Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material

Abstract

:1. Introduction

2. Material and Tests

2.1. Material and Specimen

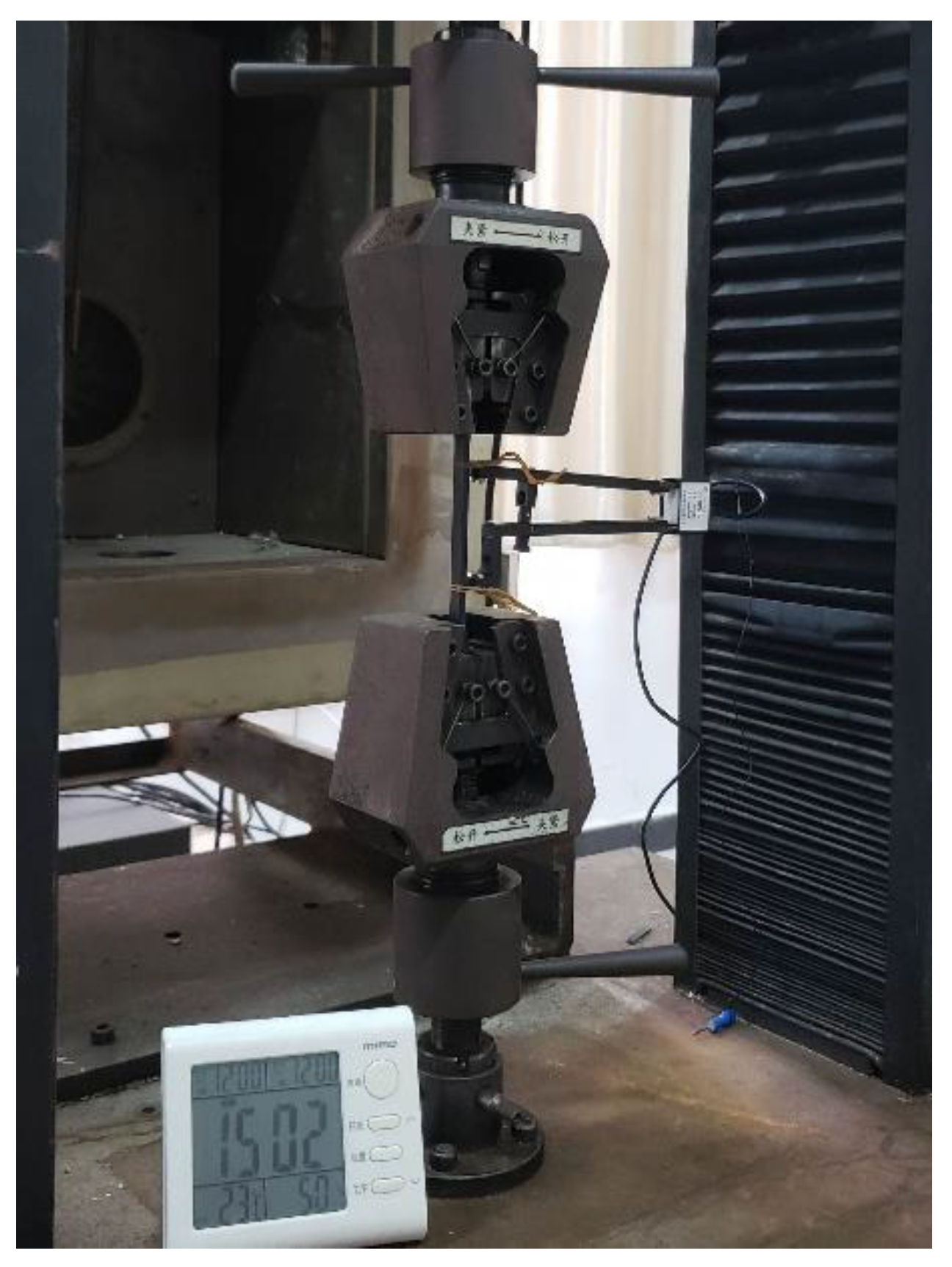

2.2. Tensile Tests with Constant Strain Rate

3. Results and Discussions

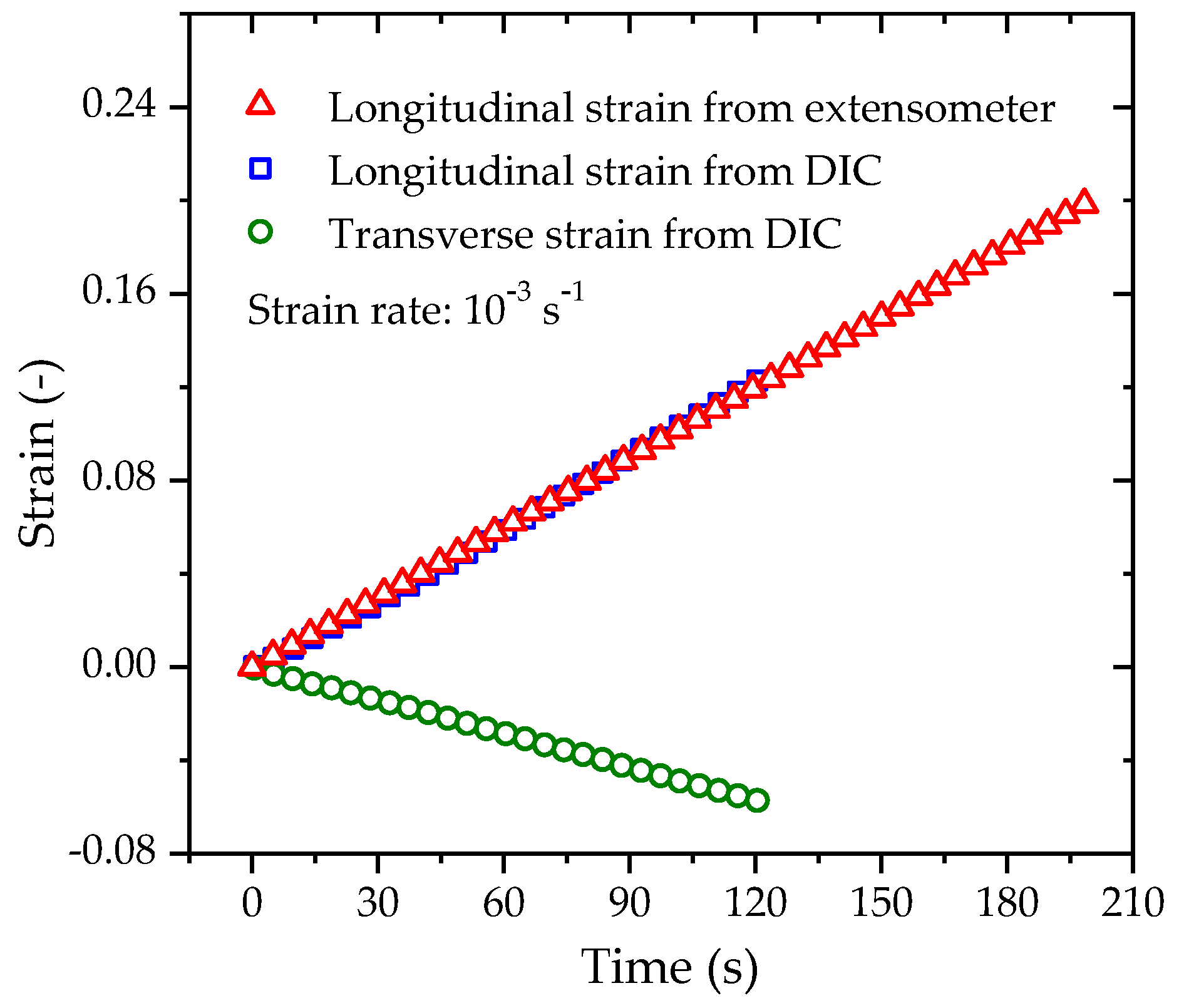

3.1. Poisson’s Ratio

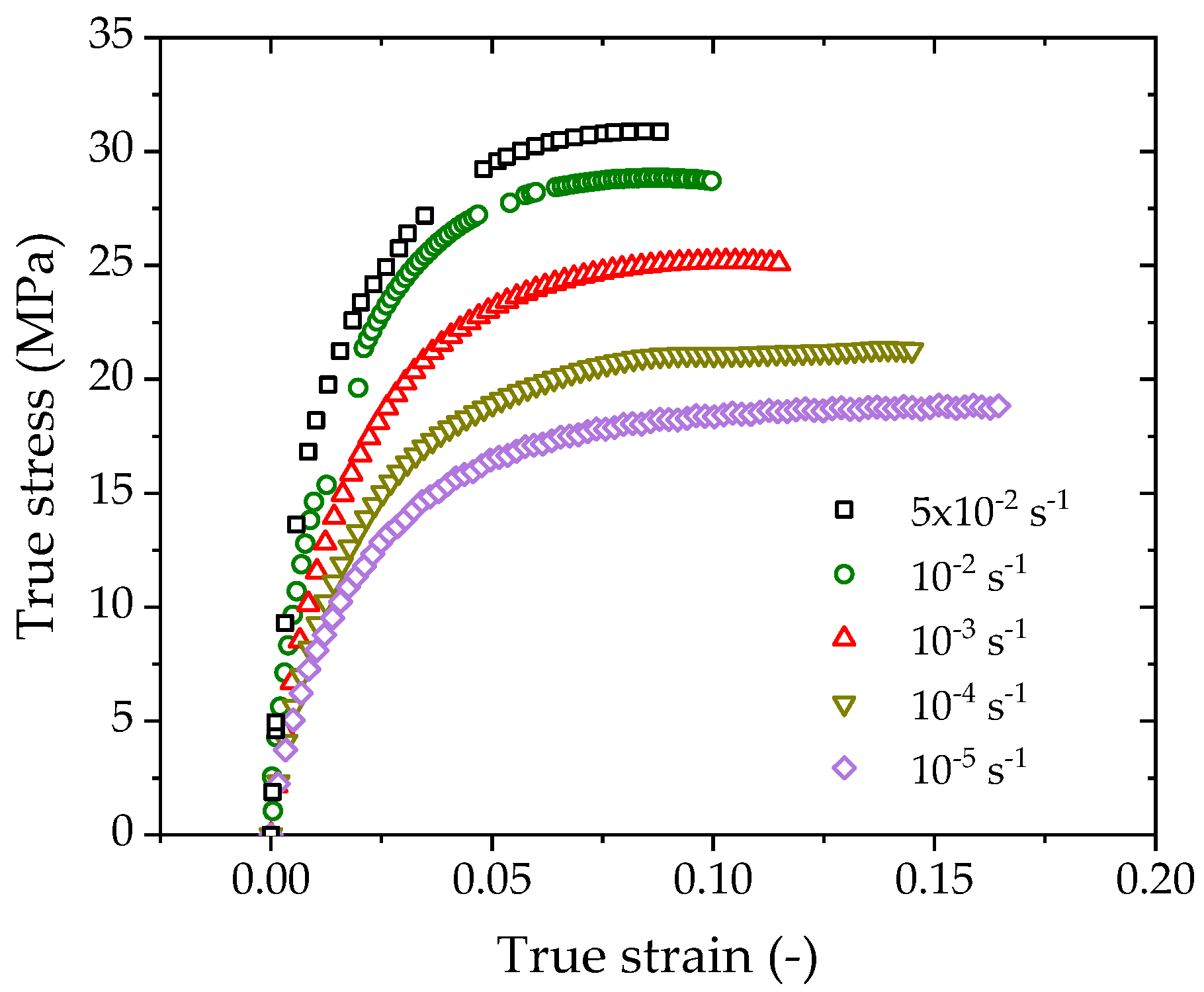

3.2. True Stress–Strain Curves

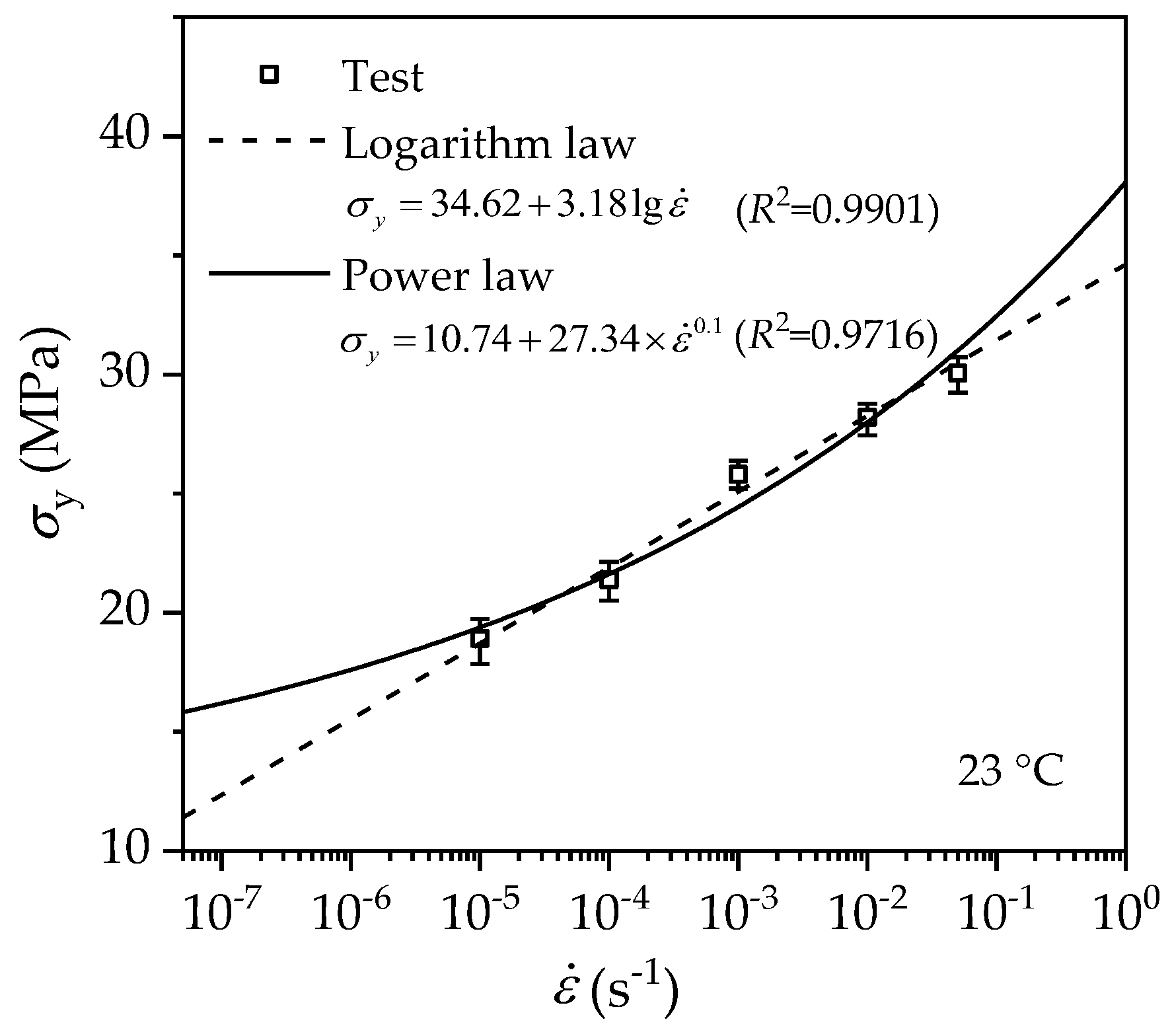

3.3. Rate-Dependent Yielding

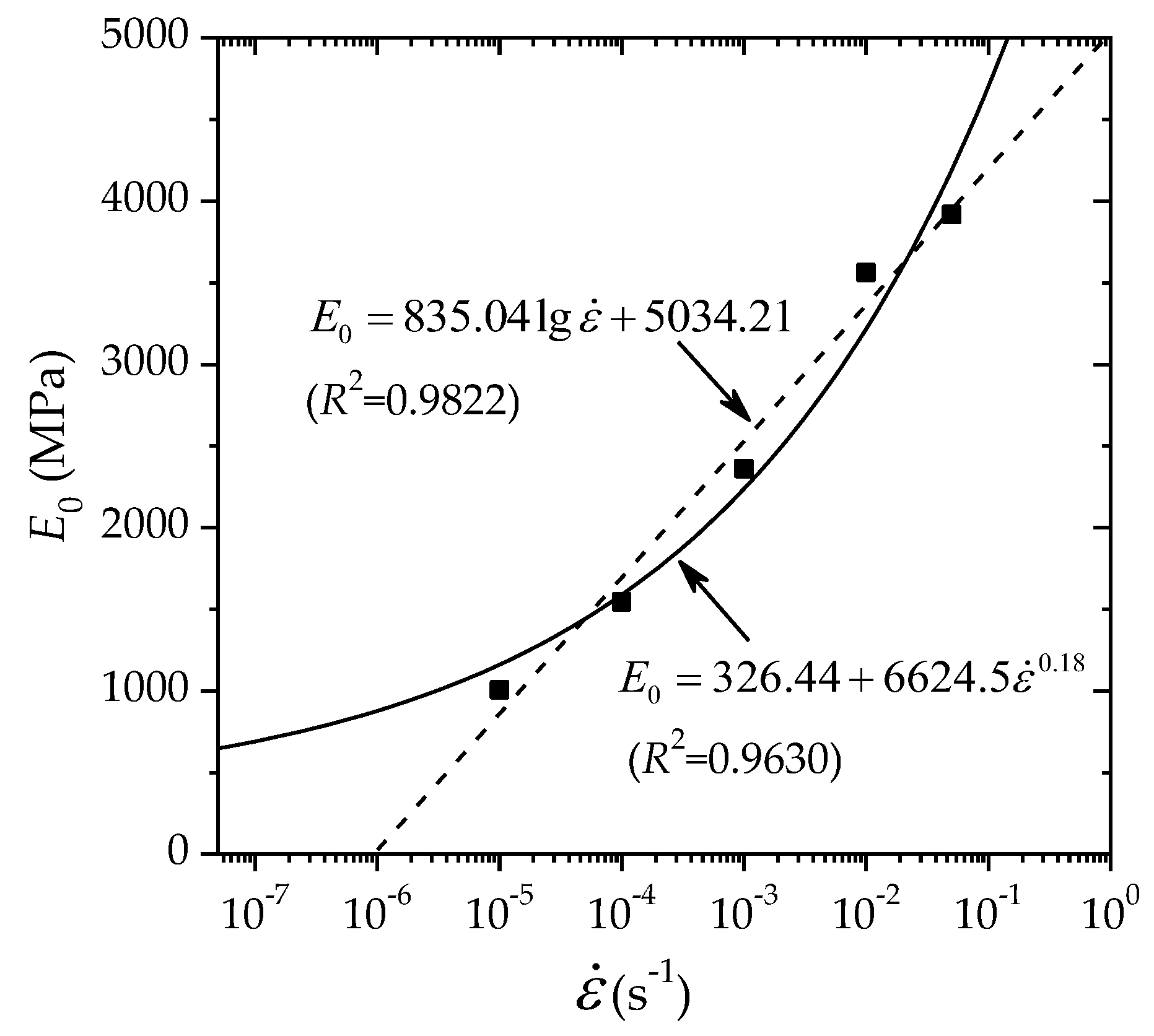

3.3.1. Logarithm Law

3.3.2. Power Law

4. Constitutive Model

4.1. Rate-Dependent Hyperbolic Model

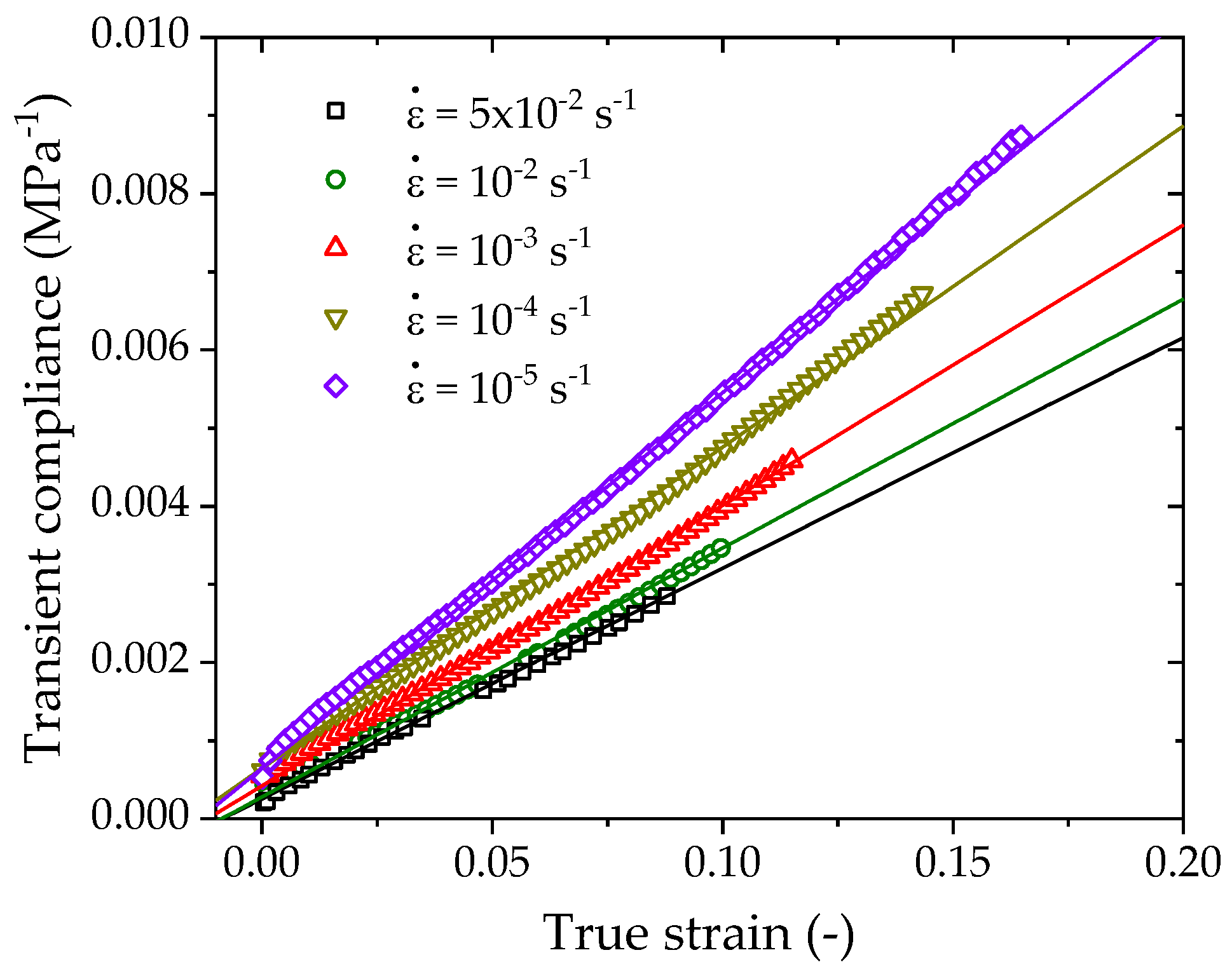

