Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the MWCNT Composite Conductive Nonwoven Fabric

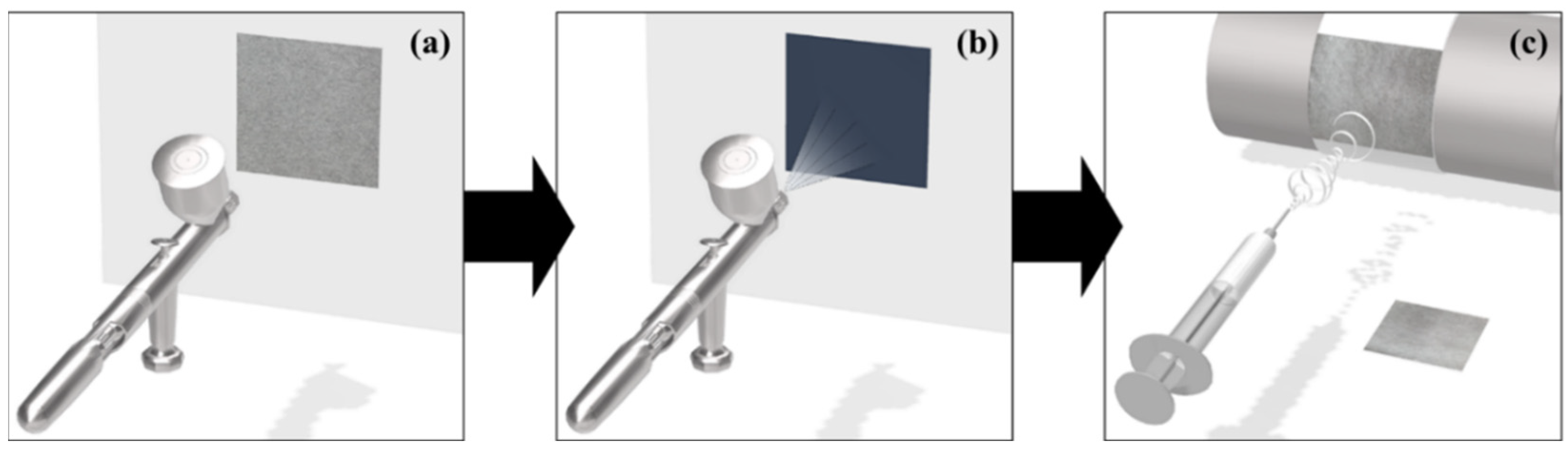

2.2.1. MWCNT Spraying Process

2.2.2. TPU Electrospinning Process

2.3. Characterization

