The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect

Abstract

:1. Introduction

2. Preparation Methods of Microcapsules

2.1. Interfacial Polymerization Method

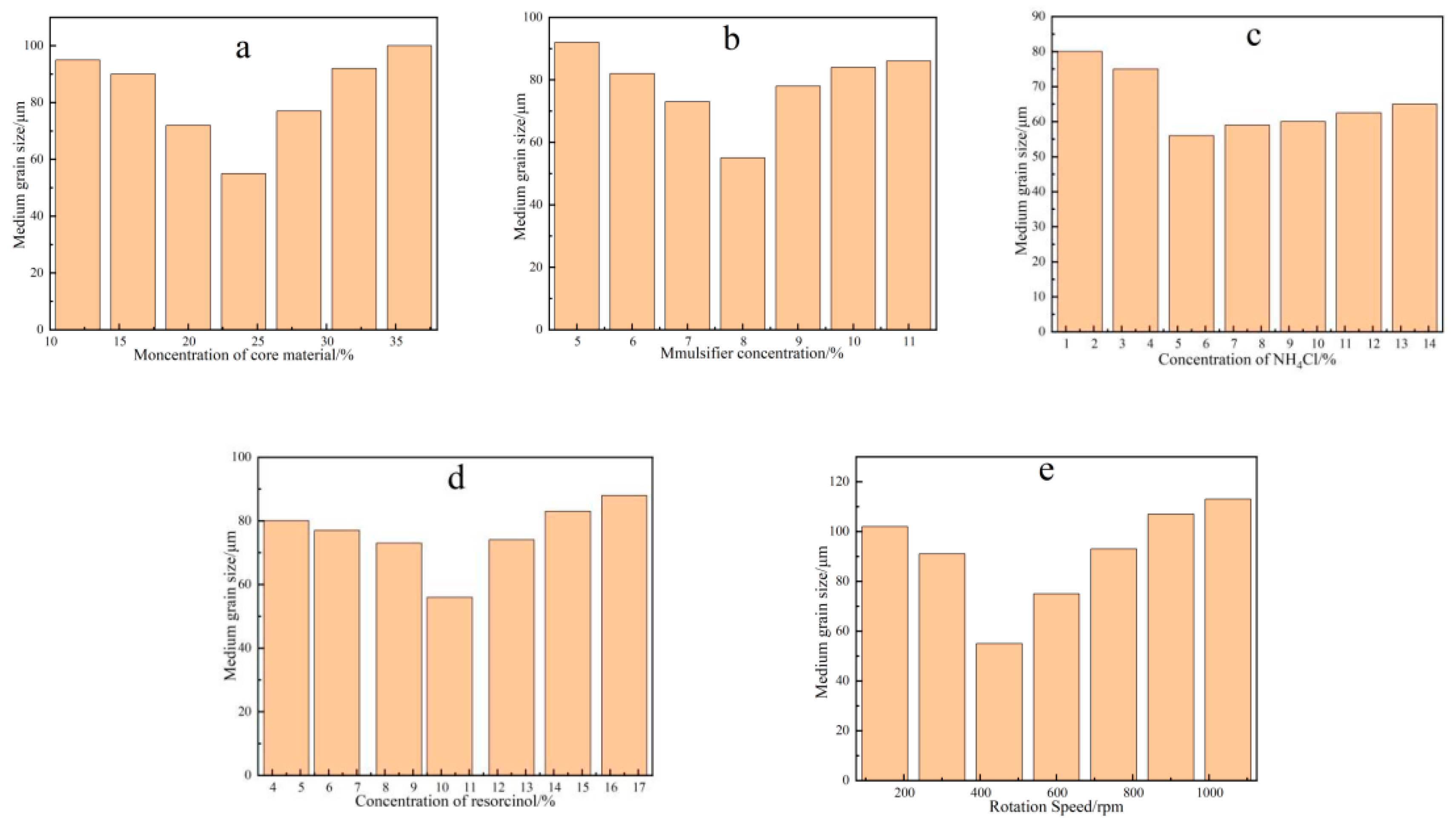

2.2. In Situ Polymerization

