Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

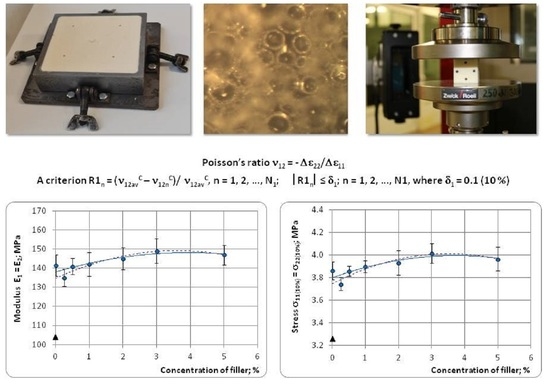

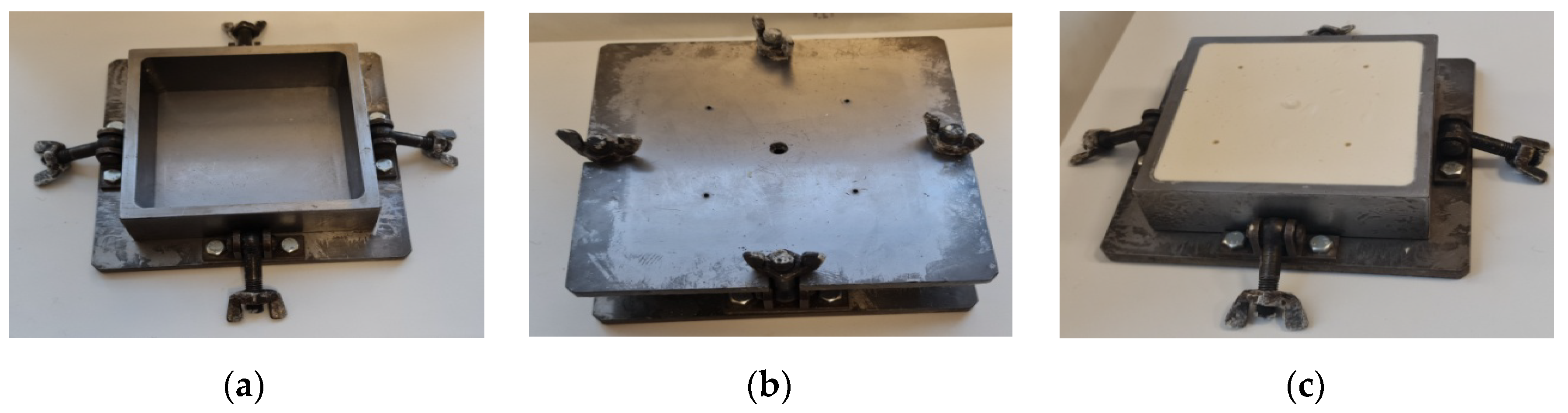

2.2. Production of NEOpolyol-380 PU Foams in a Sealed Mold

2.3. XRD Analysis

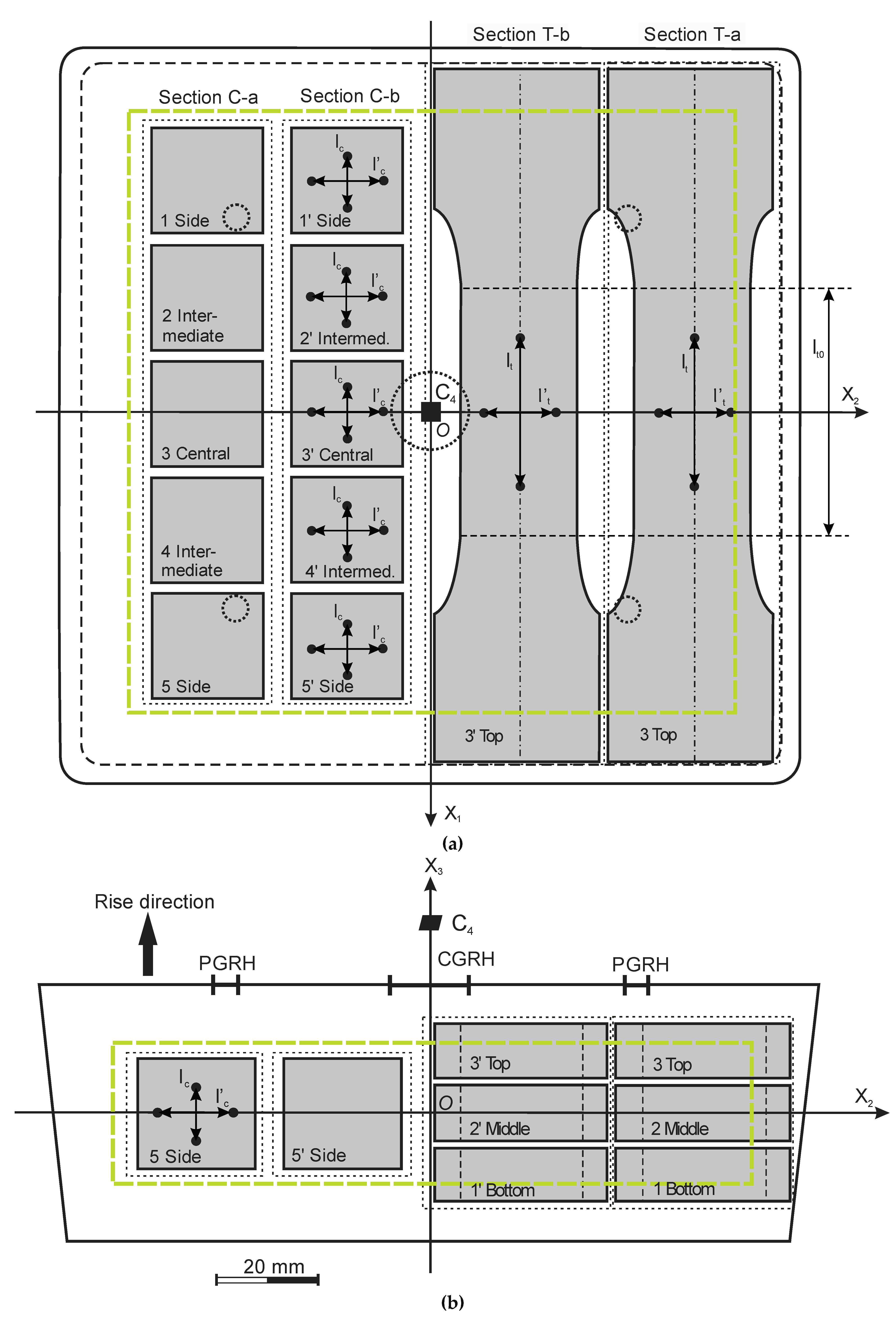

2.4. NEOpolyol-380 PU Foams’ Blocks and Specimens

2.5. Density

2.5.1. Gradient of Density

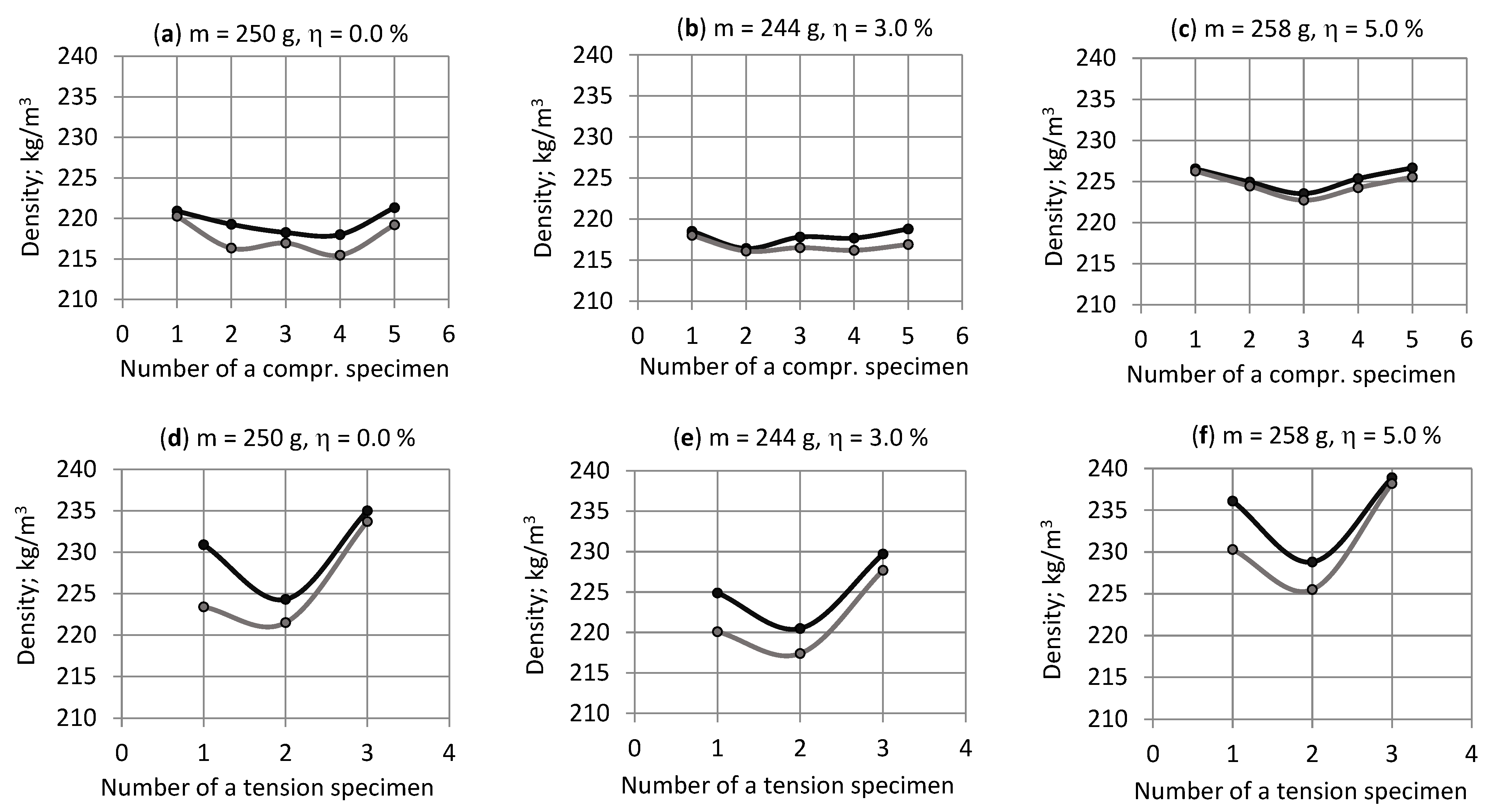

2.5.2. Density of Compression and Tension Specimens

2.6. Mechanical Testing

2.7. Poisson’s Ratios and Density

3. Theoretical Section

3.1. The Criterion of Similar Anisotropy Characteristics

∣R3n∣ ≤ δ3; n = 1, 2, …, N3, where δ1, δ2, δ3-parameters

3.2. Normalizing of the Mechanical Properties to a Common Density

3.3. Dependence of Mechanical Properties on Concentration of Filler

4. Results and Discussion

4.1. XRD Analysis Results

4.2. PU Foam Blocks

4.3. Density of Specimens

4.3.1. Gradient of Density

4.3.2. Density of Compression and Tension Specimens

4.4. Mechanical Properties of NEOpolyol-380 PU Foams

4.5. Poisson’s Ratios and Density

4.6. Selection of the Specimens of NEOpolyol-380 PU Foams

σ33(10%) = 3.6 MPa > σ11max = 3.1 MPa and

DM = E3/E1 = 138 MPa/99 MPa ≈ 1.39.

DM = E3/E1 = 160 MPa/127 MPa ≈ 1.26.