2.3.1. Morphology of the MWCNT Composite Conductive Nonwoven

2.3.2. Morphology of the MWCNT Composite Conductive Nonwoven

2.4. Characterization

2.4.1. Sensing Pad

2.4.2. Main Circuit

3. Results and Discussion

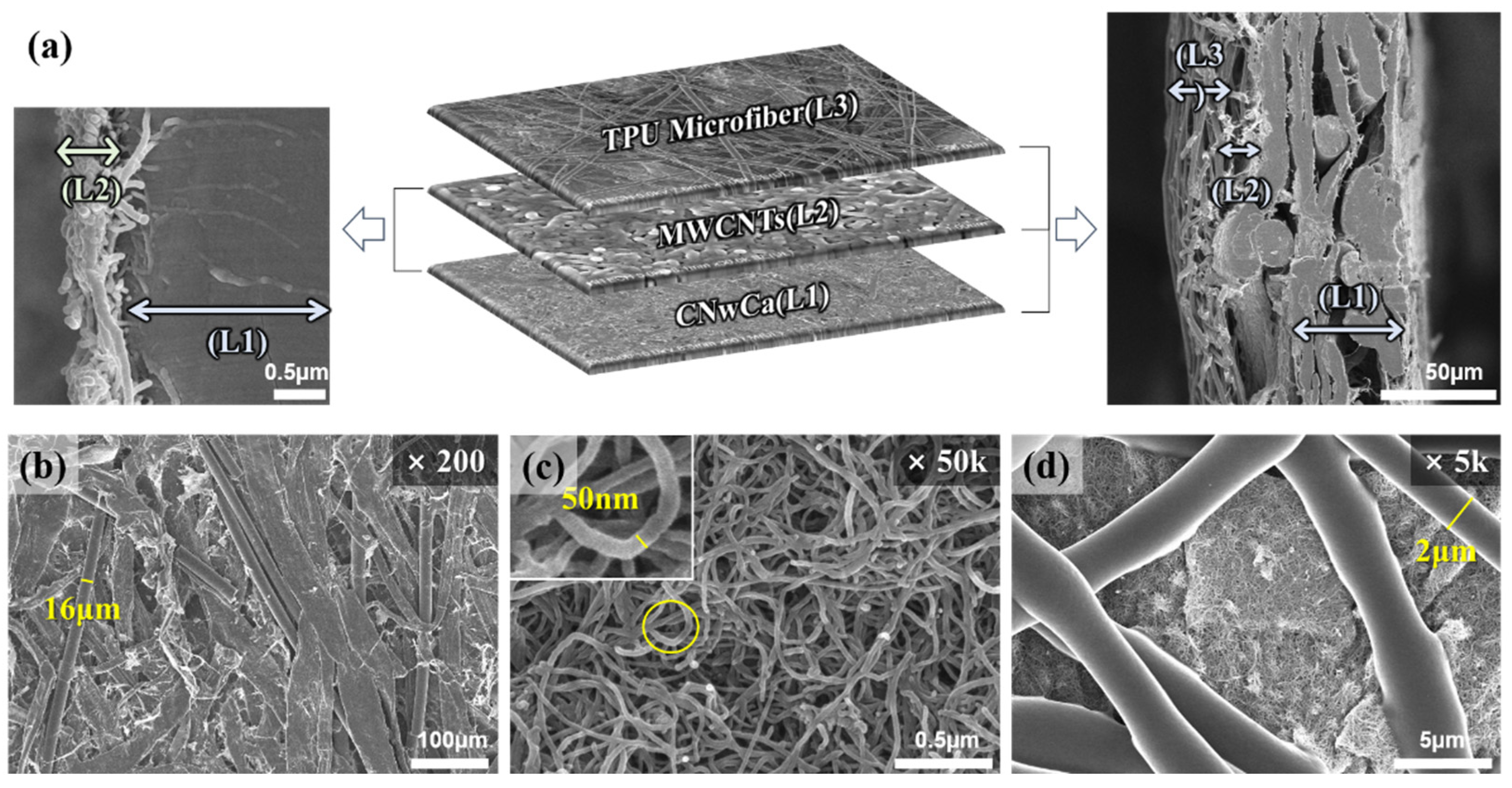

