Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength

Abstract

:1. Introduction

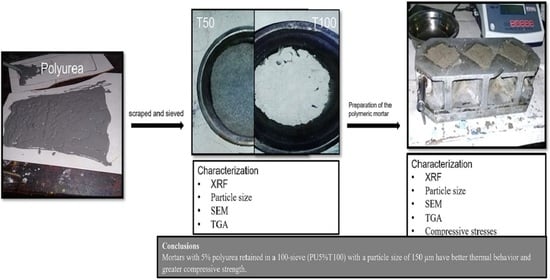

2. Materials and Methods

2.1. Materials

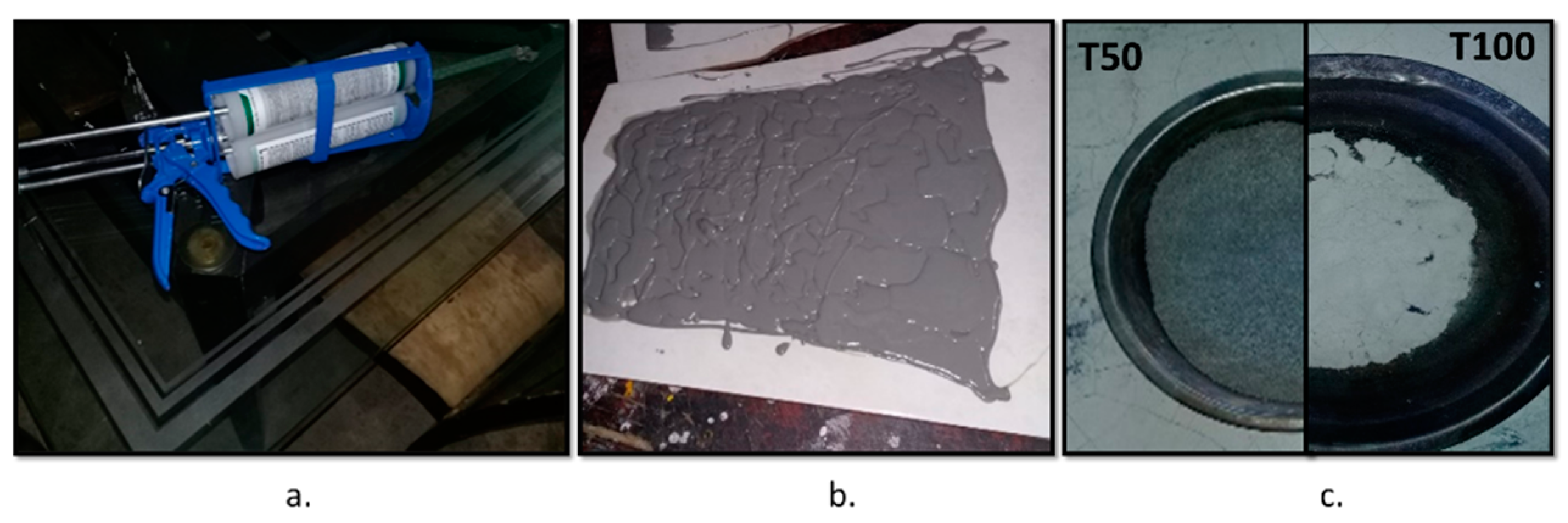

2.1.1. Polyurea (PU)

2.1.2. Sand, Cement, and Water

2.1.3. Mix Design and Polymer Mortar Manufacture

2.2. Characterization

2.2.1. X-ray Fluorescence

2.2.2. Particle Size

2.2.3. Scanning Electron Microscopy (SEM)

2.2.4. Thermogravimetric Analysis (TGA)

2.2.5. Compressive Strength Test

3. Results and Discussion

3.1. Microstructural Characterization of Polymer Mortars

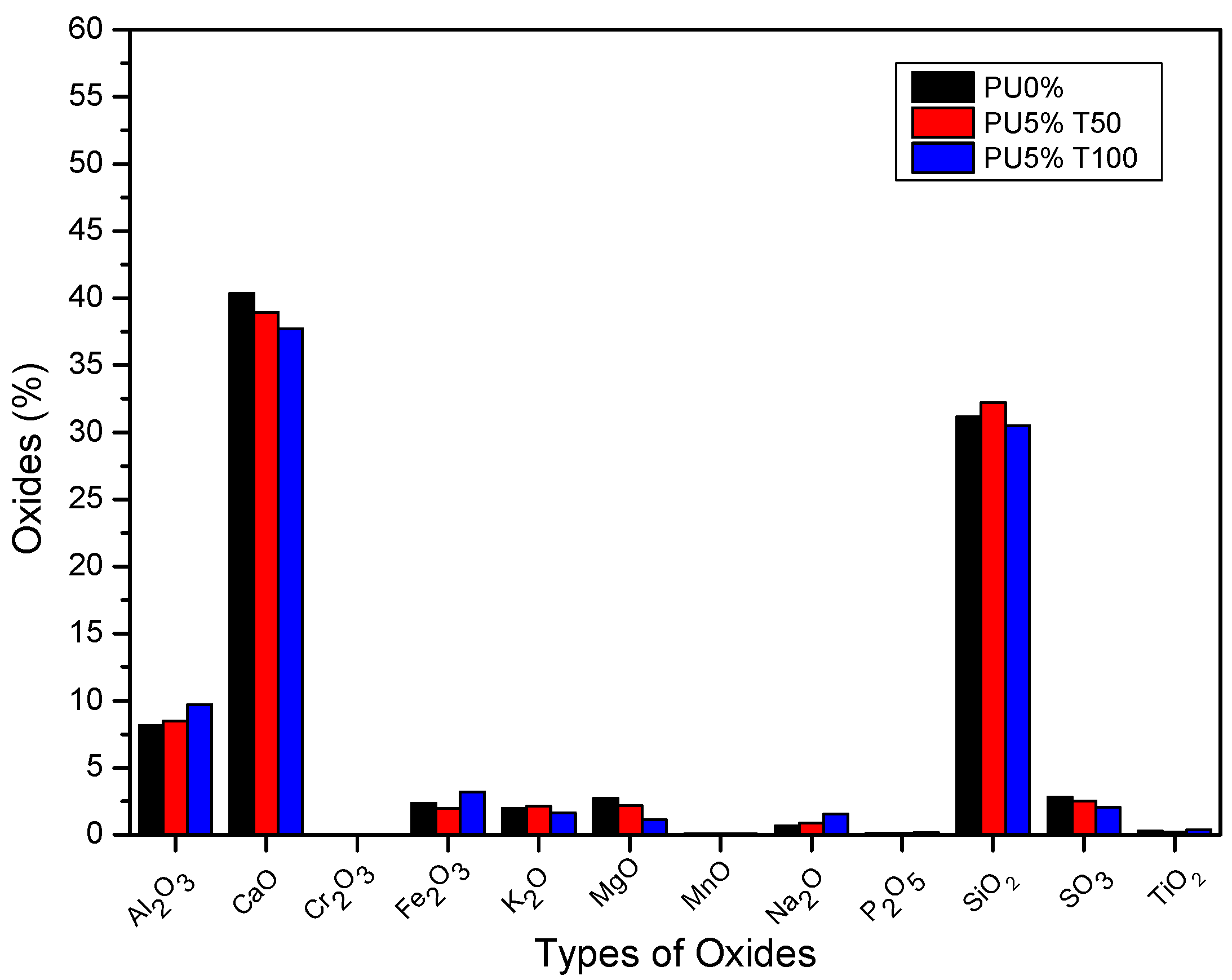

3.1.1. X-ray Fluorescence

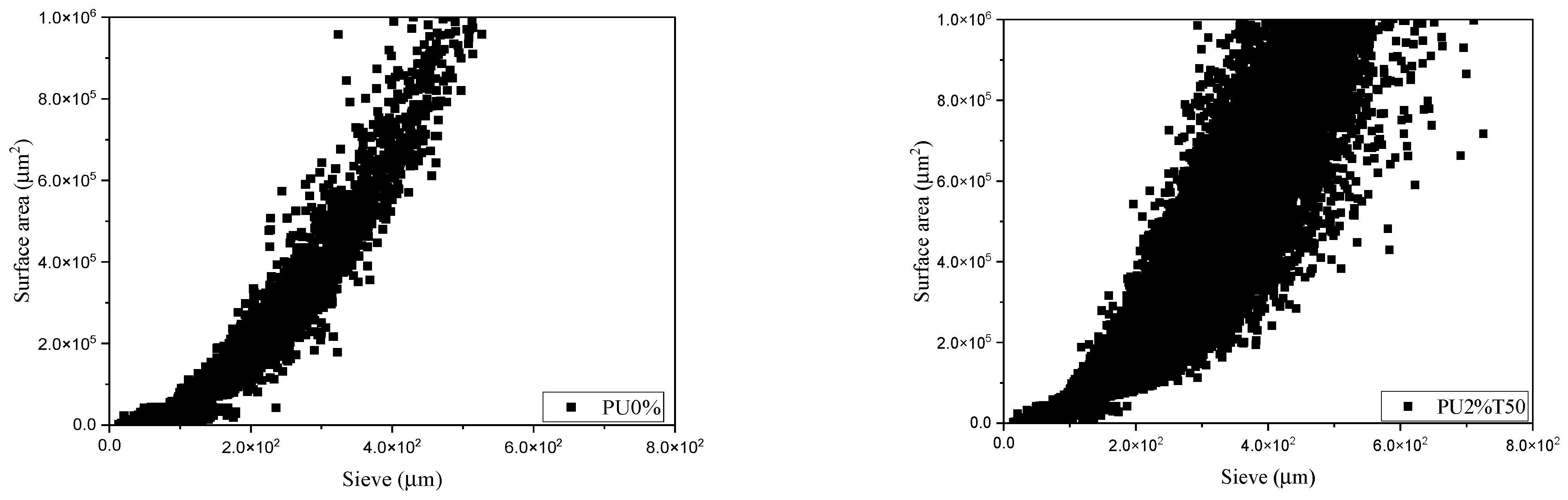

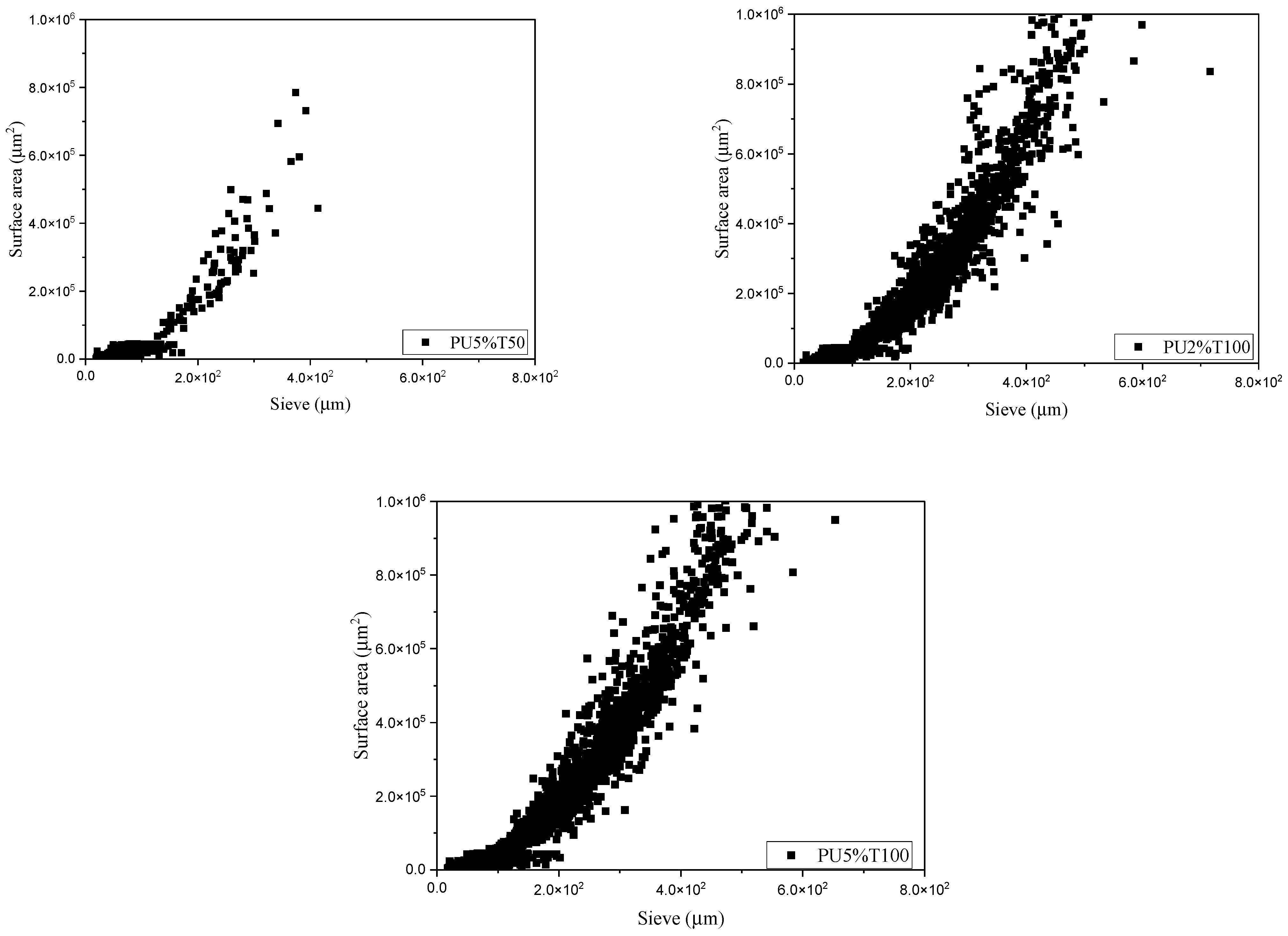

3.1.2. Particle Size

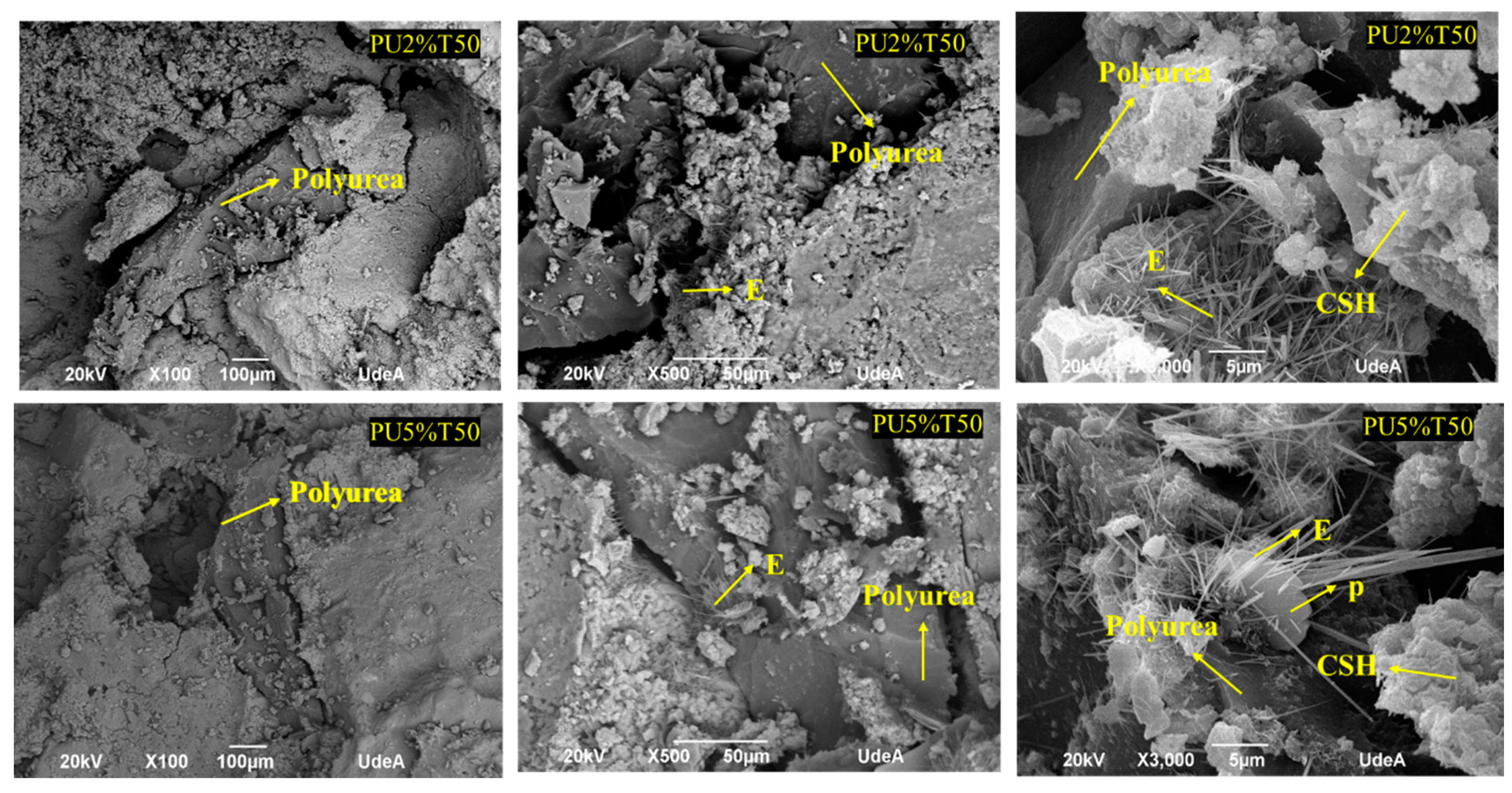

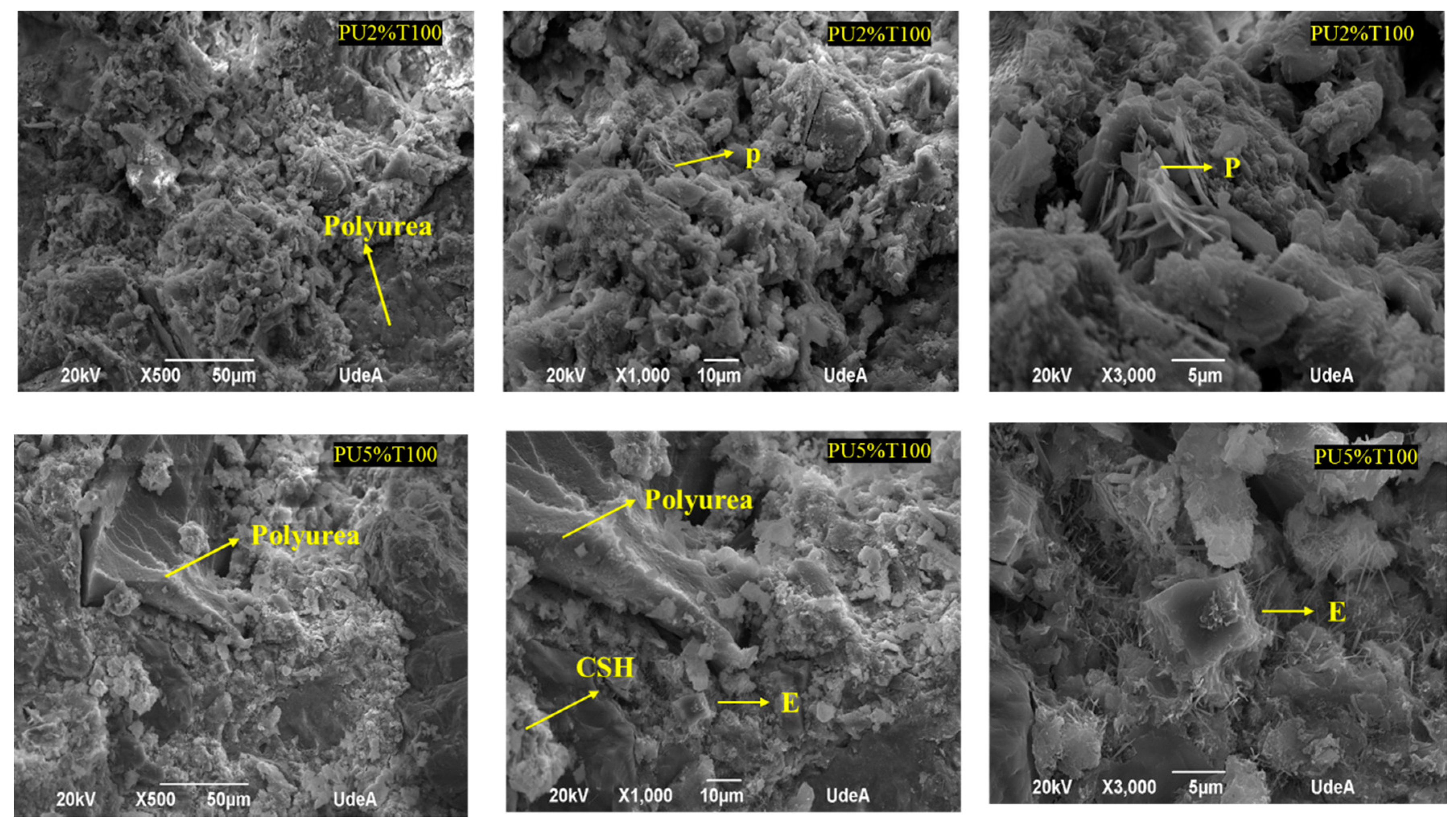

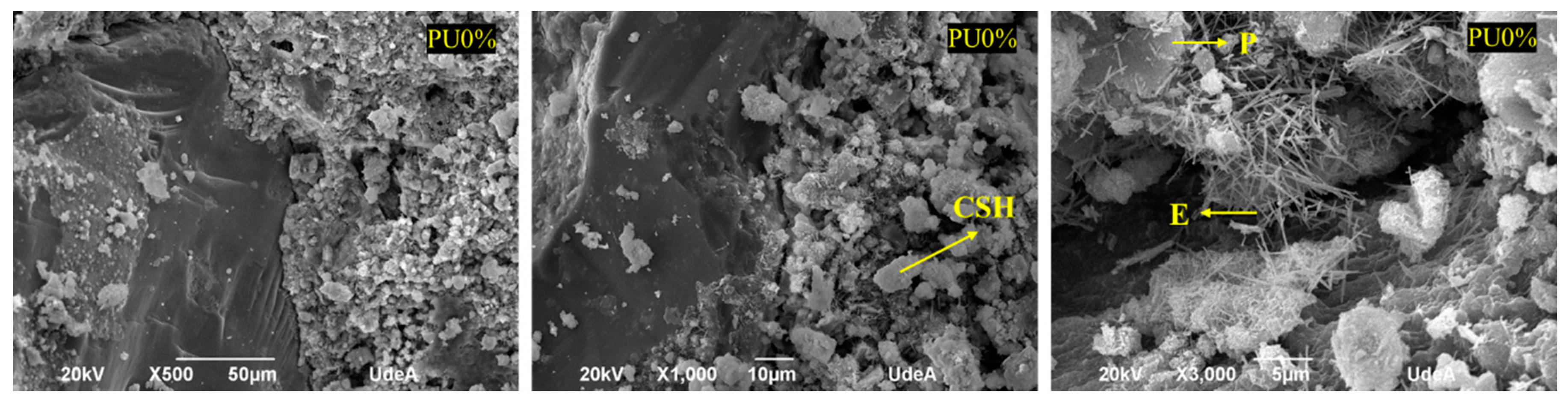

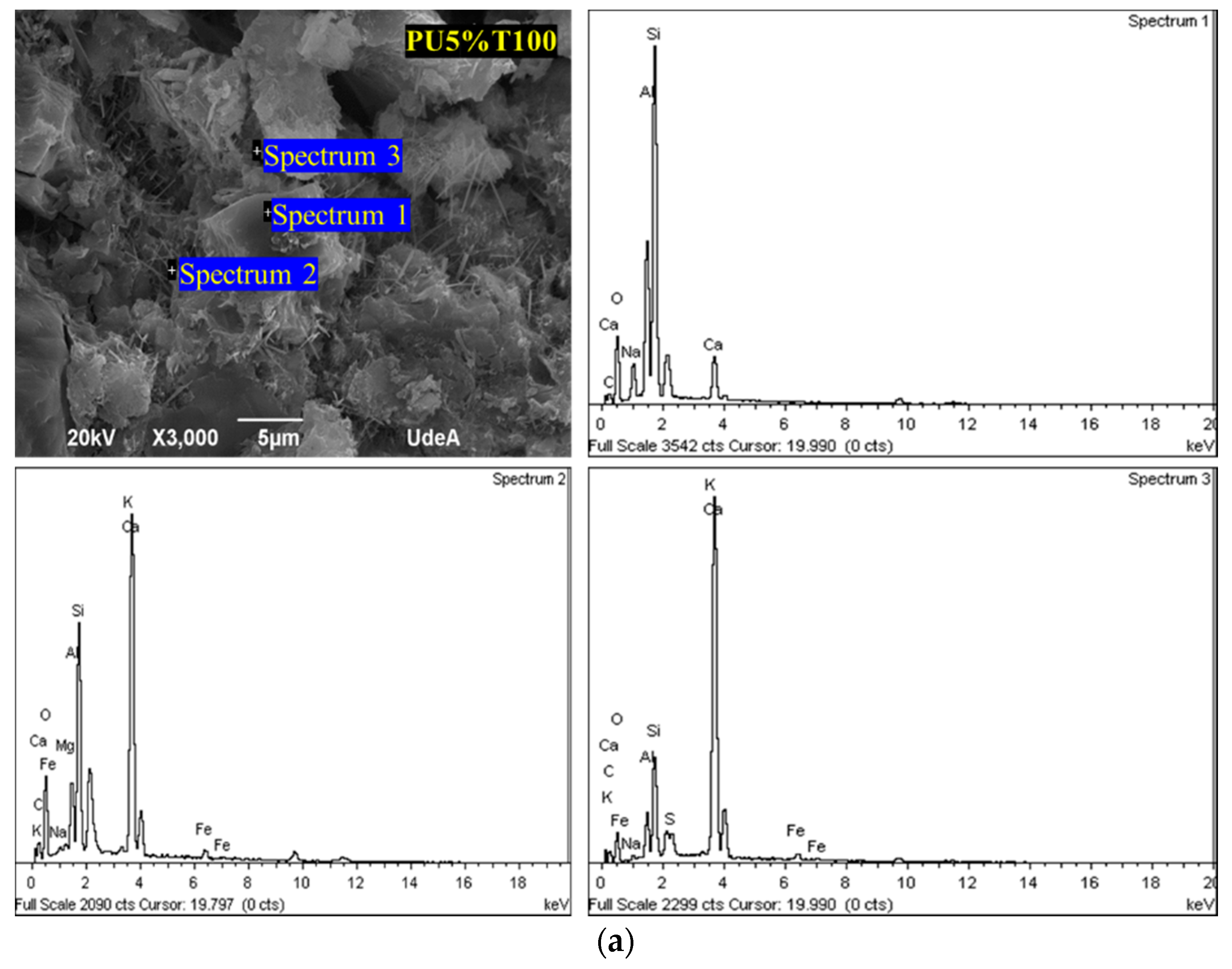

