The Programmable Design of Large-Area Piezoresistive Textile Sensors Using Manufacturing by Jacquard Processing

Abstract

:1. Introduction

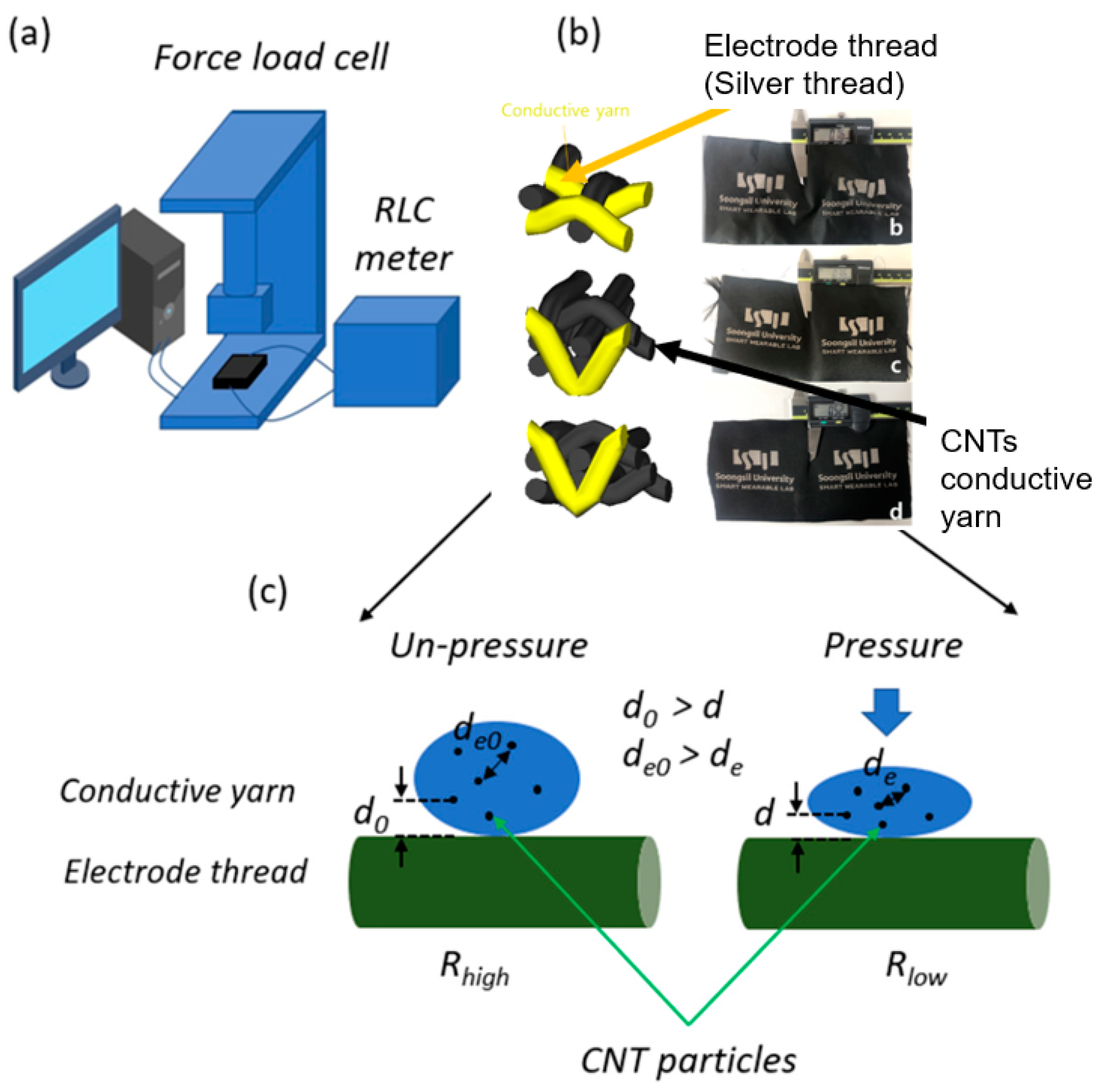

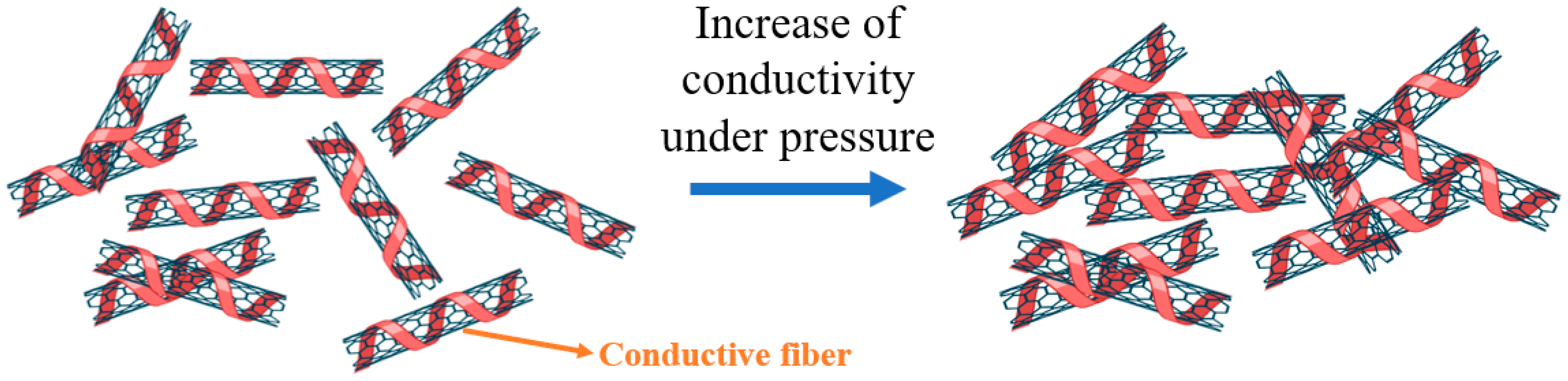

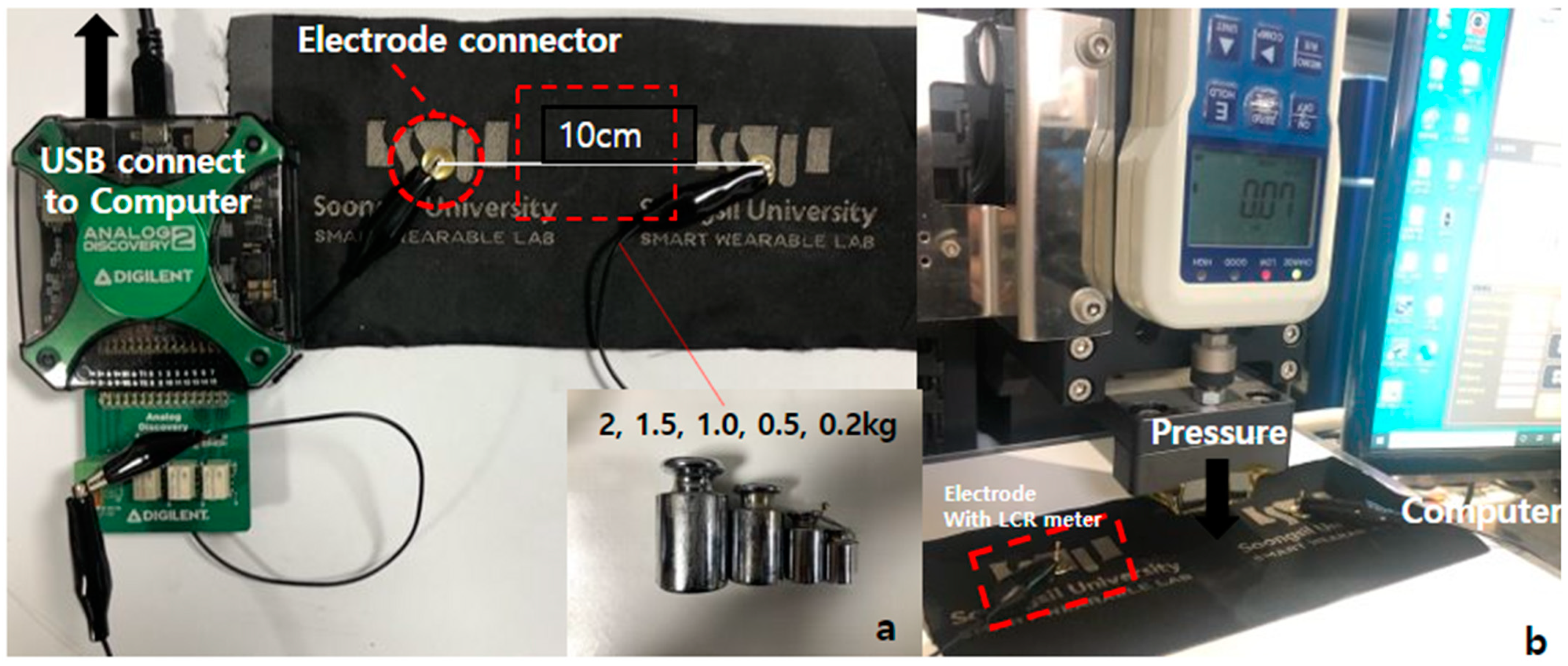

2. Experiments

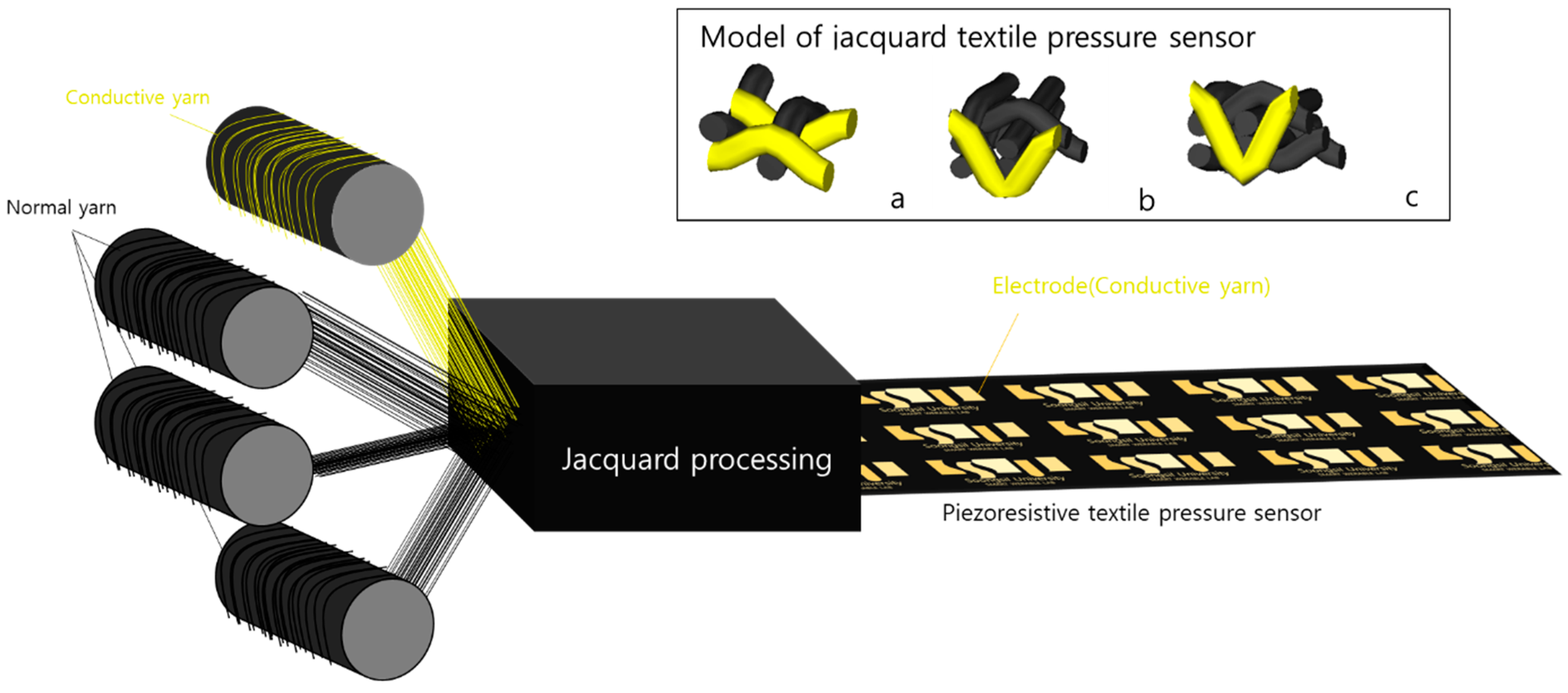

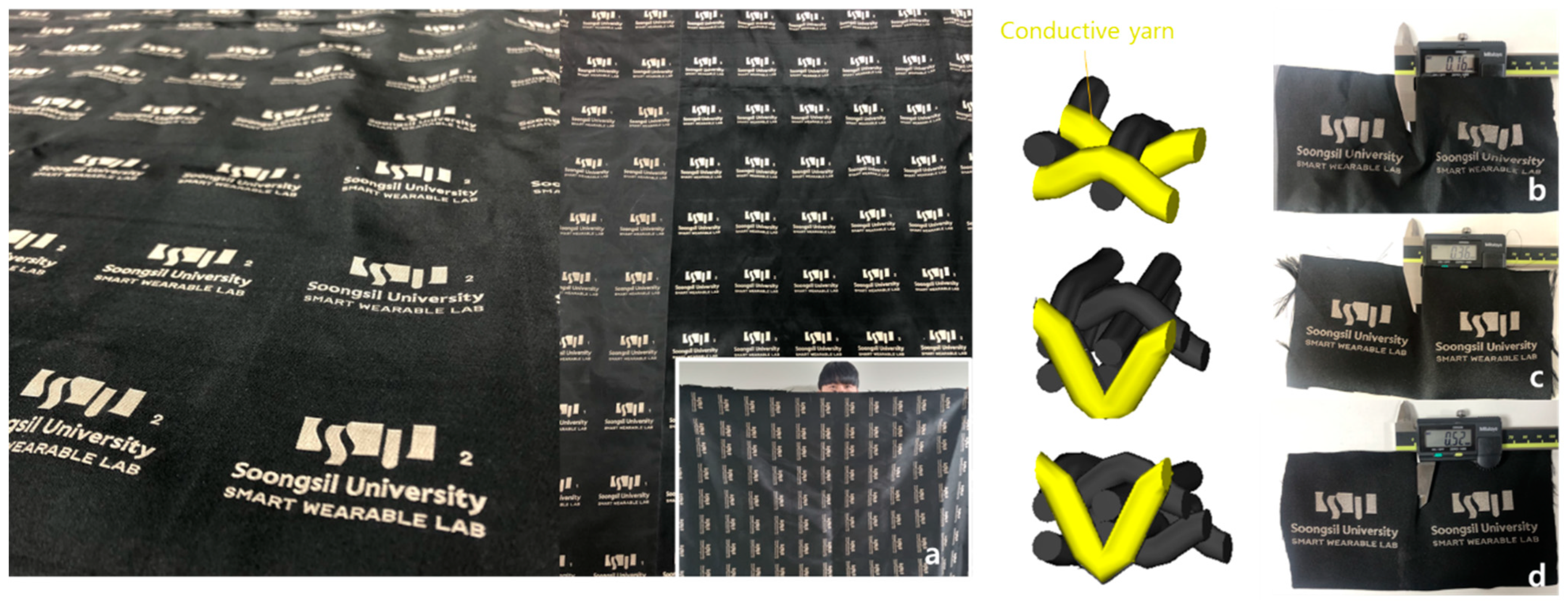

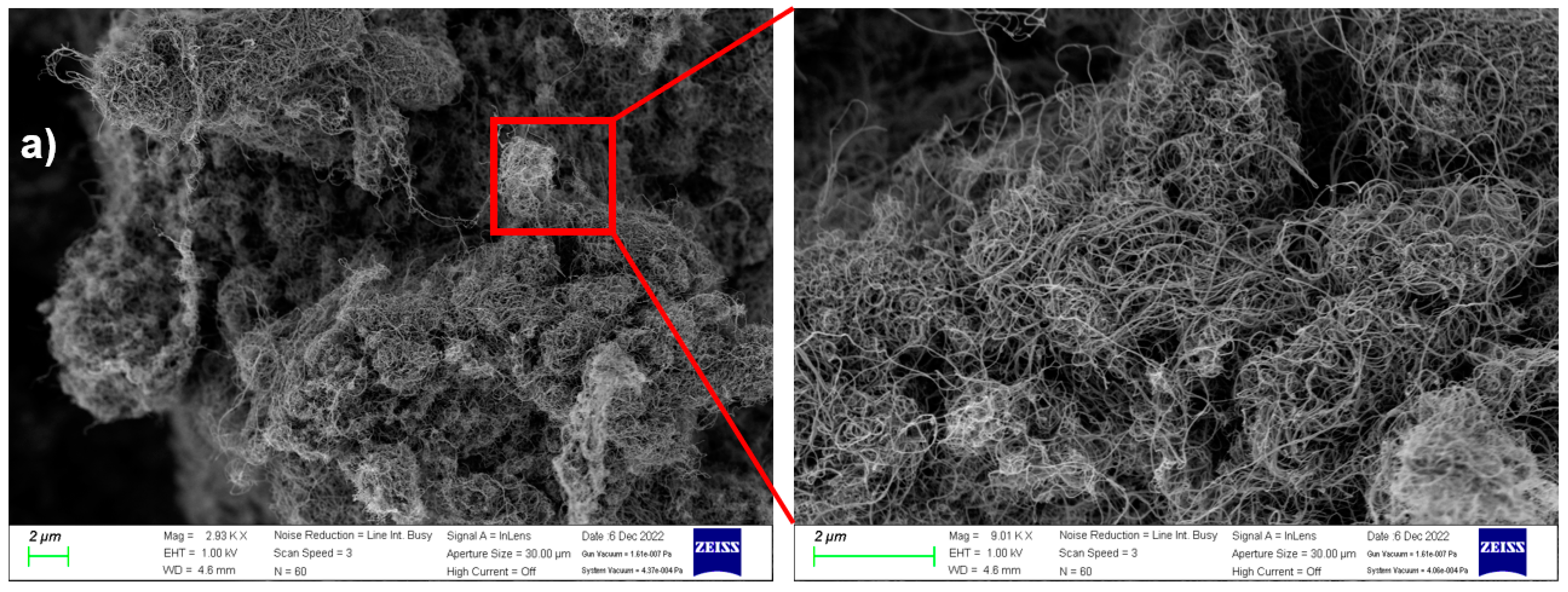

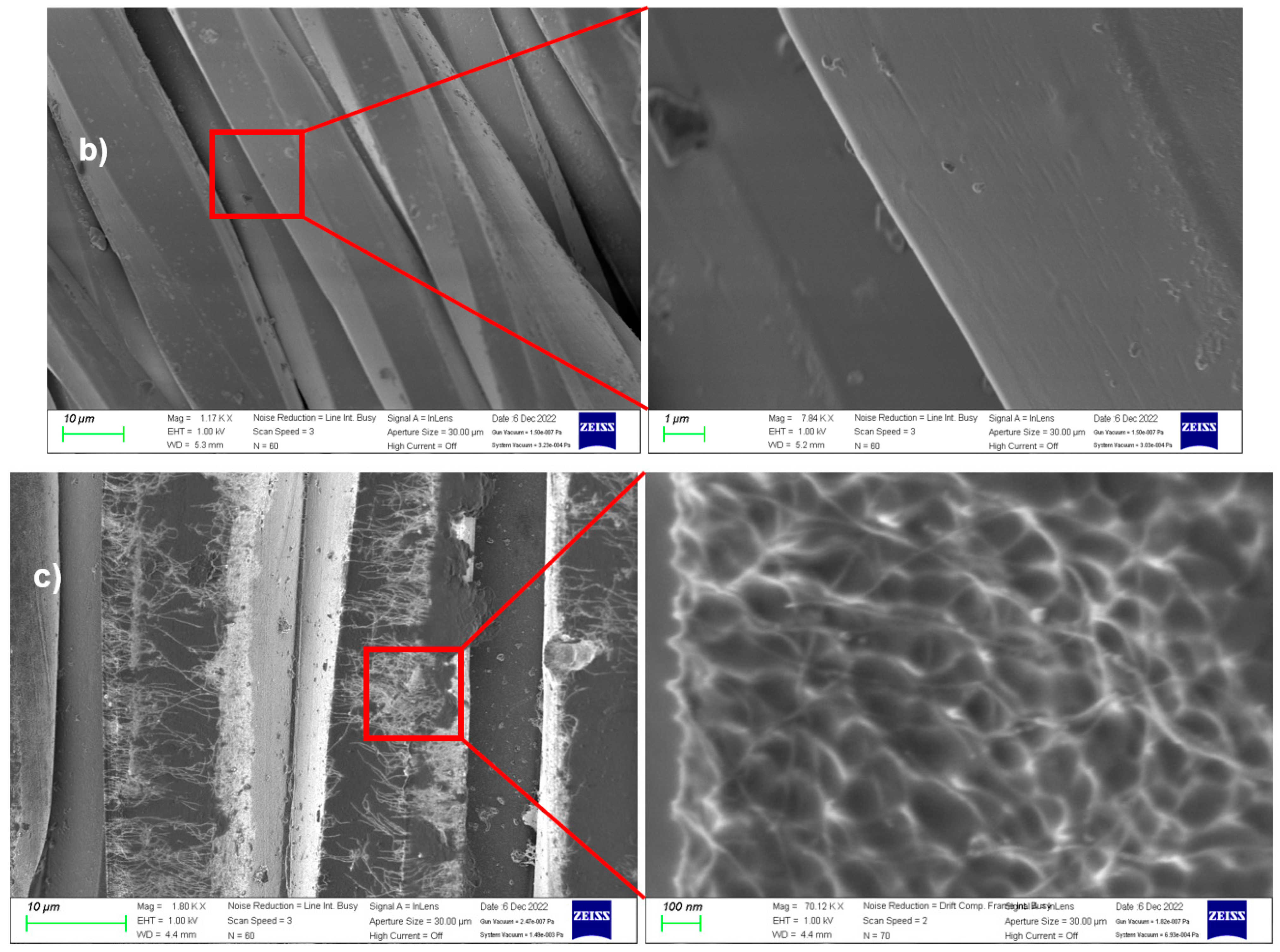

2.1. Manufacturing of Jacquard Piezoresistive Textile Pressure Sensor

2.2. Electrical Properties

