Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

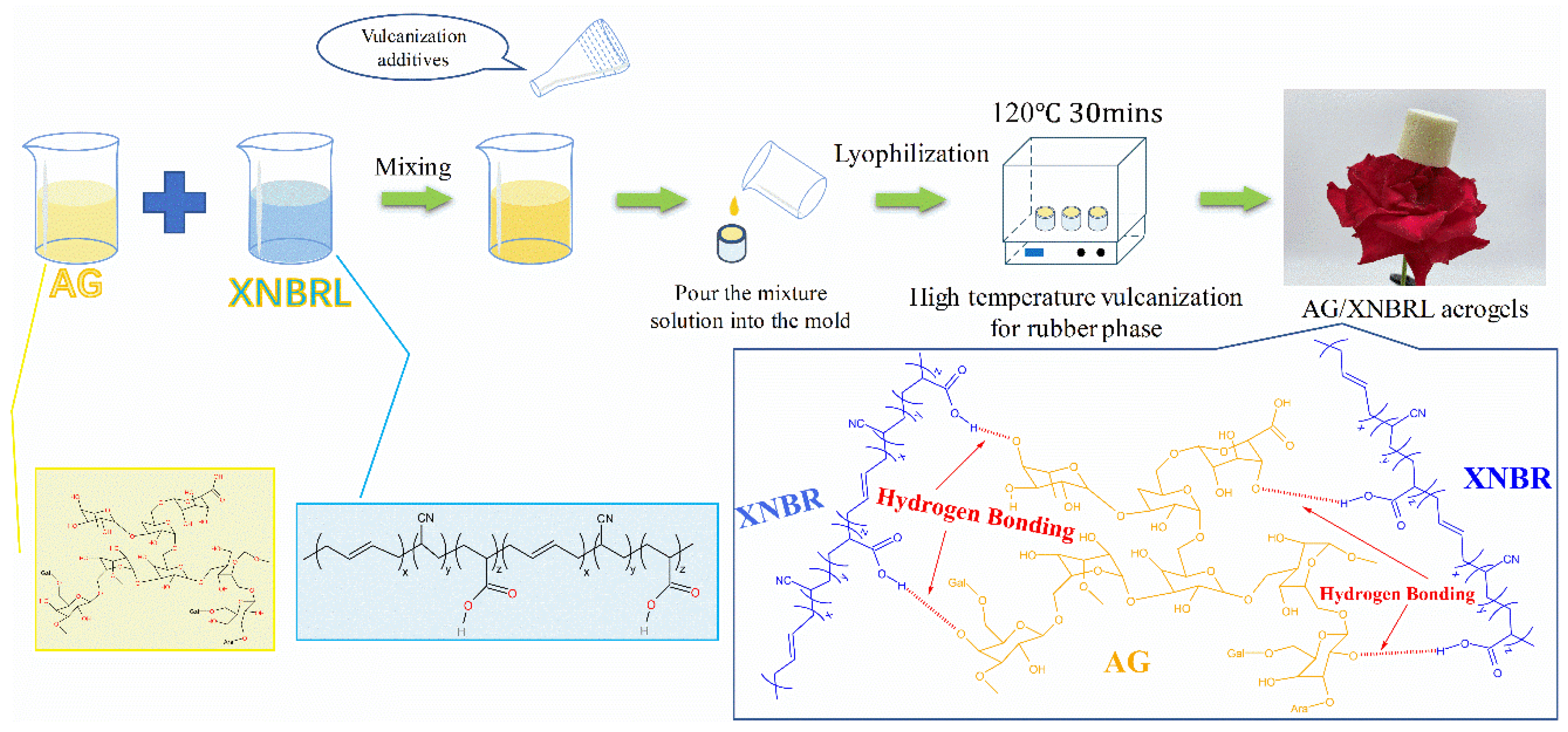

2.2. Preparation of AG/XNBRL Aerogel

2.3. Characterization

3. Results and Discussion

3.1. Thermal Stability

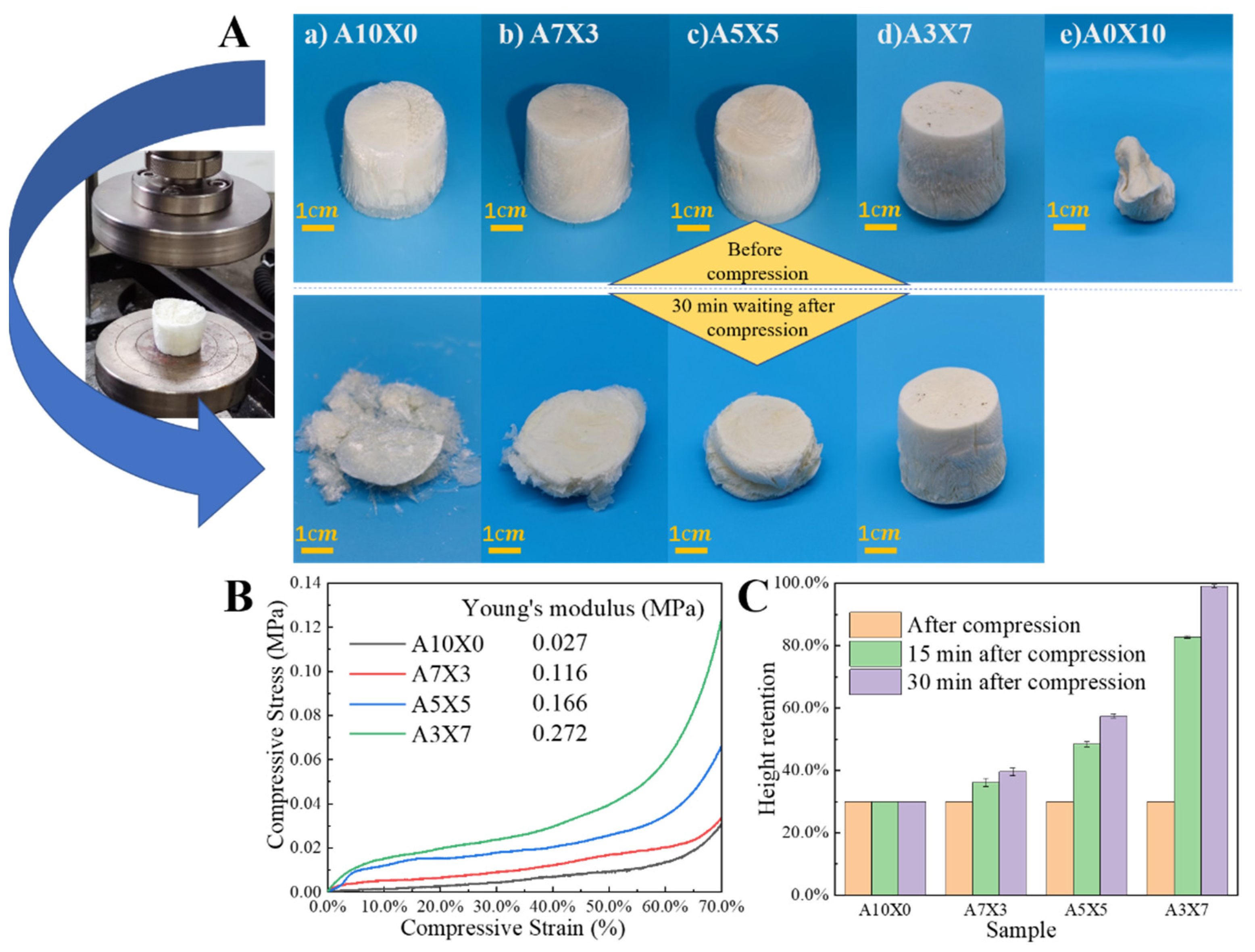

3.2. Mechanical Performance

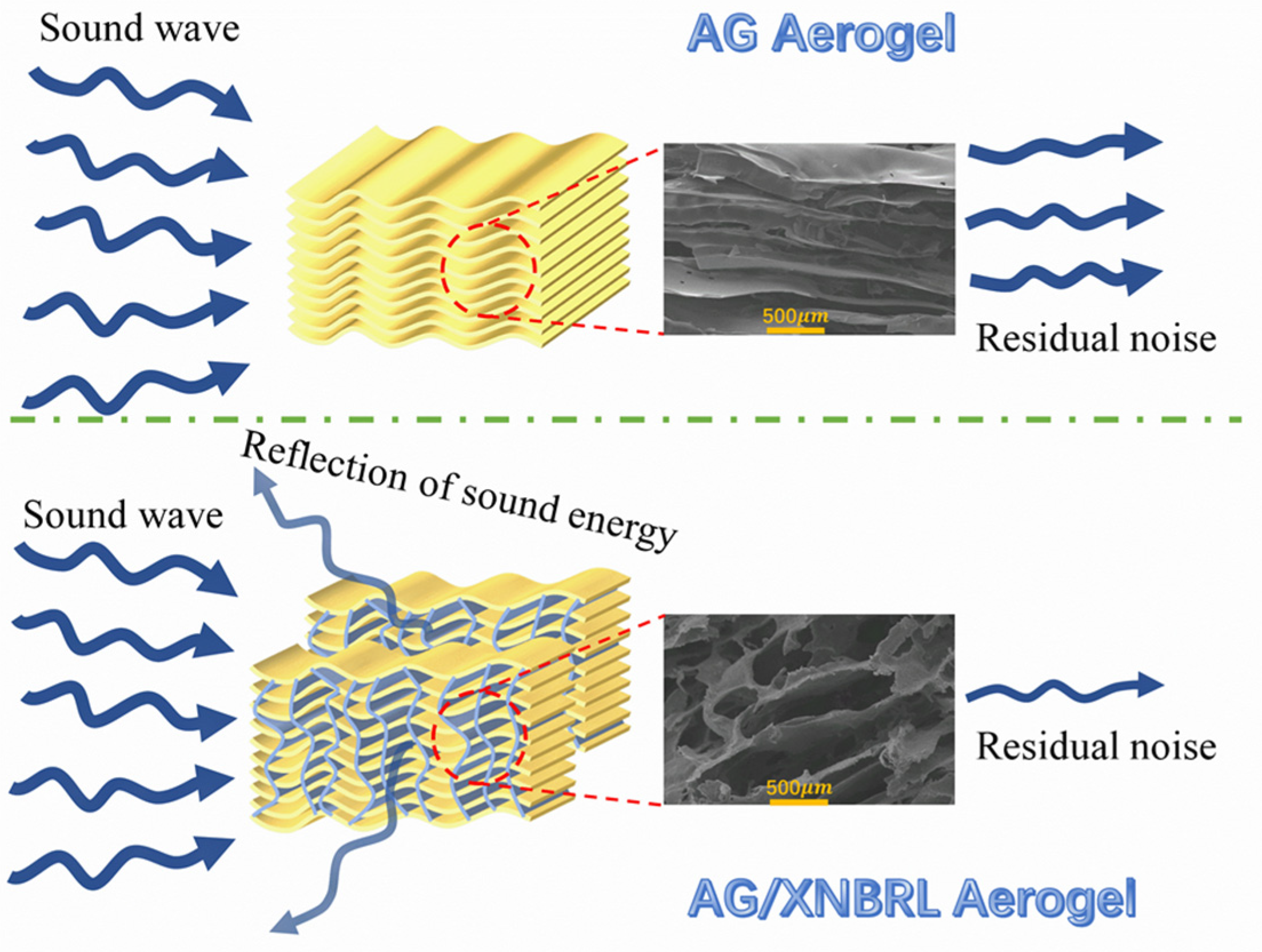

3.3. Morphology of Composite Aerogel

3.4. Density and Porosity of Composite Aerogels

3.5. Sound Absorption Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.; Yang, Z.; Wang, Z.; Zhang, F.; You, F.; Yao, C. Preparation and sound absorption properties of a barium titanate/nitrile butadiene rubber–polyurethane foam composite with multilayered structure. Materials 2018, 11, 474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, X.; Wang, Z.; Yang, Z.; Zhang, F.; You, F.; Yao, C. Structural design and sound absorption properties of nitrile butadiene rubber-polyurethane foam composites with stratified structure. Polymers 2018, 10, 946. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, X.; Wang, Z.; Yang, Z.; Zhang, F.; You, F.; Yao, C. Preparation and sound absorption properties of barium titanate/nitrile butadiene rubber-polyurethane foam composites with stratified structure. RSC Adv. 2018, 8, 20968–20975. [Google Scholar] [CrossRef] [Green Version]

