Short- and Long-Term Performance of Pipe Compounds Containing Polyethylene Post-Consumer Recyclates from Packaging Waste

Abstract

:1. Introduction

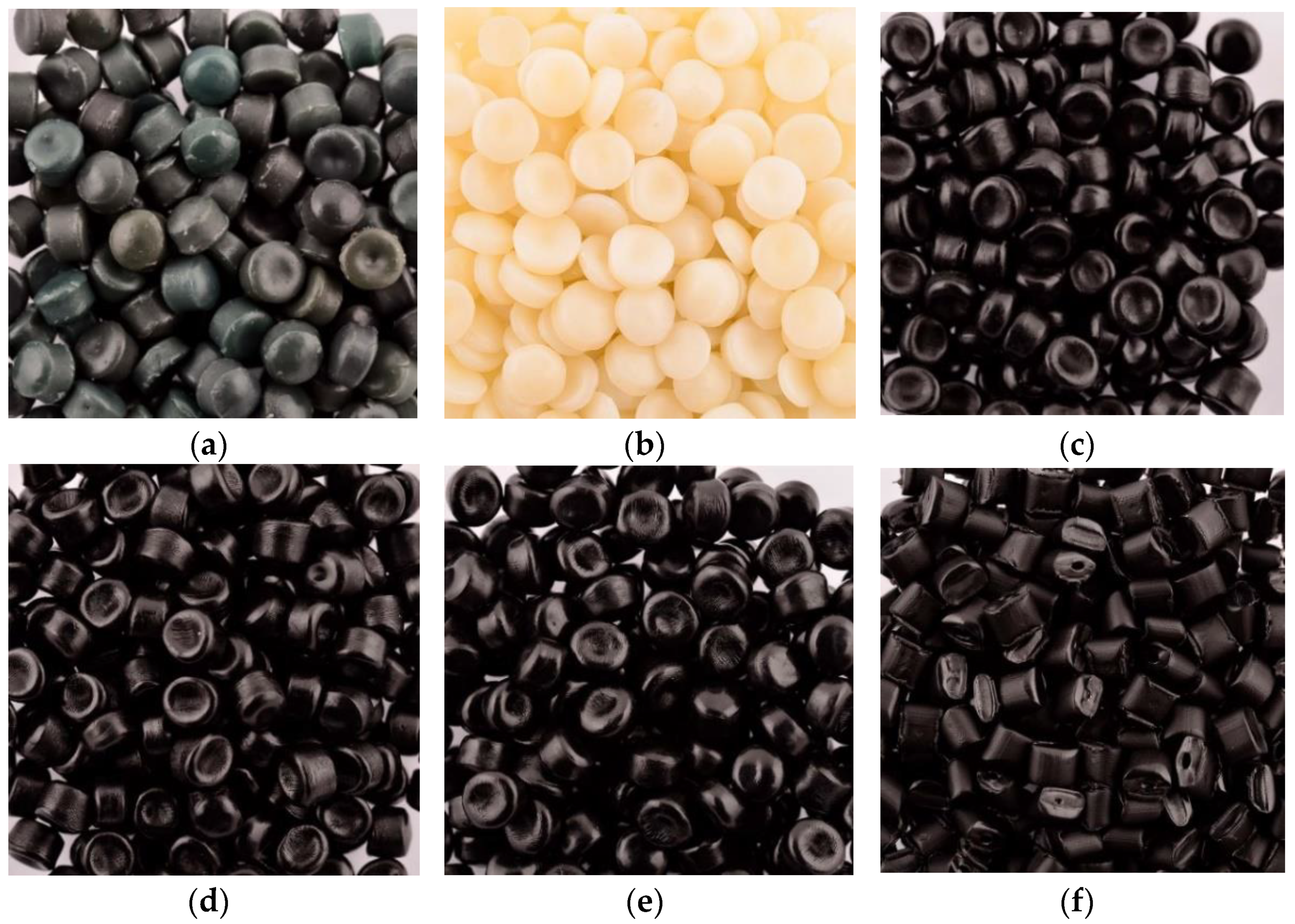

2. Materials and Methods

3. Results

3.1. Melt Flow Rate

3.2. Dynamic Scanning Calorimetry

3.3. Tensile Properties

3.4. Charpy Notched Impact Strength

3.5. Fatigue Crack Growth Resistance

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. A European Strategy for Plastics in a Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2018:28:FIN (accessed on 10 April 2022).

