Sidechain Metallopolymers with Precisely Controlled Structures: Synthesis and Application in Catalysis

Abstract

:1. Introduction

2. Synthetic Methods of Linear Polymers with Precisely Controlled Structures

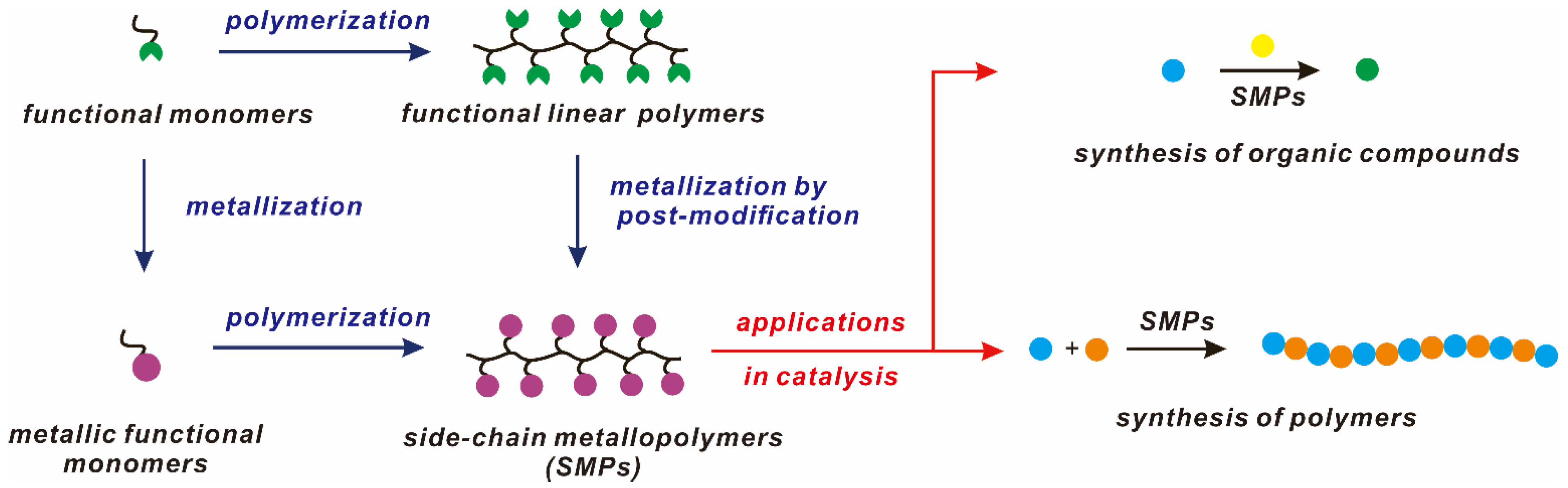

3. Preparation of SMPs

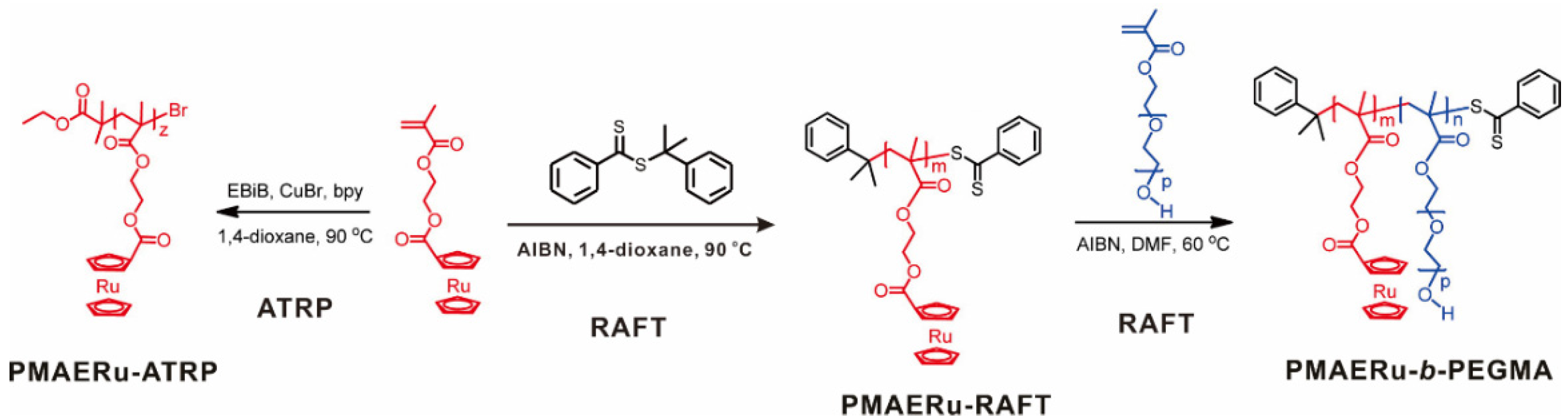

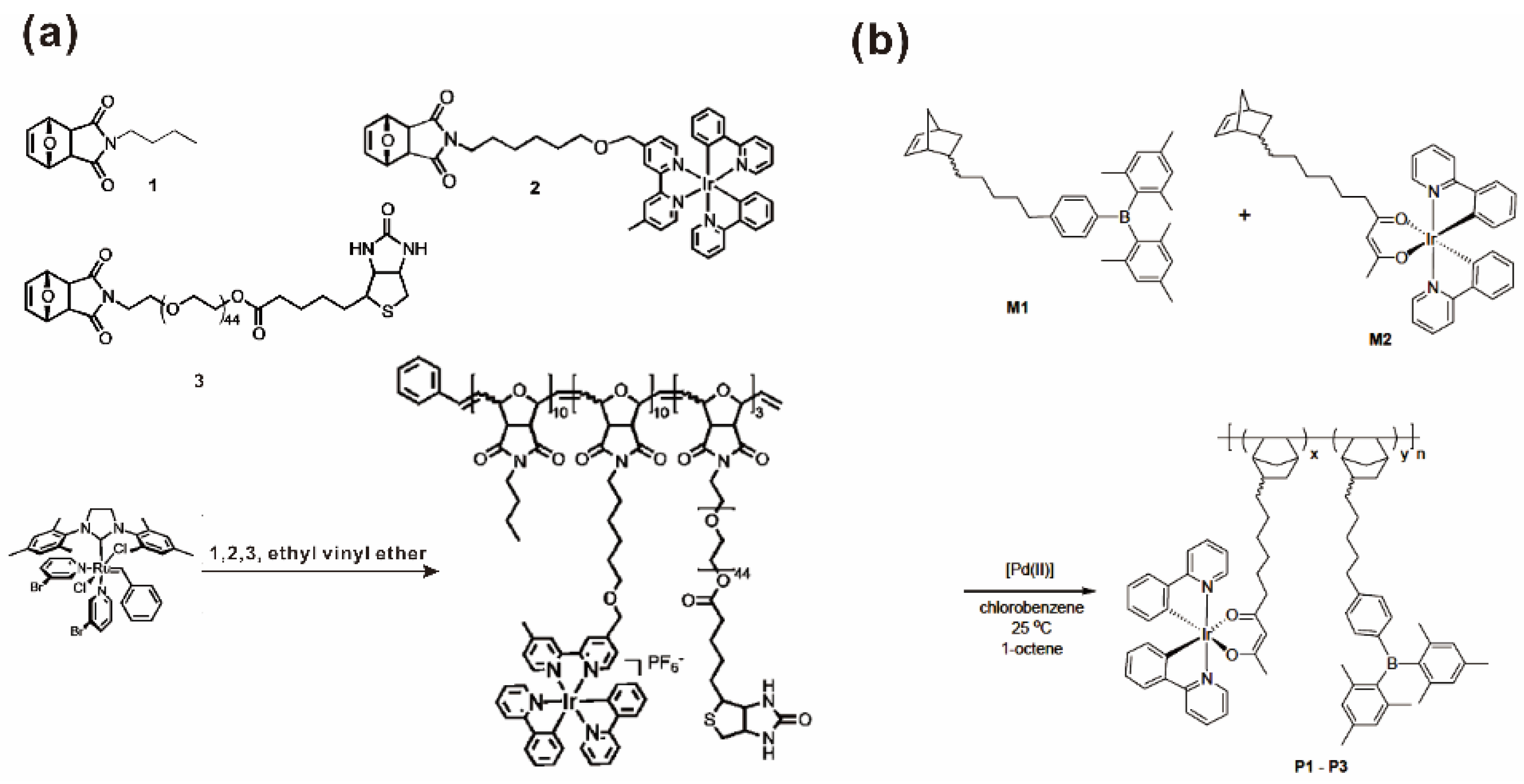

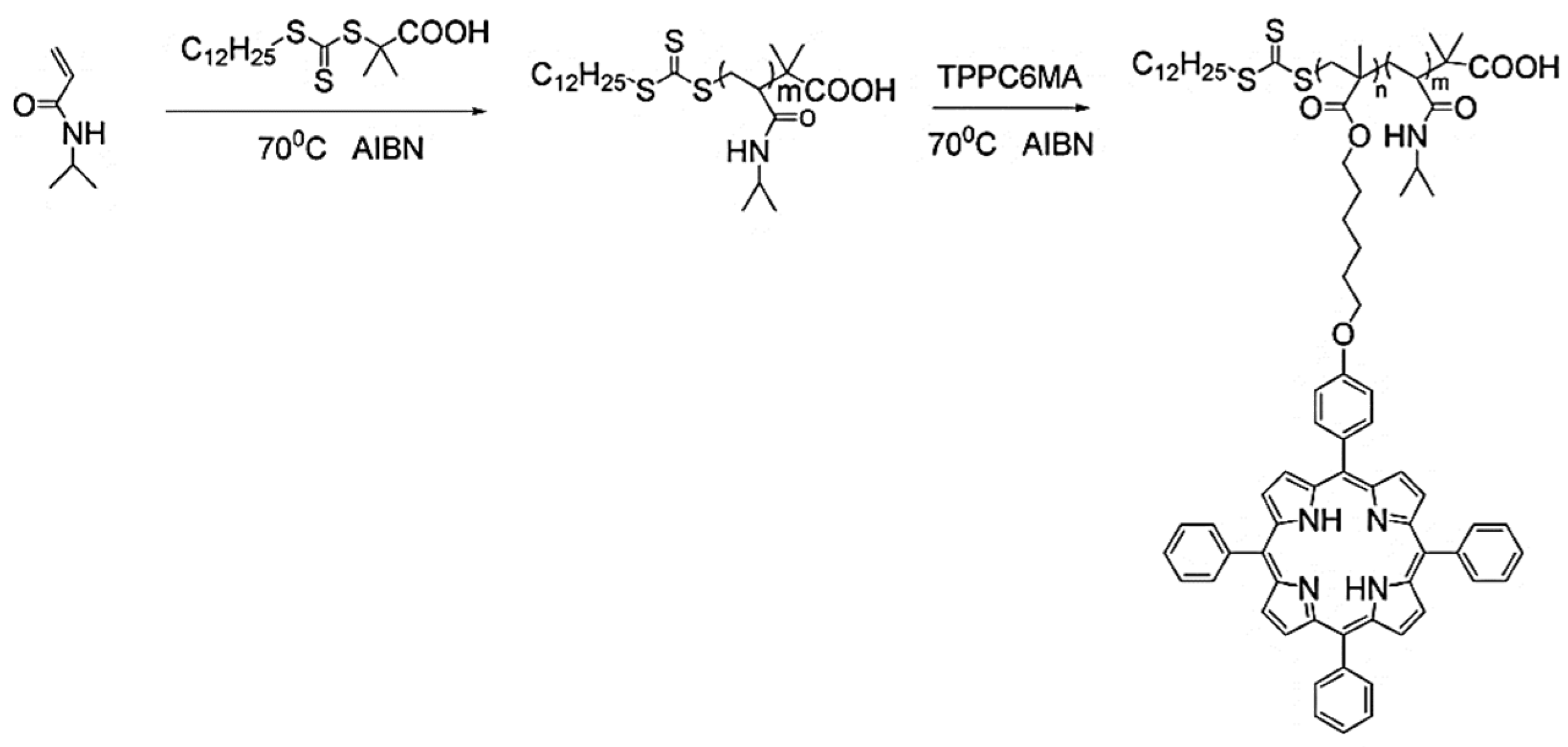

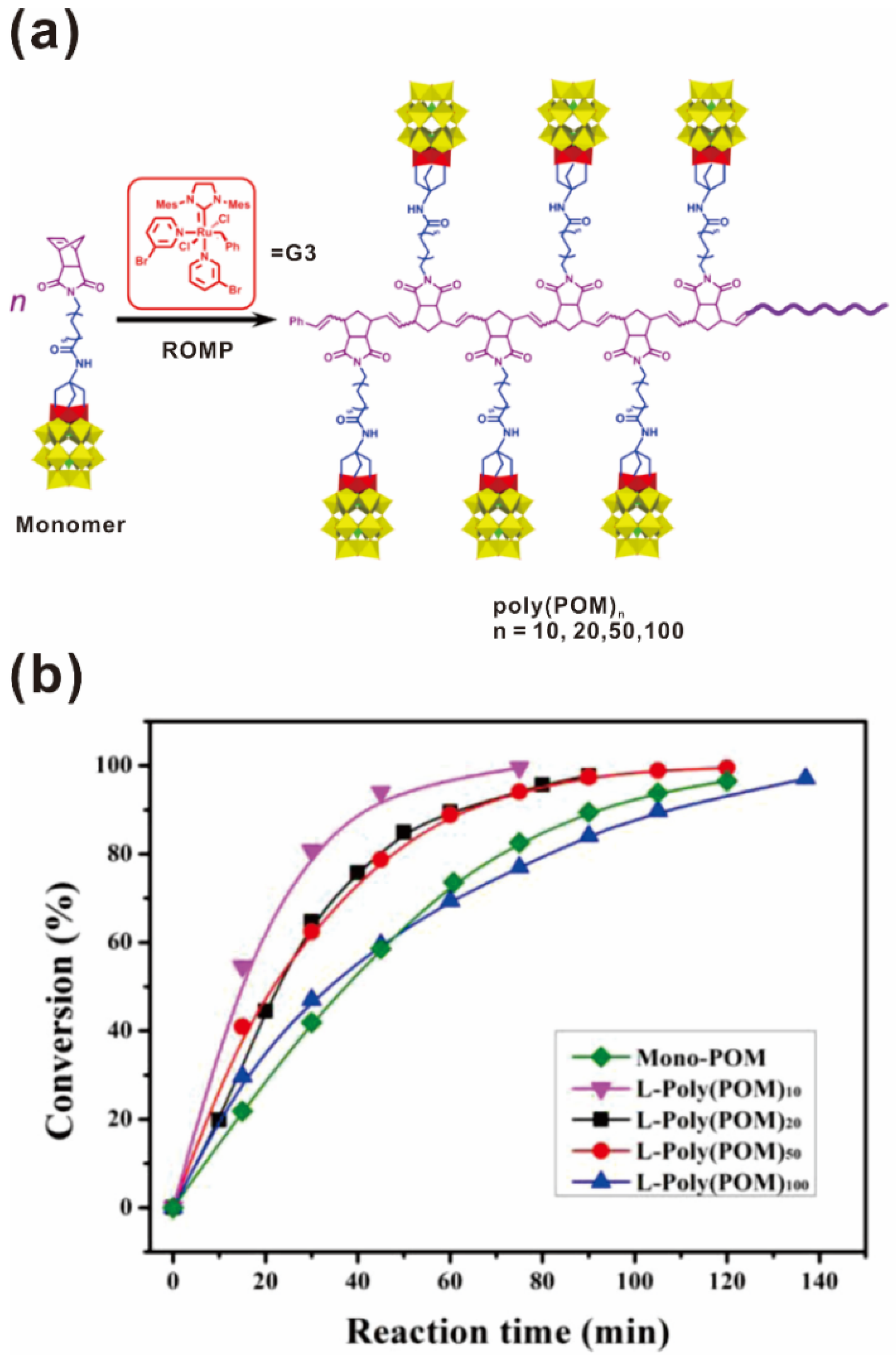

3.1. Polymerization of Metal-Containing or Ligand-Containing Monomers

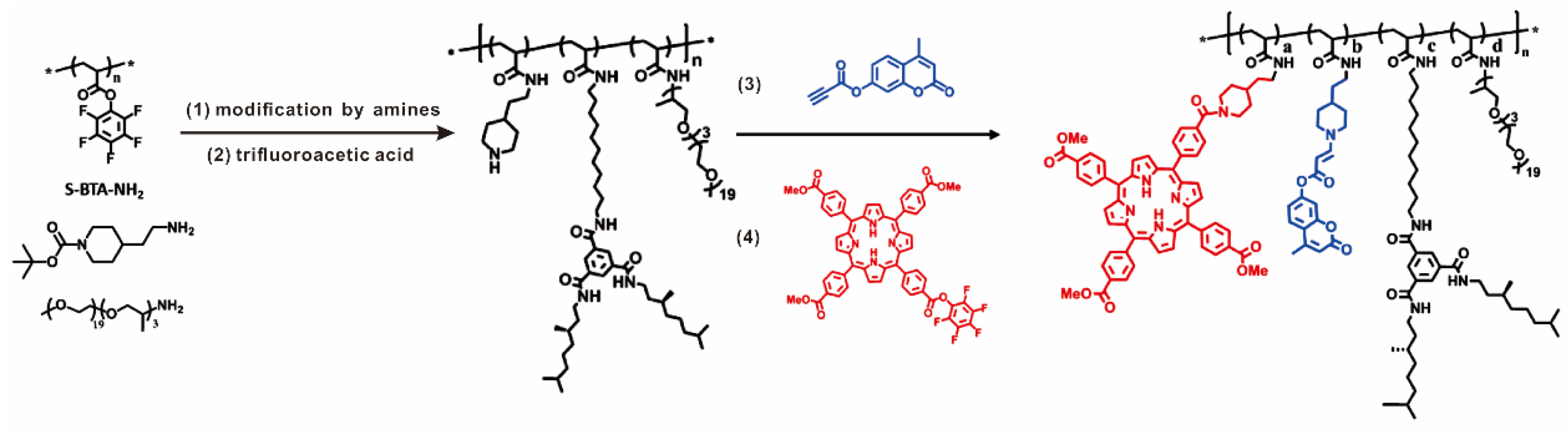

3.2. Post-Modification of Side Groups

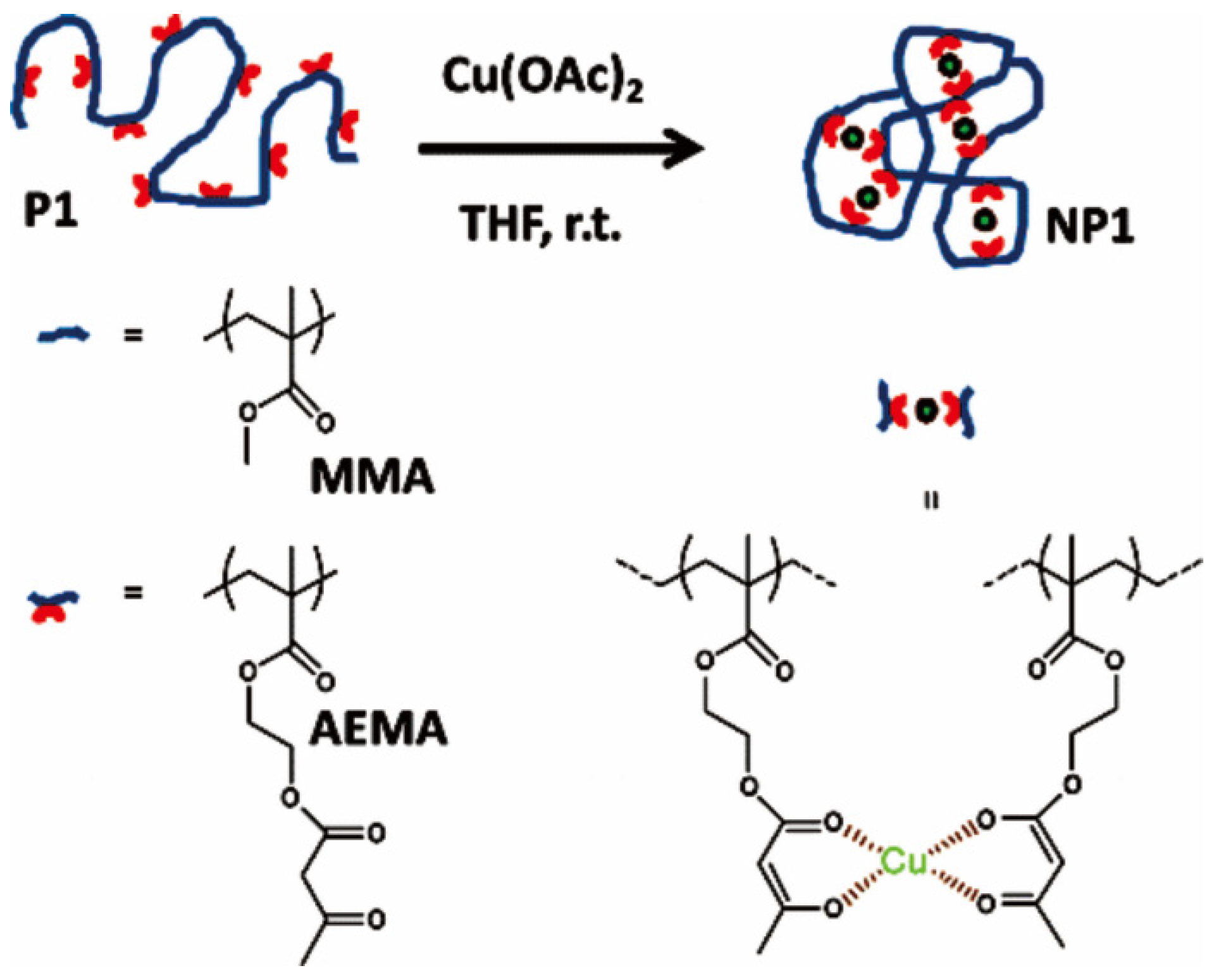

3.3. Metals as Cross-Linkers

4. Applications of SMPs in Catalysis

