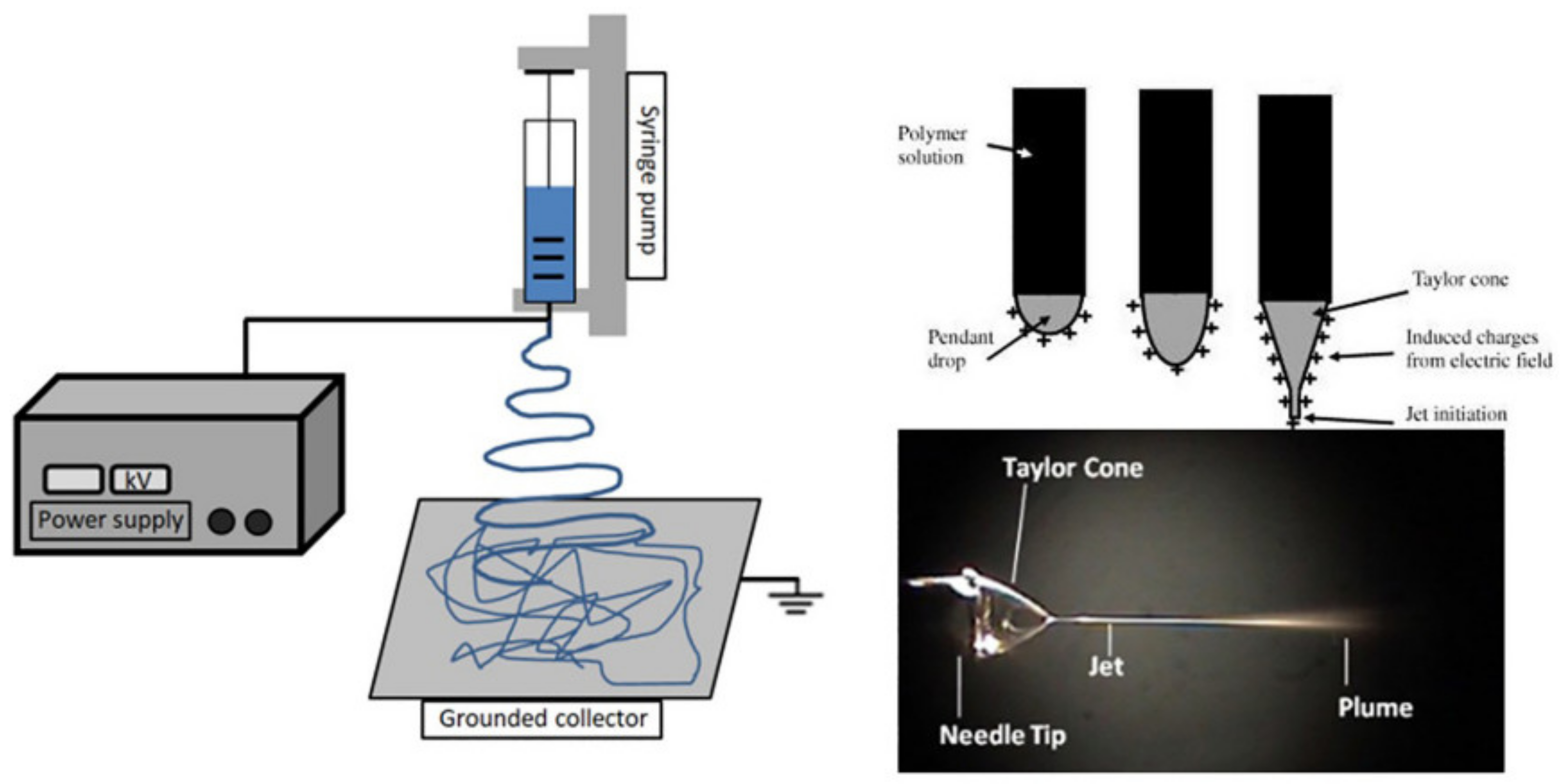

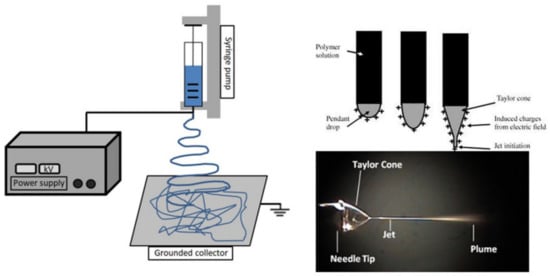

There are various methods available for processing polyesters in tissue-engineering applications. Conventional processing techniques are available, such as compression molding [116,117,118], injection molding [119,120,121], melt spinning [122], and extrusion [123], along with other newer techniques, such as electrospinning and 3D printing, and others. For producing scaffolds in tissue engineering, electrospinning is one of the most promising methods [124,125,126,127,128], as it uses a polymeric solution passed through a stainless capillary and a high potential electric field between the nozzle and a grounded collector (plate shaped or a rotational drum), as presented in Figure 4.

Figure 4.

Schematic representation of an electrospinning device, showing the formation of the Taylor cone. Reproduced from [129] with permission from Elsevier.

Producing a detailed structure with only a single layer of material can be time-consuming; however, such technique can be industrially upscaled by multiplying the number of layers being spun at once, resulting in a more complex mat structure and a faster production speed. Different factors influence the electrospinning process. The apparatus (applied electric field, distance between the needle and collector, and flow rate), solution (solvent, polymer concentration, viscosity, and solution conductivity), and environmental (humidity and temperature) parameters affect the fabrication of nanofibers [130]. Another relatively new technique used for producing scaffolds in tissue engineering is freeze-drying (or lyophilization), in which bioactive scaffolds with a porous architecture in planar 3D geometries are created. [131]. An interesting approach that combined those two methods was investigated by Chen et al. [93], in which electrospinning and freeze-drying processes were used for creating a superelastic scaffold with a cellular structure that consisted of nanofibers. The obtained scaffolds presented a porous structure, good water absorption capacity, and recyclable compressibility, while the cells seeded on them showed normal phenotypic morphology and proliferation. Salt leeching is a well-known technique still used for producing porous structures, including complex structures intended for tissue growth. This method works on the principle that a high-molecular-weight polymer solution in an organic solvent containing dispersed water-soluble salt particles is precipitated into an excess of nonsolvent. The polymer–salt composite is then processed by thermal processing methods into devices of varying shapes and sizes, and can subsequently be extracted to give the desired porous structures [132]. However, for polyesters, this method has its drawbacks, as they are prone to hydrolytic degradation. Investigating this subject, Xie et al. [133] reported a method to prepare biodegradable stereocomplex crystallite poly(lactide) (SC-PLA) porous scaffolds with high heat resistance, mechanical strength, solvent resistance, and biocompatibility by solvent casting and salt leaching. The resulted material proved to have a better biocompatibility and higher resistance to hydrolysis when compared to neat PDLA [133].

