Sustainable Development Approaches through Wooden Adhesive Joints Design

Abstract

:1. Introduction

2. Bio-Adhesives

2.1. Bio-Adhesive Families

2.1.1. Tannin-Based Adhesives

2.1.2. Lignin-Based Adhesives

2.1.3. Carbohydrate-Based Adhesives

2.1.4. Other Bio-Based Adhesives

2.2. Durability of Bio-Adhesives

3. Wood Substrates

3.1. Wood and Wood Products

3.2. Mechanical Characterisation of Wood

3.3. Wood Toughening Procedures

3.4. Wood Delignification and Densification Methods

4. Wood/Bio-Adhesive Joints

4.1. Applications of Wood/Bio-Adhesive Joints

4.2. Mechanical and Fracture Toughness Characterisation of Wood/Adhesive Joints

4.2.1. Strength Tests

4.2.2. Fracture Tests

4.3. Effects of Moisture

4.4. Effects of Fatigue Loading

5. Conclusions

- Bio-adhesives are steadily developing to gain properties similar to those of synthetic materials. Tannin, lignin, carbohydrates, proteins, and other biomaterials have been proposed as a base for these adhesives. Most of these materials must undergo adaptations before they are used industrially. However, in terms of mechanical properties, they are very promising. At this stage, the main concerns are related to the resistance of these materials to harsh environments, such as high temperatures and humidities.

- Wood has the important advantage that it can be machined into different forms. However, in its neat form, it presents limited strength and stiffness for safety-critical structural applications. Additionally, natural defects in this material may lead to structural failure. There are methods under development related to the delignification and densification of wood, which can reduce the impact of defects and make the properties of wood close to those of conventional composites used in the automotive or aerospace industry.

- Substrate toughening, paired with densification, may be an interesting alternative to improve the mechanical behaviour of wood/bio-adhesive joints by reducing the stress level in the substrate at the ends of the overlap. Only a few toughening methods using biomaterials are now available for these joints, but this may be a promising path for future research.

- Wood/bio-adhesive joints have been proven to be applicable to a wide range of structures, and the influence of moisture and fatigue on their properties has been investigated. It was seen that this is still a setback of natural joints since both wood and bio-adhesives are sensitive to humidity, temperature, and fatigue loading conditions. Thus, characterisation and development work should be carried out on this topic.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology; Springer Cham: Midtown Manhattan, NY, USA, 2018; Volume 1. [Google Scholar]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Mater. Today: Proc. 2022, 56, 2245–2251. [Google Scholar] [CrossRef]

- Yang, C.Z.; Yaniger, S.I.; Jordan, V.C.; Klein, D.J.; Bittner, G.D. Most Plastic Products Release Estrogenic Chemicals: A Potential Health Problem That Can Be Solved. Environ. Health Perspect. 2011, 119, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Gajula, S.; Antonyraj, C.A.; Odaneth, A.A.; Srinivasan, K. A consolidated road map for economically gainful efficient utilization of agro-wastes for eco-friendly products. Biofuels Bioprod. Biorefining 2019, 13, 899–911. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Bioresour. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Oliveira, P.R.; May, M.; Panzera, T.H.; Scarpa, F.; Hiermaier, S. Reinforced biobased adhesive for eco-friendly sandwich panels. Int. J. Adhes. Adhes. 2020, 98, 102550. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.; de Barros, S.; da Silva, L. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Tzatzadakis, V.; Tserpes, K. Production of a novel bio-based structural adhesive and characterization of mechanical properties. J. Adhes. 2021, 97, 936–951. [Google Scholar] [CrossRef]

- Bachmann, J.; Yi, X.; Gong, H.; Martinez, X.; Bugeda, G.; Oller, S.; Tserpes, K.; Ramon, E.; Paris, C.; Moreira, P.; et al. Outlook on ecologically improved composites for aviation interior and secondary structures. CEAS Aeronaut. J. 2018, 9, 533–543. [Google Scholar] [CrossRef] [Green Version]

- Vickers, N.J. Animal Communication: When I’m Calling You, Will You Answer Too? Curr. Biol. 2017, 27, R713–R715. [Google Scholar] [CrossRef]

