Long-Lasting Electret Melt-Blown Nonwoven Functional Filters Made of Organic/Inorganixc Macromolecular Micron Materials: Manufacturing Techniques and Property Evaluations

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

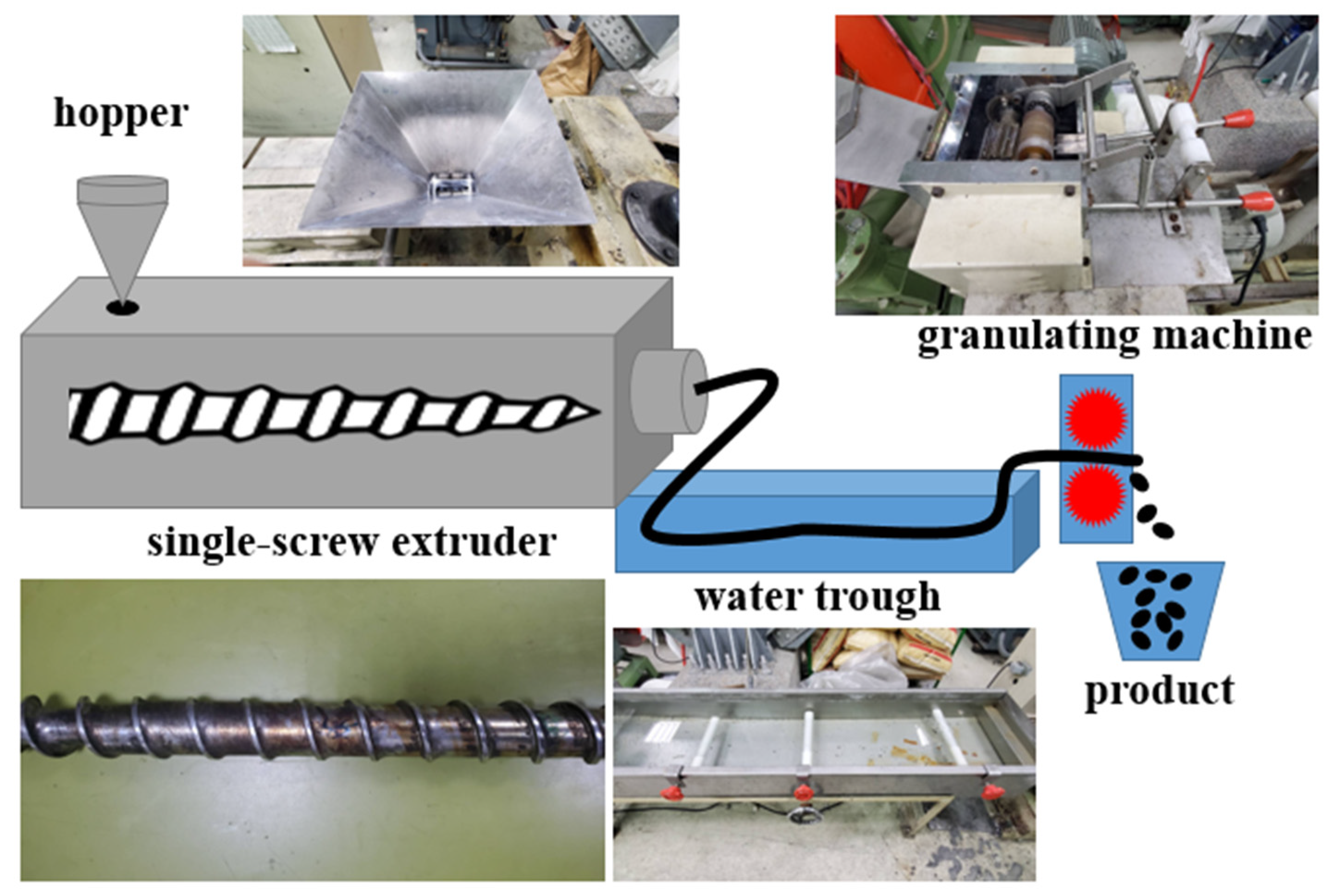

2.2. Preparation of Compound Pellets

2.3. Preparation Melt-Blown Nonwoven Fabrics

2.4. Tensile Test

2.5. Scanning Electron Microscopy (SEM)

2.6. Differential Scanning Calorimetry (DSC)

2.7. Fiber Diameter Analysis

2.8. Fourier Transform Infrared Spectroscopy (FTIR)

2.9. Fiber Covering Ratio

2.10. Filter Performance, Pressure Drop, and Quality Factor Tests

3. Results and Discussion

3.1. DSC Analyses of PP/MMT/CNT/TiO2 Films

3.2. FTIR Results of MMT/CNT/TiO2 Films as Related to the Ratio

3.3. Properties of MMT/CNT/TiO2 Melt-Blown Nonwoven Fabrics as Related to the Ratio

3.4. Effect of Die Temperature, Air Temperature, and Spinning Distance on Melt-Blown Nonwoven Fiber

3.5. Effects of Collection Distance and Air Pressure on Melt-Blown Nonwoven Fabrics

3.6. Effect of Collector Speed on Melt-Blown Nonwoven Fibers

3.7. Effect of Fiber Diameter and Covering Ratio on Melt-Blown Nonwoven Fabrics

3.8. Tensile Performance of Melt-Blown Nonwoven Fabrics as Related to the Ratio

3.9. Air Permeability of Melt-Blown Nonwoven Fabric as Related to the Ratio of Materials

3.10. Pressure Drop of Nonwoven Fabrics

3.11. Filter Performance of Nonwoven Fabrics

3.12. Quality Factor of Nonwoven Fabrics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Biswas, S.; Winoto, S. Prediction of pressure drop in non-woven filter media using a Hagen-Poiseuille model. Tribol. Trans. 2000, 43, 251–256. [Google Scholar] [CrossRef]

- Blachere, F.M.; Lemons, A.R.; Coyle, J.P.; Derk, R.C.; Lindsley, W.G.; Beezhold, D.H.; Woodfork, K.; Duling, M.G.; Boutin, B.; Boots, T. Face mask fit modifications that improve source control performance. Am. J. Infect. Control 2022, 50, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Brauer, M.; Casadei, B.; Harrington, R.A.; Kovacs, R.; Sliwa, K.; Group, W.A.P.E. Taking a stand against air pollution—The impact on cardiovascular disease: A joint opinion from the World Heart Federation, American College of Cardiology, American Heart Association, and the European Society of Cardiology. Circulation 2021, 143, e800–e804. [Google Scholar] [CrossRef] [PubMed]

