Extraction and Characterization of New Cellulosic Fiber from Catalpa bignonioides Fruits for Potential Use in Sustainable Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussions

3.1. Chemical Composition

3.2. Density

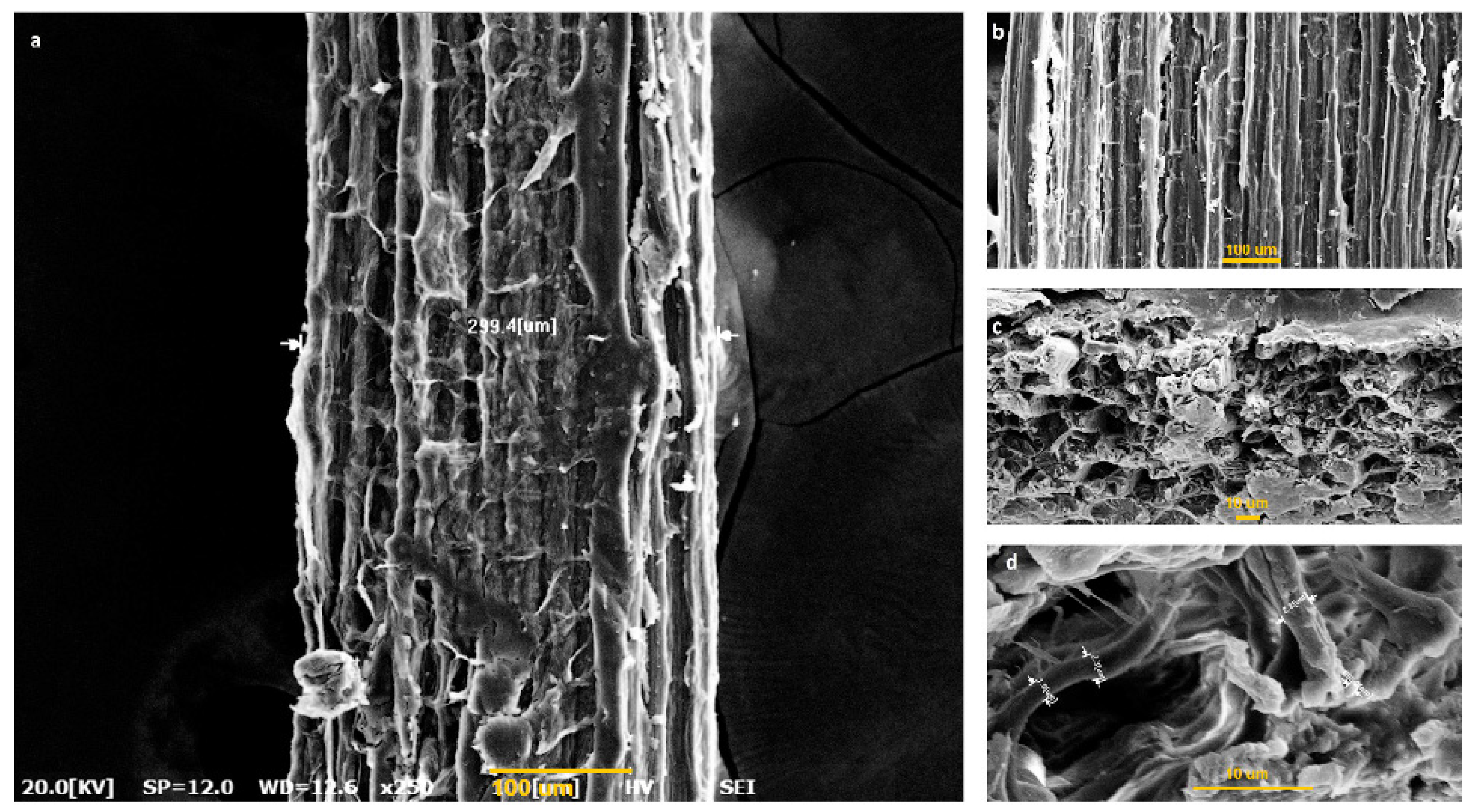

3.3. Scanning Electron Microscopy (SEM) Analysis

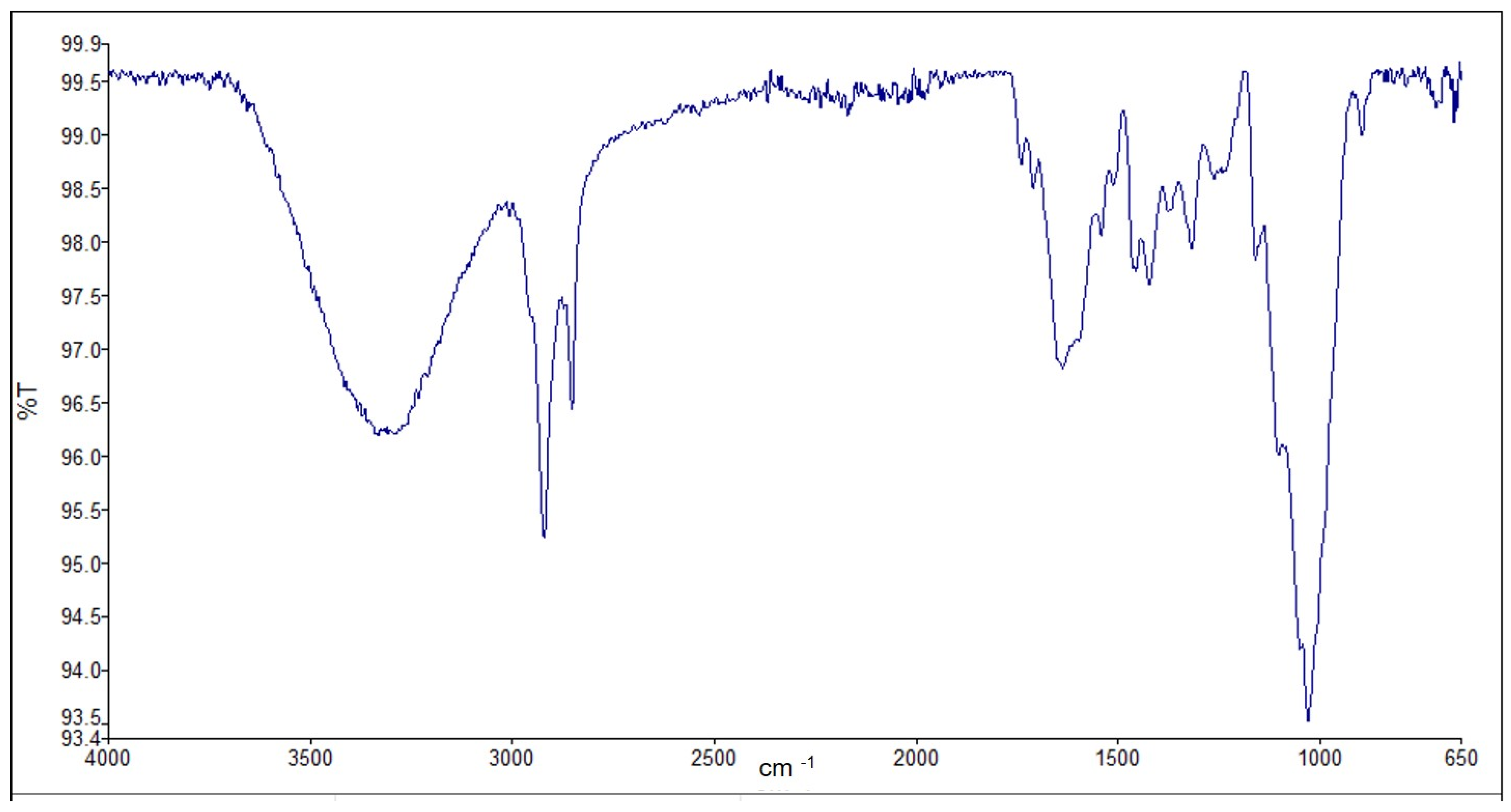

3.4. Fourier Transform Infrared Spectroscopy (FTIR-ATR) Analysis

3.5. X-ray Diffraction (XRD) Analysis

3.6. XPS

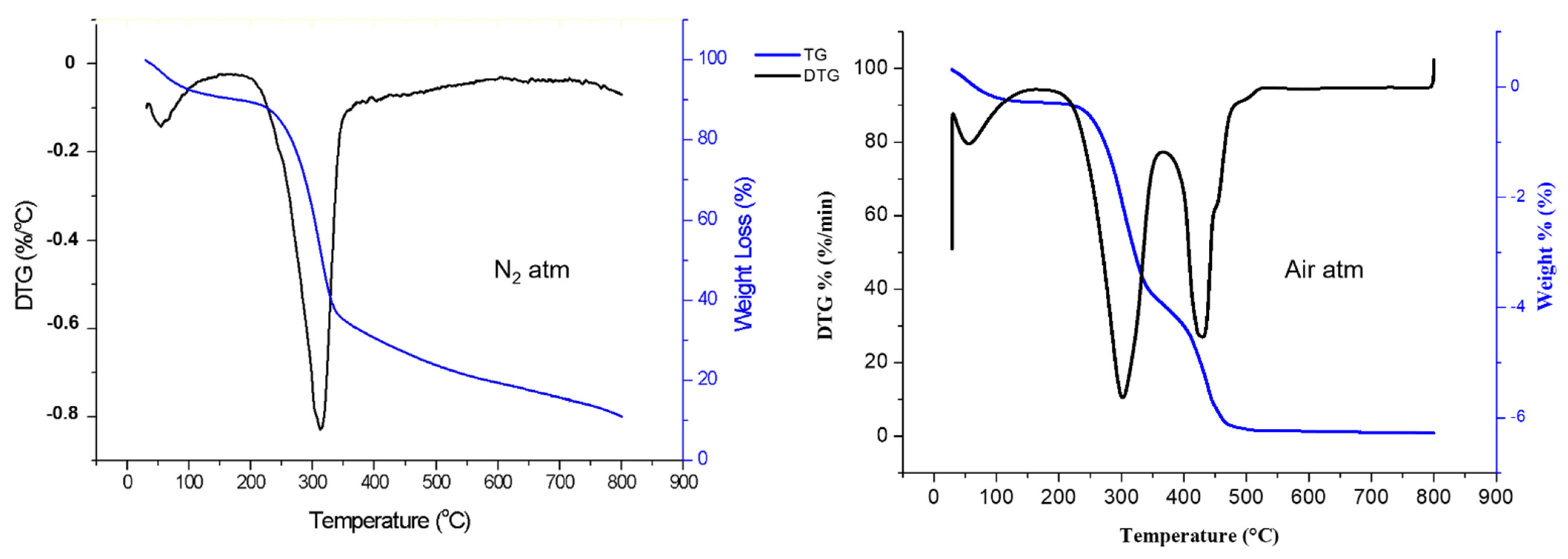

3.7. Thermogravimetric (TGA) Analysis

3.8. Tensile Strength

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jayaramudu, J.; Guduri, B.R.; Rajulu, A.V. Characterization of new natural cellulosic fabric Grewia tilifolia. Carbohydr. Polym. 2010, 79, 847–851. [Google Scholar] [CrossRef]

- Jawaid, M.H.P.S.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Durmuşkahya, C. Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos. Part B 2013, 44, 517–523. [Google Scholar] [CrossRef]

- Sarikanat, M.; Seki, Y.; Sever, K.; Durmuşkahya, C. Determination of properties of Althaea officinalis L.(Marshmallow) fibers as a potential plant fibre in polymeric composite materials. Compos. Part B 2014, 57, 180–186. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Investigation of Physico-chemical, Mechanical, and Thermal Properties of New Cellulosic Bast Fiber Extracted from the Bark of Bauhiniapurpurea. J. Nat. Fibers 2022, 19, 9624–9641. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol. 2005, 23, 22–27. [Google Scholar] [CrossRef]

