Influence of Rapid Consolidation on Co-Extruded Additively Manufactured Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Printed Specimens

2.3. Compression Press Moulding

2.4. Void Volume Fraction Analyses

2.5. Mechanical Characterisation

3. Results and Discussion

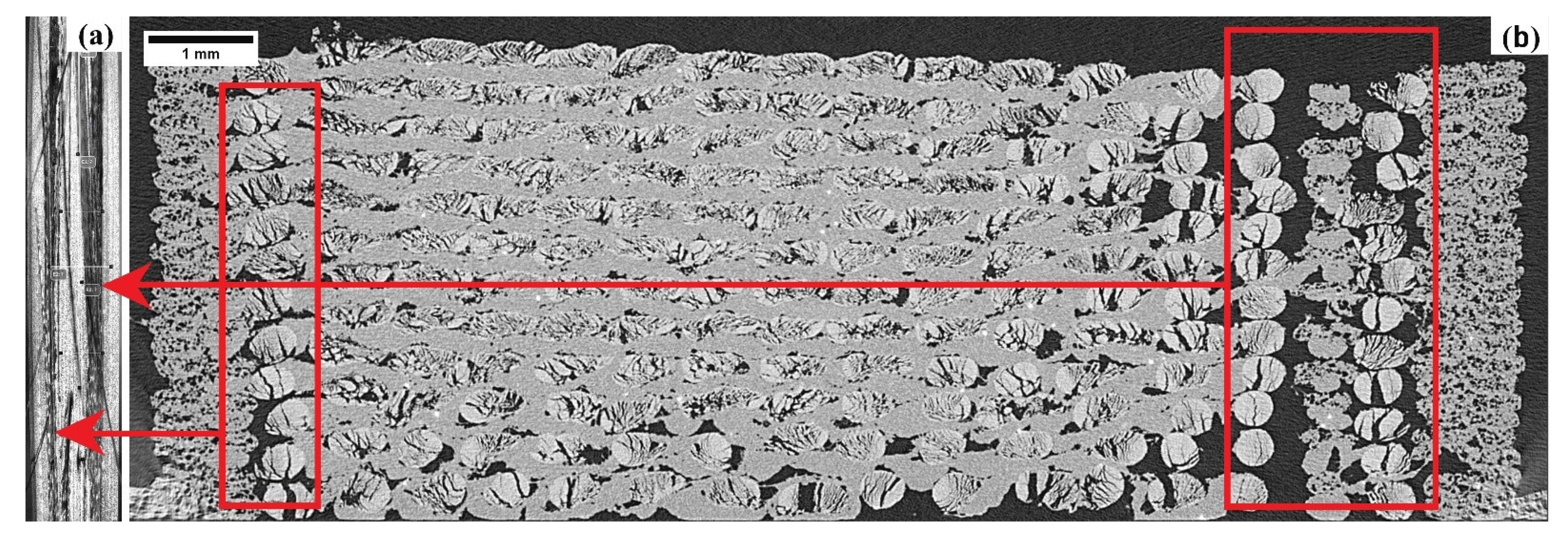

3.1. Void Volume Fraction

3.2. Tensile Properties

3.3. Flexural Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azarov, A.V.; Antonov, F.K.; Vasil’ev, V.V.; Golubev, M.V.; Krasovskii, D.S.; Razin, A.F.; Salov, V.A.; Stupnikov, V.V.; Khaziev, A.R. Development of a two-matrix composite material fabricated by 3D printing. Polym. Sci. Ser. D 2017, 10, 87–90. [Google Scholar] [CrossRef]

- Azarov, A.V.; Antonov, F.K.; Golubev, M.V.; Khaziev, A.R.; Ushanov, S.A. Composite 3D printing for the small size unmanned aerial vehicle structure. Compos. Part B Eng. 2019, 169, 157–163. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, G.; Ren, H.; Liu, G.; Xiong, Y. Fabrication strategy for joints in 3D printed continuous fiber reinforced composite lattice structures. Compos. Commun. 2022, 30, 101080. [Google Scholar] [CrossRef]