The 3D-printing methods, also known as additive manufacturing, have recently emerged on a global scale due to the decreasing equipment cost and more available and easier to operate software. One of the most common techniques is fused deposition modeling (FDM); others include stereolithography (SLA), selective laser sintering (SLS), and more [134,135,136,137]. The mentioned techniques, although time-consuming, have been shown to produce well-defined and reproducible structures that can be anatomically tailored to a specific case/patient.

3.3. Specific Performances

Even though the first attempt to formalize the tissue-engineering discipline was published almost three decades ago [138], the field still garners a lot of attention from different scientific groups. As it is a multidisciplinary field, it involves doctors, materials engineers, chemists, and many other scientists. Therefore, it still is undergoing evolution with regard to the use of different types of biodegradable materials, with special respect to polymers and polyesters, which have a special part in this group due to their unique properties, including mechanical, biocompatibility, and biodegradation. Biocompatibility is of utmost importance, because a device intended to be used in vivo requires a lack of response from the patient’s immune system. Biodegradability, on the other hand, can guarantee that there will be no need for a second surgical procedure in order to remove the device (scaffold, patch, etc.). As presented, polyesters can provide a tunable set of properties that allow them to be tailored to a specific application, granting control over degradation time and other functional properties. Out of over 90 polyesters known to man, only certain types have found applications in the tissue-engineering field. In most cases, this is due to a wide variety of native tissues and their properties, where an ideal match between the tissue and the introduced material is not easy to find. However, progress in cell biology has given us a better insight into the living tissue, providing better knowledge on how to design scaffolds and other structures that can mimic the surrounding environment and stimulate cell growth without its disruption. In order to engineer a tissue in a patient’s body, the scaffold material needs to transmit the mechanical stimulation, as it is an important factor in stimulating the cell growth and final tissue development. In addition to matching mechanical properties, the selected material needs to be easily useable, must withstand the sterilization procedure, and must demonstrate low toxic (or preferably nontoxic) behavior at the cellular level. Furthermore, most of the presented studies that involved implementing a polyester-based structure in patient’s body investigated the expected sensitivities of the selected material to in vivo conditions, especially the environment’s pH, possible inflammation at the regional scale, and effects related to enzymes and protein adsorption. Continued material development will further increase the application potential of polyesters for tissue engineering. Recent developments suggest that more value-added materials are gaining the attention of researchers. For example, poly(glycerol sebacate) (PGS) was introduced into a polymer scaffold system, creating a self-healing structure that was responsive to environmental stimuli and capable of self-healing during degradation by providing constant structural support [98]. Another type of “smart” materials are those with a shape memory effect. A device made of such materials can be manufactured as a small, easy-to-implant element that will undergo specific changes in the patient’s body once it has been implanted due to the temperature changes in the surrounding environment [139]. The presented family of “smart” materials, including polyesters, have proven to have interesting applications, including as biodegradable medical sutures, scaffolds that become elastic, or stents that will expand once implanted [140,141].

