Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation

2.3. Mechanical Tests

2.4. Thermal Properties Tests

2.5. Fourier Infrared Spectroscopy Test

2.6. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Mechanical Properties

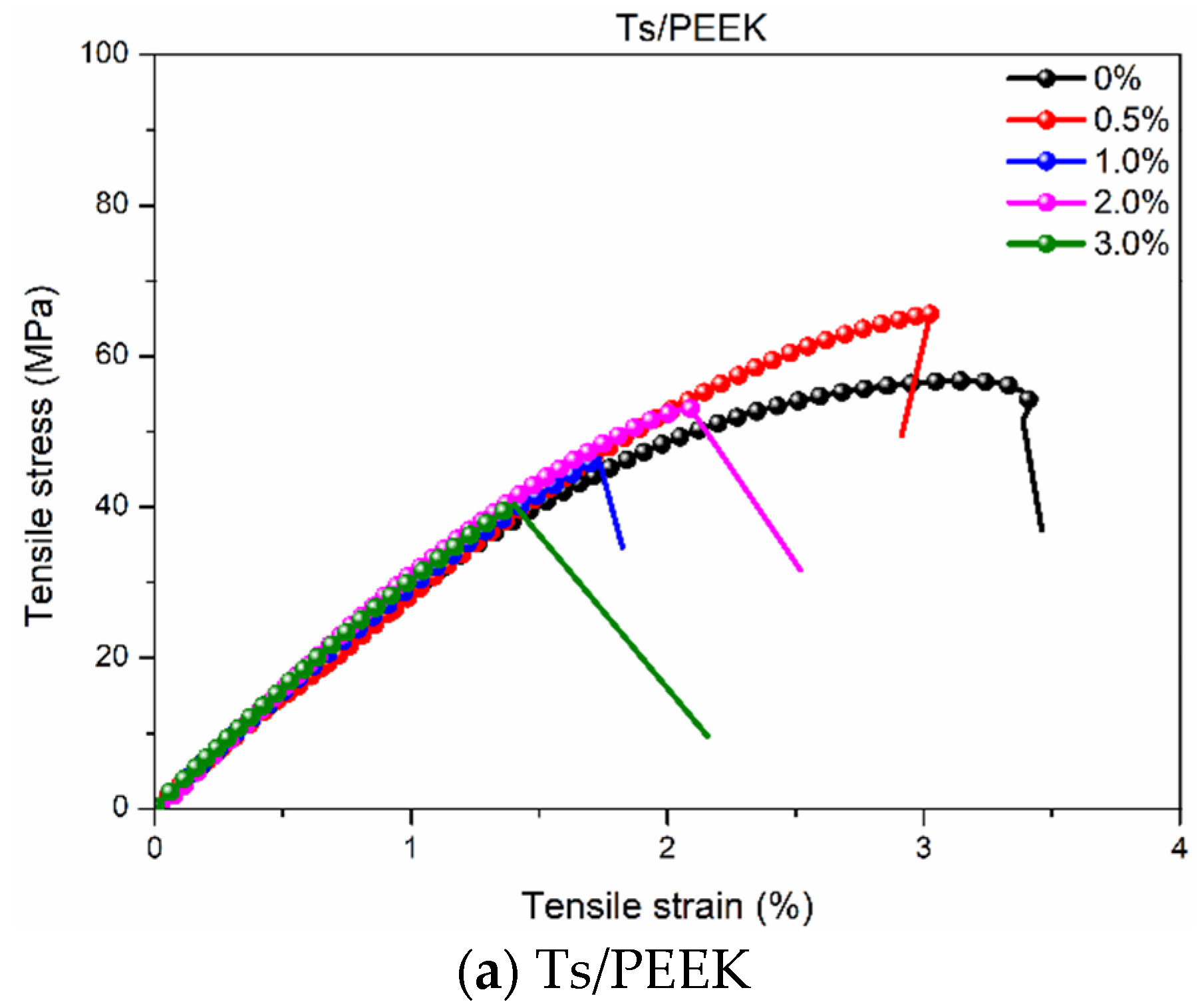

3.1.1. Tensile Properties

3.1.2. Flexural Properties

3.1.3. In-Plane Shear Strength

3.2. Thermal Properties Analysis

3.2.1. Dynamic Mechanical Analysis

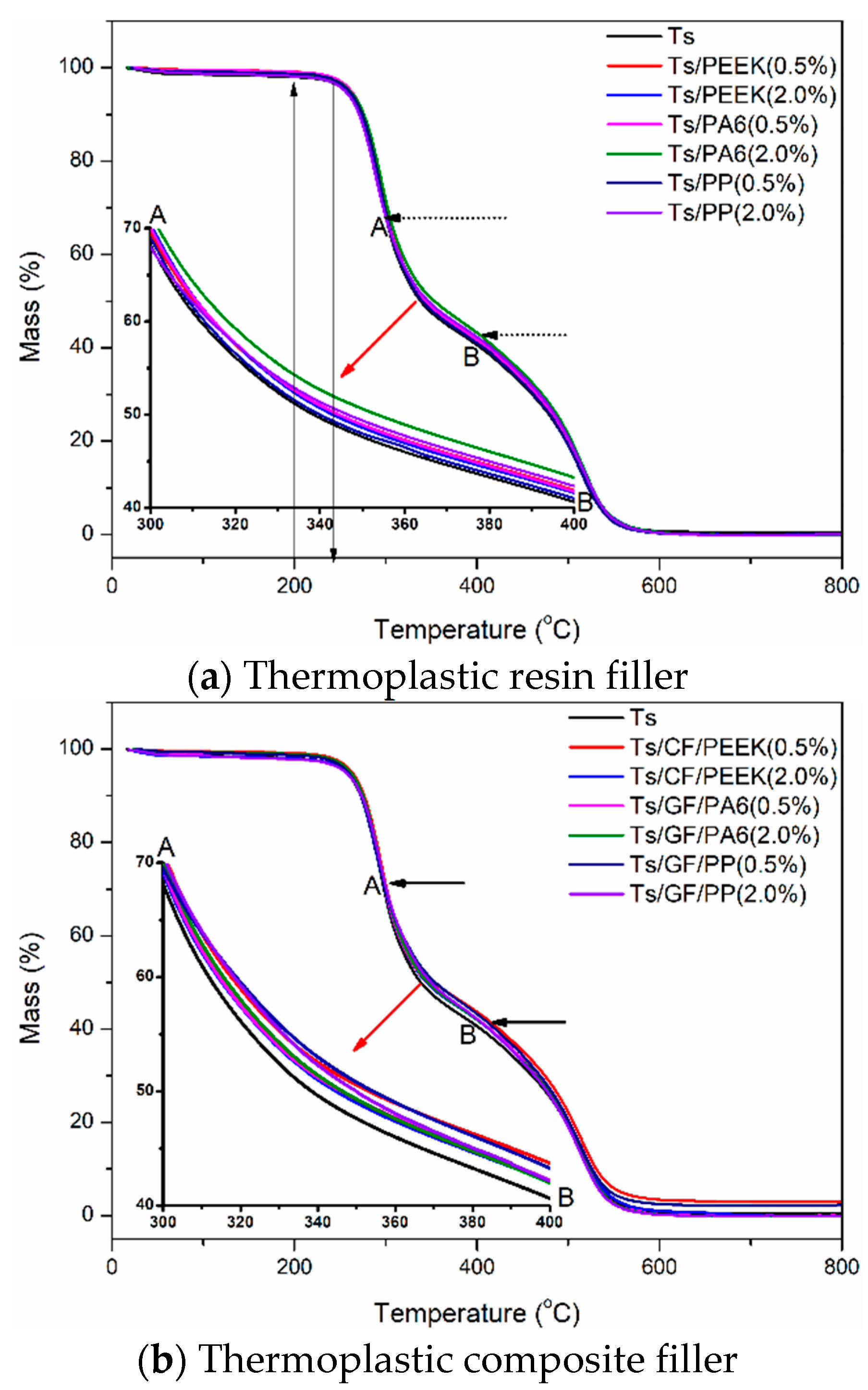

3.2.2. Thermogravimetric Analysis

