Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Development of the Composite Material

2.2. Fabrication Method

2.2.1. Casting

2.2.2. Additive Manufacturing

2.3. Morphology Characterization

2.4. Mechano-Electrical Characterization

2.5. Sensor Device to Demonstrate Human Interactive Wearable Application

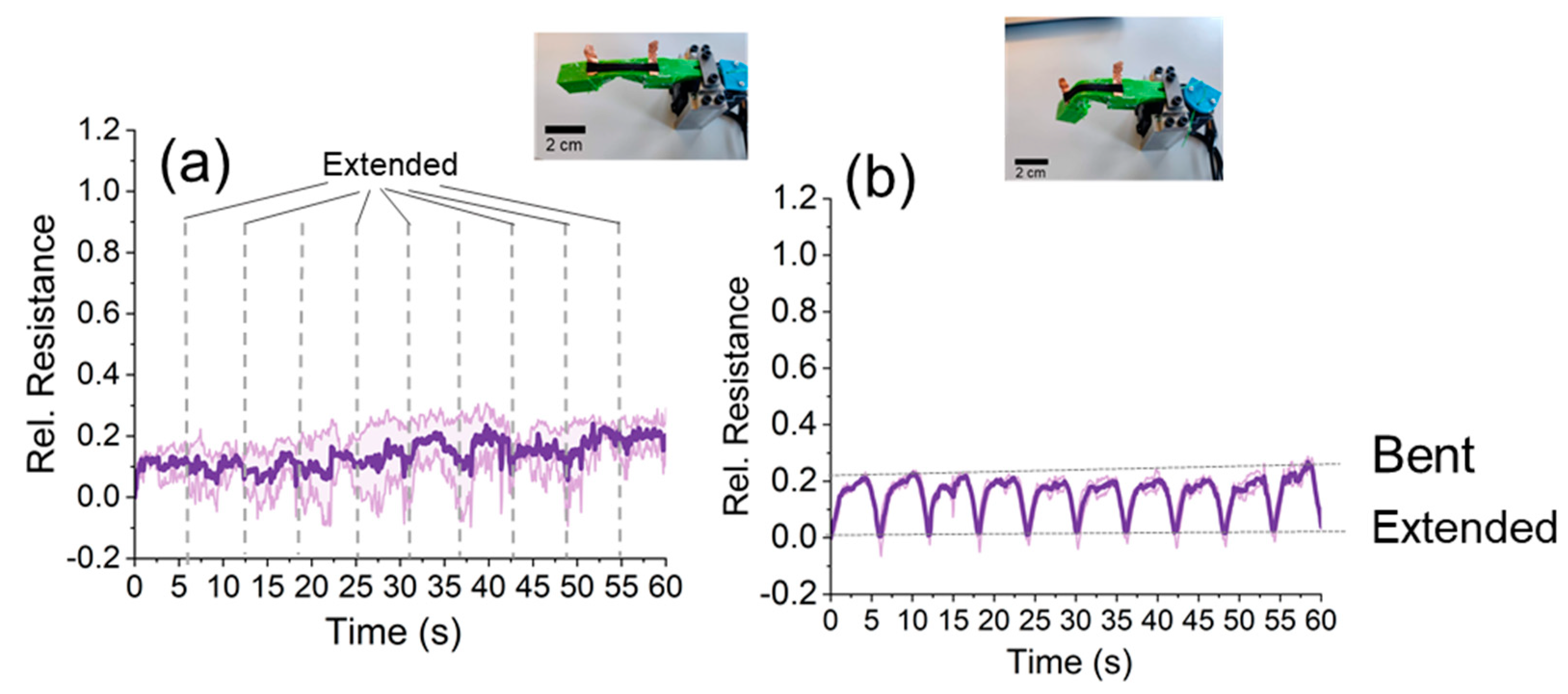

2.6. Soft Robotic Finger Demonstrator

3. Results

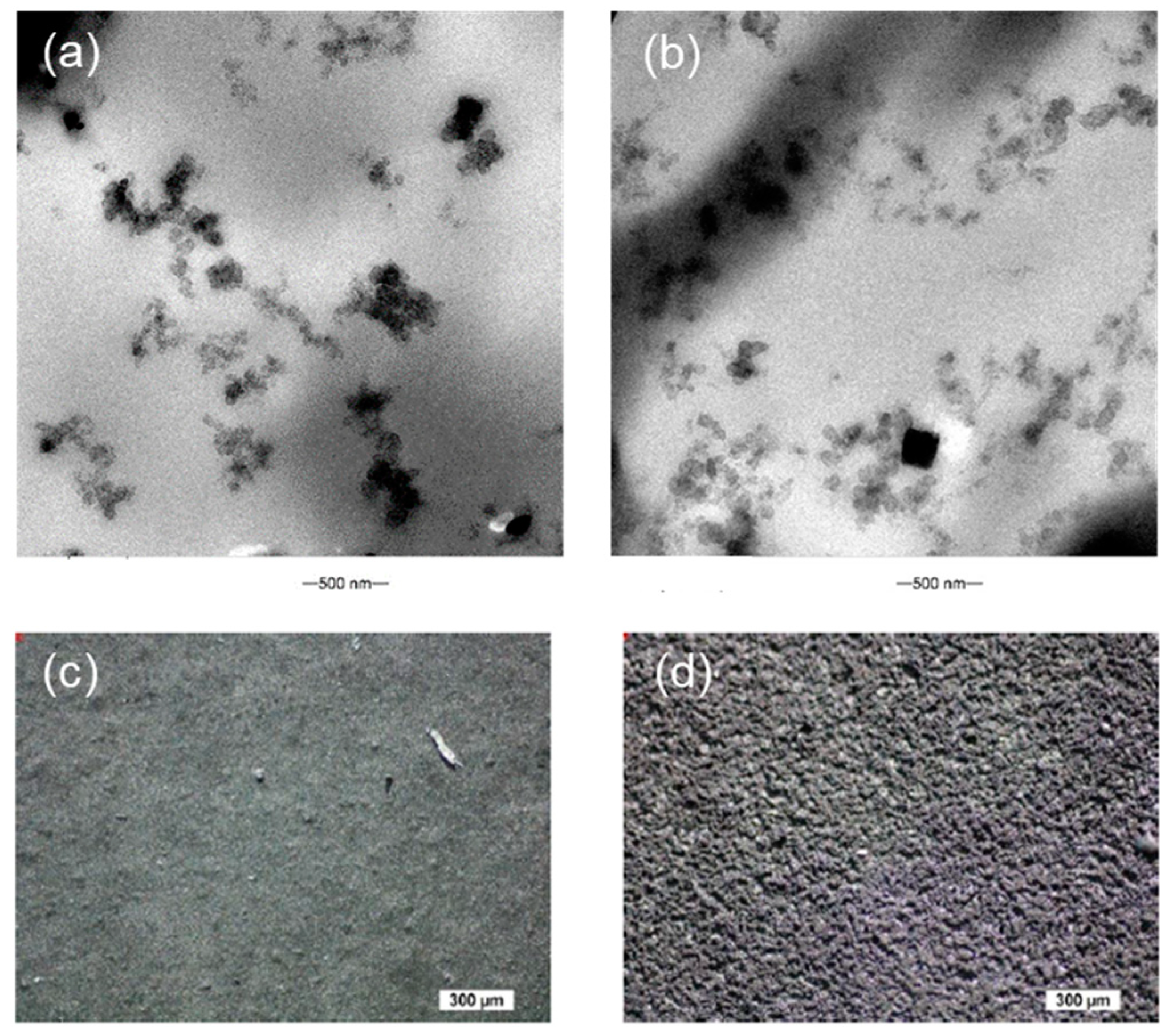

3.1. Micrographs of Conductive Networks

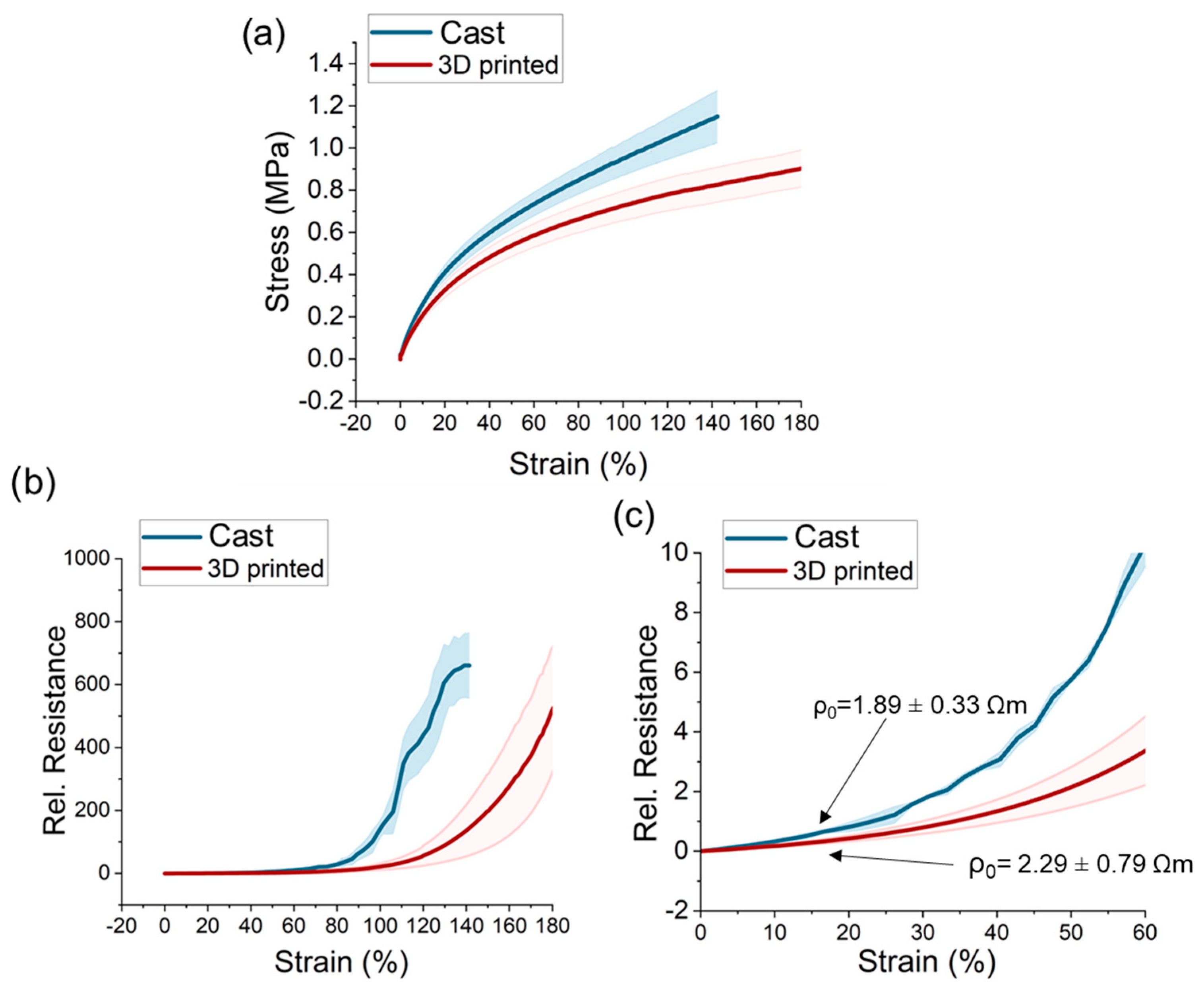

3.2. Tensile Test to the Point of Fracture

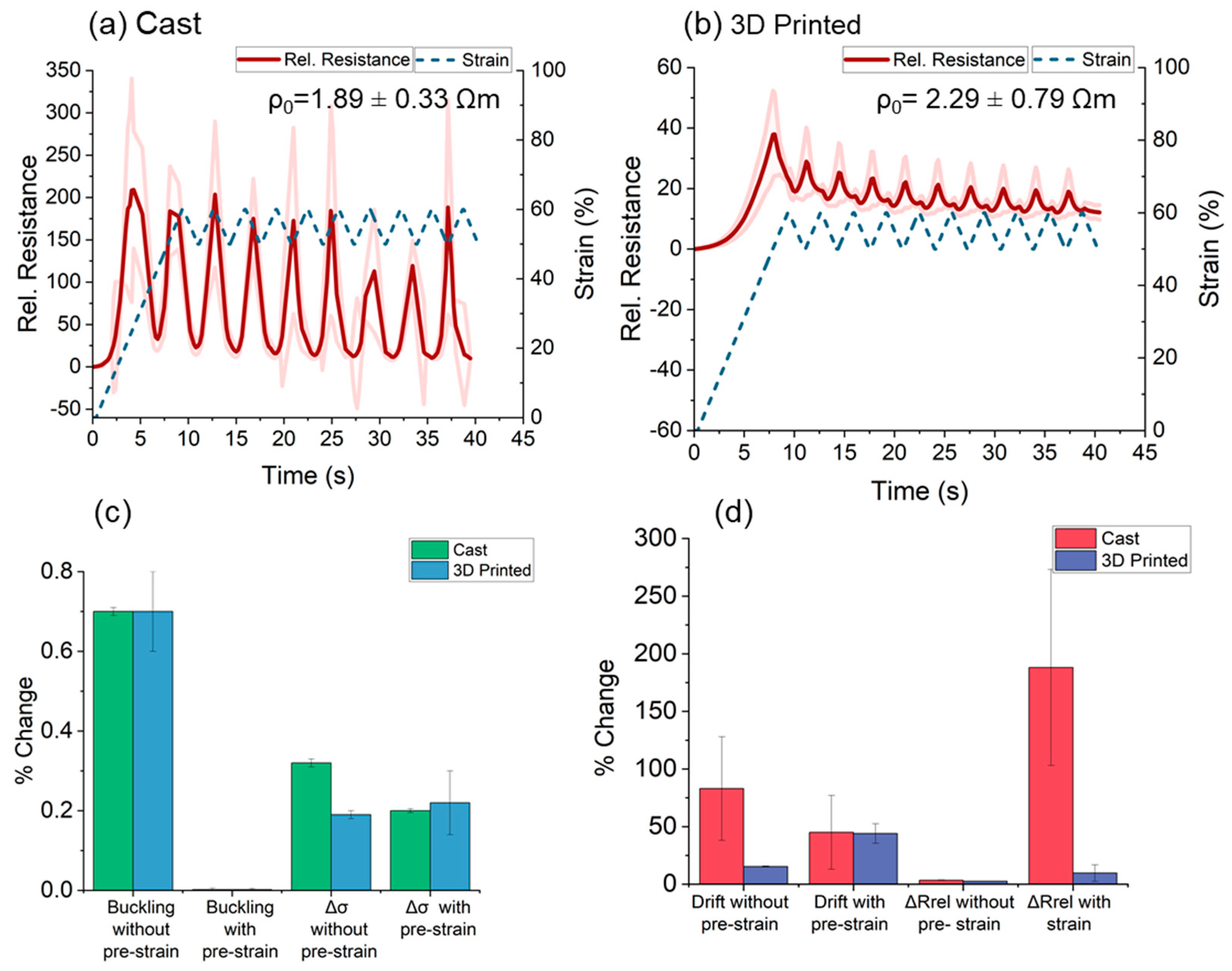

3.3. Dynamic Tensile Testing

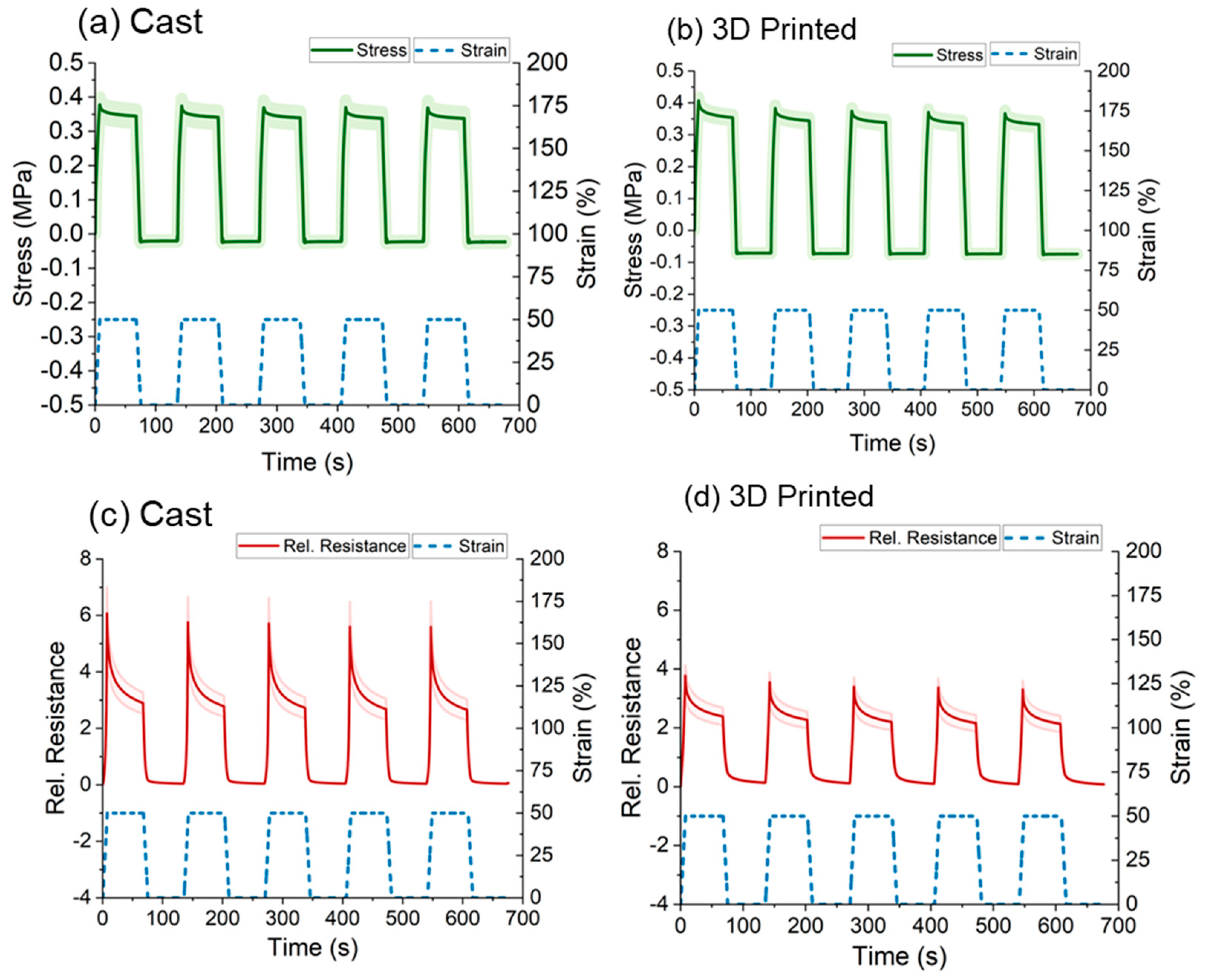

3.4. Quasi-Static Testing