- Tan, S.; Abraham, T.; Ference, D.; Macosko, C.W. Rigid polyurethane foams from a soybean oil-based Polyol. Polymer 2011, 52, 2840–2846. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Wan, C.; Jiao, Y.; Wei, S.; Zhang, L.; Wu, Y.; Li, J. Functional nanocomposites from sustainable regenerated cellulose aerogels: A review. Chem. Eng. J. 2019, 359, 459–475. [Google Scholar] [CrossRef]

- Hajimohammadi, M.; Soltani, P.; Semnani, D.; Taban, E.; Fashandi, H. Nonwoven fabric coated with core-shell and hollow nanofiber membranes for efficient sound absorption in buildings. Build. Environ. 2022, 213, 108887. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, R.; Yildirim, M.B. Acoustical properties of electrospun fibers for aircraft interior noise reduction. J. Aerosp. Eng. 2012, 25, 376–382. [Google Scholar] [CrossRef]

- Passaro, J.; Russo, P.; Bifulco, A.; De Martino, M.T.; Granata, V.; Vitolo, B.; Iannace, G.; Vecchione, A.; Marulo, F.; Branda, F. Water resistant self-extinguishing low frequency soundproofing polyvinylpyrrolidone based electrospun blankets. Polymers 2019, 11, 1205. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Zhang, S.; Wang, G.; Zhao, D.; Feng, J.; Wang, B.; He, X. Lightweight Low-Frequency Sound-Absorbing Composites of Graphene Network Reinforced by Honeycomb Structure. Adv. Mater. Interfaces 2021, 8, 2100183. [Google Scholar] [CrossRef]

- Chen, H.-B.; Liu, B.; Huang, W.; Wang, J.-S.; Zeng, G.; Wu, W.-H.; Schiraldi, D.A. Fabrication and properties of irradiation-cross-linked poly (vinyl alcohol)/clay aerogel composites. ACS Appl. Mater. Interfaces 2014, 6, 16227–16236. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Huang, J.; Li, S.; Meng, K.; Zhang, L.; Chen, Z.; Lai, Y. Mechanically resistant and sustainable cellulose-based composite aerogels with excellent flame retardant, sound-absorption, and superantiwetting ability for advanced engineering materials. ACS Sustain. Chem. Eng. 2018, 6, 927–936. [Google Scholar] [CrossRef]

- Fauziyah, M.; Widiyastuti, W.; Balgis, R.; Setyawan, H. Production of cellulose aerogels from coir fibers via an alkali–urea method for sorption applications. Cellulose 2019, 26, 9583–9598. [Google Scholar] [CrossRef]

- Takeshita, S.; Akasaka, S.; Yoda, S. Structural and acoustic properties of transparent chitosan aerogel. Mater. Lett. 2019, 254, 258–261. [Google Scholar] [CrossRef]

- Grishechko, L.I.; Amaral-Labat, G.; Szczurek, A.; Fierro, V.; Kuznetsov, B.N.; Pizzi, A.; Celzard, A. New tannin–lignin aerogels. Ind. Crops Prod. 2013, 41, 347–355. [Google Scholar] [CrossRef]

- Patel, S.; Goyal, A. Applications of Natural Polymer Gum Arabic: A Review. Int. J. Food Prop. 2015, 18, 986–998. [Google Scholar] [CrossRef]

- Khedaioui, D.; Boisson, C.; d’Agosto, F.; Montarnal, D. Polyethylene Aerogels with Combined Physical and Chemical Crosslinking: Improved Mechanical Resilience and Shape—Memory Properties. Angew. Chem. Int. Ed. 2019, 58, 15883–15889. [Google Scholar] [CrossRef]

- Zhu, G.; Chen, Z.; Wu, B.; Lin, N. Dual-enhancement effect of electrostatic adsorption and chemical crosslinking for nanocellulose-based aerogels. Ind. Crop. Prod. 2019, 139, 111580. [Google Scholar] [CrossRef]

