Bending Strength Design Method of Phyllostachys edulis Bamboo Based on Classification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bending Test

2.3. Reliability Analysis

3. Results and Discussion

3.1. Destruction Process and Destruction Form

3.2. Classification

3.3. Strength Statistical Analysis

3.4. Analysis of Factors Affecting Reliability

3.5. Determination of Partial Factors for Resistance

3.6. Determination of Design Values of Bending Strength

4. Conclusions

- MOE was used to classify bamboo grades. The grades and corresponding MOE ranges were Grade I (MOE < 16.5 GPa), Grade II (16.5 GPa ≤ MOE < 18.5 GPa), and Grade III (MOE ≥ 18.5 GPa).

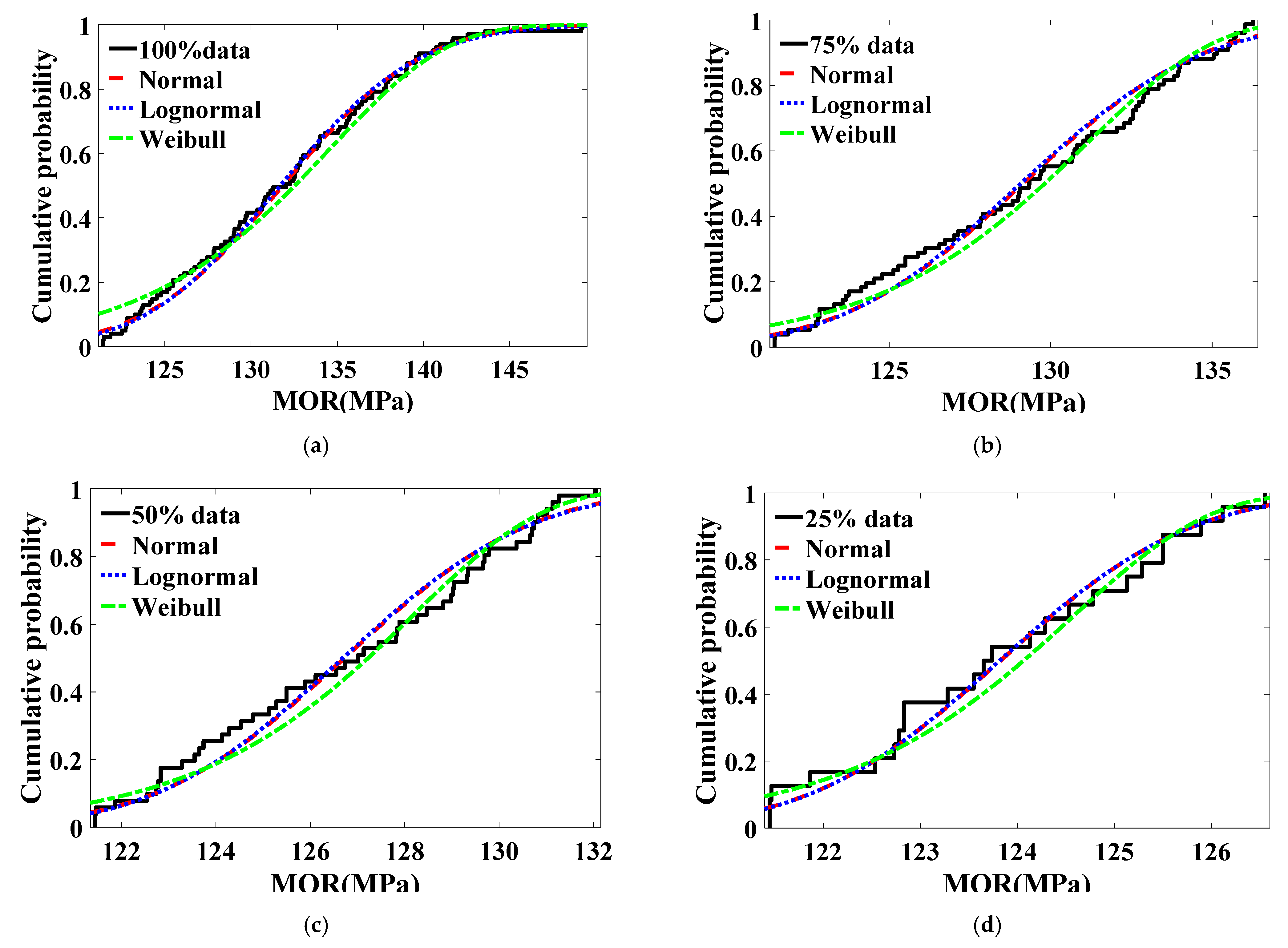