4.1. Synthesis of Organic Compounds

4.1.1. Oxidation of Sulfide

4.1.2. Hydroformylation of Alkene

4.1.3. Copper-Catalyzed Azide-Alkyne Cycloaddition

4.1.4. Reduction of Nitrophenol

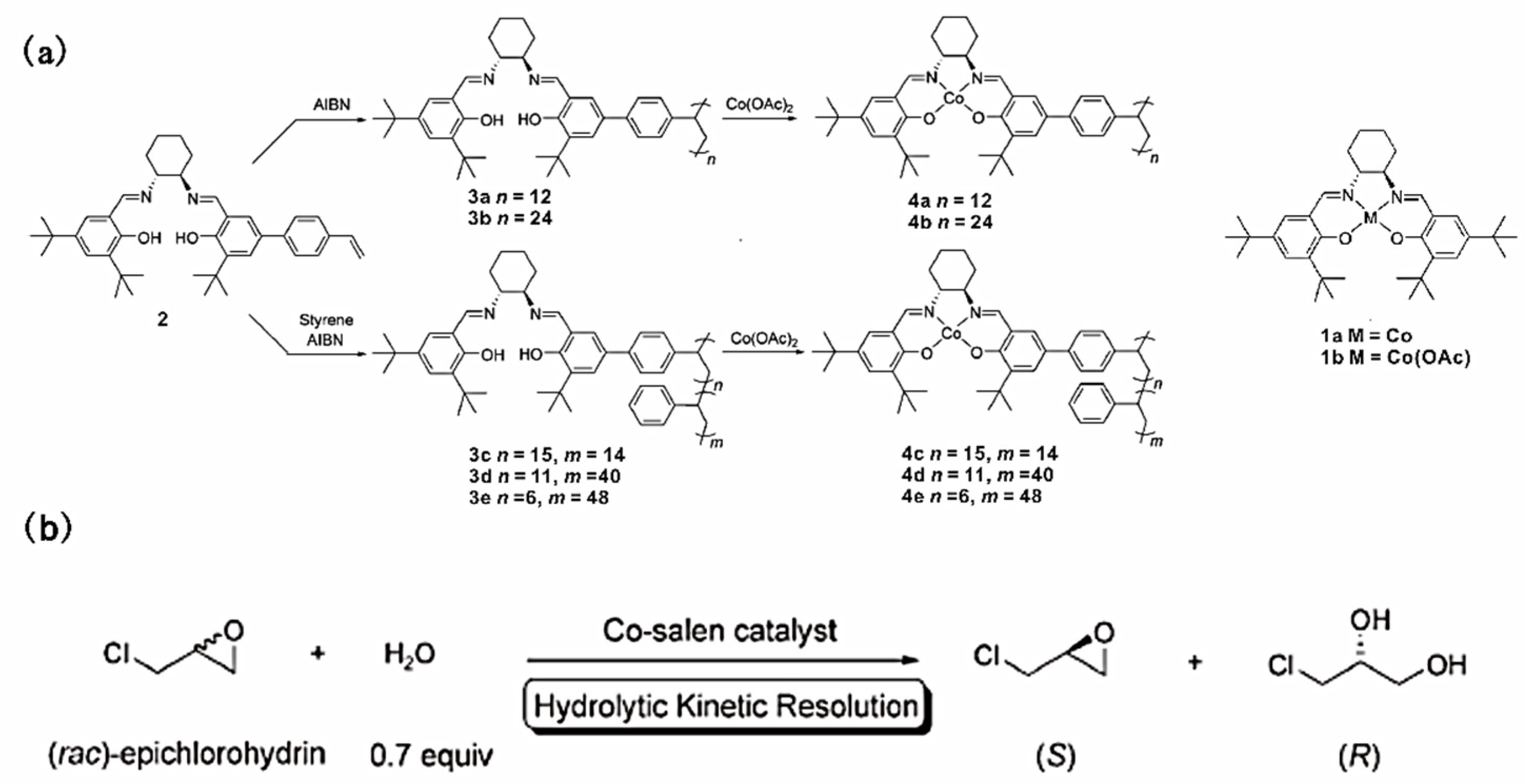

4.1.5. Hydrolytic Kinetic Resolution of Epichlorohydrin

4.2. Synthesis of Polymers

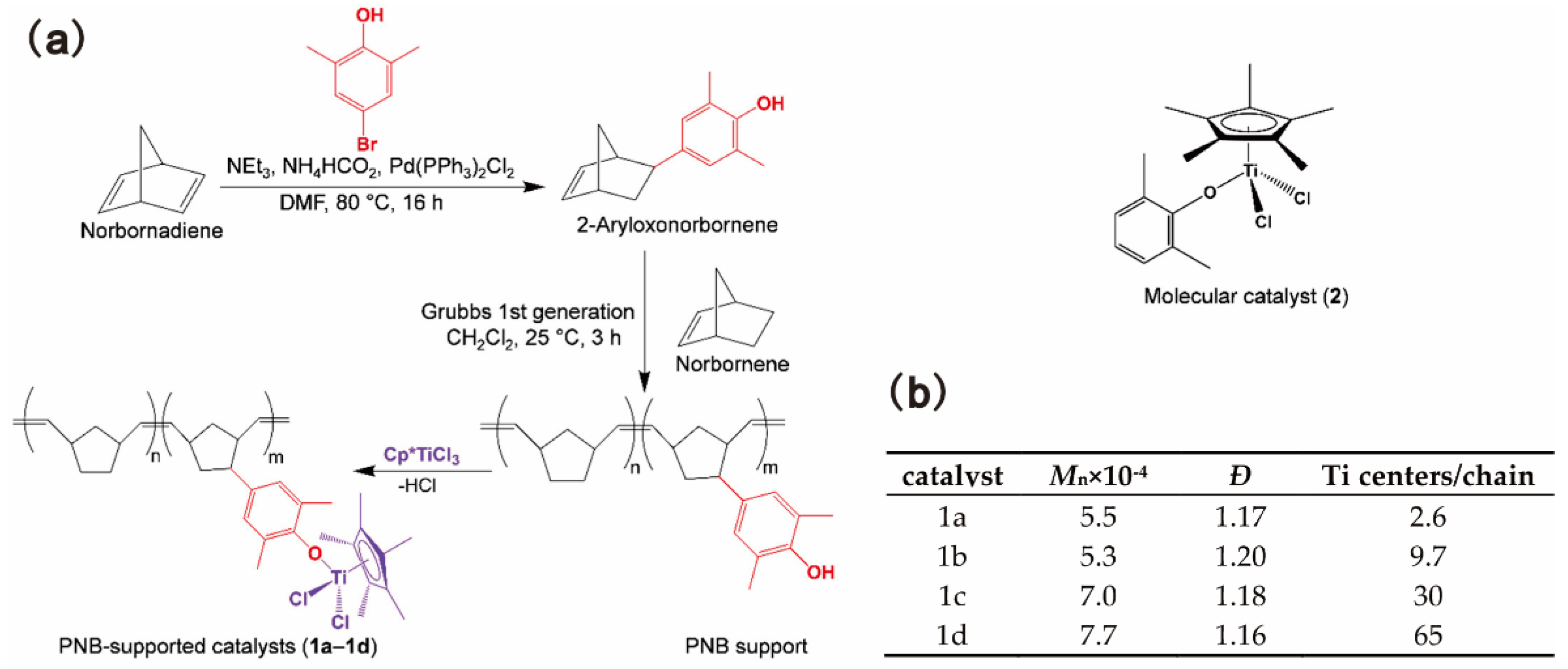

4.2.1. Olefin Polymerization

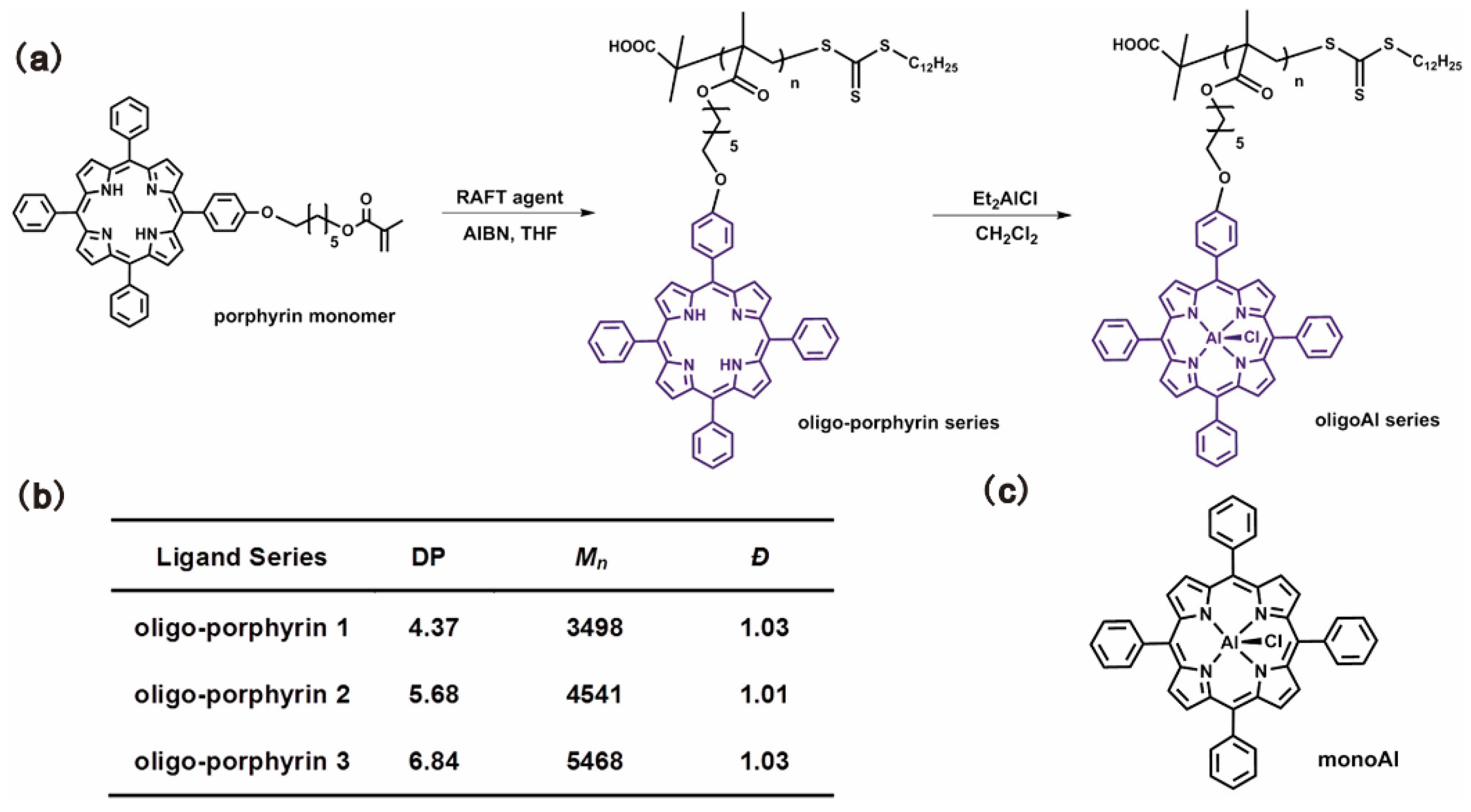

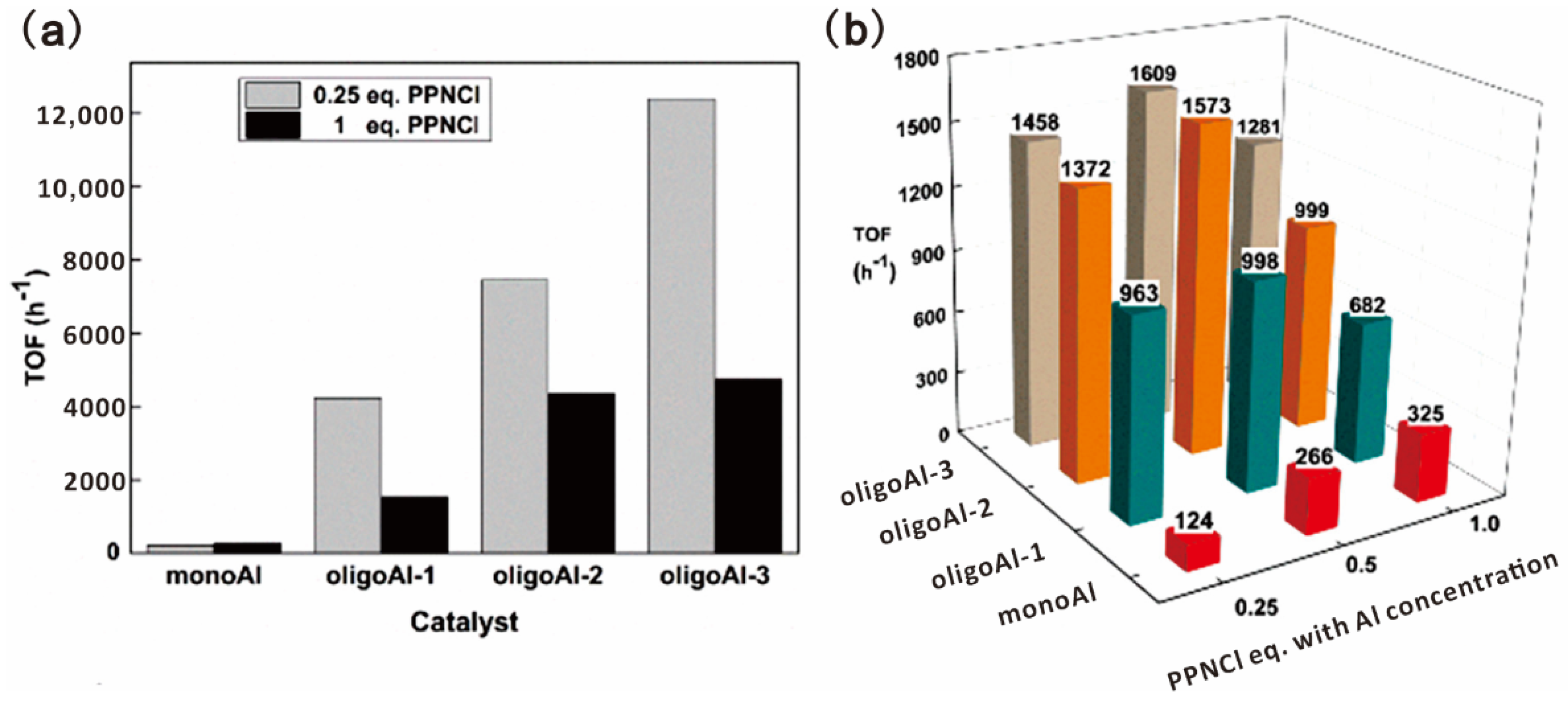

4.2.2. CO2/Epoxides Copolymerization

4.2.3. ATRP

5. Conclusions and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ellis, W.R. Metalloenzymes. In Reviews in Cell Biology and Molecular Medicine, 2nd