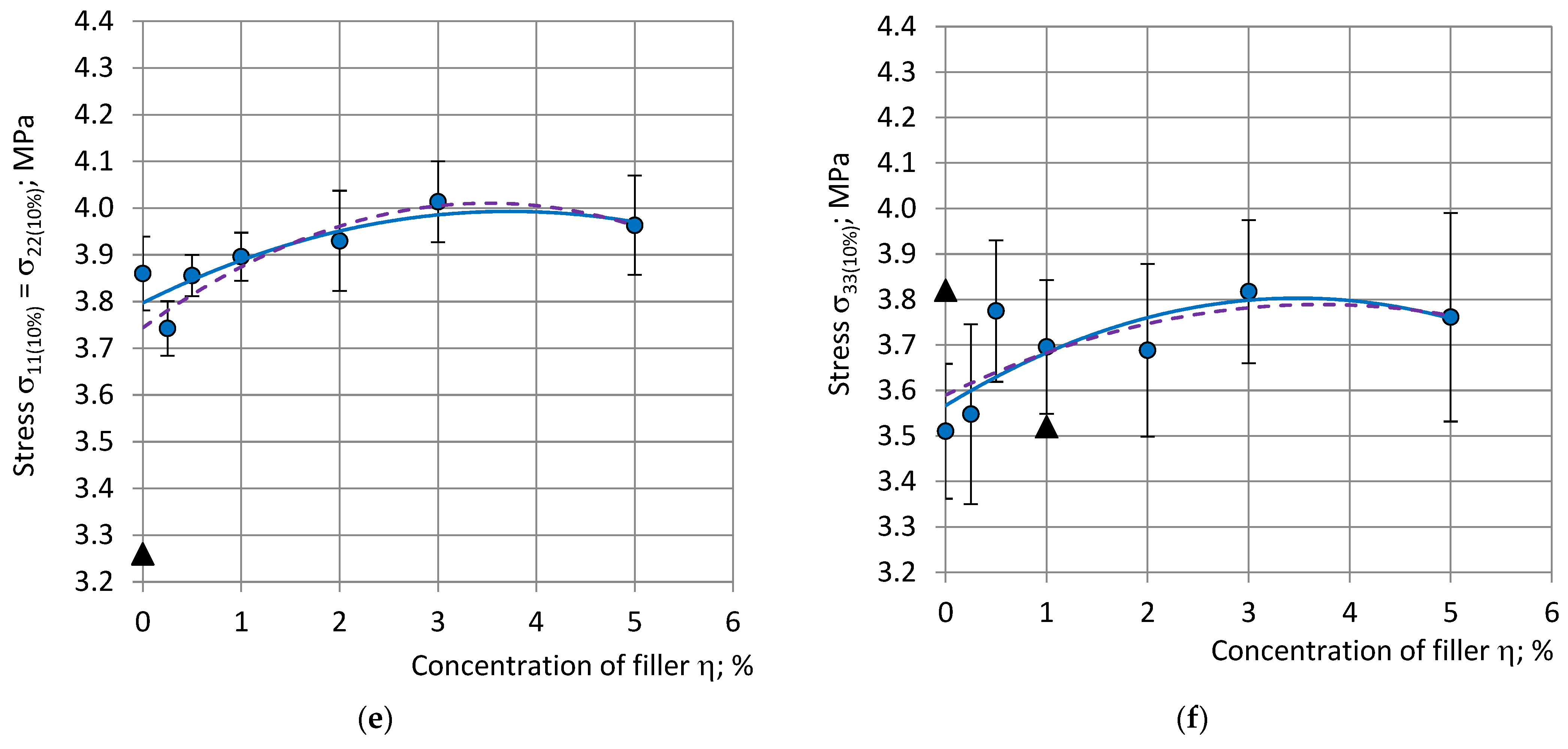

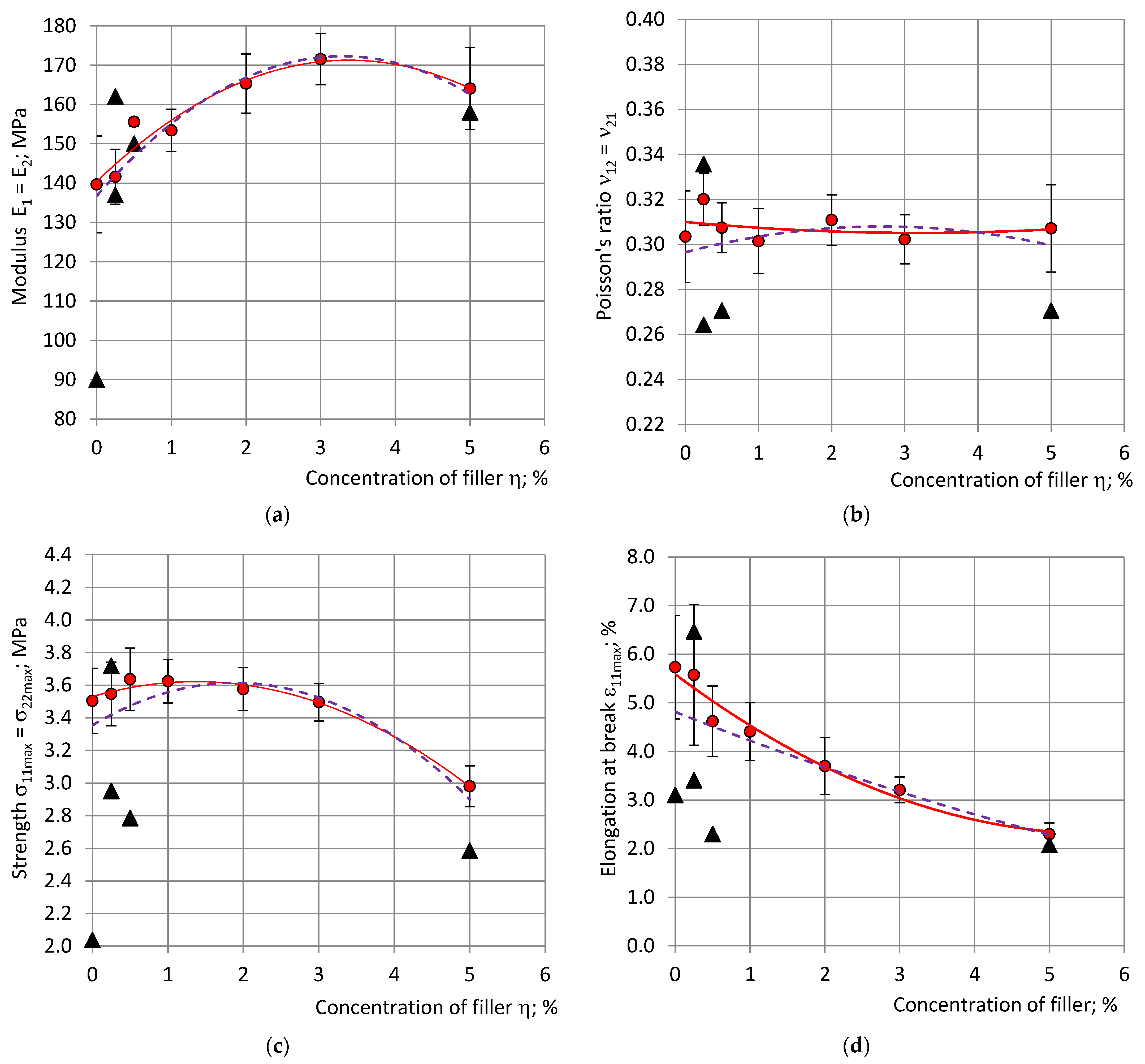

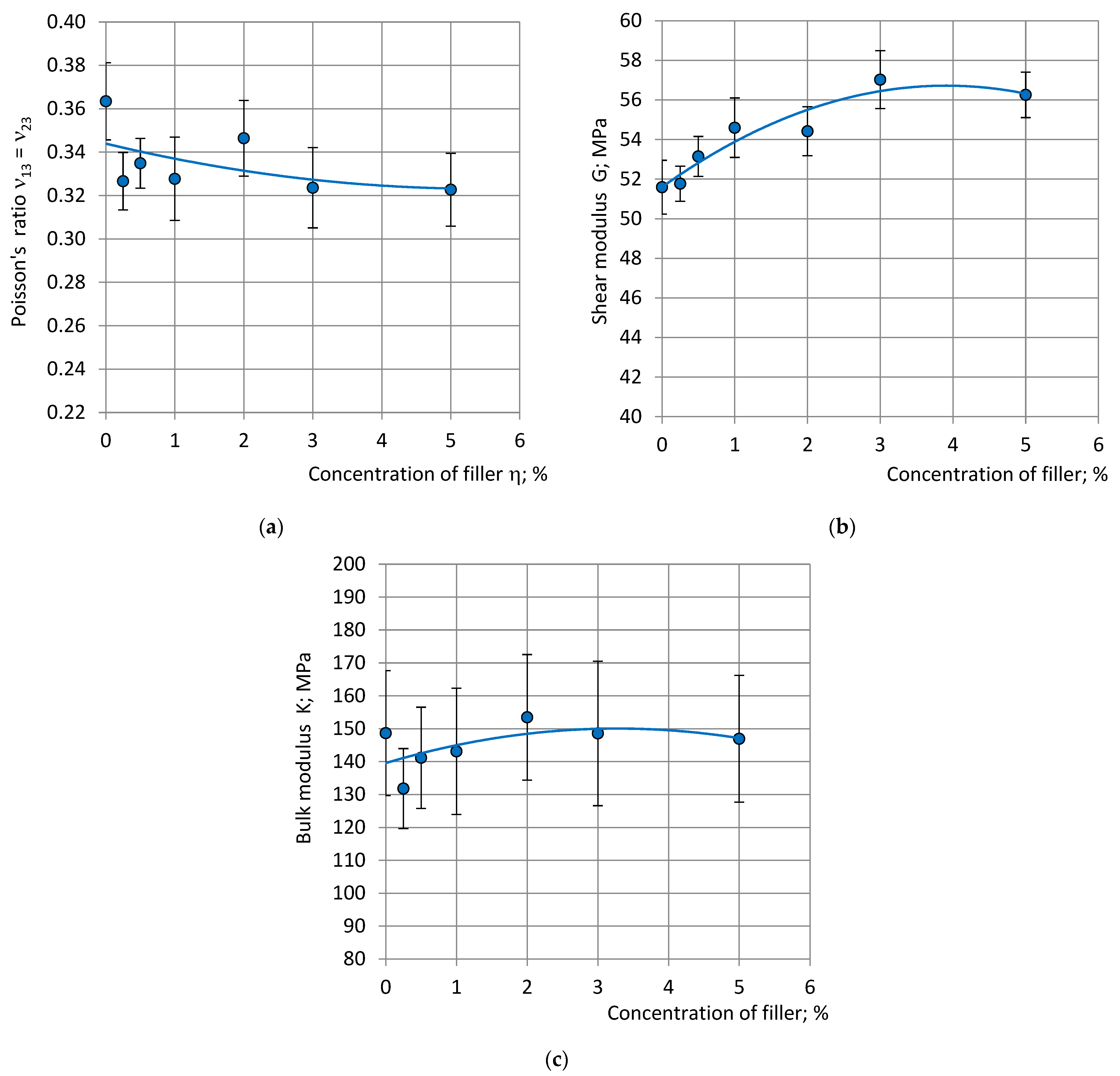

4.7. Dependence of the Mechanical Properties on Concentration of Filler

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hilyard, N.C. (Ed.) Mechanics of Cellular Plastics; MacMillan: New York, NY, USA, 1982; 360p. [Google Scholar]

- Berlin, A.A.; Shutov, F.A. Chemistry and Technology of Gas-Filled High-Polymers (Xимия и Texнoлoгия Гaзoнanoлнeнныx Bыcoкonoлимepoв); Hayкa (Science), Mocквa, USSR: Moscow, Russia, 1980; 503p. (In Russian) [Google Scholar]

- Klempner, D.; Frisch, K.C. (Eds.) Handbook of Polymeric Foams and Foam Technology; Hanser Publishers: Munich, Germany, 1991; 413p. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structures and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997; 515p. [Google Scholar]

- Goods, S.H.; Neuschwanger, C.L.; Henderson, C.C.; Skala, D.M. Mechanical properties of CRETE, a polyurethane foam. J. Appl. Polym. Sci. 1998, 68, 1045–1055. [Google Scholar] [CrossRef]