4.2. Identification of Model Parameters

4.3. Determined Rate-Dependent Constitutive Model

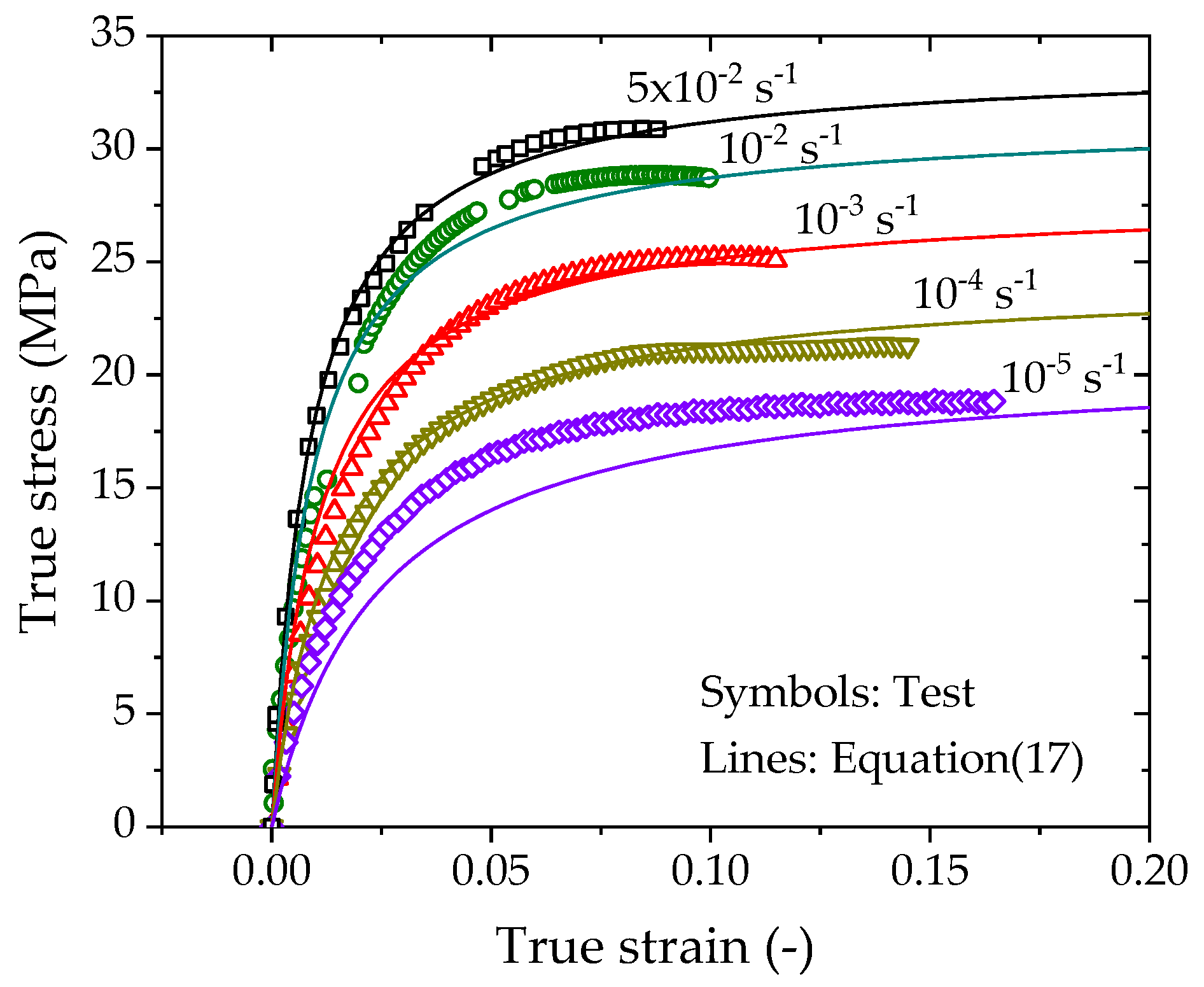

4.3.1. Model with Logarithm-Law Rate Dependence

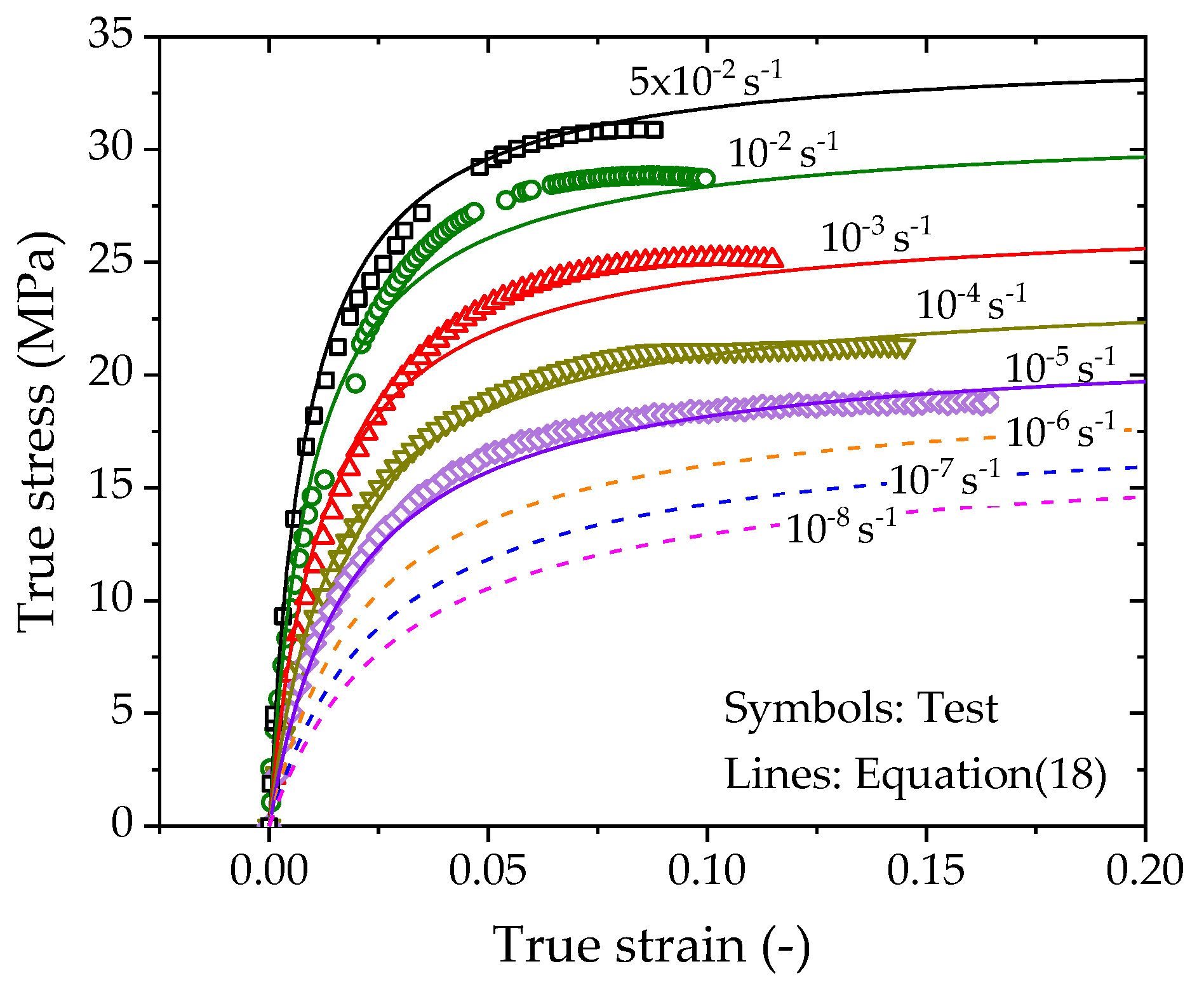

4.3.2. Model with Power-Law Rate Dependence

5. Conclusions

- (a)

- The tensile mechanical behavior of PE100 pipe material depends on the loading strain rate, and the strain-rate dependence of the yield stress and the initial tangent modulus can be described by either a power law or a logarithm law in the tested strain rate range.

- (b)