4. Surgical Implants (Suture Materials, Tissue Adhesives, Surgical Meshes)

4.1. Tissue Adhesives

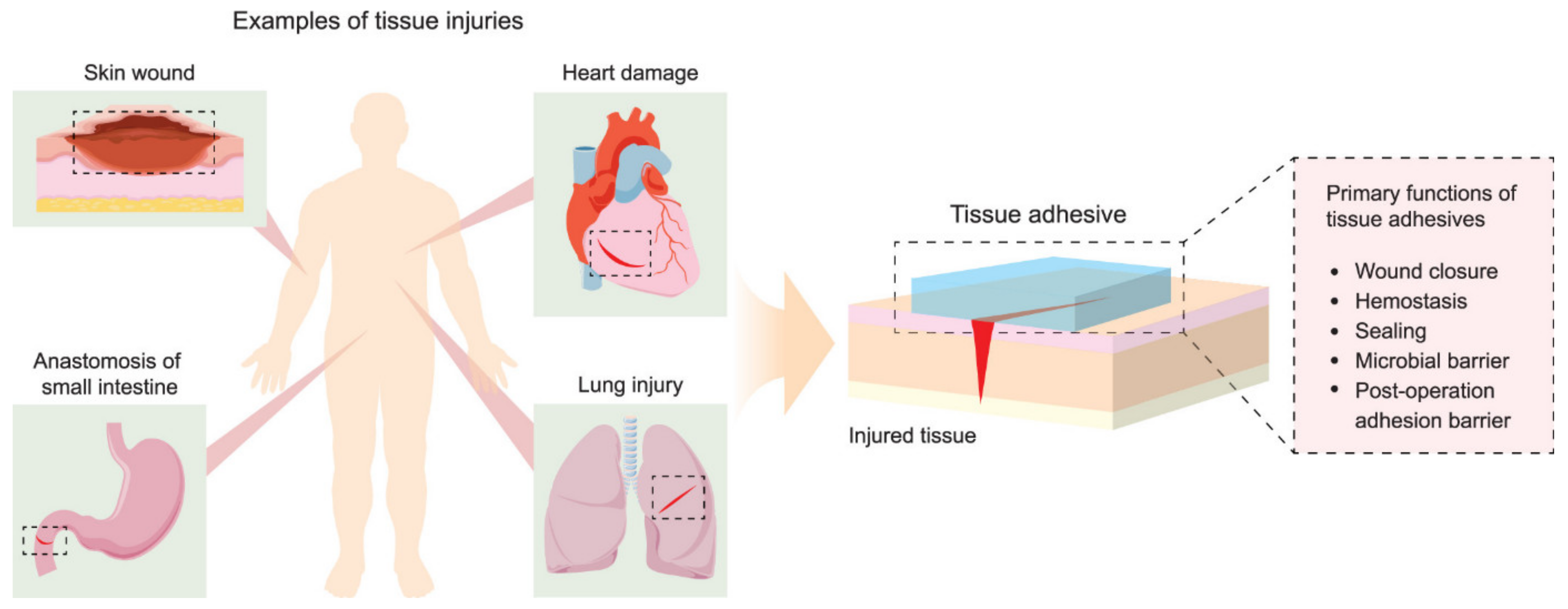

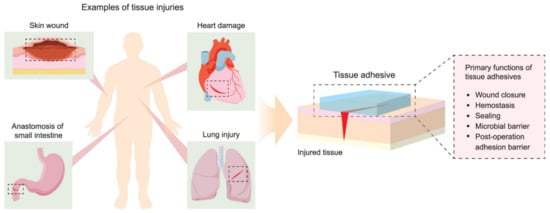

Other interesting applications for polyesters in medical implants include tissue adhesives, which must support materials that are able to promote tissue connectivity, and in some cases can reduce damage along with the healing process during the removal of the bandage or any other wound-covering mesh. The conventional approach to reconnecting damaged tissue for the time needed for a wound to heal involves use of sutures and staples. While the procedure of applying sutures is well known and provides an effective closure of relatively small wounds, it is time-consuming and requires appropriate equipment. Therefore, tissue adhesives are seen as a suitable alternative in providing wound dressings with an adhesive layer that must be in contact with the damaged tissue and a second layer consisting of the bulk polymeric network containing the adhesive [142]. The role of the adhesive layer is to keep the entire construction in place through chemical, physical, or covalent or noncovalent interactions. The adhesive matrix, on the other hand, provides structural support and determines the end properties of the adhesive in terms of stiffness, viscosity, swelling, abrasion, and degradability, as presented in Figure 5.

Figure 5.

Examples of tissue injuries and primary functions of tissue adhesives. Reprinted with permission from [142]. Copyright 2021 American Chemical Society.

Biodegradable polyesters such as PLGA or PCL have been investigated for such applications, as they are able to degrade completely into nontoxic compounds. In comparison, the nondegradable materials also used for the described applications, such as cyanoacrylates, isocyanates, aldehydes, and others that do not degrade, can cause an inflammatory reaction or release toxic byproducts. Other polyesters with the desired set of properties have been used to produce tissue adhesives, sutures, or meshes [143]. In order to better tailor the end material properties, copolymerization is often a common strategy. For example, a bioadhesive based on PCL functionalized with a low-viscosity, isocyanate-functional unsaturated acrylic ester [144] or 2-isocyanatoethyl acrylate (AOI) [145] that was manufactured into flexible transparent films with an interesting set of biomedical applications, more important for surgical adhesives, have been proposed. There are few similar UV-curable approaches that produce a tissue adhesive that can be applied quickly. Their potential is due to the requirements that such a material needs to have good interfacial contact with the wound sides, controllable solidification, and matching elastic moduli with the surrounding tissue [146]. Among other factors, the pressure application time also has an influence on the adhesion strength, as reported by Daristotle et al. [147].

4.2. Sutures

Sutures are well-known materials that join damaged tissues together. They should be biologically inert, with a repeatable set of properties; i.e., easy to handle by the surgeon, do not elicit harmful reactions, easy to sterilize, etc. From a medical point of view, the implemented suture should not promote microbial activity on the material’s surface. There have been some clinical studies regarding this issue that compared different commercially available sutures [148]. As reported, there were no significant differences between the selected materials (PET, silk, polyglactin, nylon), as all sutures were found to harbor bacteria, which in turn may have compromised healing of the surgical wounds. In order to create or generate the antimicrobial nature of a suture, it is essential that its surface be bioreceptive, allowing the biomolecules of certain bioactive components to anchor on the polymer’s surface. One of the most popular antimicrobial agents is Triclosan (2,4,4′-trichloro-2-hydroxydiphenylether), and studies of coating polyester sutures with this agent have been reported in the literature [149,150].

The ideal suture should have good mechanical properties, and should dissolve in the patient’s body after it serves its function by promoting tissue growth. Right now, the sutures commonly used can be divided into four main categories: absorbable, nonabsorbable, braided, and single filament [151]. Depending on the material used, absorbable sutures can withstand from around 10 days to 9 weeks. They can be manufactured from PLA (Polyglactin 910, Vicryl®, Polysorb®, RadikTM), PGA (Dexon®, Medifit®, Safil®) or other polymers from the PHA family (P(3HB), P(3HB-co-3HV)). In this case, the monitoring of mechanical properties over the course of in vivo degradation, as well as the correlation of mechanical properties with the provided application, are of high importance. Kehail et al. [152] investigated a copolymer P(HB-co-HHx) in vivo with a measured set of properties, and concluded that the material lost 58.5 ± 1% of its weight and 74.5 ± 2.5% of its Young’s modulus within 7 weeks. Apart from neat polymers, investigations of blends were also performed, as reported by Visco et al. [152], who developed a blend of PLA and PCL with ethyl ester l-lysine triisocyanate as a compatibilizing agent in order to explore its behavior in absorbable-suture applications.

4.3. Surgical Meshes

Surgical meshes have represented a universal way to reinforce soft tissues since the late 1950s, when Dacron® (PET) and Marlex® (polypropylene, PP) were introduced. PP meshes are especially useful for hernia repair applications [153]. Meshes can be divided into four main categories, taking into consideration the component materials: nonabsorbable synthetic polymers (i.e., polypropylene), absorbable polymers (PGA, PCL), biologic (acellular collagen), or a composite material as a combination of the three previous categories. They have been continuously developed over the years, and given their composition, the type of the material, and the histological point of view, can be classified accordingly into: first generation (synthetic nonabsorbable prosthesis), second generation (mixed or composite prosthesis), and third generation (biological prosthesis) [154]. First-generation meshes are mostly based on PP systems, but polyesters such as PCL or PGA are also used (Dexon®); second-generation meshes were developed by combining more than one synthetic material in their compositions, mostly a combination of PP, PTFE, and some additives such as titanium (Ti) or poly(vinylidene fluoride) (PVDF). Third-generation refer to a biologic mesh material based on collagen scaffolds derived from donor sources. Their primary advantage is extensive promotion of the healing process combined with a nonexistent inflammatory response related to their excellent biocompatibility. However, due to the high cost of the third-generation meshes, their wide use is limited. A possibility to utilize a cheaper alternative for commercially available meshes was investigated by Todros et al. [155], who compared the properties of two multifilament industrial nests versus a surgical mesh (Parietex™ Lightweight Monofilament Mesh). All materials were made of PET polyester. Such an approach was dictated by the fact that similar materials are being used for hernia repairs in less-developed countries. The authors found similarities in the mechanical performances of industrial nets and patented surgical mesh, although further research concerning the response in vivo in biaxial stress conditions is required.