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Consolidation of continuous fibre reinforced composites in additive processes: A review. Addit. Manuf. 2021, 48, 102458. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Antonov, F.; Khaziev, A.; Azarov, A.; Golubev, M.; Vasiliev, V.V. Novel Continuous Fiber Bi-Matrix Composite 3-D Printing Technology. Materials 2019, 12, 3011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chabaud, G.; Castro, M.; Denoual, C.; Le Duigou, A. Hygromechanical properties of 3D printed continuous carbon and glass fibre reinforced polyamide composite for outdoor structural applications. Addit. Manuf. 2019, 26, 94–105. [Google Scholar] [CrossRef]

- Becker, C.; Oberlercher, H.; Heim, R.B.; Wuzella, G.; Faller, L.-M.; Riemelmoser, F.O.; Nicolay, P.; Druesne, F. Experimental Quantification of the Variability of Mechanical Properties in 3D Printed Continuous Fiber Composites. Appl. Sci. 2021, 11, 11315. [Google Scholar] [CrossRef]

- Savandaiah, C.; Sieberer, S.; Steinbichler, G. Additively Manufactured Composite Lug with Continuous Carbon Fibre Steering Based on Finite Element Analysis. Materials 2022, 15, 1820. [Google Scholar] [CrossRef] [PubMed]

- Fedulov, B.; Fedorenko, A.; Khaziev, A.; Antonov, F. Optimization of parts manufactured using continuous fiber three-dimensional printing technology. Compos. Part B Eng. 2021, 227, 109406. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Sapkota, J.; Holzer, C. Optimization of mechanical properties of glass-spheres-filled polypropylene composites for extrusion-based additive manufacturing. Polym. Compos. 2019, 40, 638–651. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Traxler, G.; Cardon, L.; Holzer, C.; Sapkota, J. Anisotropic properties of oriented short carbon fibre filled polypropylene parts fabricated by extrusion-based additive manufacturing. Compos. Part A Appl. Sci. Manuf. 2018, 113, 95–104. [Google Scholar] [CrossRef]

- Savandaiah, C.; Maurer, J.; Gall, M.; Haider, A.; Steinbichler, G.; Sapkota, J. Impact of processing conditions and sizing on the thermomechanical and morphological properties of polypropylene/carbon fiber composites fabricated by material extrusion additive manufacturing. J. Appl. Polym. Sci. 2021, 138, 50243. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015. Additive Manufacturing—General Principles—Terminology. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-1:v1:en (accessed on 25 March 2022).

- Savandaiah, C.; Maurer, J.; Lesslhumer, J.; Haider, A.; Steinbichler, G. Enhancement of binding matrix stiffness in composite filament co-extrusion additive manufacturing. In Proceedings of the SPE—ANTEC®: Virtual Edition—2020, Plastic Technology Conference, Online, 10 March–5 May 2020. [Google Scholar]

- Van de Werken, N.; Koirala, P.; Ghorbani, J.; Doyle, D.; Tehrani, M. Investigating the hot isostatic pressing of an additively manufactured continuous carbon fiber reinforced PEEK composite. Addit. Manuf. 2021, 37, 101634. [Google Scholar] [CrossRef]

- Van de Werken, N.; Koirala, P.; Ghorbani, J.; ABEL, M.; Tehrani, M. Improving Properties of Additively Manufactured Carbon Fiber Composites via Post Pressing. In Proceedings of the American Society for Composites, Thirty-Fourth Technical Conference, Atlanta, GA, USA, 23–25 September 2019. [Google Scholar]

- Savandaiah, C.; Maurer, J.; Plank, B.; Steinbichler, G.; Sapkota, J. Rapid Consolidation of 3D Printed Composite Parts Using Compression Moulding for Improved Thermo-Mechanical Properties. RPJ 2022. accepted. [Google Scholar]

- Total Corbion. Luminy® L175. Available online: https://www.totalenergies-corbion.com/media/eushodia/pds-luminy-l175-190507.pdf (accessed on 25 March 2022).