ed.; Meyers, R.A., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; Volume 8, pp. 209–236. [Google Scholar]

- Torres, E.; Ayala, M. Biocatalysis by Metalloenzymes. In Comprehensive Inorganic Chemistry, 2nd ed.; Reedijk, J., Poeppelmeier, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; Chapter 6.24; pp. 685–735. [Google Scholar]

- Lin, Y.-W. Rational Design of Metalloenzymes: From Single to Multiple Active Sites. Coord. Chem. Rev. 2017, 336, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.; Ren, J.; Qu, X. Catalytically Active Nanomaterials: A Promising Candidate for Artificial Enzymes. Acc. Chem. Res. 2014, 47, 1097–1105. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Dong, Z.; Luo, Q.; Liu, J. Biomimetic Catalysts Designed on Macromolecular Scaffolds. Prog. Polym. Sci. 2012, 37, 1476–1509. [Google Scholar] [CrossRef]

- Chong, Y.; Liu, Q.; Ge, C.C. Advances in Oxidase-mimicking Nanozymes: Classification, Activity Regulation and Biomedical Applications. Nano Today 2021, 37, 101076. [Google Scholar] [CrossRef]

- Murakami, Y.; Kikuchi, J.-I.; Hisaeda, Y.; Hayashida, O. Artificial Enzymes. Chem. Rev. 1996, 96, 721–758. [Google Scholar] [CrossRef]

- Raynal, M.; Ballester, P.; Vidal-Ferran, A.; van Leeuwen, P.W. Supramolecular Catalysis. Part 2: Artificial Enzyme Mimics. Chem. Soc. Rev. 2014, 43, 1734–1787. [Google Scholar] [CrossRef]