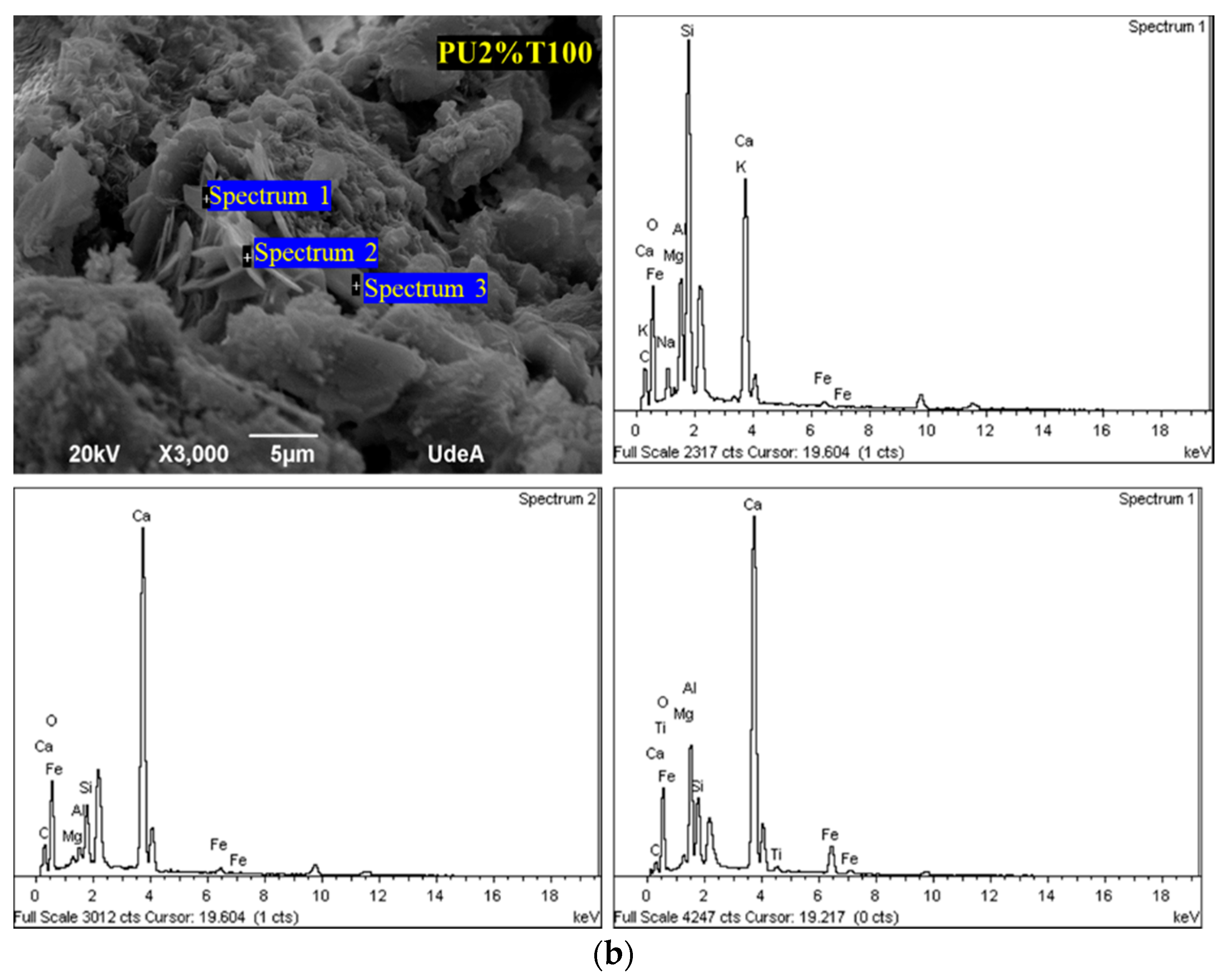

3.1.3. SEM Analysis

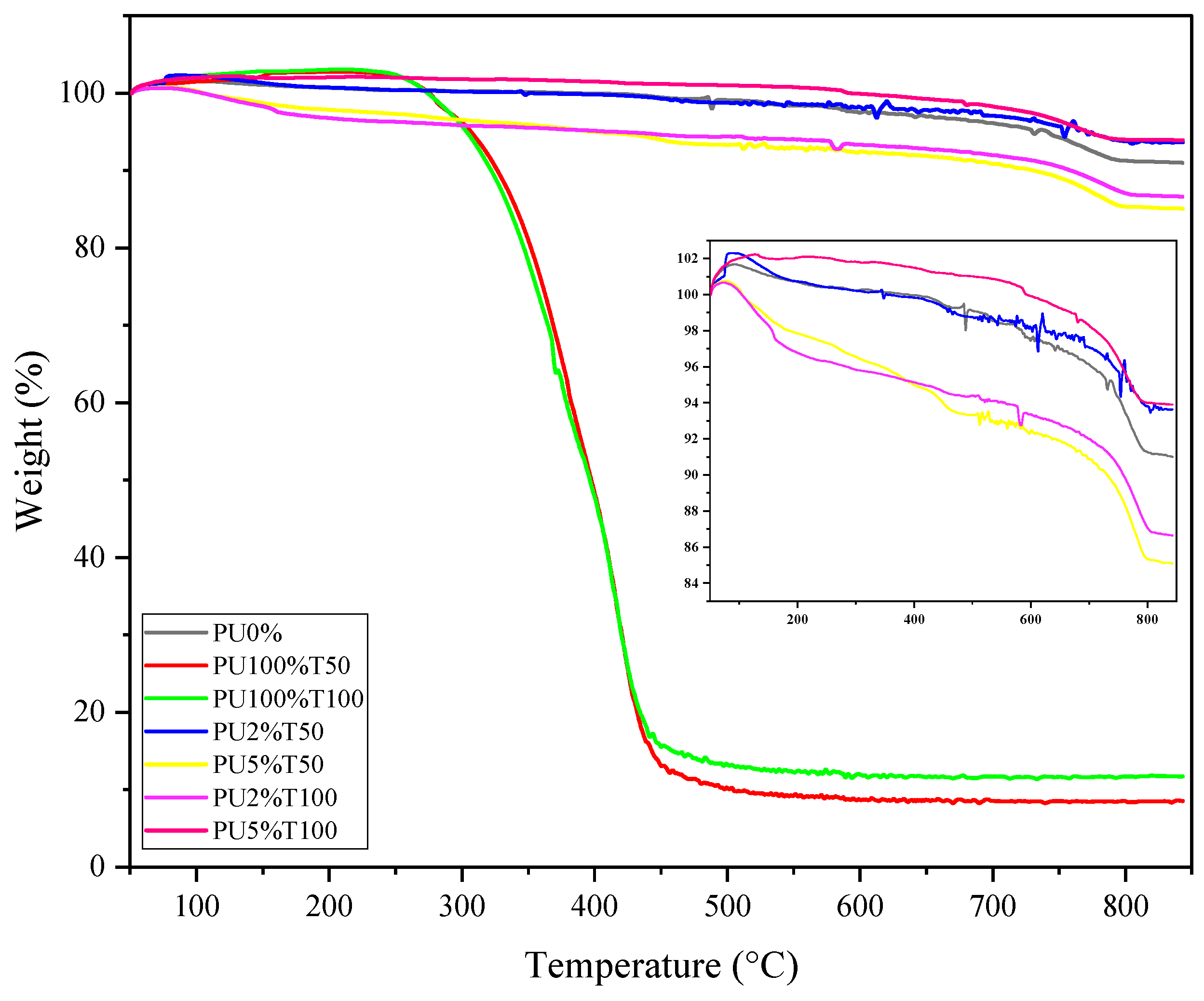

3.1.4. TGA

3.1.5. Resistance

4. Conclusions

- -

- The addition of polyurea affected the sample profile when the particle size was large.

- -

- SEM analysis revealed the presence of hydrates typical of cement.

- -

- The thermal stability of the mortars was influenced by the addition of polyurea, as determined by TGA. The sample with a smaller particle size and higher concentration of polyurea (PU5%T100) presented better results with respect to conventional mortar in terms of weight maintenance.

- -

- After 28 days of curing, polyurea with a small particle size improved the compressive strength of the sample.

- -

- Taken together, these findings suggest that polyurea retained in sieve 100 can be considered as a polymeric additive for mortars, indicating that it could be a candidate for applications such as the construction of interior and external structural walls, building facades, and nonstructural divisions, where durability, workability, and mechanical properties are required.