- European Parliament; Council of the European Union. Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste: PE/12/2018/REV/2. Available online: https://eur-lex.europa.eu/eli/dir/2018/852/oj (accessed on 10 April 2022).

- European Parliament; Council of the European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment: PE/11/2019/REV/1. Available online: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed on 10 April 2022).

- CEN/TC 107—Prefabricated District Heating and District Cooling Pipe System. In EN 253:2019 District Heating Pipes—Bonded Single Pipe Systems for Directly Buried Hot Water Networks—Factory Made Pipe Assembly of Steel Service Pipe, Polyurethane Thermal Insulation and a Casing of Polyethylene. 2019. Available online: https://www.beuth.de/de/norm/din-en-253/309495925 (accessed on 10 April 2022).

- CEN/TC 155—Plastics Piping Systems and Ducting Systems. In EN 1519-1:2019 Plastics Piping Systems for Soil and Waste Discharge (Low and High Temperature) Within the Building Structure—Polyethylene (PE)—Part 1: Requirements for Pipes, Fittings and the System. 2019. Available online: https://www.beuth.de/de/norm/din-en-1519-1/295667695 (accessed on 10 April 2022).

- CEN/TC 155—Plastics Piping Systems and Ducting Systems. In EN 1555-1:2021 Plastics Piping Systems for the Supply of Gaseous Fuels—Polyethylene (PE)—Part. 1: General. 2021. Available online: https://www.beuth.de/de/norm/din-en-1555-1/335904612 (accessed on 10 April 2022).

- CEN/TC 155: Plastics Piping Systems and Ducting Systems. In EN 12201-1:2011 Plastics Piping Systems for Water Supply, and for Drainage and Sewerage under Pressure—Polyethylene (PE)—Part 1: General. 2011. Available online: https://www.beuth.de/de/norm/din-en-12201-1/139389688 (accessed on 10 April 2022).

- CEN/TC 155: Plastics Piping Systems and Ducting Systems. In EN 12666-1:2005+A1:2011 Plastics Piping Systems for Non-Pressure Underground Drainage and Sewerage—Polyethylene (PE)—Part 1: Specifications for Pipes, Fittings and the System. 2011. Available online: https://www.beuth.de/de/norm/din-en-12666-1/139590041 (accessed on 10 April 2022).

- ISO/TC 138/SC 5 General Properties of Pipes, Fittings and Valves of Plastic Materials and Their Accessories—Test Methods and Basic Specifications. In ISO 13477:2008 Thermoplastics Pipes for the Conveyance of Fluids—Determination of Resistance to Rapid Crack Propagation (RCP)—Small-Scale Steady-State Test (S4 Test), 2nd ed. 2008. Available online: https://www.iso.org/standard/39858.html (accessed on 10 April 2022).

- ISO/TC 138/SC 5 General Properties of Pipes, Fittings and Valves of Plastic Materials and Their Accessories—Test Methods and Basic Specifications. In ISO 13479:2009 Polyolefin Pipes for the Conveyance of Fluids—Determination of Resistance to Crack Propagation—Test Method for Slow Crack Growth on Notched Pipes, 2nd ed. 2009. Available online: https://www.iso.org/standard/45812.html (accessed on 10 April 2022).