3.1. Morphology of the MWCNT Composite Conductive Nonwoven

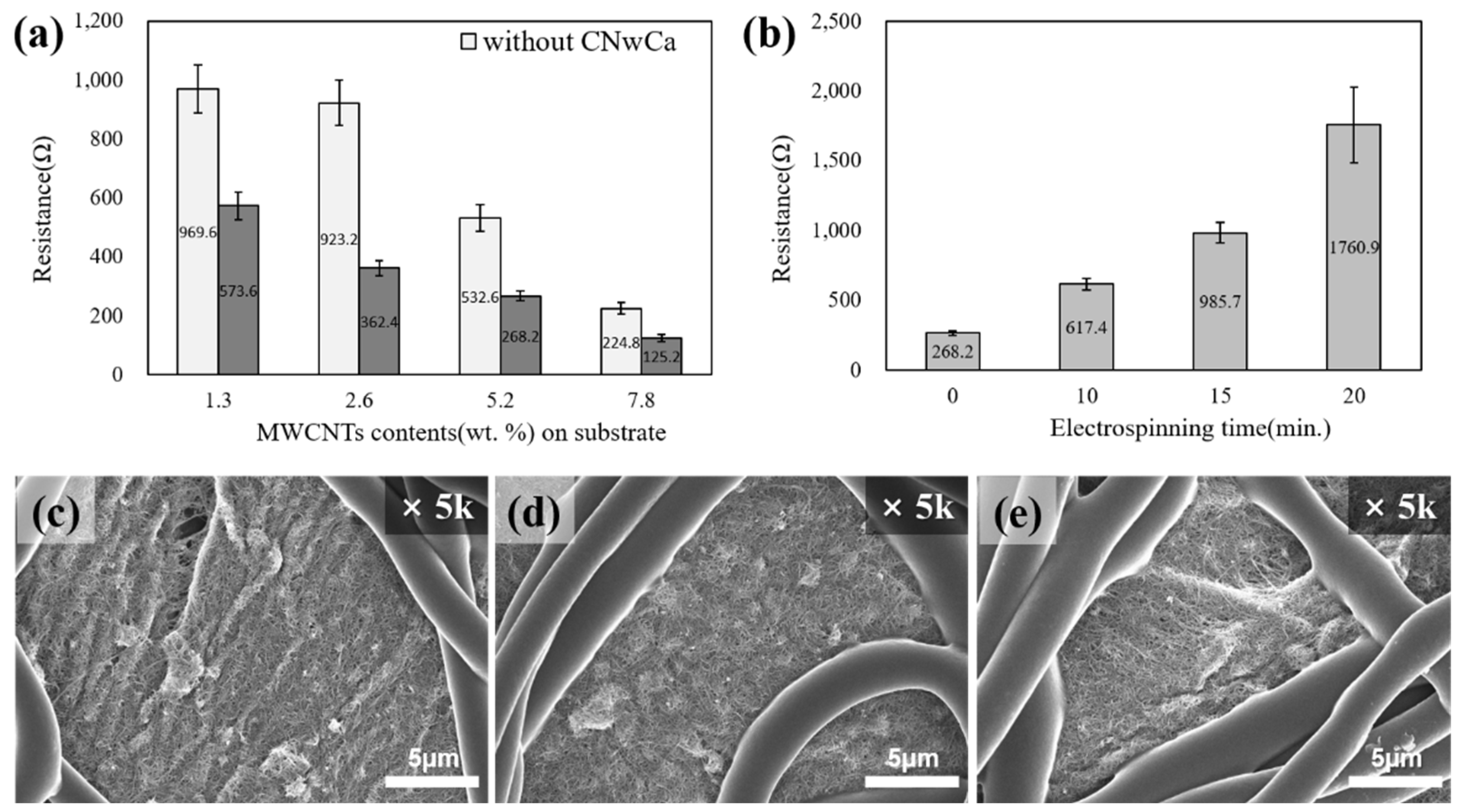

3.2. Optimization of the MWCNT Composite Conductive Nonwoven Fabrication Process

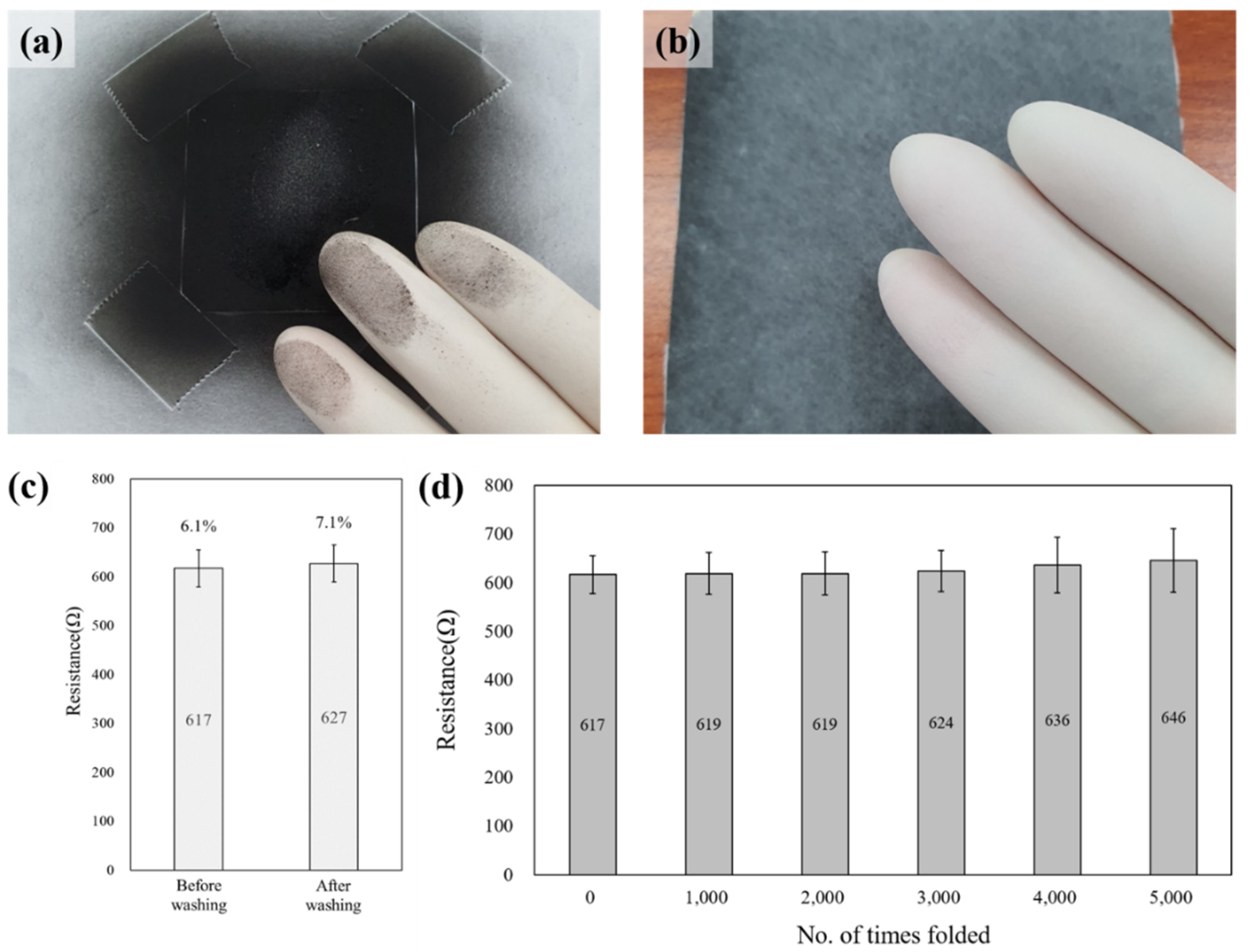

