The Effects of Cross-Linking Agents on the Mechanical Properties of Poly (Methyl Methacrylate) Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Flexural Strength Test

2.3. Impact Strength Test

2.4. Surface Hardness Test

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prajwala, N.; Kumar, C.R.; Sujesh, M.; Rao, D.C.; Pavani, L. Denture base reinforcing materials-A review. IP Ann. Prosthodont. Restor. Dent. 2020, 6, 52–59. [Google Scholar] [CrossRef]

- Elshereksi, N.W.; Kundie, F.A.; Muchtar, A.; Azhari, C.H. Protocols of improvements for PMMA denture base resin: An overview. J. Met. Mater. Miner. 2022, 32, 1–11. [Google Scholar] [CrossRef]

- Somani, M.V.; Khandelwal, M.; Punia, V.; Sharma, V. The effect of incorporating various reinforcement materials on flexural strength and impact strength of polymethylmethacrylate: A meta-analysis. J. Indian Prosthodont. Soc. 2019, 19, 101–112. [Google Scholar] [CrossRef]

- Ranganathan, A.; Karthigeyan, S.; Chellapillai, R.; Rajendran, V.; Balavadivel, T.; Velayudhan, A. Effect of novel cycloaliphatic comonomer on the flexural and impact strength of heat-cure denture base resin. J. Oral Sci. 2021, 63, 14–17. [Google Scholar] [CrossRef] [PubMed]

- Agha, H.; Flinton, R.; Vaidyanathan, T. Optimization of Fracture Resistance and Stiffness of Heat-Polymerized High Impact Acrylic Resin with Localized E-Glass FIBER FORCE® Reinforcement at Different Stress Points. J. Prosthodont. 2016, 25, 647–655. [Google Scholar] [CrossRef]

- Jagger, D.; Harrison, A.; Vowles, R.; Jagger, R. The effect of the addition of surface treated chopped and continuous poly (methyl methacrylate) fibres on some properties of acrylic resin. J. Oral Rehabil. 2001, 28, 865–872. [Google Scholar] [CrossRef]

- Murthy, H.B.; Shaik, S.; Sachdeva, H.; Khare, S.; Haralur, S.B.; Roopa, K.T. Effect of Reinforcement Using Stainless Steel Mesh, Glass Fibers, and Polyethylene on the Impact Strength of Heat Cure Denture Base Resin—An In Vitro Study. J. Int. Oral Health 2015, 7, 71–79. [Google Scholar]

- Phoenix, R.D.; Mansueto, M.A.; Ackerman, N.A.; Jones, R.E. Evaluation of mechanical and thermal properties of commonly used denture base resins. J. Prosthodont. 2004, 13, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Arima, T.; Murata, H.; Hamad, T. The effects of cross-linking agents on the water sorption and solubility characteristics of denture base resin. J. Oral Rehabil. 1996, 23, 476–480. [Google Scholar] [CrossRef]

- Ajay, R.; Suma, K.; Ali, S.A. Monomer Modifications of Denture Base Acrylic Resin: A Systematic Review and Meta-analysis. J. Pharm. Bioallied Sci. 2019, 11, 112–125. [Google Scholar] [CrossRef]

- Ajay, R.; Suma, K.; JayaKrishnaKumar, S.; Rajkumar, G.; Kumar, S.A.; Geethakumari, R. Chemical characterization of denture base resin with a novel cycloaliphatic monomer. J. Contemp. Dent. Pract. 2019, 20, 940–946. [Google Scholar]

- Cunha, T.R.; Regis, R.R.; Bonatti, M.R.; Souza, R.F.D. Influence of incorporation of fluoroalkyl methacrylates on roughness and flexural strength of a denture base acrylic resin. J. Appl. Oral Sci. 2009, 17, 103–107. [Google Scholar] [CrossRef]

- Alhareb, A.O.; Akil, H.M.; Ahmad, Z.A. Effect of nitrile butadiene rubber/Al2O3/YSZ fillers for PMMA denture base on the thermal and mechanical properties. J. Therm. Anal. Calorim. 2018, 134, 941–951. [Google Scholar] [CrossRef]

