Unlocking the Potential of Lignocellulosic Biomass Dragon Fruit (Hylocereus polyrhizus) in Bioplastics, Biocomposites and Various Commercial Applications

Abstract

:1. Introduction

2. Physiology and Morphology

3. Varieties

3.1. Pitaya (Stenocereus)

Physicochemical Characteristics

3.2. Pitahaya (Hylocereus)

Physicochemical Characteristics

4. Surface Treatments

4.1. Chemical Treatment

4.2. Physical Treatment

4.3. Biological Treatment

5. Dragon Fruit Extraction/Processing

5.1. Pectin Extraction

Pectin Extraction from Dragon Fruit Peels

5.2. Peel Powder and Pectin

6. Current Applications

6.1. Bioplastic from Pectin of Dragon Fruit (Hylocereus polyrhizus) Peel

6.2. Dragon Fruit Peel (Hylocereus costaricensis) Skin Colour Extract for Bioplastics

6.3. Dragon Fruit Peel as a Natural Dye in Food

6.4. Dragon Fruit Peel as a Raw Material in the Cosmetic Industry

7. Summary

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hua, Q.; Chen, C.; Tel Zur, N.; Wang, H.; Wu, J.; Chen, J.; Zhang, Z.; Zhao, J.; Hu, G.; Qin, Y. Metabolomic Characterization of Pitaya Fruit from Three Red-Skinned Cultivars with Different Pulp Colors. Plant Physiol. Biochem. 2018, 126, 117–125. [Google Scholar] [CrossRef]

- Jalgaonkar, K.; Mahawar, M.K.; Bibwe, B.; Kannaujia, P. Postharvest Profile, Processing and Waste Utilization of Dragon Fruit (Hylocereus spp.): A Review. Food Rev. Int. 2020, 38, 733–759. [Google Scholar] [CrossRef]

- Ismail, N.S.M.; Ramli, N.; Hani, N.M.; Meon, Z. Extraction and Characterization of Pectin from Dragon Fruit (Hylocereus polyrhizus) Using Various Extraction Conditions. Sains Malaysiana 2012, 41, 41–45. [Google Scholar]

- Hoe, K. Planting Density of Red Pitaya (Hylocereus polyrhizus) to Achieve Optimum Yield Under Malaysia Weather Condition. Int. J. Agric. Innov. Res. 2017, 6, 354–358. [Google Scholar]

- Liaotrakoon, W. Characterization of Dragon Fruit (Hylocereus spp.) Components with Valorization Potential. Ph.D. Thesis, Ghent University, Gent, Belgium, 2013. [Google Scholar]

- Gunasena, H.P.M.; Pushpakumara, D.K.N.G.; Kariyawasam, M. Dragon Fruit Hylocereus Undatus (Haw.) Britton and Rose; World Agroforestry: Nairobi, Kenya, 2006; pp. 110–135. ISBN 955-9224-25-5. [Google Scholar]

- Bakar, J.; Shu, C.E.; Kharidah, M.; Dzulkifly, M.A.; Noranizan, A. Physico-Chemical Characteristics of Red Pitaya (Hylocereus polyrhizus) Peel. Int. Food Res. J. 2011, 18, 279–286. [Google Scholar]

- Chia, S.L.; Chong, G.H. Effect of Drum Drying on Physico-Chemical Characteristics of Dragon Fruit Peel (Hylocereus polyrhizus). Int. J. Food Eng. 2015, 11, 285–293. [Google Scholar] [CrossRef]

- Mahlil, Y.; Husmaini; Warnita; Mirzah; Mahata, M.E. Using Physical and Chemical Methods to Improve the Nutrient Quality of Dragon Fruit (Hylocereus polyrhizus) Peel for Use as Feed for Laying Hens. Int. J. Poult. Sci. 2018, 17, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Le Bellec, F.; Vaillant, F.; Imbert, E. Pitahaya (Hylocereus spp.): A New Fruit Crop, a Market with a Future. Fruits 2006, 61, 237–250. [Google Scholar] [CrossRef] [Green Version]

- Sabbe, S.; Verbeke, W.; Van Damme, P. Confirmation/Disconfirmation of Consumers’ Expectations about Fresh and Processed Tropical Fruit Products. Int. J. Food Sci. Technol. 2009, 44, 539–551. [Google Scholar] [CrossRef]