3.3. Durability of the Conductive Nonwoven MWCNT Composite after Electrospinning

3.4. Piezoresistive Properties of the MWCNT Composite Conductive Nonwoven

3.5. Applications of the Touch Sensor Using Conductive Nonwoven MWCNT Composite

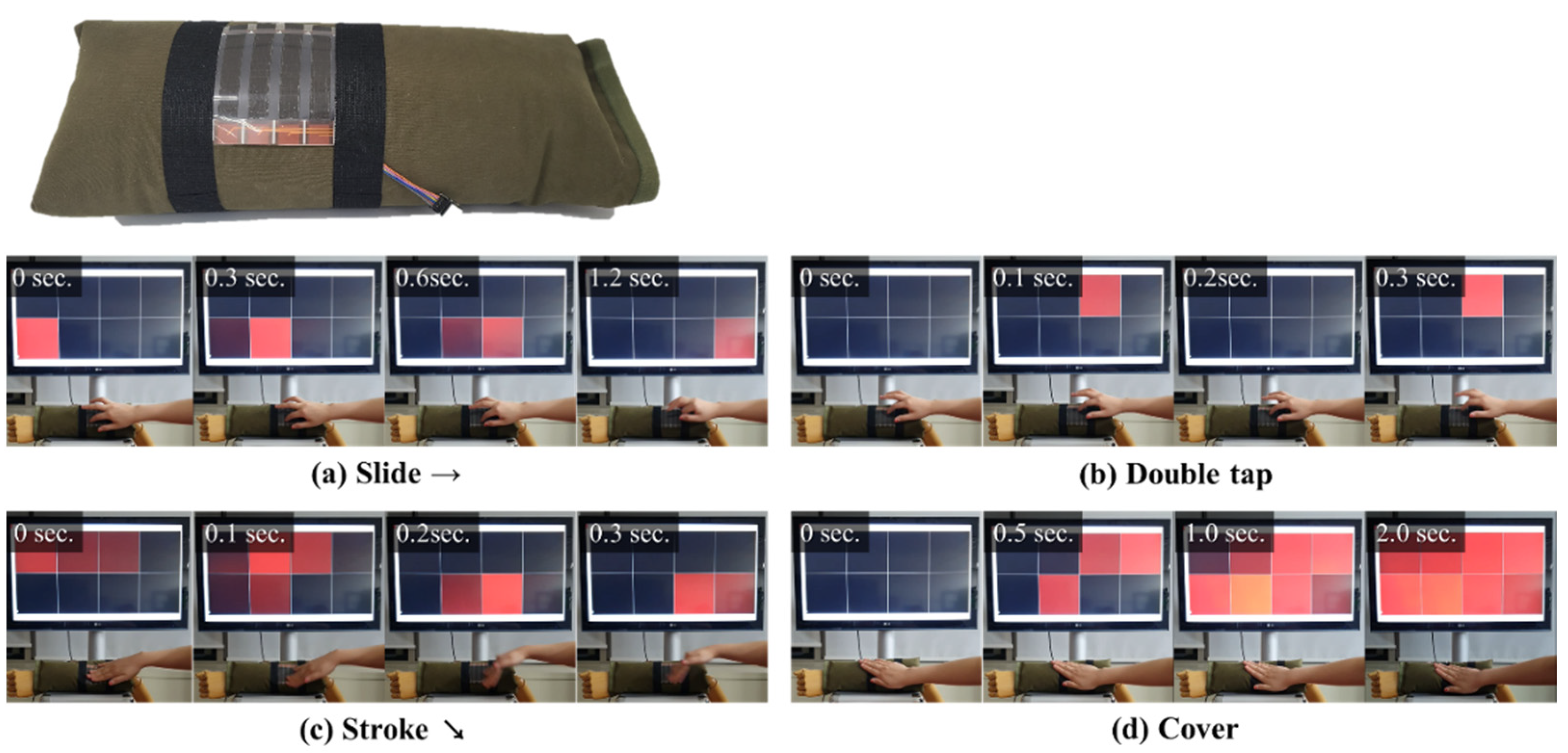

