Experimental Analysis of the Relationship between Textile Structure, Tensile Strength and Comfort in 3D Printed Structured Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materiales

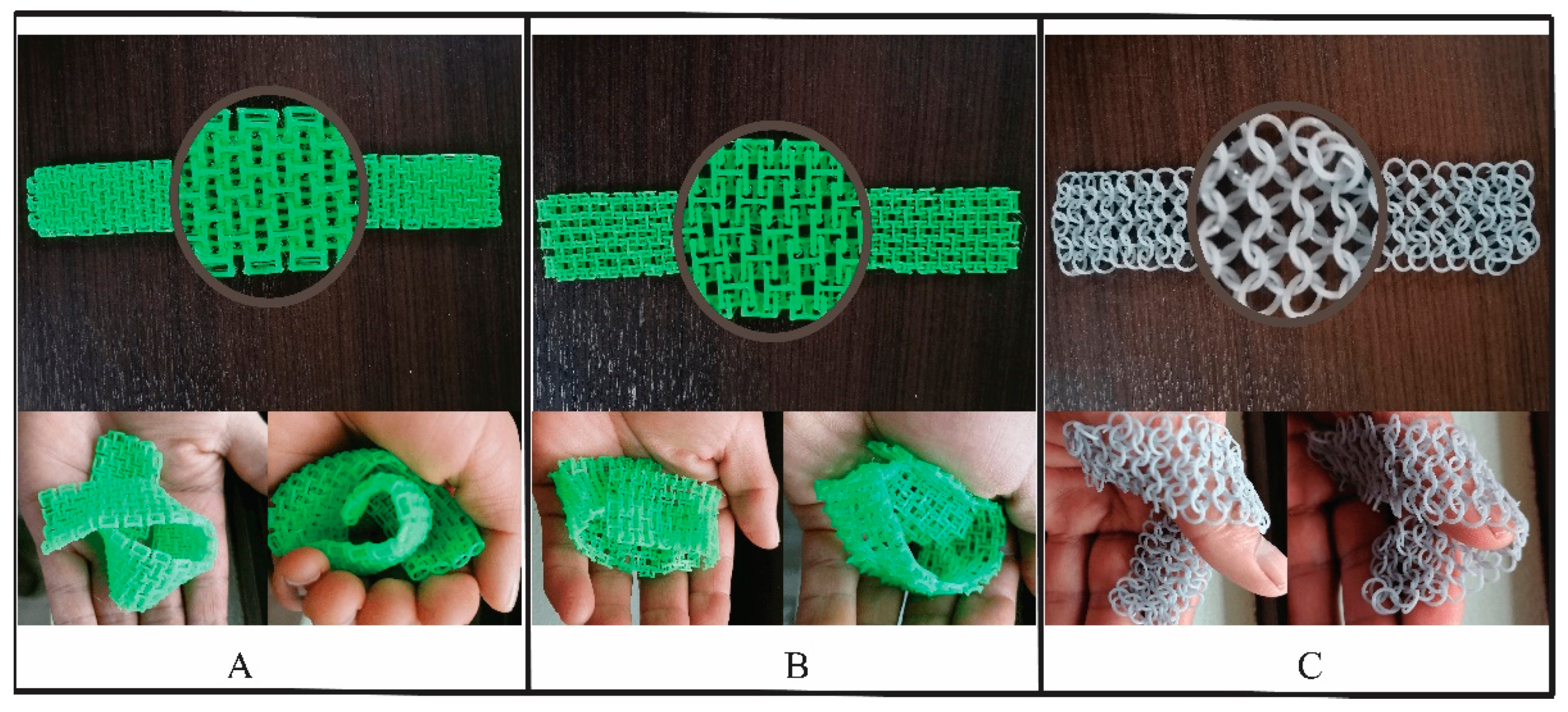

2.2. Manufacturing Process

2.3. Tensile Tests

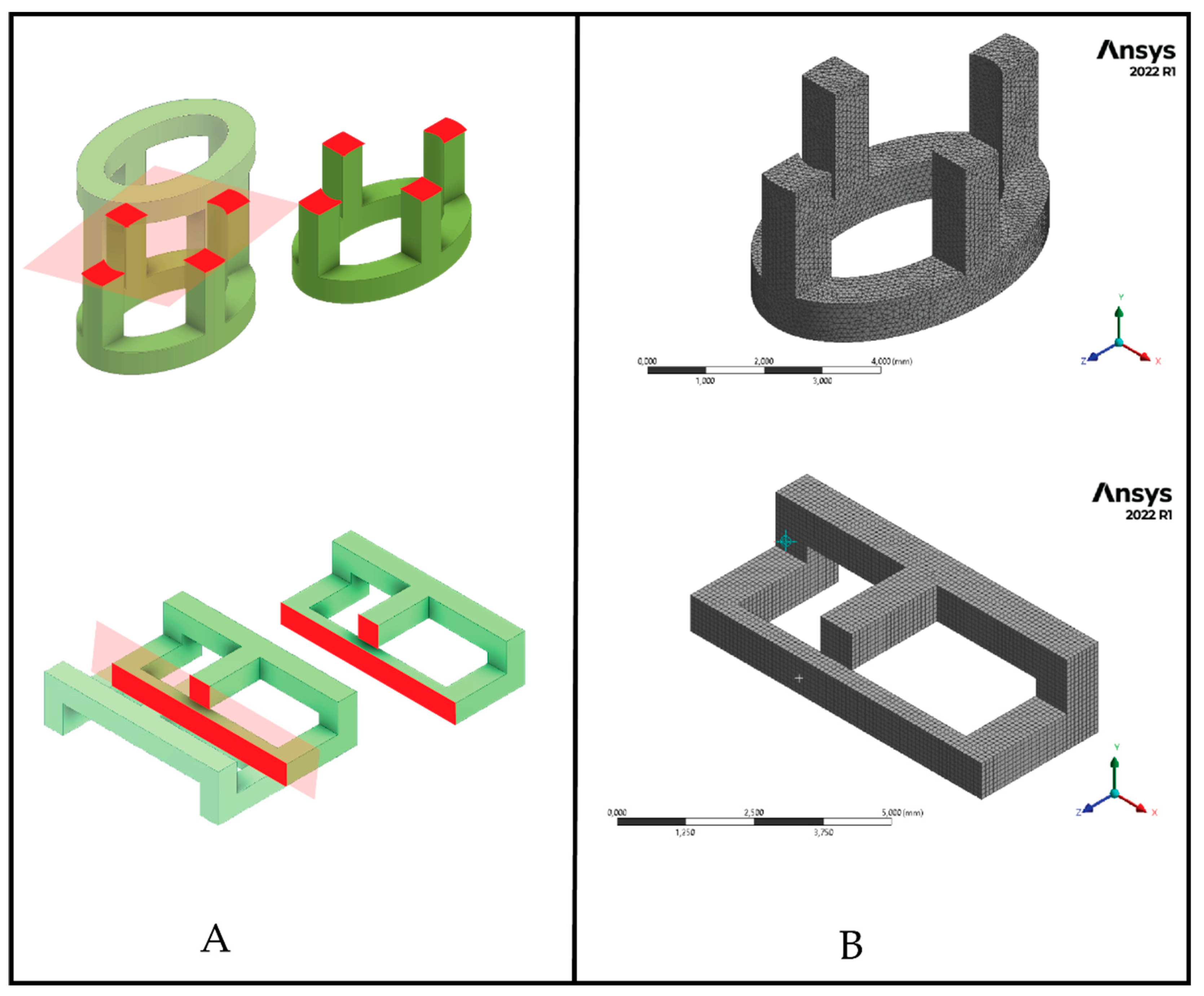

2.4. CAE Modeling

2.5. Textile Properties

3. Results

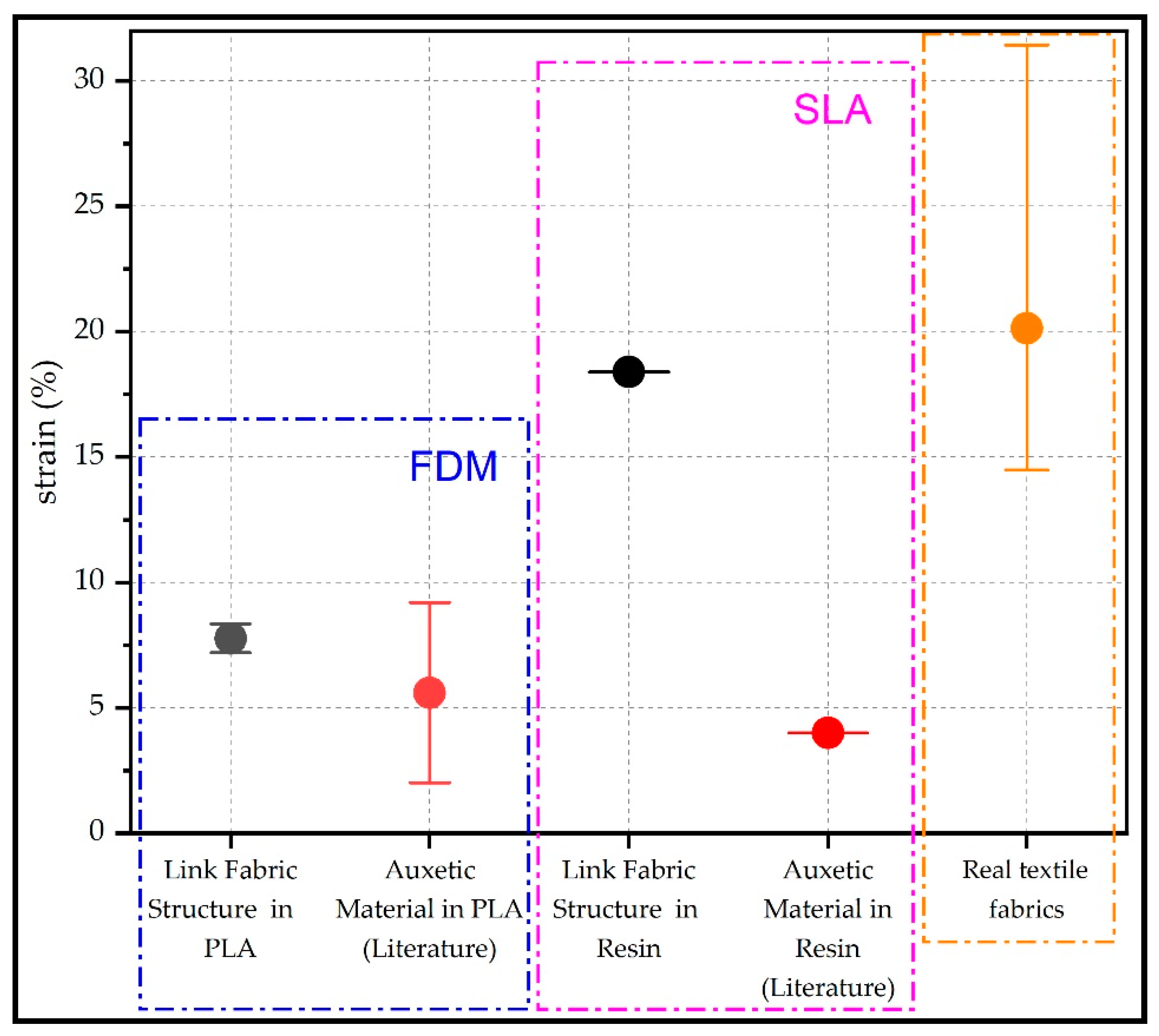

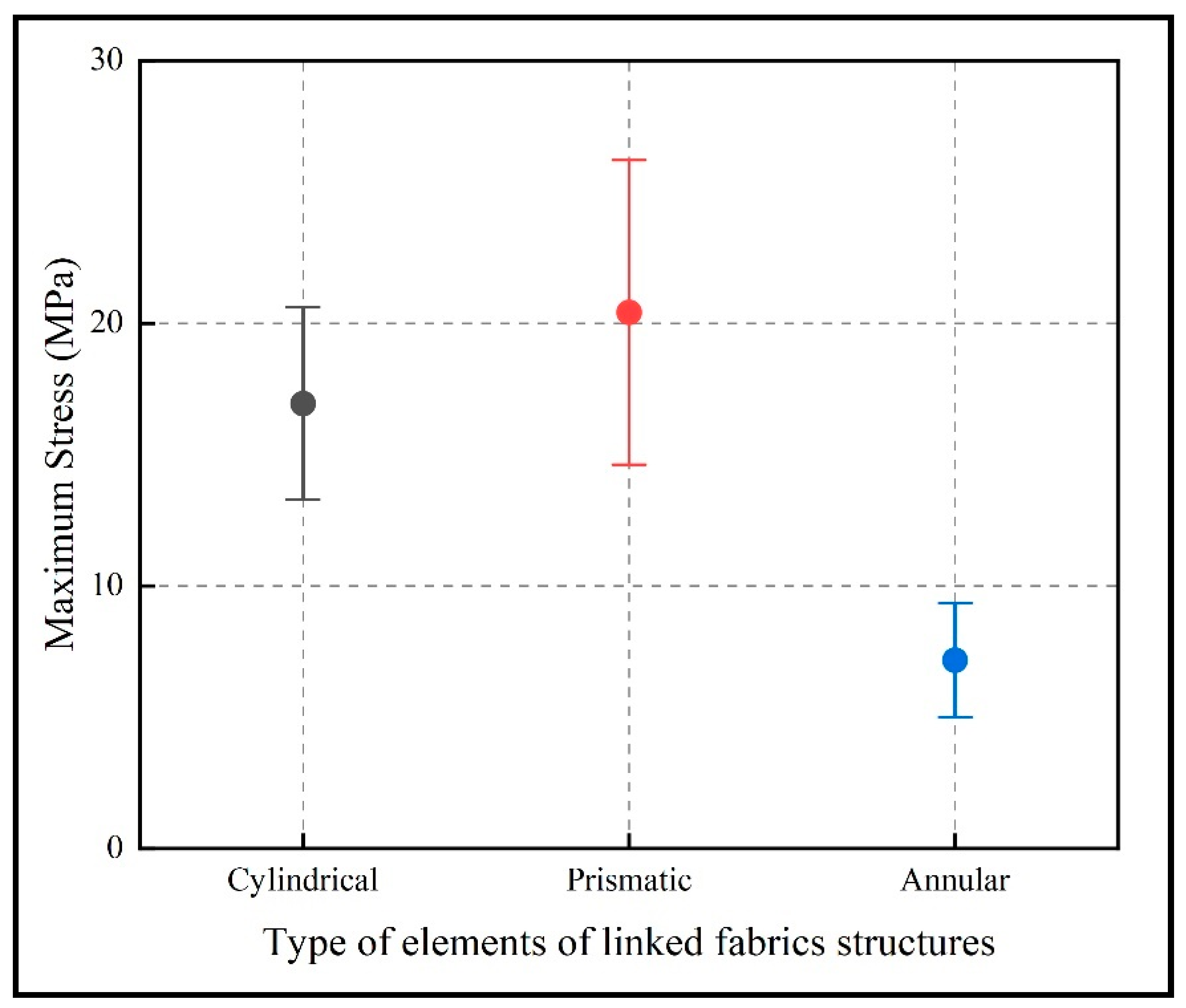

3.1. Tensile Tests Results

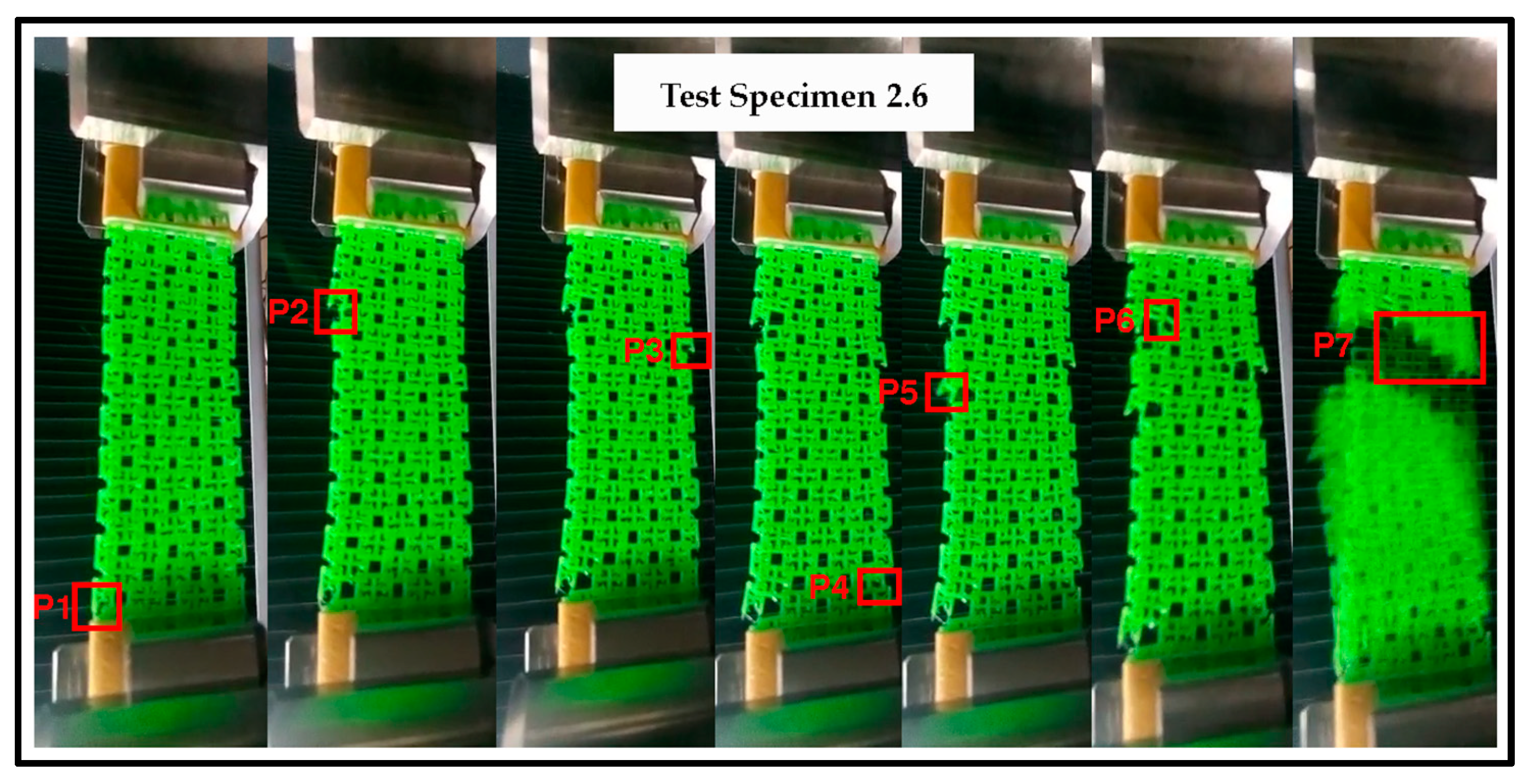

3.2. Fracture Zone Morphology

3.3. Textile Characteristics of 3D Printed Fabrics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Lin, Q. The Study of the Innovation of Commercial Operation Pattern of Chinese Design Industry under the Influence of 3DP. In Proceedings of the International Conference on Cognitive Based Information Processing and Applications (CIPA 2021), Online, 21 August 2021; Jansen, B.J., Liang, H., Ye, J., Eds.; Springer: Beijing, China, 2021; pp. 558–564. [Google Scholar]