3.3. Mechanism Analysis

3.3.1. Functional Group Analysis

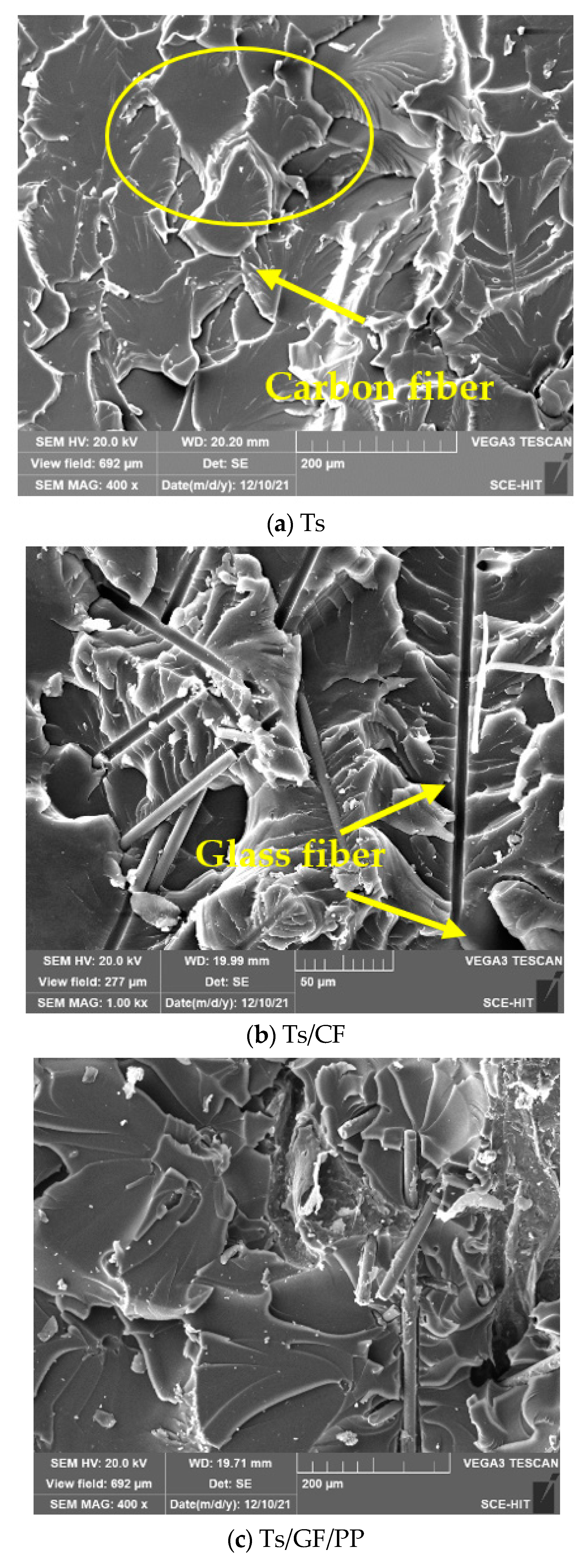

3.3.2. Surface Morphology Analysis

3.3.3. Mechanism Summary

3.4. Proportioning Design of Optimal Thermoplastic Filler

3.5. Application Prospect Analysis

4. Conclusions

- (1)

- Adding thermoplastic resin and composite fillers at the low mass ratio of 0.5~1.0% brought about the maximum improvement of the tensile strength (7~15%), flexural strength (7~15%) and in-plane shear strength (20~30%) of Ts resin. With the increase of filler content to 2.0~3.0%, Ts resin became weakened and brittle owing to the agglomeration effect.

- (2)

- After adding the thermoplastic resin, Tg had a descent within 5 °C. This was attributed to the addition of thermoplastic resin improved the flexibility of Ts resin due to the linear molecular structure of thermoplastic resin. Adding the GF/PP filler brought about the increase (~4 °C) of Tg and weight decomposition capacity of Ts resin at elevated temperature compared to CF/PEEK and GF/PA6.

