Effect of Strain Rate on Tensile Properties of Carbon Fiber-Reinforced Epoxy Laminates with Different Stacking Sequences and Ply Orientations

Abstract

:1. Introduction

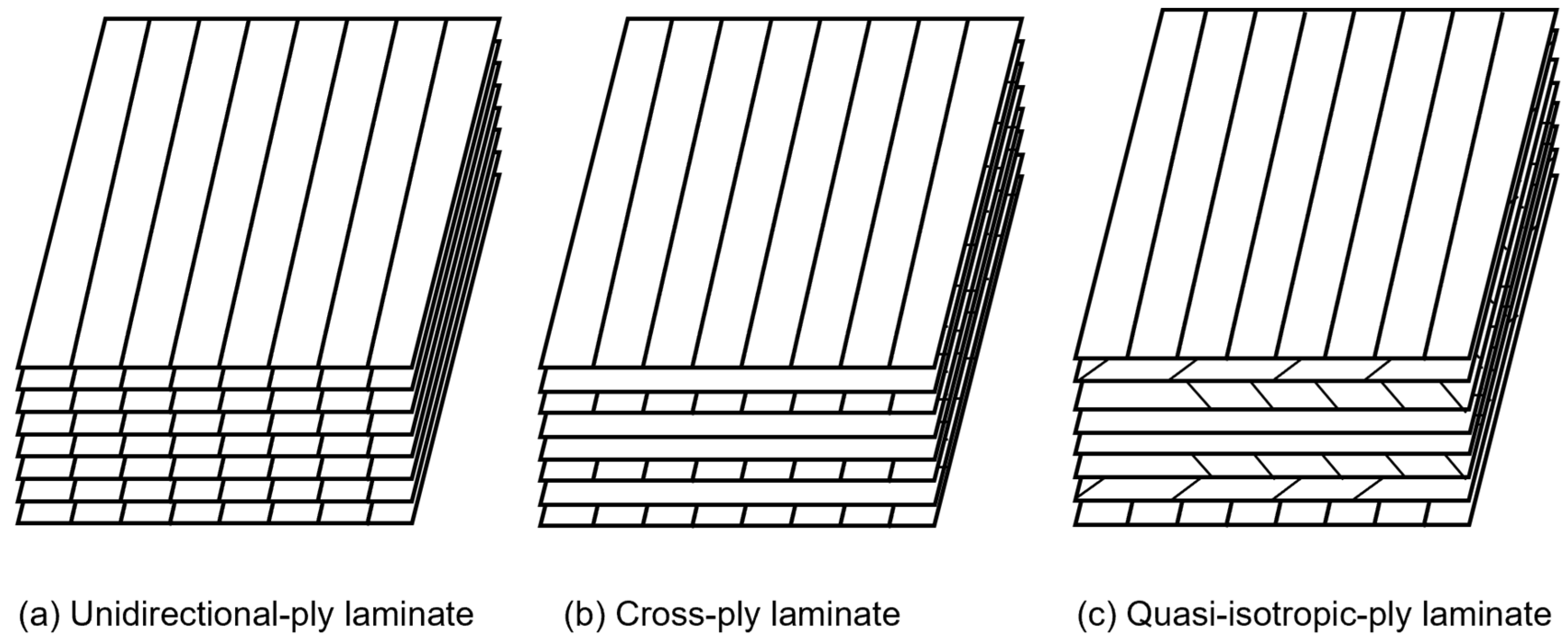

2. Materials and Methods

2.1. Materials

2.2. Mechanical Property Test

2.3. Dynamic Stress Equilibrium

3. Results and Discussion

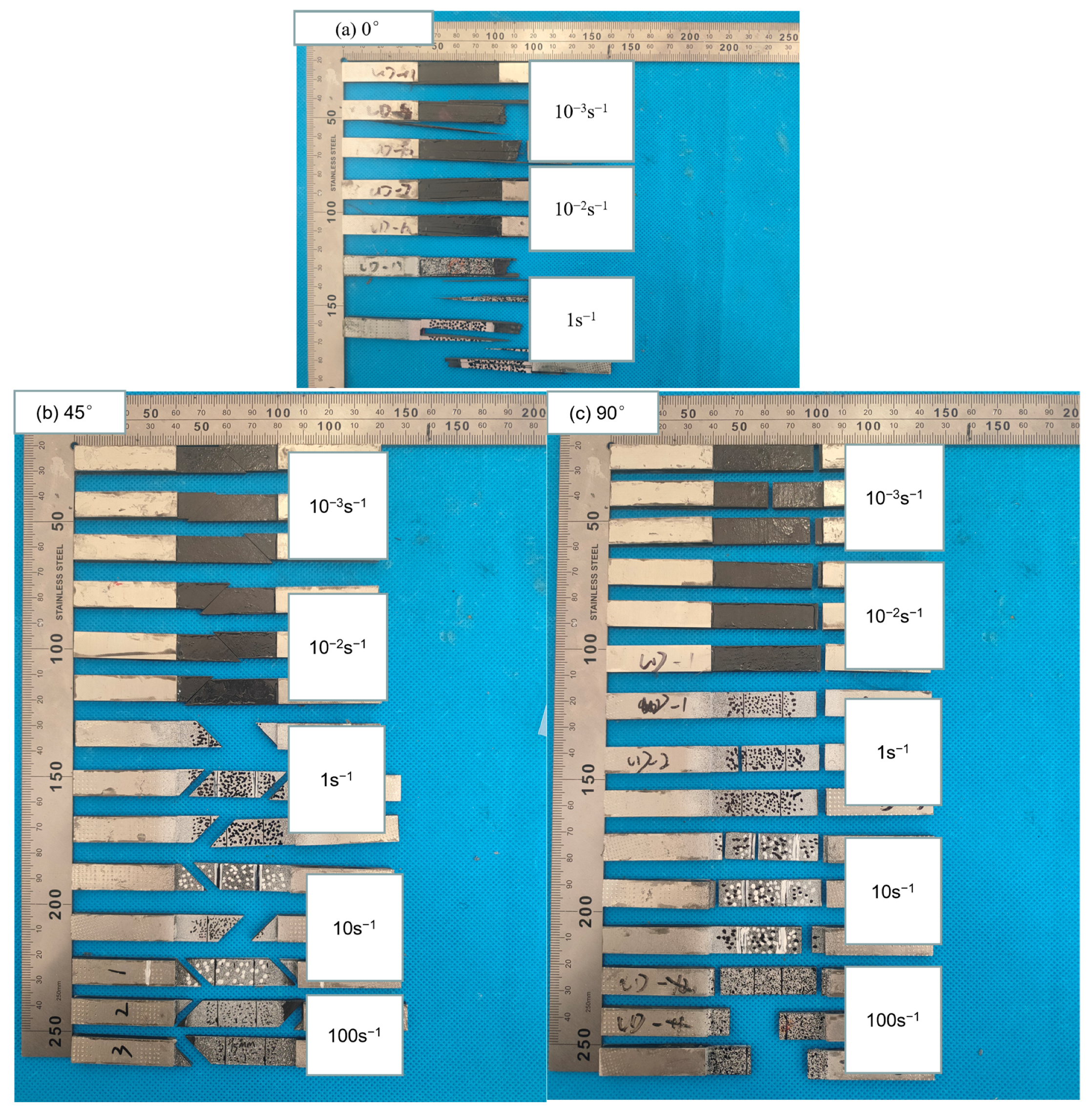

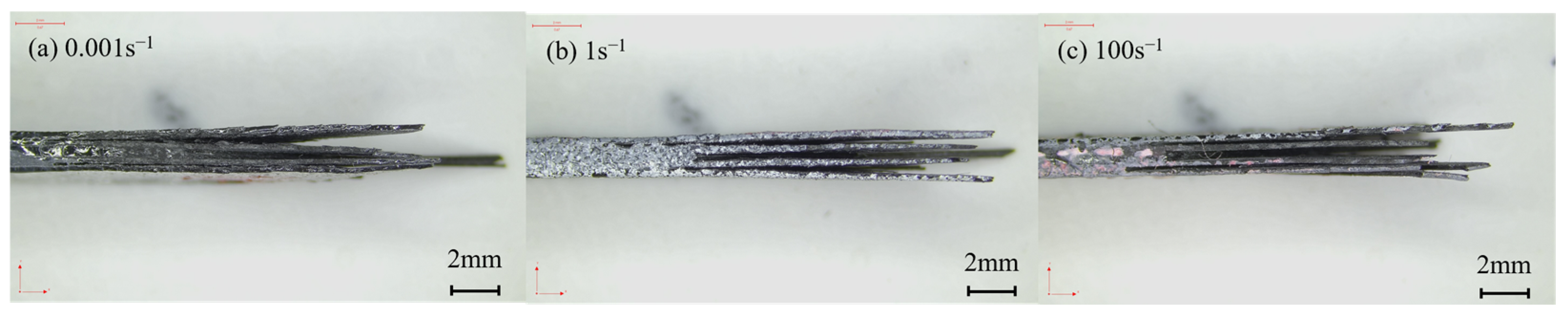

3.1. Mechanical Property Test

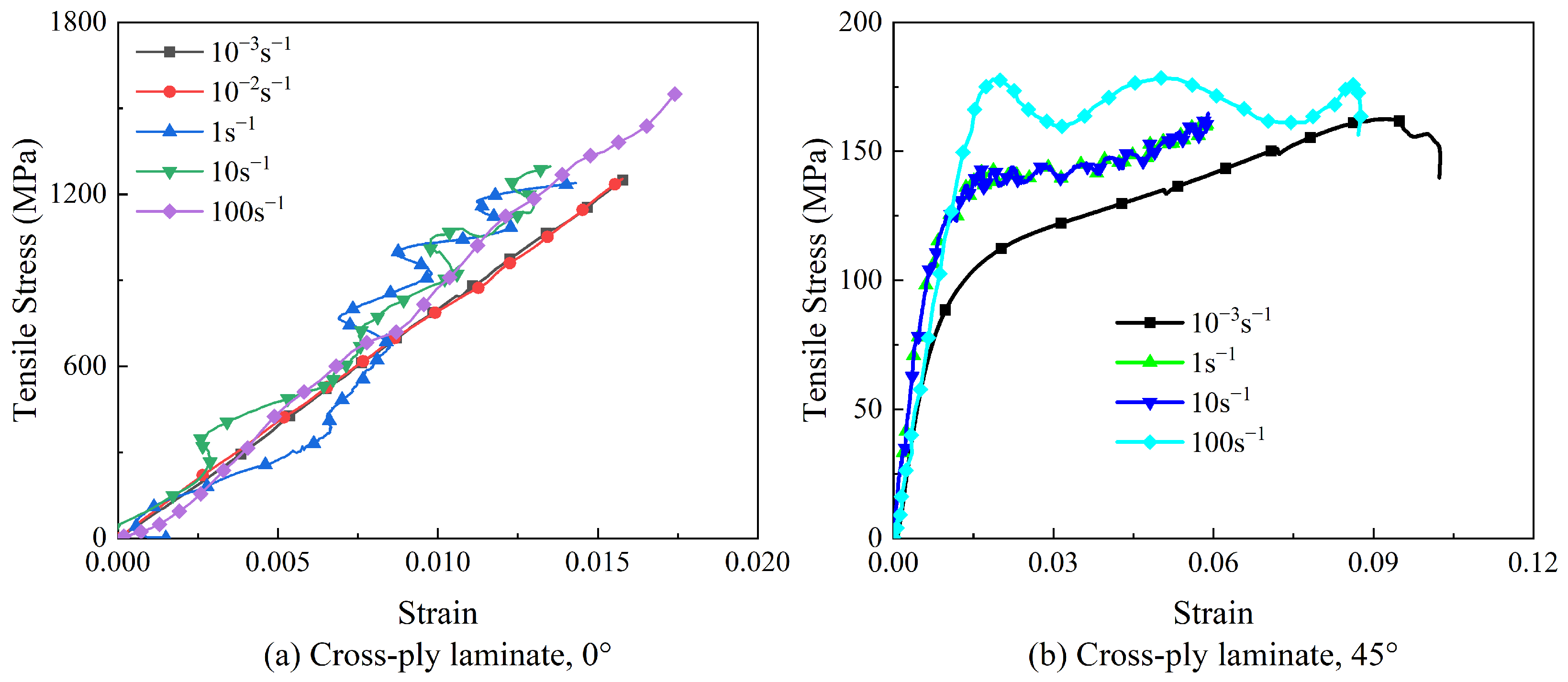

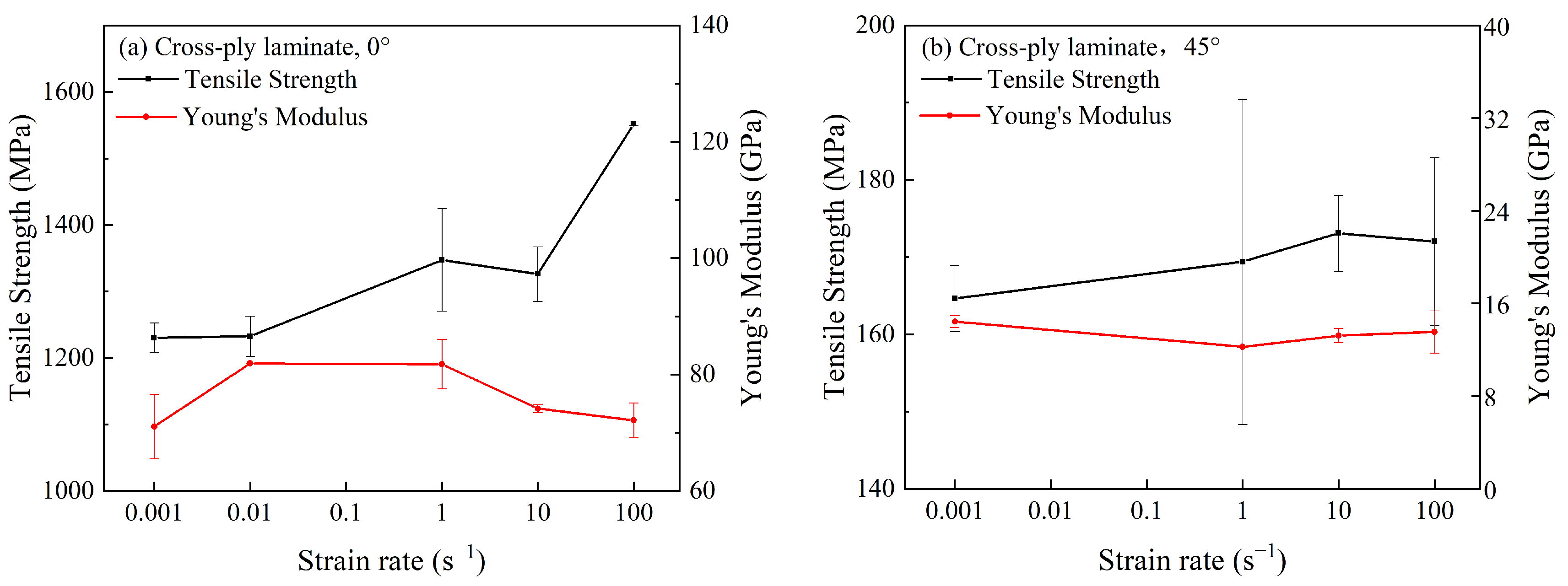

3.2. Cross-Ply Laminates

3.3. Quasi-Isotropic-Ply Laminates

4. Conclusions

- (1)

- Generally, the tensile strengths of CFRP laminates were sensitive to the strain rate. The sensitivity was related to the stacking sequences and ply orientations, while Young’s modulus was independent of the strain rate.