- Hogger, E.M.; van Herwijnen, H.W.G.; Moser, J.; Kantner, W.; Konnerth, J. Systematic assessment of wheat extenders in condensation resins for plywood production: Part I—Physico-chemical adhesive properties. J. Adhes. 2021, 97, 1404–1422. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Biopolymers in wood-based materials—A recent review. Ann. WULS For. Wood Technol. 2020, 110, 25–34. [Google Scholar] [CrossRef]

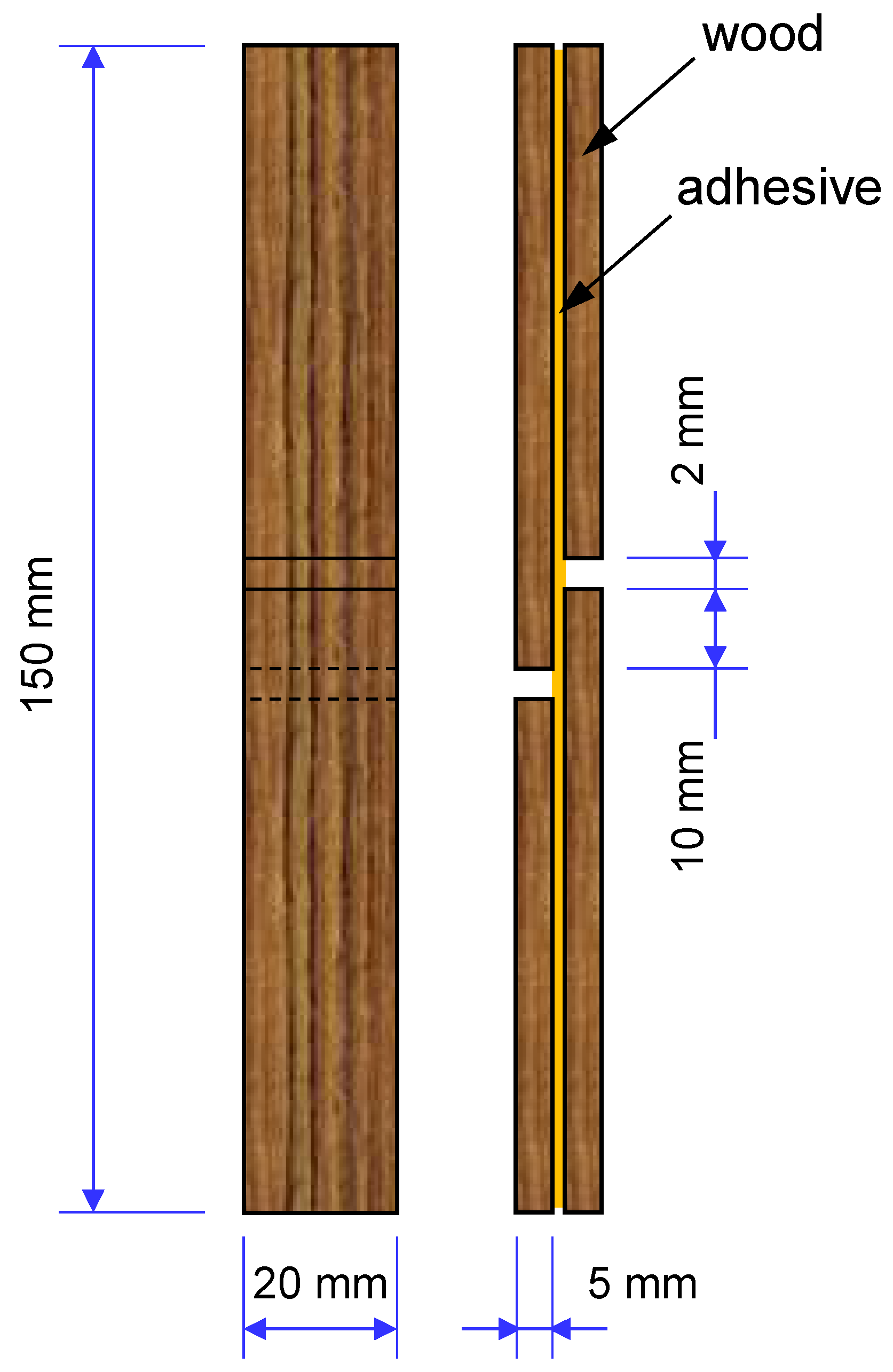

- Corte-Real, L.M.R.M.; Jalali, S.; Borges, C.S.P.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Development and Characterisation of Joints with Novel Densified and Wood/Cork Composite Substrates. Materials 2022, 15, 7163. [Google Scholar] [CrossRef] [PubMed]