3.5. Application: Wearable Device to Monitor Finger Motion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Afsarimanesh, N.; Nag, A.; Sarkar, S.; Sabet, G.S.; Han, T.; Mukhopadhyay, S.C. A Review on Fabrication, Characterization and Implementation of Wearable Strain Sensors. Sens. Actuators A Phys. 2020, 315, 112355. [Google Scholar] [CrossRef]

- Yu, M.; Yu, G.; Dai, B. Graphene Fiber-Based Strain-Insensitive Wearable Temperature Sensor. IEEE Sens. Lett. 2020, 4, 2501304. [Google Scholar] [CrossRef]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef] [PubMed]

- Melnykowycz, M.; Tschudin, M.; Clemens, F. Piezoresistive Soft Condensed Matter Sensor for Body-Mounted Vital Function Applications. Sensors 2016, 16, 326. [Google Scholar] [CrossRef] [PubMed]

- Georgopoulou, A.; Clemens, F. Piezoresistive Elastomer-Based Composite Strain Sensors and Their Applications. ACS Appl. Electron. Mater. 2020, 2, 1826–1842. [Google Scholar] [CrossRef]

- Khoshmanesh, F.; Thurgood, P.; Pirogova, E.; Nahavandi, S.; Baratchi, S. Wearable Sensors: At the Frontier of Personalised Health Monitoring, Smart Prosthetics and Assistive Technologies. Biosens. Bioelectron. 2021, 176, 112946. [Google Scholar] [CrossRef]

- Rao, Z.; Ershad, F.; Almasri, A.; Gonzalez, L.; Wu, X.; Yu, C. Soft Electronics for the Skin: From Health Monitors to Human–Machine Interfaces. Adv. Mater. Technol. 2020, 5, 2000233. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and Highly Sensitive Graphene Strain Sensors for Human Motion Monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Liao, M.; Wan, P.; Wen, J.; Gong, M.; Wu, X.; Wang, Y.; Shi, R.; Zhang, L. Wearable, Healable, and Adhesive Epidermal Sensors Assembled from Mussel-Inspired Conductive Hybrid Hydrogel Framework. Adv. Funct. Mater. 