- Esquivel, P.; Stintzing, F.C.; Carle, R. Comparison of Morphological and Chemical Fruit Traits from Different Pitaya Genotypes (Hylocereus Sp.) Grown in Costa Rica. J. Appl. Bot. Food Qual. 2007, 81, 7–14. [Google Scholar]

- Lim, H.K.; Tan, C.P.; Karim, R.; Ariffin, A.A.; Bakar, J. Chemical Composition and DSC Thermal Properties of Two Species of Hylocereus Cacti Seed Oil: Hylocereus Undatus and Hylocereus polyrhizus. Food Chem. 2010, 119, 1326–1331. [Google Scholar] [CrossRef]

- Mahattanatawee, K.; Manthey, J.A.; Luzio, G.; Talcott, S.T.; Goodner, K.; Baldwin, E.A. Total Antioxidant Activity and Fiber Content of Select Florida-Grown Tropical Fruits. J. Agric. Food Chem. 2006, 54, 7355–7363. [Google Scholar] [CrossRef]

- Chuck-Hernández, C.; Parra-Saldívar, R.; Sandate-Flores, L. Pitaya (Stenocereus spp.). Encycl. Food Health 2015, 385–391. [Google Scholar] [CrossRef]

- Siddiq, M.; Nasir, M. Dragon Fruit and Durian. In Tropical and Subtropical Fruits: Postharvest Physiology, Processing and Packaging; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 587–596. ISBN 9780813811420. [Google Scholar]

- Norziah, M.H.; Ruri, A.S.; Tang, C.S.; Fazilah, A. Utilization of Red Pitaya (H. polyrhizus) Fruit Peels for Value Added Food Ingredients. In Proceedings of the International Conference on Environmental. Research and Technology (ICERT 2008), Parkroyal Penang, Malaysia, 28–30 May 2008; pp. 72–75. [Google Scholar]

- Makris, D.P.; Boskou, G.; Andrikopoulos, N.K. Polyphenolic Content and in Vitro Antioxidant Characteristics of Wine Industry and Other Agri-Food Solid Waste Extracts. J. Food Compos. Anal. 2007, 20, 125–132. [Google Scholar] [CrossRef]

- Chantaro, P.; Devahastin, S.; Chiewchan, N. Production of Antioxidant High Dietary Fiber Powder from Carrot Peels. LWT-Food Sci. Technol. 2008, 41, 1987–1994. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martín-Belloso, O. Comparison of Dietary Fibre from By-Products of Processing Fruits and Greens and from Cereals. LWT-Food Sci. Technol. 1999, 32, 503–508. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; Elachaby, M.; Bouhfid, R.; Vaudreuil, S.; Essassi, M.; Qaiss, A. Mechanical and Thermal Properties of Polypropylene Reinforced with Alfa Fiber under Different Chemical Treatment. Mater. Des. 2012, 35, 318–322. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Jabbar, A. Sustainable Jute-Based Composite Materials: Mechanical and Thermomechanical Behaviour; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783319654560. [Google Scholar]

- Bledzki, A.; Gassan, J. Composites Reinforced with Cellulose_Bledzki_1999.Pdf. Prog. Polym. Sci 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Koubala, B.B.; Kansci, G.; Mbome, L.I.; Crépeau, M.J.; Thibault, J.F.; Ralet, M.C. Effect of Extraction Conditions on Some Physicochemical Characteristics of Pectins from “Améliorée” and “Mango” Mango Peels. Food Hydrocoll. 2008, 22, 1345–1351. [Google Scholar] [CrossRef]

- Mohamadzadeh, J.; Sadeghi-Mahoonak, A.R.; Yaghbani, M.; Aalami, M. Extraction of Pectin from Sunflower Head Residues of Selected Iranian Cultivars. World Appl. Sci. J. 2010, 8, 21–24. [Google Scholar]

