Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

2.2. Preparation and Details of Specimens

2.3. Experimental Instrumentation and Methods

3. Results and Discussion

3.1. Failure Mechanism

3.2. Compressive Stress–Strain Behavior

3.3. Stress–Strain Characteristics

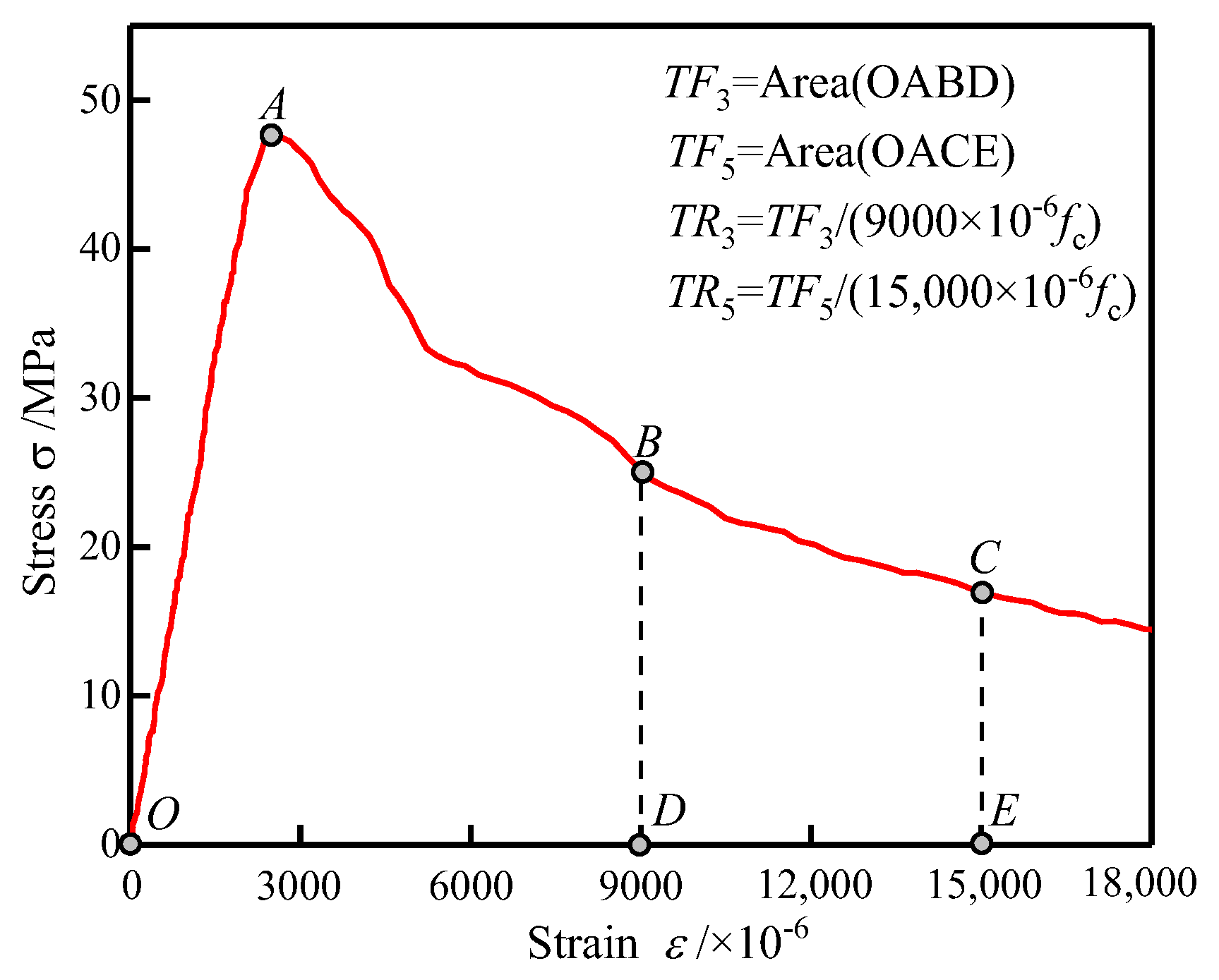

3.4. Toughness

3.5. Assessment of Synergy

4. Compressive Stress–Strain Model

4.1. Modeling of Compressive Strength

4.2. Modeling of Critical Strain at Peak Compressive Stress

4.3. Modeling of the Stress–Strain Curve

4.3.1. Existing Models

4.3.2. New Proposal for the Stress–Strain Curve of FLWAC

4.4. Comparison between Experimental Results and the Proposed Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| fcu | Cubic compressive strength/MPa |