Author Contributions

Funding

Conflicts of Interest

References

- Wu, G.; Ji, C.; Wang, X.; Gao, F.; Zhao, C.; Liu, Y.; Yang, G. Blast response of clay brick masonry unit walls unreinforced and reinforced with polyurea elastomer. Def. Technol. 2021, 18, 643–662. [Google Scholar] [CrossRef]

- Sivan, P.P.; Gajendran, C.; Praveen, A.; Mahendran, C. Earthquake preparedness of new masonry constructions at seismically exposed regions a data driven approach. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- NSR-10 Titulo de Mampostería Structural. Available online: https://www.idrd.gov.co/sites/default/files/documentos/Construcciones/4titulo-d-nsr-100.pdf (accessed on 15 December 2021).

- Rodríguez Sierra, F.A. Uso de Polímeros en la Reducción de Patologías de Origen Químico en Estructuras de Concreto. Bachelor’s Thesis, Universidad Catolica de Colombia, Bogotá, Colombia, 2014. [Google Scholar]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Agavriloaie, L.; Oprea, S.; Barbuta, M.; Luca, F. Characterization of polymer concrete with epoxy polyurethane acryl matrix. Constr. Build. Mater. 2012, 37, 190–196. [Google Scholar] [CrossRef]

- Huang, H.; Pang, H.; Huang, J.; Zhao, H.; Liao, B. Synthesis and characterization of ground glass fiber reinforced polyurethane-based polymer concrete as a cementitious runway repair material. Constr. Build. Mater. 2020, 242, 117221. [Google Scholar] [CrossRef]

- Wang, R.; Yao, L.; Wang, P. Mechanism analysis and effect of styrene-acrylate copolymer powder on cement hydrates. Constr. Build. Mater. 2013, 41, 538–544. [Google Scholar] [CrossRef]

- Hussain, H.K.; Liu, G.W.; Yong, Y.W. Experimental study to investigate mechanical properties of new material polyurethane-cement composite (PUC). Constr. Build. Mater. 2014, 50, 200–208. [Google Scholar] [CrossRef]