- Dong, Z.; Luo, Q.; Liu, J. Artificial Enzymes Based on Supramolecular Scaffolds. Chem. Soc. Rev. 2012, 41, 7890–7908. [Google Scholar] [CrossRef]

- Haak, R.M.; Wezenberg, S.J.; Kleij, A.W. Cooperative Multimetallic Catalysis Using Metallosalens. Chem. Commun. 2010, 46, 2713–2723. [Google Scholar] [CrossRef]

- Sträter, N.; Lipscomb, W.N.; Klabunde, T.; Krebs, B. Two-Metal Ion Catalysis in Enzymatic Acyl- and Phosphoryl-Transfer Reactions. Angew. Chem. Int. Ed. 1996, 35, 2024–2055. [Google Scholar] [CrossRef]

- Mitić, N.; Smith, S.J.; Neves, A.; Guddat, L.W.; Gahan, L.R.; Schenk, G. The Catalytic Mechanisms of Binuclear Metallohydrolases. Chem. Rev. 2006, 106, 3338–3363. [Google Scholar] [CrossRef] [Green Version]

- Winnacker, M.; Vagin, S.; Rieger, B. Cooperative Catalysis in Polymerization Reactions. In Cooperative Catalysis, 1st ed.; Peters, R., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; Chapter 13; pp. 373–416. [Google Scholar]

- Ji, P.; Solomon, J.B.; Lin, Z.M.; Wilders, A.; Jordan, R.F.; Lin, W. Transformation of Metal–Organic Framework Secondary Building Units into Hexanuclear Zr-Alkyl Catalysts for Ethylene Polymerization. J. Am. Chem. Soc. 2017, 139, 11325–11328. [Google Scholar] [CrossRef]

- Zheng, X.; Jones, C.W.; Weck, M. Ring-Expanding Olefin Metathesis: A Route to Highly Active Unsymmetrical Macrocyclic Oligomeric Co-Salen Catalysts for the Hydrolytic Kinetic Resolution of Epoxides. J. Am. Chem. Soc. 2007, 129, 1105–1112. [Google Scholar] [CrossRef]

- Deacy, A.C.; Kilpatrick, A.F.R.; Regoutz, A.; Williams, C.K. Understanding Metal Synergy in Heterodinuclear Catalysts for the Copolymerization of CO2 and Epoxides. Nat. Chem. 2020, 12, 372–380. [Google Scholar] [CrossRef]

- Thakur, A.; Baba, R.; Wada, T.; Chammingkwan, P.; Taniike, T. Cooperative Catalysis by Multiple Active Centers of a Half-Titanocene Catalyst Integrated in Polymer Random coils. ACS Catal. 2019, 9, 3648–3656. [Google Scholar] [CrossRef]

- Cao, H.; Qin, Y.; Zhuo, C.; Wang, X.; Wang, F. Homogeneous Metallic Oligomer Catalyst with Multisite Intramolecular Cooperativity for the Synthesis of CO2-Based Polymers. ACS Catal. 2019, 9, 8669–8676. [Google Scholar] [CrossRef]

- Ferreira, R.B.; Murray, L.J. Cyclophanes as Platforms for Reactive Multimetallic Complexes. Acc. Chem. Res. 2019, 52, 447–455. [Google Scholar] [CrossRef]

- Radlauer, M.R.; Buckley, A.K.; Henling, L.M.; Agapie, T. Bimetallic Coordination Insertion Polymerization of Unprotected Polar Monomers: Copolymerization of Amino Olefins and Ethylene by Dinickel Bisphenoxyiminato Catalysts. J. Am. Chem. Soc. 2013, 135, 3784–3787. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; von Malotki, C.; Arnold, L.; Koshino, N.; Higashimura, H.; Baumgarten, M.; Müllen, K. Triangular Trinuclear Metal-N4 Complexes with High Electrocatalytic Activity for Oxygen Reduction. J. Am. Chem. Soc. 2011, 133, 10372–10375. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, X.; Gong, X.; Xu, D.; Ma, Y. Macrocyclic Trinuclear Nickel Phenoxyimine Catalysts for High-Temperature Polymerization of Ethylene and Isospecific Polymerization of Propylene. Macromolecules 2017, 50, 6561–6568. [Google Scholar] [CrossRef]

- Heurtefeu, B.; Bouilhac, C.; Cloutet, É.; Taton, D.; Deffieux, A.; Cramail, H. Polymer Support of “Single-site” Catalysts for Heterogeneous Olefin Polymerization. Prog. Polym. Sci. 2011, 36, 89–126. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Li, C.; Yan, L.; Jiang, M.; Ding, Y. State-of-the-Art Multifunctional Heterogeneous POP Catalyst for Cooperative Transformation of CO2 to Cyclic Carbonates. ACS Sustain. Chem. Eng. 2017, 5, 4523–4528. [Google Scholar] [CrossRef]

- Mastrorilli, P.; Nobile, C.F. Catalytic Activity of Macromolecules Obtained from Metal-Containing Monomers. In Macromolecules Containing Metal and Metal-Like Elements; Abd-El-Aziz, A.S., Carraher, C.E., Pittman, C.U., Zeldin, M., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 2005; Volume 5, pp. 227–257. [Google Scholar]

- Knapen, J.W.J.; Vandermade, A.W.; Dewilde, J.C.; Vanleeuwen, P.; Wijkens, P.; Grove, D.M.; Vankoten, G. Homogeneous Catalysts Based On Silane Dendrimers Functionalized With Arylnickel(II) Complexes. Nature 1994, 372, 659–663. [Google Scholar] [CrossRef]

- Hardy, C.G.; Zhang, J.; Yan, Y.; Ren, L.; Tang, C. Metallopolymers with Transition Metals in the Side-chain by Living and Controlled Polymerization Techniques. Prog. Polym. Sci. 2014, 39, 1742–1796. [Google Scholar] [CrossRef]

- Rothfuss, H.; Knöfel, N.D.; Roesky, P.W.; Barner-Kowollik, C. Single-Chain Nanoparticles as Catalytic Nanoreactors. J. Am. Chem. Soc. 2018, 140, 5875–5881. [Google Scholar] [CrossRef]

- Rubio-Cervilla, J.; Gonzalez, E.; Pomposo, J.A. Advances in Single-Chain Nanoparticles for Catalysis Applications. Nanomaterials 2017, 7, 341. [Google Scholar] [CrossRef]

- Ouchi, M.; Badi, N.; Lutz, J.F.; Sawamoto, M. Single-chain Technology Using Discrete Synthetic Macromolecules. Nat. Chem. 2011, 3, 917–924. [Google Scholar] [CrossRef]

- Penczek, S.; Pretula, J.B. Fundamental Aspects of Chain Polymerization. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 3, pp. 3–38. [Google Scholar]

- Grubbs, R.B.; Grubbs, R.H. 50th Anniversary Perspective: Living Polymerization—Emphasizing the Molecule in Macromolecules. Macromolecules 2017, 50, 6979–6997. [Google Scholar] [CrossRef]

- Billingham, N.C. Molecular Weight Distributions. In Comprehensive Polymer Science and Supplements; Allen, G., Bevington, J.C., Eds.; Pergamon: Amsterdam, The Netherlands, 1989; Volume 3, pp. 43–57. [Google Scholar]

- Pollard, J.; Bruns, N. Biocatalytic ATRP. In Reversible Deactivation Radical Polymerization: Mechanisms and Synthetic Methodologies; Matyjaszewski, K., Gao, H., Sumerlin, B.S., Tsarevsky, N.V., Eds.; American Chemical Society: Washington, DC, USA, 2018; Chapter 19; pp. 379–393. [Google Scholar]

- Klumperman, B. Reversible Deactivation Radical Polymerization. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Inc.: New York, NY, USA, 2015; pp. 1–27. [Google Scholar]

- Zhu, Z.; Xu, N.; Yu, Q.; Guo, L.; Cao, H.; Lu, X.; Cai, Y. Construction and Self-Assembly of Single-Chain Polymer Nanoparticles via Coordination Association and Electrostatic Repulsion in Water. Macromol. Rapid Commun. 2015, 36, 1521–1527. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, Y.-J.; Kim, B.; Kim, B.; Jung, K.-S.; Paik, H.-J. Colored Single-Chain Polymeric Nanoparticles via Intramolecular Copper Phthalocyanine Formation. Polym. Chem. 2015, 6, 3392–3397. [Google Scholar] [CrossRef]

- Wang, F.; Pu, H.; Jin, M.; Wan, D. Supramolecular Nanoparticles via Single-Chain Folding Driven by Ferrous Ions. Macromol. Rapid Commun. 2016, 37, 330–336. [Google Scholar] [CrossRef]

- Sanchez-Sanchez, A.; Akbari, S.; Etxeberria, A.; Arbe, A.; Gasser, U.; Moreno, A.J.; Colmenero, J.; Pomposo, J.A. “Michael” Nanocarriers Mimicking Transient-Binding Disordered Proteins. ACS Macro Lett. 2013, 2, 491–495. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, J.; Qiao, Y.; Ganewatta, M.; Tang, C. Ruthenocene-Containing Homopolymers and Block Copolymers via ATRP and RAFT Polymerization. Macromolecules 2013, 46, 8816–8823. [Google Scholar] [CrossRef]

- Berki, T.R.; Martinelli, J.; Tei, L.; Willcock, H.; Butler, S.J. Polymerizable Gd(III) Building Blocks for the Synthesis of High Relaxivity Macromolecular MRI Contrast Agents. Chem. Sci. 2021, 12, 3999–4013. [Google Scholar] [CrossRef] [PubMed]

- Bielawski, C.W.; Grubbs, R.H. Living Ring-Opening Metathesis Polymerization. Prog. Polym. Sci. 2007, 32, 1–29. [Google Scholar] [CrossRef]