| fc | Compressive strength corresponding to the peak point of stress–strain curve/MPa |

| εc | Critical strain corresponding to the peak point of the stress–strain curve |

| ε0 | Critical strain for corresponding plain LWAC |

| Ec | Initial tangential elastic modulus/GPa |

| E0 | Peak secant elastic modulus/GPa |

| TFi | Toughness |

| TRi | Specific toughness |

| αx−i | Synergistic effect coefficients |

References

- Kockal, N.U.; Ozturan, T. Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J. Hazard. Mater. 2010, 179, 954–965. [Google Scholar] [CrossRef] [PubMed]

- Sohel, K.M.A.; Al-Jabri, K.; Zhang, M.H.; Liew, J.Y.R. Flexural fatigue behavior of ultra-lightweight cement composite and high strength lightweight aggregate concrete. Constr. Build. Mater. 2018, 173, 90–100. [Google Scholar] [CrossRef]

- Guler, S. The effect of polyamide fibers on the strength and toughness properties of structural lightweight aggregate concrete. Constr. Build. Mater. 2018, 173, 394–402. [Google Scholar] [CrossRef]

- Li, J.J.; Niu, J.G.; Wan, C.J.; Jin, Z. Comparison of flexural property between high performance polypropylene fiber reinforced lightweight aggregate concrete and steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- El-Mal, H.; Sherbini, A.S.; Sallam, H. Mode II fracture toughness of Hybrid FRCs. Int. J. Concr. Struct. Mater. 2015, 9, 475–486. [Google Scholar] [CrossRef] [Green Version]

- Qian, K.; Geng, S.Y.; Liang, S.L.; Fu, F.; Yu, J. Effects of loading regimes on the structural behavior of RC beam-column sub-assemblages against disproportionate collapse. Eng. Struct. 2022, 251, 113470. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shafigh, P.; Mahmud, H.B. Lightweight aggregate concrete fiber reinforcement—A review. Constr. Build. Mater. 2012, 37, 452–461. [Google Scholar] [CrossRef]

- Erdem, S.; Dawson, A.R.; Thom, N.H. Impact load-induced micro-structural damage and micro-structure associated mechanical response of concrete made with different surface roughness and porosity aggregates. Cem. Concr. Res. 2012, 42, 291–305. [Google Scholar] [CrossRef]

- Yanga, G.J.; Parkb, M.; Parka, S.J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Lu, Z.H.; Zhao, Y.G. Empirical stress-strain model for unconfined high-strength concrete under uniaxial compression. J. Mater. Civ. Eng. 2010, 22, 1181–1186. [Google Scholar] [CrossRef]

- Weng, Y.H.; Qian, K.; Fu, F.; Fang, Q. Numerical investigation on load redistribution capacity of flat slab substructures to resist progressive collapse. J. Build. Eng. 2020, 29, 101109. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. ACI J. 1985, 82, 797–804. [Google Scholar]

- Guo, Z.H. Concrete Strength and Deformation; Tsinghua University Press: Beijing, China, 1997; pp. 127–131. [Google Scholar]

- Wee, T.H.; Chin, M.S.; Mansur, M.A. Stress-strain relationship of high-strength concrete in compression. J. Mater. Civ. Eng. 1986, 8, 70–76. [Google Scholar] [CrossRef]

- Desnerck, I.P.; Schutter, G.D.; Taerwe, L. Stress-strain behaviour of self-compacting concretes containing limestone fillers. Struct. Concr. 2012, 13, 95–101. [Google Scholar] [CrossRef]