- Caycik, S.; Jagger, R.G. The effect of cross-linking chain length on mechanical properties of a dough-molded poly(methylmethacrylate) resin. Dent. Mater. 1992, 8, 153–157. [Google Scholar] [CrossRef] [PubMed]

- Aldegheishem, A.; AlDeeb, M.; Al-Ahdal, K.; Helmi, M.; Alsagob, E.I. Influence of Reinforcing Agents on the Mechanical Properties of Denture Base Resin: A Systematic Review. Polymers 2021, 13, 3083. [Google Scholar] [CrossRef] [PubMed]

- Jagger, R.G.; Huggett, R. Effect of cross-linking on sorption properties of a denture-base material. Dent. Mater. 1990, 6, 276–278. [Google Scholar] [CrossRef]

- Mabilleau, G.; Stancu, I.; Honore, T.; Legeay, G.; Cincu, C.; Basle, M.; Chappard, D. Effects of the length of crosslink chain on poly (2-hydroxyethyl methacrylate) (pHEMA) swelling and biomechanical properties. J. Biomed. Mater. Res. A 2006, 77, 35–42. [Google Scholar] [CrossRef]

- Prpić, V.; Schauperl, Z.; Ćatić, A.; Dulčić, N.; Čimić, S. Comparison of Mechanical Properties of 3D-Printed, CAD/CAM, and Conventional Denture Base Materials. J. Prosthodont. 2020, 29, 524–528. [Google Scholar] [CrossRef]

- Janeva, N.M.; Kovacevska, G.; Elencevski, S.; Panchevska, S.; Mijoska, A.; Lazarevska, B. Advantages of CAD/CAM versus conventional complete dentures-a review. Open Access Maced. J. Med. Sci. 2018, 6, 1498–1502. [Google Scholar] [CrossRef]

- ISO 1567:1999; Dentistry-Denture Base Polymers. International Organization for Standardization: Geneva, Switzerland, 2003.

- BS 2487; British Standart Spesification for Denture Base Polymers. British Standards Institution: London, UK, 1989.

- BS 6747; British Standard Spesification for Orthodontic Resins. British Standards Institution: London, UK, 1987.

- Zafar, M.S. Prosthodontic applications of polymethyl methacrylate (PMMA): An update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Fareed, M.A.; Alshehri, A.H.; Aldegheishem, A.; Alharthi, R.; Saadaldin, S.A.; Zafar, M.S. Mechanical Properties of the Modified Denture Base Materials and Polymerization Methods: A Systematic Review. Int. J. Mol. Sci. 2022, 23, 5737. [Google Scholar] [CrossRef] [PubMed]

- Vallittu, P.K. A review of methods used to reinforce polymethyl methacrylate resin. J. Prosthodont. 1995, 4, 183–187. [Google Scholar] [CrossRef]

- Podgórski, M. Synthesis and characterization of novel dimethacrylates of different chain lengths as possible dental resins. Dent. Mater. 2010, 26, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Puska, M.A.; Närhi, T.O.; Aho, A.J.; Yli-Urpo, A.; Vallittu, P.K. Flexural properties of crosslinked and oligomer-modified glass-fibre reinforced acrylic bone cement. J. Mater. Sci. Mater. Med. 2004, 15, 1037–1043. [Google Scholar] [CrossRef]

- Faot, F.; Panza, L.H.; Garcia, R.C.R.; Cury, A.A.D.B. Impact and flexural strength, and fracture morphology of acrylic resins with impact modifiers. Open Dent. J. 2009, 3, 137–143. [Google Scholar] [CrossRef] [PubMed]

- Kostić, M.; Igić, M.; Gligorijević, N.; Nikolić, V.; Stošić, N.; Nikolić, L. The Use of Acrylate Polymers in Dentistry. Polymers 2022, 14, 4511. [Google Scholar] [CrossRef] [PubMed]

