Bistable Morphing Composites for Energy-Harvesting Applications

Abstract

:1. Introduction

2. Mathematical Modeling

3. Artificial-Intelligence-Based Modeling

4. Actuation Techniques

5. Energy Harvesting

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Showaib, E.A.; Elsheikh, A.H. Effect of surface preparation on the strength of vibration welded butt joint made from PBT composite. Polym. Test. 2020, 83, 106319. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Ramesh, B.; Egiza, M.; Al-qaness, M.A.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Alsaleh, N.A.; Farouk, W.M.; Elsheikh, A.; Abu-Oqail, A.; Abdelraouf, Y.A.; Ghafaar, M.A. Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. J. Mater. Res. Technol. 2021, 14, 2624–2637. [Google Scholar] [CrossRef]

- Rangasamy, G.; Mani, S.; Senathipathygoundar Kolandavelu, S.K.; Alsoufi, M.S.; Mahmoud Ibrahim, A.M.; Muthusamy, S.; Panchal, H.; Sadasivuni, K.K.; Elsheikh, A.H. An extensive analysis of mechanical, thermal and physical properties of jute fiber composites with different fiber orientations. Case Stud. Therm. Eng. 2021, 28, 101612. [Google Scholar] [CrossRef]

- Kamal, A.; Ashmawy, M.; Algazzar, A.M.; Elsheikh, A.H. Fabrication techniques of polymeric nanocomposites: A comprehensive review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 4843–4861. [Google Scholar] [CrossRef]

- Ramesh, B.; Sathish Kumar, S.; Elsheikh, A.H.; Mayakannan, S.; Sivakumar, K.; Duraithilagar, S. Optimization and experimental analysis of drilling process parameters in radial drilling machine for glass fiber/nano granite particle reinforced epoxy composites. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Ramesh, B.; Kumar, S.S.; Saravanan, I.; Elsheikh, A.H.; Karthikeyan, T. Experimental investigation of polymer matrix composite characterization using jute & carbon fiber in helmet application. AIP Conf. Proc. 2021, 2417, 020005. [Google Scholar]

- Li, Y.; Zhang, Z.; Yu, X.; Chai, H.; Lu, C.; Wu, H.; Wu, H.; Jiang, S. Tristable behaviour of cross-shaped unsymmetric fibre-reinforced laminates with concave–convex boundaries. Eng. Struct. 2020, 225, 111253. [Google Scholar] [CrossRef]

- Ding, S.; Sun, M.; Li, Y.; Ma, W.; Zhang, Z. Novel Deployable Panel Structure Integrated with Thick Origami and Morphing Bistable Composite Structures. Materials 2022, 15, 1942. [Google Scholar] [CrossRef]

- Dong, T.; Guo, Z.; Jiang, G. Global and Local Dynamics of a Bistable Asymmetric Composite Laminated Shell. Symmetry 2021, 13, 1690. [Google Scholar] [CrossRef]

- Zhang, Z.; Ni, X.; Gao, W.; Shen, H.; Sun, M.; Guo, G.; Wu, H.; Jiang, S. Pneumatically Controlled Reconfigurable Bistable Bionic Flower for Robotic Gripper. Soft Robot. 2021. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Li, X.; Yu, X.; Chai, H.; Li, Y.; Wu, H.; Jiang, S. Magnetic actuation bionic robotic gripper with bistable morphing structure. Compos. Struct. 2019, 229, 111422. [Google Scholar] [CrossRef]

- Daynes, S.; Weaver, P.M. Review of shape-morphing automobile structures: Concepts and outlook. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 1603–1622. [Google Scholar] [CrossRef]

- Emam, S.A.; Inman, D.J. A Review on Bistable Composite Laminates for Morphing and Energy Harvesting. Appl. Mech. Rev. 2015, 67, 060803. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Yu, X.; Li, X.; Wu, H.; Wu, H.; Jiang, S.; Chai, G. Bistable morphing composite structures: A review. Thin-Walled Struct. 2019, 142, 74–97. [Google Scholar] [CrossRef]

- Hyer, M.W. Some Observations on the Cured Shape of Thin Unsymmetric Laminates. J. Compos. Mater. 1981, 15, 175–194. [Google Scholar] [CrossRef]

- Hyer, M.W. The Room-Temperature Shapes of Four-Layer Unsymmetric Cross-Ply Laminates. J. Compos. Mater. 1982, 16, 318–340. [Google Scholar] [CrossRef]