- Tasnimi, A.A. Mathematical model for complete stress–strain curve prediction of normal, lightweight and high-strength concretes. Mag. Concr. Res. 1994, 56, 23–34. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Stress-strain model for normal-and lightweight concretes under uniaxial and triaxial compression. Constr. Build. Mater. 2014, 71, 92–509. [Google Scholar] [CrossRef]

- Wang, D.H.; Ju, Y.Z.; Shen, H.; Jin, Z. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- CS (Chinese Standard) GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods—Part 2: Test Methods for Lightweight Aggregates. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- CS (Chinese Standard) GB 175-2007; Common Portland Cement. China Architecture and Building Press: Beijing, China, 2007. (In Chinese)

- CS (Chinese Standard) GB/T 18736-2017; Mineral Admixtures for High Strength and High Performance Concrete. China Architecture and Building Press: Beijing, China, 2017. (In Chinese)

- CS (Chinese Standard) GB/T 50081-2007; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2007. (In Chinese)

- Wei, Y.; Wu, Y.F. Compressive behavior of concrete columns confined by high strength steel wire. Constr. Build. Mater. 2014, 54, 443–453. [Google Scholar] [CrossRef]

- Domagała, L. Modification of properties of structural lightweight concrete with steel fibres. J. Civ. Eng. Manag. 2011, 17, 36–44. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- CS (Chinese Standard) GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- Gao, D.Y.; Zhang, L.J.; Nokken, M. Compressive behavior of steel fiber reinforced recycled coarse aggregate concrete designed with equivalent cubic compressive strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef] [Green Version]

- CEB-FIP. CEB-FIP Model Code 2010. In Model Code for Concrete Structures; CEB-FIP: London, UK, 2010. [Google Scholar]

- Han, B.; Xiang, T.Y. Axial compressive stress-strain relation and poisson effect of structural lightweight aggregate concrete. Constr. Build. Mater. 2017, 14, 338–343. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete and Commentary; ACI 318-14; ACI: Farmington Hills, MI, USA, 2018. [Google Scholar]

- Fanella, D.A.; Naaman, A.E. Stress-strain properties of fiber reinforced mortar in compression. ACI J. Proc. 1985, 82, 475–483. [Google Scholar]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in hybrid fiber reinforced concrete (HyFRC) in flexure and direct shear. Cem. Concr. Res. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y.; Siddiqui, N. Mechanical properties of hybrid fibre-reinforced concrete–analytical modelling and experimental behavior. Mag. Concr. Res. 2015, 68, 823–843. [Google Scholar] [CrossRef]

- Abbass, M.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, M.S.; Liu, K.Y.; Chang, K.C. Compressive behavior of steel fiber reinforced concrete with a high reinforcing index. J. Mater. Civ. Eng. 2012, 24, 207–215. [Google Scholar] [CrossRef]

- Oliveira Júnior, L.A.; Borges, V.E.S.; Danin, A.R. Stress-strain curves for steel fiber-reinforced concrete in compression. Matéria 2010, 15, 260–266. [Google Scholar] [CrossRef] [Green Version]

| Bulk Density (kg/m3) | Apparent Density (kg/m3) | Crushing Strength (MPa) | 1 h/24 h Water Absorption (%) | Total Porosity (%) | Particle Size Distribution (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.36~5 mm | 5~10 mm | 10~16 mm | ||||||||||||

| 860 | 1512 | 6.9 | 2.2/2.6 | 43.12 | 11 | 68 | 21 | |||||||

| Chemical Composition | ||||||||||||||

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | TiO2 (%) | CaO (%) | MgO (%) | SiO3 (%) | Alkalis as Na2O (%) | LOI (%) | ||||||

| 65.4 | 15.9 | 4.2 | 0.7 | 2.4 | 3.7 | 0.23 | 3.8 | 3.67 | ||||||

| Fiber Details | Carbon Fiber | Polypropylene Fiber |

|---|---|---|

| View |  |  |

| Fiber shape | Straight, filaments | Straight, fibrillated |

| Cut length (Lf) (mm) | 8~10 | 15~22 |

| Diameter (Df) (μm) | 7 | 80 |

| Aspect ratio (Lf/Df) | 1100 | 225 |

| Specific gravity (g/cm3) | 1.8 | 0.91 |

| Elongation (%) | 2.1 | 17 |

| Tensile strength (MPa) | 4000 | >400 |

| Elastic modulus (GPa) | 240 | 22 |

| Water absorption | <1% by weight | Nil |

| Mixture | W/B | Cement | Silica Fume | Fly Ash | LWA | Sand | Water | Superplasticizer |