2.3. Spray Drying Method

2.4. Melt Condensation Method

3. Intrinsic Properties of Microcapsules

3.1. Core Fraction

3.2. Sealing Performance

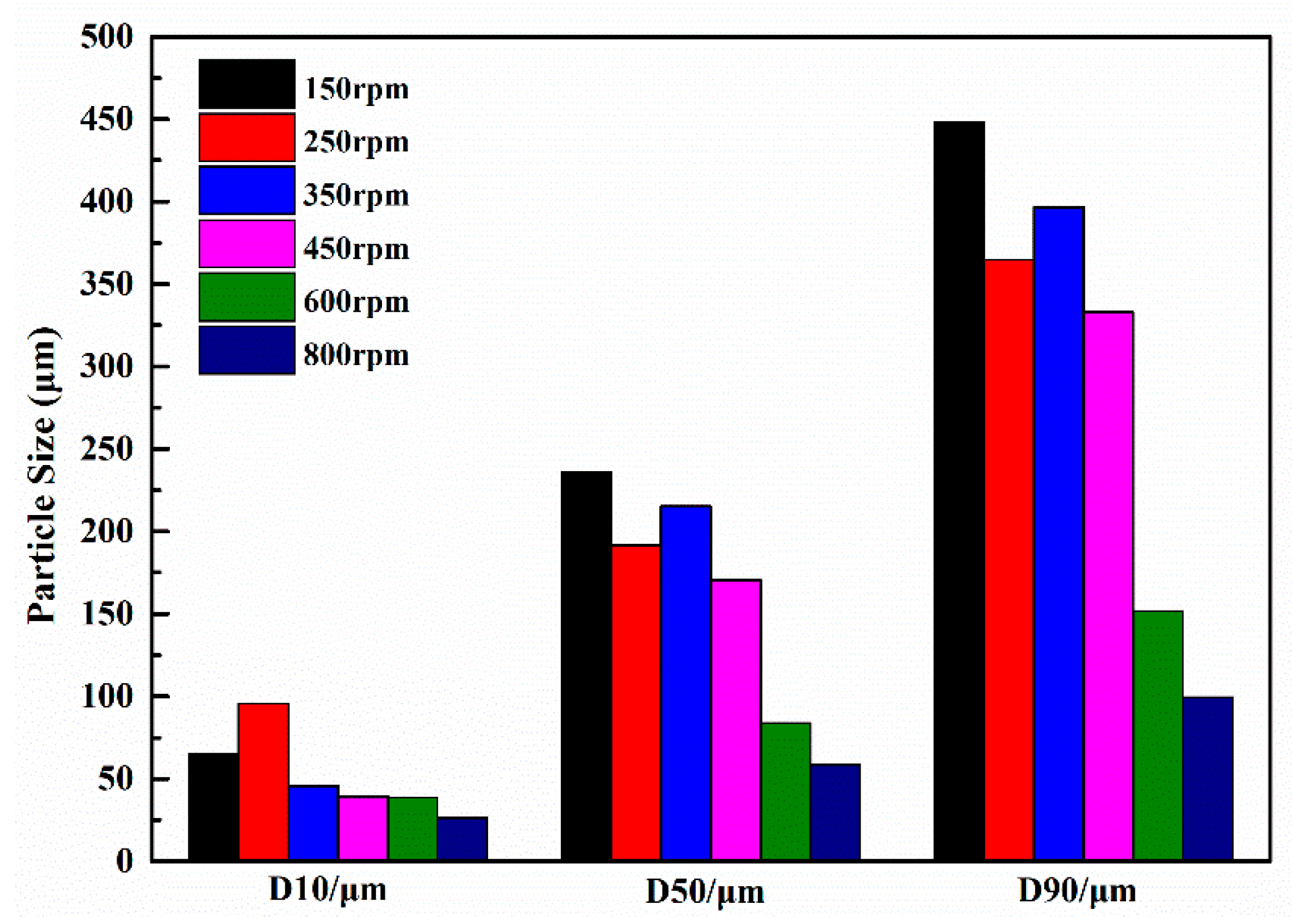

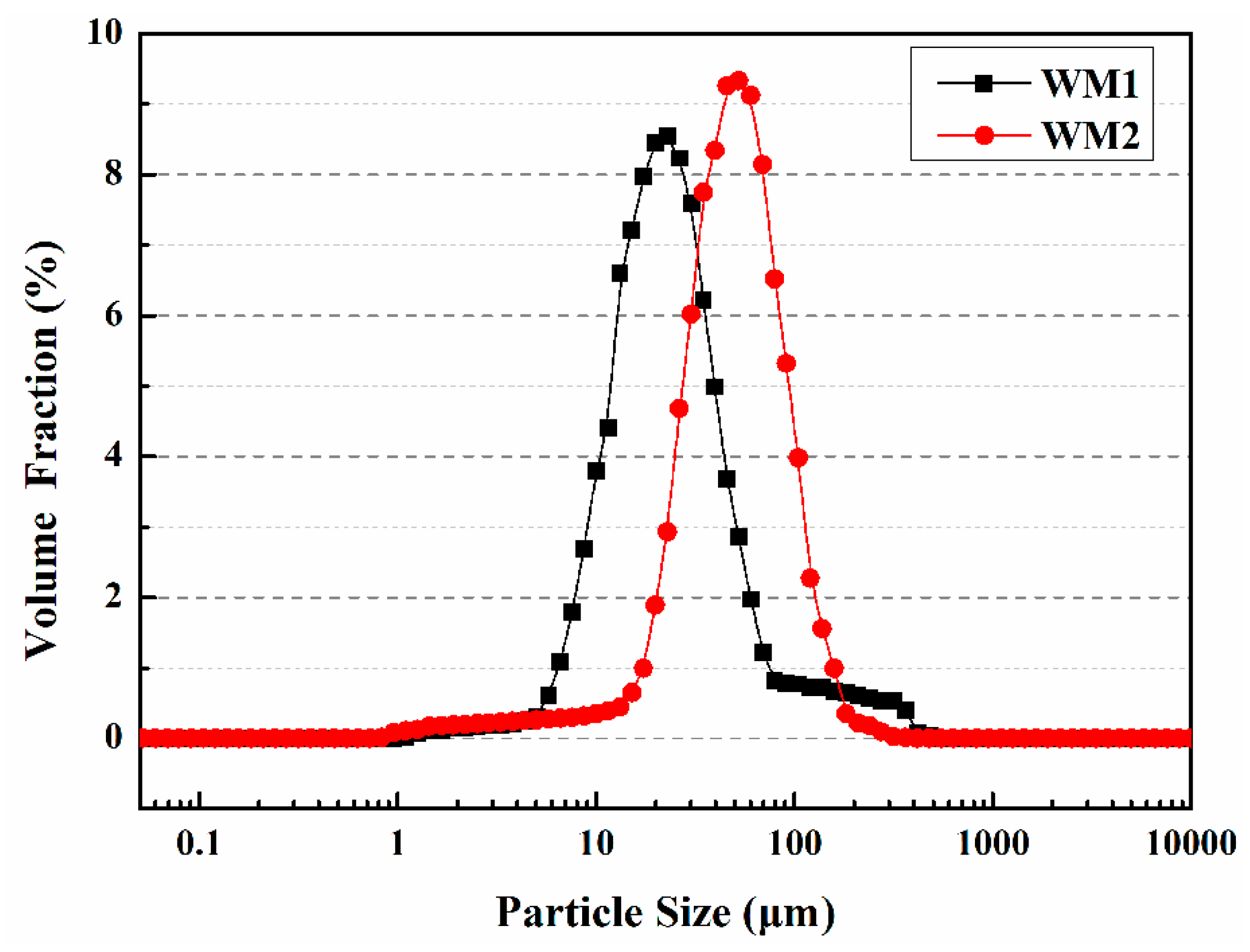