- Cai, R.-R.; Zhang, L.-Z.; Bao, A.-B. PM collection performance of electret filters electrospun with different dielectric materials-a numerical modeling and experimental study. Build. Environ. 2018, 131, 210–219. [Google Scholar] [CrossRef]

- Cutright, C.; Finkelstein, R.; Orlowski, E.; McIntosh, E.; Brotherton, Z.; Fabiani, T.; Khan, S.; Genzer, J.; Menegatti, S. Nonwoven fiber mats with thermo-responsive permeability to inorganic and organic electrolytes. J. Membr. Sci. 2020, 616, 118439. [Google Scholar] [CrossRef]

- Fan, C.; Huang, Y.-Z.; Lin, J.-N.; Li, J. Microplastic constituent identification from admixtures by Fourier-transform infrared (FTIR) spectroscopy: The use of polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and nylon (NY) as the model constituents. Environ. Technol. Innov. 2021, 23, 101798. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless melt-electrospinning of polypropylene nanofibres. J. Nanomater. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Forouzandeh, P.; O’Dowd, K.; Pillai, S.C. Face masks and respirators in the fight against the COVID-19 pandemic: An overview of the standards and testing methods. Saf. Sci. 2021, 133, 104995. [Google Scholar] [CrossRef]

- Ghosal, A.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Numerical prediction of the effect of uptake velocity on three-dimensional structure, porosity and permeability of meltblown nonwoven laydown. Polymer 2016, 85, 19–27. [Google Scholar] [CrossRef]

- Ghosh, S. Composite nonwovens in medical applications. Compos. Non-Woven Mater. 2014, 211–224. [Google Scholar] [CrossRef]

- Hassan, M.A.; Yeom, B.Y.; Wilkie, A.; Pourdeyhimi, B.; Khan, S.A. Fabrication of nanofiber meltblown membranes and their filtration properties. J. Membr. Sci. 2013, 427, 336–344. [Google Scholar] [CrossRef]