|---|---|---|---|---|---|---|---|---|

| Plain–a | 0.27 | 440 | 44 | 66 | 603 | 684 | 148.5 | 6.8 |

| Plain–b | 0.3 | 440 | 44 | 66 | 578 | 667 | 165 | 5.2 |

| Fiber | W/B | Carbon Fiber/(%) | Polypropylene Fiber/(%) | Carbon–Polypropylene Hybrid Fibers/(%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.4 | 0.2 | 0.4 | 0.2/0.2 | 0.2/0.4 | 0.4/0.2 | 0.4/0.4 | ||

| Mix code | 0.27 | CF0.2a | CF0.4a | PF0.2a | PF0.4a | CF0.2PF0.2a | CF0.2PF0.4a | CF0.4PF0.2a | CF0.4PF0.4a |

| 0.3 | CF0.2b | CF0.4b | PF0.2b | PF0.4b | CF0.2PF0.2b | CF0.2PF0.4b | CF0.4PF0.2b | CF0.4PF0.4b | |

| Specimen | W/B | VCF (%) | VPF (%) | fcu (MPa) | fc (MPa) | εc (10−6) | εc/ε0 | Ec (GPa) | E0 (GPa) | Ec/E0 |

|---|---|---|---|---|---|---|---|---|---|---|

| Plain–a | 0.27 | 0 | 0 | 61.34 (0.041) | 50.38 | 2492 | 1.000 | 23.4 | 20.2 | 1.157 |

| CF0.2a | 0.2 | 0 | 61.17 (0.038) | 55.97 | 3807 | 1.528 | 22.9 | 14.7 | 1.558 | |

| CF0.4a | 0.4 | 0 | 74.03 (0.054) | 63.86 | 3940 | 1.581 | 23.1 | 16.2 | 1.425 | |

| PF0.2a | 0 | 0.2 | 50.83 (0.045) | 41.15 | 2547 | 1.022 | 20.1 | 16.2 | 1.244 | |

| PF0.4a | 0 | 0.4 | 42.15 (0.036) | 36.05 | 2307 | 0.926 | 19.4 | 15.6 | 1.241 | |

| CF0.2PF0.2a | 0.2 | 0.2 | 48.15 (0.062) | 40.71 | 2834 | 1.137 | 20.7 | 14.4 | 1.441 | |

| CF0.2PF0.4a | 0.2 | 0.4 | 42.90 (0.049) | 39.93 | 2685 | 1.077 | 20.8 | 14.9 | 1.399 | |

| CF0.4PF0.2a | 0.4 | 0.2 | 47.98 (0.039) | 43.25 | 2769 | 1.111 | 21.1 | 15.6 | 1.351 | |

| CF0.4PF0.4a | 0.4 | 0.4 | 62.15 (0.061) | 50.15 | 2847 | 1.142 | 22.2 | 17.6 | 1.260 | |

| Plain–b | 0.3 | 0 | 0 | 58.24 (0.030) | 47.87 | 2500 | 1.000 | 22.7 | 19.1 | 1.186 |

| CF0.2b | 0.2 | 0 | 57.99 (0.033) | 52.29 | 3680 | 1.472 | 23.2 | 14.2 | 1.633 | |

| CF0.4b | 0.4 | 0 | 67.11 (0.031) | 56.06 | 3870 | 1.548 | 22.4 | 14.5 | 1.546 | |

| PF0.2b | 0 | 0.2 | 49.64 (0.041) | 42.07 | 2354 | 0.942 | 21.8 | 17.9 | 1.220 | |

| PF0.4b | 0 | 0.4 | 40.99 (0.064) | 34.16 | 2314 | 0.926 | 18.6 | 14.8 | 1.260 | |