3.5.1. Airbag Touch Sensor for Soft Robot

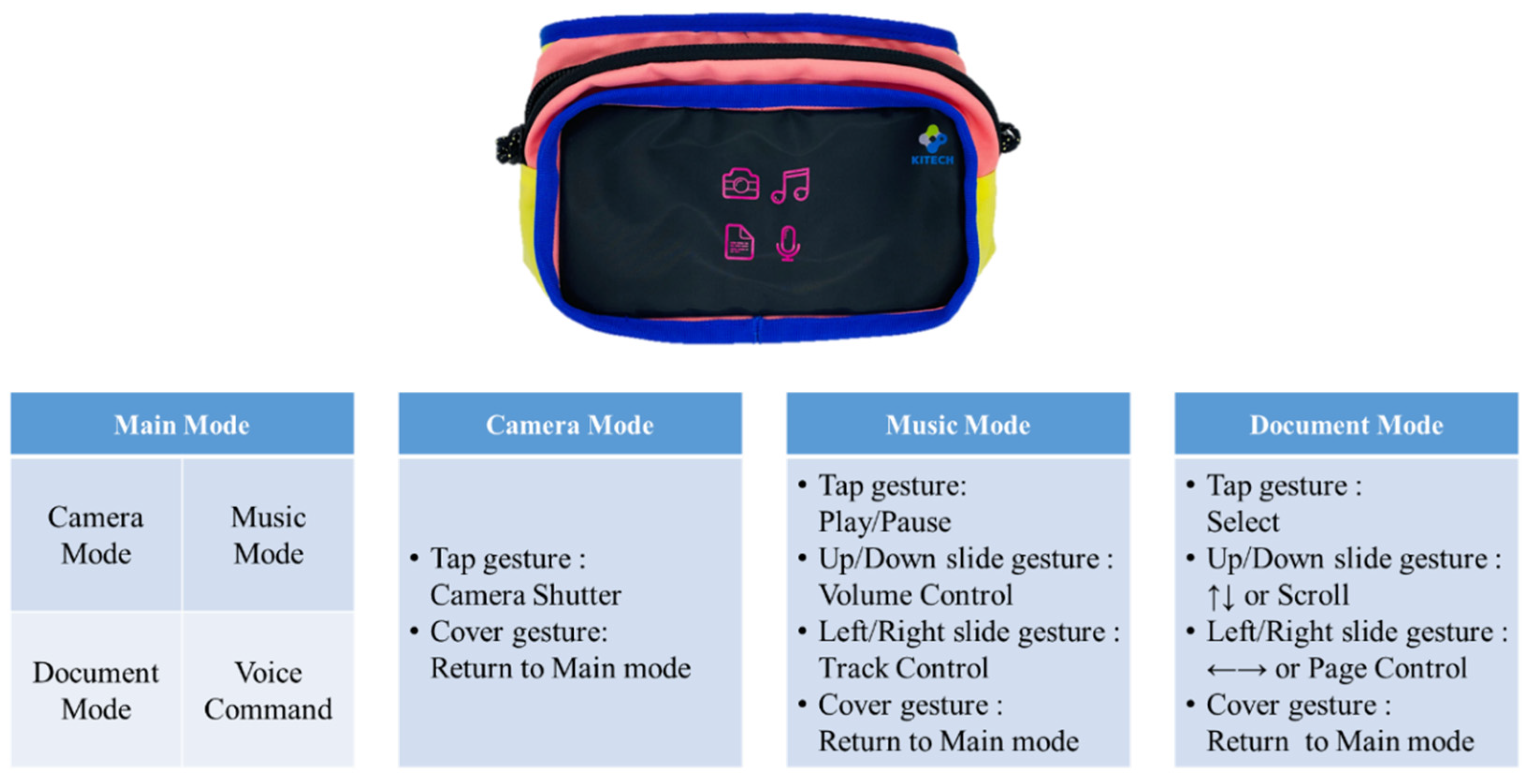

3.5.2. Smart Bag Prototype with a Mode Switchable Touch Sensor

- If the ADC values of all the sensing cells are less than 30, it is not recognized as a gesture;