- De Pietro, G.; Giunta, G.; Hui, Y.; Belouettar, S.; Hu, H.; Carrera, E. A novel computational framework for the analysis of bistable composite beam structures. Compos. Struct. 2021, 257, 113167. [Google Scholar] [CrossRef]

- Nicassio, F.; Scarselli, G.; Pinto, F.; Ciampa, F.; Iervolino, O.; Meo, M. Low energy actuation technique of bistable composites for aircraft morphing. Aerosp. Sci. Technol. 2018, 75, 35–46. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Wu, H.; Chen, D.; Yang, J.; Wu, H.; Jiang, S.; Chai, G. Viscoelastic bistable behaviour of antisymmetric laminated composite shells with time-temperature dependent properties. Thin-Walled Struct. 2018, 122, 403–415. [Google Scholar] [CrossRef]

- Lee, A.J.; Inman, D.J. Electromechanical modelling of a bistable plate with Macro Fiber Composites under nonlinear vibrations. J. Sound Vib. 2019, 446, 326–342. [Google Scholar] [CrossRef]

- Mukherjee, A.; Ali, S.F.; Arockiarajan, A. Hybrid bistable composite laminates for structural assemblies: A numerical and experimental study. Compos. Struct. 2021, 260, 113467. [Google Scholar] [CrossRef]

- Shaw, A.D.; Neild, S.A.; Wagg, D.J.; Weaver, P.M.; Carrella, A. A nonlinear spring mechanism incorporating a bistable composite plate for vibration isolation. J. Sound Vib. 2013, 332, 6265–6275. [Google Scholar] [CrossRef] [Green Version]

- Dano, M.-L.; Hyer, M.W. Thermally-induced deformation behavior of unsymmetric laminates. Int. J. Solids Struct. 1998, 35, 2101–2120. [Google Scholar] [CrossRef]

- Dano, M.-L.; Hyer, M.W. Snap-through of unsymmetric fiber-reinforced composite laminates. Int. J. Solids Struct. 2002, 39, 175–198. [Google Scholar] [CrossRef]

- Brampton, C.J.; Betts, D.N.; Bowen, C.R.; Kim, H.A. Sensitivity of bistable laminates to uncertainties in material properties, geometry and environmental conditions. Compos. Struct. 2013, 102, 276–286. [Google Scholar] [CrossRef] [Green Version]

- Mattioni, F.; Weaver, P.M.; Friswell, M. Multistable composite plates with piecewise variation of lay-up in the planform. Int. J. Solids Struct. 2009, 46, 151–164. [Google Scholar] [CrossRef] [Green Version]

- Diaconu, C.G.; Weaver, P.M.; Arrieta, A.F. Dynamic analysis of bi-stable composite plates. J. Sound Vib. 2009, 322, 987–1004. [Google Scholar] [CrossRef]

- Alazwari, M.A.; Rao, S.S. Modeling and analysis of composite laminates in the presence of uncertainties. Compos. Part B Eng. 2019, 161, 107–120. [Google Scholar] [CrossRef]

- Saberi, S.; Abdollahi, A.; Inam, F. Reliability analysis of bistable composite laminates. AIMS Mater. Sci. 2021, 8, 29–41. [Google Scholar] [CrossRef]

- Saberi, S.; Abdollahi, A.; Friswell, M.I. Probability analysis of bistable composite laminates using the subset simulation method. Compos. Struct. 2021, 271, 114120. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Sharshir, S.W.; Abd Elaziz, M.; Kabeel, A.E.; Guilan, W.; Haiou, Z. Modeling of solar energy systems using artificial neural network: A comprehensive review. Sol. Energy 2019, 180, 622–639. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Katekar, V.P.; Muskens, O.L.; Deshmukh, S.S.; Elaziz, M.A.; Dabour, S.M. Utilization of LSTM neural network for water production forecasting of a stepped solar still with a corrugated absorber plate. Process Saf. Environ. Prot. 2021, 148, 273–282. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shehabeldeen, T.A.; Zhou, J.; Showaib, E.; Abd Elaziz, M. Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. J. Intell. Manuf. 2021, 32, 1377–1388. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Elsheikh, A.H.; Moustafa, E.B.; Basha, M.; Mosleh, A.O. Prediction of residual stresses in turning of pure iron using artificial intelligence-based methods. J. Mater. Res. Technol. 2021, 11, 2181–2194. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Das, S.R.; Muthuramalingam, T.; Lu, S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J. Manuf. Process. 2021, 67, 562–578. [Google Scholar] [CrossRef]

