Emulsion Templated Porous Poly(thiol-enes): Influence of Photopolymerisation, Emulsion Composition, and Phase Behaviour on the Porous Structure and Morphology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

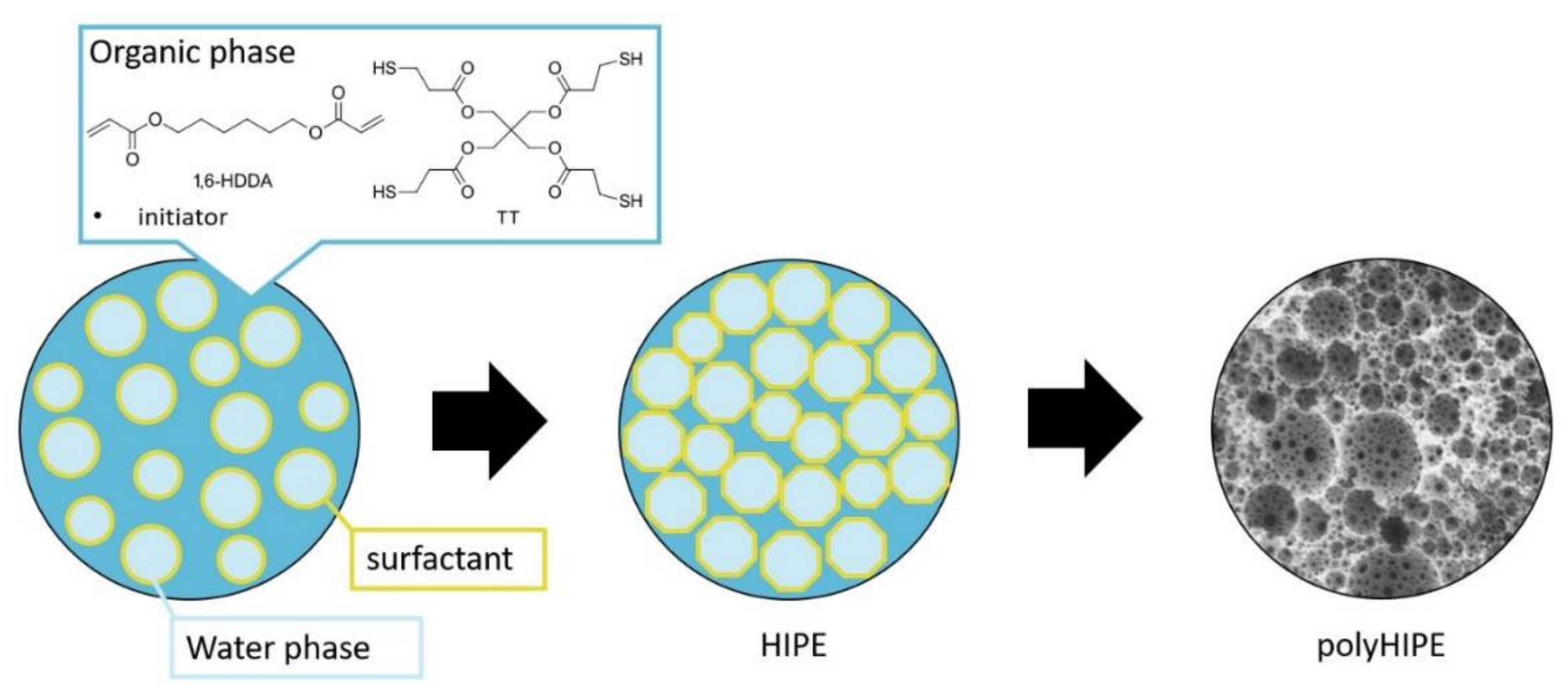