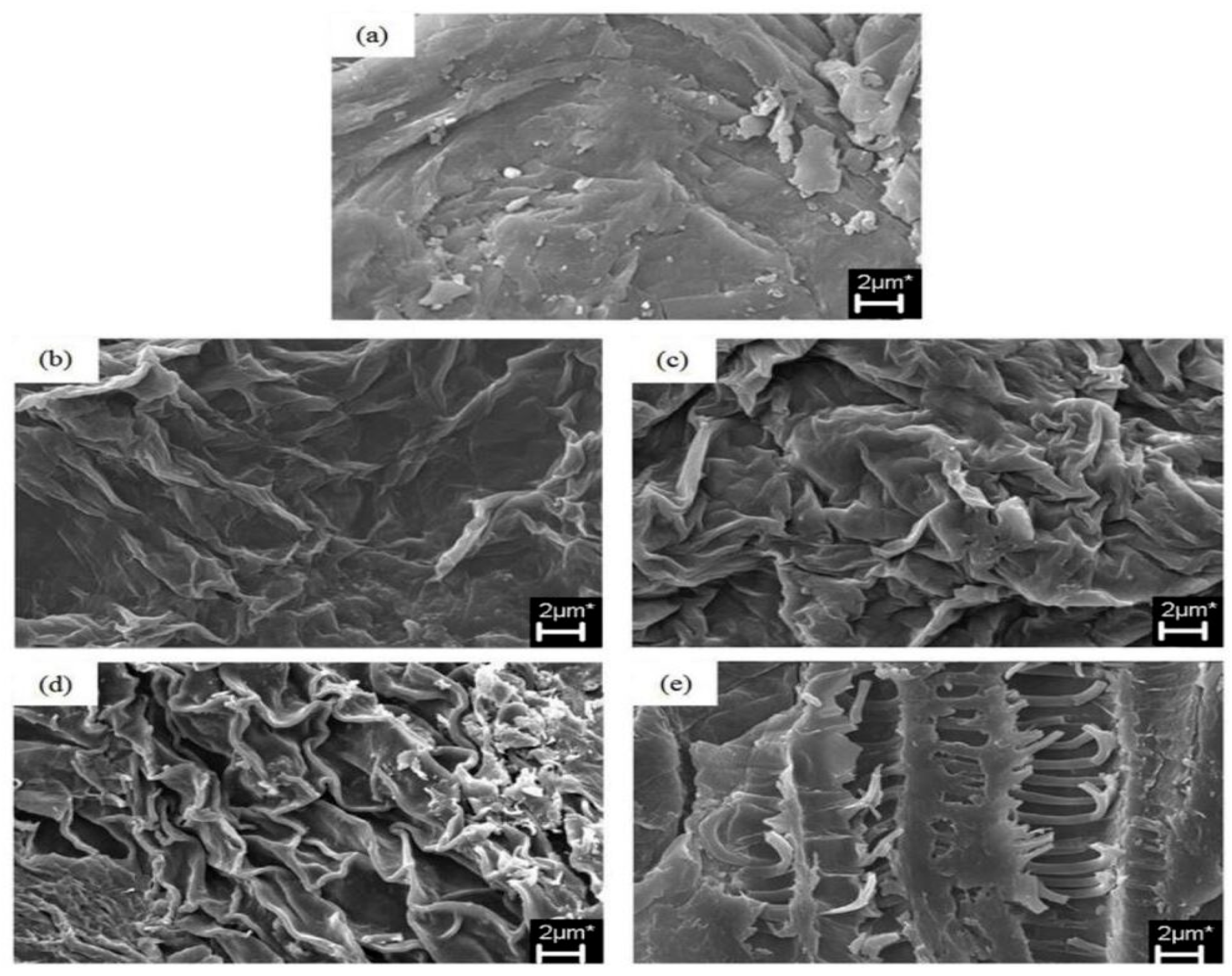

- Mahlil, Y.; Husmaini; Warnita; Mirzah; Kobayashi, M.; Mahata, M.E. The Processing Effects of Anthocyanins Extracted from Dragon Fruit (Hylocereus polyrhizus) Peel on Total Amount of Anthocyanins and SEM Image in Poultry Nutrition. J. World Poult. Res. 2020, 10, 513–519. [Google Scholar] [CrossRef]

- Mulyawanti, I.; Budijanto, S.; Yasni, S. Stability of Anthocyanin During Processing, Storage and Simulated Digestion of Purple Sweet Potato Pasta. Indones. J. Agric. Sci. 2018, 19, 1. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Kunnika, S.; Pranee, A. Influence of Enzyme Treatment on Bioactive Compounds and Colour Stability of Betacyanin in Flesh and Peel of Red Dragon Fruit Hylocereus polyrhizus (Weber) Britton and Rose. Int. Food Res. J. 2011, 18, 1437–1448. [Google Scholar]

- Valdés, A.; Burgos, N.; Jiménez, A.; Garrigós, M.C. Natural Pectin Polysaccharides as Edible Coatings. Coatings 2015, 5, 865–886. [Google Scholar] [CrossRef] [Green Version]