- Chakraborty, S.; Biswas, M.C. 3D Printing Technology of Polymer-Fiber Composites in Textile and Fashion Industry: A Potential Roadmap of Concept to Consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Pirjan, A.; Petrosanu, D.-M. The Impact of 3D Printing Technology on the Society and Economy. J. Inf. Syst. Oper. Manag. 2013, 7, 360–370. [Google Scholar]

- Kai Chua, C.; Fai Leong, K.; Sing Lim, C.; Thien Vu, T. Multimedia Courseware for Teaching of Rapid Prototyping Systems. Rapid Prototyp. J. 2010, 16, 80–89. [Google Scholar] [CrossRef]

- Yeole, S.N. Importance and Utilization of 3D Printing in Various Applications. Int. J. Mod. Eng. Res. 2016, 1, 6. [Google Scholar]

- Koszewska, M. Circular Economy—Challenges for the Textile and Clothing Industry. Autex Res. J. 2018, 18, 337. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, K.; Ghosh, T.K. 3D Printing of Textiles: Potential Roadmap to Printing with Fibers. Adv. Mater. 2020, 32, 1902086. [Google Scholar] [CrossRef]

- Vanderploeg, A.; Lee, S.-E.; Mamp, M. The Application of 3D Printing Technology in the Fashion Industry. Int. J. Fash. Des. Technol. Educ. 2017, 10, 170–179. [Google Scholar] [CrossRef]

- de Oliveira, C.R.S.; da Silva Júnior, A.H.; Immich, A.P.S.; Fiates, J. Use of Advanced Materials in Smart Textile Manufacturing. Mater. Lett. 2022, 316, 132047. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material Issues in Additive Manufacturing: A Review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Fink, J.K. 3D Industrial Printing with Polymers, 1st ed.; John Wiley & Sons, Incorporated: Newark, NJ, USA, 2018; ISBN 978-1-119-55531-5. [Google Scholar]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Stress, Strain and Deformation of Poly-Lactic Acid Filament Deposited onto Polyethylene Terephthalate Woven Fabric through 3D Printing Process. Sci. Rep. 2019, 9, 14333. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, H.; Kim, J. 3D Printed Fabric: Techniques for Design and 3D Weaving Programmable Textiles. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology, Association for Computing Machinery, New York, NY, USA, 17 October 2019; pp. 43–51. [Google Scholar]

- Wang, Y.; Li, L.; Hofmann, D.; Andrade, J.E.; Daraio, C. Structured Fabrics with Tunable Mechanical Properties. Nature 2021, 596, 238–243. [Google Scholar] [CrossRef] [PubMed]

- Brown, E.; Nasto, A.; Athanassiadis, A.G.; Jaeger, H.M. Strain Stiffening in Random Packings of Entangled Granular Chains. Phys. Rev. Lett. 2012, 108, 108302. [Google Scholar] [CrossRef] [PubMed]

- Djumas, L.; Simon, G.P.; Estrin, Y.; Molotnikov, A. Deformation Mechanics of Non-Planar Topologically Interlocked Assemblies with Structural Hierarchy and Varying Geometry. Sci. Rep. 2017, 7, 11844. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirkhalaf, M.; Tanguay, J.; Barthelat, F. Carving 3D Architectures within Glass: Exploring New Strategies to Transform the Mechanics and Performance of Materials. Extrem. Mech. Lett. 2016, 7, 104–113. [Google Scholar] [CrossRef]

- Bloomfield, M.; Borstrock, S. Modeclix. The Additively Manufactured Adaptable Textile. Mater. Today Commun. 2018, 16, 212–216. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D Printing of Textile-Based Structures by Fused Deposition Modelling (FDM) with Different Polymer Materials. IOP Conf. Ser. Mater. Sci. Eng. 2014, 62, 012018. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Zhang, Y.S.; Heinrich, M.A.; De Ferrari, F.; Jang, H.L.; Bakht, S.M.; Alvarez, M.M.; Yang, J.; Li, Y.-C.; Trujillo-de Santiago, G.; et al. Rapid Continuous Multimaterial Extrusion Bioprinting. Adv. Mater. 2017, 29, 1604630. [Google Scholar] [CrossRef] [Green Version]