- De Souza, M.H.; de Souza, R.A. Análise de argamassas de reparo compostas por copolímero vinílico, PVA e SBR. Rev. Alconpat 2019, 9, 277–287. [Google Scholar] [CrossRef] [Green Version]

- Maherzi, W.; Ennahal, I.; Benzerzour, M.; Mammindy-Pajany, Y.; Abriak, N.E. Study of the polymer mortar based on dredged sediments and epoxy resin: Effect of the sediments on the behavior of the polymer mortar. Powder Technol. 2020, 361, 968–982. [Google Scholar] [CrossRef]

- Mahdi, F.; Khan, A.A.; Abbas, H. Physiochemical properties of polymer mortar composites using resins derived from post-consumer PET bottles. Cem. Concr. Compos. 2007, 29, 241–248. [Google Scholar] [CrossRef]

- Valero Luna, J.C.; NarváezYepes, L.F. Análisis de Construcción y Sistemas de Impermeabilización de Cubiertas en el Laboratorio Nacional de la Dirección de Impuestos y Aduanas Nacionales. Bachelor’s Thesis, Universidad Catolica de Colombia, Bogotá, Colombia, 2018. [Google Scholar]

- Vásquez Suarez, L.I.; Villadiego Cárcamo, N.C. Caracterización Mecánica y Química del Sistema Mortero-Poliurea. Bachelor’s Thesis, Universidad de la Costa, Barranquilla, Colombia, 2018. [Google Scholar]

- Osuská, L.; Hela, R. The Impact of Different Aggregate Types and Its Composition on Resulting Concrete Properties Representing the Water Impermeability Level of Concrete for the Construction of White Boxes. Civ. Eng. Archt. 2020, 8, 39–45. [Google Scholar] [CrossRef]

- Cho, B.H.; Nam, B.H.; Seo, S.; Kim, J.; An, J.; Youn, H. Waterproofing performance of waterstop with adhesive bonding used at joints of underground concrete structures. Constr. Build. Mater. 2019, 221, 491–500. [Google Scholar] [CrossRef]

- Hoja de Datos de Seguridad de EUCO QWIKJOINT 200. Available online: https://www.toxement.com.co/media/2966/hs-euco-qwikjoint-200.pdf (accessed on 21 July 2021).