- If the maximum ADC value of all the sensing cells is greater than or equal to 30, it is determined that the corresponding cell has been touched;

- If there is a touched cell, and the sum of the ADC values of all the cells is greater than 200, and the standard deviation is less than two, it is recognized as a cover gesture;

- If there is a touched cell in the current sampling, and there is no touched cell in the next sampling, it is recognized as a tap gesture;

- If there is a touched cell in the current sampling and next sampling, and the touched cells in the current sampling and next sampling are different, it is recognized as a slide gesture;

- If there is a touched cell in the current sampling and next sampling, and the touched cells in the current sampling and next sampling are the same, it is recognized as a long tap gesture.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Maharjan, P.; Toyabur, R.M.; Park, J.Y. A human locomotion inspired hybrid nanogenerator for wrist-wearable electronic device and sensor applications. Nano Energy 2018, 46, 383–395. [Google Scholar] [CrossRef]

- Chang, C.C.; Shih, J.F.; Chiou, Y.C.; Lee, R.T.; Tseng, S.F.; Yang, C.R. Development of textile-based triboelectric nanogenerators integrated with plastic metal electrodes for wearable devices. Int. J. Adv. Manuf. Technol. 2019, 104, 2633–2644. [Google Scholar] [CrossRef]

- Lee, S.P.; Ha, G.; Wright, D.E.; Ma, Y.; Sen-Gupta, E.; Haubrich, N.R.; Branche, P.C.; Li, W.; Huppert, G.L.; Johnson, M.; et al. Highly flexible, wearable, and disposable cardiac biosensors for remote and ambulatory monitoring. NPJ Digit Med. 2018, 1, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, S.; Lou, Z.; Chen, D.; Chen, Z.; Jiang, K.; Shen, G. Highly flexible strain sensor based on ZnO nanowires and P(VDF-TrFE) fibers for wearable electronic device. Sci. China Mater. 2016, 59, 173–181. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Zhang, Y.; Huang, Y.; Xie, J.; Zhao, X.; Li, C.; Qu, J.; Zhang, Q.; Sun, J.; He, B.; et al. 3D Printing fiber electrodes for an all-fiber integrated electronic device via hybridization of an asymmetric supercapacitor and a temperature sensor. Adv. Sci. 2018, 5, 1801114. [Google Scholar] [CrossRef]

- Zhao, M.; Li, D.; Huang, J.; Wang, D.; Mensaha, A.; Wei, Q. A multifunctional and highly stretchable electronic device based on silver nanowire/wrap yarn composite for a wearable strain sensor and heater. J. Mater. Chem. C 2019, 7, 13468–13476. [Google Scholar] [CrossRef]

- Xiong, J.; Lee, P.S. Progress on wearable triboelectric nanogenerators in shapes of fiber, yarn, and textile. STAM 2019, 20, 837–857. [Google Scholar] [CrossRef] [Green Version]

- Qu, S.; Chen, Y.; Shi, W.; Wang, M.; Yao, Q.; Chen, L. Cotton-based wearable poly(3-hexylthiophene) electronic device for thermoelectric application with cross-plane temperature gradient. Thin Solid Films 2018, 667, 59–63. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, C.; Yin, Y.; Li, Y.; Xing, Y.; Song, J. Functional soft composites as thermal protecting substrates for wearable electronics. Adv. Funct. Mater. 2019, 7, 1905470. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, T.; Yao, J.; Zhang, Y.; Xu, J.; Yang, G. Flexible, transparent and ultra-broadband photodetector based on large-area WSe2 film for wearable devices. Nanotechnology 2016, 27, 225501. [Google Scholar] [CrossRef]

- Nascimento, B.; Oliveira, T.; Tam, C. Wearable technology: What explains continuance intention in smartwatches? J. Retail. Consum. Serv. 2018, 43, 157–169. [Google Scholar] [CrossRef]

- Rai, P.; Oh, S.; Shyamkumar, P.; Ramasamy, M.; Harbaugh, R.E.; Varadan, V.K. Nano- bio-textile sensors with mobile wireless platform for wearable health monitoring of neurological and cardiovascular disorders. J. Electrochem. Soc. 2014, 161, B3116. [Google Scholar] [CrossRef]