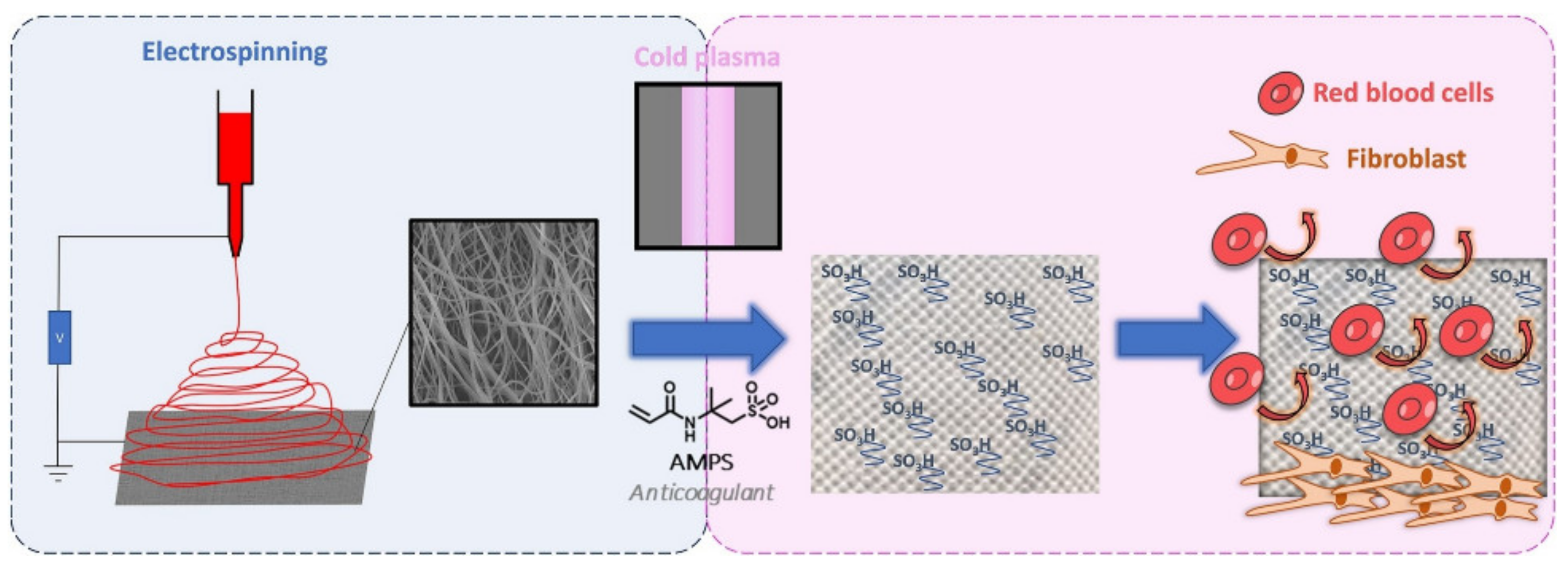

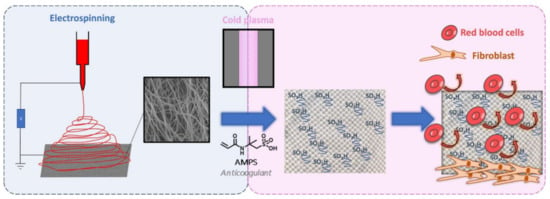

The human body’s response to foreign objects has been investigated, and according to [156], the mesh used for soft-tissue reinforcement may elicit a chronic inflammatory response that can be persistent over time. What also must be underlined is that the chemical structure of a polymeric mesh can be altered by the oxidative stress in biological tissues. According to [157], the structural changes in PP meshes can lead to crosslinking in polymer chains and formation of hydrogen bonds between the carboxyl groups, which can increase the mesh stiffness. Polyesters, on the other hand, are susceptible to hydrolysis, bulk or surface degradation, water uptake, and more, all of which influence their mechanical properties. In order to reduce the negative influence of meshes, different approaches have been investigated. Shokry et al. [158] developed a polyester fiber mesh layered with chitosan that increased the biocompatibility and increased the healing promotion for repairing abdominal wall hernias and prosthetics. Similar in concept but different in design was the investigation by Alin et al. [159], in which they proposed a polymer/nanotube coating on different surgical meshes, including polyester, by matrix-assisted pulsed laser evaporation. An electrospinning method for obtaining new surgical meshes is also being implemented (Figure 6).

Figure 6.

Schematic representation of the functionalization of PP mesh with PCL electrospun nanofiber monomer copolymerization. Reproduced from [160] with permission from Elsevier.

Dufay et al. [88] implemented a new method for covering a PP mesh with PCL electrospun nanofibers, although it was necessary to functionalize these polymeric nanofiber cover layers through an adequate surface treatment technique by cold plasma graft-copolymerization of the monomer (2-acrylamido-2-methylpropane sulfonic acid, AMPS) onto the surface of the nanofibers. The authors successfully grafted PCL fibers, and in terms of anticoagulant activity, the obtained samples with AMPS exhibited properties similar to that of 0.5 unit of heparin, without being affected by the plasma treatment and with acceptable cytocompatibility with fibroblast NIH3T3.

5. Wound Dressings

Manufacturing of Polyesters with Improved Functionalities

The compositions of some polyesters used for fabrication of wound dressings are shown in Table 3.

Table 3.

The main technological parameters and performance for polyester-material-based wound dressings.

Many innovative polyester-based materials were developed in 2021 to meet the general requirements for wound dressings. Healing of wounds requires dressings with hydrophilic surfaces, which contribute to supporting cell adhesion better than hydrophobic surfaces. For example, CuO and ZnO NPs with contact angle values of 85° and 78° [20] and TiO2 NPs [18] were successfully used to increase the surface wettability of polyesters for wound applications.

The PLA and PHB aliphatic polyesters are the most important bioresorbable polymer matrices used for development of wound dressings with excellent biocompatibility and biodegradability characteristics. They are bioresorbed by the body and act as a carrier for releasing of the bioactive compounds. The lactic acid oligomers containing carboxyl and hydroxyl end groups were quantified by EMI-MS tandem mass spectrometry as degradation products of P(D,L)LA/a-PHB and P(D,L)LA/a-PHB/proanthocianidins (PCAN) [161]. However, the neat PLA did not have good mechanical properties and bioactivity, having a great impact on the limiting of its applications in wound-healing management. The graft copolymerization technique has become a good strategy for chemical modification of lactic acid with cyanoacrylate directly in contact with tissue [165]; the study showed that the addition of graphene oxide (GO) up to 1% to a PLA solution for electrospinning enhanced its hydrophilicity, which positively influenced the drug-release kinetics [162]. Another study showed that the introduction of quercetin (Q), a natural flavonoid, could be fully released from PLA/GO electrospun scaffolds in just 1–2 min with the help of an external electric stimulus, showing an application for personalized wound healing [162]. Another model drug investigated for in vitro release was gentamicin sulfate loaded into PLA/poly(vinyl alcohol) (PVA) bioscaffolds [166].