2017, 27, 1703852. [Google Scholar] [CrossRef]

- Lu, Y.; Biswas, M.C.; Guo, Z.; Jeon, J.-W.; Wujcik, E.K. Recent Developments in Bio-Monitoring via Advanced Polymer Nanocomposite-Based Wearable Strain Sensors. Biosens. Bioelectron. 2019, 123, 167–177. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, T.; Wang, J.; Zheng, Z.; Li, Y.; Li, J.; Lai, Y. Functionalized Fiber-Based Strain Sensors: Pathway to Next-Generation Wearable Electronics. Nano-Micro Lett. 2022, 14, 61. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, P.; Zhang, D.; Lin, H.; Chen, Y. Wearable Resistive-Type Sensors Based on Graphene Fibers for Monitoring Human Motions. ACS Appl. Nano Mater. 2022, 5, 10912–10921. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, Y.; Qiao, M.; Ai, L.; Sun, K.; Mi, Q.; Zang, S.; Zuo, Y.; Yuan, X.; Wang, Q. Human Motion Monitoring in Sports Using Wearable Graphene-Coated Fiber Sensors. Sens. Actuators A Phys. 2018, 274, 132–140. [Google Scholar] [CrossRef]

- He, Z.; Wang, K.; Zhao, Z.; Zhang, T.; Li, Y.; Wang, L. A Wearable Flexible Acceleration Sensor for Monitoring Human Motion. Biosensors 2022, 12, 620. [Google Scholar] [CrossRef]

- Liu, W.; Long, Z.; Yang, G.; Xing, L. A Self-Powered Wearable Motion Sensor for Monitoring Volleyball Skill and Building Big Sports Data. Biosensors 2022, 12, 60. [Google Scholar] [CrossRef]

- Hughes, J.; Iida, F. Multi-Functional Soft Strain Sensors for Wearable Physiological Monitoring. Sensors 2018, 18, 3822. [Google Scholar] [CrossRef]