2.2. Preparation Procedure of TT:1,6-HDDA Polymer Monoliths

2.3. Characterisation

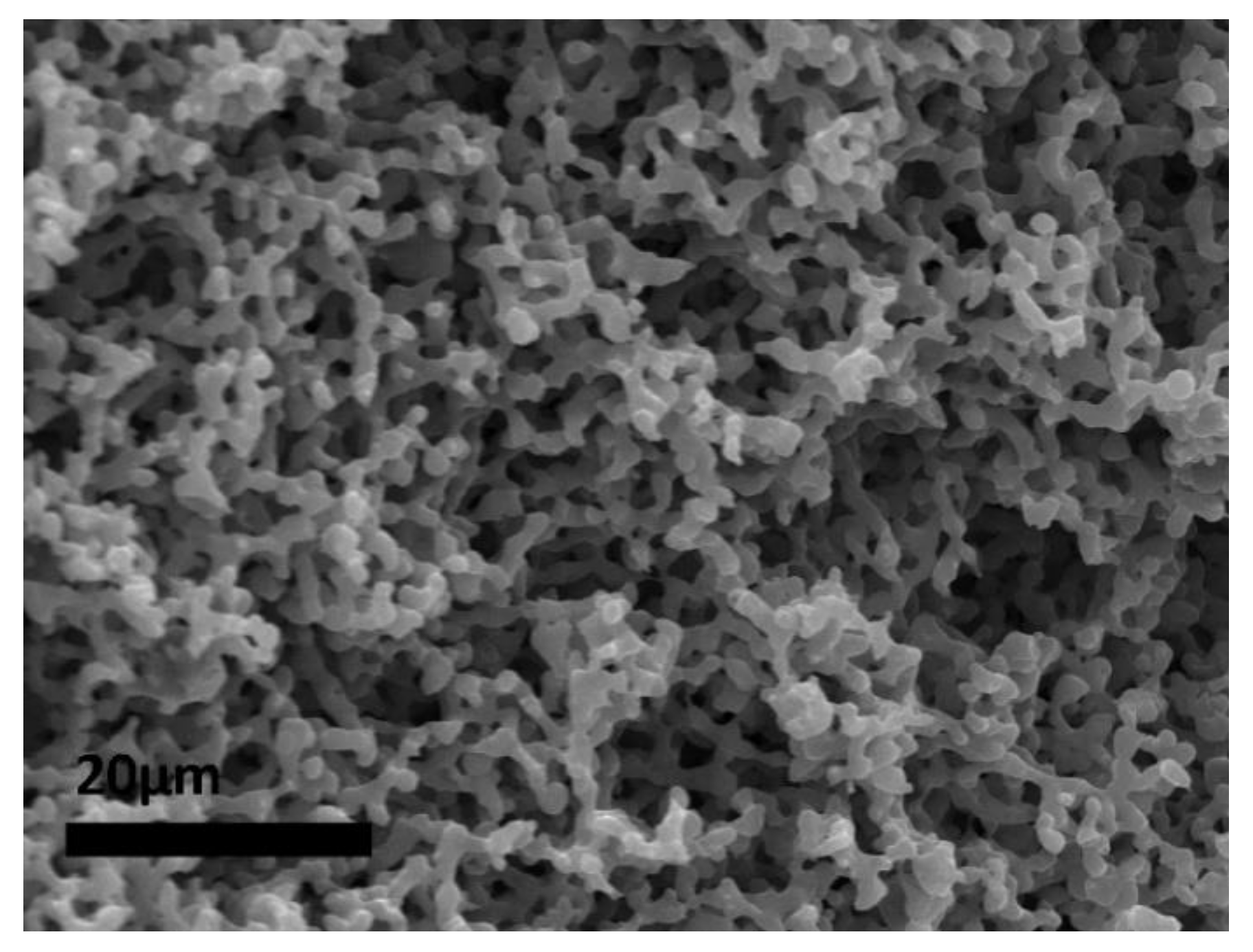

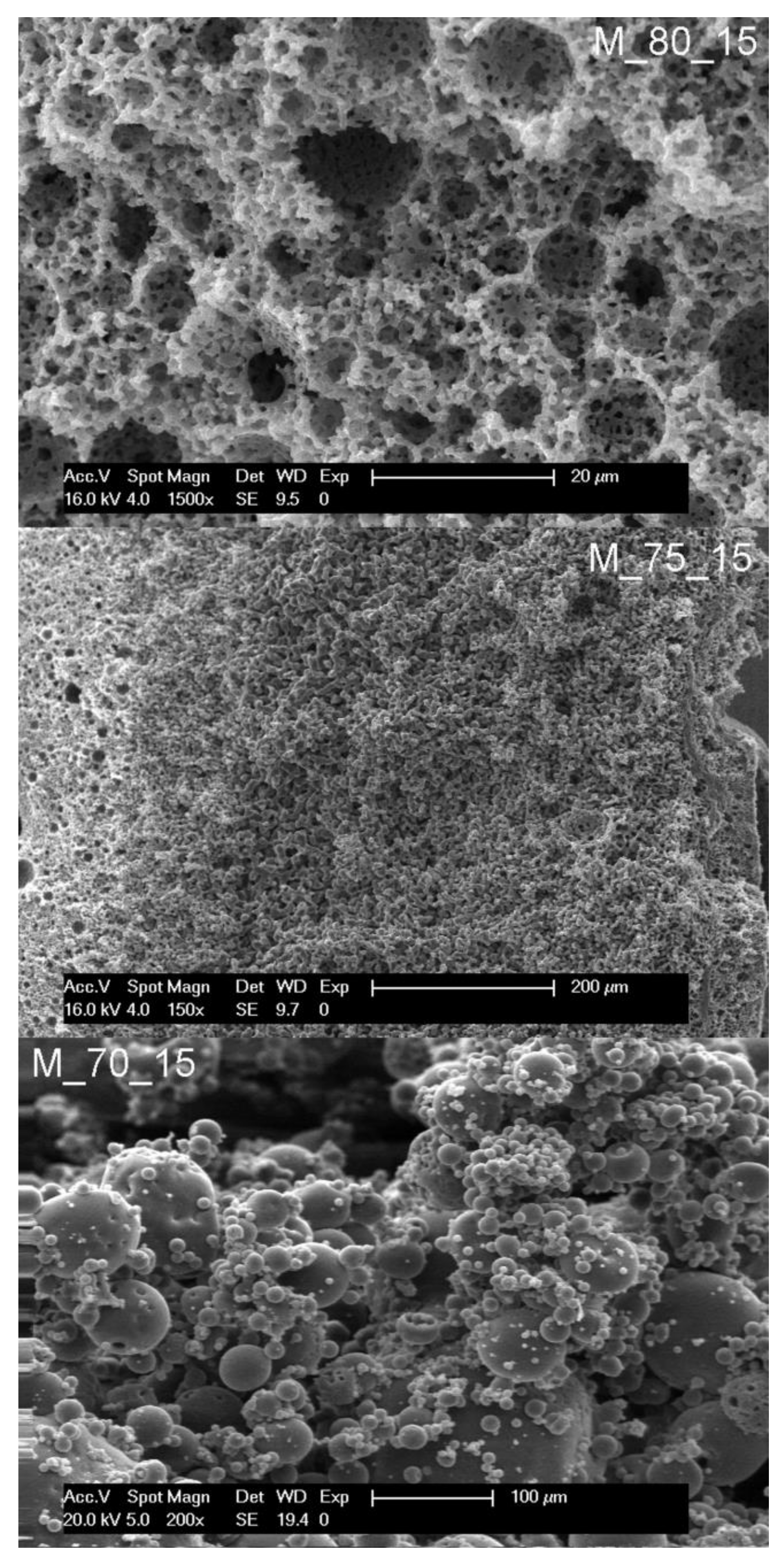

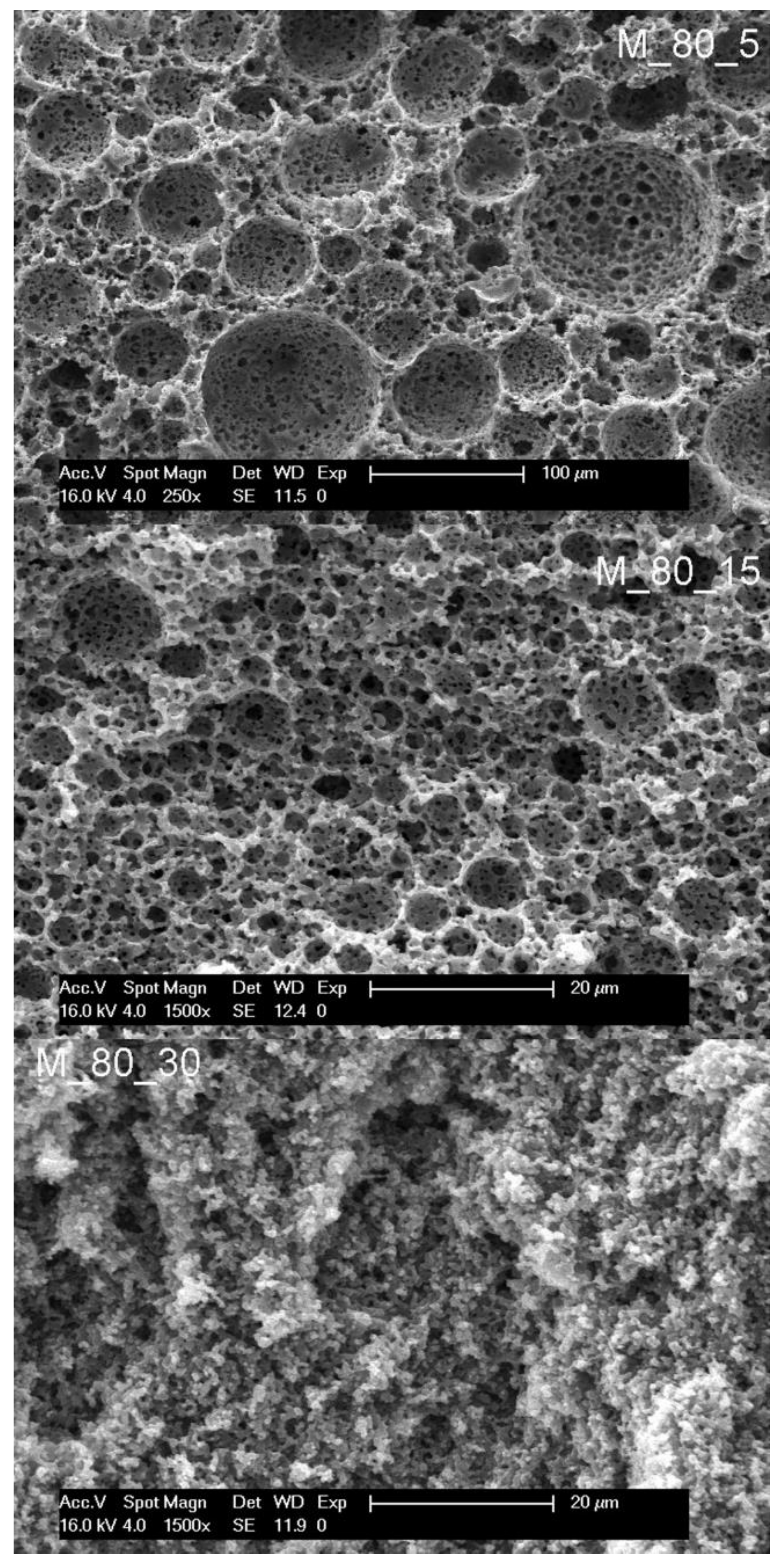

3. Results and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pulko, I.; Krajnc, P. High internal phase emulsion templating—A path to hierarchically porous functional polymers. Macromol. Rapid Commun. 2012, 33, 1731–1746. [Google Scholar] [CrossRef] [PubMed]

- Foudazi, R. HIPEs to PolyHIPEs. React. Funct. Polym. 2021, 164, 104917. [Google Scholar] [CrossRef]

- Silverstein, M.S. PolyHIPEs: Recent advances in emulsion-templated porous polymers. Prog. Polym. Sci. 2014, 39, 199–234. [Google Scholar] [CrossRef]