- The strain-rate dependent Kondner hyperbolic constitutive model takes the yield stress and initial tangent modulus of the material as model parameters, and it can describe the tensile mechanical behavior of PE100 pipes prior to yielding under various strain rates. The predictions agree well with the tests and provide the stress–strain responses at very low strain rates. In contrast, the power-law rate-dependent Kondner model is more suitable for describing the rate-dependent tensile behavior of PE100 pipe than the logarithm-law rate-dependent Kondner model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robledo, N.; Dominguez, C.; Garcia-Munoz, R.A. Alternative accelerated and short-term methods for evaluating slow crack growth in polyethylene resins with high crack resistance. Polym. Test. 2017, 62, 366–372. [Google Scholar] [CrossRef]

- Gholami, F.; Pircheraghi, G.; Rashedi, R.; Sepahi, A. Correlation between isothermal crystallization properties and slow crack growth resistance of polyethylene pipe materials. Polym. Test. 2019, 80, 106128. [Google Scholar] [CrossRef]

- Yang, P.Y.; Zhao, L.; Pan, X.F.; Zhou, F.Q.; Yang, Z.X.; He, X.L. The effect of branched structure on the lamellae evolution under uniaxial extension and SCG resistance of polyolefins. Polym. Test. 2020, 87, 106555. [Google Scholar] [CrossRef]

