Effect of Cymbopogan citratus Fibre on Physical and Impact Properties of Thermoplastic Cassava Starch/Palm Wax Composites

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

2.2. Sample Preparation of Biocomposites

2.3. Density

2.4. Moisture Content of Composite Materials

2.5. Water Absorption

2.6. Thickness Swelling

2.7. Impact Testing of Composites Material

2.8. Water Solubility of Composite Materials

2.9. Statistical Analysis of Composites Material

3. Results and Discussions

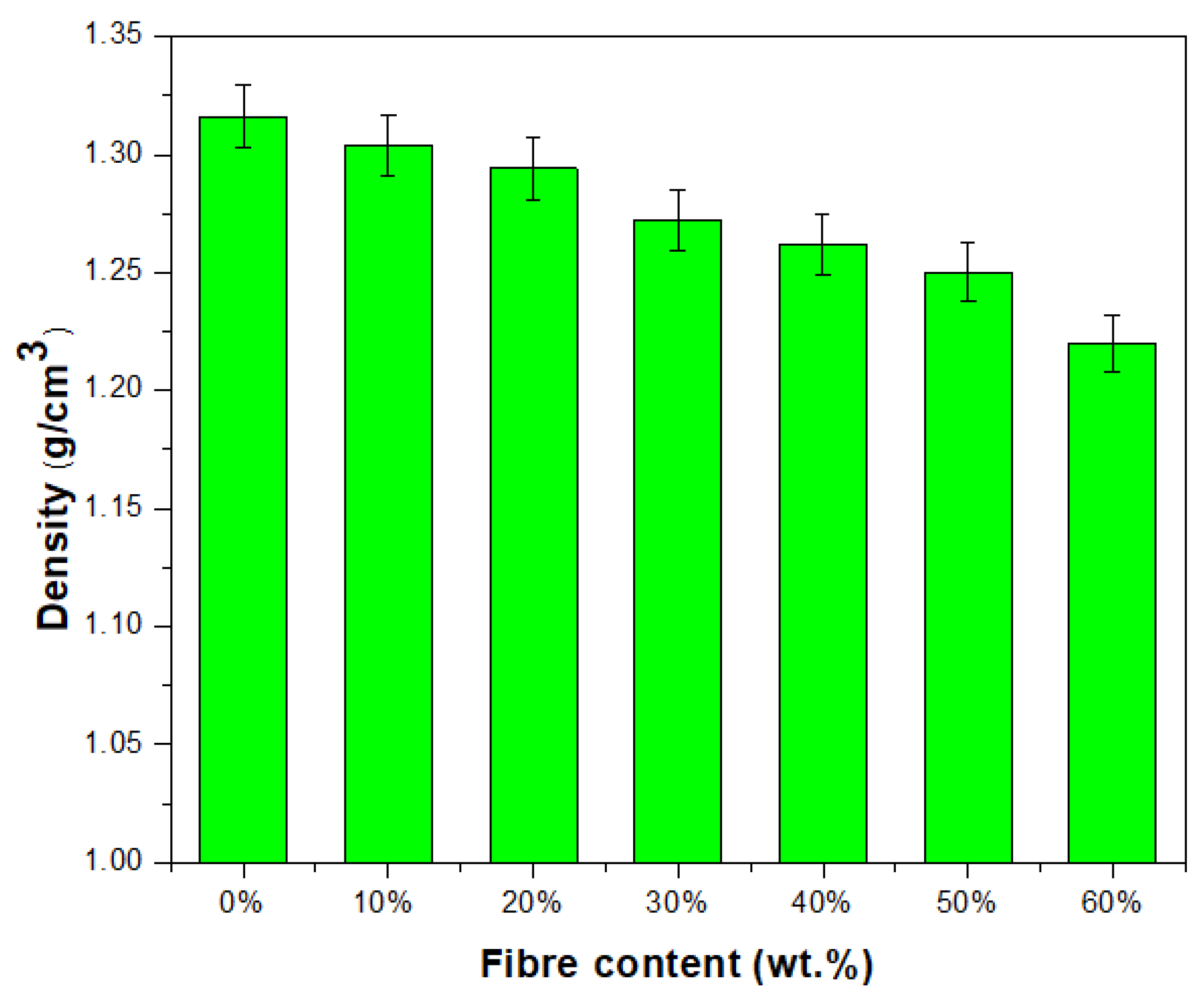

3.1. Density

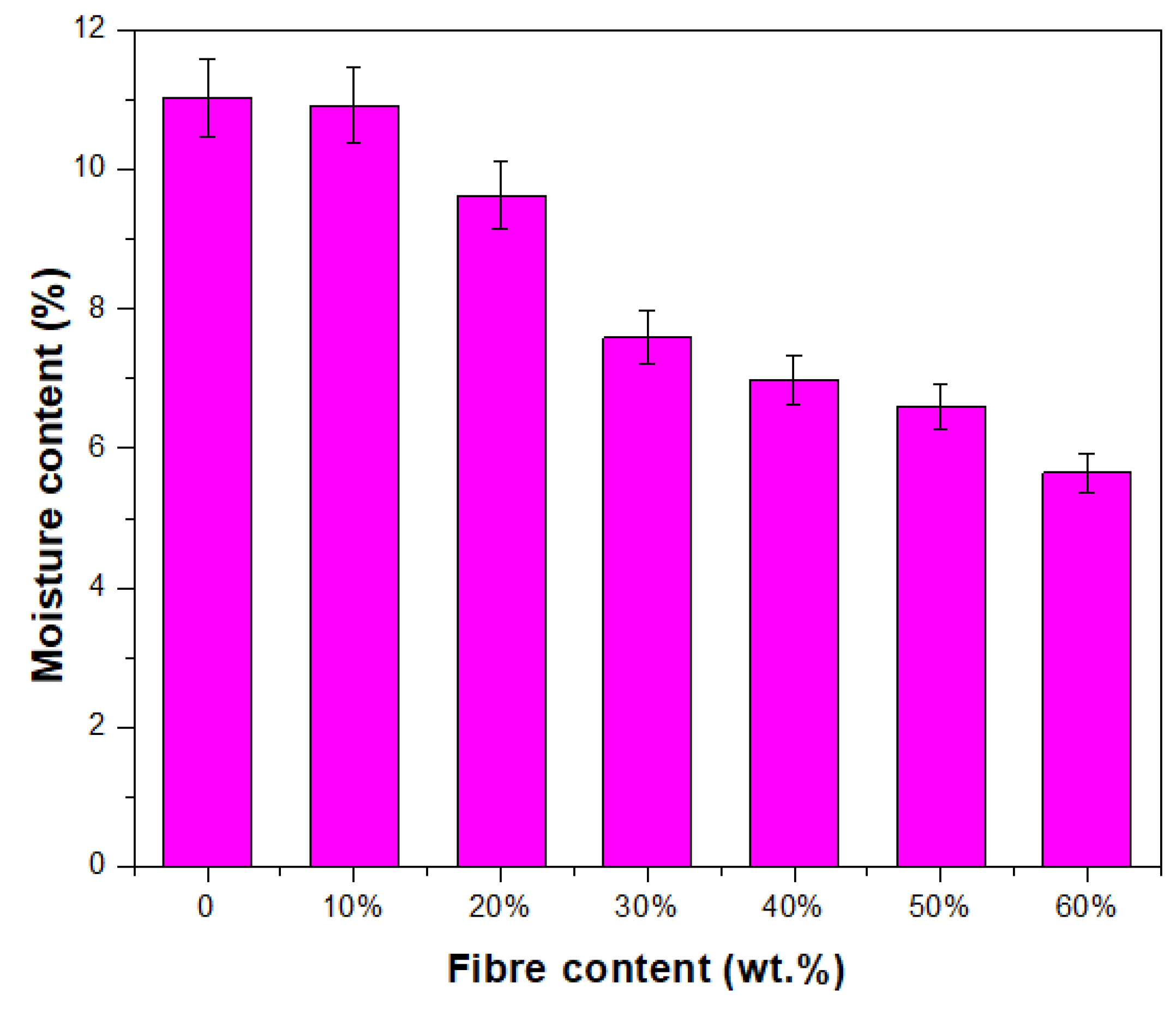