- Domeier, L.; Hunter, M. Epoxy Foam Encapsulants: Processing and Dielectric Characterization. 1999. Available online: https://www.osti.gov/biblio/5988 (accessed on 5 April 2023).

- Vitkauskiene, I.; Makuška, R. Glycolysis of industrial poly (ethylene terephthalate) waste directed to bis(hydroxyethylene) terephthalate and aromatic polyesterpolyols. Chemija 2008, 19, 29–34. [Google Scholar]

- Vitkauskiene, I.; Makuška, R.; Stirna, U.; Cabulis, U. Thermal properties of polyurethane-polyisocyanurate foams based on poly (ethylene terephthalate) waste. Mater. Sci. Medžiagotyra 2011, 17, 249–253. [Google Scholar] [CrossRef] [Green Version]

- Kirpļuks, M. Development of Renewable Feedstock Based Rigid Polyurethane Foam and Nanoclay Composites. Ph.D. Thesis, Riga Technical University, Riga, Latvia, 2020. Available online: https://ortus.rtu.lv/science/en/publications/31088 (accessed on 5 April 2023).

- Kirpluks, M.; Cabulis, U.; Paberza, A.; Kuranska, M.; Zieleniewska, M.; Auguscik, M. Mechanical and thermal properties of high density rigid polyurethane foams from renewable resources. J. Renew. Mater. 2016, 4, 86–100. [Google Scholar] [CrossRef]

- Cao, X.; Lee, L.J.; Widya, T.; Macosko, C. Polyurethane/clay nanocomposites foams: Processing, structure and properties. Polymer 2005, 46, 775–783. [Google Scholar] [CrossRef]

- Saha, M.C.; Kabir, M.E.; Jeelani, S. Enhancement in thermal and mechanical properties of polyurethane foam infused with nanoparticles. Mater. Sci. Eng. A 2008, 479, 213–222. [Google Scholar] [CrossRef]

- Cabulis, U.; Sevastyanova, I.; Andersons, J.; Beverte, I. Rapeseed oil-based rigid polyisocyanurate foams modified with nanoparticles of various type. Polimery 2014, 59, 207–212. [Google Scholar] [CrossRef]

- Pauzi, N.N.P.; Majid, R.A.; Dzulkifli, M.H.; Yahya, M.Y. Development of rigid bio-based polyurethane foam reinforced with nanoclay. Compos. Part B 2014, 67, 521–526. [Google Scholar] [CrossRef]