- (2)

- The strain rate effect of CFRP laminates was mainly caused by the resin matrix and interface bonding. For unidirectional-ply laminates, the tensile strength of 90° specimens displayed strong strain rate effects. Additionally, the sensitivity of the tensile properties of the 45° specimen to the strain rate was between that of the 0° and 90° specimens.

- (3)

- The strain rate sensitivity of the tensile strengths of the cross- and quasi-isotropic-ply laminates were lower than that of unidirectional-ply laminates. The difference in the strain rate effect between the matrix and the fiber facilitated the crack initiation and propagation in the cross- and quasi-isotropic-ply laminates, delaying the resin matrix deformation, which was the main attributor for the strain rate effect of the composites.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Al Zahmi, S.; Alhammadi, S.; El Hassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Liu, W.; Xu, W.; Ji, Y. Durability Investigation on CFRP Strengthened Cementitious Materials in Cold Region. Polymers 2022, 14, 2190. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-H.; Hsu, P.-W.; Huang, C.-H.; Lai, M.-F.; Shiu, B.-C.; Lou, C.-W. A Study on Carbon Fiber Composites with Low-Melting-Point Polyester Nonwoven Fabric Reinforcement: A Highly Effective Electromagnetic Wave Shield Textile Material. Polymers 2022, 14, 1181. [Google Scholar] [CrossRef] [PubMed]

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F.; Eltai, E.; Khraisheh, M. Towards the Development of Novel Hybrid Composite Steel Pipes: Electrochemical Evaluation of Fiber-Reinforced Polymer Layered Steel against Corrosion. Polymers 2021, 13, 3805. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, X.T.; Hou, S.; Liu, T.; Han, X. A potential natural energy absorption material—Coconut mesocarp: Part A: Experimental investigations on mechanical properties. Int. J. Mech. Sci. 2016, 115, 564–573. [Google Scholar] [CrossRef]

- Wang, S.-X.; Wu, L.-Z.; Ma, L. Low-velocity impact and residual tensile strength analysis to carbon fiber composite laminates. Mater. Des. 2010, 31, 118–125. [Google Scholar] [CrossRef]