- Meyer, P.; Döpke, C.; Ehrmann, A. Improving Adhesion of Three-Dimensional Printed Objects on Textile Fabrics by Polymer Coating. J. Eng. Fibers Fabr. 2019, 14, 1558925019895257. [Google Scholar] [CrossRef] [Green Version]

- Ehrmann, A.; Steinmetz, P. Influence of Elastic 3D Printed Polymers on the Mechanical Properties and Tribology of Textile Fabrics. Commun. Dev. Assem. Text. Prod. 2021, 2, 115–122. [Google Scholar] [CrossRef]

- Sabantina, L.; Kinzel, F.; Ehrmann, A.; Finsterbusch, K. Combining 3D Printed Forms with Textile Structures—Mechanical and Geometrical Properties of Multi-Material Systems. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012005. [Google Scholar] [CrossRef]

- Ayvali, M.; Bussieweke, L.; Druzinin, G.; Korkmaz, M.; Ehrmann, A. 3D Printing on Warp-Knitted Fabrics. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1031, 012019. [Google Scholar] [CrossRef]

- Zahra, T. Characterization of 3D Printed Re-Entrant Chiral Auxetic Geometries. Int. J. Mater. Metall. Eng. 2021, 15, 117–121. [Google Scholar]

- Zahra, T. Behaviour of 3D Printed Re-Entrant Chiral Auxetic (RCA) Geometries under in-Plane and out-of-Plane Loadings. Smart Mater. Struct. 2021, 30, 115011. [Google Scholar] [CrossRef]

- Bagewadi, S.S.; Sugavaneswaran, M.; Bhagchandani, R.K. Investigation on Mechanical Properties of Additive Manufactured Hybrid Auxetic Structure. J. Mater. Eng Perform 2022, 1, 14. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Yang, Z.; Lu, Z. Novel Auxetic Structures with Enhanced Mechanical Properties. Extrem. Mech. Lett. 2019, 27, 59–65. [Google Scholar] [CrossRef]

- Pei, E.; Shen, J.; Watling, J. Direct 3D Printing of Polymers onto Textiles: Experimental Studies and Applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef] [Green Version]

- Mirkhalaf, M.; Zhou, T.; Barthelat, F. Simultaneous Improvements of Strength and Toughness in Topologically Interlocked Ceramics. Proc. Natl. Acad. Sci. USA 2018, 115, 9128–9133. [Google Scholar] [CrossRef] [Green Version]

- Alomarah, A.; Ruan, D.; Masood, S.; Sbarski, I.; Faisal, B. An Investigation of In-Plane Tensile Properties of Re-Entrant Chiral Auxetic Structure. Int. J. Adv. Manuf. Technol. 2018, 96, 2013–2029. [Google Scholar] [CrossRef]

- Ali, M.; Zeeshan, M.; Qadir, M.B.; Riaz, R.; Ahmad, S.; Nawab, Y.; Anjum, A.S. Development and Mechanical Characterization of Weave Design Based 2D Woven Auxetic Fabrics for Protective Textiles. Fibers Polym. 2018, 19, 2431–2438. [Google Scholar] [CrossRef]

- Shah, A.A.; Shahid, M.; Siddiqui, N.A.; Nawab, Y.; Iqbal, M. Effect of Geometric Arrangement on Mechanical Properties of 2D Woven Auxetic Fabrics. Textiles 2022, 2, 606–623. [Google Scholar] [CrossRef]

- Aruchamy, K.; Pavayee Subramani, S.; Palaniappan, S.K.; Sethuraman, B.; Velu Kaliyannan, G. Study on Mechanical Characteristics of Woven Cotton/Bamboo Hybrid Reinforced Composite Laminates. J. Mater. Res. Technol. 2020, 9, 718–726. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for High-Value Textile Applications: The Effective Long Fiber Yield and Quality of Different Hemp Varieties, Processed Using Industrial Flax Equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Abbas, S.; Amjad, R.; Nehdi, M.L.; Ali, S. Material Characterization of Locally Available Textile Fabrics for Structural Applications. Buildings 2022, 12, 1589. [Google Scholar] [CrossRef]