| CF0.2PF0.2b | 0.2 | 0.2 | 48.26 (0.019) | 41.68 | 2790 | 1.116 | 22.0 | 14.9 | 1.473 | |

| CF0.2PF0.4b | 0.2 | 0.4 | 50.65 (0.030) | 44.19 | 2548 | 1.019 | 21.7 | 17.3 | 1.251 | |

| CF0.4PF0.2b | 0.4 | 0.2 | 51.36 (0.047) | 44.46 | 2764 | 1.106 | 22.5 | 16.1 | 1.399 | |

| CF0.4PF0.4b | 0.4 | 0.4 | 56.88 (0.028) | 49.18 | 2968 | 1.187 | 21.3 | 16.6 | 1.285 |

| Specimen | σ0.009 (MPa) | σ0.015 (MPa) | Toughness | Specific Toughness (%) | ||

|---|---|---|---|---|---|---|

| TF3 | TF5 | TR3 | TR5 | |||

| Plain-a | 22.09 | 13.88 | 0.2933 | 0.3954 | 0.6468 (-) | 0.5232 (-) |

| CF0.2a | 39.58 | 20.73 | 0.3882 | 0.5465 | 0.7703 | 0.6506 |

| CF0.4a | 37.83 | 18.58 | 0.3888 | 0.5419 | 0.6764 | 0.5657 |

| PF0.2a | 26.01 | 15.98 | 0.2801 | 0.4030 | 0.7563 | 0.6529 |

| PF0.4a | 17.23 | 13.19 | 0.2177 | 0.3082 | 0.6701 | 0.5699 |

| CF0.2PF0.2a | 29.32 | 21.71 | 0.3070 | 0.4591 | 0.8379 (29.5%) | 0.7518 (43.7%) |

| CF0.2PF0.4a | 28.45 | 26.08 | 0.3018 | 0.4650 | 0.8399 (29.9%) | 0.7764 (48.4%) |

| CF0.4PF0.2a | 34.57 | 27.78 | 0.3206 | 0.5049 | 0.8656 (33.8%) | 0.8178 (56.3%) |

| CF0.4PF0.4a | 34.63 | 25.69 | 0.3664 | 0.5413 | 0.8007 (23.8%) | 0.7097 (35.6%) |

| Plain-b | 25.15 | 16.97 | 0.2919 | 0.4145 | 0.6775 (-) | 0.5772 (-) |

| CF0.2b | 31.79 | 21.14 | 0.3317 | 0.4822 | 0.7049 | 0.6148 |

| CF0.4b | 38.02 | 31.60 | 0.3651 | 0.5600 | 0.7236 | 0.6897 |

| PF0.2b | 20.28 | 9.18 | 0.2525 | 0.3371 | 0.6669 | 0.5342 |

| PF0.4b | 17.73 | 11.77 | 0.2159 | 0.3046 | 0.7022 | 0.5944 |

| CF0.2PF0.2b | 31.94 | 23.03 | 0.3116 | 0.4712 | 0.8322 (22.8%) | 0.7551 (30.8%) |

| CF0.2PF0.4b | 30.25 | 23.96 | 0.3128 | 0.4827 | 0.7866 (16.1%) | 0.7282 (26.2%) |

| CF0.4PF0.2b | 37.65 | 28.16 | 0.3280 | 0.5296 | 0.8198 (21.0%) | 0.7942 (37.6%) |

| CF0.4PF0.4b | 42.12 | 30.89 | 0.3642 | 0.5871 | 0.8229 (21.5%) | 0.7985 (38.3%) |

| Specimen | αt3−1 | αt5−1 |

|---|---|---|

| CF0.2PF0.2a | 1.053 | 1.076 |

| CF0.2PF0.4a | 1.087 | 1.103 |

| CF0.4PF0.2a | 1.132 | 1.207 |

| CF0.4PF0.4a | 1.092 | 1.127 |

| CF0.2PF0.2b | 1.093 | 1.122 |

| CF0.2PF0.4b | 1.058 | 1.094 |

| CF0.4PF0.2b | 1.069 | 1.085 |

| CF0.4PF0.4b | 1.070 | 1.084 |

| Models | Fitting Expressions | Crucial Parameters |

|---|---|---|

| Carreira and Chu, 1985 | ||

| Abbass et al., 2018 | ||

| Ou et al., 2012 | ||

| Júnior et al., 2010 | ||

| Wang et al., 2019 | Ascending branch: Descending branch: |

| Specimen | VCF (%) | VPF (%) | β | k1 | k2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Experimental | Calculated | Ratio | Experimental | Calculated | Ratio | ||||