- Drdlová, M.; Čechmánek, R. Comparison of tensile behaviour of polypropylene, aramid and carbon fibre reinforced cementitious composite at high strain rate loading. Procedia Struct. Integr. 2018, 13, 1731–1738. [Google Scholar] [CrossRef]

- Hou, J.P.; Ruiz, C. Measurement of the properties of woven CFRP T300/914 at different strain rates. Compos. Sci. Technol. 2000, 60, 2829–2834. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Xia, Y.; Jeelani, S. Tensile behavior of carbon fiber bundles at different strain rates. Mater. Lett. 2010, 64, 246–248. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, Y.; Li, Z.-X. Experimental study on the tensile behavior of unidirectional and plain weave CFRP laminates under different strain rates. Compos. Part B Eng. 2019, 164, 524–536. [Google Scholar] [CrossRef]

- Kapoor, R.; Pangeni, L.; Bandaru, A.K.; Ahmad, S.; Bhatnagar, N. High strain rate compression response of woven Kevlar reinforced polypropylene composites. Compos. Part B Eng. 2016, 89, 374–382. [Google Scholar] [CrossRef]

- Wang, J.; Wen, L.; Xiao, J.; Liang, T.; Hu, X.; Li, P. The mechanical properties and constitutive model of two woven composites including the influences of temperature, strain rate and damage growth. Compos. Part B Eng. 2019, 161, 502–513. [Google Scholar] [CrossRef]

- Gilat, A.; Goldberg, R.K.; Roberts, G.D. Experimental study of strain-rate-dependent behavior of carbon/epoxy composite. Compos. Sci. Technol. 2002, 62, 1469–1476. [Google Scholar] [CrossRef]

- Taniguchi, N.; Nishiwaki, T.; Kawada, H. Tensile strength of unidirectional CFRP laminate under high strain rate. Adv. Compos. Mater. 2007, 16, 167–180. [Google Scholar] [CrossRef]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S. High strain rate compression response of carbon/epoxy laminate composites. Compos. Struct. 2001, 52, 405–417. [Google Scholar] [CrossRef]

- Xiao, X. Dynamic tensile testing of plastic materials. Polym. Test. 2008, 27, 164–178. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, S.; Mao, Y.; He, L.; Han, X. Rate-related study on the ply orientation of carbon fiber reinforced epoxy composite laminates. Int. J. Mech. Sci. 2020, 188, 105968. [Google Scholar] [CrossRef]

- Guo, F. Research on the Failure of Carbon Fiber Braided Composites under Dynamic Loading. Ph.D. Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar]

- Chen, X.; Li, Y.; Zhi, Z.; Guo, Y.; Ouyang, N. The compressive and tensile behavior of a 0/90 C fiber woven composite at high strain rates. Carbon 2013, 61, 97–104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Bao, Z.; Han, W.; Wang, X.; Huang, S.; Huang, L.; Chen, Q.; Zhao, H.; Xu, Y. Effect of Strain Rate on Tensile Properties of Carbon Fiber-Reinforced Epoxy Laminates with Different Stacking Sequences and Ply Orientations. Polymers 2023, 15, 2711. https://doi.org/10.3390/polym15122711

Gao D, Bao Z, Han W, Wang X, Huang S, Huang L, Chen Q, Zhao H, Xu Y. Effect of Strain Rate on Tensile Properties of Carbon Fiber-Reinforced Epoxy Laminates with Different Stacking Sequences and Ply Orientations. Polymers. 2023; 15(12):2711. https://doi.org/10.3390/polym15122711

Chicago/Turabian StyleGao, Donglin, Zuguo Bao, Weijian Han, Xianpeng Wang, Shiyao Huang, Li Huang, Qiuren Chen, Hailong Zhao, and Yahong Xu. 2023. "Effect of Strain Rate on Tensile Properties of Carbon Fiber-Reinforced Epoxy Laminates with Different Stacking Sequences and Ply Orientations" Polymers 15, no. 12: 2711. https://doi.org/10.3390/polym15122711

APA StyleGao, D., Bao, Z., Han, W., Wang, X., Huang, S., Huang, L., Chen, Q., Zhao, H., & Xu, Y. (2023). Effect of Strain Rate on Tensile Properties of Carbon Fiber-Reinforced Epoxy Laminates with Different Stacking Sequences and Ply Orientations. Polymers, 15(12), 2711. https://doi.org/10.3390/polym15122711