- Euco-Qwikjoint-200. Available online: https://www.toxement.com.co/media/2880/euco-qwikjoint-200.pdf (accessed on 19 August 2021).

- Standard Test Method for Particle-Size Analysis of Soils (Withdrawn 2016). Available online: https://www.astm.org/DATABASE.CART/WITHDRAWN/D422.htm (accessed on 28 September 2021).

- NTC121—Especificación de Desempeño Para Cemento Hidráulico. Available online: https://tienda.icontec.org/ (accessed on 18 August 2021).

- ASTM C1157/C1157M-17 Standard Performance Specification for Hydraulic Cement. Available online: www.astm.org (accessed on 23 August 2021).

- Ficha Técnica Cemento Tipo I. Available online: https://mnisaccp01.blob.core.windows.net/honduras/AF%20-%20Argos%20Ficha%20teicnica%20Cemento%20Tipo%20I%20ultima%20version.pdf (accessed on 28 September 2021).

- ASTM C109/C109M-21, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). Available online: http://www.astm.org/cgi-bin/resolver.cgi?C109C109M-21 (accessed on 28 September 2021).

- Ávila, Y.; Restrepo, S.; Jiménez, J.; Castillo, M.; Parody, A. Análisis comparativo de la concentración de óxidos presentes en el cemento portland y lodos de plantas de tratamiento de agua potable. Afinidad 2017, 75, 68–73. [Google Scholar]

- Giraldo, M.A. Evolución mineralógica del cemento Portland durante el proceso de hidratación. Dyna 2021, 73, 69–81. [Google Scholar]

- Hernández-Fernández, J.; Rayón, E.; López, J.; Arrieta, M.P. Enhancing the Thermal Stability of Polypropylene by Blending with Low Amounts of Natural Antioxidants. Macromol. Mater. Eng. 2019, 304, 1900379. [Google Scholar] [CrossRef]

- Pavon, C.; Aldas, M.; López-Martínez, J.; Hernández-Fernández, J.; Patricia Arrieta, M. Films based on thermoplastic starch blended with pine resin derivatives for food packaging. Foods 2021, 10, 117. [Google Scholar] [CrossRef] [PubMed]

- Trochez, J.J.; Torres Agredo, J.; Mejía de Gutiérrez, R. Study of hydration of cement pastes added with used catalytic cracking catalyst (FCC) from a colombian refinery. Rev. Fac. Ing. Univ. Antioq. 2010, 55, 26–34. [Google Scholar]

- Giraldo, M.A.; Tobón, J.I. Mineralogical evolution of Portland cement during hydration process. Dyna. 2006, 73, 69–81. [Google Scholar]

- Garcia-Lodeiro, I.; Goracci, G.; Dolado, J.S.; Blanco-Varela, M.T. Mineralogical and microstructural alterations in a portland cement paste after an accelerated decalcification process. Cem. Concr. Compos. 2021, 140, 106312. [Google Scholar] [CrossRef]

- Norma Técnica Colombiana NTC 321. Available online: https://tienda.icontec.org/gp-especificacion-de-desempeno-para-cemento-hidraulico-ntc121-2021.html (accessed on 5 September 2021).

- Alberto, E.; Gómez, C.; Enrique, J.; Sastoque, P. Estudio Comparativo de las Características Físico-Mecánicas de Cuatro Cementos Comerciales Portland Tipo I. Bachelor’s Thesis, Universidad Militar Nueva Granada, Bogotá, Colombia, 2014. [Google Scholar]

- Clemente, O.J.G.; Díaz, M.B.; Boadas, Z.D.V.M.; Carrera, J.M. Caracterización de las arenas y arcillas minerales de los depósitos de canal y planicie de inundación del río portuguesa, Venezuela. Investig. Geográficas Boletín Inst. Geogr. 2014, 2014, 18–32. [Google Scholar]

- Angelin, A.F.; Miranda, E.J.P., Jr.; dos Santos, J.M.C.; Lintz, R.C.C.; Gachet-Barbosa, L.A. Rubberized mortar: The influence of aggregate granulometry in mechanical resistances and acoustic behavior. Constr. Build. Mater. 2019, 200, 248–254. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.; Leung, C.K.; Tang, S.; Pan, J.; Huang, W.; Chen, E. Properties of rubberized concrete modified by using silane coupling agent and carboxylated SBR. J. Clean. Prod. 2016, 112, 797–807. [Google Scholar] [CrossRef]

- Traversa, L.P.; Iloro, F.; Benito, D.E. Determination by thermal test of CO2 absorbed by cement mortars. Cienc. Tecnol. 2013, 3, 333–341. [Google Scholar]

- Barbadillo Jove, F. Estudio Cinético de Degradación Térmica de Poliuretanos Mediante Análisis Termogravimétrico (TGA). Ph.D. Thesis, Universidad da Coruña, Galicia, Spain, 2015. [Google Scholar]

- Won-In, K.; Boonruang, C.; Dararutana, P. Characterization of polyurea elastomer used for blast mitigation. AIP Conf. Proc. 2020, 2279, 070003. [Google Scholar]

- Ateş, E. Optimization of Compression Strength by Granulometry and Change of Binder Rates in Epoxy and Polyester Resin Concrete. J. Reinf. Plast. Compos. 2009, 28, 235–246. [Google Scholar] [CrossRef]