- (3)

- Microstructure analysis showed that the thermoplastic resin and composite fillers can be evenly dispersed in Ts resin. The addition of thermoplastic fillers can prolong the cracking path and delay the failure process through the load bearing of fiber, energy absorption of thermoplastic resin and superior interface bonding.

- (4)

- The optimal proportions of thermoplastic resin filler were 0.5~1.0% (PEEK), 1.0~2.0% (PA6) and 0.5~1.0% (PP) to obtain the desirable improvement of mechanical and thermal properties. For example, the maximum improvement of mechanical properties was up to 45.53% (in-plane shear strength). In contrast, the optimal mass ratios of three kinds of composite were determined to be 0.5~1.0%. After the improvement, Ts resin can be used as the resin matrix, interface adhesive and anti-corrosion coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paolillo, S.; Bose, R.K.; Santana, M.H.; Grande, A.M. Intrinsic Self-Healing Epoxies in Polymer Matrix Composites (PMCs) for Aerospace Applications. Polymers 2021, 13, 201. [Google Scholar] [CrossRef]

- Nikonova, T.; Zharkevich, O.; Dandybaev, E.; Baimuldin, M.; Daich, L.; Sichkarenko, A.; Kotov, E. Developing a Measuring System for Monitoring the Thickness of the 6 m Wide HDPE/LDPE Polymer Geomembrane with Its Continuous Flow Using Automation Equipment. Appl. Sci. 2021, 11, 10045. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Li, J.; Mai, Z.; Xie, J.; Lu, Z. Durability of components of FRP-concrete bonded reinforcement systems exposed to chloride environments. Compos. Struct. 2021, 279, 114697. [Google Scholar] [CrossRef]

- Bilisik, K. Syduzzaman Carbon nanotubes in carbon/epoxy multiscale textile preform composites: A review. Polym. Compos. 2021, 42, 1670–1697. [Google Scholar] [CrossRef]

- Xie, J.; Li, Y.; Lu, Z.; Fan, Z.; Li, J.; Li, S. Effects of Immersion in Water, Alkaline Solution, and Seawater on the Shear Performance of Basalt FRP Bars in Seawater–Sea Sand Concrete. J. Compos. Constr. 2022, 26, 04021071. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Novel wedge-shaped bond anchorage system for pultruded CFRP plates. Mater. Struct. 2018, 51, 162. [Google Scholar] [CrossRef]

- Das, A.D.; Mannoni, G.; Fruh, A.E.; Orsi, D.; Pinalli, R.; Dalcanale, E. Damage-Reporting Carbon Fiber Epoxy Composites. Acs. Appl. Polym. Mater. 2019, 1, 2990–2997. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Yin, X.; Liu, Y.; Guo, R.; Xian, G. Long-term service evaluation of a pultruded carbon/glass hybrid rod exposed to elevated temperature, hydraulic pressure and fatigue load coupling. Int. J. Fatigue 2020, 134, 105480. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, F.; Li, C.; Hong, B. Hygrothermal resistance of pultruded carbon, glass and carbon/glass hybrid fiber reinforced epoxy composites. Constr. Build. Mater. 2021, 315, 125710. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Xian, G.; Li, C. Effect of Immersion in Water or Alkali Solution on the Structures and Properties of Epoxy Resin. Polymers 2021, 13, 1902. [Google Scholar] [CrossRef]

- Baltzis, D.; Bekas, D.; Tsirka, K.; Parlamas, A.; Ntaflos, A.; Zafeiropoulos, N.; Lekatou, A.G.; Paipetis, A.S. Multi-scaled carbon epoxy composites underwater immersion: A durability study. Compos. Sci. Technol. 2020, 199, 108373. [Google Scholar] [CrossRef]

- Uthaman, A.; Xian, G.J.; Thomas, S.; Wang, Y.J.; Zheng, Q.; Liu, X.L. Durability of an Epoxy Resin and Its Carbon Fiber-Reinforced Polymer Composite upon Immersion in Water, Acidic, and Alkaline Solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef] [Green Version]