- With the decrease of fitted data points, the cumulative probability density curves and reliability-partial factor for resistance curves under normal distribution, lognormal distribution, and Weibull distribution become closer; 75% data points and normal distribution were used to analyze the reliability of P. edulis bamboo.

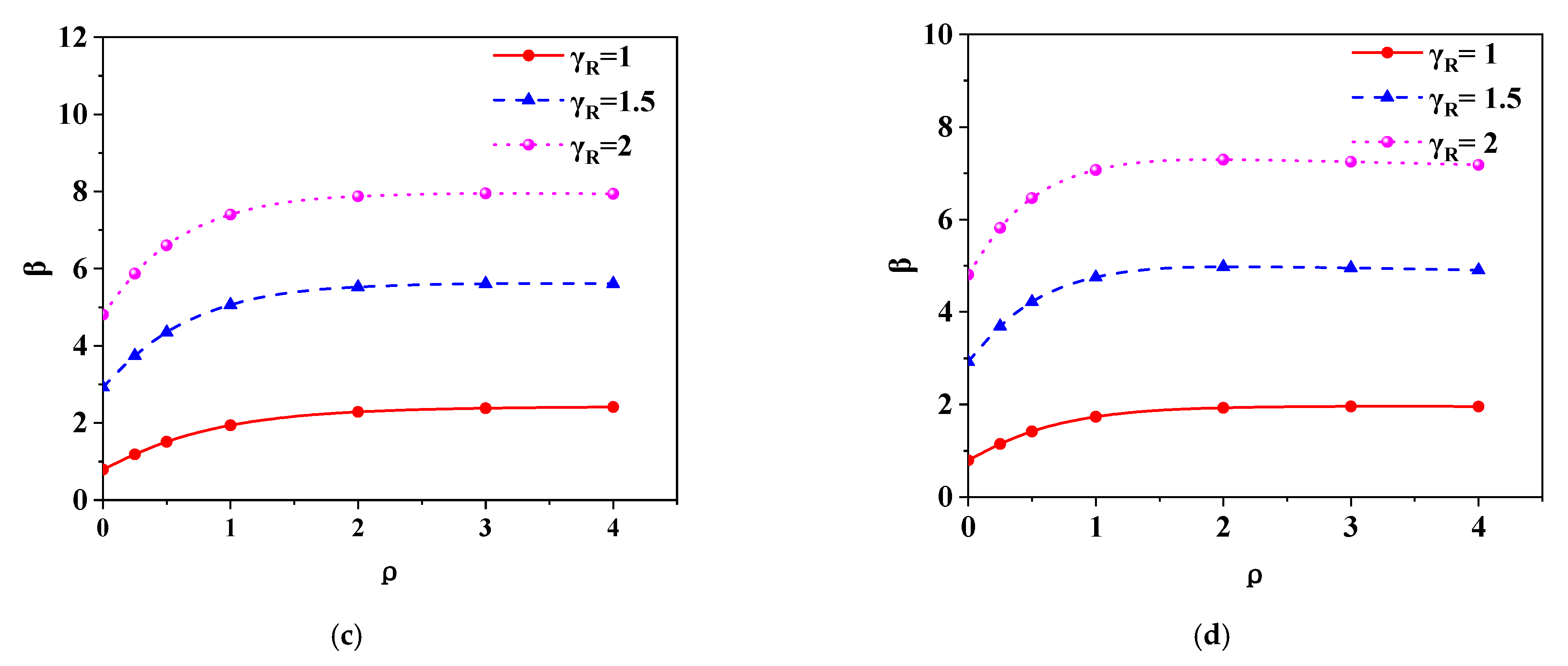

- With the increase of partial factor for resistance and load ratio. The partial factor for resistance under target reliability decreases with the increase of load ratio. The partial factor for resistance under constant load and snow load combination is the largest, and the partial factor for resistance under constant load and office building load combination is the smallest. Under the same load ratio and load combination, the partial factor for resistance of grade III is the largest, while that of grade I is the smallest.