- Teraoka, F.; Nakagawa, M.; Takahashi, J. Adaptation of acrylic dentures reinforced with metal wire. J. Oral Rehabil. 2001, 28, 937–942. [Google Scholar] [CrossRef]

- Al-Thobity, A.M. The impact of polymerization technique and glass-fiber reinforcement on the flexural properties of denture base resin material. Eur. J. Dent. 2020, 14, 92–99. [Google Scholar] [CrossRef]

- Machado, A.L.; Puckett, A.D.; Breeding, L.C.; Wady, A.F.; Vergani, C.E. Effect of thermocycling on the flexural and impact strength of urethane-based and high-impact denture base resins. Gerodontology 2012, 29, 318–323. [Google Scholar] [CrossRef] [PubMed]

- Zappini, G.; Kammann, A.; Wachter, W. Comparison of fracture tests of denture base materials. J. Prosthet. Dent. 2003, 90, 578–585. [Google Scholar] [CrossRef] [PubMed]

- Memon, M.S.; Yunus, N.; Razak, A.A.A.; Memon, M.; Yunus, N.; Razak, A. Some mechanical properties of a highly cross-linked, microwave-polymerized, injection-molded denture base polymer. Int. J. Prosthodont. 2001, 14, 214–218. [Google Scholar]

- Straioto, F.G.; Ricomini Filho, A.P.; Fernandes Neto, A.J.; Del Bel Cury, A.A. Polytetrafluorethylene added to acrylic resins: Mechanical properties. Braz. Dent. J. 2010, 21, 55–59. [Google Scholar] [CrossRef]

- Apimanchindakul, C.; Na Nan, P.; Aimjirakul, N. Effect of Reinforced Self-Cured Acrylic Resin on Flexural Strength. Int. J. Dent. 2022, 2022, 2698995. [Google Scholar] [CrossRef] [PubMed]

- Consani, R.L.; de Paula, A.B.; Fugolin, A.P.P.; Pfeifer, C.S. Effect of the combination of a crosslinking agent and a thiourethane additive on the properties of acrylic denture bases processed with microwave energy. J. Mech. Behav. Biomed. Mater. 2019, 98, 90–95. [Google Scholar] [CrossRef]

- Arima, T.; Murata, H.; Hamada, T. Properties of highly cross-linked autopolymerizing reline acrylic resins. J. Prosthet. Dent. 1995, 73, 55–59. [Google Scholar] [CrossRef]

- Farina, A.P.; Cecchin, D.; Soares, R.G.; Botelho, A.L.; Takahashi, J.M.F.K.; Mazzetto, M.O.; Mesquita, M.F. Evaluation of Vickers hardness of different types of acrylic denture base resins with and without glass fibre reinforcement. Gerodontology 2012, 29, 155–160. [Google Scholar] [CrossRef]

- Fouda, S.M.; Gad, M.M.; Ellakany, P.; Al Ghamdi, M.A.; Khan, S.Q.; Akhtar, S.; Ali, M.S.; Al-Harbi, F.A. Flexural properties, impact strength, and hardness of nanodiamond-modified PMMA denture base resin. Int. J. Biomater. 2022, 2022, 6583084. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, C.E.L.; Canevarolo, S.V.; Reis, J.M.; Machado, A.L.; Pavarina, A.C.; Giampaolo, E.T.; Vergani, C.E. Effect of microwave irradiation and water storage on the viscoelastic properties of denture base and reline acrylic resins. J. Mech. Behav. Biomed. Mater. 2012, 5, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Keul, C.; Seidl, J.; Güth, J.F.; Liebermann, A. Impact of fabrication procedures on residual monomer elution of conventional polymethyl methacrylate (PMMA)—A measurement approach by UV/Vis spectrophotometry. Clin. Oral Investig. 2020, 24, 4519–4530. [Google Scholar] [CrossRef]