- AbuShanab, W.S.; Abd Elaziz, M.; Ghandourah, E.I.; Moustafa, E.B.; Elsheikh, A.H. A new fine-tuned random vector functional link model using Hunger games search optimizer for modeling friction stir welding process of polymeric materials. J. Mater. Res. Technol. 2021, 14, 1482–1493. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Huang, Y.; Ji, J.; Lee, K.M. Temperature field sensing of a thin-wall component during machining: Numerical and experimental investigations. Int. J. Heat Mass Transf. 2018, 126, 935–945. [Google Scholar] [CrossRef]

- Saberi, S.; Ghayour, M.; Mirdamadi, H.; Ghamami, M. Free vibration analysis and mode management of bistable composite laminates using deep learning. Arch. Appl. Mech. 2021, 91, 2795–2816. [Google Scholar] [CrossRef]

- Sun, M.; Gao, W.; Zhang, Z.; Shen, H.; Zhou, Y.; Wu, H.; Jiang, S. A Unified High-Order Semianalytical Model and Numerical Simulation for Bistable Polymer Composite Structures. Polymers 2022, 14, 818. [Google Scholar] [CrossRef] [PubMed]

- Le Chau, N.; Tran, N.T.; Dao, T.-P. A multi-response optimal design of bistable compliant mechanism using efficient approach of desirability, fuzzy logic, ANFIS and LAPO algorithm. Appl. Soft Comput. 2020, 94, 106486. [Google Scholar] [CrossRef]

- Liu, F.; Jiang, X.; Wang, X.; Wang, L. Machine learning-based design and optimization of curved beams for multistable structures and metamaterials. Extrem. Mech. Lett. 2020, 41, 101002. [Google Scholar] [CrossRef]

- Panesar, A.S.; Weaver, P.M. Optimisation of blended bistable laminates for a morphing flap. Compos. Struct. 2012, 94, 3092–3105. [Google Scholar] [CrossRef]

- Prasad, J.; Diaz, A.R. Synthesis of Bistable Periodic Structures Using Topology Optimization and a Genetic Algorithm. J. Mech. Des. 2005, 128, 1298–1306. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, C.; Chai, H.; Ni, X.; Pei, K.; Sun, M.; Wu, H.; Jiang, S. Multi-objective optimization of controllable configurations for bistable laminates using NSGA-Ⅱ. Compos. Struct. 2021, 266, 113764. [Google Scholar] [CrossRef]

- Abd Elaziz, M.; Elsheikh, A.H.; Oliva, D.; Abualigah, L.; Lu, S.; Ewees, A.A. Advanced Metaheuristic Techniques for Mechanical Design Problems: Review. Arch. Comput. Method. Eng. 2021, 29, 695–716. [Google Scholar] [CrossRef]

- Oliva, D.; Elaziz, M.A.; Elsheikh, A.H.; Ewees, A.A. A review on meta-heuristics methods for estimating parameters of solar cells. J. Power Sources 2019, 435, 126683. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Muthuramalingam, T.; Shanmugan, S.; Mahmoud Ibrahim, A.M.; Ramesh, B.; Khoshaim, A.B.; Moustafa, E.B.; Bedairi, B.; Panchal, H.; Sathyamurthy, R. Fine-tuned artificial intelligence model using pigeon optimizer for prediction of residual stresses during turning of Inconel 718. J. Mater. Res. Technol. 2021, 15, 3622–3634. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Hammad, A.H.; Elsheikh, A.H. A new optimized artificial neural network model to predict thermal efficiency and water yield of tubular solar still. Case Stud. Therm. Eng. 2022, 30, 101750. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, H.; Ye, G.; Wu, H.; He, X.; Chai, G. Systematic experimental and numerical study of bistable snap processes for anti-symmetric cylindrical shells. Compos. Struct. 2014, 112, 368–377. [Google Scholar] [CrossRef]

- Wang, B.; Ge, C.; Fancey, K.S. Snap-through behaviour of a bistable structure based on viscoelastically generated prestress. Compos. Part B Eng. 2017, 114, 23–33. [Google Scholar] [CrossRef]