- Freitas de Oliveira, C.; Giordani, D.; Lutckemier, R.; Gurak, P.D.; Cladera-Olivera, F.; Ferreira Marczak, L.D. Extraction of Pectin from Passion Fruit Peel Assisted by Ultrasound. LWT-Food Sci. Technol. 2016, 71, 110–115. [Google Scholar] [CrossRef]

- Pinheiro, E.R.; Silva, I.M.D.A.; Gonzaga, L.V.; Amante, E.R.; Teófilo, R.F.; Ferreira, M.M.C.; Amboni, R.D.M.C. Optimization of Extraction of High-Ester Pectin from Passion Fruit Peel (Passiflora edulis flavicarpa) with Citric Acid by Using Response Surface Methodology. Bioresour. Technol. 2008, 99, 5561–5566. [Google Scholar] [CrossRef]

- Liew, S.Q.; Ngoh, G.C.; Yusoff, R.; Teoh, W.H. Sequential Ultrasound-Microwave Assisted Acid Extraction (UMAE) of Pectin from Pomelo Peels. Int. J. Biol. Macromol. 2016, 93, 426–435. [Google Scholar] [CrossRef]

- Pagán, J.; Ibarz, A.; Llorca, M.; Pagán, A.; Barbosa-Cánovas, G.V. Extraction and Characterization of Pectin from Stored Peach Pomace. Food Res. Int. 2001, 34, 605–612. [Google Scholar] [CrossRef]

- Maran, J.P. Statistical Optimization of Aqueous Extraction of Pectin from Waste Durian Rinds. Int. J. Biol. Macromol. 2015, 73, 92–98. [Google Scholar] [CrossRef]

- Wai, W.W.; Alkarkhi, A.F.M.; Easa, A.M. Effect of Extraction Conditions on Yield and Degree of Esterification of Durian Rind Pectin: An Experimental Design. Food Bioprod. Process. 2010, 88, 209–214. [Google Scholar] [CrossRef]

- Chaharbaghi, E.; Khodaiyan, F.; Hosseini, S.S. Optimization of Pectin Extraction from Pistachio Green Hull as a New Source. Carbohydr. Polym. 2017, 173, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Li, D.Q.; Jia, X.; Wei, Z.; Liu, Z.Y. Box-Behnken Experimental Design for Investigation of Microwave-Assisted Extracted Sugar Beet Pulp Pectin. Carbohydr. Polym. 2012, 88, 342–346. [Google Scholar] [CrossRef]

- Priyantha, N.; Lim, L.; Dahri, M.K.; Lim, L.B.L. Dragon Fruit Skin as a Potential Low-Cost Biosorbent for the Removal of Manganese(II) Ions. J. Appl. Sci. Environ. Sanit. 2013, 8, 179–188. [Google Scholar]

- Ridley, B.L.; O’Neill, M.A.; Mohnen, D. Pectins: Structure, Biosynthesis, and Oligogalacturonide-Related Signaling. Phytochemistry 2001, 57, 929–967. [Google Scholar] [CrossRef]

- Rahmati, S.; Abdullah, A.; Momeny, E.; Kang, O.L. Optimization Studies on Microwave Assisted Extraction of Dragon Fruit (Hylocereus polyrhizus) Peel Pectin Using Response Surface Methodology. Int. Food Res. J. 2015, 22, 233–239. [Google Scholar]

- Zaidel, D.N.A.; Rashid, J.M.; Hamidon, N.H.; Salleh, L.M.; Kassim, A.S.M. Extraction and Characterisation of Pectin from Dragon Fruit (Hylocereus polyrhizus) Peels. Chem. Eng. Trans. 2017, 56, 805–810. [Google Scholar] [CrossRef]

- Joye, D.D.; Luzio, G.A. Process for Selective Extraction of Pectins from Plant Material by Differential PH. Carbohydr. Polym. 2000, 43, 337–342. [Google Scholar] [CrossRef]

- Yeoh, S.; Shi, J.; Langrish, T.A.G. Comparisons between Different Techniques for Water-Based Extraction of Pectin from Orange Peels. Desalination 2008, 218, 229–237. [Google Scholar] [CrossRef]

- Seixas, F.L.; Fukuda, D.L.; Turbiani, F.R.B.; Garcia, P.S.; Petkowicz, C.L.d.O.; Jagadevan, S.; Gimenes, M.L. Extraction of Pectin from Passion Fruit Peel (Passiflora Edulis f.Flavicarpa) by Microwave-Induced Heating. Food Hydrocoll. 2014, 38, 186–192. [Google Scholar] [CrossRef]