- Ayman, A.D. The residual monomer content and mechanical properties of CAD\CAM resins used in the fabrication of complete dentures as compared to heat cured resins. Electron. Phys. 2017, 9, 4766–4772. [Google Scholar] [CrossRef] [PubMed]

- Vojdani, M.; Giti, R. Polyamide as a denture base material: A literature review. J. Dent. 2015, 16, 1–9. [Google Scholar]

- Pacqueti, W.; Benoit, A.; Hatège-Kimana, C.; Wulfman, C. Mechanical properties of CAD/CAM denture base resins. Int. J. Prosthodont. 2019, 32, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Murakami, N.; Wakabayashi, N.; Matsushima, R.; Kishida, A.; Igarashi, Y. Effect of high-pressure polymerization on mechanical properties of PMMA denture base resin. J. Mech. Behav. Biomed. Mater. 2013, 20, 98–104. [Google Scholar] [CrossRef] [PubMed]

| Name | Manufacturer | Abbreviation | Batch Number | Chemical Property | Molecular Weight (g/mol) |

|---|---|---|---|---|---|

| Meliodent | Heraeus Kulzer, Hanau, Germany | M | 012294 | Heat Cure Acrylic Resin | 198.22 g/mol−1 |

| Methylmethacrylate | Sigma-Aldrich, Steinheim | MMA | 55909 | Monomer | 100.12 g/mol−1 |

| Ethylene glycol dimethacrylate | Merck, Darmstadt, Germany | EGDMA | 818847/0250 | Cross-linking Agent | 198.22 g/mol−1 |

| Tetraethylene glycol diacrylate | Sigma-Aldrich, Steinheim | TEGDA | 398802 | Cross-linking Agent | 302.32 g/mol−1 |

| Tetraethylene glycol dimethacrylate | Sigma-Aldrich, (Fluka) Steinheim | TEGDMA | 86680 | Cross-linking Agent | 330.37 g/mol−1 |

| Polyethylene glycol dimethacrylate | Sigma-Aldrich, Steinheim | PEGDMA | 409510 | Cross-linking Agent | 550 g/mol−1 |