- Li, C.G.; Yin, X.L.; Wang, Y.J.; Zhang, L.; Zhang, Z.H.; Liu, Y.C.; Xian, G.J. Mechanical property evolution and service life prediction of pultruded carbon/glass hybrid rod exposed in harsh oil -well condition. Compos. Struct. 2020, 246, 112418. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments. J. Mater. Res. Technol. 2021, 14, 2812–2831. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Kovács, J.G. A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation. Polymers 2019, 11, 1555. [Google Scholar] [CrossRef] [Green Version]

- Naito, K.; Nagai, C. Effects of temperature and water absorption on the interfacial mechanical properties of carbon/glass-reinforced thermoplastic epoxy hybrid composite rods. Compos. Struct. 2022, 282, 115103. [Google Scholar] [CrossRef]

- Jena, K.K.; AlFantazi, A.; Mayyas, A.T. Efficient and cost-effective hybrid composite materials based on thermoplastic polymer and recycled graphite. Chem. Eng. J. 2021, 430, 132667. [Google Scholar] [CrossRef]

- Fujigaya, T.; Saegusa, Y.; Momota, S.; Uda, N.; Nakashima, N. Interfacial engineering of epoxy/carbon nanotubes using reactive glue for effective reinforcement of the composite. Polym. J. 2015, 48, 183–188. [Google Scholar] [CrossRef]

- Awad, S.A.; Fellows, C.M.; Mahini, S.S. Evaluation of bisphenol A-based epoxy resin containing multiwalled carbon nanotubes to improve resistance to degradation. J. Compos. Mater. 2018, 53, 2981–2991. [Google Scholar] [CrossRef]

- Guo, F.L.; Zhou, Z.L.; Wu, T.; Hu, J.M.; Li, Y.Q.; Huang, P.; Hu, N.; Fu, S.Y.; Hong, Y. Experimental and multiscale modeling investigations of cryo-thermal cycling effects on the mechanical behaviors of carbon fiber reinforced epoxy composites. Compos. Part. B Eng. 2022, 230, 109534. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, C.; Huang, X.; Xin, M. Effect of fiber hybridization types on the mechanical properties of carbon/glass fiber reinforced polymer composite rod. Mech. Adv. Mater. Struct. 2021, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.K.; Zhao, X.L.; Xian, G.J.; Wu, G.; Raman, R.K.S.; Al-Saadi, S. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr. Build. Mater. 2017, 156, 985–1004. [Google Scholar] [CrossRef]

- Wang, Z.K.; Zhao, X.L.; Xian, G.J.; Wu, G.; Raman, R.K.S.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Tian, J.; Li, C.; Xian, G. Reciprocating friction and wear performances of nanometer sized-TiO2 filled epoxy composites. Polym. Compos. 2021, 42, 2061–2072. [Google Scholar] [CrossRef]

- Uthaman, A.; Lal, H.; Li, C.; Xian, G.; Thomas, S. Mechanical and Water Uptake Properties of Epoxy Nanocomposites with Surfactant-Modified Functionalized Multiwalled Carbon Nanotubes. Nanomaterials 2021, 11, 1234. [Google Scholar] [CrossRef]

- Baghdadi, Y.N.; Youssef, L.; Bouhadir, K.; Harb, M.; Mustapha, S.; Patra, D.; Tehrani-Bagha, A.R. Thermal and mechanical properties of epoxy resin reinforced with modified iron oxide nanoparticles. J. Appl. Polym. Sci. 2021, 138, 50533. [Google Scholar] [CrossRef]

- Carbas, R.; da Silva, L.; Andrés, L. Effect of carbon black nanoparticles concentration on the mechanical properties of a structural epoxy adhesive. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 232, 403–415. [Google Scholar] [CrossRef]