3.2. Moisture Content

3.3. Water Absorption of Composites

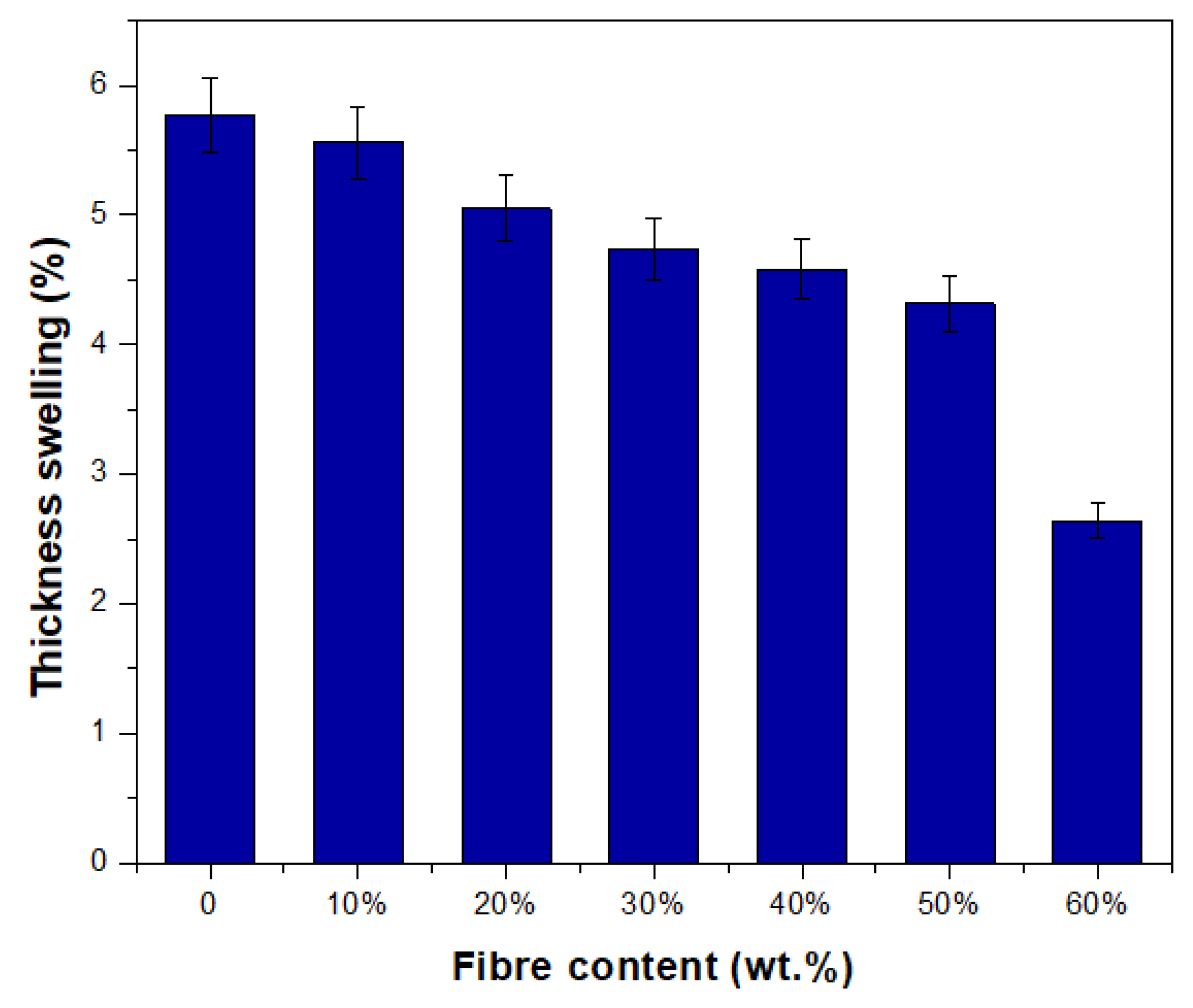

3.4. Thickness Swelling

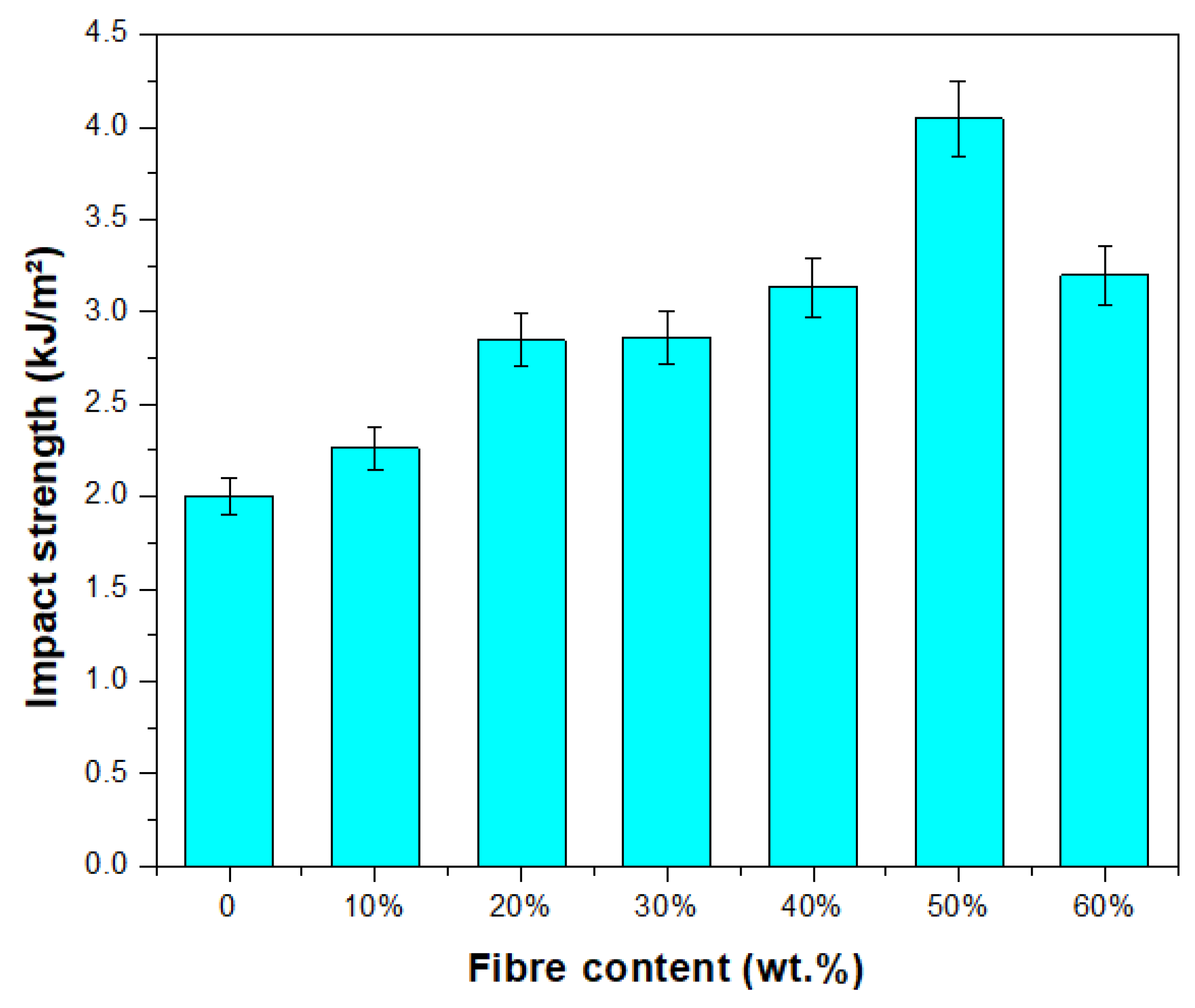

3.5. Impact Testing of Composites

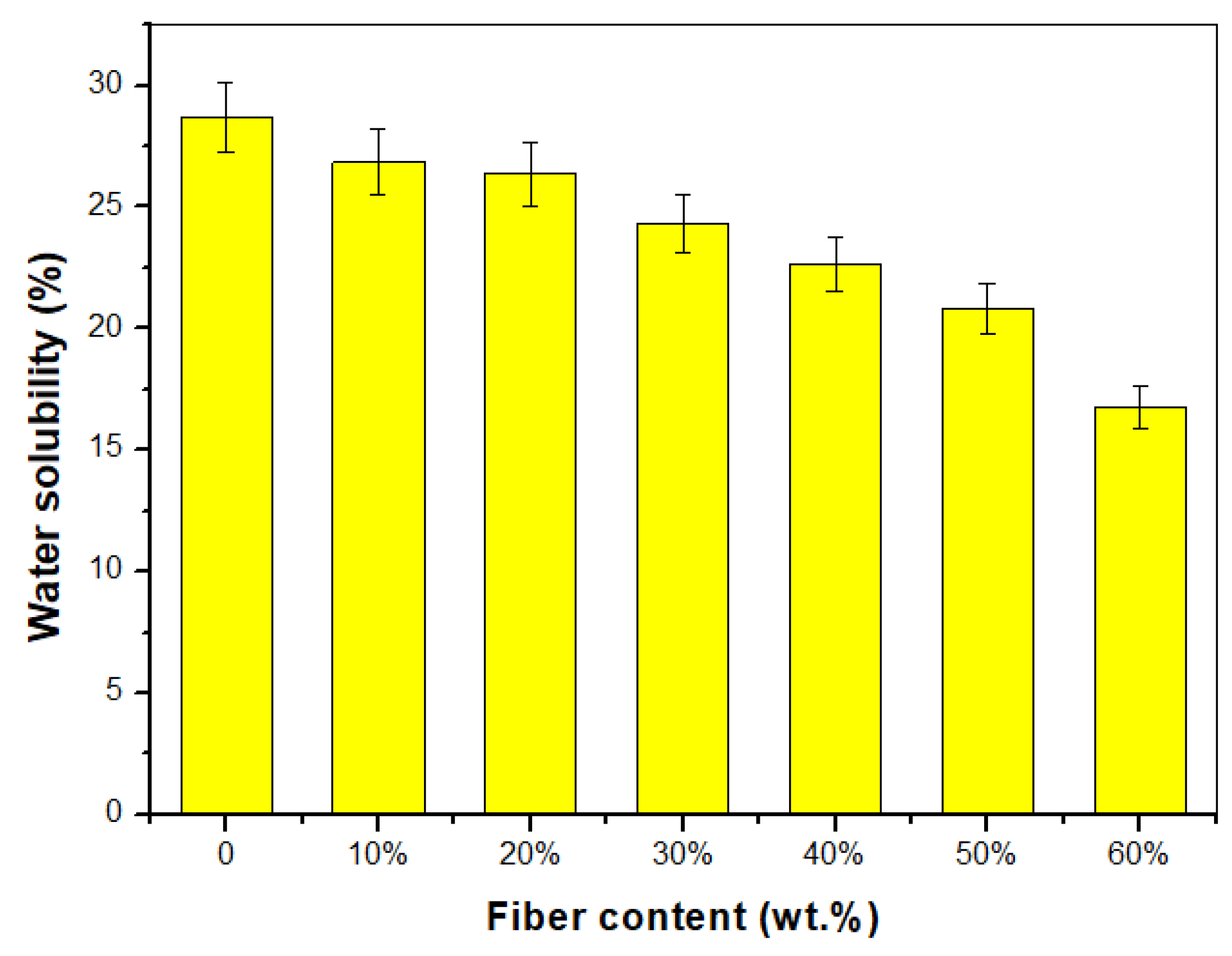

3.6. Water Solubility of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ali, S.S.S.; Razman, M.R.; Awang, A.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Lawrence, R.J. Critical Determinants of Household Electricity Consumption in a Rapidly Growing City. Sustainability 2021, 13, 4441. [Google Scholar] [CrossRef]