- Chen, Y.; Abdellatif, M.M.; Nomura, K. Olefin Metathesis Polymerization: Some Recent Developments in the Precise Polymerizations for Synthesis of Advanced Materials (by ROMP, ADMET). Tetrahedron 2018, 74, 619–643. [Google Scholar] [CrossRef]

- Zha, Y.; Thaker, H.D.; Maddikeri, R.R.; Gido, S.P.; Tuominen, M.T.; Tew, G.N. Nanostructured Block-Random Copolymers with Tunable Magnetic Properties. J. Am. Chem. Soc. 2012, 134, 14534–14541. [Google Scholar] [CrossRef]

- Miao, W.-K.; Yan, Y.-K.; Wang, X.-L.; Xiao, Y.; Ren, L.-J.; Zheng, P.; Wang, C.-H.; Ren, L.-X.; Wang, W. Incorporation of Polyoxometalates into Polymers to Create Linear Poly(polyoxometalate)s with Catalytic Function. ACS Macro Lett. 2014, 3, 211–215. [Google Scholar] [CrossRef]

- Tefashe, U.M.; Metera, K.L.; Sleiman, H.F.; Mauzeroll, J. Electrogenerated Chemiluminescence of Iridium-Containing ROMP Block Copolymer and Self-Assembled Micelles. Langmuir 2013, 29, 12866–12873. [Google Scholar] [CrossRef]

- Metera, K.L.; Hänni, K.D.; Zhou, G.; Nayak, M.K.; Bazzi, H.S.; Juncker, D.; Sleiman, H.F. Luminescent Iridium(III)-Containing Block Copolymers: Self-Assembly into Biotin-Labeled Micelles for Biodetection Assays. ACS Macro Lett. 2012, 1, 954–959. [Google Scholar] [CrossRef]

- Pawar, G.M.; Bantu, B.; Weckesser, J.; Blechert, S.; Wurst, K.; Buchmeiser, M.R. Ring-Opening Metathesis Polymerization-Derived, Polymer-Bound Cu-catalysts for Click-Chemistry and Hydrosilylation Reactions under Micellar Conditions. Dalton Trans. 2009, 41, 9043–9051. [Google Scholar] [CrossRef]

- Sutthasupa, S.; Shiotsuki, M.; Sanda, F. Recent Advances in Ring-Opening Metathesis Polymerization, and Application to Synthesis of Functional Materials. Polym. J. 2010, 42, 905–915. [Google Scholar] [CrossRef]

- Parker, K.A.; Sampson, N.S. Precision Synthesis of Alternating Copolymers via Ring-Opening Polymerization of 1-Substituted Cyclobutenes. Acc. Chem. Res. 2016, 49, 408–417. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez, H.; Ren, N.; Matta, M.E.; Hillmyer, M.A. Ring-Opening Metathesis Polymerization of 8-Membered Cyclic Olefins. Polym. Chem. 2014, 5, 3507–3532. [Google Scholar] [CrossRef]

- Mavila, S.; Diesendruck, C.E.; Linde, S.; Amir, L.; Shikler, R.; Lemcoff, N.G. Polycyclooctadiene Complexes of Rhodium(I): Direct Access to Organometallic Nanoparticles. Angew. Chem. Int. Ed. 2013, 52, 5767–5770. [Google Scholar] [CrossRef]

- Revanur, R.; McCloskey, B.; Breitenkamp, K.; Freeman, B.D.; Emrick, T. Reactive Amphiphilic Graft Copolymer Coatings Applied to Poly (vinylidene fluoride) Ultrafiltration Membranes. Macromolecules 2007, 40, 3624–3630. [Google Scholar] [CrossRef]

- Janiak, C. Metallocene and Related Catalysts for Olefin, Alkyne and Silane Dimerization and Oligomerization. Coord. Chem. Rev. 2006, 250, 66–94. [Google Scholar] [CrossRef]

- Bermeshev, M.; Chapala, P. Addition Polymerization of Functionalized Norbornenes as a Powerful Tool for Assembling Molecular Moieties of New Polymers with Versatile Properties. Prog. Polym. Sci. 2018, 84, 1–46. [Google Scholar] [CrossRef]

- Jiang, X.; Li, R.; Feng, C.; Lu, G.; Huang, X. Triple-Stimuli-Responsive Ferrocene-Containing Homopolymers by RAFT Polymerization. Polym. Chem. 2017, 8, 2773–2784. [Google Scholar] [CrossRef] [Green Version]

- Shi, M.; Li, A.-L.; Liang, H.; Lu, J. Reversible Addition−Fragmentation Transfer Polymerization of a Novel Monomer Containing Both Aldehyde and Ferrocene Functional Groups. Macromolecules 2007, 40, 1891–1896. [Google Scholar] [CrossRef]

- Sankaran, N.B.; Rys, A.Z.; Nassif, R.; Nayak, M.K.; Metera, K.; Chen, B.; Bazzi, H.S.; Sleiman, H.F. Ring-Opening Metathesis Polymers for Biodetection and Signal Amplification: Synthesis and Self-Assembly. Macromolecules 2010, 43, 5530–5537. [Google Scholar] [CrossRef]

- Kim, T.; Lim, S.; Park, S.-R.; Han, C.J.; Lee, M.H. Polynorbornene Copolymer with Side-Chain Triarylborane and Iridium (III) Groups: An Emissive Layer Material with Electron Transporting Properties for PhOLEDs. Polymer 2015, 66, 67–75. [Google Scholar] [CrossRef]

- Zhang, W.; Lai, W.; Cao, R. Energy-Related Small Molecule Activation Reactions: Oxygen Reduction and Hydrogen and Oxygen Evolution Reactions Catalyzed by Porphyrin- and Corrole-Based Systems. Chem. Rev. 2017, 117, 3717–3797. [Google Scholar] [CrossRef] [PubMed]

- Anderson, C.E.; Vagin, S.I.; Xia, W.; Jin, H.P.; Rieger, B. Cobaltoporphyrin-Catalyzed CO2/Epoxide Copolymerization: Selectivity Control by Molecular Design. Macromolecules 2012, 45, 6840–6849. [Google Scholar] [CrossRef]

- Xu, L.; Liu, L.; Liu, F.; Cai, H.; Zhang, W. Porphyrin-Containing Amphiphilic Block Copolymers for Photodynamic Therapy. Polym. Chem. 2015, 6, 2945–2954. [Google Scholar] [CrossRef]

- Zheng, X.; Jones, C.W.; Weck, M. Poly(styrene)-Supported Co-Salen Complexes as Efficient Recyclable Catalysts for the Hydrolytic Kinetic Resolution of Epichlorohydrin. Chem.—A Eur. J. 2005, 12, 576–583. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Rapakousiou, A.; Astruc, D. ROMP Synthesis of Cobalticenium–Enamine Polyelectrolytes. Macromolecules 2014, 47, 3767–3774. [Google Scholar] [CrossRef]

- Wang, X.Y.; Kimyonok, A.; Weck, M. Functionalization of Polymers with Phosphorescent Iridium Complexes via Click Chemistry. Chem. Commun. 2006, 37, 3933–3935. [Google Scholar] [CrossRef]

- Liu, Y.; Pauloehrl, T.; Presolski, S.I.; Albertazzi, L.; Palmans, A.R.A.; Meijer, E.W. Modular Synthetic Platform for the Construction of Functional Single-Chain Polymeric Nanoparticles: From Aqueous Catalysis to Photosensitization. J. Am. Chem. Soc. 2015, 137, 13096–13105. [Google Scholar] [CrossRef]

- Blazquez-Martín, A.; Verde-Sesto, E.; Moreno, A.J.; Arbe, A.; Colmenero, J.; Pomposo, J.A. Advances in the Multi-Orthogonal Folding of Single Polymer Chains into Single-Chain Nanoparticles. Polymers 2021, 13, 293. [Google Scholar] [CrossRef]

- Gonzalez-Burgos, M.; Latorre-Sanchez, A.; Pomposo, J.A. Advances in Single Chain Technology. Chem. Soc. Rev. 2015, 44, 6122–6142. [Google Scholar] [CrossRef] [Green Version]

- Bai, Y.; Feng, X.; Xing, H.; Xu, Y.; Kim, B.K.; Baig, N.; Zhou, T.; Gewirth, A.A.; Lu, Y.; Oldfield, E.; et al. A Highly Efficient Single-Chain Metal–Organic Nanoparticle Catalyst for Alkyne–Azide “Click” Reactions in Water and in Cells. J. Am. Chem. Soc. 2016, 138, 11077–11080. [Google Scholar] [CrossRef] [PubMed]

- Yamada, Y.M.A.; Sarkar, S.M.; Uozumi, Y. Amphiphilic Self-Assembled Polymeric Copper Catalyst to Parts per Million Levels: Click Chemistry. J. Am. Chem. Soc. 2012, 134, 9285–9290. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Sanchez, A.; Arbe, A.; Colmenero, J.; Pomposo, J.A. Metallo-Folded Single-Chain Nanoparticles with Catalytic Selectivity. ACS Macro Lett. 2014, 3, 439–443. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Wang, J.; Bai, Y.; Li, K.; Garcia, E.S.; Ferguson, A.L.; Zimmerman, S.C. Enzyme-like Click Catalysis by a Copper-Containing Single-Chain Nanoparticle. J. Am. Chem. Soc. 2018, 140, 13695–13702. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-L.; Miao, W.-K.; Ren, L.-J.; Yan, Y.-K.; Lin, Y.; Wang, W. Twining Poly(polyoxometalate) Chains into Nanoropes. Chem.—A Eur. J. 2019, 25, 13396–13401. [Google Scholar] [CrossRef]