- de Luna, M.S.; Ascione, C.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Buonocore, G.; Castaldo, R.; Filippone, G.; Xia, H.; Ambrosio, L. Optimization of dye adsorption capacity and mechanical strength of chitosan aerogels through crosslinking strategy and graphene oxide addition. Carbohydr. Polym. 2019, 211, 195–203. [Google Scholar] [CrossRef]

- Karamikamkar, S.; Naguib, H.E.; Park, C.B. Advances in precursor system for silica-based aerogel production toward improved mechanical properties, customized morphology, and multifunctionality: A review. Adv. Colloid Interface Sci. 2020, 276, 102101. [Google Scholar] [CrossRef]

- Pan, J.; Li, Y.; Chen, K.; Zhang, Y.; Zhang, H. Enhanced physical and antimicrobial properties of alginate/chitosan composite aerogels based on electrostatic interactions and noncovalent crosslinking. Carbohydr. Polym. 2021, 266, 118102. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Sánchez-Soto, M.; Abt, T. Properties of bio-based gum Arabic/clay aerogels. Ind. Crops Prod. 2016, 91, 15–21. [Google Scholar] [CrossRef]

- Li, F.; Gao, Y.; Zhang, C.; Jin, J.; Ji, X.; Zhang, Y.; Zhang, X.; Jiang, W. Design of high impact thermal plastic polymer composites with balanced toughness and rigidity: Effect of matrix polymer molecular weight. Polymer 2020, 208, 122957. [Google Scholar] [CrossRef]

- Maroufkhani, M.; Katbab, A.; Liu, W.; Zhang, J. Polylactide (PLA) and acrylonitrile butadiene rubber (NBR) blends: The effect of ACN content on morphology, compatibility and mechanical properties. Polymer 2017, 115, 37–44. [Google Scholar] [CrossRef]

- Romo-Uribe, A.; Santiago-Santiago, K.; Reyes-Mayer, A.; Aguilar-Franco, M. Functional PDMS enhanced strain at fracture and toughness of DGEBA epoxy resin. Eur. Polym. J. 2017, 89, 101–118. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Lan, P.; Xu, H.; Lin, N. Hydrophobic and thermal-insulating aerogels based on rigid cellulose nanocrystal and elastic rubber. Carbohydr. Polym. 2022, 275, 118708. [Google Scholar] [CrossRef]

- Voronina, N. An empirical model for rigid frame porous materials with high porosity. Appl. Acoust. 1997, 51, 181–198. [Google Scholar] [CrossRef]

- Cozic, C.; Picton, L.; Garda, M.-R.; Marlhoux, F.; Le Cerf, D. Analysis of arabic gum: Study of degradation and water desorption processes. Food Hydrocoll. 2009, 23, 1930–1934. [Google Scholar] [CrossRef]

- Yu, Z.; Li, J.; Yang, L.; Yao, Y.; Su, Z.; Chen, X. Synthesis and properties of nano carboxylic acrylonitrile butadiene rubber latex toughened phenolic resin. J. Appl. Polym. Sci. 2012, 123, 1079–1084. [Google Scholar] [CrossRef]

- Patil, S.P.; Shendye, P.; Markert, B. Molecular investigation of mechanical properties and fracture behavior of graphene aerogel. J. Phys. Chem. B 2020, 124, 6132–6139. [Google Scholar] [CrossRef]

- Shang, K.; Liao, W.; Wang, J.; Wang, Y.-T.; Wang, Y.-Z.; Schiraldi, D.A. Nonflammable alginate nanocomposite aerogels prepared by a simple freeze-drying and post-cross-linking method. ACS Appl. Mater. Interfaces 2016, 8, 643–650. [Google Scholar] [CrossRef] [PubMed]

- Somlai, L.S.; Bandi, S.A.; Schiraldi, D.A.; Mathias, L.J. Facile processing of clays into organically-modified aerogels. AIChE J. 2006, 52, 1162–1168. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Thai, Q.B.; Chong, R.O.; Nguyen, P.T.T.; Le, D.K.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Recycling of waste tire fibers into advanced aerogels for thermal insulation and sound absorption applications. J. Environ. Chem. Eng. 2020, 8, 104279. [Google Scholar] [CrossRef]