- Dai, F.; Li, H.; Du, S. Cured shape and snap-through of bistable twisting hybrid [0/90/metal]T laminates. Compos. Sci. Technol. 2013, 86, 76–81. [Google Scholar] [CrossRef]

- Ni, X.; Liao, C.; Li, Y.; Zhang, Z.; Sun, M.; Chai, H.; Wu, H.; Jiang, S. Experimental study of multi-stable morphing structures actuated by pneumatic actuation. Int. J. Adv. Manuf. Technol. 2020, 108, 1203–1216. [Google Scholar] [CrossRef]

- Lee, A.J.; Moosavian, A.; Inman, D.J. Control and characterization of a bistable laminate generated with piezoelectricity. Smart Mater. Struct. 2017, 26, 085007. [Google Scholar] [CrossRef]

- Lee, A.J.; Moosavian, A.; Inman, D.J. A piezoelectrically generated bistable laminate for morphing. Mater. Lett. 2017, 190, 123–126. [Google Scholar] [CrossRef]

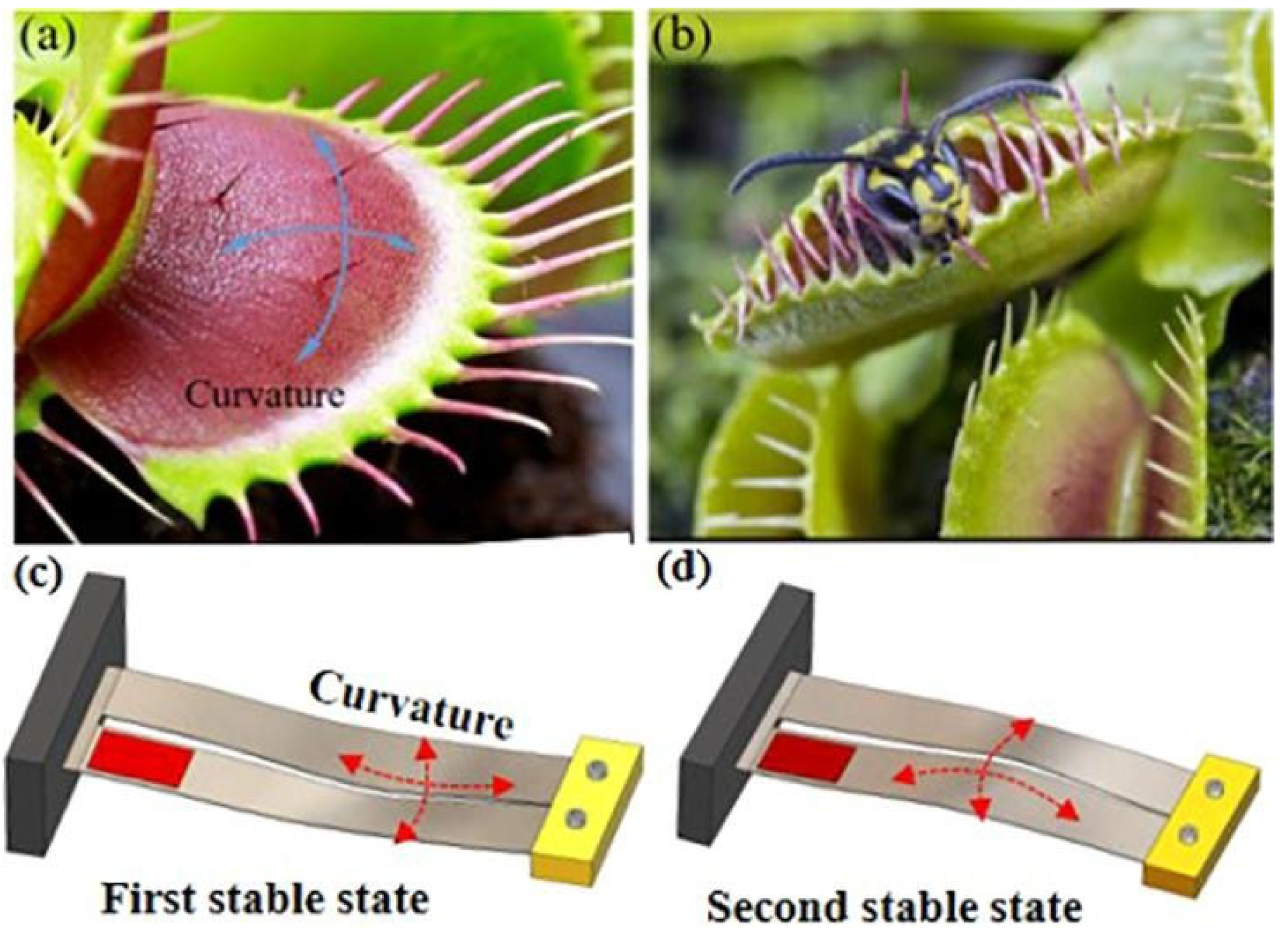

- Kim, S.-W.; Koh, J.-S.; Lee, J.-G.; Ryu, J.; Cho, M.; Cho, K.-J. Flytrap-inspired robot using structurally integrated actuation based on bistability and a developable surface. Bioinspiration Biomim. 2014, 9, 036004. [Google Scholar] [CrossRef]

- Zhang, Z.; Pei, K.; Wu, H.; Sun, M.; Chai, H.; Wu, H.; Jiang, S. Bistable characteristics of hybrid composite laminates embedded with bimetallic strips. Compos. Sci. Technol. 2021, 212, 108880. [Google Scholar] [CrossRef]

- Zhang, Z.; Pei, K.; Sun, M.; Wu, H.; Yu, X.; Wu, H.; Jiang, S.; Zhang, F. A novel solar tracking model integrated with bistable composite structures and bimetallic strips. Compos. Struct. 2020, 248, 112506. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Y.; Shen, H.; Sun, M.; Chai, H.; Wu, H.; Jiang, S. Experimental study of orthogonal bistable laminated composite shell driven by magnetorheological elastomer. Compos. Struct. 2021, 271, 114119. [Google Scholar] [CrossRef]

- Anilkumar, P.M.; Haldar, A.; Scheffler, S.; Jansen, E.L.; Rao, B.N.; Rolfes, R. Morphing of bistable variable stiffness composites using distributed MFC actuators. Compos. Struct. 2022, 289, 115396. [Google Scholar] [CrossRef]