- May, C.D. Industrial Pectins: Sources, Production and Applications. Carbohydrate Polymers. J. Ind. Appl. pectin 1990, 12, 79–99. [Google Scholar]

- Guo, X.; Han, D.; Xi, H.; Rao, L.; Liao, X.; Hu, X.; Wu, J. Extraction of Pectin from Navel Orange Peel Assisted by Ultra-High Pressure, Microwave or Traditional Heating: A Comparison. Carbohydr. Polym. 2012, 88, 441–448. [Google Scholar] [CrossRef]

- Bagherian, H.; Zokaee Ashtiani, F.; Fouladitajar, A.; Mohtashamy, M. Comparisons between Conventional, Microwave- and Ultrasound-Assisted Methods for Extraction of Pectin from Grapefruit. Chem. Eng. Process. Process Intensif. 2011, 50, 1237–1243. [Google Scholar] [CrossRef]

- Tongkham, N.; Juntasalay, B.; Lasunon, P.; Sengkhamparn, N. Dragon Fruit Peel Pectin: Microwave-Assisted Extraction and Fuzzy Assessment. Agric. Nat. Resour. 2017, 51, 262–267. [Google Scholar] [CrossRef]

- Rahmati, S.; Abdullah, A.; Kang, O.L. Effects of Different Microwave Intensity on the Extraction Yield and Physicochemical Properties of Pectin from Dragon Fruit (Hylocereus polyrhizus) Peels. Bioact. Carbohydrates Diet. Fibre 2019, 18, 100186. [Google Scholar] [CrossRef]

- Thirugnanasambandham, K.; Sivakumar, V.; Prakash Maran, J. Process Optimization and Analysis of Microwave Assisted Extraction of Pectin from Dragon Fruit Peel. Carbohydr. Polym. 2014, 112, 622–626. [Google Scholar] [CrossRef]

- Lin, C.B.; Kai, N.Y.; Ali, A. Ultrasound Assisted Extraction of Pectin from Dragon Fruit Peels. J. Eng. Sci. Technol. 2018, 13, 65–81. [Google Scholar]

- Nguyen, B.M.N.; Pirak, T. Physicochemical Properties and Antioxidant Activities of White Dragon Fruit Peel Pectin Extracted with Conventional and Ultrasound-Assisted Extraction. Cogent Food Agric. 2019, 5, 1–13. [Google Scholar] [CrossRef]

- Kratchanova, M.; Pavlova, E.; Panchev, I. The Effect of Microwave Heating of Fresh Orange Peels on the Fruit Tissue and Quality of Extracted Pectin. Carbohydr. Polym. 2004, 56, 181–185. [Google Scholar] [CrossRef]

- Bakar, J.; Ee, S.C.; Muhammad, K.; Hashim, D.M.; Adzahan, N. Spray-Drying Optimization for Red Pitaya Peel (Hylocereus polyrhizus). Food Bioprocess Technol. 2013, 6, 1332–1342. [Google Scholar] [CrossRef]

- Lee, K.H.; Wu, T.Y.; Siow, L.F. Spray Drying of Red (Hylocereus polyrhizus) and White (Hylocereus Undatus) Dragon Fruit Juices: Physicochemical and Antioxidant Properties of the Powder. Int. J. Food Sci. Technol. 2013, 48, 2391–2399. [Google Scholar] [CrossRef]

- Ee, S.C.; Bakar, J.; Kharidah, M.; Dzulkifly, M.H.; Noranizan, A. Physico-Chemical Properties of Spray-Dried Red Pitaya (Hylocereus polyrhizus) Peel Powder during Storage. Int. Food Res. J. 2014, 21, 1177–1182. [Google Scholar]

- Dos Santos, F.S.; de Figueirêdo, R.M.F.; Queiroz, A.J.d.M.; Santos, D. da C. Drying Kinetics and Physical and Chemical Characterization of White-Fleshed ‘Pitaya’ Peels. Rev. Bras. Eng. Agric. Ambient. 2017, 21, 872–877. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of Process Conditions on the Physicochemical Properties of Açai (Euterpe Oleraceae Mart.) Powder Produced by Spray Drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Listyarini, R.V.; Susilawatib, P.R.; Nukung, E.N.; Anastasia, M.; Yua, T. Bioplastic from Pectin of Dragon Fruit (Hylocereus polyrhizus) Peel. J. Sci. Appl. Chem. 2020, 23, 203–208. [Google Scholar] [CrossRef]