| n | Min | Max | Mean ± SD | p | |

|---|---|---|---|---|---|

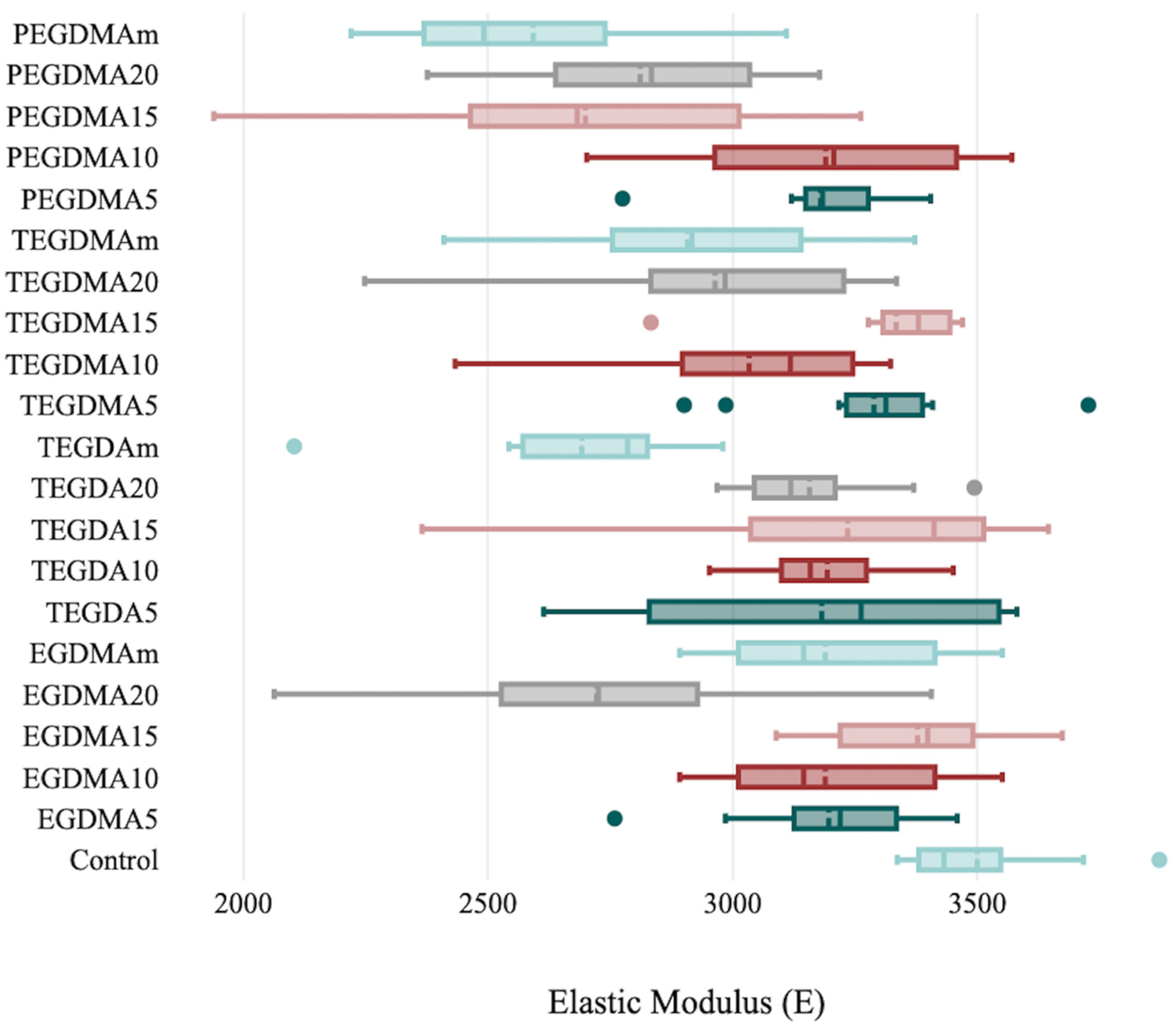

| Elastic Modulus | 210 | 1939.50 | 3726.82 | 3071.88 ± 356.66 | 0.034 |

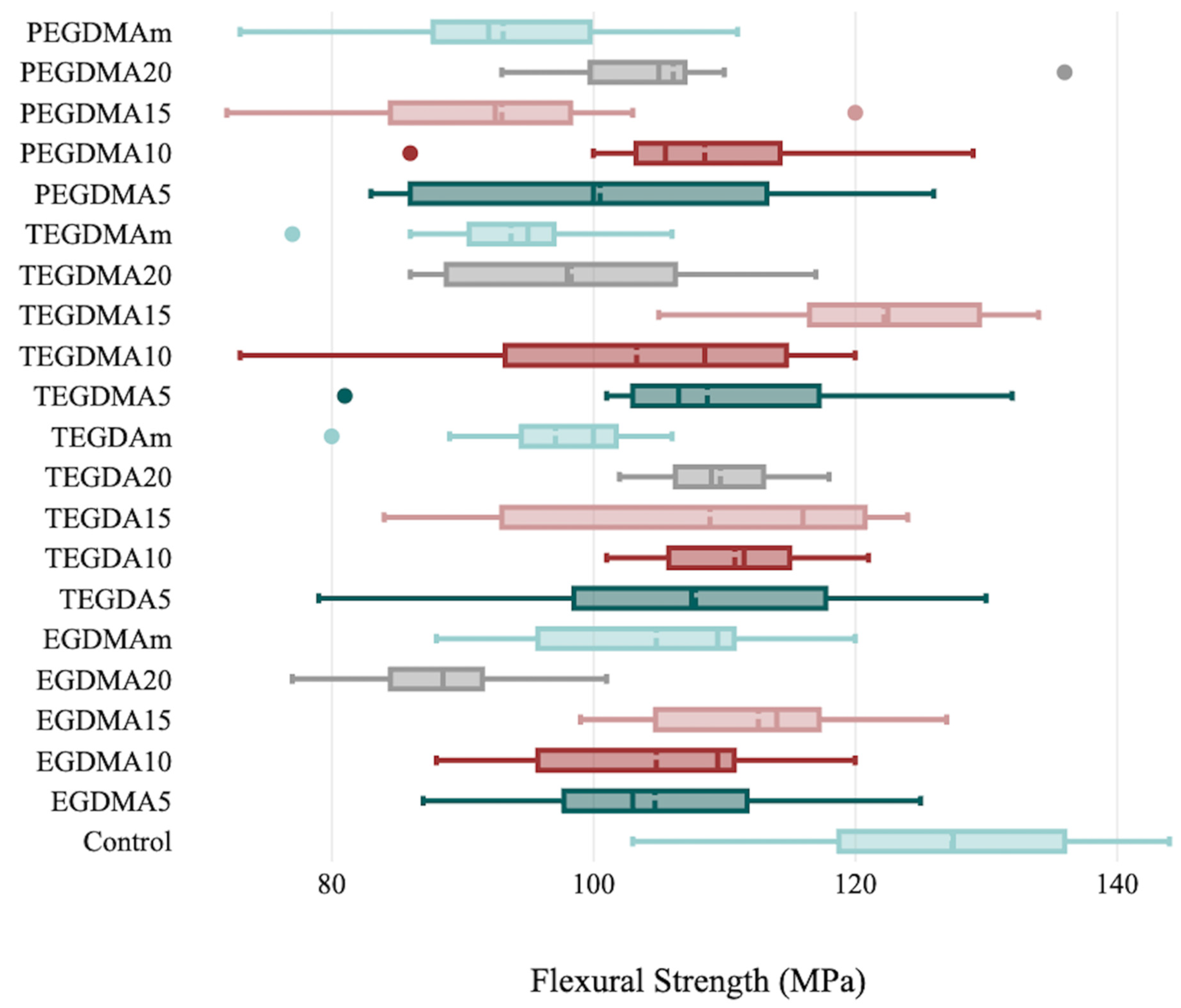

| Flexural Strength | 210 | 71.60 | 135.86 | 104.51 ± 13.76 | 0.734 |

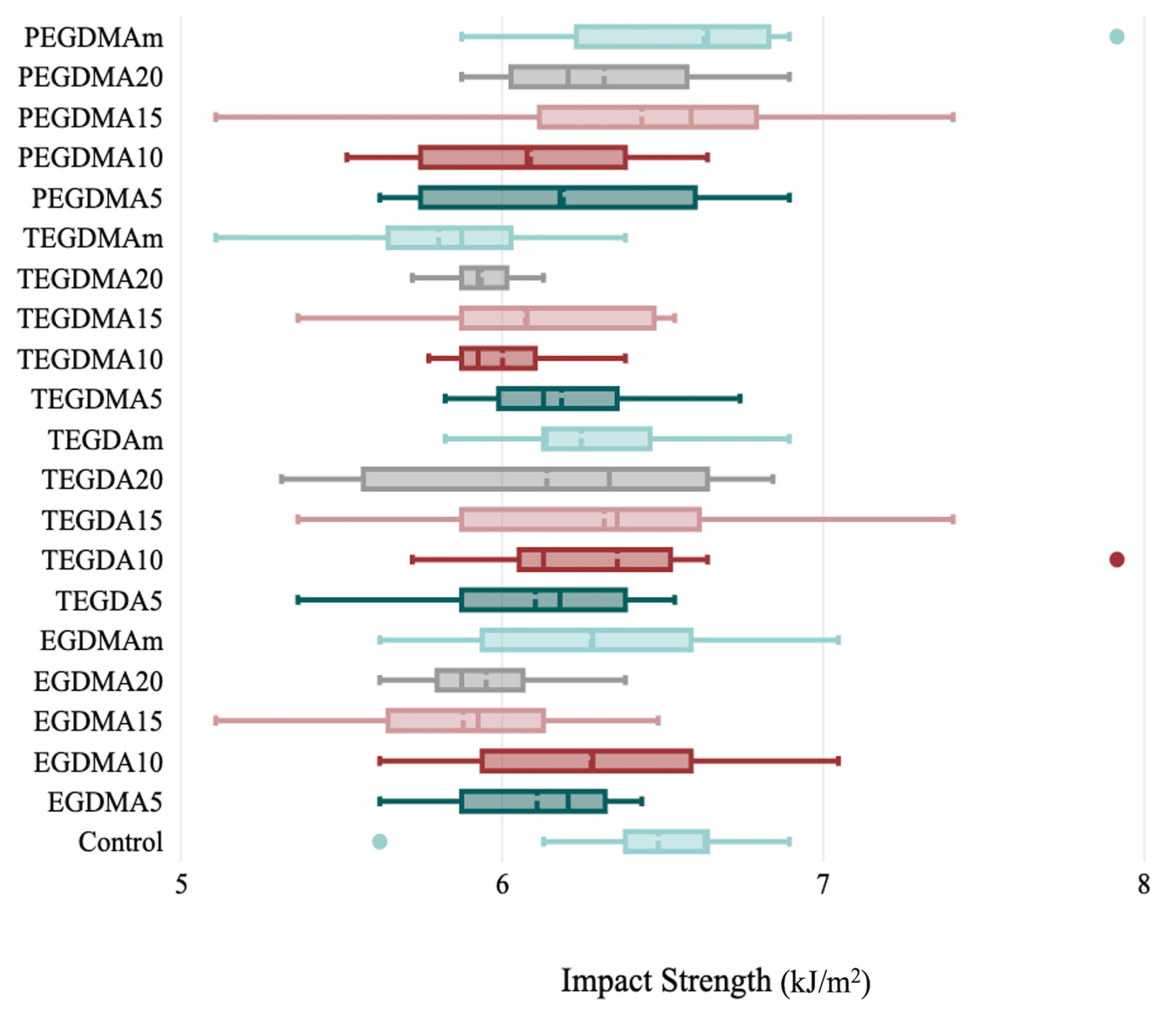

| Impact Strength | 210 | 5.11 | 7.92 | 6.18 ± 0.46 | 0.024 |

| Surface Hardness | 210 | 13.00 | 21.20 | 16.59 ± 1.54 | 0.718 |