| Plain–a | 0 | 0 | 7.3508 | 0.56 | 0.6092 | 0.92 | 0.3833 | 0.3691 | 1.04 |

| CF0.2a | 0.2 | 0 | 2.7933 | 0.9546 | 0.9646 | 0.99 | 0.8572 | 0.8169 | 1.05 |

| CF0.4a | 0.4 | 0 | 3.3518 | 1.071 | 0.8724 | 1.23 | 0.8793 | 0.7230 | 1.22 |

| PF0.2a | 0 | 0.2 | 5.0967 | 0.4895 | 0.6614 | 0.74 | 0.4066 | 0.4948 | 0.82 |

| PF0.4a | 0 | 0.4 | 5.1409 | 0.4429 | 0.5124 | 0.86 | 0.4139 | 0.3771 | 1.10 |

| CF0.2PF0.2a | 0.2 | 0.2 | 3.2675 | 0.549 | 0.7781 | 0.71 | 0.5332 | 0.6537 | 0.82 |

| CF0.2PF0.4a | 0.2 | 0.4 | 3.5085 | 0.5538 | 0.6119 | 0.90 | 0.5083 | 0.5151 | 0.99 |

| CF0.4PF0.2a | 0.4 | 0.2 | 3.8499 | 0.5331 | 0.6838 | 0.78 | 0.4493 | 0.5572 | 0.81 |

| CF0.4PF0.4a | 0.4 | 0.4 | 4.8419 | 0.4509 | 0.4519 | 1.00 | 0.397 | 0.3391 | 1.17 |

| Plain–b | 0 | 0 | 6.3908 | 0.6855 | 0.6932 | 0.99 | 0.4144 | 0.4708 | 0.88 |

| CF0.2b | 0.2 | 0 | 2.5804 | 1.194 | 0.9833 | 1.21 | 0.9684 | 0.8395 | 1.15 |

| CF0.4b | 0.4 | 0 | 2.8304 | 0.812 | 0.9181 | 0.88 | 0.7265 | 0.7782 | 0.93 |

| PF0.2b | 0 | 0.2 | 5.5495 | 0.7507 | 0.6218 | 1.21 | 0.4665 | 0.4469 | 1.04 |

| PF0.4b | 0 | 0.4 | 4.8467 | 0.8236 | 0.5382 | 1.53 | 0.5093 | 0.4083 | 1.25 |

| CF0.2PF0.2b | 0.2 | 0.2 | 3.1157 | 0.6874 | 0.7914 | 0.87 | 0.5717 | 0.6698 | 0.85 |

| CF0.2PF0.4b | 0.2 | 0.4 | 4.9805 | 0.4463 | 0.4831 | 0.92 | 0.3622 | 0.3592 | 1.01 |

| CF0.4PF0.2b | 0.4 | 0.2 | 3.5076 | 0.7719 | 0.7137 | 1.08 | 0.5258 | 0.5934 | 0.89 |

| CF0.4PF0.4b | 0.4 | 0.4 | 4.5032 | 0.5982 | 0.4816 | 1.24 | 0.4146 | 0.3749 | 1.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wu, T.; Liu, X. Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers. Polymers 2022, 14, 1675. https://doi.org/10.3390/polym14091675

Yang X, Wu T, Liu X. Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers. Polymers. 2022; 14(9):1675. https://doi.org/10.3390/polym14091675

Chicago/Turabian StyleYang, Xue, Tao Wu, and Xi Liu. 2022. "Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers" Polymers 14, no. 9: 1675. https://doi.org/10.3390/polym14091675

APA StyleYang, X., Wu, T., & Liu, X. (2022). Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers. Polymers, 14(9), 1675. https://doi.org/10.3390/polym14091675