- Henry, J.J.; Goldbach, J.; Stabler, S.; Devisme, S.; Chauveau, J. Advancements in the production of meltblown fibres. Filtr. Sep. 2016, 53, 36–40. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, H.; Xu, H.; Chen, X. Surface potential and crystal structure of injection isotactic polypropylene electret at different charging voltages. Polym. Test. 2019, 80, 106119. [Google Scholar] [CrossRef]

- Jafari, M.; Shim, E.; Joijode, A. Fabrication of Poly (lactic acid) filter media via the meltblowing process and their filtration performances: A comparative study with polypropylene meltblown. Sep. Purif. Technol. 2021, 260, 118185. [Google Scholar] [CrossRef]

- Ji, J.; Bae, G.; Kang, S.; Hwang, J. Effect of particle loading on the collection performance of an electret cabin air filter for submicron aerosols. J. Aerosol Sci. 2003, 34, 1493–1504. [Google Scholar] [CrossRef]

- Ju, J.T.; Boisvert, L.N.; Zuo, Y.Y. Face masks against COVID-19: Standards, efficacy, testing and decontamination methods. Adv. Colloid Interface Sci. 2021, 292, 102435. [Google Scholar] [CrossRef]

- Kadam, V.; Kyratzis, I.L.; Truong, Y.B.; Schutz, J.; Wang, L.; Padhye, R. Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration. Sep. Purif. Technol. 2019, 224, 247–254. [Google Scholar] [CrossRef]

- Kang, Y.O.; Im, J.N.; Park, W.H. Morphological and permeable properties of antibacterial double-layered composite nonwovens consisting of microfibers and nanofibers. Compos. Part B Eng. 2015, 75, 256–263. [Google Scholar] [CrossRef]

- Lasagabaster, A.; Abad, M.J.; Barral, L.; Ares, A. FTIR study on the nature of water sorbed in polypropylene (PP)/ethylene alcohol vinyl (EVOH) films. Eur. Polym. J. 2006, 42, 3121–3132. [Google Scholar] [CrossRef]

- Li, X.; Hu, Z.; Cao, J.; Xu, X. The impact of environmental accountability on air pollution: A public attention perspective. Energy Policy 2022, 161, 112733. [Google Scholar] [CrossRef]

- Ma, Y.; He, A.; Liu, C. Crystallization kinetics, crystalline structures and properties of PB/PP blends regulated by poly (butene-block-propylene) copolymers. Polymer 2021, 228, 123901. [Google Scholar] [CrossRef]

- Majewsky, M.; Bitter, H.; Eiche, E.; Horn, H. Determination of microplastic polyethylene (PE) and polypropylene (PP) in environmental samples using thermal analysis (TGA-DSC). Sci. Total Environ. 2016, 568, 507–511. [Google Scholar] [CrossRef] [PubMed]

- Oberg, T.; Brosseau, L.M. Surgical mask filter and fit performance. Am. J. Infect. Control 2008, 36, 276–282. [Google Scholar] [CrossRef]

- Piazza, D.; Silveira, D.S.; Lorandi, N.P.; Birriel, E.J.; Scienza, L.C.; Zattera, A.J. Polyester-based powder coatings with montmorillonite nanoparticles applied on carbon steel. Prog. Org. Coat. 2012, 73, 42–46. [Google Scholar] [CrossRef]

- Pourdeyhimi, B.; Maze, B.; Farukh, F.; Silberschmidt, V.V. Nonwovens—Structure-process-property relationships. In Structure and Mechanics of Textile Fibre Assemblies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 109–143. [Google Scholar]

- Schawe, J.E. Analysis of non-isothermal crystallization during cooling and reorganization during heating of isotactic polypropylene by fast scanning DSC. Thermochim. Acta 2015, 603, 85–93. [Google Scholar] [CrossRef]

- Seo, S.; Ruzycki, C.A.; Finlay, W.H.; Romanyk, D.L.; Martin, A.R. Size-specific Filtration Efficiency and Pressure Drop of School-aged Children’s Woven and Nonwoven Masks at Varying Face Velocities. Am. J. Infect. Control 2023. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. A TG-FTIR investigation on the co-pyrolysis of the waste HDPE, PP, PS and PET under high heating conditions. J. Energy Inst. 2020, 93, 1020–1035. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Yarin, A.; Pourdeyhimi, B. Meltblown fiber mats and their tensile strength. Polymer 2014, 55, 4241–4247. [Google Scholar] [CrossRef]