- Pizzi, A. Advanced Wood Adhesives Technology; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Pizzi, A.; Mittal, K.L. Wood Adhesives; VSP: Zeist, The Netherlands, 2010. [Google Scholar]

- Bacelo, H.A.M.; Santos, S.C.R.; Botelho, C.M.S. Tannin-based biosorbents for environmental applications—A review. Chem. Eng. J. 2016, 303, 575–587. [Google Scholar] [CrossRef]

- Pizzi, A.; Meikleham, N.; Dombo, B.; Roll, W. Autocondensation-based, zero-emission, tannin adhesives for particleboard. Holz als Roh-und Werkst. 1995, 53, 201–204. [Google Scholar] [CrossRef]

- Pizzi, A.; Roll, W.; Dombo, B. Hitzehärtende bindemittel. U.S. Patent 5,532,330, 1996. [Google Scholar]

- Ghaffar, S.H.; Fan, M. Lignin in straw and its applications as an adhesive. Int. J. Adhes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- Chen, X.; Xi, X.; Pizzi, A.; Fredon, E.; Du, G.; Gerardin, C.; Amirou, S. Oxidized demethylated lignin as a bio-based adhesive for wood bonding. J. Adhes. 2021, 97, 873–890. [Google Scholar] [CrossRef]

- García, J.L.; Pans, G.; Phanopoulos, C. Use of lignin in polyurethane-based structural wood adhesives. J. Adhes. 2018, 94, 814–828. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.-D. Enhancing the performance of low molar ratio urea–formaldehyde resin adhesives via in-situ modification with intercalated nanoclay. J. Adhes. 2021, 97, 1271–1290. [Google Scholar] [CrossRef]

- Tejado, A.; Peña, C.; Labidi, J.; Echeverria, J.M.; Mondragon, I. Physico-chemical characterization of lignins from different sources for use in phenol–formaldehyde resin synthesis. Bioresour. Technol. 2007, 98, 1655–1663. [Google Scholar] [CrossRef] [PubMed]

- Khosravi, S.; Khabbaz, F.; Nordqvist, P.; Johansson, M. Protein-based adhesives for particleboards. Ind. Crop. Prod. 2010, 32, 275–283. [Google Scholar] [CrossRef] [Green Version]

- Islam, N.; Rahman, F.; Das, A.K.; Hiziroglu, S. An overview of different types and potential of bio-based adhesives used for wood products. Int. J. Adhes. Adhes. 2022, 112, 102992. [Google Scholar] [CrossRef]

- Hamarneh, A.; Heeres, H.; Broekhuis, A.; Picchioni, F. Extraction of Jatropha curcas proteins and application in polyketone-based wood adhesives. Int. J. Adhes. Adhes. 2010, 30, 615–625. [Google Scholar] [CrossRef]

- Santoni, I.; Pizzo, B. Evaluation of alternative vegetable proteins as wood adhesives. Ind. Crop. Prod. 2013, 45, 148–154. [Google Scholar] [CrossRef]

- De Graaf, L.A.; Harmsen, P.F.H.; Vereijken, J.M.; Mönikes, M. Requirements for non-food applications of pea proteins A Review. Food / Nahr. 2001, 45, 408–411. [Google Scholar] [CrossRef]

- Dongre, P.; Driscoll, M.; Amidon, T.; Bujanovic, B. Lignin-Furfural Based Adhesives. Energies 2015, 8, 7897–7914. [Google Scholar] [CrossRef] [Green Version]

- Geng, X.; Li, K. Investigation of wood adhesives from kraft lignin and polyethylenimine. J. Adhes. Sci. Technol. 2006, 20, 847–858. [Google Scholar] [CrossRef]

- Frihart, C.R. Potential for Biobased adhesives in wood bonding. In Proceedings of the 59th International Convention of Society of Wood Science and Technology, Curitiba, Brazil, 6–10 March 2016; pp. 84–91. [Google Scholar]

- Kawalerczyk, J.; Walkiewicz, J.; Woźniak, M.; Dziurka, D.; Mirski, R. The effect of urea-formaldehyde adhesive modification with propylamine on the properties of manufactured plywood. J. Adhes. 2022, 1–14. [Google Scholar] [CrossRef]