- Abulyazied, D.E.; Ene, A. An Investigative Study on the Progress of Nanoclay-Reinforced Polymers: Preparation, Properties, and Applications. A Review. Polymers 2021, 13, 4401. [Google Scholar] [CrossRef]

- Mondal, P.; Khakhar, D.V. Rigid polyurethane-clay nanocomposite foams: Preparation and properties. J. Appl. Polym. Sci. 2007, 103, 2802–2809. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, M.C.; Kim, H.D.; Park, H.C.; Jeong, H.M.; Yoon, K.S.; Kim, B.K. Nanoclay Reinforced Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2010, 117, 1992–1997. [Google Scholar] [CrossRef]

- Fan, H.; Tekeei, A.; Suppes, G.J.; Hsieh, F.H. Properties of Biobased Rigid Polyurethane Foams Reinforced with Fillers: Microspheres and Nanoclay. Int. J. Polym. Sci. 2012, 2012, 474803. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Rende, D.; Schadler, L.S.; Ozisik, R. Polymer nanocomposite foams. J. Mater. Chem. A 2013, 1, 3837–3850. [Google Scholar] [CrossRef]

- Lobos, J.; Velankar, S. How much do nanoparticle fillers improve the modulus and strength of polymer foams? J. Cell. Plast. 2014, 52, 57–88. [Google Scholar] [CrossRef]

- Kirpluks, M.; Stiebra, L.; Trubaca-Boginska, A.; Cabulis, U.; Andersons, J. Rigid closed-cell PUR foams containing polyols derived from renewable resources: The effect of polymer composition, foam density, and organoclay filler on their mechanical properties. In Handbook of Composites from Renewable Materials, Design and Manufacturing; Thakur Vijay, K., Thakur, M.K., Kessler, M.R., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2017; pp. 313–339. [Google Scholar] [CrossRef]

- Stirna, U.; Sevastyanova, I.; Misane, M.; Cabulis, U.; Beverte, I. Structure and properties of polyurethane foams obtained from rapeseed oil polyols. Proc.-Est. Acad. Sci. Chem. 2006, 55, 101–110. [Google Scholar]

- Beverte, I. Determination of Highly Porous Plastic Foams’ Structural Characteristics by Processing LM Images Data. J. Appl. Polym. Sci. 2014, 131, 39477. [Google Scholar] [CrossRef]

- Nazerian, M.; Naderi, F.; Partovinia, A.; Papadopoulos, A.N.; Younesi-Kordkheili, H. Developing adaptive neuro-fuzzy inference system-based models to predict the bending strength of polyurethane foam-cored sandwich panels. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 3–22. [Google Scholar] [CrossRef]

- Huang, L.; Deng, H.; Wang, C. Mechanical properties of rigid polyurethane foam used in metal composite roof panels. Jianzhu Cailiao Xuebao 2014, 17, 320–325+348. [Google Scholar]

- Hawkins, M.C.; O’Toole, B.; Jackovich, D. Cell Morphology and Mechanical Properties of Rigid Polyurethane Foam. J. Cell. Plast. 2005, 41, 267–285. [Google Scholar] [CrossRef]

- O’Toole, B.; Hawkins, M.C.; Sapochak, L. Temperature and Mold Size Effects on Physical and Mechanical Properties in a Polyurethane Foam. J. Cell. Plast. 2005, 41, 153–168. [Google Scholar] [CrossRef]

- Renz, R. Zum Zuegigen und Zyklischen Verfomungsverhalten Polymerer Hartschaumstoffe. Ph.D. Thesis, Universität Karlsruhe (TH), Karlsruhe, Germany, 1977. (In German). [Google Scholar]

- Malmeister, A.K.; Tamuzh, V.P.; Teters, G.A. Resistance of Polymeric and Composite Materials, 3rd ed.; Zinatne (Science): Riga, Latvia, 1980; 571p. (In Russian) [Google Scholar]

- Beverte, I. Poisson ratio of light transversely isotropic foam plastics. Mech. Compos. Mater. 1990, 25, 699–705. [Google Scholar] [CrossRef]

- Beverte, I. Poisson’s ratios of lightweight transversally isotropic foam plastics subjected to deformation perpendicular to the rise direction. Mech. Compos. Mater. 1992, 27, 463–470. [Google Scholar] [CrossRef]

- Beverte, I.; Cabulis, U.; Andersons, J.; Kirpluks, M.; Skruls, V.; Cabulis, P. Light Microscopy of Medium-Density Rigid Polyurethane Foams Filled with Nanoclay. Polymers 2022, 14, 1154. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Evans, J.R.G. Elastic moduli of clay platelets. Scr. Mater. 2006, 54, 1581–1585. [Google Scholar] [CrossRef]

- Vanorio, T.; Prasad, M.; Nur, M. Elastic properties of dry clay mineral aggregates, suspensions and sandstones. Geophys. J. Int. 2003, 155, 319–326. [Google Scholar] [CrossRef] [Green Version]

- Gul, S.; Kausar, A.; Muhammad, B.; Jabeen, S. Research progress on properties and applications of polymer/clay nanocomposite. Polym. Plast. Technol. Eng. 2016, 55, 684–703. [Google Scholar] [CrossRef]