| Elastic Modulus * | Flexural Strength ** | Impact Strength * | Surface Hardness ** | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Groups | % | Mean ± SD | χ2 | p a | Mean ± SD | F | p a | Mean ± SD | χ2 | p a | Mean ± SD | F | p a |

| M | 3374.13 ± 108.370 | 117.89 ± 6.680 | 6.49 ± 0.384 | 17.83 ± 0.800 | |||||||||

| 5 | 3196.41 ± 209.310 | 18.392 | 0.001 | 104.62 ± 11.654 | 7.187 | 0.0001 | 6.11 ± 0.279 | 7.770 | 0.100 | 17.45 ± 0.536 | 1.728 | 0.161 | |

| 10 | 3189.32 ± 240.757 | 104.72 ± 11.576 | 6.28 ± 0.438 | 17.00 ± 0.741 | |||||||||

| EGDMA | 15 | 3378.06 ± 195.915 | 112.48 ± 8.941 | 5.88 ± 0.383 | 16.97 ± 0.657 | ||||||||

| 20 | 2721.90 ± 368.983 | 88.51 ± 7.252 | 5.95 ± 0.231 | 16.63 ± 0.801 | |||||||||

| m10 | 3189.32 ± 240.757 | 104.72 ± 11.576 | 6.28 ± 0.438 | 17.00 ± 0.741 | |||||||||

| 5 | 3182.07 ± 388.092 | 16.487 | 0.002 | 107.71 ± 15.885 | 2.371 | 0.067 | 6.10 ± 0.357 | 0.880 | 0.927 | 17.20 ± 0.845 | 2.838 | 0.035 | |