- Karthik, T.; Murugan, R. Characterization and analysis of ligno-cellulosic seed fiber from Pergularia daemia plant for textile applications. Fibers Polym. 2013, 14, 465–472. [Google Scholar] [CrossRef]

- Lemita, N.; Deghboudj, S.; Rokbi, M.; Rekbi, F.M.L.; Halimi, R. Characterization and analysis of novel natural cellulosic fiber extracted from Strelitzia reginae plant. J. Compos. Mater. 2022, 56, 99–114. [Google Scholar] [CrossRef]

- Indran, S.; Raj, R.E.; Sreenivasan, V.S. Characterization of new natural cellulosic fiber from Cissus quadrangularis root. Carbohydr. Polym. 2014, 110, 423–429. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R. Characterization of new cellulose sansevieria ehrenbergii fibers for polymer composites. Compos. Interfaces 2013, 20, 575–593. [Google Scholar] [CrossRef]

- Belouadah, Z.; Ati, A.; Rokbi, M. Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohydr. Polym. 2015, 134, 429–437. [Google Scholar] [CrossRef]

- Arthanarieswaran, V.P.; Kumaravel, A.; Saravanakumar, S.S. Characterization of new natural cellulosic fiber from Acacia leucophloea bark. Int. J. Polym. Anal. Charact. 2015, 20, 367–376. [Google Scholar] [CrossRef]

- Baskaran, P.G.; Kathiresan, M.; Senthamaraikannan, P.; Saravanakumar, S.S. Characterization of new natural cellulosic fiber from the bark of dichrostachys cinerea. J. Nat. Fibers 2018, 15, 62–68. [Google Scholar] [CrossRef]

- Hyness, N.R.J.; Vignesh, N.J.; Senthamaraikannan, P.; Saravanakumar, S.; Sanjay, M. Characterization of new natural cellulosic fiber from heteropogon contortus plant. J. Nat. Fibers 2015, 15, 146–153. [Google Scholar] [CrossRef]

- Eyupoglu, S.; Merdan, N. Physicochemical Properties of New Plant Based Fiber from Lavender Stem. J. Nat. Fibers 2021, 19, 9248–9258. [Google Scholar] [CrossRef]

- Konyar, S.T. An Overview of Pollen and Anther Wall Development in Catalpa bignonioides Walter (BIGNONIACEAE). Trak. Univ. J. Nat. Sci. 2017, 18, 123–132. [Google Scholar]

- Demeshko, O.V.; Krivoruchko, O.V.; Volochai, V.I.; Kovalev, V.V. Biological active substances of leaves of Catalpa bignonioides from Ukraine. In Proceedings of the XIII International Symposium on the Chemistry of Natural Compounds, Shanghai, China, 16–19 October 2019; p. 84. [Google Scholar]

- Erper, I.; Ozer, G.; Kalkan, C. First report of powdery mildew caused by Erysiphe elevata on Catalpa bignonioides in Turkey. J. Plant Pathol. 2019, 101, 195. [Google Scholar] [CrossRef]

- Cragg, G.M.; Newman, D.J. Plants as a source of anti-cancer agents. J. Ethnopharmacol. 2005, 100, 72–79. [Google Scholar] [CrossRef]

- Choudhury, S.; Datta, S.; Talukdar, A.D.; Choudhury, M.D. Phytochemistry of the family Bignoniaceae—A review. Assam Univ. J. 2011, 7, 145–150. [Google Scholar]

- De Abreu, M.B.; Temraz, A.; Vassallo, A.; Braca, A. De Tommasi, N. Phenolic glycosides from Tabebuia argentea and Catalpa bignonioides. Phytochem. Lett. 2014, 7, 85–88. [Google Scholar] [CrossRef]