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Song, H.; Kim, K.; Kwon, E.E.; Jae, Y. Production of Bioplastic through Food Waste Valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef]

- Bátori, V.; Jabbari, M.; Åkesson, D.; Lennartsson, P.R.; Taherzadeh, M.J.; Zamani, A. Production of Pectin-Cellulose Biofilms: A New Approach for Citrus Waste Recycling. J. Polym. Sci. 2017, 2017, 9732329. [Google Scholar] [CrossRef] [Green Version]

- Gustafsson, J.; Landberg, M.; Veronika, B.; Åkesson, D. Development of Bio-Based Films and 3D Objects from Apple Pomace. Polymers 2019, 11, 289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bátori, V.; Lundin, M.; Åkesson, D.; Lennartsson, P.R.; Taherzadeh, M.J.; Zamani, A. The Effect of Glycerol, Sugar, and Maleic Anhydride on Pectin-Cellulose Thin Films Prepared from Orange Waste. Polymers 2019, 11, 392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and Opportunities of Biodegradable Plastics: A Mini Review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Ginting, M.H.S.; Hasibuan, R.; Lubis, M.; Alanjani, F.; Winoto, F.A.; Siregar, R.C. Utilization of Avocado Seeds as Bioplastic Films Filler Chitosan and Ethylene Glycol Plasticizer. Asian J. Chem. 2018, 30, 1569–1573. [Google Scholar] [CrossRef]

- Sprajcar, M.; Horvat, P.; Krzan, A. Biopolymers and Bioplastics: Plastics Aligned with Nature; National Institute of Chemistry: Ljubljana, Slovenia, 2012; pp. 1–32. [Google Scholar]

- Putra, E.P.D.; Thamrin, E.S.; Saputra, H. Effect of Dragon Fruit Skin Extract (Hylocereus costaricensis) on Bio-Plastic Physical and Mechanical Properties of Cassava Starch and Polyvinyl Alcohol. IOP Conf. Ser. Earth Environ. Sci. 2019, 258, 012047. [Google Scholar] [CrossRef]

- Azeredo, H.M.C. Betalains: Properties, Sources, Applications, and Stability-A Review. Int. J. Food Sci. Technol. 2009, 44, 2365–2376. [Google Scholar] [CrossRef] [Green Version]

- Strack, D.; Vogt, T.; Schliemann, W. Recent Advances in Betalain Research. Phytochemistry 2003, 62, 247–269. [Google Scholar] [CrossRef]

- Cai, Y.; Sun, M.; Corke, H. Colorant Properties and Stability of Amaranthus Betacyanin Pigments. J. Agric. Food Chem. 1998, 46, 4491–4495. [Google Scholar] [CrossRef]

- Stintzing, F.C.; Schieber, A.; Carle, R. Identification of Betalains from Yellow Beet (Beta vulgaris L.) and Cactus Pear [Opuntia ficus-indica (L.) Mill.] by High-Performance Liquid Chromatography-Electrospray Ionization Mass Spectrometry. J. Agric. Food Chem. 2002, 50, 2302–2307. [Google Scholar] [CrossRef]

- Kugler, F.; Stintzing, F.C.; Carle, R. Identification of Betalains from Petioles of Differently Colored Swiss Chard (Beta vulgaris L. ssp. Cicla [L.] Alef. Cv. Bright Lights) by High-Performance Liquid Chromatography-Electrospray Ionization Mass Spectrometry. J. Agric. Food Chem. 2004, 52, 2975–2981. [Google Scholar] [CrossRef]

- Vaillant, F.; Perez, A.; Davila, I.; Dornier, M.; Reynes, M. Colorant and Antioxidant Properties of Red-Purple Pitahaya (Hylocereus sp.). Fruits 2005, 60, 3–12. [Google Scholar] [CrossRef] [Green Version]

- Lu, G.; Edwards, C.G.; Fellman, J.K.; Scott Mattinson, D.; Navazio, J. Biosynthetic Origin of Geosmin in Red Beets (Beta vulgaris L.). J. Agric. Food Chem. 2003, 51, 1026–1029. [Google Scholar] [CrossRef]

- Stintzing, C.; Kugler, F.; Carle, R.; Conrad, J. First 13 C-NMR Assignments of Betaxanthins. Helv. Chim. Acta 2006, 89, 1008–1016. [Google Scholar] [CrossRef]