- DSM. Akulon® F132-E1. Available online: https://plasticsfinder.com/api/document/tech/Akulon%C2%AE%20F132-E1/EAuBundva/en (accessed on 25 March 2022).

- Savandaiah, C.; Plank, B.; Maurer, J.; Lesslhumer, J.; Steinbichler, G. Comparative Study of Filled and Unfilled Polylactic Acid Produced via Injection Molding and 3D Printing. In Proceedings of the SPE ANTEC® Classic: Plastic Technology Conference, Online, 10–21 May 2021. [Google Scholar]

- ASTM D3039-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/d3039_d3039m-17.html (accessed on 25 March 2022).

- ASTM D6272-17; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d6272-17e01.html (accessed on 25 March 2022).

- ASTM D618-21; Standard Practice for Conditioning Plastics for Testing. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/d0618-21.html (accessed on 25 March 2022).

- Plank, B.; Rao, G.; Kastner, J. Evaluation of CFRP-Reference Samples for Porosity made by Drilling and Comparison with Industrial Porosity Samples by Means of Quantitative X-ray Computed Tomography. In Proceedings of the 7th International Symposium on NDT in Aerospace, Bremen, Germany, 16–18 November 2015; p. 10. [Google Scholar]

- Senck, S.; Scheerer, M.; Revol, V.; Dobes, K.; Plank, B.; Kastner, J. Non-Destructive Evaluation of Defects in Polymer Matrix Composites for Aerospace Applications Using X-ray Talbot-Lau Interferometry and Micro CT. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Khudiakova, A.; Berer, M.; Niedermair, S.; Plank, B.; Truszkiewicz, E.; Meier, G.; Stepanovsky, H.; Wolfahrt, M.; Pinter, G.; Lackner, J. Systematic analysis of the mechanical anisotropy of fibre-reinforced polymer specimens produced by laser sintering. Addit. Manuf. 2020, 36, 101671. [Google Scholar] [CrossRef]

- Albrecht, H.; Savandaiah, C.; Lepschi, A.; Loew-Baselli, B.; Haider, A. Parametric study in co-extrusion-based additive manufacturing of continuous fiber-reinforced plastic composites. In Proceedings of the II International Conference on Simulation for Additive Manufacturing, Sim-AM—II, Pavia, Italy, 11–13 September 2019. [Google Scholar]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

| Material Description | Nomenclature |

|---|---|

| Neat PLA | N-PLA |

| Injection-moulded neat PLA | N-PLA-IM |

| Neat PLA material extruded with a raster angle of 0° | N-PLA-MEX-0° |

| Neat PLA as a binding matrix in CFC | N-PLA-CFC |

| Post-consolidated neat PLA as a binding matrix in CFC | N-PLA-CFC-PC |

| Short carbon fibre-filled PLA | S-PLA |

| Injection-moulded short carbon fibre-filled PLA | S-PLA-IM |

| Short carbon fibre-filled PLA material extruded with a raster angle of 0° | S-PLA-MEX-0° |

| Short carbon fibre-filled PLA as a binding matrix in CFC | S-PLA-CFC |

| Post-consolidated short carbon fibre-filled PLA as a binding matrix in CFC | S-PLA-CFC-PC |

| Neat PA6 | N-PA6 |

| Injection-moulded neat PA6 | N-PA6-IM |

| Neat PA6 material extruded with a raster angle of 0° | N-PA6-MEX-0° |

| Neat PA6 as a binding matrix in CFC | N-PA6-CFC |

| Post-consolidated neat PA6 as a binding matrix in CFC | N-PA6-CFC-PC |

| Long carbon fibre-reinforced PA6 | L-PA6 |

| Injection-moulded long carbon fibre-reinforced PA6 | L-PA6-IM |

| Long carbon fibre reinforced PA6 material extruded with a raster angle of 0° | L-PA6-MEX-0° |