- Yang, J.; Li, Q.; Wang, X.; Di, P.; Ding, H.; Bai, Y.; Dong, W.; Zhu, S. Smart Wearable Monitoring System Based on Multi-Type Sensors for Motion Recognition. Smart Mater. Struct. 2021, 30, 035017. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Kwak, Y.H.; Kim, W.; Park, K.B.; Kim, K.; Seo, S. Flexible Heartbeat Sensor for Wearable Device. Biosens. Bioelectron. 2017, 94, 250–255. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Brancart, J.; Terryn, S.; Bosman, A.W.; Norvez, S.; Van Assche, G.; Iida, F.; Vanderborght, B.; Clemens, F. Soft Self-Healing Resistive-Based Sensors Inspired by Sensory Transduction in Biological Systems. Appl. Mater. Today 2022, 29, 101638. [Google Scholar] [CrossRef]

- Devaraj, H.; Yellapantula, K.; Stratta, M.; McDaid, A.; Aw, K. Embedded Piezoresistive Pressure Sensitive Pillars from Piezoresistive Carbon Black Composites towards a Soft Large-Strain Compressive Load Sensor. Sens. Actuator A-Phys. 2019, 285, 645–651. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, F.; Zhao, X.; Liu, M. High-Performance Strain Sensors Based on Spirally Structured Composites with Carbon Black, Chitin Nanocrystals, and Natural Rubber. ACS Sustain. Chem. Eng. 2018, 6, 10595–10605. [Google Scholar] [CrossRef]

- Sencadas, V.; Mutiu, R.; Alici, G. Large Area and Ultra-Thin Compliant Strain Sensors for Prosthetic Devices. Sens. Actuator A-Phys. 2017, 266, 56–64. [Google Scholar] [CrossRef]

- Wang, L.; Ding, T.; Wang, P. Research on Stress and Electrical Resistance of Skin-Sensing Silicone Rubber/Carbon Black Nanocomposite during Decompressive Stress Relaxation. Smart Mater. Struct. 2009, 18, 065002. [Google Scholar] [CrossRef]

- Tang, Z.; Jia, S.; Shi, X.; Li, B.; Zhou, C. Coaxial Printing of Silicone Elastomer Composite Fibers for Stretchable and Wearable Piezoresistive Sensors. Polymers 2019, 11, 666. [Google Scholar] [CrossRef] [PubMed]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D Printed Highly Elastic Strain Sensors of Multiwalled Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Michel, S.; Vanderborght, B.; Clemens, F. Piezoresistive Sensor Fiber Composites Based on Silicone Elastomers for the Monitoring of the Position of a Robot Arm. Sens. Actuators A Phys. 2021, 318, 112433. [Google Scholar] [CrossRef]

- Turgut, A.; Tuhin, M.O.; Toprakci, O.; Pasquinelli, M.A.; Spontak, R.J.; Toprakci, H.A.K. Thermoplastic Elastomer Systems Containing Carbon Nanofibers as Soft Piezoresistive Sensors. ACS Omega 2018, 3, 12648–12657. [Google Scholar] [CrossRef]

- Sarkar, P.; Bhowmick, A.K. Sustainable Rubbers and Rubber Additives. J. Appl. Polym. Sci. 2018, 135, 45701. [Google Scholar] [CrossRef]

- Chen, X.; An, J.; Cai, G.; Zhang, J.; Chen, W.; Dong, X.; Zhu, L.; Tang, B.; Wang, J.; Wang, X. Environmentally Friendly Flexible Strain Sensor from Waste Cotton Fabrics and Natural Rubber Latex. Polymers 2019, 11, 404. [Google Scholar] [CrossRef]

- Khabbaz, F.; Albertsson, A.-C. Great Advantages in Using a Natural Rubber Instead of a Synthetic SBR in a Pro-Oxidant System for Degradable LDPE. Biomacromolecules 2000, 1, 665–673. [Google Scholar] [CrossRef] [PubMed]

- Selvan, N.T.; Eshwaran, S.B.; Das, A.; Stöckelhuber, K.W.; Wießner, S.; Pötschke, P.; Nando, G.B.; Chervanyov, A.I.; Heinrich, G. Piezoresistive Natural Rubber-Multiwall Carbon Nanotube Nanocomposite for Sensor Applications. Sens. Actuators A Phys. 2016, 239, 102–113. [Google Scholar] [CrossRef]

- Faibunchan, P.; Pichaiyut, S.; Chueangchayaphan, W.; Kummerlöwe, C.; Venneman, N.; Nakason, C. Influence Type of Natural Rubber on Properties of Green Biodegradable Thermoplastic Natural Rubber Based on Poly(Butylene Succinate). Polym. Adv. Technol. 2019, 30, 1010–1026. [Google Scholar] [CrossRef]

- Azarian, M.H.; Boochathum, P.; Kongsema, M. Biocompatibility and Biodegradability of Filler Encapsulated Chloroacetated Natural Rubber/Polyvinyl Alcohol Nanofiber for Wound Dressing. Mater. Sci. Eng. C 2019, 103, 109829. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Jian, R.; Chen, H.; Tian, X.; Sun, C.; Zhu, J.; Yang, Z.; Sun, J.; Wang, C. Application of Biodegradable and Biocompatible Nanocomposites in Electronics: Current Status and Future Directions. Nanomaterials 2019, 9, 950. [Google Scholar] [CrossRef] [PubMed]