- Miao, W.-K.; Yi, A.; Yan, Y.-K.; Ren, L.-J.; Chen, D.; Wang, C.-H.; Wang, W. A Poly(polyoxometalate)-b-Poly(hexanoic acid) Block Copolymer: Synthesis, Self-Assembled Micelles and Catalytic Activity. Polym. Chem. 2015, 6, 7418–7426. [Google Scholar] [CrossRef]

- Lu, Z.-Q.; Zhang, L.-L.; Yan, Y.; Wang, W. Polyelectrolytes of Inorganic Polyoxometalates: Acids, Salts, and Complexes. Macromolecules 2021, 54, 6891–6900. [Google Scholar] [CrossRef]

- Pawar, G.M.; Weckesser, J.; Blechert, S.; Buchmeiser, M.R. Ring Opening Metathesis Polymerization-Derived Block Copolymers Bearing Chelating Ligands: Synthesis, Metal Immobilization and Use in Hydroformylation Under Micellar Conditions. Beilstein J. Org. Chem. 2010, 6, 28. [Google Scholar] [CrossRef] [Green Version]

- Huang, P.-T.; Chen, Y.-N.; Chen, K.-C.; Wu, S.-H.; Liu, C.-P. Confinement of Silver Nanoparticles in Polystyrenes Through Molecular Entanglements and Their Application for Catalytic Reduction of 4-Nitrophenol. J. Mater. Chem. A 2019, 7, 20919–20925. [Google Scholar] [CrossRef]

- Thakur, A.; Baba, R.; Chammingkwan, P.; Terano, M.; Taniike, T. Synthesis of Aryloxide-Containing Half-Titanocene Catalysts Grafted to Soluble Polynorbornene Chains and Their Application in Ethylene Polymerization: Integration of Multiple Active Centres in a Random coil. J. Catal. 2018, 357, 69–79. [Google Scholar] [CrossRef]

- Dong, Z.; Huang, W.; Liu, X.; Yu, F.; Long, C.; Feng, S.; Luo, L.; Chen, Z.-R. Molecular Bottlebrush Supported Mono(phenoxy–imine) Metal Complexes: Synthesis and Ethylene Polymerization. Macromolecules 2021, 54, 9385–9392. [Google Scholar] [CrossRef]

- Cao, H.; Gong, R.N.; Zhou, Z.Z.; Wang, X.H.; Wang, F.S. Precise Synthesis of Functional Carbon Dioxide-polyols. Acta Polym. Sin. 2021, 52, 1006–1014. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, R.; Zhou, Z.; Liu, S.; Tao, Y.; Wang, F.; Wang, X. On-Demand Transformation of Carbon Dioxide into Polymers Enabled by a Comb-Shaped Metallic Oligomer Catalyst. ACS Catal. 2021, 12, 481–490. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, J.; Wilbon, P.; Qiao, Y.; Tang, C. Ring-Opening Metathesis Polymerization of 18-e Cobalt(I)-Containing Norbornene and Application as Heterogeneous Macromolecular Catalyst in Atom Transfer Radical Polymerization. Macromol. Rapid Commun. 2014, 35, 1840–1845. [Google Scholar] [CrossRef] [PubMed]

- Dolbecq, A.; Dumas, E.; Mayer, C.R.; Mialane, P. Hybrid Organic−Inorganic Polyoxometalate Compounds: From Structural Diversity to Applications. Chem. Rev. 2010, 110, 6009–6048. [Google Scholar] [CrossRef] [PubMed]

- Neumann, R. Polyoxometalate Complexes in Organic Oxidation Chemistry. In Progress in Inorganic Chemistry; Karlin, K.D., Ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1998; Volume 47, pp. 317–370. [Google Scholar]

- Cornils, B.; Herrmann, W.A.; Eckl, R.W. Industrial Aspects of Aqueous Catalysis. J. Mol. Catal. A Chem. 1997, 116, 27–33. [Google Scholar] [CrossRef]

- Bantu, B.; Wurst, K.; Buchmeiser, M.R. N-Acetyl-N,N-Dipyrid-2-Yl (cyclooctadiene) Rhodium (I) and Iridium (I) Complexes: Synthesis, X-ray Structures, Their Use in Hydroformylation and Carbonyl Hydrosilylation Reactions and in the Polymerization of Diazocompounds. J. Organomet. Chem. 2007, 692, 5272–5278. [Google Scholar] [CrossRef]

- Ungváry, F. Application of Transition Metals in Hydroformylation Annual Survey Covering the Year 2004. Coord. Chem. Rev. 2005, 249, 2946–2961. [Google Scholar] [CrossRef]

- Kolb, H.C.; Finn, M.G.; Sharpless, K.B. Click Chemistry: Diverse Chemical Function from a Few Good Reactions. Angew. Chem. Int. Ed. 2001, 40, 2004–2021. [Google Scholar] [CrossRef]

- Rostovtsev, V.V.; Green, L.G.; Fokin, V.V.; Sharpless, K.B. A Stepwise Huisgen Cycloaddition Process: Copper(I)-Catalyzed Regioselective “Ligation” of Azides and Terminal Alkynes. Angew. Chem. Int. Ed. 2002, 41, 2596–2599. [Google Scholar] [CrossRef]

- Deraedt, C.; Pinaud, N.; Astruc, D. Recyclable Catalytic Dendrimer Nanoreactor for Part-Per-Million CuI Catalysis of “Click” Chemistry in Water. J. Am. Chem. Soc. 2014, 136, 12092–12098. [Google Scholar] [CrossRef] [PubMed]

- Rode, C.V.; Vaidya, M.J.; Chaudhari, R.V. Synthesis of p-Aminophenol by Catalytic Hydrogenation of Nitrobenzene. Org. Process Res. Dev. 1999, 3, 465–470. [Google Scholar] [CrossRef]

- Lin, F.-H.; Doong, R.-A. Highly Efficient Reduction of 4-Nitrophenol by Heterostructured Gold-Magnetite Nanocatalysts. Appl. Catal. A 2014, 486, 32–41. [Google Scholar] [CrossRef]

- Wunder, S.; Polzer, F.; Lu, Y.; Mei, Y.; Ballauff, M. Kinetic Analysis of Catalytic Reduction of 4-Nitrophenol by Metallic Nanoparticles Immobilized in Spherical Polyelectrolyte Brushes. J. Phys. Chem. C 2010, 114, 8814–8820. [Google Scholar] [CrossRef]

- Saha, S.; Pal, A.; Kundu, S.; Basu, S.; Pal, T. Photochemical Green Synthesis of Calcium-Alginate-Stabilized Ag and Au Nanoparticles and Their Catalytic Application to 4-Nitrophenol Reduction. Langmuir 2010, 26, 2885–2893. [Google Scholar] [CrossRef]

- Horecha, M.; Kaul, E.; Horechyy, A.; Stamm, M. Polymer Microcapsules Loaded with Ag Nanocatalyst as Active Microreactors. J. Mater. Chem. A 2014, 2, 7431–7438. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Loebach, J.L.; Wilson, S.R.; Jacobsen, E.N. Enantioselective Epoxidation of Unfunctionalized Olefins Catalyzed by Salen Manganese Complexes. J. Am. Chem. Soc. 1990, 112, 2801–2803. [Google Scholar] [CrossRef]

- Schaus, S.E.; Brandes, B.D.; Larrow, J.F.; Tokunaga, M.; Hansen, K.B.; Gould, A.E.; Furrow, M.E.; Jacobsen, E.N. Highly Selective Hydrolytic Kinetic Resolution of Terminal Epoxides Catalyzed by Chiral (Salen)CoIII Complexes. Practical Synthesis of Enantioenriched Terminal Epoxides and 1,2-Diols. J. Am. Chem. Soc. 2002, 124, 1307–1315. [Google Scholar] [CrossRef]

- Schaus, S.E.; Brånalt, J.; Jacobsen, E.N. Asymmetric Hetero-Diels−Alder Reactions Catalyzed by Chiral (Salen)Chromium(III) Complexes. J. Org. Chem. 1998, 63, 403–405. [Google Scholar] [CrossRef]

- Sammis, G.M.; Danjo, H.; Jacobsen, E.N. Cooperative Dual Catalysis: Application to the Highly Enantioselective Conjugate Cyanation of Unsaturated Imides. J. Am. Chem. Soc. 2004, 126, 9928–9929. [Google Scholar] [CrossRef]

- Delferro, M.; Marks, T.J. Multinuclear Olefin Polymerization Catalysts. Chem. Rev. 2011, 111, 2450–2485. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Metz, M.V.; Li, H.; Chen, M.-C.; Marks, T.J.; Liable-Sands, L.; Rheingold, A.L. Catalyst/Cocatalyst Nuclearity Effects in Single-Site Polymerization. Enhanced Polyethylene Branching and α-Olefin Comonomer Enchainment in Polymerizations Mediated by Binuclear Catalysts and Cocatalysts via a New Enchainment Pathway. J. Am. Chem. Soc. 2002, 124, 12725–12741. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Motta, A.; Mouat, A.R.; Delferro, M.; Marks, T.J. Very Large Cooperative Effects in Heterobimetallic Titanium-Chromium Catalysts for Ethylene Polymerization/Copolymerization. J. Am. Chem. Soc. 2014, 136, 10460–10469. [Google Scholar] [CrossRef] [PubMed]

- McInnis, J.P.; Delferro, M.; Marks, T.J. Multinuclear Group 4 Catalysis: Olefin Polymerization Pathways Modified by Strong Metal–Metal Cooperative Effects. Acc. Chem. Res. 2014, 47, 2545–2557. [Google Scholar] [CrossRef]

- Xie, G.; Martinez, M.R.; Olszewski, M.; Sheiko, S.S.; Matyjaszewski, K. Molecular Bottlebrushes as Novel Materials. Biomacromolecules 2019, 20, 27–54. [Google Scholar] [CrossRef]