3.3. Particle Size Distributions

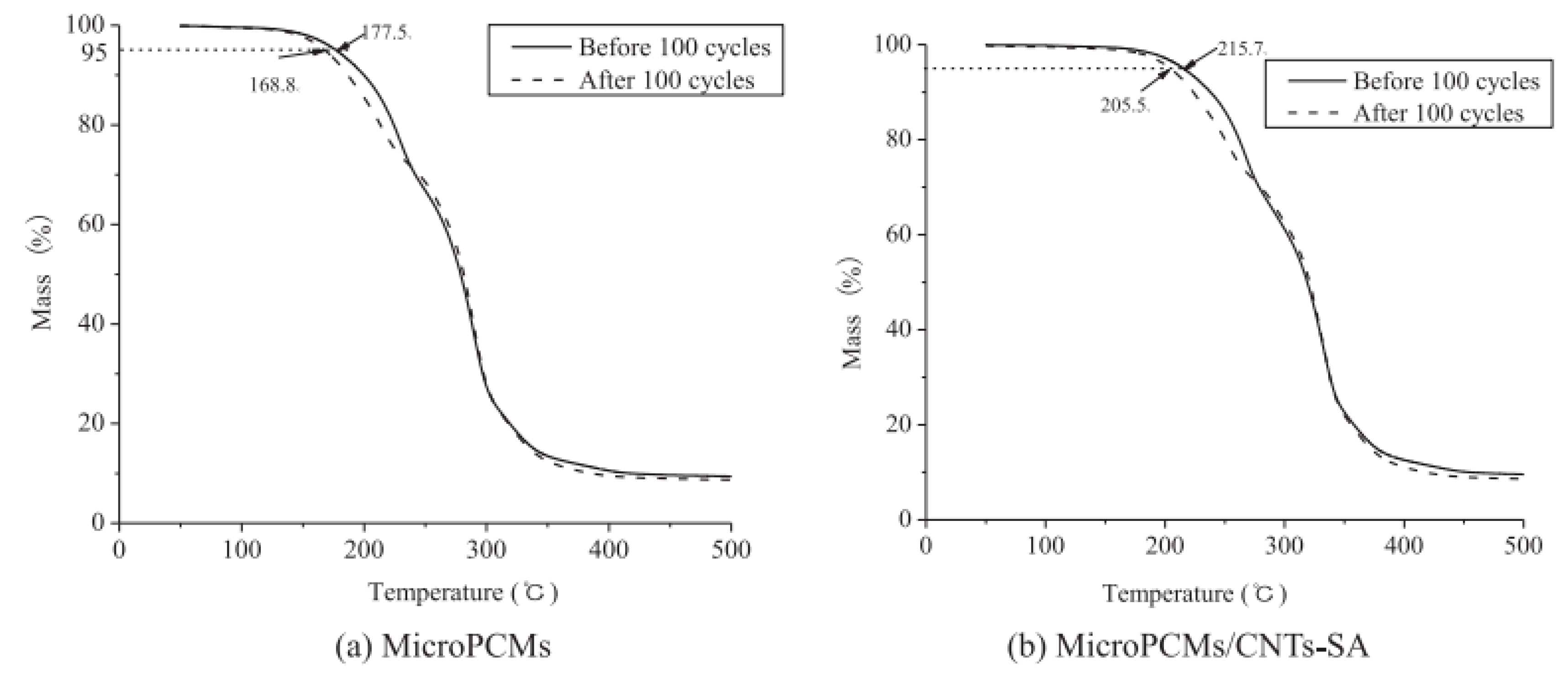

3.4. Thermal Performance