- Kimmins, S.D.; Cameron, N.R. Functional porous polymers by emulsion templating: Recent advances. Adv. Funct. Mater. 2011, 21, 211–225. [Google Scholar] [CrossRef]

- Kramer, S.; Cameron, N.; Krajnc, P. Porous polymers from high internal phase emulsions as scaffolds for biological applications. Polymers 2021, 13, 1786. [Google Scholar] [CrossRef]

- Aldemir Dikici, B.; Claeyssens, F. Basic principles of emulsion templating and its use as an emerging manufacturing method of tissue engineering scaffolds. Front. Bioeng. Biotechnol. 2020, 8, 875. [Google Scholar] [CrossRef]

- Mravljak, R.; Bizjak, O.; Božič, B.; Podlogar, M.; Podgornik, A. Flow-through PolyHIPE silver-based catalytic reactor. Polymers 2021, 13, 880. [Google Scholar] [CrossRef]

- Pulko, I.; Wall, J.; Krajnc, P.; Cameron, N.R. Ultra-high surface area functional porous polymers by emulsion templating and hypercrosslinking: Efficient nucleophilic catalyst supports. Chem. Eur. J. 2010, 16, 2350–2354. [Google Scholar] [CrossRef]

- Taylor-Pashow, K.M.L.; Pribyl, J.G. PolyHIPEs for separations and chemical transformations: A review. Solvent Extr. Ion Exch. 2019, 37, 1–26. [Google Scholar] [CrossRef]

- Lovelady, E.; Kimmins, S.D.; Wu, J.; Cameron, N.R. Preparation of emulsion-templated porous polymers using thiol-ene and thiol-yne chemistry. Polym. Chem. 2011, 2, 559–562. [Google Scholar] [CrossRef]

- Sušec, M.; Liska, R.; Russmüller, G.; Kotek, J.; Krajnc, P. Microcellular open porous monoliths for cell growth by thiol-ene polymerization of low-toxicity monomers in high internal phase emulsions. Macromol. Biosci. 2015, 15, 253–261. [Google Scholar] [CrossRef] [PubMed]

- Sušec, M.; Ligon, S.C.; Stampfl, J.; Liska, R.; Krajnc, P. hierarchically porous materials from layer-by-layer photopolymerization of high internal phase emulsions. Macromol. Rapid Commun. 2013, 34, 938–943. [Google Scholar] [CrossRef] [PubMed]

- Owen, R.; Sherborne, C.; Paterson, T.; Green, N.; Reilly, G.C.; Claeyssens, F. Emulsion templated scaffolds with tunable mechanical properties for bone tissue engineering. J. Mech. Behav. Biomed. Mater. 2016, 54, 159–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hobiger, V.; Zahoranova, A.; Baudis, S.; Liska, R.; Krajnc, P. Thiol–Ene Cross-linking of Poly(ethylene glycol) within high internal phase emulsions: Degradable hydrophilic PolyHIPEs for controlled drug release. Macromolecules. 2021, 54, 10370–10380. [Google Scholar] [CrossRef] [PubMed]

- Yong, C.P.; Gan, L.M. Microemulsion Polymerizations and Reactions. In Polymer Particles; Okubo, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 257–298. ISBN 978-3-540-31565-0. [Google Scholar]

- Cameron, N.R.; Krajnc, P.; Silverstein, M.S. Colloidal templating. In Porous Polymers; Silverstein, M.S., Cameron, N.R., Hillamyer, M.A., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2011; pp. 119–172. [Google Scholar] [CrossRef]

- Hosoya, K.; Hira, N.; Yamamoto, K.; Nishimura, A.M.; Tanaka, N. High-performance polymer-based monolithic capillary column. Anal. Chem. 2006, 78, 5729–5735. [Google Scholar] [CrossRef]

- Tran-Cong-Miyata, Q.; Nakanishi, H. Phase separation of polymer mixtures driven by photochemical reactions: Current status and perspectives. Polym. Int. 2017, 66, 213–222. [Google Scholar] [CrossRef]