- Stintzing, F.C.; Schieber, A.; Carle, R. Evaluation of Colour Properties and Chemical Quality Parameters of Cactus Juices. Eur. Food Res. Technol. 2003, 216, 303–311. [Google Scholar] [CrossRef]

- Castellar, M.R.; Obón, J.M.; Fernández-López, J.A. The Isolation and Properties of a Concentrated Red-Purple Betacyanin Food Colourant from Opuntia Stricta Fruits. J. Sci. Food Agric. 2006, 86, 122–128. [Google Scholar] [CrossRef]

- Handayani, M.N.; Khoerunnisa, I.; Cakrawati, D.; Sulastri, A. Microencapsulation of Dragon Fruit (Hylocereus polyrhizus) Peel Extract Using Maltodextrin. IOP Conf. Ser. Mater. Sci. Eng. 2018, 288, 012099. [Google Scholar] [CrossRef]

- de Mello, F.R.; Bernardo, C.; Dias, C.O.; Gonzaga, L.; Amante, E.R.; Fett, R.; Candido, L.M.B. Antioxidant Properties, Quantification and Stability of Betalains from Pitaya (Hylocereus undatus) Peel. Cienc. Rural 2015, 45, 323–328. [Google Scholar] [CrossRef]

- Vergara, C.; Saavedra, J.; Sáenz, C.; García, P.; Robert, P. Microencapsulation of Pulp and Ultrafiltered Cactus Pear (Opuntia Ficus-Indica) Extracts and Betanin Stability during Storage. Food Chem. 2014, 157, 246–251. [Google Scholar] [CrossRef]

- Pichayajittipong, P.; Thaiudom, S. Optimum Condition of Beta-Cyanin Colorant Production from Red Dragon Fruit (Hylocercus Polyrhizus) Peels Using Response Surface Methodology. Chiang Mai Univ. J. Nat. Sci. 2014, 13, 483–496. [Google Scholar] [CrossRef] [Green Version]

- Delgado-Vargas, F.; Jimenez, A.R.; Lopez, O.P. Natural Pigments: Carotenoids, Anthocyanins, and Betalains—Characteristics, Biosynthesis, Processing, and Stability. Food Sci. Nutr. 2000, 40, 176–271. [Google Scholar] [CrossRef]

- Schliemann, W.; Kobayashi, N.; Strack, D. The Decisive Step in Betaxanthin Biosynthesis Is a Spontaneous Reaction. Plant Physiol. 1999, 119, 1217–1232. [Google Scholar] [CrossRef] [Green Version]

- Afandi, A.; Lazim, A.M.; Azwanida, N.N.; Bakar, M.A.; Airianah, O.B.; Fazry, S. Antibacterial Properties of Crude Aqueous Hylocereus polyrhizus Peel Extracts in Lipstick Formulation against Gram-Positive and Negative Bacteria. Malaysian Appl. Biol. 2017, 46, 29–34. [Google Scholar]

- Aher, A.A.; Bairagi, S.M.; Kadaskar, P.T.; Desai, S.S.; Nimase, P.K. Formulation and Evaluation of Herbal Lipstick from Colour Pigments of Bixa orellana (Bixaceae) Seeds. Int. J. Pharm. Pharm. Sci. 2012, 4, 357–359. [Google Scholar]

| Dragon fruit | Pulp | Fresh cut |

| Juice | ||

| Juice powder | ||

| Jelly | ||

| Jam | ||

| Peel | Peel powder | |

| Pectin | ||

| Colour extract | ||

| Seed | Seed oil | |

| Tree seedling |

| No. | Variety | pH | Acidity (Malic Acid and Citric Acid %) | Total Sugar (%) |