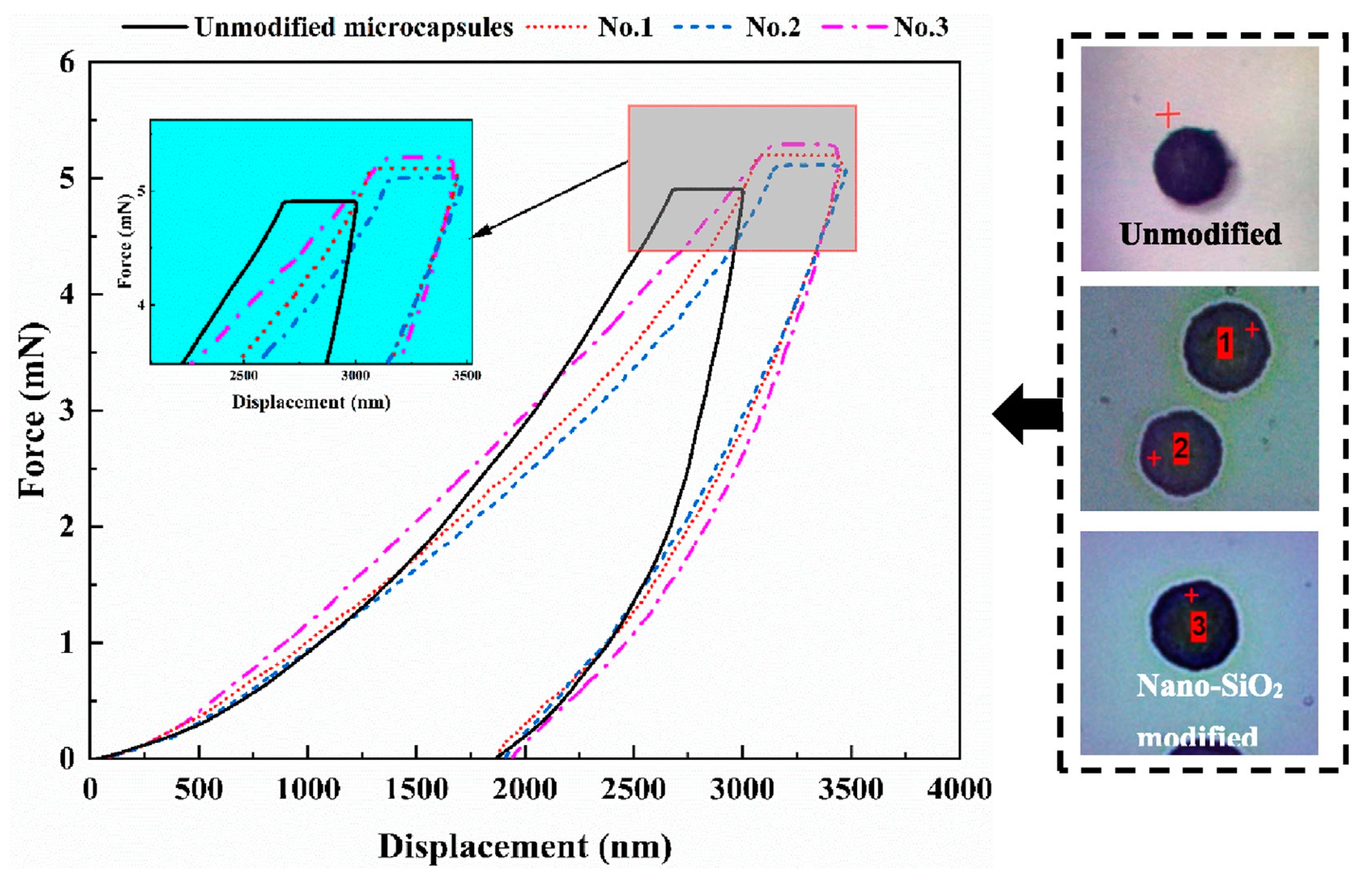

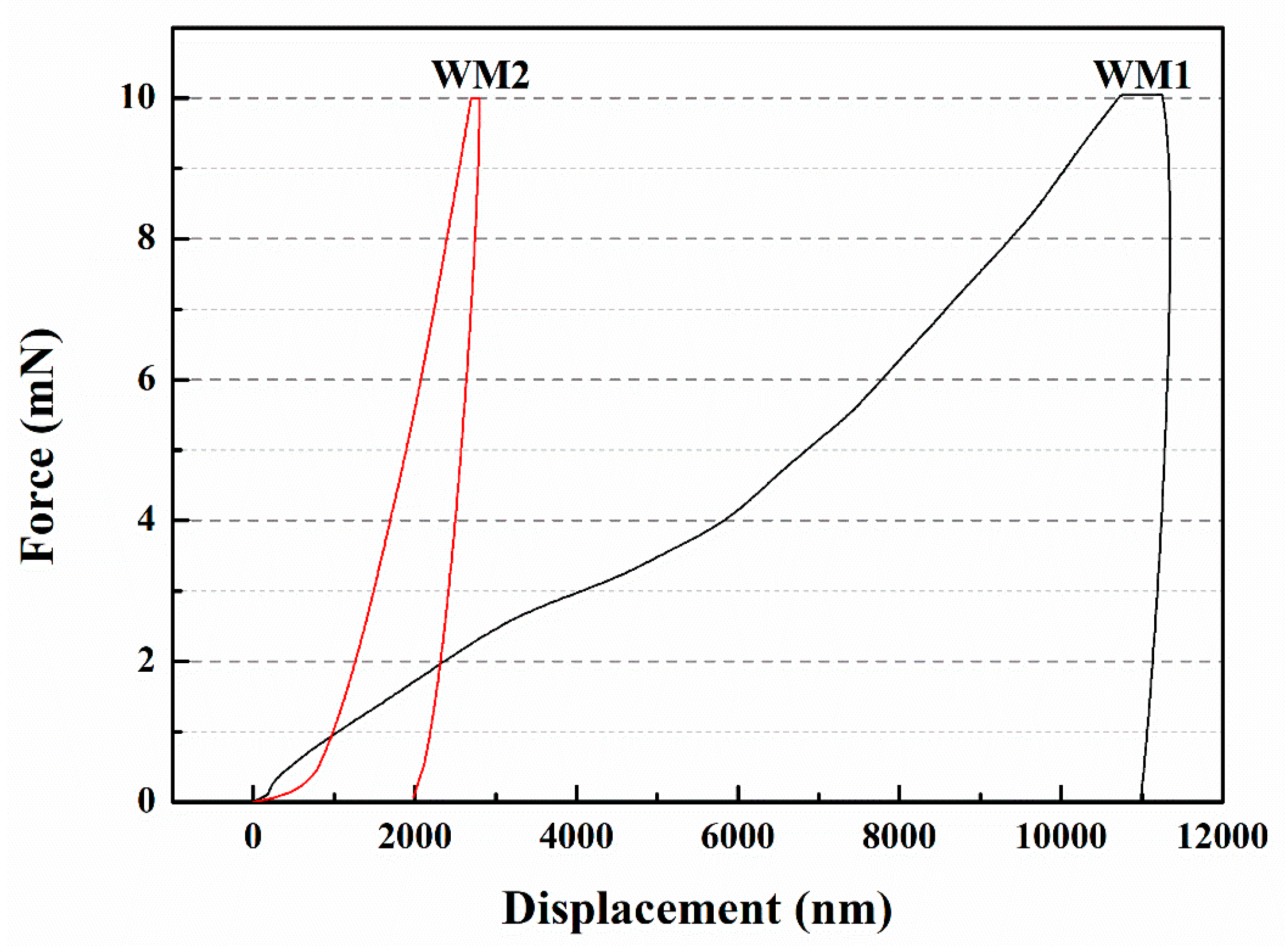

3.5. Micromechanical Properties

4. The Effect of