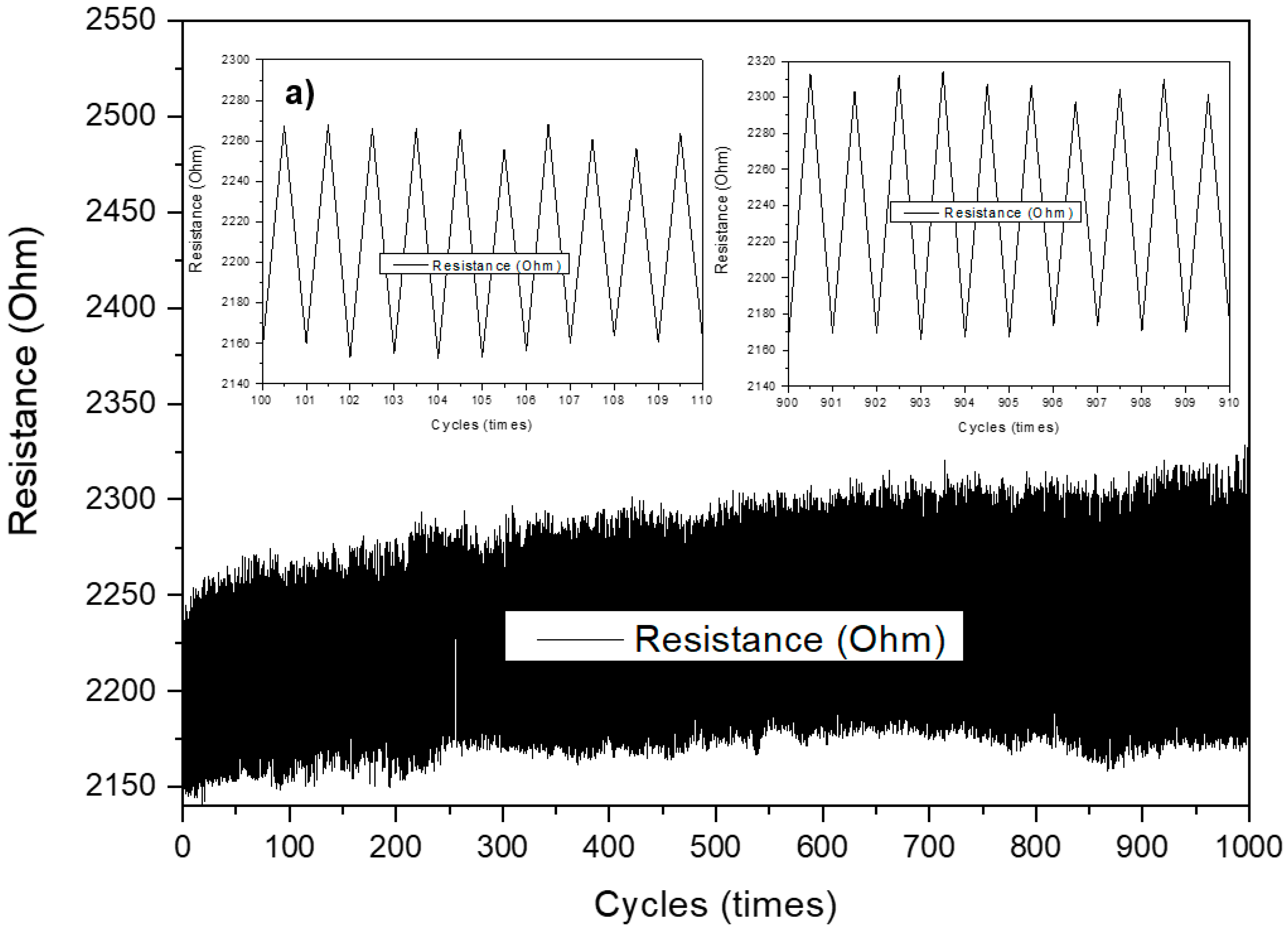

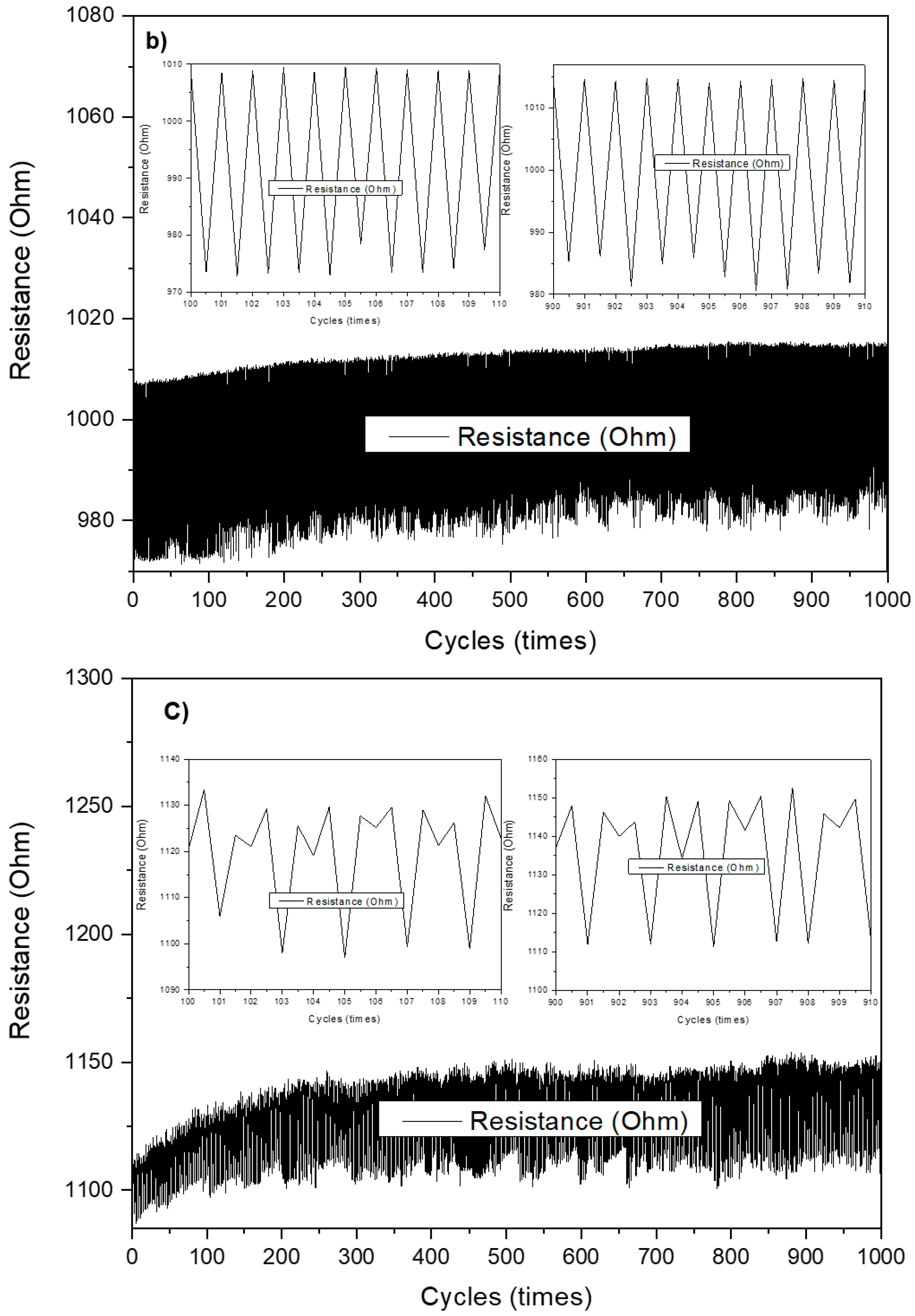

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eskandarian, L.; Lam, E.; Rupnow, C.; Meghrazi, M.; Naguib, H.E. Robust and Multifunctional Conductive Yarns for Biomedical Textile Computing. ACS Appl. Electron. Mater. 2020, 2, 1554–1566. [Google Scholar] [CrossRef]

- Tat, T.; Chen, G.; Zhao, X.; Zhou, Y.; Xu, J.; Chen, J. Smart Textiles for Healthcare and Sustainability. ACS Nano 2022, 16, 13301–13313. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Jia, Y.; Wang, X.; Zhou, K.; Zhai, W.; Zheng, G.; Dai, K.; Mi, L.; Liu, C.; Shen, C. Highly stretchable and durable fiber-shaped strain sensor with porous core-sheath structure for human motion monitoring. Compos. Sci. Technol. 2020, 189, 108038. [Google Scholar] [CrossRef]

- Di Giminiani, R.; Cardinale, M.; Ferrari, M.; Quaresima, V. Validation of Fabric-Based Thigh-Wearable EMG Sensors and Oximetry for Monitoring Quadriceps Activity during Strength and Endurance Exercises. Sensors 2020, 20, 4664. [Google Scholar] [CrossRef] [PubMed]

- Vojtech, L.; Bortel, R.; Neruda, M.; Kozak, M. Wearable Textile Electrodes for ECG Measurement. Adv. Electr. Electron. Eng. 2013, 11, 410–414. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Lee, T. Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-Area All-Textile Pressure Sensors for Monitoring Human Motion and Physiological Signals. Adv. Mater. 2017, 29, 1703700. [Google Scholar] [CrossRef]

- Wang, H.; Zuo, S.; Cerezo-Sánchez, M.; Arekhloo, N.; Nazarpour, K.; Heidari, H. Wearable super-resolution muscle-machine interfacing. Front. Neurosci. 