- Pagliero, M.; Alloisio, M.; Costa, C.; Firpo, R.; Mideksa, E.A.; Comite, A. Carbon Black/Polyvinylidene Fluoride Nanocomposite Membranes for Direct Solar Distillation. Energies 2022, 15, 740. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Xu, L.L.; Ryu, C.H.; Kumar, A.; Hong, S.D.; Jeon, D.H.; Cho, J.Y.; Ahn, J.H.; Joo, Y.H.; Jeong, I.W.; et al. Wearable Shoe-Mounted Piezoelectric Energy Harvester for a Self-Powered Wireless Communication System. Energies 2022, 15, 237. [Google Scholar] [CrossRef]

- Kang, M.-G.; Jung, W.-S.; Kang, C.-Y.; Yoon, S.-J. Recent Progress on PZT Based Piezoelectric Energy Harvesting Technologies. Actuators 2016, 5, 5. [Google Scholar] [CrossRef]

- Alvarado, U.; Juanicorena, A.; Adin, I.; Sedano, B.; Gutiérrez, I.; de Nó, J. Energy harvesting technologies for low-power electronics. Trans. Emerg. Telecommun. Technol. 2012, 23, 728–741. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; He, X.; Wang, M.; Shu, H.; Xue, K. Comparisons of bioinspired piezoelectric wind energy harvesters with different layout of stiffeners based on leaf venation prototypes. Sens. Actuators A Phys. 2019, 298, 111570. [Google Scholar] [CrossRef]

- Tommasino, D.; Moro, F.; Bernay, B.; De Lumley Woodyear, T.; de Pablo Corona, E.; Doria, A. Vibration Energy Harvesting by Means of Piezoelectric Patches: Application to Aircrafts. Sensors 2022, 22, 363. [Google Scholar] [CrossRef]

- Wen, Q.; He, X.; Lu, Z.; Streiter, R.; Otto, T. A comprehensive review of miniatured wind energy harvesters. Nano Mater. Sci. 2021, 3, 170–185. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Xu, L.; Ali, M.K.A.; Elagouz, A.; Mi, J.; Guo, S.; Liu, Y.; Zuo, L. Vibration energy harvesting in automotive suspension system: A detailed review. Appl. Energy 2018, 229, 672–699. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Da Ronch, A.; Xiang, J. Energy harvesting by means of flow-induced vibrations on aerospace vehicles. Prog. Aerosp. Sci. 2016, 86, 28–62. [Google Scholar] [CrossRef] [Green Version]