- Adak, B.; Butola, B.S.; Joshi, M. Effect of organoclay-type and clay-polyurethane interaction chemistry for tuning the morphology, gas barrier and mechanical properties of clay/polyurethane nanocomposites. Appl. Clay Sci. 2018, 161, 343–353. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A review of the synthesis and applications of polymer–nanoclay composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef] [Green Version]

| Formulation of Polyol (pbw) * | ||

| 1 | Recycled APP NEOpolyol-380 | 80.0 |

| 2 | Cross-linking agent, Lupranol 3422 | 20.0 |

| 3 | Flame retardant, TCPP | 20.0 |

| 4 | Blowing agent, water | 1.0 |

| 5 | Reactive catalyst, PC CAT NP-10 | 1.6 |

| 6 | Surfactant, NIAX Silicone L6915 | 2.0 |

| Polyisocyanate (pbw) | 193 | |

| Characteristics of Formulation | ||

| 1 | Recycled materials in PU foams (%) | 15 |

| 2 | Isocyanate index | 160 |

| Technological Parameters | ||

| 1 | Cream time (s) | 25 |

| 2 | String time (s) | 45 |

| 3 | Tack-free time (s) | 60 |

| 4 | Foaming end time (s) | 60 |

| Mechanical Property | Compression | Tension | ||

|---|---|---|---|---|

| A (MPa·kg·m−3)−b) | b | A (MPa·(kg·m−3)−b) | b | |

| Modulus E | 0.0109 | 1.68 | 0.0110 | 1.75 |

| Stress σ 10% /strength | 0.00030 | 1.75 | 0.0035 | 1.30 |

| Mechanical Property | Average Density; kg/m3 | Compression | Average Density; kg/m3 | Tension | ||

|---|---|---|---|---|---|---|

| Aav (MPa·(kg·m−3)−b) | b | Aav (MPa·(kg⋅m−3)−b) | b | |||

| Modulus E1 | 218 | 0.0159 | 1.68 | 227 | 0.0108 | 1.75 |

| Modulus E3 | 220 | 0.0150 | 1.68 | - | - | - |

| Stress σ11(10%)/strength | 218 | 0.00030 | 1.75 | 227 | 0.0031 | 1.30 |

| Stress σ33(10%)/strength | 220 | 0.00027 | 1.75 | - | - | - |

| Property/Block No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| (1) Compression parallel to the axis OX1 | |||||

| Density ρ (kg/m3) | 33 | 39 | 56 | 76 | 82 |

| Relative density γ (%) | 2.8 | 3.2 | 4.6 | 6.3 | 6.9 |

| Modulus E1 (MPa) | 4.3 | 5.6 | 9.7 | 22.5 | 7.9 |

| Poisson’s ratio ν12 | 0.27 | 0.38 | 0.33 | 0.36 | 0.30 |

| Poisson’s ratio ν13 | 0.17 | 0.29 | 0.23 | 0.31 | 0.22 |

| Strength σ11max (MPa) | 0.17 | 0.19 | 0.32 | 0.60 | 0.66 |

| Strain ε11max (%) | 5.4 | 6.5 | 5.3 | 5.4 | 4.4 |

| (2) Compression parallel to the axis OX3 | |||||

| Density ρ (kg/m3) | 32 | 38 | 55 | 75 | 81 |

| Relative density γ (%) | 2.7 | 3.2 | 4.6 | 6.3 | 6.8 |

| Modulus E3 (MPa) | 9.3 | 9.4 | 19.2 | 31.5 | 28.7 |

| Poisson’s ratio ν31 | 0.44 | 0.46 | 0.49 | 0.42 | 0.38 |

| Poisson’s ratio ν32 | 0.52 | 0.54 | 0.52 | 0.41 | 0.44 |

| Strength σ33max (MPa) | 0.28 | 0.26 | 0.52 | 0.72 | 0.73 |

| Strain ε33max (%) | 4.1 | 4.4 | 3.3 | 3.1 | 3.0 |

| Characteristics of anisotropy | |||||

| Ratio E3/E1 | 2.2 | 2.0 | 1.7 | 1.4 | 1.6 |

| Ratio ν31/ν13 | 2.5 | 2.1 | 1.6 | 1.4 | 1.7 |

| (3) Tension parallel to the axis OX3 | |||||

| Density ρ (kg/m3) | 34 | 34 | 51 | 76 | 77 |

| Relative density γ (%) | 2.8 | 2.9 | 4.2 | 6.4 | 6.5 |

| Modulus E3 (MPa) | 11.1 | 15.3 | 26.3 | 37.9 | 40.2 |

| Poisson’s ratio ν31 | 0.65 | 0.64 | 0.56 | 0.46 | 0.46 |

| Poisson’s ratio ν32 | 0.58 | 0.66 | 0.65 | 0.50 | 0.50 |

| Strength σ33max (MPa) | 0.46 | 0.46 | 0.82 | 0.96 | 0.99 |

| Elongation at break ε33max (%) | 8.7 | 7.8 | 6.9 | 3.7 | 1.0 |

| Section C-a | Section C-b | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E3 (MPa) | Poisson’s Ratio ν32 | Stress σ33(10%) (MPa) | Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E1 (MPa) | Poisson’s Ratio ν12 | Stress σ11(10%) (MPa) |

| 1 Side | 221 | 130 | 0.35 | 3.4 | 1′ Side | 220 | 143 | 0.34 | 3.8 |

| 2 Intermediate | 219 | 130 | 0.36 | 3.3 | 2′ Intermediate | 216 | 136 | 0.33 | 3.7 |