- Haeri, S.; Asghari, M.; Ramezanzadeh, B. Enhancement of the mechanical properties of an epoxy composite through inclusion of graphene oxide nanosheets functionalized with silica nanoparticles through one and two steps sol-gel routes. Prog. Org. Coat. 2017, 111, 1–12. [Google Scholar] [CrossRef]

- Graziano, A.; Jaffer, S.; Sain, M. Review on modification strategies of polyethylene/polypropylene immiscible thermoplastic polymer blends for enhancing their mechanical behavior. J. Elastomers Plast. 2018, 51, 291–336. [Google Scholar] [CrossRef]

- Dev, V.G.; Dhanakodi, A. Studies on mechanical properties of thermoplastic composites prepared from flax-polypropylene needle punched nonwovens. Sci. Eng. Compos. Mater. 2018, 25, 489–499. [Google Scholar]

- Schricker, K.; Bergmann, J.P.; Hopfeld, M.; Spiess, L. Effect of thermoplastic morphology on mechanical properties in laser-assisted joining of polyamide 6 with aluminum. Weld. World 2021, 65, 699–711. [Google Scholar] [CrossRef]

- Lin, J.; Li, J.; Wang, J.; Guan, Y.; Wang, G.; Chen, L. Effects of thermoplastic elastomer on the morphology and mechanical properties of glass fiber-reinforced polycarbonate/acrylonitrile-butadiene-styrene. Polym. Eng. Sci. 2018, 59, E144–E151. [Google Scholar] [CrossRef]

- El-Fattah, A.A.; Youssef, H.; Gepreel, M.A.H.; Abbas, R.; Kandil, S. Surface Morphology and Mechanical Properties of Polyether Ether Ketone (PEEK) Nanocomposites Reinforced by Nano-Sized Silica (SiO2) for Prosthodontics and Restorative Dentistry. Polymers 2021, 13, 3006. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Yu, S.; Mao, J.; Wang, Y.; Li, M.; Li, X. Effect of basalt fiber on tribological and mechanical properties of polyether-ether-ketone (PEEK) composites. Compos. Struct. 2021, 266, 113847. [Google Scholar] [CrossRef]

- Okan, M.; Aydin, H.M.; Barsbay, M. Current approaches to waste polymer utilization and minimization: A review. J. Chem. Technol. Biotechnol. 2018, 94, 8–21. [Google Scholar] [CrossRef] [Green Version]

- Exconde, M.K.J.; Co, J.A.A.; Manapat, J.Z.; Magdaluyo, E.R. Materials selection of 3D filament and utilization of recycled polyethylene terephthalate (PET) in a redesigned breadborad. Procedia CIRP 2019, 84, 28–32. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lim, T.-W.; Sottos, N.R.; White, S. Manufacture of carbon-fiber prepreg with thermoplastic/epoxy resin blends and microencapsulated solvent healing agents. Compos. Part A Appl. Sci. Manuf. 2019, 121, 365–375. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Xu, L.; Chen, Z.; Wang, Y.; Tusiime, R.; Cheng, C.; Zhou, S.; Liu, Y.; Yu, M.; Zhang, H. Enhancing the Mechanical and Thermal Properties of Epoxy Resin via Blending with Thermoplastic Polysulfone. Polymers 2019, 11, 461. [Google Scholar] [CrossRef] [Green Version]

- Dzul-Cervantes, M.; Pacheco-Salazar, O.; Can-Herrera, L.; Moreno-Chulim, M.; Cauich-Cupul, J.; Herrera-Franco, P.; Valadez-González, A. Effect of moisture content and carbon fiber surface treatments on the interfacial shear strength of a thermoplastic-modified epoxy resin composites. J. Mater. Res. Technol. 2020, 9, 15739–15749. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Mechanical properties of carbon/glass fiber reinforced polymer plates with sandwich structure exposed to freezing-thawing environment: Effects of water immersion, bending loading and fiber hybrid mode. Mech. Adv. Mater. Struct. 2022, 1–21. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, P.; Fu, S.; Chen, F. Morphological structure and mechanical properties of epoxy/polysulfone/cellulose nanofiber ternary nanocomposites. Compos. Sci. Technol. 2015, 115, 66–71. [Google Scholar] [CrossRef]