PLA can be used as carrier for encapsulating bioactive compounds to design electrospun materials. For example, the antimicrobial agent cefazolin was encapsulated into a PLA–PEO solution as a core, while collagen was added to poly(vinylpyrrolidone) (PVP) as a shell to prove the accelerating of wound healing [16].

Coated melanin–TiO2/PCL/PHB mats allowed researchers to obtain a water absorption of 300 wt % [18], further supporting a key role for keeping the moisture balance in wound-dressing materials. The adding of gelatin to PHB nanofibers enabled them to obtain a wound-dressing material useful in treating second-degree burn wounds by decreasing the dressing frequency and the controlled released of silver sulfadiazine (SS) [24].

The inhibition of bacterial growth was reported in the case of copper oxide (CuO), zinc oxide (ZnO) nanoparticles, and tranexamic acid (TXA) added into PLA-coated sterile gauze [20]; silver sulfadiazine (SS) loaded into PBAT/PCL microfibers [22]; and neomycin (NEO), an aminoglycoside antibiotic, incorporated into carboxymethyl cellulose hydrogels [167]. Inhibitions of about 50%, 94%, and 95% were also observed in the case of PHB/gelatin/SS nanofibers against S. aureus, P. aeruginosa, and E. coli, and were assigned only to controlled release of SS [24].

A bioadhesive wound-healing gel prepared from a 30% gelatin solution coupled with poly(ethylene glycol) (PEG) and diethyl ether (DEE) as highly volatile solvents was shown to be an alternative to traditional first-aid dressings [17].

Electrospinning is a simple, low-cost, and scalable technique to prepare polymeric nano- and microfibers with different diameters, from microns to around 30 nanometers [161]. This method is based on using electrostatic forces to produce continuous polymer fibers from polymer melt or solution. Electrospun mats, due to their unique properties, great surface-area-to-volume ratio, and small pore size, are very beneficial in the absorption of body fluids, hemostasis, and the prevention of the penetration of bacteria. Additionally, the mats allow a good capability of cell attachment and proliferation, supporting skin wound healing.

Nanofibers based on PBSu [15], PLCL/PCL [163], PLA/Hypericum perforatum oil (HPO) [21], PLA/GO/Q [162], PLA/silver (I)-diclofenac complex with (2-methylimidazole) [168], and PBAT/PCL [22] are few examples of polyester-based materials successfully obtained via the electrospinning method.

The main conditions for processing of polyester-based materials via electrospinning method are shown in Table 3. The optimal conditions for obtaining free-bead fibers via electrospinning involve the setting of the flow rate, voltage, and distance between the needle and collector, as well as the working temperature and humidity, until a stable Taylor cone is formed. The choice of solvent is an important step in obtaining continuous and uniform fibers. The most common solvent mixtures used are chloroform:methanol, chloroform:ethanol, and dichloromethane (DCM):methanol at 90:10, 80:20, and 70:30 solvent ratios, respectively, for electrospinning of PBSu/food-grade agents [15]; DCM/N, N-dimethylformamide (DMF) at a ratio of 1:9 to obtain PLA/graphene oxide (GO)/quercetin (Q) electrospun scaffolds [162]; and DCM/DMF (7:3, v/v) and 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP)/ethanol (7:3, v/v) for preparing encapsulated antimicrobial agents in PLA/PEO/PVP matrices [16]. The addition of acetic acid to the mixture of chloroform:ethanol to dissolve the PLCL/PCL copolymer prevented the formation of beads, and led to fibers with diameters in the range of 200 nm to 2.8 µm [163]. There were also reported nanofibers with diameters of 1.68 ± 0.58 µm and 1.51 ± 0.64 µm in the case of electrospun PLA/HPO [21], 1.107–1.243 µm in the case of PLA/GO/Q [162], and 1.9 ± 0.5 μm in the case of PHB/PCL modified with hybrid melanin–TiO2 nanostructures [18], which are considered as adequate for cell adhesion and attachment. However, the nanofibers’ average diameters of 599.94 ± 112.04 nm [16], or in the range of 250–300 nm [20], permitted the controlled drug release, antimicrobial activity, and acceleration of the wound-healing process. Thus, PHB/gelatin nanofibrous composition (70:30) with bead-free nanofibers, a uniform diameter, and a porosity of 55 ± 2.08% allowed the loading of a silver sulfadiazine (SS) drug [24]. The in vitro SS delivery revealed a burst release of ∼40% of the drug up to 5 h.

In addition, the thickness of electrospun nonwoven fabrics is an important parameter for air permeability favoring the healing of wound. It can be set from the volume of solution, as the thickness of the fabric can be ∼224 µm [21]. Innovative wound dressings made from renewable materials with proper mechanical properties were created by using a synthetic aliphatic polyester, PBSu, in the presence of a chain extender, diisocyanahexane (DCH), and natural food-grade components such as edible gums, essential oils, and free fatty acids by the electrospinning technique [15].

Wound dressings with adequate air permeability, water sorption, and good resistance against microbial organisms were also obtained by dip-coating of polyester/viscose samples in the presence of biogenic silver nano sol (AgNS) prepared using manuka honey [169]. In another study, poly(3-hydroxybutyrate) (P(3HB))/poly(3-hydroxyoctanoate-co-3-hydroxy decanoate) (P(3HO-co-3HD)) nanofibers were prepared via electrospinning, then an aqueous colloidal silver solution of 4000 ppm was used for dip-coating of nanofibrous scaffolds with dimensions of 30 mm × 60 mm at a rate of 170 mm/min to obtain antimicrobial wound dressings [170].