- ISO/TC 138/SC 5 General Properties of Pipes, Fittings and Valves of Plastic Materials and Their Accessories—Test Methods and Basic Specifications. In ISO 18488:2015 Polyethylene (PE) Materials for Piping Systems—Determination of Strain Hardening Modulus in Relation to Slow Crack Growth—Test Method, 1st ed. 2015. Available online: https://www.iso.org/standard/62592.html (accessed on 10 April 2022).

- ISO/TC 61/SC 9 Thermoplastic Materials. In ISO 16770:2004 Plastics—Determination of Environmental Stress Cracking (ESC) of Polyethylene—Full-Notch Creep Test (FNCT), 1st ed. 2004. Available online: https://www.iso.org/standard/70480.html (accessed on 10 April 2022).

- ISO/TC 138/SC 5 General Properties of Pipes, Fittings and Valves of Plastic Materials and Their Accessories—Test Methods and Basic Specifications. In ISO 18489:2015 Polyethylene (PE) Materials for Piping Systems—Determination of Resistance to Slow Crack Growth under Cyclic Loading—Cracked Round Bar Test Method, 1st ed. 2016. Available online: https://www.iso.org/standard/62593.html (accessed on 10 April 2022).

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; García-Muñoz, R.A. Incorporation of Recycled High-Density Polyethylene to Polyethylene Pipe Grade Resins to Increase Close-Loop Recycling and Underpin the Circular Economy. J. Clean. Prod. 2020, 276, 124081. [Google Scholar] [CrossRef]

- Lang, R.W.; Bradler, P.R.; Fischer, J.; Poehlmann, D.; Schmidt, S.; Niehoff, A. Quality and performance assessment of in-plant and post-use PE recyclates for pipe applications. In Proceedings of the 18th Plastic Pipes Conference PPXVIII, Berlin, Germany, 12–14 September 2016. [Google Scholar]

- Gall, M.; Lang, R.W.; Fischer, J.; Niehoff, A.; Schmidt, S. Characterization of post-use polyethylene and polypropylene recyclate blends for pipe applications. In Proceedings of the 19th Plastic Pipes Conference PPXIX, Las Vegas, NV, USA, 24–26 September 2018. [Google Scholar]

- Frank, A.; Pinter, G. Evaluation of the applicability of the cracked round bar test as standardized PE-pipe ranking tool. Polym. Test. 2014, 33, 161–171. [Google Scholar] [CrossRef]

- Arbeiter, F.; Schrittesser, B.; Frank, A.; Berer, M.; Pinter, G. Cyclic tests on cracked round bars as a quick tool to assess the long term behaviour of thermoplastics and elastomers. Polym. Test. 2015, 45, 83–92. [Google Scholar] [CrossRef]

- Lang, R.W.; Pinter, G.; Balika, W. Konzept zur Nachweisführung für Nutzungsdauer und Sicherheit von PE-Druckrohren bei beliebiger Einbausituation. 3r Int. 2005, 44, 32–41. [Google Scholar]

- Pinter, G.; Haager, M.; Balika, W.; Lang, R.W. Cyclic crack growth tests with CRB specimens for the evaluation of the long-term performance of PE pipe grades. Polym. Test. 2007, 26, 180–188. [Google Scholar] [CrossRef]

- Frank, A.; Freimann, W.; Pinter, G.; Lang, R.W. A fracture mechanics concept for the accelerated characterization of creep crack growth in PE-HD pipe grades. Eng. Fract. Mech. 2009, 76, 2780–2787. [Google Scholar] [CrossRef]

- Fischer, J.; Bradler, P.R.; Lang, R.W. Test equipment for fatigue crack growth testing of polymeric materials in chlorinated water at different temperatures. Eng. Fract. Mech. 2018, 203, 44–53. [Google Scholar] [CrossRef]

- Fischer, J.; Freudenthaler, P.J.; Bradler, P.R.; Lang, R.W. Novel test system and test procedure for fatigue crack growth testing with cracked round bar (CRB) specimens. Polym. Test. 2019, 78, 105998. [Google Scholar] [CrossRef]