- Lee, S.E.; Jeong, E.; Lee, M.Y.; Lee, M.K.; Lee, Y.S. Improvement of the mechanical and thermal properties of polyethersulfone-modified epoxy composites. J. Ind. Eng. Chem. 2016, 33, 73–79. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, Y.; Wang, P.; Li, Y.; Sui, J. Mechanical and Thermal Properties of Epoxy Resins Modified by a Novel Thermoplastic-polyimide. Fibers Polym. 2021, 22, 205–212. [Google Scholar] [CrossRef]

- Bakar, M.; Duk, R.; Przybylek, M.; Kostrzewa, M. Mechanical and Thermal Properties of Epoxy Resin Modified with Polyurethane. J. Reinf. Plast. Comp. 2009, 28, 2107–2118. [Google Scholar] [CrossRef]

- Mimura, K.; Ito, H.; Fujioka, H. Improvement of thermal and mechanical properties by control of morphologies in PES-modified epoxy resins. Polymer 2000, 41, 4451–4459. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, Y.; Cheng, C.; Zhou, J.; Liu, B.; Yu, M.; Zhang, H. Enhanced mechanical and thermal properties of monocomponent high performance epoxy resin by blending with hydroxyl terminated polyethersulfone. Polym. Test. 2018, 69, 302–309. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, Z.; Tusiime, R.; Cheng, C.; Sun, Z.; Xu, L.; Liu, Y.; Jiang, M.; Zhou, J.; Zhang, H.; et al. Highly improving the mechanical and thermal properties of epoxy resin via blending with polyetherketone cardo. Compos. Commun. 2019, 13, 80–84. [Google Scholar] [CrossRef]

- Lal, H.M.; Uthaman, A.; Li, C.G.; Xian, G.J.; Thomas, S. Combined effects of cyclic/sustained bending loading and water immersion on the interface shear strength of carbon/glass fiber reinforced polymer hybrid rods for bridge cable. Constr. Build. Mater. 2022, 314, 125587. [Google Scholar] [CrossRef]

| Filler Type | Mass Ratio (%) | Mechanical Tests | Thermal Properties Tests |

|---|---|---|---|

| PEEK CF/PEEK | 0.5 | Tensile test Flexural test In-plane test | Dynamic mechanical analysis Thermogravimetric analysis |

| 1.0 | |||

| 2.0 | |||

| 3.0 | |||

| PA6 GF/PA6 | 0.5 | Tensile test Flexural test In-plane test | Dynamic mechanical analysis Thermogravimetric analysis |

| 1.0 | |||

| 2.0 | |||

| 3.0 | |||

| PP GF/PP | 0.5 | Tensile test Flexural test In-plane test | Dynamic mechanical analysis Thermogravimetric analysis |