- Huš, S.; Krajnc, P. PolyHIPEs from methyl methacrylate: Hierarchically structured microcellular polymers with exceptional mechanical properties. Polymers 2014, 55, 4420–4424. [Google Scholar] [CrossRef]

- Kovačič, S.; Jeřábek, K.; Krajnc, P.; Slugovc, C. Ring opening metathesispolymerisation of emulsion templated dicyclopentadiene giving open porous materials with excellent mechanical properties. Polym. Chem. 2012, 3, 325–328. [Google Scholar] [CrossRef]

- Kovačič, S.; Štefanec, D.; Krajnc, P. Highly porous open-cellular monoliths from 2-hydroxyethyl methacrylate based high internal phase emulsions (HIPEs): Preparation and void size tuning. Macromolecules 2007, 40, 8056–8060. [Google Scholar] [CrossRef]

- Dunstan, T.S.; Fletcher, P.D.I.; Mashinchi, S. High internal phase emulsions: Catastrophic phase inversion, stability and triggered destabilization. Langmuir 2012, 28, 339–349. [Google Scholar] [CrossRef]

- Sušec, M.; Paljevac, M.; Kotek, J.; Krajnc, P. Microcellular open porous polyester membranes from thiol-ene polymerisations of high internal phase emulsions. Des. Monomers Polym. 2016, 19, 577–583. [Google Scholar] [CrossRef] [Green Version]

| Sample | HDDA [g] | TT [g] | PEL-121 [%] | PEL-121 [g] | Internal Phase Volume [%] | Water Phase [mL] | Porosity * [%] |

|---|---|---|---|---|---|---|---|

| M_80_20 | 2.415 | 2.070 | 20 | 0.912 | 80 | 16 | 78 |

| M_75_20 | 2.324 | 2.089 | 20 | 0.841 | 75 | 11.6 | 76 |

| M_70_20 | 2.323 | 2.005 | 20 | 0.883 | 70 | 9 | - |

| M_80_15 | 2.420 | 2.089 | 15 | 0.690 | 80 | 16 | 86 |

| M_75_15 | 2.420 | 2.089 | 15 | 0.671 | 75 | 12 | 62 |

| M_70_15 | 2.005 | 2.323 | 15 | 0.649 | 70 | 9 | - |

| M_80_5 | 2.423 | 2.097 | 5 | 0.224 | 80 | 16 | 87 |

| M_80_15 | 2.416 | 2.095 | 15 | 0.666 | 80 | 16 | 88 |

| M_80_30 | 2.406 | 2.107 | 30 | 1.359 | 80 | 16 | 37 |

| Sample | DVA [g] | TT [g] | Surfactant [%] | Surfactant Amount [g] | Internal Phase Volume [%] | Water Phase [mL] | Porosity * [%] |