| 10 | 3193.30 ± 155.631 | 110.80 ± 6.147 | 6.36 ± 0.621 | 16.01 ± 1.260 | |||||||||

| TEGDMA | 15 | 3235.03 ± 439.363 | 109.07 ± 16.483 | 6.32 ± 0.594 | 16.52 ± 1.463 | ||||||||

| 20 | 3157.30 ± 167.349 | 109.62 ± 5.575 | 6.14 ± 0.606 | 15.70 ± 0.979 | |||||||||

| m10 | 2691.71 ± 251.567 | 97.09 ± 7.857 | 6.25 ± 0.321 | 15.83 ± 1.122 | |||||||||

| 5 | 3288.76 ± 228.717 | 19.024 | 0.001 | 108.84 ± 13.554 | 8.823 | 0.0001 | 6.18 ± 0.289 | 7.186 | 0.126 | 17.34 ± 1.195 | 0.207 | 0.933 | |

| 10 | 3033.73 ± 285.522 | 103.33 ± 15.640 | 6.00 ± 0.193 | 17.41 ± 2.415 | |||||||||

| TEGDA | 15 | 3334.06 ± 188.939 | 122.26 ± 9.051 | 6.07 ± 0.426 | 17.76 ± 1.985 | ||||||||

| 20 | 2963.93 ± 330.215 | 98.18 ± 10.767 | 5.93 ± 0.112 | 17.95 ± 1.156 | |||||||||

| m10 | 2908.15 ± 329.223 | 93.67 ± 8.250 | 5.80 ± 0.373 | 17.54 ± 1.706 | |||||||||

| 5 | 3179.54 ± 167.796 | 23.025 | 0.0001 | 100.58 ± 15.162 | 3.043 | 0.027 | 6.19 ± 0.467 | 6.462 | 0.167 | 16.22 ± 0.637 | 4.090 | 0.007 | |

| 10 | 3190.05 ± 310.729 | 108.53 ± 12.864 | 6.09 ± 0.414 | 15.30 ± 1.434 | |||||||||

| PEGDMA | 15 | 2699.19 ± 412.407 | 92.86 ± 13.064 | 6.44 ± 0.663 | 15.47 ± 0.930 | ||||||||

| 20 | 2811.04 ± 269.901 | 106.10 ± 11.731 | 6.32 ± 0.375 | 14.73 ± 1.384 | |||||||||

| m10 | 2592.52 ± 299.765 | 93.06 ± 12.481 | 6.63 ± 0.566 | 14.43 ± 0.814 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceylan, G.; Emik, S.; Yalcinyuva, T.; Sunbuloğlu, E.; Bozdag, E.; Unalan, F. The Effects of Cross-Linking Agents on the Mechanical Properties of Poly (Methyl Methacrylate) Resin. Polymers 2023, 15, 2387. https://doi.org/10.3390/polym15102387

Ceylan G, Emik S, Yalcinyuva T, Sunbuloğlu E, Bozdag E, Unalan F. The Effects of Cross-Linking Agents on the Mechanical Properties of Poly (Methyl Methacrylate) Resin. Polymers. 2023; 15(10):2387. https://doi.org/10.3390/polym15102387

Chicago/Turabian StyleCeylan, Gulsum, Serkan Emik, Tuncer Yalcinyuva, Emin Sunbuloğlu, Ergun Bozdag, and Fatma Unalan. 2023. "The Effects of Cross-Linking Agents on the Mechanical Properties of Poly (Methyl Methacrylate) Resin" Polymers 15, no. 10: 2387. https://doi.org/10.3390/polym15102387

APA StyleCeylan, G., Emik, S., Yalcinyuva, T., Sunbuloğlu, E., Bozdag, E., & Unalan, F. (2023). The Effects of Cross-Linking Agents on the Mechanical Properties of Poly (Methyl Methacrylate) Resin. Polymers, 15(10), 2387. https://doi.org/10.3390/polym15102387