- Li, N.; Qi, G.; Sun, X.S.; Stamm, M.J.; Wang, D. Physicochemical Properties and Adhesion Performance of Canola Protein Modified with Sodium Bisulfite. J. Am. Oil Chem. Soc. 2012, 89, 897–908. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Chemical Modification of Soy Protein for Wood Adhesives. Macromol. Rapid Commun. 2002, 23, 739–742. [Google Scholar] [CrossRef]

- Zhong, Z.; Sun, X.S.; Wang, D.; Ratto, J.A. Wet Strength and Water Resistance of Modified Soy Protein Adhesives and Effects of Drying Treatment. J. Polym. Environ. 2003, 11, 137–144. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, T.; Zeng, G.; Cai, Y.; Luo, J.; Li, K.; Tian, D.; Li, J.; Fang, Z. A tough, anti-mildew and anti-counterfeiting soybean protein adhesive enhanced by gecko-inspired functional fiber and bio-based epoxide. J. Clean. Prod. 2021, 323, 129194. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Zhang, F.; Lyu, Y.; Li, X.; Li, K.; Li, J. Spider silk-inspired high-performance soybean meal-based adhesive reinforced by greenly produced chitosan-functionalized boron nitride nanosheets. Chem. Eng. J. 2022, 438, 135442. [Google Scholar] [CrossRef]

- Zhou, Y.; Zeng, G.; Zhang, F.; Luo, J.; Li, K.; Li, X.; Li, J.; Fang, Z. High strength and flame retardant soybean polysaccharide-based wood adhesive produced by borate chemistry and crosslinking strategy. Eur. Polym. J. 2022, 164, 110973. [Google Scholar] [CrossRef]

- Ma, Y.; He, L.; Jia, M.; Zhao, L.; Zuo, Y.; Hu, P. Cage and linear structured polysiloxane/epoxy hybrids for coatings: Surface property and film permeability. J. Colloid Interface Sci. 2017, 500, 349–357. [Google Scholar] [CrossRef]

- Huang, X.; Chen, Y.; Li, J.; Li, J.; Gao, Q.; Mao, A. Development of a strong soy protein-based adhesive with excellent antibacterial and antimildew properties via biomineralized silver nanoparticles. Ind. Crop. Prod. 2022, 188, 115567. [Google Scholar] [CrossRef]

- Sulaiman, N.S.; Hashim, R.; Sulaiman, O.; Nasir, M.; Amini, M.H.M.; Hiziroglu, S. Partial replacement of urea-formaldehyde with modified oil palm starch based adhesive to fabricate particleboard. Int. J. Adhes. Adhes. 2018, 84, 1–8. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, M.; Zhang, J.; Li, J.; Shi, S.Q.; Gao, Q. A High-Performance Bio-Adhesive Using Hyperbranched Aminated Soybean Polysaccharide and Bio-Based Epoxide. Adv. Mater. Interfaces 2020, 7, 2000148. [Google Scholar] [CrossRef] [Green Version]

- Phillips, G.O.; Williams, P.A. Handbook of Hydrocolloids; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Tian, H.; Zhang, L.; Wu, Q.; Wang, X.; Chen, Y. Creation of hydrophobic materials fabricated from soy protein and natural rubber: Surface, interface, and properties. Macromol. Mater. Eng. 2010, 295, 451–459. [Google Scholar] [CrossRef]

- Ding, Z.; Ding, Z.; Zhang, D.; Chao, C. The hydrolytic stability and structure of the cured melamine-urea-formaldehyde resin. J. Adhes. 2022, 98, 1614–1634. [Google Scholar] [CrossRef]

- Tian, H.; Guo, G.; Fu, X.; Yao, Y.; Yuan, L.; Xiang, A. Fabrication, properties and applications of soy-protein-based materials: A review. Int. J. Biol. Macromol. 2018, 120, 475–490. [Google Scholar] [CrossRef] [PubMed]

- Dash, S.; Swain, S.K. Effect of nanoboron nitride on the physical and chemical properties of soy protein. Compos. Sci. Technol. 2013, 84, 39–43. [Google Scholar] [CrossRef]

- Altuna, F.I.; Espósito, L.H.; Ruseckaite, R.A.; Stefani, P.M. Thermal and mechanical properties of anhydride-cured epoxy resins with different contents of biobased epoxidized soybean oil. J. Appl. Polym. Sci. 2011, 120, 789–798. [Google Scholar] [CrossRef]