- Carrión, F.; Montalbán, L.; Real, J.I.; Real, T. Mechanical and Physical Properties of Polyester Polymer Concrete Using Recycled Aggregates from Concrete Sleepers. Sci. World J. 2014, 2014, 526346. [Google Scholar] [CrossRef] [PubMed]

| Chemical Identity | CAS | Concentration in Percentage (%w/w) | |

|---|---|---|---|

| Part A | Part B | ||

| 4,4′-Methylene bis(phenylisocyanate) | 101-68-8 | 15–40% | - |

| Diphenylmethane diisocyanate | 26447-40-5 | 10–30% | - |

| Diethyltoluenediamine | 68479-98-1 | - | 15–40% |

| Propoxylated Amine | 102-60-3 | - | 3–7% |

| Amorphous silica | 7631-86-9 | - | 1–5% |

| Titanium dioxide | 13463-67-7 | - | 0.5–1.5% |

| Sieves | Opening (mm) | Retained Mass (g) | % Retained | Cumulative Retained % | % PASS |

|---|---|---|---|---|---|

| No. | |||||

| 1″ | 25.000 | ||||

| 3/4″ | 19.000 | ||||

| 1/2″ | 12.500 | ||||

| 3/8″ | 9.500 | 0.0 | 0.0 | 0.0 | 100.0 |

| 4 | 4.750 | 1.9 | 0.0 | 0.0 | 100.0 |

| 8 | 2.360 | 13.8 | 0.3 | 0.3 | 99.7 |

| 16 | 1.180 | 121.5 | 2.5 | 2.9 | 97.1 |

| 30 | 0.600 | 1.2058 | 25.1 | 28.0 | 72.0 |

| 50 | 0.300 | 2.4758 | 51.6 | 79.5 | 20.5 |

| 100 | 0.150 | 839.2 | 17.5 | 97.0 | 3.0 |

| 200 | 0.075 | 31.1 | 0.65 | 97.67 | 2.33 |

| P 200 | 0.000 | 111.7 | 2.33 | 100.00 | 0.00 |

| Starting Weight (g): | 4800.8 | Final Weight (g): | 4689.1 | ||

| Polymer Mortar | Number of Mortars | PU Addition (%) | PU Particle Size (μm) (Sieve) | Mix Design | |||

|---|---|---|---|---|---|---|---|

| Cement (g) | Sand (g) | Water (g) | PU (g) | ||||

| PU0% | 9 | 0 | - | 750 | 1736.4 | 390 | - |

| PU2%T50 | 9 | 2 | 300 (50) | 750 | 1736.4 | 390 | 14.25 |

| PU5%T50 | 9 | 5 | 300 (50) | 750 | 1736.4 | 390 | 37.5 |

| PU2%T100 | 9 | 2 | 150 (100) | 750 | 1736.4 | 390 | 14.25 |

| PU5%T100 | 9 | 5 | 150 (100) | 750 | 1736.4 | 390 | 37.5 |

| Oxides | PU0% | PU2%T100 | PU5%T100 | PU2%T50 | PU5%T50 |

|---|---|---|---|---|---|

| % p/p | |||||

| Al2O3 | 8.16 | 9.61 | 9.71 | 5.24 | 8.46 |

| CaO | 40.35 | 36.23 | 37.7 | 51.9 | 38.92 |

| Cr2O3 | 0.022 | 0.009 | 0.008 | 0.023 | 0.01 |

| Fe2O3 | 2.34 | 2.95 | 3.202 | 2.87 | 1.98 |

| K2O | 1.98 | 1.75 | 1.62 | 2.25 | 2.11 |

| MgO | 2.73 | 1.08 | 1.16 | 1.08 | 2.2 |

| MnO | 0.054 | 0.055 | 0.059 | 0.071 | 0.053 |

| Na2O | 0.675 | 1.49 | 1.55 | 0.16 | 0.829 |

| P2O5 | 0.126 | 0.154 | 0.163 | 0.094 | 0.143 |

| SiO2 | 31.17 | 32.48 | 30.49 | 24.05 | 32.21 |

| SO3 | 2.81 | 1.84 | 2.04 | 2.83 | 2.52 |

| TiO2 | 0.274 | 0.331 | 0.397 | 0.381 | 0.217 |

| 1 LOI 550 °C | 3.11 | 4.686 | 4.95 | 3.225 | 4.012 |

| LOI 950 °C | 9.046 | 11.763 | 11.643 | 8.73 | 10.149 |

| Samples | Decomposition Temperature °C | ||

|---|---|---|---|

| Tinicial | T50% | Tend | |

| PU0% | 50.8 | 722.55 | 842.63 |

| PU100%T50 | 51.2 | 391.28 | 843.05 |

| PU100%T100 | 51.2 | 386.17 | 843.15 |

| PU2%T50 | 51.3 | 715.47 | 833.7 |

| PU5%T50 | 51.1 | 573.43 | 841.59 |

| PU2%T100 | 51.1 | 579.33 | 841.11 |

| PU5%T100 | 51.1 | 740.82 | 839.38 |

| Age (Days) | Maximum Load (kN) | Average Stress (Mpa) | Standard Deviation (σ) | Average Resistance (%) | |

|---|---|---|---|---|---|

| PU0% | 7 | 36.03 | 14.41 | 0.18 | 70 |

| 14 | 44.53 | 17.81 | 0.08 | 86 | |

| 28 | 55.37 | 22.14 | 0.23 | 107 | |

| PU2%T50 | 7 | 24.03 | 9.61 | 0.13 | 46.70 |

| 14 | 49.43 | 19.77 | 0.10 | 95.30 | |

| 28 | 38.00 | 15.20 | 0.11 | 73.30 | |

| PU5%T50 | 7 | 28.93 | 11.57 | 0.05 | 56.00 |

| 14 | 38.36 | 15.34 | 0.08 | 74.30 | |

| 28 | 33.33 | 13.33 | 0.19 | 64.30 | |

| PU2%T10 | 7 | 29,30 | 11.72 | 0.31 | 57 |

| 14 | 37.43 | 14.97 | 0.26 | 72.3 | |

| 28 | 62.20 | 24.88 | 0.06 | 120.3 | |

| PU5%T100 | 7 | 24.13 | 9.65 | 0.18 | 47 |

| 14 | 38.57 | 15.43 | 0.15 | 74.7 | |

| 28 | 60.73 | 24.29 | 0.15 | 117.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chacon, H.; Cano, H.; Fernández, J.H.; Guerra, Y.; Puello-Polo, E.; Ríos-Rojas, J.F.; Ruiz, Y. Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength. Polymers 2022, 14, 1753. https://doi.org/10.3390/polym14091753

Chacon H, Cano H, Fernández JH, Guerra Y, Puello-Polo E, Ríos-Rojas JF, Ruiz Y. Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength. Polymers. 2022; 14(9):1753. https://doi.org/10.3390/polym14091753

Chicago/Turabian StyleChacon, Hernan, Heidis Cano, Joaquin Hernández Fernández, Yoleima Guerra, Esneyder Puello-Polo, John Fredy Ríos-Rojas, and Yolima Ruiz. 2022. "Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength" Polymers 14, no. 9: 1753. https://doi.org/10.3390/polym14091753

APA StyleChacon, H., Cano, H., Fernández, J. H., Guerra, Y., Puello-Polo, E., Ríos-Rojas, J. F., & Ruiz, Y. (2022). Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength. Polymers, 14(9), 1753. https://doi.org/10.3390/polym14091753