- Tadakaluru, S.; Thongsuwan, W.; Singjai, P. Stretchable and Flexible High-Strain Sensors Made Using Carbon Nanotubes and Graphite Films on Natural Rubber. Sensors 2014, 14, 868–876. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, X.; Wu, X.; Lu, C. Tailoring Percolating Conductive Networks of Natural Rubber Composites for Flexible Strain Sensors via a Cellulose Nanocrystal Templated Assembly. Soft Matter. 2016, 12, 845–852. [Google Scholar] [CrossRef] [PubMed]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of Natural Rubber with Silica/Carbon Black Hybrid Filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Natarajan, T.S.; Eshwaran, S.B.; Stöckelhuber, K.W.; Wießner, S.; Pötschke, P.; Heinrich, G.; Das, A. Strong Strain Sensing Performance of Natural Rubber Nanocomposites. ACS Appl. Mater. Interfaces 2017, 9, 4860–4872. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Kummerloewe, C.; Nakason, C.; Pichaiyut, S.; Wisunthon, S.; Clemens, F. Piezoresistive Carbon-Based Composites for Sensor Applications: Effects of Polarity and Non-Rubber Components on Shape Recovery. Express Polym. Lett. 2020, 14, 970–986. [Google Scholar] [CrossRef]

- He, Q.; Yuan, T.; Zhang, X.; Guo, S.; Liu, J.; Liu, J.; Liu, X.; Sun, L.; Wei, S.; Guo, Z. Heavy Duty Piezoresistivity Induced Strain Sensing Natural Rubber/Carbon Black Nanocomposites Reinforced with Different Carbon Nanofillers. Mater. Res. Express 2014, 1, 035029. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.T.H.; Su, B.; Si, K.J.; Ma, Z.; Yap, L.W.; Guo, P.; Cheng, W. Highly Stretchy Black Gold E-Skin Nanopatches as Highly Sensitive Wearable Biomedical Sensors. Adv. Electron. Mater. 2015, 1, 1400063. [Google Scholar] [CrossRef]

- Sripomsawar, B.; Georgopoulou, A.; Tulaphol, S.; Thitithammawong, A.; Johns, J.; Nakaramontri, Y.; Clemens, F. Use of Modified Deep Eutectic Solvent as an Additional Chemical in a Flexible Conductive Natural Rubber Sensor for Motion Analysis. Express Polym. Lett. 2023, 17, 69–89. [Google Scholar]

- Georgopoulou, A.; Vanderborght, B.; Clemens, F. Fabrication of a Soft Robotic Gripper with Integrated Strain Sensing Elements Using Multi-Material Additive Manufacturing. Front. Robot. AI 2021, 8, 326. [Google Scholar] [CrossRef]

- Haryńska, A.; Gubanska, I.; Kucinska-Lipka, J.; Janik, H. Fabrication and Characterization of Flexible Medical-Grade TPU Filament for Fused Deposition Modeling 3DP Technology. Polymers 2018, 10, 1304. [Google Scholar] [CrossRef] [PubMed]

- Tessanan, W.; Daniel, P.; Phinyocheep, P. Development of Photosensitive Natural Rubber as a Mechanical Modifier for Ultraviolet-Curable Resin Applied in Digital Light Processing-Based Three-Dimensional Printing Technology. ACS Omega 2021, 6, 14838–14847. [Google Scholar] [CrossRef] [PubMed]

- Quetzeri-Santiago, M.A.; Hedegaard, C.L.; Castrejón-Pita, J.R. Additive Manufacturing with Liquid Latex and Recycled End-of-Life Rubber. 3D Print. Addit. Manuf. 2019, 6, 149–157. [Google Scholar] [CrossRef]

- Srisawadi, S.; Lapapong, S.; Dokkhan, S.; Wiroonpochit, P. Stereolithography of Natural Rubber Latex, a Highly Elastic Material. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- Khan, A.; Ali, S.; Khan, S.; Bermak, A. Rapid Fabrication of Soft Strain Sensors by Multi-Nozzle Electrohydrodynamic Inkjet Printing for Wearable Electronics. In Proceedings of the 2021 Ieee International Symposium on Circuits and Systems (iscas), Daegu, Republic of Korea, 22–28 May 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Srimongkol, S.; Wiroonpochit, P.; Utra, K.; Sethayospongsa, R.; Muthitamongkol, P.; Methachan, B.; Butsri, N.; Srisawadi, S. Carbon-Based Conductive Rubber Composite for 3D Printed Flexible Strain Sensors. Polym. Adv. Technol. 2023, 34, 287–298. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, E.; Tang, H.; Li, A.; Cui, C.; Guo, R.; Zhou, M.; Jiang, S.; Shen, H. Carbon Nanotubes/Acetylene Black/Ecoflex with Corrugated Microcracks for Enhanced Sensitivity for Stretchable Strain Sensors. J. Mater. Sci. Mater Electron. 2020, 31, 14145–14156. [Google Scholar] [CrossRef]