|---|---|---|---|---|---|---|---|

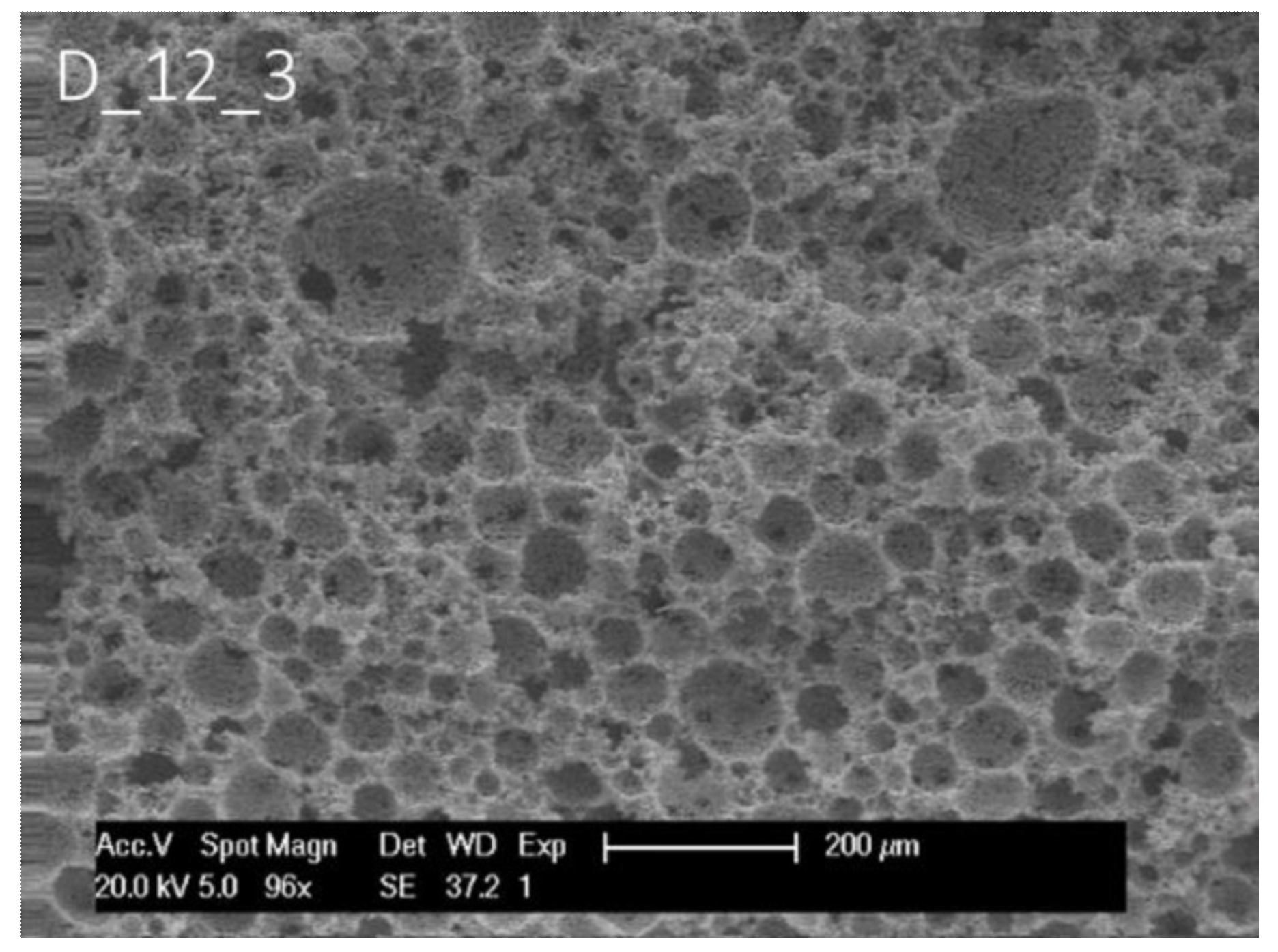

| D_12_3 | 1.982 | 2.443 | PEL-121 (12) | 0.564 | 80 | 11.4 | 73 |

| Span 65 (3) | 0.099 | ||||||

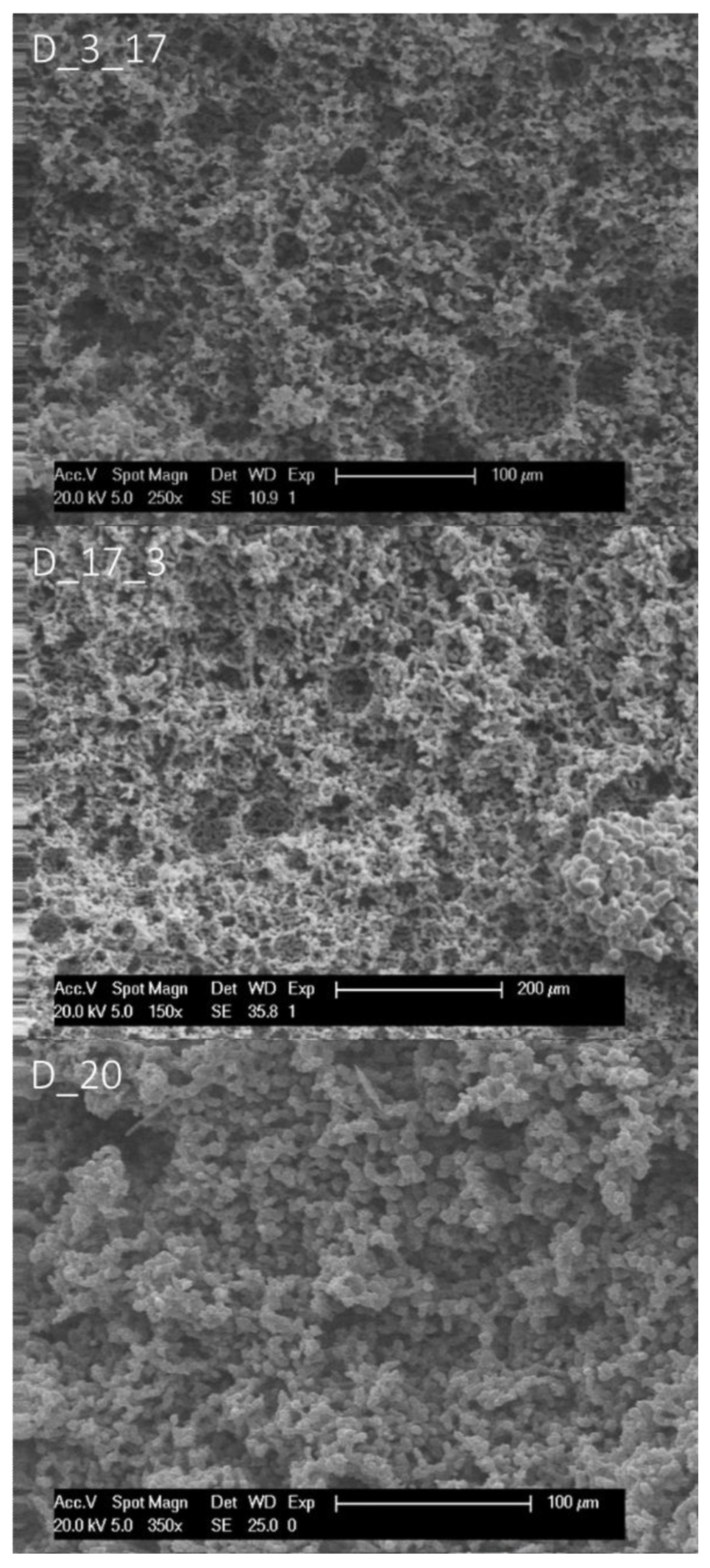

| D_3_17 | 1.982 | 2.443 | PEL-121 (3) | 0.133 | 80 | 11.4 | 74 |

| Span 65 (17) | 0.752 | ||||||

| D_17_3 | 1.982 | 2.443 | PEL-121 (17) | 0.752 | 80 | 11.4 | 82 |

| Span 65 (3) | 0.133 | ||||||

| D_20 | 1.982 | 2.443 | PEL-121 (20) | 0.885 | 75 | 10.7 | 66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hobiger, V.; Paljevac, M.; Krajnc, P. Emulsion Templated Porous Poly(thiol-enes): Influence of Photopolymerisation, Emulsion Composition, and Phase Behaviour on the Porous Structure and Morphology. Polymers 2022, 14, 1338. https://doi.org/10.3390/polym14071338

Hobiger V, Paljevac M, Krajnc P. Emulsion Templated Porous Poly(thiol-enes): Influence of Photopolymerisation, Emulsion Composition, and Phase Behaviour on the Porous Structure and Morphology. Polymers. 2022; 14(7):1338. https://doi.org/10.3390/polym14071338

Chicago/Turabian StyleHobiger, Viola, Muzafera Paljevac, and Peter Krajnc. 2022. "Emulsion Templated Porous Poly(thiol-enes): Influence of Photopolymerisation, Emulsion Composition, and Phase Behaviour on the Porous Structure and Morphology" Polymers 14, no. 7: 1338. https://doi.org/10.3390/polym14071338