- Betts, D.N.; Bowen, C.R.; Kim, H.A.; Gathercole, N.; Clarke, C.T.; Inman, D.J. Nonlinear dynamics of a bistable piezoelectric-composite energy harvester for broadband application. Eur. Phys. J. Spec. Top. 2013, 222, 1553–1562. [Google Scholar] [CrossRef] [Green Version]

- Betts, D.N.; Kim, H.A.; Bowen, C.R.; Inman, D.J. Optimal configurations of bistable piezo-composites for energy harvesting. Appl. Phys. Lett. 2012, 100, 114104. [Google Scholar] [CrossRef] [Green Version]

- Nan, W.; Yuncheng, H.; Jiyang, F. Bistable energy harvester using easy snap-through performance to increase output power. Energy 2021, 226, 120414. [Google Scholar] [CrossRef]

- Lee, A.J.; Inman, D.J. A multifunctional bistable laminate: Snap-through morphing enabled by broadband energy harvesting. J. Intell. Mater. Syst. Struct. 2018, 29, 2528–2543. [Google Scholar] [CrossRef] [Green Version]

- Kwon, S.-C.; Oh, H.-U. Experimental validation of satellite micro-jitter management strategy in energy harvesting and vibration isolation. Sens. Actuators A Phys. 2016, 249, 172–185. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Kuang, J.; Luhrs, G. Energy-harvesting shock absorber with a mechanical motion rectifier. Smart Mater. Struct. 2012, 22, 025008. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, R.; Yu, K.; Lee, H.P.; Liao, B. Simultaneous energy harvesting and vibration isolation via quasi-zero-stiffness support and radially distributed piezoelectric cantilever beams. Appl. Math. Model. 2021, 100, 152–169. [Google Scholar] [CrossRef]

- Lu, Z.-Q.; Shao, D.; Fang, Z.-W.; Ding, H.; Chen, L.-Q. Integrated vibration isolation and energy harvesting via a bistable piezo-composite plate. J. Vib. Control 2019, 26, 779–789. [Google Scholar] [CrossRef]

- Wu, M.Q.; Zhang, W.; Niu, Y. Experimental and numerical studies on nonlinear vibrations and dynamic snap-through phenomena of bistable asymmetric composite laminated shallow shell under center foundation excitation. Eur. J. Mech.-A Solids 2021, 89, 104303. [Google Scholar] [CrossRef]

- Qian, F.; Hajj, M.R.; Zuo, L. Bio-inspired bi-stable piezoelectric harvester for broadband vibration energy harvesting. Energy Convers. Manag. 2020, 222, 113174. [Google Scholar] [CrossRef]

- Qian, F.; Liu, M.; Huang, J.; Zhang, J.; Jung, H.; Deng, Z.D.; Hajj, M.R.; Zuo, L. Bio-inspired bistable piezoelectric energy harvester for powering animal telemetry tags: Concept design and preliminary experimental validation. Renew. Energy 2021, 187, 34–43. [Google Scholar] [CrossRef]

- Brinkmeyer, A.; Pellegrino, S.; Weaver, P.M. Effects of Long-Term Stowage on the Deployment of Bistable Tape Springs. J. Appl. Mech. 2015, 83, 001008. [Google Scholar] [CrossRef] [Green Version]

- Mao, H.; Shipsha, A.; Tibert, G. Design and Analysis of Laminates for Self-Deployment of Viscoelastic Bistable Tape Springs After Long-Term Stowage. J. Appl. Mech. 2017, 84, 071004. [Google Scholar] [CrossRef]

- Wang, B.; Seffen, K.A.; Guest, S.D. Folded strains of a bistable composite tape-spring. Int. J. Solids Struct. 2021, 233, 111221. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. https://doi.org/10.3390/polym14091893

Elsheikh A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers. 2022; 14(9):1893. https://doi.org/10.3390/polym14091893

Chicago/Turabian StyleElsheikh, Ammar. 2022. "Bistable Morphing Composites for Energy-Harvesting Applications" Polymers 14, no. 9: 1893. https://doi.org/10.3390/polym14091893

APA StyleElsheikh, A. (2022). Bistable Morphing Composites for Energy-Harvesting Applications. Polymers, 14(9), 1893. https://doi.org/10.3390/polym14091893