- Liu, H.; Xu, J.; Xu, X.; Yuan, Z.; Song, H.; Yang, L.; Zhu, D. Structure/function relationships of bean polysaccharides: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 330–344. [Google Scholar] [CrossRef]

- Averina, E.; Konnerth, J.; van Herwijnen, H.W. Protein-based glyoxal–polyethyleneimine-crosslinked adhesives for wood bonding. J. Adhes. 2022, 1–16. [Google Scholar] [CrossRef]

- Kowaluk, G.; Wronka, A. Bonding of sawmill birch wood with selected biopolymer-based glues. Ann. WULS For. Wood Technol. 2020, 109, 32–36. [Google Scholar] [CrossRef]

- Vallée, T.; Tannert, T.; Murcia-Delso, J.; Quinn, D.J. Influence of stress-reduction methods on the strength of adhesively bonded joints composed of orthotropic brittle adherends. Int. J. Adhes. Adhes. 2010, 30, 583–594. [Google Scholar] [CrossRef]

- Baumberger, S.; Lapierre, C.; Monties, B.; Della Valle, G. Use of kraft lignin as filler for starch films. Polym. Degrad. Stab. 1998, 59, 273–277. [Google Scholar] [CrossRef] [Green Version]

- Moreira, F.; Borges, C.; Marques, E.; Da Silva, L. Effect of Surface Contamination on the Peel Properties of Adhesive Joints. J. Mech. Solids 2022, 1, 3–8. [Google Scholar] [CrossRef]

- Yıldızhan, Ş.; Çalık, A.; Ozcanli, M.; Serin, H. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Souza, A.M.; Nascimento, M.F.; Almeida, D.H.; Silva, D.A.L.; Almeida, T.H.; Christoforo, A.L.; Lahr, F.A.R. Wood-based composite made of wood waste and epoxy based ink-waste as adhesive: A cleaner production alternative. J. Clean. Prod. 2018, 193, 549–562. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Dourado, N. Wood Fracture Characterisation; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Yang, H.; Gao, M.; Wang, J.; Mu, H.; Qi, D. Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation. Forests 2021, 12, 567. [Google Scholar] [CrossRef]

- Grunwald, C.; Fecht, S.; Vallée, T.; Tannert, T. Adhesively bonded timber joints–Do defects matter? Int. J. Adhes. Adhes. 2014, 55, 12–17. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, 5. [Google Scholar] [CrossRef] [Green Version]

- Clerc, G.; Brunner, A.J.; Josset, S.; Niemz, P.; Pichelin, F.; Van de Kuilen, J.W.G. Adhesive wood joints under quasi-static and cyclic fatigue fracture Mode II loads. Int. J. Fatigue 2019, 123, 40–52. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Li, Y.; Li, J.; Li, J.; Gao, Q. Preparation of a strong, mildew-resistant, and flame-retardant biomimetic multifunctional soy protein adhesive via the construction of an organic-inorganic hybrid multiple-bonding structure. Chem. Eng. J. 2022, 437, 135437. [Google Scholar] [CrossRef]

- Sadatnezhad, S.H.; Khazaeian, A.; Sandberg, D.; Tabarsa, T. Continuous Surface Densification of Wood: A New Concept for Large-scale Industrial Processing. BioResources 2017, 12, 3122–3132. [Google Scholar] [CrossRef] [Green Version]

- Abrahão, C.P.; Varella, C.A.A.; de Assis de Carvalho Pinto, F.; Junior, J.K.K. Measuring wood failure percentage using a machine vision system. Rev. Árvore 2003, 27, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Timber Struct. Struct. Timber Glued Laminated Timber. Determ. Some Phys. Mech. Prop. BSI, London. BS EN 408:2010+A1:2012. Available online: https://knowledge.bsigroup.com/products/timber-structures-structural-timber-and-glued-laminated-timber-determination-of-some-physical-and-mechanical-properties/standard. (accessed on 4 December 2022).