- Tan, D.H.; Zhou, C.; Ellison, C.J.; Kumar, S.; Macosko, C.W.; Bates, F.S. Meltblown fibers: Influence of viscosity and elasticity on diameter distribution. J. Non-Newton. Fluid Mech. 2010, 165, 892–900. [Google Scholar] [CrossRef]

- Tcharkhtchi, A.; Abbasnezhad, N.; Seydani, M.Z.; Zirak, N.; Farzaneh, S.; Shirinbayan, M. An overview of filtration efficiency through the masks: Mechanisms of the aerosols penetration. Bioact. Mater. 2021, 6, 106–122. [Google Scholar] [CrossRef]

- Wong, M.; Paramsothy, M.; Xu, X.; Ren, Y.; Li, S.; Liao, K. Physical interactions at carbon nanotube-polymer interface. Polymer 2003, 44, 7757–7764. [Google Scholar] [CrossRef]

- Wu, I.-P.; Liao, S.-L.; Lai, S.-H.; Wong, K.-S. The respiratory impacts of air pollution in children: Global and domestic (Taiwan) situation. Biomed. J. 2022, 45, 88–94. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Xiao, X.; Zhang, W.; Xu, R.; Kim, S.C.; Cui, Y.; Howard, T.T.; Wu, E. Air-filtering masks for respiratory protection from PM2.5 and pandemic pathogens. One Earth 2020, 3, 574–589. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Liang, G.; Zhai, H.; Tang, S.; Hang, G.; Pan, W.-P. Preparation and crystallization behaviour of PP/PP-g-MAH/Org-MMT nanocomposite. Eur. Polym. J. 2003, 39, 1467–1474. [Google Scholar] [CrossRef]

- Shen, J.X. Fabrication of Polypropylene Air Filter by Meltblwon Technique; Feng Chia University: Taichung, Taiwan, 2019. [Google Scholar]

- Al-Amin, M.; Dey, S.C.; Rashid, T.U.; Ashaduzzaman, M.; Shamsuddin, S.M. Solar assisted photocatalytic degradation of reactive azo dyes in presence of anatase titanium dioxide. Int. J. Latest Res. Eng. Technol. 2016, 2, 14–21. [Google Scholar]

- Girei, S.A.; Thomas, S.P.; Atieh, M.A.; Mezghani, K.; De, S.; Bandyopadhyay, S.; Al-Juhani, A. Effect of–COOH functionalized carbon nanotubes on mechanical, dynamic mechanical and thermal properties of polypropylene nanocomposites. J. Thermoplast. Compos. Mater. 2012, 25, 333–350. [Google Scholar] [CrossRef]

- Martins, M.G.; Martins, D.O.; de Carvalho, B.L.; Mercante, L.A.; Soriano, S.; Andruh, M.; Vieira, M.D.; Vaz, M.G. Synthesis and characterization of montmorillonite clay intercalated with molecular magnetic compounds. J. Solid State Chem. 2015, 228, 99–104. [Google Scholar] [CrossRef]

| Name | MMT Temperature (Orillonite) (wt%) | TiO2 (wt%) |

|---|---|---|

| 4M | 4 | 0 |

| 3M1T | 3 | 1 |

| 2M2T | 2 | 2 |

| 1M3T | 1 | 3 |

| 4T | 0 | 4 |

| Name | MMT Temperature (Orillonite) (wt%) | CNT (wt%) |

| 3M1C | 3 | 1 |

| 2M2C | 2 | 2 |

| 1M3C | 1 | 3 |

| 4C | 0 | 4 |

| Sample Name | Tm (°C) | Tc (°C) | Tm Area (J/g) | Tc Area (J/g) | Crystallinity (%) |