- Xu, W.; Yuan, F.; Li, C.; Huang, W.; Wu, X.; Yin, Z.; Yang, W. Acetylene Black Paste Electrode Modified with Molecularly Imprinted Polymers/Graphene for the Determination of Bisphenol A. J. Sep. Sci. 2016, 39, 4851–4857. [Google Scholar] [CrossRef]

- Lahaye, J.; Ehrburger-Dolle, F. Mechanisms of Carbon Black Formation. Correlation with the Morphology of Aggregates. Carbon 1994, 32, 1319–1324. [Google Scholar] [CrossRef]

- Wissler, M. Graphite and Carbon Powders for Electrochemical Applications. J. Power Sources 2006, 156, 142–150. [Google Scholar] [CrossRef]

- Yan, G.; Han, D.; Li, W.; Qiu, J.; Jiang, C.; Li, L.; Wang, C. Effect of Pyrolysis Carbon Black and Carbon Nanotubes on Properties of Natural Rubber Conductive Composites. J. Appl. Polym. Sci. 2022, 139, 52321. [Google Scholar] [CrossRef]

- Song, J.; Tian, K.; Ma, L.; Li, W.; Yao, S. The Effect of Carbon Black Morphology to the Thermal Conductivity of Natural Rubber Composites. Int. J. Heat Mass Transfer. 2019, 137, 184–191. [Google Scholar] [CrossRef]

- Kuru, G.; Goksuzoglu, M.; Ak, E.C.; Arabacı, T.N. The Effect of Acetylene Black Amount, Operating Pressure and Temperature of Capillary Rheometer on Thermal Conductivity in Natural Rubber. Plast. Rubber Compos. 2023, 52, 276–291. [Google Scholar] [CrossRef]

- Song, J.P.; He, Y.; Ma, L.X. Study on Thermal Conductivity of Composites of Rubber/CB with Good Electrical Properties. Adv. Mater. Res. 2011, 221, 466–471. [Google Scholar] [CrossRef]

- Merzouki, A.; Haddaoui, N. Electrical Conductivity Modeling of Polypropylene Composites Filled with Carbon Black and Acetylene Black. Int. Sch. Res. Not. 2012, 2012, e493065. [Google Scholar] [CrossRef]

- Polley, M.H.; Boonstra, B.B.S.T. Carbon Blacks for Highly Conductive Rubber. Rubber Chem. Technol. 1957, 30, 170–179. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Michel, S.; Clemens, F. Sensorized Robotic Skin Based on Piezoresistive Sensor Fiber Composites Produced with Injection Molding of Liquid Silicone. Polymers 2021, 13, 1226. [Google Scholar] [CrossRef]

| Process Parameters | Value |

|---|---|

| Laser repetition rate (kHz) | 70 |

| Scan speed (mm/s) | 480 |

| Hatch spacing (µm) | 40 |

| Scan pattern | Crosshatching at 0° and 90° |

| Layer thickness (µm) | 150 |

| Cast | 3D-Printed | |

|---|---|---|

| Resistivity (top) at extended position | 2.5 ± 0.1 Ωm | 3.8 ± 0.2 Ωm |

| Resistivity (bottom) at extended position | 2.5 ± 0.2 Ωm | 3.8 ± 0.2 Ωm |

| Resistivity (top) at bent position | 3.0 ± 0.3 Ωm | 4.0 ± 0.1 Ωm |

| Resistivity (bottom) at bent position | 2.9 ± 0.3 Ωm | 11.5 ± 1.5 Ωm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgopoulou, A.; Srisawadi, S.; Wiroonpochit, P.; Clemens, F. Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process. Polymers 2023, 15, 2410. https://doi.org/10.3390/polym15102410

Georgopoulou A, Srisawadi S, Wiroonpochit P, Clemens F. Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process. Polymers. 2023; 15(10):2410. https://doi.org/10.3390/polym15102410

Chicago/Turabian StyleGeorgopoulou, Antonia, Sasitorn Srisawadi, Panithi Wiroonpochit, and Frank Clemens. 2023. "Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process" Polymers 15, no. 10: 2410. https://doi.org/10.3390/polym15102410

APA StyleGeorgopoulou, A., Srisawadi, S., Wiroonpochit, P., & Clemens, F. (2023). Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process. Polymers, 15(10), 2410. https://doi.org/10.3390/polym15102410