- The bending strength design values of P. edulis bamboo are as follows: grade I (29.54 MPa), grade II (29.62 MPa), grade III (30.63 MPa). The classification method and the bending design values of P. edulis bamboo presented in this paper can provide a reference for the design and engineering application of bamboo structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, Y.; Zhu, J. The application of bamboo weaving in modern furniture. BioResources 2021, 16, 5024–5035. [Google Scholar] [CrossRef]

- Fadlelmola, A.; Chen, Z.; Du, Y.; Ma, R.; Ma, J. Experimental investigation and design method on a lightweight bamboo-concrete sandwich panel under bending load. Structures 2021, 34, 856–874. [Google Scholar] [CrossRef]

- Bakar, N.; Chin, S. Performance of Bamboo Fiber Reinforced Composites: Mechanical Properties. Key Eng. Mater. 2021, 879, 284–293. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, W.; Zhuang, X. Bonding Mechanism of Bamboo Particleboards Made by Laccase Treatment. J. Renew. Mater. 2021, 9, 557–568. [Google Scholar] [CrossRef]

- Yang, B. Bamboo and Bamboo Architecture; Yunnan People’s Publishing House: Kunming, China, 2014. (In Chinese) [Google Scholar]

- Vo, T.; Nguyen, T.; Le, K.; Antonov, S. Study on the Effects of Technology Parameters on the Bending Strength of Press Bamboo Powder Plywood. Key Eng. Mater. 2020, 863, 19–24. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, C. Experimental study on bending mechanical properties of moso bamboo. In E3S Web of Conferences 2021; EDP Sciences: Les Ulis, France, 2021; Volume 293, p. 03010. [Google Scholar]

- Xuan, Y.; Li, H.; Bei, Z.; Xiong, Z.; Lorenzo, R.; Corbi, I.; Corbi, O. Nodes Effect on the Bending Performance of Laminated Bamboo Lumber Unit. J. Renew. Mater. 2021, 9, 1143–1156. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Z.; Fei, B.; Hse, C.; Sun, Z. Tensile behaviour and fracture mechanism of moso bamboo (Phyllostachys pubescens). Holzforschung 2015, 69, 47–52. [Google Scholar] [CrossRef]

- Lin, Q.; Huang, Y.; Li, X.; Yu, W. Effects of shape, location and quantity of the joint on bending properties of laminated bamboo lumber. Constr. Build. Mater. 2020, 230, 117023. [Google Scholar] [CrossRef]

- Liu, P.; Qin, Y.; Zhou, Q.; Xiang, P.; Zhou, X.; Shan, Y. Experimental investigation on the physical and mechanical properties of P. edulis bamboo and their correlations. Eur. J. Wood Wood Prod. 2022. [Google Scholar] [CrossRef]

- Liu, P.; Xiang, P.; Zhou, Q.; Zhang, H.; Tian, J.; Demis Argaw, M. Prediction of Mechanical Properties of Structural Bamboo and Its Relationship with Growth Parameters. J. Renew. Mater. 2021, 9, 2223–2239. [Google Scholar] [CrossRef]

- Zhou, Q.; Tian, J.; Liu, P.; Zhang, H. Test and prediction of mechanical properties of Moso bamboo. J. Eng. Fibers Fabr. 2021, 16. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Q.; Tian, J. A two-variable model for predicting the effects of moisture content and density on mechanical properties of P. edulis bamboo. Bioresource 2022, 17, 410. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Q.; Fu, F.; Li, W. Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo. Forests 2021, 12, 1309. [Google Scholar] [CrossRef]