- Marculescu, D.; Marculescu, R.; Zamora, N.H.; Stanley-Marbell, P.; Khosla, P.K.; Park, S.; Jayaraman, S.; Jung, S.; Lauterbach, C.; Weber, W. Electronic textiles: A platform for pervasive computing. Proc. IEEE 2003, 91, 1995. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Rudnicki, C.; Chatterjee, R.; Mina, K.; Onyeije, O.; Starner, T. JacquardToolkit: Enabling interactions with the Levi’s Jacquard jacket. In Proceedings of the 23rd International Symposium on Wearable Computers (ISWC), New York, NY, USA, 9–13 September 2019; pp. 106–108. [Google Scholar]

- Kumar, A.; Rudnicki, C.; Chatterjee, R.; Mina, K.; Onyeije, O.; Starner, T. JacquardToolkit: Enabling and exploring interactions with the Levi’s jacquard jacket. In Proceedings of the Adjunct Proceedings of the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing and Proceedings of the 2019 ACM International Symposium on Wearable Computers (UbiComp/ISWC), London, UK, 11–13 September 2019; pp. 306–307. [Google Scholar]

- Chronakis, I.S.; Grapenson, S.; Jakob, A. Conductive polypyrrole nanofibers via electrospinning: Electrical and morphological properties. Polymer 2006, 47, 1597–1603. [Google Scholar] [CrossRef]

- Karim, M.R. Fabrication of electrospun aligned nanofibers from conducting polyaniline copolymer/polyvinyl alcohol/chitosan oligossacaride in aqueous solutions. Synth. Met. 2013, 178, 34–37. [Google Scholar] [CrossRef]

- Sun, B.; Long, Y.Z.; Liu, S.L.; Huang, Y.Y.; Ma, J.; Zhang, H.D.; Shen, G.; Xu, S. Fabrication of curled conducting polymer microfibrous arrays via a novel electrospinning method for stretchable strain sensors. Nanoscale 2013, 5, 7041–7045. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, H.; Liu, Y.; Wang, H.; Huang, Z.; Peijs, T.; Bilotti, E. Synergistic effects of spray-coated hybrid carbon nanoparticles for enhanced electrical and thermal surface conductivity of CFRP laminates. Compos. Part A 2018, 105, 9–18. [Google Scholar] [CrossRef]

- Smith, J. A comparison of spray-guided stratified-charge combustion performance with outwardly-opening piezo and multi-hole solenoid injectors. SAE Int. J. Engines 2011, 4, 1481–1497. [Google Scholar] [CrossRef]

- Wang, X.; Sparkman, J.; Gou, J. Strain sensing of printed carbon nanotube sensors on polyurethane substrate with spray deposition modeling. Compos. Commun. 2017, 3, 1–6. [Google Scholar] [CrossRef]

- Mazinani, S.; Ajji, A.; Dubois, C. Morphology, structure and properties of conductive PS/CNT nanocomposite electrospun mat. Polymer 2009, 14, 3329–3342. [Google Scholar] [CrossRef]

- Liu, W.W.; Chai, S.P.; Mohamed, A.R.; Hashim, U. Synthesis and characterization of graphene and carbon nanotubes: A review on the past and recent developments. J. Ind. Eng. Chem. 2014, 20, 1171–1185. [Google Scholar] [CrossRef]

- Giofre, S.V.; Tiecco, M.; Celesti, C.; Patane, S.; Triolo, C.; Gulino, A.; Spitaleri, L.; Scalese, S.; Scuderi, M.; Iannazzo, D. Eco-Friendly 1,3-Dipolar Cycloaddition Reactions on Graphene Quantum Dots in Natural Deep Eutectic Solvent. Nanomaterials 2020, 10, 2549. [Google Scholar] [CrossRef] [PubMed]

- Khayal, A.; Dawane, V.; Amin, M.A.; Tirth, V.; Yadav, V.K.; Algahtani, A.; Khan, S.H.; Islam, S.; Yadav, K.K.; Jeon, B.H. Advances in the Methods for the Synthesis of Carbon Dots and Their Emerging Applications. Polymers 2021, 13, 3190. [Google Scholar] [CrossRef]

- Tuccitto, N.; Catania, G.; Pappalardo, A.; Sfrazzetto, T. Agile Detection of Chemical Warfare Agents by Machine Vision: A Supramolecular Approach. Chem. Eur. J. 2021, 27, 13715–13718. [Google Scholar] [CrossRef] [PubMed]