- Fischer, J.; Freudenthaler, P.J.; Lang, R.W.; Buchberger, W.; Mantell, S.C. Chlorinated Water Induced Aging of Pipe Grade Polypropylene Random Copolymers. Polymers 2019, 11, 996. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Umweltbundesamt: Präsidialbereich/Presse- und Öffentlichkeitsarbeit, Internet. Verpackungen. Available online: https://www.umweltbundesamt.de/themen/abfall-ressourcen/produktverantwortung-in-der-abfallwirtschaft/verpackungen#undefined (accessed on 15 February 2022).

- Ehrenstein, G.W.; Pongratz, S. Beständigkeit von Kunststoffen; Hanser: München, Germany, 2007; ISBN 978-3-446-21851-2. [Google Scholar]

- Gustenau, T. Einfluss von Antioxidantien auf die Alterung von Polyethylen. Master’s Thesis, TU Wien, Vienna, Austria, 2016. [Google Scholar]

- Pospíšil, J.; Horák, Z.; Pilař, J.; Billingham, N.; Zweifel, H.; Nešpůrek, S. Influence of testing conditions on the performance and durability of polymer stabilisers in thermal oxidation. Polym. Degrad. Stab. 2003, 82, 145–162. [Google Scholar] [CrossRef]

- ISO/TC 61/SC 5 Physical-Chemical Properties. In ISO 1133-1:2011 Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method, 1st ed. 2011. Available online: https://www.iso.org/standard/44273.html (accessed on 10 April 2022).

- ISO/TC 61/SC 9 Thermoplastic Materials. In ISO 17855-2:2016 Plastics—Polyethylene (PE) Moulding and Extrusion Materials—Part 2: Preparation of Test Specimens and Determination of Properties, 1st ed. 2016. Available online: https://www.iso.org/standard/66827.html (accessed on 10 April 2022).

- ISO/TC 61/SC 2 Mechanical Behavior. In ISO 3167:2014 Plastics—Multipurpose Test Specimens, 5th ed. 2014. Available online: https://www.iso.org/standard/65105.html (accessed on 10 April 2022).

- ISO/TC 61/SC 2 Mechanical Behavior. In ISO 179-1:2010 Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test, 2nd ed. 2010. Available online: https://www.iso.org/standard/44852.html (accessed on 10 April 2022).

- ISO/TC 61/SC 5 Physical-Chemical Properties. In ISO 11357-1:2016 Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles, 3rd ed. 2016. Available online: https://www.iso.org/standard/70024.html (accessed on 10 April 2022).

- ISO/TC 61/SC 5 Physical-Chemical Properties. In ISO 11357-3:2018 Plastics—Differential Scanning Calorimetry (DSC)—Part 3: DETERMINATION of Temperature and Enthalpy of Melting and Crystallization, 3rd ed. 2018. Available online: https://www.iso.org/standard/72460.html (accessed on 10 April 2022).

- ISO/TC 61/SC 11 Products. In ISO 527-3:2018 Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Sheets, 2nd ed. 2018. Available online: https://www.iso.org/standard/70307.html (accessed on 10 April 2022).

- ISO/TC 61/SC 2 Mechanical Behavior. In ISO 527-1:2019 Plastics—Determination of Tensile Properties—Part 1: General Principles, 3rd ed. 2019. Available online: https://www.iso.org/standard/75824.html (accessed on 10 April 2022).

- ISO/TC 61/SC 2 Mechanical Behavior. In ISO 527-2:2012 Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics, 2nd ed. 2012. Available online: https://www.iso.org/standard/56046.html (accessed on 10 April 2022).