- Tian, L.; Wei, J.; Hao, J.; Wang, Q. Characterization of the Flexural Behavior of Bamboo Beams. J. Renew. Mater. 2021, 9, 1571–1597. [Google Scholar] [CrossRef]

- Bahtiar, E.; Malkowska, D.; Trujillo, D.; Nugroho, N. Experimental study on buckling resistance of Guadua angustifolia bamboo column. Eng. Struct. 2021, 228, 111548. [Google Scholar] [CrossRef]

- Tian, L.; Kou, Y.; Hao, J.; Wang, B. Study on flexural behavior of bamboo composite slabs with sprayed thermal insulation material. J. Huazhong Univ. Sci. Technol. Nat. Sci. Ed. 2017, 45, 41–45. [Google Scholar]

- Hu, C.; Cheng, R.; Cheng, Q.; Liu, J. Study on Behavior of Steel Hoop Connections for Raw Bamboo Members. Materials 2021, 14, 7253. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Q.; Zhang, H.; Tian, J. Design strengths of bamboo based on reliability analysis. Wood Mater. Sci. Eng. 2021, 1–11. [Google Scholar] [CrossRef]

- Zhu, E.; Niu, S.; Qiao, L.; Pan, J. Reliability analysis of wood structure and determination method of wood strength design value. J. Build. Struct. 2017, 38, 28–36. [Google Scholar]

- Zhong, Y.; Jiang, Z.; Shangguan, W.; Ren, H. Design Value of the Compressive Strength for Bamboo Fiber-Reinforced Composite Based on a Reliability Analysis. BioResources 2014, 9, 7737–7748. [Google Scholar] [CrossRef] [Green Version]

- JG/T199-2007; Testing Methods for Physical And Mechanical Properties Of Bamboo Used in Building. Ministry of Construction Engineering: Beijing, China, 2007. (In Chinese)

- Wu, M.; Shang, Y.; Li, Y. Study on design values of material parameters of ETFE foil. J. Build. Struct. 2014, 35, 114–119. [Google Scholar]

- Lou, W.; Ren, H.; Wang, Z.; Zhou, H.; Luo, X.; Jiang, J.; Guo, W. Grading of structural larch dimension lumber. J. Build. Mater. 2013, 16, 734–738. (In Chinese) [Google Scholar]

- Zhong, Y.; Wu, G.; Ren, H.; Jiang, Z. A determination method of compressive design value of dimensional lumber. J. Wood Sci. 2018, 64, 526–537. [Google Scholar] [CrossRef] [Green Version]

- GBJ 68-1984; Unified Standard for the Design of Building Structures. China Architecture & Building Press: Beijng, China, 1985. (In Chinese)

- GB 50009-2012; Load Code for the Designof Building Structures. China Architecture & Building Press: Beiing, China, 2012. (In Chinese)

- Zhong, Y.; Jiang, Z.; Ren, H. Reliability analysis of compression strength of dimension lumber of Northeast China Larch. Constr. Build. Mater. 2015, 84, 12–18. [Google Scholar] [CrossRef]

- GB 50005-2003; Code for Design of Timber Structures. China Architecture & Building Press: Bejjing, China, 2003. (In Chinese)

| Grade | I | II | III | |

|---|---|---|---|---|

| Grade boundary (GPa) | <16.5 | (16.5, 18.5) | ≥18.5 | |

| Quantity n | 22 | 101 | 32 | |

| Proportion (%) | 14.19 | 65.16 | 20.65 | |

| MOE | Mean | 15.90 | 17.41 | 19.22 |

| 5% quantile | 15.25 | 16.57 | 18.56 | |

| CV/% | 2.35 | 3.12 | 2.59 | |

| Grade I | Grade II | Grade III | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Normal | Lognormal | Weibull | Normal | Lognormal | Weibull | Normal | Lognormal | Weibull | ||

| mf/MPa | 100% | 130.94 | 130.95 | 130.66 | 131.84 | 131.85 | 131.45 | 136.46 | 136.47 | 136.20 |