|---|---|---|---|---|---|

| PP | 150.28 | 107.30 | 79.29 | 92.44 | 29.7 |

| 4C | 160.67 | 125.50 | 71.68 | 84.00 | 27.7 |

| 4M | 164.44 | 114.84 | 72.03 | 89.02 | 27.9 |

| 4T | 162.88 | 118.60 | 93.21 | 112.2 | 36.1 |

| Wavenumber (cm−1) | Vibration | Functional Group |

|---|---|---|

| 2950 | asymmetrical stretching | CH3 |

| 2925 | asymmetrical stretching | CH2 |

| 2870 | stretching | CH3 |

| 1456 | symmetrical bending | CH3 |

| 1375 | symmetrical bending | CH |

| 1160 | wagging | C-H |

| 1160 | rocking | CH3 |

| 998 | rocking | CH3 |

| 996 | stretching | C-C |

| 840 | rocking | CH3 |

| 839 | rocking | C-H |

| 809 | stretching | C-C |

| Die Temperature (°C) | Air Temperature (°C) | Diameter (μm) | Air Permeability (cm3/s/cm2) | Thickness (mm) | Basis Weight (g/m2) |

|---|---|---|---|---|---|

| 200 | 160 | 41.1 ± 4.49 | 195.7 ± 13.3 | 1.83 ± 0.05 | 181 ± 5.1 |

| 200 | 200 | 38.9 ± 5.13 | 212.3 ± 13.5 | 1.95 ± 0.04 | 183 ± 6.6 |

| 220 | 160 | 36.8 ± 5.57 | 189.7 ± 14.6 | 1.98 ± 0.04 | 185 ± 7.2 |

| 220 | 200 | 35.9 ± 3.25 | 188.5 ± 7.8 | 1.82 ± 0.02 | 189 ± 6.9 |

| 240 | 160 | 40.5 ± 4.23 | 197.1 ± 6.5 | 1.88 ± 0.03 | 186 ± 4.4 |

| 240 | 200 | 38.3 ± 5.09 | 190.5 ± 7.4 | 1.95 ± 0.03 | 191 ± 7.3 |

| DCD (cm) | Air Pressure (MPa) | Diameter (μm) | Air Permeability (cm3/s/cm2) | Thickness (mm) | Basis Weight (g/m2) |

|---|---|---|---|---|---|

| 35 | 0.008 | 21.1 ± 4.22 | 212.7 ± 12.4 | 1.85 ± 0.03 | 191 ± 3.1 |

| 40 | 0.008 | 18.9 ± 3.76 | 187.3 ± 11.2 | 1.85 ± 0.04 | 190 ± 4.2 |

| 35 | 0.008 | 21.2 ± 4.31 | 213.7 ± 11.9 | 1.78 ± 0.02 | 192 ± 5.1 |

| 35 | 0.010 | 17.3 ± 2.97 | 171.5 ± 10.1 | 1.76 ± 0.02 | 190 ± 2.3 |

| 40 | 0.008 | 17.5 ± 3.18 | 197.1 ± 12.3 | 1.88 ± 0.03 | 193 ± 3.4 |

| 40 | 0.010 | 15.1 ± 1.91 | 190.5 ± 13.7 | 1.85 ± 0.04 | 192 ± 4.3 |

| Collector Speed (m/min) | Diameter (μm) | Air Permeability (cm3/s/cm2) | Thickness (mm) | Basis Weight (g/m2) |

|---|---|---|---|---|

| 1 | 21.1 ± 4.22 | 212.7 ± 12.4 | 1.85 ± 0.03 | 191 ± 3.1 |

| 2 | 18.9 ± 3.76 | 187.3 ± 11.2 | 1.54 ± 0.08 | 153 ± 7.5 |

| 3 | 21.2 ± 4.31 | 213.7 ± 11.9 | 1.23 ± 0.05 | 102 ± 9.8 |

| 4 | 17.3 ± 2.97 | 228.3 ± 10.1 | 0.76 ± 0.04 | 73 ± 6.9 |

| Sample Name | Diameter (μm) | Pore Size (μm2) | Fiber Covering Ratio (%) | Basis Weight (g/m2) |

|---|---|---|---|---|

| Pure PP | 9.1 ± 3.07 | 712 ± 25.3 | 68.1 | 183 ± 3.6 |

| 4T | 9.7 ± 2.34 | 649 ± 35.7 | 69.3 | 191 ± 2.3 |

| 4M | 8.9 ± 1.94 | 697 ± 49.3 | 67.7 | 188 ± 5.1 |

| 4C | 9.6 ± 2.63 | 714 ± 30.7 | 69.3 | 199 ± 3.1 |

| Mark1 | 7.6 ± 1.03 | 453 ± 25.7 | 85.6 | 81 ± 0.9 |

| Name | PP (wt%) | TiO2 (wt%) | CNT (wt%) | MMT (wt%) | Filtration Efficiency (%) |