- Bliem, P.; Konnerth, J.; Frömel-Frybort, S.; Gartner, C.; Mauritz, R.; Van Herwijnen, H.W.G. Influence of drying and curing parameters on phenol-formaldehyde impregnated wood veneers. J. Adhes. 2020, 96, 253–271. [Google Scholar] [CrossRef]

- Hader-Kregl, L.; Wallner, G.M.; Kralovec, C.; Eyßell, C. Effect of inter-plies on the short beam shear delamination of steel/composite hybrid laminates. J. Adhes. 2019, 95, 1088–1100. [Google Scholar] [CrossRef]

- Vogelesang, L.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Schijve, J.; Vogelesang, L.B.; Marissen, R. Laminate of Aluminum Sheet Material and Aramid Fibres. Google Patents EP0056289A1, 19 February 1985. [Google Scholar]

- Uzay, C.; Bayramoglu, M.; Boztepe, M.H.; Necdet, G. Adhesion Surface Bonding Capability of Different Metal Sheets for Fibre Metal Laminate (FML) Applications. In Proceedings of the 1st International Mediterranean Science and Engineering Congress (IMSEC 2016), Adana, Turkey, 26–28 October 2016; pp. 26–28. [Google Scholar]

- Bano, S.; Fida, S.; Israr, A. Design Modification of Lap Joint of Fibre Metal Laminates (CARALL). Int. J. Mater. Metall. Eng. 2018, 11, 716–721. [Google Scholar]

- Palmares, M.P. Strength of Hybrid Laminates Aluminium Carbon-Fibre Joints with Different Lay-up Configurations; FEUP: Porto, Portugal, 2016. [Google Scholar]

- dos Santos, D.G. Optimization of CFRP Joints with Fibre Metal Laminates; FEUP: Porto, Portugal, 2018. [Google Scholar]

- Shang, X.; Marques, E.; Machado, J.; Carbas, R.; Jiang, D.; da Silva, L. A strategy to reduce delamination of adhesive joints with composite substrates. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 521–530. [Google Scholar] [CrossRef]

- Keplinger, T.; Wittel, F.K.; Rüggeberg, M.; Burgert, I. Wood derived cellulose scaffolds—Processing and mechanics. Adv. Mater. 2021, 33, 2001375. [Google Scholar] [CrossRef]

- Modenbach, A.A.; Nokes, S.E. Effects of sodium hydroxide pretreatment on structural components of biomass. Trans. ASABE 2014, 57, 1187–1198. [Google Scholar]

- Morsing, N. Densification of Wood. The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to Gain. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2000. [Google Scholar]

- Laine, K.; Belt, T.; Rautkari, L.; Ramsay, J.; Hill, C.A.S.; Hughes, M. Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J. Mater. Sci. 2013, 48, 8530–8538. [Google Scholar] [CrossRef]

- Schwarzkopf, M. Densified wood impregnated with phenol resin for reduced set-recovery. Wood Mater. Sci. Eng. 2021, 16, 35–41. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In Situ Wood Delignification toward Sustainable Applications. Accounts Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Follrich, J.; Höra, M.; Müller, U.; Teischinger, A.; Gindl, W. Adhesive bond strength of end grain joints in balsa wood with different density. Wood Res. 2010, 55, 21–32. [Google Scholar]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Novel, D.; Ghio, S.; Gaiardo, A.; Picciotto, A.; Guidi, V.; Speranza, G.; Boscardin, M.; Bellutti, P.; Pugno, N.M. Strengthening of Wood-like Materials via Densification and Nanoparticle Intercalation. Nanomaterials 2020, 10, 478. [Google Scholar] [CrossRef]

- Pečnik, J.G.; Gavrić, I.; Sebera, V.; Kržan, M.; Kwiecień, A.; Zając, B.; Azinović, B. Mechanical performance of timber connections made of thick flexible polyurethane adhesives. Eng. Struct. 2021, 247, 113125. [Google Scholar] [CrossRef]

- Vallée, T.; Tannert, T.; Fecht, S. Adhesively bonded connections in the context of timber engineering—A Review. J. Adhes. 2017, 93, 257–287. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L: J. Mater. Des. Appl. 2019, 234, 198–217. [Google Scholar] [CrossRef]

- Loo, W.Y.; Kun, C.; Quenneville, P.; Chouw, N. Experimental testing of a rocking timber shear wall with slip-friction connectors. Earthq. Eng. Struct. Dyn. 2014, 43, 1621–1639. [Google Scholar] [CrossRef]