2022, 16. Available online: https://www.frontiersin.org/articles/10.3389/fnins.2022.1020546 (accessed on 2 December 2022). [CrossRef]

- Xu, G.; Wan, Q.; Deng, W.; Guo, T.; Cheng, J. Smart-Sleeve: A Wearable Textile Pressure Sensor Array for Human Activity Recognition. Sensors 2022, 22, 1702. [Google Scholar] [CrossRef]

- Rapp, A.; Tirabeni, L. Personal Informatics for Sport: Meaning, Body, and Social Relations in Amateur and Elite Athletes. ACM Trans. Comput.-Hum. Interact. 2018, 25, 1–30. [Google Scholar] [CrossRef]

- Uno, M.O.; Morita, S.; Omori, M.; Yoshimura, K. Pressure sensor yarns with a sheath-core structure using multi-fiber polymer. Sens. Actuators A Phys. 2022, 337, 113440. [Google Scholar] [CrossRef]

- Zhou, B.; Cheng, J.; Lukowicz, P.; Reiss, A.; Amft, O. Monitoring Dietary Behavior with a Smart Dining Tray. IEEE Pervasive Comput. 2015, 14, 46–56. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.; Yoo, H.-J. Electrical Characterization of Screen-Printed Circuits on the Fabric. IEEE Trans. Adv. Packag. 2010, 33, 196–205. [Google Scholar] [CrossRef]

- Tajitsu, Y. Development of e-textile sewn together with embroidered fabric having motion-sensing function using piezoelectric braided cord for embroidery. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1644–1649. [Google Scholar] [CrossRef]

- Song, H.Y.; Lee, J.H.; Kang, D.; Cho, H.; Cho, H.S.; Lee, J.W.; Lee, Y.J. Textile electrodes of jacquard woven fabrics for biosignal measurement. J. Text. Inst. 2010, 101, 758–770. [Google Scholar] [CrossRef]

- Towards Accepted Smart Interactive Textiles. SpringerLink. Available online: https://link.springer.com/chapter/10.1007/978-3-319-58481-2_22 (accessed on 2 December 2022).