- Munoz-Mingarro, D.; Acero, N.; Llinares, F.; Pozuelo, J.M.; de Mera, A.G.; Vicenten, J.A.; Perez, C. Biological activity of extracts from Catalpa bignonioides Walt. (Bignoniaceae). J. Ethnopharmacol. 2003, 87, 163–167. [Google Scholar] [CrossRef] [PubMed]

- Ekmekçi Körlü, A.; Bozacı, E. Properties of Flax and Retting of Flax. Text. Appar. 2006, 16, 276–280. [Google Scholar]

- Balaji, A.N.; Nagarajan, K.J. Characterization of alkali treated and untreated new cellulosic fiber from Saharan aloe vera cactus leaves. Carbohydr. Polym. 2017, 174, 200–208. [Google Scholar]

- Altinisik, A.; Seki, Y.; Ertas, S.; Akar, E.; Bozacı, E.; Seki, Y. Evaluating of Agave americana fibers for biosorption of dye from aqueous solution. Fibers Polym. 2015, 16, 370–377. [Google Scholar] [CrossRef]

- Sumihartati, A.; Wardiningsih, W.; Al Kautsar, N.; Permana, M.; Pradana, S.; Rudy, R. Natural cellulosic fiber from Cordyline Australis leaves for textile application: Extraction and characterization. Res. J. Text. Appar. 2021, 26, 276–290. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. Influence of alkali treatment and fibre length on mechanical properties of short Agave fibre reinforced epoxy composites. Mater. Des. 2011, 32, 4629–4640. [Google Scholar] [CrossRef]

- Bulut, Y.; Aksit, A. A comparative study on chemical treatment of jute fiber: Potassium dichromate, potassium permanganate and sodium perborate trihydrate. Cellulose 2013, 20, 3155–3164. [Google Scholar] [CrossRef]

- Seki, Y.; Seki, Y.; Sarikanat, M.; Sever, K.; Durmuşkahya, C.; Bozacı, E. Evaluation of linden fibre as a potential reinforcement material for polymer composites. J. Ind. Text. 2016, 45, 1221–1238. [Google Scholar] [CrossRef]

- Muensri, P.; Kunanopparat, T.; Menut, P.; Siriwattanayotin, S. Effect of lignin removal on the properties of coconut coir fiber/wheat gluten biocomposite. Compos. Part A 2011, 42, 173–179. [Google Scholar] [CrossRef]

- Shebani, A.N.; Van Reenen, A.J.; Meincken, M. The effect of wood extractives on the thermal stability of different wood-LLDPE composites. Thermochim. Acta 2009, 481, 52–56. [Google Scholar] [CrossRef]

- Tajvidi, M.; Takemura, A. Thermal degradation of natural fiber-reinforced polypropylene composites. Thermoplast. Compos. Mater. 2010, 23, 281–298. [Google Scholar] [CrossRef]

- ArunRamnath, R.; Murugan, S.; Sanjay, M.R.; Vinod, A.; Indran, S.; Elnaggar, A.Y.; Siengchin, S. Characterization of novel natural cellulosic fibers from Abutilon Indicum for potential reinforcement in polymer composites. Polym. Compos. 2022, in press. [Google Scholar] [CrossRef]

- Rao, H.J.; Singh, S.; Janaki Ramulu, P. Characterization of a Careya Arborea Bast Fiber as Potential Reinforcement for Light Weight Polymer Biodegradable Composites. J. Nat. Fibers 2022, 20, 1–17. [Google Scholar] [CrossRef]

- Seki, Y.; Selli, F.; Erdoğan, Ü.H.; Atagür, M.; Seydibeyoğlu, M.Ö. A review on alternative raw materials for sustainable production: Novel plant fibers. Cellulose 2022, 29, 4877–4918. [Google Scholar]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B 2019, 176, 107305. [Google Scholar] [CrossRef]

- Jeyabalaji, V.; Kannan, G.R.; Ganeshan, P.; Raja, K.; NagarajaGanesh, B.; Raju, P. Extraction and characterization studies of cellulose derived from the roots of Acalypha indica L. J. Nat. Fibers 2021, 19, 4544–4556. [Google Scholar] [CrossRef]