PCL is a synthetic degradable polyester that is highly hydrophobic, but without the ability to support cell adhesion and growth. This drawback is removed by co-polymerization with L-lactic acid, resulting in PLCL copolymers with certain applications in wound-healing management. For example, low- and high-molecular-weight PLCL masses were investigated as blend adhesives in healing, and were comparable with a polyurethane bandage [171]. Nanofibrous membranes based on PLCL/PCL and platelet lysate (PL) containing a mixture of various growth factors are a new therapeutic approach for wound healing to stimulate skin regeneration and the proliferation and differentiation of keratinocytes [163]. It was found that the composition with a 50:50 mass ratio of components showed a high adhesion strength, and was proposed for replacement of conventional bandage adhesives.

The impregnation method of polyesters was employed for designing halloysite nanotube (HNT)-coated PET dressings to accelerate hemostasis [172], or loading with Annona leaf extract (ALE) for developing antioxidant and antimicrobial polyester transdermal patches [164]. The comparison of impregnation of ALE into a hydrocolloid sodium carboxymethyl cellulose (NaCMC) natural wound dressing and PD revealed that antioxidant activity was obtained the case of PD due to the swelling effect of the PD at supercritical solvent impregnation (SSI) conditions, which favored the large diffusion of the plant extract into the macromolecular chains of the polyester, and a high impregnation yield [164].

Weft-knitted spacer fabric production is a new advanced technology for developing 3D hydrocellular functional wound dressings from PET and PU yarn impregnated with 15 g L−1 of quaternary ammonium salt (QAS) solution [173]. This cost-effective construction showed a good property in moisture management and a broad-spectrum antimicrobial effect compared with conventional wound dressings based on carboxymethyl cellulose alginate, enzyme-based autolytic hydrogel, and polyhexamethylene biguanide dressings. Thus, the need for repetitive wound-dressing changes for diabetic patients could be reduced.

An increased attention to fabrication of personalized wound-dressing materials has been addressed to the 3D-printing (3DP) or additive-manufacturing (AM) technique. Fused deposition modeling (FDM)/fused filament fabrication (FFF) is one of the most common low-cost AM techniques. The designed model, microarchitecture, and geometry of wound-dressing materials were obtained by providing the successive layers of materials using appropriate computer-aided design (CAD) software or Digital Imaging and Communications in Medicine (DICOM) files [75].

In an attempt to reduce the effects of adverse antibiotics, modern wound dressings loaded with natural antimicrobial agents such as proanthocyanidins (PCAN) extracted from Pelargonium sidoides [161], Annona leaf extracts [164], babassu oil [19], Hypericum perforatum oil (HPO) [21], melanin [18], and arginine and chitosan [174] were developed. Immunomodulatory properties toward skin keratinocytes in vitro were related in the case of olive leaf extract (OLE) incorporation in poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV) and PHB/poly(hydroxyoctanoate-co-hydroxydecanoate) (PHB/PHOHD) nanofibers, due to the antioxidant activity of oleuropein [175]. An antibacterial and antibiofilm dressing for wound healing was developed based on L-tryptophan and L-phenylalanine-based poly(ester urea)s electrospun fibers, which aimed at delivery of nitric oxide (NO), promoting proliferation, enhancing collagen, and accelerating wound treatment [176,177].

Kaempferol nanocrystals (KPF-NCs) loaded into a PHB/chitosan (CS) film could be another interesting blend for wound dressings, and had a remarkable blood clotting capacity for 20 min [178]. An accelerated improvement in wound healing was reported in the case of acrylate-endcapped urethane-based polymers (AUPs) prepared as films and electrospun mats [179]. In addition to showing the elimination of excess exudates and the provision of good mechanical properties, when these materials were analyzed in an acute wound model conducted in rats in vivo, they showed significant wound contractions as compared with positive controls.

Injectable hydrogels are a new class of wound healers that permit the moisture of wounds and oxygen permeability. Recently, boronic ester dynamic injectable hydrogels were developed as a novel self-healing, dual-stimuli-responsive, antioxidant, and antibacterial class of materials for healing of chronic wounds [180].

6. Vascular Applications

6.1. Polyesters with Improved Functionalities

Vascular grafts are essential in the replacement of damaged blood vessels and the treatment of cardiovascular diseases.

Transcatheter arterial embolization (TAE), a safe and innovative interventional therapeutic technique efficiently used for special vascular diseases treatments, consists of an embolic agent injection into a target artery [181]. The medical applications of TAE include: (a) treatment of vascular lesions (e.g., intracranial aneurysms and arteriovenous malformations) [181]; (b) supporting hemostasis [182]; (c) cancer treatment, including transcatheter arterial chemoembolization (TACE) for hepatic carcinoma [183]; (d) redistribution of blood (e.g., obstetrics and gynecology) [184]; and (e) promoting the surgical resection of internal tissue [185].