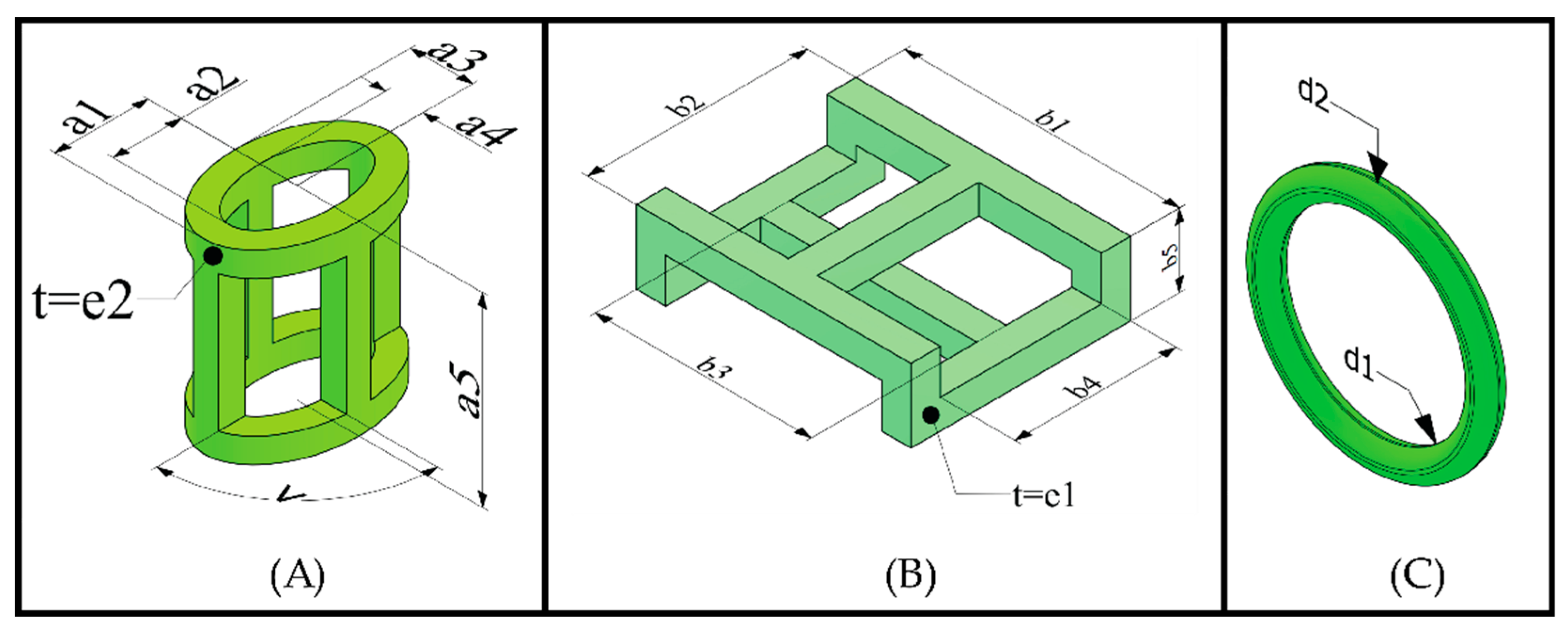

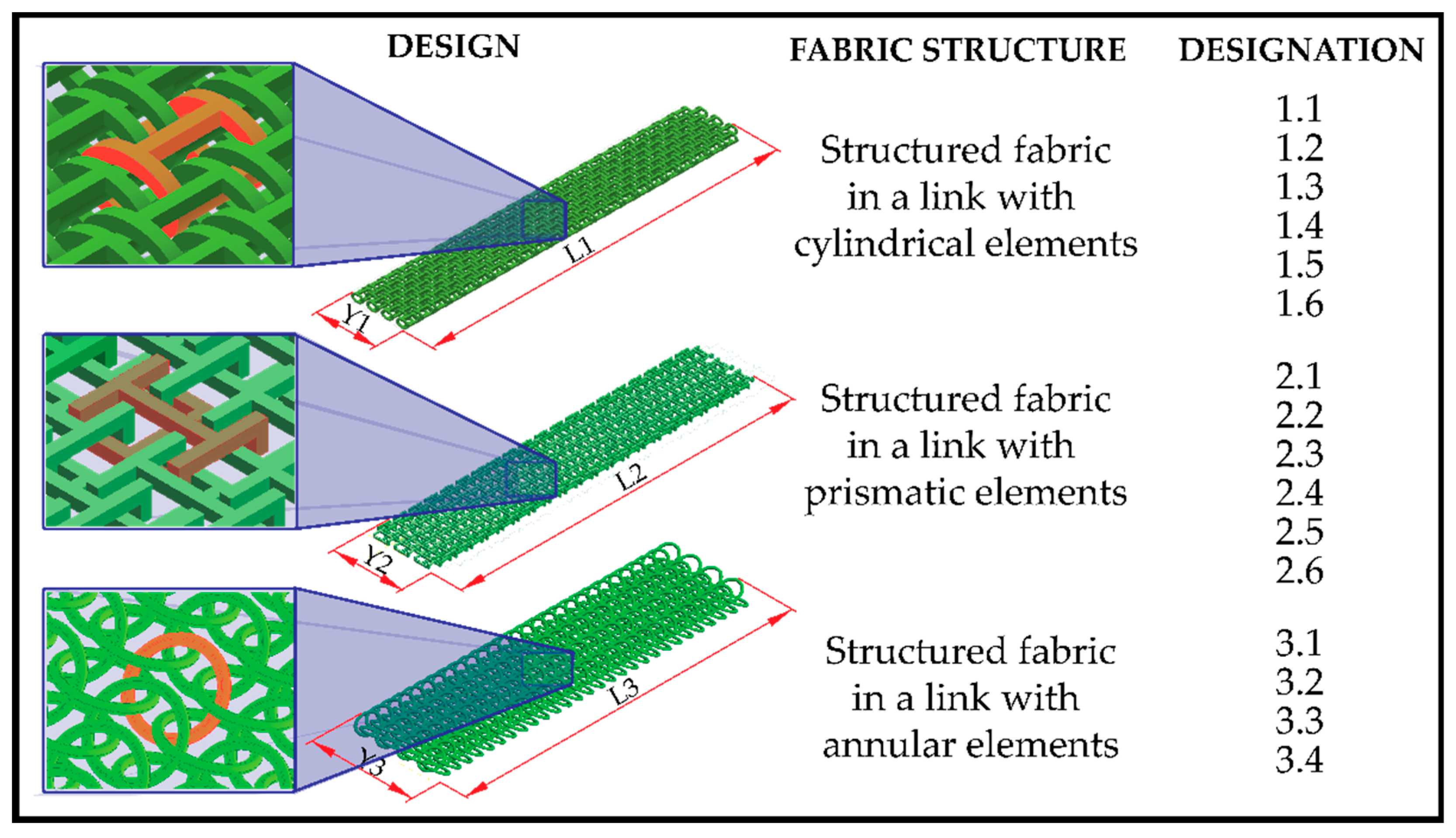

| Design | Dimension (mm) | Specimen | Dimension (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cylindrical element | a1 | a2 | a3 | a4 | a5 | e1 | < | 1.1–1.6 | L1 | Y1 |

| 3 | 2.2 | 2 | 1.2 | 6 | 0.8 | 90° | 163 | 27 | ||

| Prismatic element | b1 | b2 | b3 | b4 | b5 | e2 | 2.1–2.6 | L2 | Y2 | |

| 7.5 | 6 | 5.9 | 4.4 | 2 | 0.8 | 162 | 31.4 | |||

| Annular element | d1 | d2 | 3.1–3.6 | L3 | Y3 | |||||

| 7 | 5.4 | 100 | 30.5 | |||||||

| Designation | Maximum Stress | Strain | Young’s Modulus |

|---|---|---|---|

| (MPa) | (%) | (MPa) | |

| 1.1–1.6 | 16.94 | 8.34 | 217.84 |

| 2.1–2.6 | 20.41 | 7.19 | 265.25 |

| 3.1–3.4 | 6.88 | 18.38 | 36.89 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Between-group | 357.362 | 2 | 178.681 | 12.83 | 0.0008 |

| Intra-group | 181.099 | 13 | 13.9307 | ||

| Total (Corr.) | 538.461 | 15 |

| Specimen | Direct System “tex” | Indirect System | Fabric Areal Density | Yield |

|---|---|---|---|---|

| Structured fabrics in a link with cylindrical elements | 0.20 | 28.60 | ||