- Roslan, Z.B.; Ramli, Z.; Razman, M.R.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Nurazzi, N.M. Reflections on Local Community Identity by Evaluating Heritage Sustainability Protection in Jugra, Selangor, Malaysia. Sustainability 2021, 13, 8705. [Google Scholar] [CrossRef]

- Rafidah, M.; Asyraf, M.R.M.; Nurazzi, N.M.; Hassan, S.A.; Ilyas, R.A.; Khan, T.; Saad, W.A.A.; Rashedi, A.; Sharma, S.; Hussein, E.K. Unlocking the Potential of Lignocellulosic Biomass in Road Construction: A Brief Review of OPF. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Khan, T.; Syamsir, A.; Supian, A.B.M. Synthetic and Natural Fiber-Reinforced Polymer Matrix Composites for Advanced Applications. Materials 2022, 15, 6030. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Knight, V.F.; Nurazzi, N.M.; Jenol, M.A.; Misenan, M.S.M.; Janudin, N.; Kasim, N.A.M.; Shukor, M.F.A.; Ilyas, R.A.; Asyraf, M.R.M.; et al. The Frontiers of Functionalized Nanocellulose-Based Composites and Their Application as Chemical Sensors. Polymers 2022, 14, 4461. [Google Scholar] [CrossRef] [PubMed]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Mamaev, N. Buckling Analysis of CNT-Reinforced Polymer Composite Beam Using Experimental and Analytical Methods. Materials 2023, 16, 614. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.R.; Li, S.; Li, X.G. Longan Shell as Novel Biomacromolecular Sorbent for Highly Selective Removal of Lead and Mercury Ions. J. Phys. Chem. B 2010, 114, 3534–3542. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- YHazrati, K.Z.; Sapuan, S.M.; Zuhri, M.Y.M.; Jumaidin, R. Recent and Potential Developments in Dioscorea Hispida Biopolymer Composites: A Review. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020, Serdang, Malaysia, 17 November 2020; pp. 14–17. [Google Scholar]

- Li, X.G.; Xie, Y.B.; Huang, M.R.; Umeyama, T.; Ohara, T.; Imahori, H. Effective Role of Eco-Friendly Acetyl Tributyl Citrate in Large-Scale Catalyst-Free Synthesis of Waterborne Polyurethanes without Volatile Organic Compounds. J. Clean. Prod. 2019, 237, 117543. [Google Scholar] [CrossRef]

- Li, X.G.; Song, G.; Huang, M.R.; Ohara, T.; Yamada, H.; Umeyama, T.; Higashino, T.; Imahori, H. Cleaner Synthesis and Systematical Characterization of Sustainable Poly(Isosorbide-Co-Ethylene Terephthalate) by Environ-Benign and Highly Active Catalysts. J. Clean. Prod. 2019, 206, 483–497. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Abdan, K.; Ilyas, R.A.; Zainudin, E.S.; Sherwani, S.F.K.; Hazrati, K.Z. Physical and Barrier Roperties of Arrowroot (Maranta arundinacea) Starch Based Composites: A Review. In Proceedings of the International Conference on Sugar Palm and Allied Fibre Polymer Composites 2021, Online, 11 December 2021; pp. 180–182. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Nurazzi, N.M.; Shazleen, S.S.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Recent Advances of Thermal Properties of Sugar Palm Lignocellulosic Fibre Reinforced Polymer Composites. Int. J. Biol. Macromol. 2021, 193, 1587–1599. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical Properties of Oil Palm Fibre-Reinforced Polymer Composites: A Review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Zainudin, E.S.; Khalina, A.; Ilyas, R.A.; Hazrati, K.Z.; Aliyu, I. A Comparative Review of the Effects of Different Fibre Concentrations on Arrowroot Fibre and Other Fibre-Reinforced Composite Films. Mater. Today Proc. 2022, 74, 411–414. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Ain, N.; Mohamd, H. Water Affinity Properties of Thermoplastic Cassava Starch/Wax Reinforced with Sugarcane Bagasse Fiber. In Proceedings of the 7th International Conference and Exhibition on Sustainable Energy and Advanced Materials (ICE-SEAM 2021), Melaka, Malaysia, 17 November 2021; pp. 1–6. [Google Scholar]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Arpitha, G.R.; Sanjay, M.R. Extraction and Characterization of Vetiver Grass (Chrysopogon zizanioides) and Kenaf Fiber (Hibiscus cannabinus) as Reinforcement Materials for Epoxy. Integr. Med. Res. 2019, 9, 773–778. [Google Scholar] [CrossRef]