- Duan, W.; Bian, X.; Bu, Y. Applications of Bioadhesives: A Mini Review. Front. Bioeng. Biotechnol. 2021, 9, 716035. [Google Scholar] [CrossRef]

- Harsha, K.S.S.; Vasudha, P. Cyanoacrylates: An overview in its application as a tissue adhesive. Der Pharma Chem. 2018, 10, 42–46. [Google Scholar]

- Li, S.; Zhou, J.; Huang, Y.; Roy, J.; Zhou, N.; Yum, K.; Sun, X.; Tang, L. Injectable Click Chemistry-based Bioadhesives for Accelerated Wound Closure. Acta Biomater. 2020, 110, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Conner, A.H. Wood: Adhesives. Encycl. Mater. Sci. Technol.; Elsevier Science, Ltd.: Amsterdam, The Netherlands; New York, NY, USA, 2001; pp. 9583–9599. [Google Scholar]

- Tserpes, K.; Barroso-Caro, A.; Carraro, P.A.; Beber, V.C.; Floros, I.; Gamon, W.; Kozłowski, M.; Santandrea, F.; Shahverdi, M.; Skejić, D.; et al. A review on failure theories and simulation models for adhesive joints. J. Adhes. 2022, 98, 1855–1915. [Google Scholar] [CrossRef]

- Tzatzadakis, V.; Tserpes, K. Experimental characterization of the hygrothermal ageing effects on the bulk mechanical properties and lap-shear strength of the novel bio-based epichlorohydrin/cardanol adhesive. J. Adhes. 2022, 98, 49–67. [Google Scholar] [CrossRef]

- Müller, U.; Sretenovic, A.; Vincenti, A.; Gindl, W. Direct measurement of strain distribution along a wood bond line. Part 1: Shear strain concentration in a lap joint specimen by means of electronic speckle pattern interferometry. Holzforschung 2005, 59, 300–306. [Google Scholar] [CrossRef]

- Fecht, S.; Vallée, T.; Tannert, T.; Fricke, H. Adhesively bonded hardwood joints under room temperature and elevated temperatures. J. Adhes. 2014, 90, 401–419. [Google Scholar] [CrossRef]

- Clauß, S.; Joscak, M.; Niemz, P. Thermal stability of glued wood joints measured by shear tests. Eur. J. Wood Wood Prod. 2011, 69, 101–111. [Google Scholar] [CrossRef]

- Tannert, T.; Vallée, T.; Hehl, S. Experimental and numerical investigations on adhesively bonded hardwood joints. Int. J. Adhes. Adhes. 2012, 37, 65–69. [Google Scholar] [CrossRef]

- Tiryaki, S.; Bardak, S.; Bardak, T. Experimental investigation and prediction of bonding strength of Oriental beech (Fagus orientalis Lipsky) bonded with polyvinyl acetate adhesive. J. Adhes. Sci. Technol. 2015, 29, 2521–2536. [Google Scholar] [CrossRef]

- Xavier, J.; Morais, J.; Dourado, N.; Moura, M.F.S.F. Measurement of Mode I and Mode II Fracture Properties of Wood-Bonded Joints. J. Adhes. Sci. Technol. 2011, 25, 2881–2895. [Google Scholar] [CrossRef]

- Silva, F.; Morais, J.; Dourado, N.; Xavier, J.; Pereira, F.; de Moura, M. Determination of cohesive laws in wood bonded joints under mode II loading using the ENF test. Int. J. Adhes. Adhes. 2014, 51, 54–61. [Google Scholar] [CrossRef]

- Wimmer, R.; Kläusler, O.; Niemz, P. Water sorption mechanisms of commercial wood adhesive films. Wood Sci. Technol. 2013, 47, 763–775. [Google Scholar] [CrossRef]

- Kläusler, O.; Clauß, S.; Lübke, L.; Trachsel, J.; Niemz, P. Influence of moisture on stress–strain behaviour of adhesives used for structural bonding of wood. Int. J. Adhes. Adhes. 2013, 44, 57–65. [Google Scholar] [CrossRef]

- Ammann, S.; Niemz, P. Mixed-mode fracture toughness of bond lines of PRF and PUR adhesives in European beech wood. Holzforschung 2015, 69, 415–420. [Google Scholar] [CrossRef]

- Ammann, S.; Niemz, P. Specific fracture energy at glue joints in European beech wood. Int. J. Adhes. Adhes. 2015, 60, 47–53. [Google Scholar] [CrossRef]