| Structured fabrics in a link with prismatic elements | 0.24 | 40.61 | ||

| Structured fabrics in a link with annular elements | 0.31 | 40.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fajardo, J.I.; Farez, M.V.; Paltán, C.A. Experimental Analysis of the Relationship between Textile Structure, Tensile Strength and Comfort in 3D Printed Structured Fabrics. Polymers 2023, 15, 152. https://doi.org/10.3390/polym15010152

Fajardo JI, Farez MV, Paltán CA. Experimental Analysis of the Relationship between Textile Structure, Tensile Strength and Comfort in 3D Printed Structured Fabrics. Polymers. 2023; 15(1):152. https://doi.org/10.3390/polym15010152

Chicago/Turabian StyleFajardo, Jorge I., Marco V. Farez, and César A. Paltán. 2023. "Experimental Analysis of the Relationship between Textile Structure, Tensile Strength and Comfort in 3D Printed Structured Fabrics" Polymers 15, no. 1: 152. https://doi.org/10.3390/polym15010152

APA StyleFajardo, J. I., Farez, M. V., & Paltán, C. A. (2023). Experimental Analysis of the Relationship between Textile Structure, Tensile Strength and Comfort in 3D Printed Structured Fabrics. Polymers, 15(1), 152. https://doi.org/10.3390/polym15010152