- Engel, J.B.; Ambrosi, A.; Tessaro, I.C. Development of Biodegradable Starch-Based Foams Incorporated with Grape Stalks for Food Packaging. Carbohydr. Polym. 2019, 225, 115234. [Google Scholar] [CrossRef]

- Jumaidin, R.; Ahmad Diah, N.; Alamjuri, R.H.; Ahmad Rushdan, I.; Yusof, F.A. Processing and Characterisation of Banana Leaf Fibre Reinforced Thermoplastic Cassava Starch Composites Ridhwan. Polymers 2021, 13, 1420. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic Mechanical Behaviour of Kenaf Cellulosic Fibre Biocomposites: A Comprehensive Review on Chemical Treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ebadi, S.; Azrina, A.; Razman, M.R. Mechanical Properties of Sugar Palm Lignocellulosic Fibre Reinforced Polymer Composites: A Review. Cellulose 2022, 29, 6493–6516. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Amir, A.L.; Nurazzi, N.M.; Ilyas, R.A.; Asrofi, M.; Rafidah, M.; Razman, M.R. Potential of Flax Fiber Reinforced Biopolymer Composites for Cross-Arm Application in Transmission Tower: A Review. Fibers Polym. 2022, 23, 853–877. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.M.; Ilyas, R.A.; Fudholi, A. Effect of Sonication Time on the Thermal Stability, Moisture Absorption, and Biodegradation of Water Hyacinth (Eichhornia crassipes) Nanocellulose-Filled Bengkuang (Pachyrhizus erosus) Starch Biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Norizan, M.N.; Shazleen, S.S.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.R.M.; Zainudin, E.S.; Abdullah, N.; Samsudin, M.S.; Kamarudin, S.H.; Norrrahim, M.N.F. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials 2022, 12, 3483. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, P.; Durga Prasad, B.; Narayana, K.L. Characterization of Kenaf Fiber and Its Composites: A Review. J. Reinf. Plast. Compos. 2018, 37, 731–737. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Development and Characterization of Sugar Palm Starch and Poly(Lactic Acid) Bilayer Films. Carbohydr. Polym. 2016, 146, 36–45. [Google Scholar] [CrossRef]

- Hazrati, K.Z.; Sapuan, S.M.; Zuhri, M.Y.M.; Jumaidin, R. Preparation and Characterization of Starch-Based Biocomposite Films Reinforced by Dioscorea Hispida Fibers. J. Mater. Res. Technol. 2021, 15, 1342–1355. [Google Scholar] [CrossRef]

- Martinez Villadiego, K.; Arias Tapia, M.J.; Useche, J.; Escobar Macías, D. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. J. Polym. Environ. 2022, 30, 75–91. [Google Scholar] [CrossRef]

- Hafila, K.Z.; Jumaidin, R.; Ilyas, R.A.; Selamat, M.Z.; Yusof, F.A.M. Effect of Palm Wax on the Mechanical, Thermal, and Moisture Absorption Properties of Thermoplastic Cassava Starch Composites. Int. J. Biol. Macromol. 2022, 194, 851–860. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Selamat, M.Z.; Ilyas, R.A. Characteristics and Properties of Lemongrass (Cymbopogan Citratus): A Comprehensive Review. J. Nat. Fibers 2021, 19, 8101–8118. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Physical, Thermal, Morphological, and Tensile Properties of Cornstarch-Based Films as Affected by Different Plasticizers. Int. J. Food Prop. 2019, 22, 925–941. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Nurazzi, N.M.; Norrrahim, M.N.F.; Hazrati, K.Z.; Ghani, A.; Sabaruddin, F.A.; Lee, S.H.; Shazleen, S.S.; Razman, M.R. Thermal Properties of Oil Palm Lignocellulosic Fibre Reinforced Polymer Composites: A Comprehensive Review on Thermogravimetry Analysis. Cellulose 2023, 30, 2753–2790. [Google Scholar] [CrossRef]

- Panrong, T.; Karbowiak, T.; Harnkarnsujarit, N. Thermoplastic Starch and Green Tea Blends with LLDPE Films for Active Packaging of Meat and Oil-Based Products. Food Packag. Shelf Life 2019, 21, 100331. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Ilyas, R.A.; Nurazzi, N.M.; Norrrahim, M.N.F.; Razman, M.R.; Zakaria, S.Z.S.; Sharma, S.; et al. Sugar Palm Fibre-Reinforced Polymer Composites: Influence of Chemical Treatments on Its Mechanical Properties. Materials 2022, 15, 3852. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef] [PubMed]