| 1.0 | |||

| 2.0 | |||

| 3.0 |

| Filler Type | Residual Weight of Composite at Elevated Temperature (%) | |||||

|---|---|---|---|---|---|---|

| 250 °C | 300 °C | 350 °C | 400 °C | 450 °C | 500 °C | |

| No | 96.01 | 68.18 | 47.63 | 40.65 | 32.17 | 19.18 |

| PEEK-0.5% | 97.16 | 69.63 | 48.94 | 41.89 | 33.24 | 19.65 |

| PEEK-2.0% | 96.66 | 70.51 | 48.61 | 41.61 | 33.24 | 20.27 |

| CF/PEEK-0.5% | 97.32 | 70.92 | 50.57 | 43.73 | 35.34 | 22.18 |

| CF/PEEK-2.0% | 96.04 | 69.13 | 49.03 | 42.03 | 33.39 | 19.92 |

| PA6-0.5% | 97.18 | 70.05 | 48.92 | 41.76 | 33.06 | 19.73 |

| PA6-2.0% | 96.80 | 71.53 | 50.63 | 43.25 | 34.62 | 21.42 |

| GF/PA6-0.5% | 96.90 | 69.55 | 49.32 | 42.24 | 33.48 | 19.67 |

| GF/PA6-2.0% | 97.06 | 70.14 | 49.32 | 42.03 | 33.23 | 19.43 |

| PP-0.5% | 96.66 | 69.01 | 47.99 | 41.01 | 32.54 | 19.15 |

| PP-2.0% | 95.93 | 67.95 | 49.38 | 42.33 | 33.96 | 20.75 |

| GF/PP-0.5% | 96.59 | 69.53 | 50.82 | 43.30 | 34.41 | 20.53 |

| GF/PP-2.0% | 95.91 | 70.59 | 50.00 | 42.18 | 32.99 | 19.05 |

| Filler Type and Mass Ratio | Increase Percentage of Tensile Strength (%) | Increase Percentage of Flexural Strength (%) | Increase Percentage of In-Plane Shear Strength (%) | Increase Percentage of Tg (%) | Increase Percentage of Residual Weight at Elevated Temperature (%) |

|---|---|---|---|---|---|

| PEEK-0.5 | / | 4.44 | 22.01 | / | 3.05 |

| PEEK-1.0 | / | 4.99 | 23.85 | / | / |

| PEEK-2.0 | / | / | / | / | 2.36 |

| PEEK-3.0 | / | / | / | / | / |

| PA6-0.5 | / | 3.02 | 8.59 | / | 2.73 |

| PA6-1.0 | / | 9.49 | 10.95 | / | / |

| PA6-2.0 | / | 12.55 | 15.81 | / | 6.40 |

| PA6-3.0 | / | 11.29 | 5.57 | / | / |

| PP-0.5 | / | 13.32 | 18.35 | / | 0.89 |

| PP-1.0 | / | 10.12 | 34.99 | / | / |

| PP-2.0 | / | / | 19.29 | / | 4.13 |

| PP-3.0 | / | 9.87 | 21.81 | / | / |

| Filler Type and Mass Ratio | Increase Percentage of Tensile Strength (%) | Increase Percentage of Flexural Strength (%) | Increase Percentage of In-Plane Shear Strength (%) | Increase Percentage of Tg (%) | Increase Percentage of Residual Weight at Elevated Temperature (%) |

|---|---|---|---|---|---|

| CF/PEEK-0.5 | 13.70 | 9.45 | 12.50 | / | 7.58 |

| CF/PEEK-1.0 | 15.21 | 6.64 | 8.81 | / | / |

| CF/PEEK-2.0 | 0.81 | / | / | / | 3.39 |

| CF/PEEK-3.0 | 5.98 | / | / | / | / |

| GF/PA6-0.5 | 11.45 | 3.22 | 8.07 | / | 3.91 |

| GF/PA6-1.0 | 7.55 | 6.66 | 9.02 | / | / |

| GF/PA6-2.0 | / | / | 20.86 | / | 3.39 |

| GF/PA6-3.0 | / | / | 15.24 | / | / |

| GF/PP-0.5 | 8.48 | 3.54 | 45.53 | 3.87 | 6.52 |

| GF/PP-1.0 | 1.51 | 6.45 | 20.13 | 2.46 | / |

| GF/PP-2.0 | / | / | 28.08 | 0.80 | 3.76 |

| GF/PP-3.0 | / | / | 6.10 | / | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Li, C.; Hailatihan, B.; Mi, L.; Baheti, Y.; Yan, Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers 2022, 14, 1087. https://doi.org/10.3390/polym14061087

Wu J, Li C, Hailatihan B, Mi L, Baheti Y, Yan Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers. 2022; 14(6):1087. https://doi.org/10.3390/polym14061087

Chicago/Turabian StyleWu, Jingyu, Chenggao Li, Bahetihan Hailatihan, Longlong Mi, Yeerna Baheti, and Yuze Yan. 2022. "Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin" Polymers 14, no. 6: 1087. https://doi.org/10.3390/polym14061087

APA StyleWu, J., Li, C., Hailatihan, B., Mi, L., Baheti, Y., & Yan, Y. (2022). Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers, 14(6), 1087. https://doi.org/10.3390/polym14061087