- Bozaci, E. Optimization of the alternative treatment methods for Ceiba pentandra (L.) Gaertn (kapok) fiber using response surface methodology. J. Text. Inst. 2019, 110, 1404–1414. [Google Scholar] [CrossRef]

- Selvan, M.T.G.A.; Binoj, J.S.; Moses, J.T.E.J.; Sai, N.P.; Siengchin, S.; Sanjay, M.R.; Liu, Y. Extraction and characterization of natural cellulosic fiber from fragrant screw pine prop roots as potential reinforcement for polymer composites. Polym. Compos. 2022, 43, 320–329. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Köktaş, S.; Keskin, Ö.Y.; Dalmiş, R.; Seki, Y.; Balci Kiliç, G. Extraction and Characterization of Natural Cellulosic Fiber from Taraxacum Sect. Ruderalia. J. Nat. Fibers 2022, 19, 14328–14336. [Google Scholar] [CrossRef]

- Belaadi, A.; Amroune, S.; Seki, Y.; Keskin, O.Y.; Köktaş, S.; Bourchak, M.; Jawaid, M. Extraction and Characterization of a New Lignocellulosic Fiber from Yucca Treculeana L. Leaf as Potential Reinforcement for Industrial Biocomposites. J. Nat. Fibers 2022, 19, 12235–12250. [Google Scholar] [CrossRef]

- Ilangovan, M.; Guna, V.; Prajwal, B.; Jiang, Q.; Reddy, N. Extraction and characterisation of natural cellulose fibers from Kigelia Africana. Carbohydr. Polym. 2020, 236, 115996. [Google Scholar] [CrossRef] [PubMed]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.R.; Marichelvam, M.K.; Jawaid, M. Study on characterization of furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef] [PubMed]

- Korte, S. Processing-Property Relationships of Hemp Fibre. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2006. [Google Scholar]

- Manimaran, P.; Saravanan, S.P.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Khan, A. Characterization of new cellulosic fiber: Dracaena reflexa as a reinforcement for polymer composite structures. J. Mater. Res. Technol. 2019, 8, 1952–1963. [Google Scholar] [CrossRef]

- Albayrak, D.; Seki, Y.; Balcı Kılıç, G.; Koktas, S.; Keskin, Ö.Y.; Dalmış, R.; Karademir, C. Exploration of alternative cellulosic natural fiber from the stem of Malva Slyvestris. J. Nat. Fibers 2022, 19, 12614–12631. [Google Scholar] [CrossRef]

- Divya, D.; Suyambulingam, I.; Sanjay, M.R.; Siengchin, S. Suitability examination of novel cellulosic plant fiber from Furcraea selloa K. Koch peduncle for a potential polymeric composite reinforcement. Polym. Compos. 2022, in press. [Google Scholar] [CrossRef]

- Bright, B.M.; Joseph Selvi, B.; Abu Hassan, S.; Mustapha Jaafar, M.; Siengchin, S.; Mavinkere Rangappa, S.; Padmavathy, S.R. Characterization of chemically treated new natural cellulosic fibers from peduncle of Cocos nucifera L. Var typica. Polym. Compos. 2021, 42, 6403–6416. [Google Scholar] [CrossRef]

- Keskin, O.Y.; Dalmis, R.; Balci Kilic, G.; Seki, Y.; Koktas, S. Extraction and characterization of cellulosic fiber from Centaurea solstitialis for composites. Cellulose 2020, 27, 9963–9974. [Google Scholar] [CrossRef]

- Buchert, J.; Pere, J.; Johansson, L.S.; Campbell, J.M. Analysis of the surface chemistry of linen and cotton fabrics. Text. Res. J. 2001, 71, 626–629. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C. Thermal, morphological, and electrical characterization of microwave processed natural fiber composites. Compos. Sci. Technol. 2007, 67, 1986–1991. [Google Scholar] [CrossRef]