- Zadeh, K.M.; Ponnamma, D.; Al Ali Al-Maadeed, M. Date Palm Fibre Filled Recycled Ternary Polymer Blend Composites with Enhanced Flame Retardancy. Polym. Test. 2017, 61, 341–348. [Google Scholar] [CrossRef]

- Zou, Y.; Yuan, C.; Cui, B.; Liu, P.; Wu, Z.; Zhao, H. Formation of High Amylose Corn Starch / Konjac Glucomannan Composite Film with Improved Mechanical and Barrier Properties. Carbohydr. Polym. 2021, 251, 117039. [Google Scholar] [CrossRef]

- Hernández, V.; Ibarra, D.; Triana, J.F.; Martínez-Soto, B.; Faúndez, M.; Vasco, D.A.; Gordillo, L.; Herrera, F.; García-Herrera, C.; Garmulewicz, A. Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance. Materials 2022, 15, 3954. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable Biobased Composites for Advanced Applications: Recent Trends and Future Opportunities—A Critical Review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Bathich, H.; Itam, Z.; Supian, A.B.M.; Norhisham, S.; Nurazzi, N.M.; Khan, T.; Rashid, M.Z.A. Effect of Fibre Layering Sequences on Flexural Creep Properties of Kenaf Fibre-Reinforced Unsaturated Polyester Composite for Structural Applications. Fibers Polym. 2022, 23, 3232–3240. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and Characterization of Nanocrystalline Cellulose from Sugar Palm Fibres (Arenga pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef]

- Wifek, M.; Saeed, A.; Rehman, R.; Nisar, S. Lemongrass: A Review on Its Botany, Properties, Applications and Active Components. Int. J. Chem. Biochem. Sci. 2016, 9, 79–84. [Google Scholar]

- Putri, K.N.A.; Kaewpichai, S.; Keereerak, A.; Chinpa, W. Facile Green Preparation of Lignocellulosic Biosorbent from Lemongrass Leaf for Cationic Dye Adsorption. J. Polym. Environ. 2021, 29, 1681–1693. [Google Scholar] [CrossRef]

- Ahmad, M.A.; Ahmed, N.B.; Adegoke, K.A.; Bello, O.S. Adsorptive Potentials of Lemongrass Leaf for Methylene Blue Dye Removal. Chem. Data Collect. 2021, 31, 100578. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Rushdan, A.I.; Selamat, M.Z.; Alamjuri, R.H. Characterization of Natural Cellulosic Fiber Isolated from Malaysian Cymbopogan Citratus Leaves. BioResources 2021, 16, 7729–7750. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Ilyas, R.A.; Selamat, M.Z.; Alamjuri, R.H.; Yusof, F.A.M. Biocomposite of Cassava Starch-Cymbopogan Citratus Fibre: Mechanical, Thermal and Biodegradation Properties. Polymers 2022, 14, 514. [Google Scholar] [CrossRef] [PubMed]

- Technique, G. Standard Test Methods for Apparent Density, Bulk Factor, and Pourability of Plastic. Methods 2003, 08, 1–5. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Effect of Delignification on the Physical, Thermal, Chemical, and Structural Properties of Sugar Palm Fibre. BioResources 2017, 12, 8734–8754. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Noorunnisa Khanam, P.; Abu Bakar, A. Hybrid Composites Made from Oil Palm Empty Fruit Bunches/Jute Fibres: Water Absorption, Thickness Swelling and Density Behaviours. J. Polym. Environ. 2011, 19, 106–109. [Google Scholar] [CrossRef]

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. Annu. B. ASTM Stand. 2019, 10, 1–20.

- Zhang, Y.; Simpson, B.K.; Dumont, M.J. Effect of Beeswax and Carnauba Wax Addition on Properties of Gelatin Films: A Comparative Study. Food Biosci. 2018, 26, 88–95. [Google Scholar] [CrossRef]

- Shakuntala, O.; Raghavendra, G.; Samir Kumar, A. Effect of Filler Loading on Mechanical and Tribological Properties of Wood Apple Shell Reinforced Epoxy Composite. Adv. Mater. Sci. Eng. 2014, 2014, 538651. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Potential of Using Multiscale Corn Husk Fiber as Reinforcing Filler in Cornstarch-Based Biocomposites. Int. J. Biol. Macromol. 2019, 139, 596–604. [Google Scholar] [CrossRef] [PubMed]

- Sanhawong, W.; Banhalee, P.; Boonsang, S.; Kaewpirom, S. Effect of Concentrated Natural Rubber Latex on the Properties and Degradation Behavior of Cotton-Fiber-Reinforced Cassava Starch Biofoam. Ind. Crop. Prod. 2017, 108, 756–766. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Biodegradable Foam Tray from Cassava Starch Blended with Natural Fiber and Chitosan. Ind. Crop. Prod. 2012, 37, 542–546. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Supaphol, P.; Rujiravanit, R. Preparation and Characterization of Jute-and Flax-Reinforced Starch-Based Composite Foams. Carbohydr. Polym. 2004, 58, 53–63. [Google Scholar] [CrossRef]