| Long carbon fibre-reinforced PA6 as a binding matrix in CFC | L-PA6-CFC |

| Post-consolidated long carbon fibre-reinforced PA6 as a binding matrix in CFC | L-PA6-CFC-PC |

| Properties | Test | Unit | N-PLA | S-PLA | N-PA6 | L-PA6 |

|---|---|---|---|---|---|---|

| MT | ISO-11357-1:2016 | °C | 170–175 | 170–175 | 220–225 | 220–225 |

| HDT | EN ISO 75-HDT A | °C | 58.0 ± 0.1 | 59.0 ± 0.2 | 48.0 ± 0.3 | -- * |

| HDT | EN ISO 75-HDT C | °C | -- | -- | -- | 133.0 ± 3.0 |

| Properties | Unit | Value |

|---|---|---|

| Diameter | mm | 0.36 |

| Tensile strength | MPa | 2224 ± 283 |

| Young’s modulus | MPa | 130000 ± 9000 |

| Elongation at break | % | 1.6 ± 0.2 |

| Fibre volume fraction | % | 57 |

| Parameter | Unit | PLA | PA6 |

|---|---|---|---|

| CFC nozzle temperature | °C | 225 | 255 |

| MEX nozzle temperature | °C | 220 | 250 |

| CFC TP flow multiplier | -- | 0.95 | 1.05 |

| CFC layer height | mm | 0.36 | 0.36 |

| CFC extrusion width | mm | 0.75 | 0.75 |

| MEX TP flow multiplier | -- | 0.90 | 1 |

| MEX layer height | mm | 0.12 | 0.12 |

| MEX extrusion width co-efficient | -- | 1 | 1.05 |

| Bed temperature | °C | 80 | 95 |

| TP perimeter count | -- | 2 | 2 |

| Inner CCF perimeter count | -- | 1 | 1 |

| CCF infill pattern | -- | Solid | Solid |

| CCF infill angle | ° | 0 | 0 |

| MEX print speed | mm·s−1 | 60 | 60 |

| CFC print speed | mm·s−1 | 10 | 10 |

| Setting | PLA | PA6 |

|---|---|---|

| Set temperature | 180 °C | 220 |

| 1st cooling cycle | cool down to 70 °C at 50 °C·min−1 | cool down to 150 °C at 50 °C·min−1 |

| 2nd cooling cycle | cool down to 23 °C at 5 °C·min−1 | cool down to 50 °C at 5 °C·min−1 |

| Void (Vol. %) | |||

|---|---|---|---|

| Material | MEX-0° | CFC | CFC-PC |

| N-PLA | 12.2 * | 14.0 | 1.0 |

| S-PLA | 15.9 * | 16.3 | 8.6 |

| N-PA6 | 14.3 * | 16.8 * | 8.3 |

| L-PA6 | 27.0 * | 29.2 | 18.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savandaiah, C.; Sieberer, S.; Plank, B.; Maurer, J.; Steinbichler, G.; Sapkota, J. Influence of Rapid Consolidation on Co-Extruded Additively Manufactured Composites. Polymers 2022, 14, 1838. https://doi.org/10.3390/polym14091838

Savandaiah C, Sieberer S, Plank B, Maurer J, Steinbichler G, Sapkota J. Influence of Rapid Consolidation on Co-Extruded Additively Manufactured Composites. Polymers. 2022; 14(9):1838. https://doi.org/10.3390/polym14091838

Chicago/Turabian StyleSavandaiah, Chethan, Stefan Sieberer, Bernhard Plank, Julia Maurer, Georg Steinbichler, and Janak Sapkota. 2022. "Influence of Rapid Consolidation on Co-Extruded Additively Manufactured Composites" Polymers 14, no. 9: 1838. https://doi.org/10.3390/polym14091838

APA StyleSavandaiah, C., Sieberer, S., Plank, B., Maurer, J., Steinbichler, G., & Sapkota, J. (2022). Influence of Rapid Consolidation on Co-Extruded Additively Manufactured Composites. Polymers, 14(9), 1838. https://doi.org/10.3390/polym14091838