- Ma, B.; Jin, Z.; Su, Y.; Lu, W.; Qi, H.; Hu, P. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material. Constr. Build. Mater. 2020, 234, 117346. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Putra, A.; Loo, S.C.; Alengaram, U.J.; Ling, T.-C. Sound absorption performance of modified concrete: A review. J. Build. Eng. 2020, 30, 101219. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, J.; Tang, H.; Wang, J.; Ao, Q.; Bao, T.; Song, W. Gradient-structural optimization of metal fiber porous materials for sound absorption. Powder Technol. 2016, 301, 1235–1241. [Google Scholar] [CrossRef]

| Samples | ρa (g/cm3) | ρt (g/cm3) | Porosity (%) |

|---|---|---|---|

| A10X0 | 0.0508 | 1.36 | 96.3 |

| A7X3 | 0.0692 | 1.22 | 94.3 |

| A5X5 | 0.092 | 1.13 | 91.9 |

| A3X7 | 0.134 | 1.03 | 87 |

| Sample | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 3000 Hz | 4000 Hz | 5000 Hz | Average |

|---|---|---|---|---|---|---|---|---|

| A10X0 | 0.070 | 0.230 | 0.639 | 0.877 | 0.804 | 0.739 | 0.738 | 0.585 |

| A7X3 | 0.126 | 0.338 | 0.697 | 0.887 | 0.784 | 0.791 | 0.842 | 0.638 |

| A5X5 | 0.091 | 0.194 | 0.567 | 0.981 | 0.869 | 0.779 | 0.807 | 0.613 |

| A3X7 | 0.110 | 0.353 | 0.707 | 0.813 | 0.688 | 0.707 | 0.727 | 0.586 |

| Materials | Thickness (mm) | Density (g/cm3) | NRC |

|---|---|---|---|

| Our work | 23 | 0.060 | 0.512 |

| Aerated concrete | 90 | 0.670 | 0.165 |

| Cane board | 13 | 0.200 | 0.375 |

| Superfine glass wool | 20 | 0.020 | 0.425 |

| Cement expanded perlite slab | 80 | 0.300 | 0.430 |

| Microcellular polyurethane foam | 40 | 0.030 | 0.430 |

| Coarse-porous polyurethane foam | 40 | 0.030 | 0.443 |

| Phenolic resin glass wool board | 30 | 0.100 | 0.465 |

| Perlite suction panel | 18 | 0.340 | 0.343 |

| Nitrocellulose foam | 25 | 0.025 | 0.458 |

| Urea-formaldehyde miboro | 30 | 0.020 | 0.485 |

| Concrete with lightweight aggregate | 25 | 2.310 | 0.150 |

| Geopolymer concrete with lightweight aggregate | <10 | 1.510 | 0.290 |

| Plaster with lightweight aggregate | 10 | 0.300 | 0.060 |

| Alkali-activated cellular concrete | - | 0.720 | 0.410 |

| Pervious concrete | 4 | 0.640 | 0.350 |

| Hemp concrete | 5 | 0.590 | 0.450 |

| Metal fiber porous materials | 2.1 | - | 0.044 |

| β-HPG porous sound-absorbing material | 40 | - | 0.320 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Hu, R.; Jiang, X.; You, F.; Yao, C.; Yang, H.; Yu, P. Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer. Polymers 2022, 14, 1344. https://doi.org/10.3390/polym14071344

Shen J, Hu R, Jiang X, You F, Yao C, Yang H, Yu P. Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer. Polymers. 2022; 14(7):1344. https://doi.org/10.3390/polym14071344

Chicago/Turabian StyleShen, Junshi, Ruofei Hu, Xueliang Jiang, Feng You, Chu Yao, Huan Yang, and Peng Yu. 2022. "Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer" Polymers 14, no. 7: 1344. https://doi.org/10.3390/polym14071344

APA StyleShen, J., Hu, R., Jiang, X., You, F., Yao, C., Yang, H., & Yu, P. (2022). Enhanced Toughness and Sound Absorption Performance of Bio-Aerogel via Incorporation of Elastomer. Polymers, 14(7), 1344. https://doi.org/10.3390/polym14071344