- Tuccitto, N.; Riela, L.; Zammataro, A.; Spitaleri, L.; Li-Destri, G.; Sfuncia, G.; Nicotra, G.; Pappalardo, A.; Capizzi, G.; Sfrazzetto, G.T. Functionalized Carbon Nanoparticle-Based Sensors for Chemical Warfare Agents. ACS Appl. Nano Mater. 2020, 3, 8182–8191. [Google Scholar] [CrossRef]

- Jang, D.; Park, J.E.; Kim, Y.K. Evaluation of (CNT@CIP)-Embedded Magneto-Resistive Sensor Based on Carbon Nanotube and Carbonyl Iron Powder Polymer Composites. Polymers 2022, 14, 542. [Google Scholar] [CrossRef] [PubMed]

- Tuccitto, N.; Spitaleri, L.; Destri, G.L.; Pappalardo, A.; Gulino, A.; Sfrazzetto, G.T. Supramolecular Sensing of a Chemical Warfare Agents Simulant by Functionalized Carbon Nanoparticles. Molecules 2020, 25, 5731. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.; Lanceros-Mende, S. Piezoresistive response of spray-printed carbon nanotube/poly(vinylidene fluoride) composites. Compos. Part B 2016, 96, 242–247. [Google Scholar] [CrossRef]

- Ahmed, A.; Jia, Y.; Huang, Y.; Khoso, N.A.; Deb, H.; Fan, O.; Shao, J. Preparation of PVDF-TrFE based electrospun nanofibers decorated with PEDOT-CNT/rGO composites for piezo-electric pressure sensor. J. Mater. Sci. Mater. Electron. 2019, 30, 14007–14021. [Google Scholar] [CrossRef]

- Tran, M.T.; Tung, T.T.; Sachan, A.; Losic, D.; Castro, M.; Feller, J.F. 3D sprayed polyurethane functionalized graphene/carbon nanotubes hybrid architectures to enhance the piezo-resistive response of quantum resistive pressure sensors. Carbon 2020, 168, 564–579. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, H.B.; Yeon, S.M.; Park, J.; Lee, N.K. Flexible and stretchable piezoelectric sensor with thickness-tunable configuration of electrospun nanofiber mat and elastomeric substrates. ACS Appl. Mater. Interfaces 2016, 8, 24773–24781. [Google Scholar] [CrossRef] [PubMed]

- Hwang, Y.J.; Choi, S.; Kim, H.S. Highly flexible all-nonwoven piezoelectric generators based on electrospun poly(vinylidene fluoride). Sens. Actuators A Phys. 2019, 300, 111672. [Google Scholar] [CrossRef]

- Nag-Chowdhury, S.; Bellegou, H.; Pillin, I.; Castro, M.; Longrais, P.; Feller, J.F. Non-intrusive health monitoring of infused composites with embedded carbon quantum piezo-resistive sensors. Compos. Sci. Technol. 2016, 123, 286–294. [Google Scholar] [CrossRef]

- Poupyrev, I.; Gong, N.W.; Fukuhara, S.; Karagozler, M.E.; Schwesig, C.; Robinson, K.E. Project jacquard: Interactive digital textiles at scale. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems (CHI), San Jose, CA, USA, 7–12 May 2016; pp. 4216–4227. [Google Scholar]

- Lim, S.J.; Bae, J.H.; Han, J.H.; Jang, S.J.; Oh, H.J.; Lee, W.; Kim, S.H.; Ko, J.H. Foldable and washable fully textile-based pressure sensor. Smart Mater. Struct. 2020, 29, 055010. [Google Scholar] [CrossRef]

- Wei, X.; Cao, X.; Wang, Y.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Conductive herringbone structure carbon nanotube/thermoplastic polyurethane porous foam tuned by epoxy for high performance flexible piezoresistive sensor. Comp. Sci. Technol. 2017, 149, 166–177. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, S.J.; Kim, M.; Lim, J.Y.; Park, Y.K.; Ko, J.H. Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric. Polymers 2022, 14, 1545. https://doi.org/10.3390/polym14081545

Jang SJ, Kim M, Lim JY, Park YK, Ko JH. Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric. Polymers. 2022; 14(8):1545. https://doi.org/10.3390/polym14081545

Chicago/Turabian StyleJang, Seong Jin, Minhee Kim, Jee Young Lim, Young Ki Park, and Jae Hoon Ko. 2022. "Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric" Polymers 14, no. 8: 1545. https://doi.org/10.3390/polym14081545

APA StyleJang, S. J., Kim, M., Lim, J. Y., Park, Y. K., & Ko, J. H. (2022). Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric. Polymers, 14(8), 1545. https://doi.org/10.3390/polym14081545