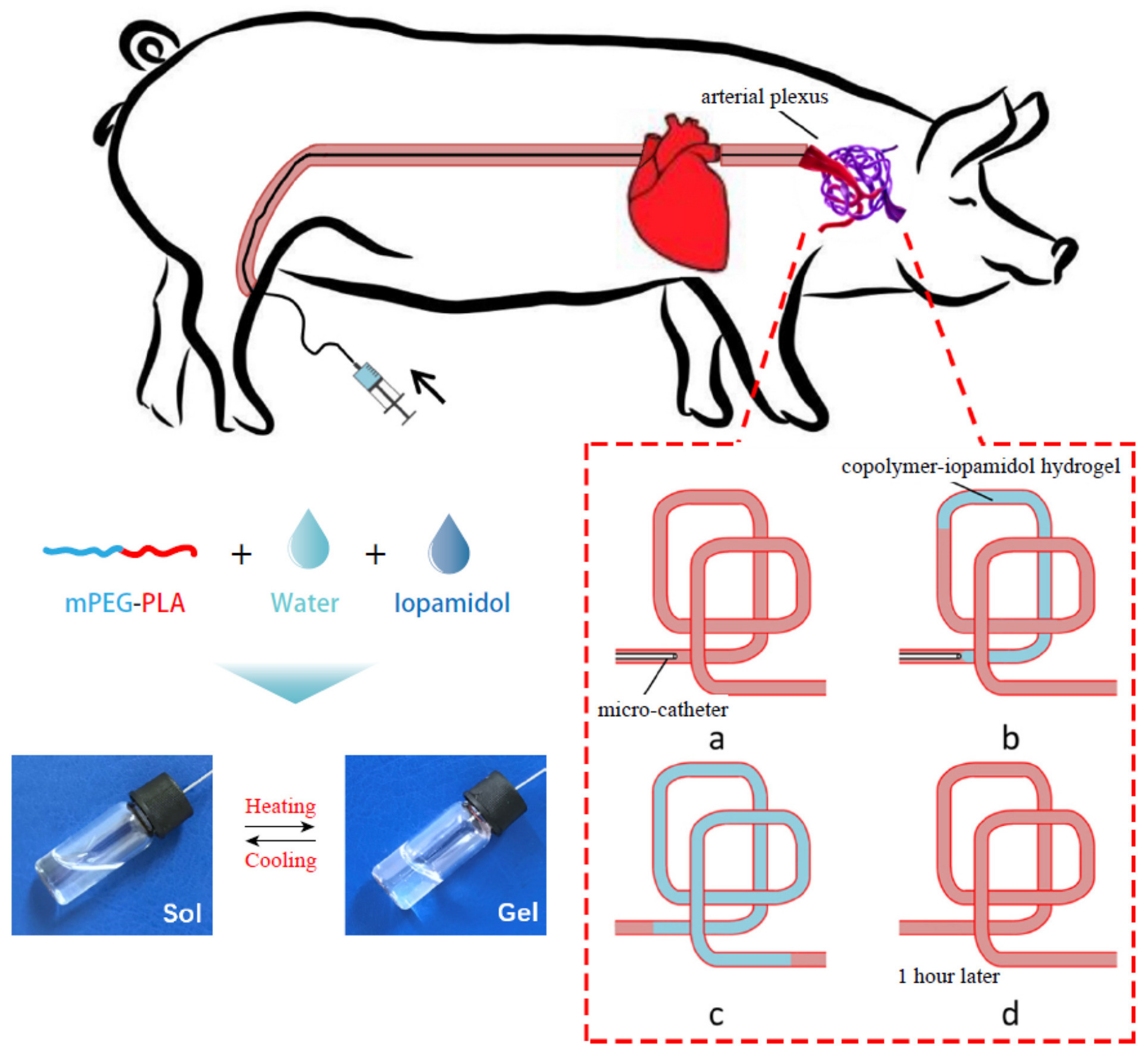

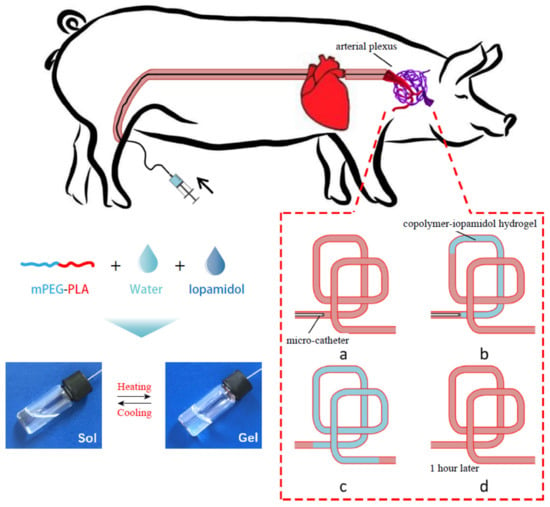

Yang et al. [186] evaluated the efficiency of an injectable methoxy PEG-poly(D,L-lactide) copolymer (mPEG-PLA) thermogel in temporary vascular interventional therapy in the case of a large animal (swine). The results showed unique thermoreversible sol-gel transitions and superior injectability for PEG/polyester thermogels when compared with Onyx™, the only liquid embolic agent approved by the FDA so far. Figure 7 shows a schematic diagram for the in vivo use of mPEG-PLA thermogel as a temporary embolic agent for TAE in a swine model. The microcatheter was introduced and advanced in order to conduct the embolization in the neck of the pig (a); then an aqueous copolymer–iopamidol solution was injected, flowing along the blood vessels, and observed under X-ray exposure (b); successful embolization of the target artery was reached after microcatheter extraction, as at body temperature, the aqueous mPEG–PLA solution transformed to a semisolid gel, leading to temporary occlusion of the pharyngeal artery (angiography) (c); which was recanalized 1 h after the operation (d). The mPEG–PLA thermogel can thus be used as a potential temporary presurgical embolic agent for tumor resection, although extensive studies regarding the improvement in the mechanical strength of the gel are required in order to further enhance the embolization efficiency of the PEG/polyester thermogel.

Figure 7.

Schematic representation of the application of an mPEG–PLA thermogel as a temporary embolic agent for TAE. The aqueous mPEG–PLA solution containing iopamidol transformed from a free-flowing liquid at low temperatures to a gel when increasing the temperature (reversible sol-gel transition). Reproduced with permission from Elsevier [186].

Various synthetic vascular grafts have been used successfully, with clinical approval for medium to large vessels, while for small revascularizations, mainly autologous vascular grafts are approved at the clinical level. Due to qualitative and quantitative limitations of the latter, there is an enormous need to develop small-diameter (<5 mm) synthetic vascular grafts; therefore, new materials and innovative methods, such as decellularization, electrospinning, lyophilization, knitting, 3D printing, or even the combination of these approaches, have been considered [187].

Several examples of polyester-based materials used in vascular reconstructive surgery, along with their important features and specific applications, are presented in Table 4.

Table 4.

Examples of polyester-based materials obtained by different techniques for vascular applications.

6.2. Risks and Limitations

Peripheral vascular surgery creates a high demand for available small-diameter vascular grafts, but only a small range of newly developed materials have been successful in incipient experiments due issues such as acute thrombosis, incomplete endothelialization, and intimal hyperplasia after implantation.

A limitation of complete studies involving the development of innovative polyester-based materials for vascular applications is the limited number of patients that can be subjected to experiments, out of which some could already have additional foreign materials in their organs/vessels. In addition, the risk factor for the new graft material is difficult to prove due to the diversity of vascular graft infections. Vascularization potential, reduced thrombogenicity, and secure pseudointima growth are key parameters that could affect the successful integration and functionality of prosthetic vascular grafts [200].

7. Ophthalmological Applications

7.1. Manufacturing of Polyesters with Improved Functionalities

Biodegradable formulations used in ocular treatments are generally manufactured using PCL, PLA, PGA, or PLGA [202]. Thermoreversible PLGA–PEG–PLGA triblock copolymers and modified chondroitin sulfate aldehyde formulations have been proposed as corneal adhesives [203].

PLGA is a widely used biodegradable polyester in the preparation of drug-delivery systems for various vitreoretinal diseases, such as age-related macular degeneration, uveitis, and diabetic macular edema [204]. Biocompatible and biodegradable PLGA and PLA are most widely utilized at the clinical level. The FDA approved a number of long-acting injectable (LAI) microsphere formulations due to their proven safety history. The selection of the PLGA/PLA in the design of microspheres depends on several factors, such as the specific administration route for a particular drug, the amount of microspheres distributed per dose unit, the daily rate of drug release from the microspheres in order to meet the therapeutic concentration of the specific drug, and the degradation time of the polymer. The injectability of the microspheres and drug-release behavior are influenced by the particle size of the PLGA/PLA microspheres [205].