- Xu, L.; Du, Z.; Wang, J.; Cheng, C.; Du, C.; Gao, G. A viscoelastoplastic constitutive model of semi-crystalline polymers under dynamic compressive loading: Application to PE and PA66. Mech. Adv. Mater. Struct. 2020, 27, 1331–1341. [Google Scholar] [CrossRef]

- Kühl, A.; Muñoz-Rojas, P.A. Application of a master curve and the modified superposition principle for modeling creep and loading rate effects at small strains in high-density polyethylene. Mech. Adv. Mater. Struct. 2021, 28, 891–903. [Google Scholar] [CrossRef]

- Zhang, Y.; Jar, P.Y.B. Time-strain rate superposition for relaxation behavior of polyethylene pressure pipes. Polym. Test. 2016, 50, 292–296. [Google Scholar] [CrossRef]

- Zhang, Y.; Ben Jar, P.Y. Effects of crosshead speed on the quasi-static stress-strain relationship of polyethylene pipes. J. Press. Vessel Technol.-Trans. Asme 2017, 139, 021402. [Google Scholar] [CrossRef]

- Grellmann, W.; Langer, B. (Eds.) Deformation and Fracture Behaviour of Polymer Materials; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Alimi, L.; Chaoui, K.; Amirat, A.; Azzouz, S. Study of reliability index for high-density polyethylene based on pipe standard dimension ratio and fracture toughness limits. Int. J. Adv. Manuf. Technol. 2018, 96, 123–136. [Google Scholar] [CrossRef]

- Cholewa, J.A.; Brachman, R.W.I.; Moore, I.D. Effectiveness of viscoelastic models for prediction of tensile axial strains during cyclic loading of high-density polyethylene pipe. J. Pipeline Syst. Eng. Pract. 2010, 1, 77–83. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Creep behavior and modeling of high-density polyethylene (HDPE). Polym. Test. 2021, 94, 107031. [Google Scholar] [CrossRef]

- Kanters, M.J.W.; van Erp, T.B.; van Drongelen, M.; Engels, T.A.P.; Govaert, L.E. Loading rate dependence of failure strength as predictor for the long-term performance of thermoplastic polymeric products. Polym. Test. 2017, 59, 177–184. [Google Scholar] [CrossRef]