- CEN/TC 155: Plastics Piping Systems and Ducting Systems. In EN 13476-2:2018+A1:2020 Plastics Piping Systems for Non-Pressure Underground Drainage and Sewerage—Structured-Wall Piping Systems of Unplasticized Poly(vinyl chloride) (PVC-U), Polypropylene (PP) and Polyethylene (PE)—Part 2: Specifications for Pipes and Fittings with Smooth Internal and External Surface and the System. 2020. Available online: https://www.beuth.de/de/norm/din-en-13476-2/323976389 (accessed on 10 April 2022).

- CEN/TC 155: Plastics Piping Systems and Ducting Systems. In EN 13476-3:2018+A1:2020 Plastics Piping Systems for Non-Pressure Underground Drainage and Sewerage—Structured-Wall Piping Systems of Unplasticized Poly(vinyl chloride) (PVC-U), Polypropylene (PP) and Polyethylene (PE)—Part 3: Specifications for Pipes and Fittings with Smooth Internal and Profiled External Surface and the System. 2020. Available online: https://www.beuth.de/de/norm/din-en-13476-3/323982142 (accessed on 10 April 2022).

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef] [PubMed]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Thermal Analysis of Plastics: Theory and Practice; Hanser: Munich, Germany, 2004; ISBN 978-3-446-22673-9. [Google Scholar]

- Benthem, J.P.; Koiter, W.T. Asymptotic approximations to crack problems. In Methods of Analysis and Solutions of Crack Problems: Recent Developments in Fracture Mechanics Theory and Methods of Solving Crack Problems; Sih, G.C., Ed.; Springer: Dordrecht, The Netherlands, 1973; pp. 131–178. ISBN 978-90-481-8246-6. [Google Scholar]

- Hertzberg, R.W.; Vinci, R.P.; Hertzberg, J.L. Deformation and Fracture Mechanics of Engineering Materials, 5th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; ISBN 9780470527801. [Google Scholar]

- Frank, A.; Berger, I.; Messiha, M.; Ek, C.-G.; Schuler, N.; Storheil, J.-M.; Mayrbäurl, E.; Heeley, S.; Krause, F.; Niemöller, L.; et al. Slow Crack Growth Resistance of Non-Virgin Polymers. In Proceedings of the 19th Plastic Pipes Conference PPXIX, Las Vegas, NV, USA, 24–26 September 2018. [Google Scholar]

- Frank, A.; Berger, I.J.; Messiha, M.; Pinter, G. Influence of polyolefin cross-contamination on the slow crack growth resistance of polyethylene pipe grade. In Proceedings of the SPE ANTEC 2019, Detroit, MI, USA, 18–21 March 2019; Society of Plastics Engineers, Ed.; ISBN 9781713801986. [Google Scholar]

- Ronca, S. Polyethylene. Brydson’s Plastics Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 247–278. ISBN 9780323358248. [Google Scholar]

| PE100-RC | rPE-A | rPE-B | |

|---|---|---|---|

| m% | m% | m% | |

| A25 | 75 | 25 | - |

| A50 | 50 | 50 | - |

| A75 | 25 | 75 | - |

| B25 | 75 | - | 25 |

| B50 | 50 | - | 50 |

| B75 | 25 | - | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freudenthaler, P.J.; Fischer, J.; Liu, Y.; Lang, R.W. Short- and Long-Term Performance of Pipe Compounds Containing Polyethylene Post-Consumer Recyclates from Packaging Waste. Polymers 2022, 14, 1581. https://doi.org/10.3390/polym14081581

Freudenthaler PJ, Fischer J, Liu Y, Lang RW. Short- and Long-Term Performance of Pipe Compounds Containing Polyethylene Post-Consumer Recyclates from Packaging Waste. Polymers. 2022; 14(8):1581. https://doi.org/10.3390/polym14081581

Chicago/Turabian StyleFreudenthaler, Paul J., Joerg Fischer, Yi Liu, and Reinhold W. Lang. 2022. "Short- and Long-Term Performance of Pipe Compounds Containing Polyethylene Post-Consumer Recyclates from Packaging Waste" Polymers 14, no. 8: 1581. https://doi.org/10.3390/polym14081581