One of the most common diseases in ophthalmology is eye inflammation, which can affect any part of the eye or surrounding tissues. The typical anti-inflammatory drugs used to treat ocular inflammation are corticosteroids, but their continued administration leads to serious side effects [206]. Nonsteroidal anti-inflammatory drugs (NSAIDs) are considered the principal alternatives to corticosteroids in the treatment of inflammations. New formulations of PLGA nanospheres (Nss) loaded with 0.5 and 1.0 mg/mL dexibuprofen (DXI) have been developed to upgrade the biopharmaceutical profile of the NSAIDs used for ocular administration [207]. A cell-viability analysis demonstrated the low cytotoxicity of PEGylated-PLGA nanospheres compared with free DXI.

Micellar nanocarrier formulations based on methoxy-PEG-hexyl-substituted PLA (mPEGhexPLA) were well tolerated and nontoxic, efficiently delivering poorly soluble drugs to the anterior and posterior compartments of the eye in rats [208].

Intracameral PCL implants show the advantage of bypassing the corneal epithelial barrier and enhance the quantity of drug delivered to the target tissues, in contrast with topical administration. Compared to particles that can degrade more rapidly and can show burst release, the developed systems containing a PCL reservoir can present longer and continued zero-order release due to a larger drug payload, along with increased control over the diffusive polymer barrier [209].

Other polyester-containing systems loaded with various drugs that have been proved efficient in ocular treatments are presented in Table 5.

Table 5.

Design and performance of polyester-based formulations used in ophthalmology.

A 3D-printed device known as a “cornea-on-a-chip” that contains a clear polyester porous membrane separating four lower and four upper channels has been developed in order to move fluids over corneal cells, simulating the movement of tears over a blinking eye [217]. The movement changed the cells’ shape and increased the production of filaments that kept corneal cells flexible and elastic.

7.2. Potential Risks

Besides the advantages of using polyesters in biomedical applications, particular risks have been observed in some cases and applications. In ophthalmology, clinicians need to take into consideration a probability of vision loss, especially in patients with a high risk of vascular issues.

Several studies reported destructive ophthalmic complications as a result of injecting PLA as facial filler for cosmetic purposes. A case of loss of light visual perception in the right eye was reported for a 55-year-old woman 5 days after injecting cosmetic PLA filler in the right forehead [218]. Intraretinal hemorrhages and whitening, white intravascular thromboemboli widespread within the arcades, acute ischemia of the right optic nerve, and acute cerebral artery infarctions were observed, but there were no permanent focal neurologic deficits. PLA used as forehead filler could have been injected in the supratrochlear or supraorbital arteries, which are direct branches of the ophthalmic artery. Further, the filler emboli may be pushed in the internal carotid artery and then cerebral circulation.

Wu et al. [219] described a case of a 49-year-old woman with various chronic diseases that experienced acute ocular pain and central visual loss due to retinal artery occlusion after injecting PLLA in the temporal region. Retinal whitening in the blocked vessels and optic disc edema were observed as a result of optic atrophy, with permanent vision loss in the patient being reported, despite of prompt use of a special topical treatment that included eye drops of brimonidine and hyperbaric oxygen therapy. PLLA is frequently used as effective subcutaneous filler, with results in long-term reconditioning of facial volume, because the PLLA microparticles promote the inflammatory response that stimulates collagen deposition in the extracellular matrix [220].

The evaluation of the pharmacokinetics after administration of new formulations is highly necessary. Although the PEG–PLA micelle system has shown generally good clinical prospects, the relationship between the oxidative state of the organism and the PEG-b-PLA administration has not been fully evaluated so far. Dvorakova et al. [221] demonstrated a potential health risk of PEG-b-PLA micelles that could cause neuroendocrine-disrupting effects.

8. Multiresistant Infection Prevention, including the COVID-19 Pandemic

8.1. Development of Antimicrobial, Antiviral, and Self-Sterilizing Materials Containing Polyesters

Due to the various factors that lead to the spread of antibiotic resistance, such as the use of multiple broad-spectrum agents; overuse of antibiotics in animal husbandry, human health, or aquaculture; or lack of efficient antimicrobial control, it can be estimated that by 2050, no effective antibiotic will be available if innovative drugs are not produced. Some alternative methods are being considered for controlling antibiotic-resistant pathogens, the most efficient being the use of essential oils (EOs), bacteriocins, antibodies, phage therapy, nanotherapy, or quorum-sensing inhibitors [222]. Antibacterial vaccines have recently become progressively important in managing bacterial infections and reducing the need for antibiotics. Novel nanoparticles have been designed to induce proper immune responses for effective antimicrobial defense [223].

Antimicrobial polyester materials with a functionalized PLA substrate were produced by using surface modification under γ-irradiation (doses of 10, 20, and 30 kGy), and emulsion-stabilization approaches. Two bioactive agents, namely clove essential oil and argan vegetal oil, were incorporated into chitosan, then immobilized on the surface of the functionalized PLA by a wet treatment involving carbodiimide chemistry [224]. Melt processing, another technique, was used by Darie-Nita et al. [225] to develop PLA-based antimicrobial and antioxidant materials containing bioplasticizers, as well as active agents such as vitamin E and cold-pressed rosehip seed oil encapsulated into chitosan by the emulsion method.

Microbial infections also can be treated by using electrospun PLA mats loaded with Thymus capitatus (L.) essential oil (ThymEO) [226]. Specific characterization showed negligible cytotoxicity of the novel materials, while reductions in microbial viable cells were caused by both the liquid and vapors of ThymEO released from the mats.

Antibiotic-free antibacterial polyester-based materials for biomedical applications were developed by incorporating various concentrations (1.5%, 3%, and 6% v/v) of peppermint essential oil (PEP) on PCL electrospun fiber mats with diameters of 1.6 ± 0.1 to 1.0 ± 0.2 μm [227]. The PEP loaded on the PCL fibers increased the wettability and antimicrobial activity against Staphylococcus aureus and Escherichia coli bacteria, and also improved the cell viability on electrospun fibers at all used concentrations after 48 h of cell culturing using normal human dermal fibroblast (NHDF), compared with the control.