- Hassani, M.M.; Wittel, F.K.; Ammann, S.; Niemz, P.; Herrmann, H.J. Moisture-induced damage evolution in laminated beech. Wood Sci. Technol. 2016, 50, 917–940. [Google Scholar] [CrossRef]

- Mannes, D.; Sonderegger, W.; Hering, S.; Lehmann, E.; Niemz, P. Non-destructive determination and quantification of diffusion processes in wood by means of neutron imaging. Holzforschung 2009, 63. [Google Scholar] [CrossRef] [Green Version]

- Sonderegger, W.; Glaunsinger, M.; Mannes, D.; Volkmer, T.; Niemz, P. Investigations into the influence of two different wood coatings on water diffusion determined by means of neutron imaging. Eur. J. Wood Wood Prod. 2015, 73, 793–799. [Google Scholar] [CrossRef]

- Kollmann, F.; Fengel, D. Änderungen der chemischen Zusammensetzung von Holz durch thermische Behandlung. Holz als Roh- und Werkst. 1965, 23, 461. [Google Scholar] [CrossRef]

- Mannes, D.; Sanabria, S.; Funk, M.; Wimmer, R.; Kranitz, K.; Niemz, P. Water vapour diffusion through historically relevant glutin-based wood adhesives with sorption measurements and neutron radiography. Wood Sci. Technol. 2014, 48, 591–609. [Google Scholar] [CrossRef]

- Lanvermann, C.; Evans, R.; Schmitt, U.; Hering, S.; Niemz, P. Distribution of structure and lignin within growth rings of Norway spruce. Wood Sci. Technol. 2013, 47, 627–641. [Google Scholar] [CrossRef] [Green Version]

- Jalali, S.; Ayatollahi, M.; Akhavan-Safar, A.; da Silva, L. Effects of impact fatigue on residual static strength of adhesively bonded joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1519–1531. [Google Scholar] [CrossRef]

- Tsai, K.T.; Ansell, M.P. The fatigue properties of wood in flexure. J. Mater. Sci. 1990, 25, 865–878. [Google Scholar] [CrossRef]

- Babu, T.N.; Shyam, S.; Kaul, S.; Prabha, D.R. Natural fibre composites—An alternative to plastics in the automotive industry: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 236, 237–266. [Google Scholar] [CrossRef]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical properties of adhesives for bonding wood—A review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Kurukavak, Ç.K. Surface and mechanical characterization of bionanocomposites for advanced applications: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1949–1966. [Google Scholar] [CrossRef]

- Bachtiar, E.V.; Clerc, G.; Brunner, A.J.; Kaliske, M.; Niemz, P. Static and dynamic tensile shear test of glued lap wooden joint with four different types of adhesives. Holzforschung 2017, 71, 391–396. [Google Scholar] [CrossRef] [Green Version]

- Künniger, T.; Clerc, G.; Josset, S.; Niemz, P.; Pichelin, F.; van de Kuilen, J.-W.G. Influence of humidity and frequency on the energy dissipation in wood adhesives. Int. J. Adhes. Adhes. 2019, 92, 99–104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borges, C.S.P.; Jalali, S.; Tsokanas, P.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Sustainable Development Approaches through Wooden Adhesive Joints Design. Polymers 2023, 15, 89. https://doi.org/10.3390/polym15010089

Borges CSP, Jalali S, Tsokanas P, Marques EAS, Carbas RJC, da Silva LFM. Sustainable Development Approaches through Wooden Adhesive Joints Design. Polymers. 2023; 15(1):89. https://doi.org/10.3390/polym15010089

Chicago/Turabian StyleBorges, Catarina S. P., Shahin Jalali, Panayiotis Tsokanas, Eduardo A. S. Marques, Ricardo J. C. Carbas, and Lucas F. M. da Silva. 2023. "Sustainable Development Approaches through Wooden Adhesive Joints Design" Polymers 15, no. 1: 89. https://doi.org/10.3390/polym15010089

APA StyleBorges, C. S. P., Jalali, S., Tsokanas, P., Marques, E. A. S., Carbas, R. J. C., & da Silva, L. F. M. (2023). Sustainable Development Approaches through Wooden Adhesive Joints Design. Polymers, 15(1), 89. https://doi.org/10.3390/polym15010089