- El-Bagory, T.M.A.A.; Sallam, H.E.M.; Younan, M.Y.A. Effect of loading rate and pipe wall thickness on the strength and toughness of welded and unwelded polyethylene pipes. J. Press. Vessel Technol. 2021, 143, 011505. [Google Scholar] [CrossRef]

- Boyce, M.C.; Parks, D.M.; Argon, A.S. Large inelastic deformation of glassy polymers. part I: Rate dependent constitutive model. Mech. Mater. 1988, 7, 15–33. [Google Scholar] [CrossRef]

- Drozdov, A.D.; Christiansen, J.D. Viscoelasticity and viscoplasticity of semicrystalline polymers: Structure–property relations for high-density polyethylene. Comput. Mater. Sci. 2007, 39, 729–751. [Google Scholar] [CrossRef]

- Sepiani, H.; Polak, M.A.; Penlidis, A. Modeling short- and long-term time-dependent nonlinear behavior of polyethylene. Mech. Adv. Mater. Struct. 2018, 25, 600–610. [Google Scholar] [CrossRef]

- Schapery, R.A. On the characterization of nonlinear viscoelastic materials. Polym. Eng. Sci. 1969, 9, 295–310. [Google Scholar] [CrossRef]

- Zhang, C.; Moore, I.D. Nonlinear mechanical response of high density polyethylene. Part I: Experimental investigation and model evaluation. Polym. Eng. Sci. 1997, 37, 404–413. [Google Scholar] [CrossRef]

- Zhang, C.; Moore, I.D. Nonlinear mechanical response of high density polyethylene. Part II: Uniaxial constitutive modeling. Polym. Eng. Sci. 1997, 37, 414–420. [Google Scholar] [CrossRef]

- Krempl, E.; Khan, F. Rate (time)-dependent deformation behavior: An overview of some properties of metals and solid polymers. Int. J. Plast. 2003, 19, 1069–1095. [Google Scholar] [CrossRef]

- Colak, O.U.; Dusunceli, N. Modeling viscoelastic and viscoplastic behavior of high density polyethylene (HDPE). J. Eng. Mater. Technol. 2006, 128, 572–578. [Google Scholar] [CrossRef]

- Eyring, H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J. Chem. Phys. 1936, 4, 283–291. [Google Scholar] [CrossRef]

- Ree, T.; Eyring, H. The relaxation theory of transport phenomena. In Rheology: Theory and Applications; Eirich, F.R., Ed.; Academic Press: New York, NY, USA, 1958; pp. 83–144. [Google Scholar]

- Unger, R.; Exner, W.; Arash, B.; Rolfes, R. Non-linear viscoelasticity of epoxy resins: Molecular simulation-based prediction and experimental validation. Polymer 2019, 180, 121722. [Google Scholar] [CrossRef]

- Rottler, J.; Robbins, M.O. Shear yielding of amorphous glassy solids: Effect of temperature and strain rate. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2003, 68, 011507. [Google Scholar] [CrossRef] [Green Version]

- Kondner, R. Hyperbolic stress-strain response: Cohesive soils. J. Soil Mech. Found. Div. ASCE 1963, 89, 115–143. [Google Scholar] [CrossRef]

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. ASCE 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Merry, S.M.; Bray, J.D. Time-dependent mechanical response of HDPE geomembranes. J. Geotech. Geoenviron. Eng. 1997, 123, 57–65. [Google Scholar] [CrossRef]

- Suleiman, M.T.; Coree, B.J. Constitutive model for high density polyethylene material: Systematic approach. J. Mater. Civ. Eng. 2004, 16, 511–515. [Google Scholar] [CrossRef]

| /s−1 | E0/MPa | a/MPa−1 | r | Correlation Coefficient, R2 |

|---|---|---|---|---|

| 10−5 | 1.26 × 103 | 7.93 × 10−4 | 0.90 | 0.9991 |

| 10−4 | 1.55 × 103 | 6.47 × 10−4 | 0.90 | 0.9981 |

| 10−3 | 2.36 × 103 | 4.23 × 10−4 | 0.90 | 0.9974 |

| 10−2 | 3.56 × 103 | 2.81 × 10−4 | 0.90 | 0.9977 |

| 5 × 10−2 | 3.92 × 103 | 2.55 × 10−4 | 0.90 | 0.9995 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Luo, W.; Li, M.; Yang, B.; Liu, X. Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material. Polymers 2022, 14, 1357. https://doi.org/10.3390/polym14071357

Li Y, Luo W, Li M, Yang B, Liu X. Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material. Polymers. 2022; 14(7):1357. https://doi.org/10.3390/polym14071357

Chicago/Turabian StyleLi, Yan, Wenbo Luo, Maodong Li, Bo Yang, and Xiu Liu. 2022. "Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material" Polymers 14, no. 7: 1357. https://doi.org/10.3390/polym14071357

APA StyleLi, Y., Luo, W., Li, M., Yang, B., & Liu, X. (2022). Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material. Polymers, 14(7), 1357. https://doi.org/10.3390/polym14071357