- Tran, L.Q.N.; Yuan, X.W.; Bhattacharya, D. Fibermatrix interfacial adhesion in natural fiber composites. Int. J. Mod. Phys. B 2015, 29, 1540018. [Google Scholar] [CrossRef]

- Kılınç, A.Ç.; Köktaş, S.; Seki, Y.; Atagür, M.; Dalmış, R.; Erdoğan, Ü.H.; Seydibeyoğlu, M.Ö. Extraction and investigation of lightweight and porous natural fiber from Conium maculatum as a potential reinforcement for composite materials in transportation. Compos. Part B 2018, 140, 1–8. [Google Scholar] [CrossRef]

- Dalmis, R.; Kilic, G.B.; Seki, Y.; Koktas, S.; Keskin, O.Y. Characterization of a novel natural cellulosic fiber extracted from the stem of Chrysanthemum morifolium. Cellulose 2020, 27, 8621–8634. [Google Scholar] [CrossRef]

- Reddy, L.H.; Arias, J.L.; Nicolas, J.; Couvreur, P. Magnetic nanoparticles: Design and characterization, toxicity and biocompatibility, pharmaceutical and biomedical applications. Chem. Rev. 2012, 112, 5818–5878. [Google Scholar] [CrossRef]

- Saravanakumar, S.S.; Kumaravel, A.; Nagarajan, T.; Sudhakar, P.; Baskaran, R. Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr. Polym. 2013, 92, 1928–1933. [Google Scholar] [CrossRef] [PubMed]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W.A. review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Indran, S.; Raj, R.E. Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohydr. Polym. 2015, 117, 392–399. [Google Scholar] [CrossRef]

- Seraji, S.M.; Gan, H.; Swan, S.R.; Varley, R.J. Phosphazene as an effective flame retardant for rapid curing epoxy resins. React. Funct. Polym. 2021, 164, 104910. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.A.; Hinrichsen, G.I. Biofibers, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Silva, G.G.; De Souza, D.A.; Machado, J.C.; Hourston, D.J. Mechanical and thermal characterization of native Brazilian coir fiber. J. Appl. Polym. Sci. 2020, 76, 1197–1206. [Google Scholar] [CrossRef]

| Element Survey | C1s (%) | O1s (%) | Ca2p (%) | P2p (%) | N1s (%) | S2p (%) | Mg1s (%) | Si2p (%) | Na1s (%) | C/O | O/C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 49.87 | 31.35 | 8.21 | 3.53 | 2.11 | 1.72 | 1.24 | 1.03 | 0.95 | 1.59 | 0.63 |

| Td °C | Tmax °C | Rmax %/min | CY(Air)-800 °C | CY(N2)-800 °C | |||

|---|---|---|---|---|---|---|---|

| (Air) | (N2) | (Air) | (N2) | (Air) | (N2) | ||

| 67 | 68 | 301 | 314 | 5.760 | 4.120 | 0.93 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bozaci, E.; Altınışık Tağaç, A. Extraction and Characterization of New Cellulosic Fiber from Catalpa bignonioides Fruits for Potential Use in Sustainable Products. Polymers 2023, 15, 201. https://doi.org/10.3390/polym15010201

Bozaci E, Altınışık Tağaç A. Extraction and Characterization of New Cellulosic Fiber from Catalpa bignonioides Fruits for Potential Use in Sustainable Products. Polymers. 2023; 15(1):201. https://doi.org/10.3390/polym15010201

Chicago/Turabian StyleBozaci, Ebru, and Aylin Altınışık Tağaç. 2023. "Extraction and Characterization of New Cellulosic Fiber from Catalpa bignonioides Fruits for Potential Use in Sustainable Products" Polymers 15, no. 1: 201. https://doi.org/10.3390/polym15010201

APA StyleBozaci, E., & Altınışık Tağaç, A. (2023). Extraction and Characterization of New Cellulosic Fiber from Catalpa bignonioides Fruits for Potential Use in Sustainable Products. Polymers, 15(1), 201. https://doi.org/10.3390/polym15010201