|---|---|---|---|---|---|

| PP | 100 | 0 | 0 | 0 | 65.5 ± 5.1 |

| 4T | 96 | 4 | 0 | 0 | 87.4 ± 3.0 |

| 4C | 96 | 0 | 4 | 0 | 83.1 ± 4.1 |

| 4M | 96 | 0 | 0 | 4 | 82.3 ± 3.9 |

| 3T1C | 96 | 3 | 1 | 0 | 80.6 ± 5.1 |

| 3T1M | 96 | 3 | 0 | 1 | 81.2 ± 5.4 |

| 1T3M | 96 | 1 | 3 | 0 | 75.3 ± 7.0 |

| 3C1M | 96 | 0 | 3 | 1 | 77.6 ± 7.2 |

| 1T3M | 96 | 1 | 0 | 3 | 78.5 ± 5.6 |

| 1C3M | 96 | 0 | 1 | 3 | 77.3 ± 6.0 |

| 2T2C | 96 | 2 | 2 | 0 | 78.2 ± 5.3 |

| 2T2M | 96 | 2 | 0 | 2 | 80.4 ± 4.1 |

| 2C2M | 96 | 0 | 2 | 2 | 81.2 ± 4.9 |

| Mark1 | 85.1 ± 3.1 | ||||

| Mark2 | 90.5 ± 1.5 | ||||

| Name | PP (wt%) | TiO2 (wt%) | CNT (wt%) | MMT (wt%) | Quality Factor (Pa−1) |

|---|---|---|---|---|---|

| PP | 100 | 0 | 0 | 0 | 0.080 |

| 4T | 96 | 4 | 0 | 0 | 0.156 |

| 4C | 96 | 0 | 4 | 0 | 0.136 |

| 4M | 96 | 0 | 0 | 4 | 0.132 |

| 3T1C | 96 | 3 | 1 | 0 | 0.123 |

| 3T1M | 96 | 3 | 0 | 1 | 0.127 |

| 1T3M | 96 | 1 | 3 | 0 | 0.106 |

| 3C1M | 96 | 0 | 3 | 1 | 0.113 |

| 1T3M | 96 | 1 | 0 | 3 | 0.116 |

| 1C3M | 96 | 0 | 1 | 3 | 0.113 |

| 2T2C | 96 | 2 | 2 | 0 | 0.116 |

| 2T2M | 96 | 2 | 0 | 2 | 0.123 |

| 2C2M | 96 | 0 | 2 | 2 | 0.127 |

| Mark1 | 0.145 | ||||

| Mark2 | 0.136 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.-H.; Lin, Y.-Y.; Sue, Y.-M.; Lin, M.-C.; Chen, Y.-S.; Lou, C.-W. Long-Lasting Electret Melt-Blown Nonwoven Functional Filters Made of Organic/Inorganixc Macromolecular Micron Materials: Manufacturing Techniques and Property Evaluations. Polymers 2023, 15, 2306. https://doi.org/10.3390/polym15102306

Lin J-H, Lin Y-Y, Sue Y-M, Lin M-C, Chen Y-S, Lou C-W. Long-Lasting Electret Melt-Blown Nonwoven Functional Filters Made of Organic/Inorganixc Macromolecular Micron Materials: Manufacturing Techniques and Property Evaluations. Polymers. 2023; 15(10):2306. https://doi.org/10.3390/polym15102306

Chicago/Turabian StyleLin, Jia-Horng, Yan-Yu Lin, Yang-Min Sue, Mei-Chen Lin, Yueh-Sheng Chen, and Ching-Wen Lou. 2023. "Long-Lasting Electret Melt-Blown Nonwoven Functional Filters Made of Organic/Inorganixc Macromolecular Micron Materials: Manufacturing Techniques and Property Evaluations" Polymers 15, no. 10: 2306. https://doi.org/10.3390/polym15102306

APA StyleLin, J.-H., Lin, Y.-Y., Sue, Y.-M., Lin, M.-C., Chen, Y.-S., & Lou, C.-W. (2023). Long-Lasting Electret Melt-Blown Nonwoven Functional Filters Made of Organic/Inorganixc Macromolecular Micron Materials: Manufacturing Techniques and Property Evaluations. Polymers, 15(10), 2306. https://doi.org/10.3390/polym15102306