- Truong, T.; Kim, J.-S.; Kim, J. Development of Embroidery-Type Pressure Sensor Dependent on Interdigitated Capacitive Method. Polymers 2022, 14, 3446. [Google Scholar] [CrossRef]

- Truong, T.; Kim, J.-S.; Kim, J. Design and Optimization of Embroidered Antennas on Textile Using Silver Conductive Thread for Wearable Applications. Fibers Polym. 2021, 22, 2900–2909. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Roman, G.C.; Hong, Z.; Wu, C.B.; Qu, Q.M.; Huang, J.B.; Zhou, B.; Geng, Z.-P.; Wu, J.-X.; Wen, H.-B.; et al. Parkinson’s disease in China: Prevalence in Beijing, Xian, and Shanghai. Lancet 2005, 365, 595–597. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Kim, J. 4D-Printing—Fused Deposition Modeling Printing and PolyJet Printing with Shape Memory Polymers Composite. Fibers Polym. 2020, 21, 2364–2372. [Google Scholar] [CrossRef]

- Zhong, W.; Ming, X.; Jiang, H.; Ke, Y.; Ding, X.; Li, M.; Jia, K.; Wang, D. Full-Textile Human Motion Detection Systems Integrated by Facile Weaving with Hierarchical Core-Shell Piezoresistive Yarns. ACS Appl. Mater. Interfaces 2021, 13, 52901–52911. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; Wang, H.; You, X.; Tao, X.; Li, M.; Zhou, Y.; Zhang, Y.; He, J.; Shao, W.; Cui, S. Core-sheath nanofiber yarn for textile pressure sensor with high pressure sensitivity and spatial tactile acuity. J. Colloid Interfaces Sci. 2020, 561, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Baldoli, I.; Maselli, M.; Cecchi, F.; Laschi, C. Development and characterization of a multilayer matrix textile sensor for interface pressure measurements. Smart Mater. Struct. 2017, 26, 104011. [Google Scholar] [CrossRef]

- Development of Textile-Based Pressure Sensor and Its Application. SpringerLink. Available online: https://link.springer.com/article/10.1007/s12221-018-8813-8 (accessed on 2 December 2022).

- Büscher, G.H.; Kõiva, R.; Schürmann, C.; Haschke, R.; Ritter, H.J. Flexible and stretchable fabric-based tactile sensor. Robot. Auton. Syst. 2015, 63, 244–252. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.J.; Bae, J.H.; Han, J.H.; Jang, S.J.; Oh, H.J.; Lee, W.; Kim, S.H.; Ko, J.H. Foldable and washable fully textile-based pressure sensor. Smart Mater. Struct. 2020, 29, 055010. [Google Scholar] [CrossRef]

- Jang, S.J.; Kim, M.; Lim, J.; Park, Y.; Ko, J.H. Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric. Polymers 2022, 14, 1545. [Google Scholar] [CrossRef]

| Structures | Equations | (%) | Error Rates (%) |

|---|---|---|---|

| Single-layer | 1.633x + 3.2937 | 0.9988 | 23.98 |

| Double-layer | 0.0309x + 0.4085 | 0.9921 | 3.85 |

| Quadruple-layer | 0.055x + 3.121 | 0.9735 | 4.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Truong, T.; Jang, J.; Kim, J. The Programmable Design of Large-Area Piezoresistive Textile Sensors Using Manufacturing by Jacquard Processing. Polymers 2023, 15, 78. https://doi.org/10.3390/polym15010078

Kim S, Truong T, Jang J, Kim J. The Programmable Design of Large-Area Piezoresistive Textile Sensors Using Manufacturing by Jacquard Processing. Polymers. 2023; 15(1):78. https://doi.org/10.3390/polym15010078

Chicago/Turabian StyleKim, SangUn, TranThuyNga Truong, JunHyuk Jang, and Jooyong Kim. 2023. "The Programmable Design of Large-Area Piezoresistive Textile Sensors Using Manufacturing by Jacquard Processing" Polymers 15, no. 1: 78. https://doi.org/10.3390/polym15010078

APA StyleKim, S., Truong, T., Jang, J., & Kim, J. (2023). The Programmable Design of Large-Area Piezoresistive Textile Sensors Using Manufacturing by Jacquard Processing. Polymers, 15(1), 78. https://doi.org/10.3390/polym15010078