| 75% | 128.44 | 128.45 | 128.54 | 129.14 | 129.14 | 129.10 | 133.58 | 133.59 | 133.60 | |

| 50% | 125.89 | 125.90 | 125.99 | 126.72 | 126.72 | 126.70 | 130.87 | 130.87 | 130.88 | |

| 25% | 122.62 | 122.62 | 122.46 | 123.83 | 123.83 | 123.79 | 127.56 | 127.56 | 127.66 | |

| CV | 100% | 0.051 | 0.051 | 0.060 | 0.048 | 0.047 | 0.060 | 0.051 | 0.051 | 0.059 |

| 75% | 0.040 | 0.040 | 0.037 | 0.034 | 0.034 | 0.037 | 0.039 | 0.039 | 0.039 | |

| 50% | 0.035 | 0.036 | 0.033 | 0.025 | 0.025 | 0.027 | 0.031 | 0.031 | 0.031 | |

| 25% | 0.026 | 0.026 | 0.030 | 0.013 | 0.013 | 0.014 | 0.021 | 0.021 | 0.016 | |

| fk/MPa | 100% | 120.83 | 122.73 | 126.04 | ||||||

| 75% | 118.47 | 121.86 | 126.04 | |||||||

| 50% | 118.47 | 121.47 | 122.02 | |||||||

| 25% | 118.47 | 121.45 | 122.02 | |||||||

| Load Combination | γRi | |||||||

|---|---|---|---|---|---|---|---|---|

| ρ = 0 | ρ = 0.25 | ρ = 0.5 | ρ = 1.0 | ρ = 2.0 | ρ = 3.0 | ρ = 4.0 | ||

| Grade I | D + R | 1.66 | 1.41 | 1.24 | 1.08 | 0.94 | 0.90 | 0.87 |

| D + O | 1.66 | 1.38 | 1.22 | 1.03 | 0.88 | 0.83 | 0.80 | |

| D + W | 1.66 | 1.46 | 1.35 | 1.25 | 1.18 | 1.17 | 1.17 | |

| D + S | 1.66 | 1.47 | 1.37 | 1.28 | 1.26 | 1.26 | 1.26 | |

| Grade II | D + R | 1.69 | 1.43 | 1.27 | 1.10 | 0.96 | 0.91 | 0.89 |

| D + O | 1.69 | 1.41 | 1.24 | 1.05 | 0.90 | 0.84 | 0.82 | |

| D + W | 1.69 | 1.49 | 1.38 | 1.27 | 1.20 | 1.19 | 1.19 | |

| D + S | 1.69 | 1.50 | 1.40 | 1.31 | 1.28 | 1.28 | 1.28 | |

| Grade III | D + R | 1.70 | 1.44 | 1.28 | 1.10 | 0.97 | 0.92 | 0.90 |

| D + O | 1.70 | 1.41 | 1.25 | 1.05 | 0.90 | 0.85 | 0.82 | |

| D + W | 1.70 | 1.49 | 1.39 | 1.28 | 1.21 | 1.20 | 1.19 | |

| D + S | 1.70 | 1.50 | 1.40 | 1.32 | 1.29 | 1.29 | 1.29 | |

| Grade I | Grade II | Grade III | |

|---|---|---|---|

| fd (MPa) | 27.40 | 27.69 | 28.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Zhou, Q.; Fu, F.; Li, W. Bending Strength Design Method of Phyllostachys edulis Bamboo Based on Classification. Polymers 2022, 14, 1418. https://doi.org/10.3390/polym14071418

Liu P, Zhou Q, Fu F, Li W. Bending Strength Design Method of Phyllostachys edulis Bamboo Based on Classification. Polymers. 2022; 14(7):1418. https://doi.org/10.3390/polym14071418

Chicago/Turabian StyleLiu, Pengcheng, Qishi Zhou, Feiyang Fu, and Wei Li. 2022. "Bending Strength Design Method of Phyllostachys edulis Bamboo Based on Classification" Polymers 14, no. 7: 1418. https://doi.org/10.3390/polym14071418