- Kember, M.R.; Knight, P.D.; Reung, P.T.R.; Williams, C.K. Highly Active Dizinc Catalyst for the Copolymerization of Carbon Dioxide and Cyclohexene Oxide at One Atmosphere Pressure. Angew. Chem. Int. Ed. 2009, 48, 931–933. [Google Scholar] [CrossRef]

- Lee, B.Y.; Kwon, H.Y.; Lee, S.Y.; Na, S.J.; Han, S.-I.; Yun, H.; Lee, H.; Park, Y.-W. Bimetallic Anilido-Aldimine Zinc Complexes for Epoxide/CO2 Copolymerization. J. Am. Chem. Soc. 2005, 127, 3031–3037. [Google Scholar] [CrossRef]

- Moore, D.R.; Cheng, M.; Lobkovsky, E.B.; Coates, G.W. Mechanism of the Alternating Copolymerization of Epoxides and CO2 Using beta-Diiminate Zinc Catalysts: Evidence for a Bimetallic Epoxide Enchainment. J. Am. Chem. Soc. 2003, 125, 11911–11924. [Google Scholar] [CrossRef]

- Ohkawara, T.; Suzuki, K.; Nakano, K.; Mori, S.; Nozaki, K. Facile Estimation of Catalytic Activity and Selectivities in Copolymerization of Propylene Oxide with Carbon Dioxide Mediated by Metal Complexes with Planar Tetradentate Ligand. J. Am. Chem. Soc. 2014, 136, 10728–10735. [Google Scholar] [CrossRef]

- Deacy, A.C.; Durr, C.B.; Williams, C.K. Heterodinuclear Complexes Featuring Zn(II) and M = Al(III), Ga(III) or In(III) for Cyclohexene Oxide and CO2 Copolymerisation. Dalton Trans. 2020, 49, 223–231. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Yu, Y.; Xu, S.; Wang, B. Controlled/“Living” Radical Polymerization of Methyl Methacrylate Catalyzed by CpCo(I) Complexes Conveniently Generated from Cobaltocene in situ. Polymer 2009, 50, 2258–2263. [Google Scholar] [CrossRef]

- Hibi, Y.; Ouchi, M.; Sawamoto, M. Sequence-Regulated Radical Polymerization with a Metal-Templated Monomer: Repetitive ABA Sequence by Double Cyclopolymerization. Angew. Chem. Int. Ed. 2011, 50, 7434–7437. [Google Scholar] [CrossRef] [PubMed]

- Badi, N.; Lutz, J.-F. Sequence Control in Polymer Synthesis. Chem. Soc. Rev. 2009, 38, 3383–3390. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pfeifer, S.; Lutz, J.-F. A Facile Procedure for Controlling Monomer Sequence Distribution in Radical Chain Polymerizations. J. Am. Chem. Soc. 2007, 129, 9542–9543. [Google Scholar] [CrossRef]

- Pfeifer, S.; Zarafshani, Z.; Badi, N.; Lutz, J.-F. Liquid-Phase Synthesis of Block Copolymers Containing Sequence-Ordered Segments. J. Am. Chem. Soc. 2009, 131, 9195–9197. [Google Scholar] [CrossRef]

- Satoh, K.; Ozawa, S.; Mizutani, M.; Nagai, K.; Kamigaito, M. Sequence-Regulated Vinyl Copolymers by Metal-Catalysed Step-Growth Radical Polymerization. Nat. Commun. 2010, 1, 6. [Google Scholar] [CrossRef]

- Hibi, Y.; Tokuoka, S.; Terashima, T.; Ouchi, M.; Sawamoto, M. Design of AB Divinyl “Template Monomers” Toward Alternating Sequence Control in Metal-catalyzed Living Radical Polymerization. Polym. Chem. 2011, 2, 341–347. [Google Scholar] [CrossRef]

| No. | Reaction | Reaction Type | Catalytic System | Preparation Method | Refs. |

|---|---|---|---|---|---|

| 1 | oxidation of sulfide | synthesis of organic compounds | poly(POM)s | PMM 1 | [45,73,74,75] |

| 2 | hydroformylation of alkene | Rh-SMPs | post-modification | [76] | |

| 3 | CuAAC | Cu-Nanoparticles | metals as crosslinkers | [36,69,72] | |

| 4 | reduction of nitrophenol | Ag-SMPs | post-modification | [77] | |

| 5 | HKR of epichlorohydrin | Co-SMPs | PLM 2 | [63] | |

| 6 | olefin polymerization | synthesis of polymers | Ti/Zr-SMPs | post-modification | [17,78,79] |

| 7 | CO2/epoxide copolymerization | Al-SMPs | PLM | [18,80,81] | |

| 8 | ATRP | Co-SMPs | PMM | [82] |

| Catalysts | [M]/[G3] | Mn, Theo (kDa) | Mw, SEC (kDa) | Đ |

|---|---|---|---|---|

| Mono-POM | 5.8 | 5.5 | 1.16 | |

| L-Poly(POM)10 | 10/1 | 58.3 | 59.4 | 1.09 |

| L-Poly(POM)20 | 20/1 | 116.7 | 116.7 | 1.07 |

| L-Poly(POM)50 | 50/1 | 291.6 | 270.9 | 1.15 |

| L-Poly(POM)100 | 100/1 | 583.3 | 774.9 | 1.15 |

| No. | Catalyst | Solvent | TON 2 | TOF | n:iso |

|---|---|---|---|---|---|

| 1 | poly(M1-b-M2)-Rh | water | 3800 | 1200 | 1.5 |

| 2 | C1 | toluene | 4500 | 2700 | 0.9 |

| Cu-MONP Level (ppm) | Cu Level (ppm) | NaAsc | t (h) | T (°C) | Yield (%) |

|---|---|---|---|---|---|

| 1.0 | 10 | + | 24 | 50 | 58 |

| 2.5 | 25 | + | 24 | 50 | >99 |

| 5.0 | 50 | + | 24 | 50 | >99 |

| 10 | 100 | + | 24 | 50 | >99 |

| 2.5 | 25 | + | 72 | 25 | >99 |

| 0 | 25 1 | + | 336 | 25 | 9 2 |

| 2.5 | 25 | − | 336 | 25 | 9 2 |

| 0 | 0 | − | 24 | 50 | 9 2 |

| 0 | 25 | + | 24 | 50 | 9 2 |

| Catalyst | Solvent | Ag Concentration (mg mL−1) | kapp (min−1) | Ref. |

|---|---|---|---|---|

| AgNPs/SiO2 | THF/water 9/1 (v/v) | 5.4 × 10−4 | 0.0382 | [95] |

| MC(AgNPs/SiO2) 1 | 5.1 × 10−4 | 0.2089 | ||

| L-PS-AgNPs | 5.8 × 10−4 | 0.0797 | [77] | |

| H-PS-AgNPs | 5.0 × 10−4 | 0.3880 |

| No. | Catalyst | t (h) | Conv. (%) | ee 1 (%) |

|---|---|---|---|---|

| 1 | 1a | 1.0 | 49 | 93 |

| 2 | 4a | 1.0 | 47 | 81 |

| 3 | 4b | 1.0 | 48 | 83 |

| 4 | 4c | 1.0 | 50 | 90 |

| 5 | 4d | 1.0 | 54 | 99 |

| 6 | 4e | 1.0 | 54 | 99 |

| No. | Catalyst | Activity ((kg of PE)/((mol of Ti) h)) | Mw × 10−5 | Đ |

|---|---|---|---|---|

| 1 | 2 | 16,400 ± 390 | 5.7 | 2.5 |

| 2 | 1a | 22,100 ± 50 | 6.5 | 2.9 |

| 3 | 1b | 22,800 ± 100 | 6.2 | 2.9 |

| 4 | 1c | 28,600 ± 110 | 4.9 | 2.3 |

| 5 | 1d | 29,800 ± 200 | 5.8 | 2.6 |

| No. | Catalysts | wm (%) 1 | Activity 2 | Mw (kDa) | Đ |

|---|---|---|---|---|---|

| 1 | A-Ti-1 | 9 | 2295 | 1.69 | |

| 2 | B-Ti-1 | 11 | 1704 | 2.88 | |

| 3 | MB-Ti-1 | 0.97 | 41 | 2051 | 3.35 |

| 4 | MB-Ti-2 | 0.99 | 100 | 298 | 3.41 |

| 5 | MB-Ti-3 | 0.85 | 50 | 568 | 1.76 |

| 6 | MB-Ti-4 | 0.78 | 369 | 83 | 2.20 |

| 7 | A-Zr-1 | 15 | 1309 | 2.88 | |

| 8 | B-Zr-1 | 23 | 4095 | 1.52 | |

| 9 | MB-Zr-1 | 2.50 | 16 | 260 | 4.24 |

| 10 | MB-Zr-2 | 3.00 | 22 | 188 | 13.20 |

| 11 | MB-Zr-3 | 2.53 | 460 | 372 | 6.72 |

| 12 | MB-Zr-4 | 2.63 | 461 | 496 | 4.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, R.; Suo, H.; Gu, Y.; Weng, Y.; Qin, Y. Sidechain Metallopolymers with Precisely Controlled Structures: Synthesis and Application in Catalysis. Polymers 2022, 14, 1128. https://doi.org/10.3390/polym14061128

Qu R, Suo H, Gu Y, Weng Y, Qin Y. Sidechain Metallopolymers with Precisely Controlled Structures: Synthesis and Application in Catalysis. Polymers. 2022; 14(6):1128. https://doi.org/10.3390/polym14061128

Chicago/Turabian StyleQu, Rui, Hongyi Suo, Yanan Gu, Yunxuan Weng, and Yusheng Qin. 2022. "Sidechain Metallopolymers with Precisely Controlled Structures: Synthesis and Application in Catalysis" Polymers 14, no. 6: 1128. https://doi.org/10.3390/polym14061128