| 3 Central | 218 | 138 | 0.39 | 3.6 | 3′ Central | 217 | 99 | 0.23 | 3.1 |

| 4 Intermediate | 218 | 132 | 0.33 | 3.6 | 4′ Intermediate | 215 | 130 | 0.31 | 3.5 |

| 5 Side | 221 | 125 | 0.33 | 3.3 | 5′ Side | 219 | 130 | 0.33 | 3.8 |

| Section C-a | Section C-b | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E3 (MPa) | Poisson’s Ratio ν32 | Stress σ33(10%) (MPa) | Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E1 (MPa) | Poisson’s Ratio ν12 | Stress σ11(10%) (MPa) |

| 1 Side | 221 | 151 | 0.36 | 3.5 | 1′ Side | 220 | 135 | 0.30 | 3.8 |

| 2 Intermediate | 219 | 143 | 0.34 | 3.5 | 2′ Intermediate | 219 | 144 | 0.32 | 3.8 |

| 3 Central | 221 | 150 | 0.36 | 3.8 | 3′ Central | 217 | 134 | 0.32 | 3.6 |

| 4 Intermediate | 221 | 147 | 0.34 | 3.6 | 4′ Intermediate | 217 | 141 | 0.34 | 3.7 |

| 5 Side | 221 | 160 | 0.39 | 3.4 | 5′ Side | 219 | 127 | 0.30 | 3.7 |

| Section T-a | Section T-b | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Block Number No. | Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E1 (MPa) | Poisson’s Ratio ν12 | Strength σ11max (MPa) | Number of Specimen and Location | Density ρ (kg/m3) | Stiffness E1 (MPa) | Poisson’s Ratio ν12 | Strength σ11max (MPa) |

| 1 | 1 Bottom | 231 | 159 | 0.32 | 3.9 | 1′ Bottom | 223 | 140 | 0.29 | 3.6 |

| 2 Middle | 224 | 146 | 0.30 | 3.5 | 2′ Middle | 222 | 116 | 0.28 | 3.2 | |

| 3 Top | 235 | 155 | 0.33 | 3.6 | 3′ Top | 234 | 97 | 0.18 | 2.2 | |

| 2 | 1 Bottom | 232 | 144 | 0.31 | 3.5 | 1′ Bottom | 225 | 142 | 0.32 | 3.8 |

| 2 Middle | 227 | 156 | 0.34 | 3.8 | 2′ Middle | 223 | 138 | 0.33 | 3.5 | |

| 3 Top | 236 | 165 | 0.32 | 3.8 | 3′ Top | 234 | 148 | 0.26 | 3.1 | |

| 3 | 1 Bottom | 228 | 161 | 0.31 | 3.8 | 1′ Bottom | 219 | 150 | 0.31 | 3.6 |

| 2 Middle | 221 | 151 | 0.32 | 3.5 | 2′ Middle | 217 | 146 | 0.29 | 3.7 | |

| 3 Top | 230 | 163 | 0.32 | 3.5 | 3′ Top | 230 | 157 | 0.27 | 2.9 | |

| 7 | 1 Bottom | 236 | 180 | 0.30 | 3.2 | 1′Bottom | 230 | 165 | 0.29 | 3.1 |

| 2 Middle | 229 | 182 | 0.33 | 3.2 | 2′Middle | 226 | 152 | 0.29 | 2.8 | |

| 3 Top | 239 | 194 | 0.33 | 3.3 | 3′ Top | 232 | 176 | 0.27 | 2.8 | |

| Mechanical Property | Neat PU Foams | Conc. of Filler η (%) | Filled PU Foams | Relative Change R (%) | Relative Adjustment RA (%) | |

|---|---|---|---|---|---|---|

| All Specimens | Selected Specimens | |||||

| (1) Compression | ||||||

| Modulus E1 (MPa) | 138 | 3 | 148 | 10 | 7 | −30 |

| Modulus E3 (MPa) | 139 | 3 | 156 | 12 | 13 | 8 |

| Stress σ11(10%) (MPa) | 3.8 | 3 | 4.0 | 7 | 5 | −29 |

| Stress σ33(10%) (MPa) | 3.6 | 3 | 3.8 | 5 | 6 | 20 |

| (2) Tension | ||||||

| Modulus E1 (MPa) | 139 | 3 | 170 | 26 | 22 | −15 |

| Strength σ11max (MPa) | 3.5 | 5 | 3.0 | −3 | −16 | 16 |

| Elongation at break ε11max (%) | 5.8 | 5 | 2.3 | −53 | −58 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beverte, I.; Cabulis, U.; Andersons, J.; Kirpluks, M.; Skruls, V.; Cabulis, P. Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources. Polymers 2023, 15, 2582. https://doi.org/10.3390/polym15112582

Beverte I, Cabulis U, Andersons J, Kirpluks M, Skruls V, Cabulis P. Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources. Polymers. 2023; 15(11):2582. https://doi.org/10.3390/polym15112582

Chicago/Turabian StyleBeverte, Ilze, Ugis Cabulis, Janis Andersons, Mikelis Kirpluks, Vilis Skruls, and Peteris Cabulis. 2023. "Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources" Polymers 15, no. 11: 2582. https://doi.org/10.3390/polym15112582

APA StyleBeverte, I., Cabulis, U., Andersons, J., Kirpluks, M., Skruls, V., & Cabulis, P. (2023). Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources. Polymers, 15(11), 2582. https://doi.org/10.3390/polym15112582