|---|---|---|---|---|

| 1 | Amarilla | 3.90 | 0.50 | 11.0 |

| 2 | Blanca | 4.70 | 0.18 | 11.0 |

| 3 | Mamey | 5.00 | 0.15 | 10.0 |

| 4 | Morada | 4.60 | 0.29 | 11.0 |

| 5 | Roja | 4.90 | 0.17 | 10.0 |

| 6 | Ahuatlan municipality | 4.96 | 0.11 | 8.8 |

| 7 | Santa Clara Huitziltepec municipality | 4.97 | 0.09 | 8.9 |

| 8 | S. griseus | 5.20 | 0.12 | 12.2 |

| 9 | Roja | 4.20 | 0.53 | 9.2 |

| 10 | Blanco | 4.40 | 0.39 | 10.0 |

| 11 | Amarillo | 4.46 | 0.50 | 9.1 |

| 12 | Solferina | 3.70 | 0.47 | 9.0 |

| 13 | S. stellatus | 3.95 | 0.64 | 9.1 |

| 14 | Red | - | 0.17 | 9.3 |

| 15 | Orange | 0.13 | 10.3 |

| Carbohydrates Compositions | Percentage (%) |

|---|---|

| Cellulose | 9.25 ± 1.33 |

| Starch | 11.07 ± 0.03 |

| Pectin | 10.79 ± 0.01 |

| Lignin | 37.18 ± 1.02 |

| Sugars i. Glucose ii. Maltose iii. Fructose iv. Sucrose v. Galactose Total sugars | 4.15 ± 0.03 3.37 ± 0.01 0.86 ± 0.02 ND ND 8.38 |

| Total dietary fibre i. Insoluble ii. Soluble iii. Ratio of IDF SDF | 69.30 ± 0.53 56.50 ± 0.20 14.82 ± 0.42 3.8:1.0 |

| Extraction Method | Model | Parameters | Pectin Yield Extraction (%) | Ref. |

|---|---|---|---|---|

| Microwave-Assisted Extraction (MAE) | Respond surface methodology (RSM) | pH 2.07, 65 s and solid–liquid ratio of 66.57 g/mL | 18.53 | Rahmati et al. [42] |

| Respond surface methodology (RSM) | 450 W, 5 min | 21.68 | Tongkham et al. [50] | |

| Respond surface methodology (RSM) | 400 W, 45 °C, 20 min, and solid–liquid ratio of 24 g/mL | 7.5 | Thirugnanasambandham, Sivakumar and Prakash Maran [52] | |

| Ultrasound-Assisted Extraction (UAE) | Respond surface methodology (RSM) | 71.8 °C, 25 min, and solid–liquid ratio of 35.6 g/mL | 7.49 | Lin, Kai and Ali [53] |

| - | 45 °C, 30 min | 9.38 | Nguyen and Pirak [54] |

| Drying Method | Varieties Used | Operational Parameters | Findings | Ref. |

|---|---|---|---|---|

| Drum Drying | Red dragon fruit (Hylocereus polyrhizus) |

|

| [8] |

| Spray Drying | Red dragon (Hylocereus polyrhizus) and white dragon (Hylocereus undatus) fruit |

|

| [57] |

| Spray Drying | Red pitaya fruits (Hylocereus polyrhizus) |

|

| [56] |

| Spray Drying | Red pitaya fruit (Hylocereus polyrhizus) |

|

| [58] |

| Tray Drying | White dragon fruit (Hylocereus undatus) |

| Increase in the drying temperature from 50 to 70 °C led to increases in:

| [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taharuddin, N.H.; Jumaidin, R.; Mansor, M.R.; Hazrati, K.Z.; Tarique, J.; Asyraf, M.R.M.; Razman, M.R. Unlocking the Potential of Lignocellulosic Biomass Dragon Fruit (Hylocereus polyrhizus) in Bioplastics, Biocomposites and Various Commercial Applications. Polymers 2023, 15, 2654. https://doi.org/10.3390/polym15122654

Taharuddin NH, Jumaidin R, Mansor MR, Hazrati KZ, Tarique J, Asyraf MRM, Razman MR. Unlocking the Potential of Lignocellulosic Biomass Dragon Fruit (Hylocereus polyrhizus) in Bioplastics, Biocomposites and Various Commercial Applications. Polymers. 2023; 15(12):2654. https://doi.org/10.3390/polym15122654

Chicago/Turabian StyleTaharuddin, N. H., R. Jumaidin, M. R. Mansor, K. Z. Hazrati, J. Tarique, M. R. M. Asyraf, and M. R. Razman. 2023. "Unlocking the Potential of Lignocellulosic Biomass Dragon Fruit (Hylocereus polyrhizus) in Bioplastics, Biocomposites and Various Commercial Applications" Polymers 15, no. 12: 2654. https://doi.org/10.3390/polym15122654

APA StyleTaharuddin, N. H., Jumaidin, R., Mansor, M. R., Hazrati, K. Z., Tarique, J., Asyraf, M. R. M., & Razman, M. R. (2023). Unlocking the Potential of Lignocellulosic Biomass Dragon Fruit (Hylocereus polyrhizus) in Bioplastics, Biocomposites and Various Commercial Applications. Polymers, 15(12), 2654. https://doi.org/10.3390/polym15122654