- Belhassen, R.; Boufi, S.; Vilaseca, F.; López, J.P.; Méndez, J.A.; Franco, E.; Pèlach, M.A.; Mutjé, P. Biocomposites Based on Alfa Fibers and Starch-Based Biopolymer. Polym. Adv. Technol. 2009, 20, 1068–1075. [Google Scholar] [CrossRef]

- Syahida, N.; Fitry, I.; Zuriyati, A.; Hanani, N. Effects of Palm Wax on the Physical, Mechanical and Water Barrier Properties of Fish Gelatin Films for Food Packaging Application. Food Packag. Shelf Life 2020, 23, 100437. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and Characterization of Cornhusk/Sugar Palm Fiber Reinforced Cornstarch-Based Hybrid Composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Rosa, M.F.; Chiou, B.S.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imam, S.H. Effect of Fiber Treatments on Tensile and Thermal Properties of Starch/Ethylene Vinyl Alcohol Copolymers/Coir Biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, Mechanical, and Physical Properties of Seaweed/Sugar Palm Fibre Reinforced Thermoplastic Sugar Palm Starch/Agar Hybrid Composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef]

- Sarifuddin, N.; Ismail, H.; Ahmad, Z. Effect of Fiber Loading on Properties of Thermoplastic Sago Starch/Kenaf Core Fiber Biocomposites. BioResources 2012, 7, 4294–4306. [Google Scholar]

- Jumaidin, R.; Saidi, Z.A.S.; Ilyas, R.A.; Ahmad, M.N.; Wahid, M.K.; Yaakob, M.Y.; Maidin, N.A.; Ab Rahman, M.H.; Osman, M.H. Characteristics of Cogon Grass Fibre Reinforced Thermoplastic Cassava Starch Biocomposite: Water Absorption and Physical Properties. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 62, 43–52. [Google Scholar]

- Lomelí Ramírez, M.G.; Satyanarayana, K.G.; Iwakiri, S.; De Muniz, G.B.; Tanobe, V.; Flores-Sahagun, T.S. Study of the Properties of Biocomposites. Part I. Cassava Starch-Green Coir Fibers from Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/Sugar Palm Fiber Reinforced Cassava Starch Hybrid Composites: Physical, Thermal and Structural Properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Khiruddin, M.A.A.; Asyul Sutan Saidi, Z.; Salit, M.S.; Ilyas, R.A. Effect of Cogon Grass Fibre on the Thermal, Mechanical and Biodegradation Properties of Thermoplastic Cassava Starch Biocomposite. Int. J. Biol. Macromol. 2020, 146, 746–755. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Khan, A.; Asiri, A.M.; Malik, M.A. Effects of Date Palm Fibres Loading on Mechanical, and Thermal Properties of Date Palm Reinforced Phenolic Composites. J. Mater. Res. Technol. 2020, 9, 3614–3621. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M.; Ghori, W. Date Palm Reinforced Epoxy Composites: Tensile, Impact and Morphological Properties. J. Mater. Res. Technol. 2019, 8, 3959–3969. [Google Scholar] [CrossRef]

| Variables | df | Impact Strength |

|---|---|---|

| Mixture | 6 | 0.00 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamaruddin, Z.H.; Jumaidin, R.; Kamaruddin, Z.H.; Asyraf, M.R.M.; Razman, M.R.; Khan, T. Effect of Cymbopogan citratus Fibre on Physical and Impact Properties of Thermoplastic Cassava Starch/Palm Wax Composites. Polymers 2023, 15, 2364. https://doi.org/10.3390/polym15102364

Kamaruddin ZH, Jumaidin R, Kamaruddin ZH, Asyraf MRM, Razman MR, Khan T. Effect of Cymbopogan citratus Fibre on Physical and Impact Properties of Thermoplastic Cassava Starch/Palm Wax Composites. Polymers. 2023; 15(10):2364. https://doi.org/10.3390/polym15102364

Chicago/Turabian StyleKamaruddin, Zatil Hafila, Ridhwan Jumaidin, Zatil Hazrati Kamaruddin, Muhammad Rizal Muhammad Asyraf, Muhammad Rizal Razman, and Tabrej Khan. 2023. "Effect of Cymbopogan citratus Fibre on Physical and Impact Properties of Thermoplastic Cassava Starch/Palm Wax Composites" Polymers 15, no. 10: 2364. https://doi.org/10.3390/polym15102364

APA StyleKamaruddin, Z. H., Jumaidin, R., Kamaruddin, Z. H., Asyraf, M. R. M., Razman, M. R., & Khan, T. (2023). Effect of Cymbopogan citratus Fibre on Physical and Impact Properties of Thermoplastic Cassava Starch/Palm Wax Composites. Polymers, 15(10), 2364. https://doi.org/10.3390/polym15102364