Microcapsule Addition on the Initial Properties of the Cement-Based Material

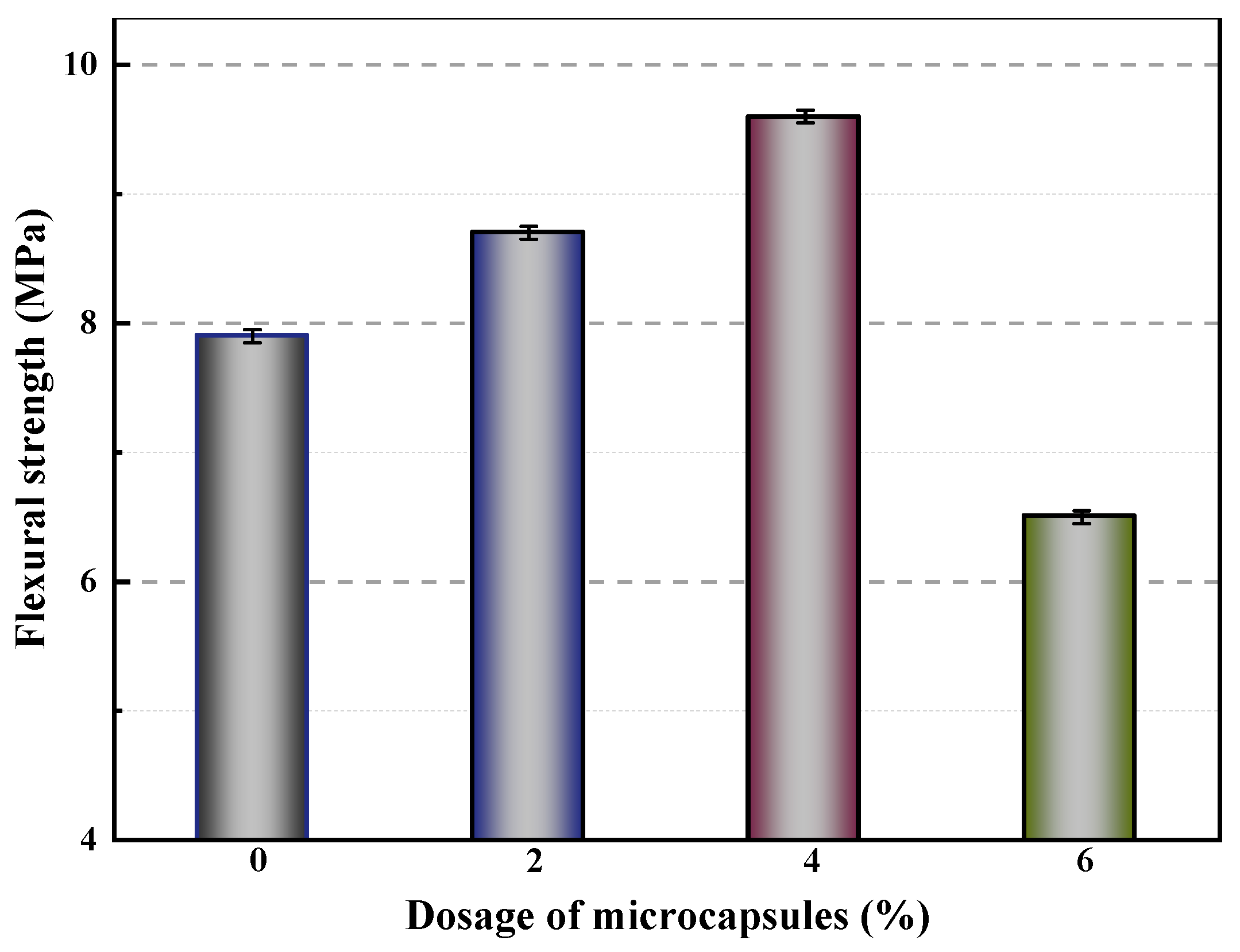

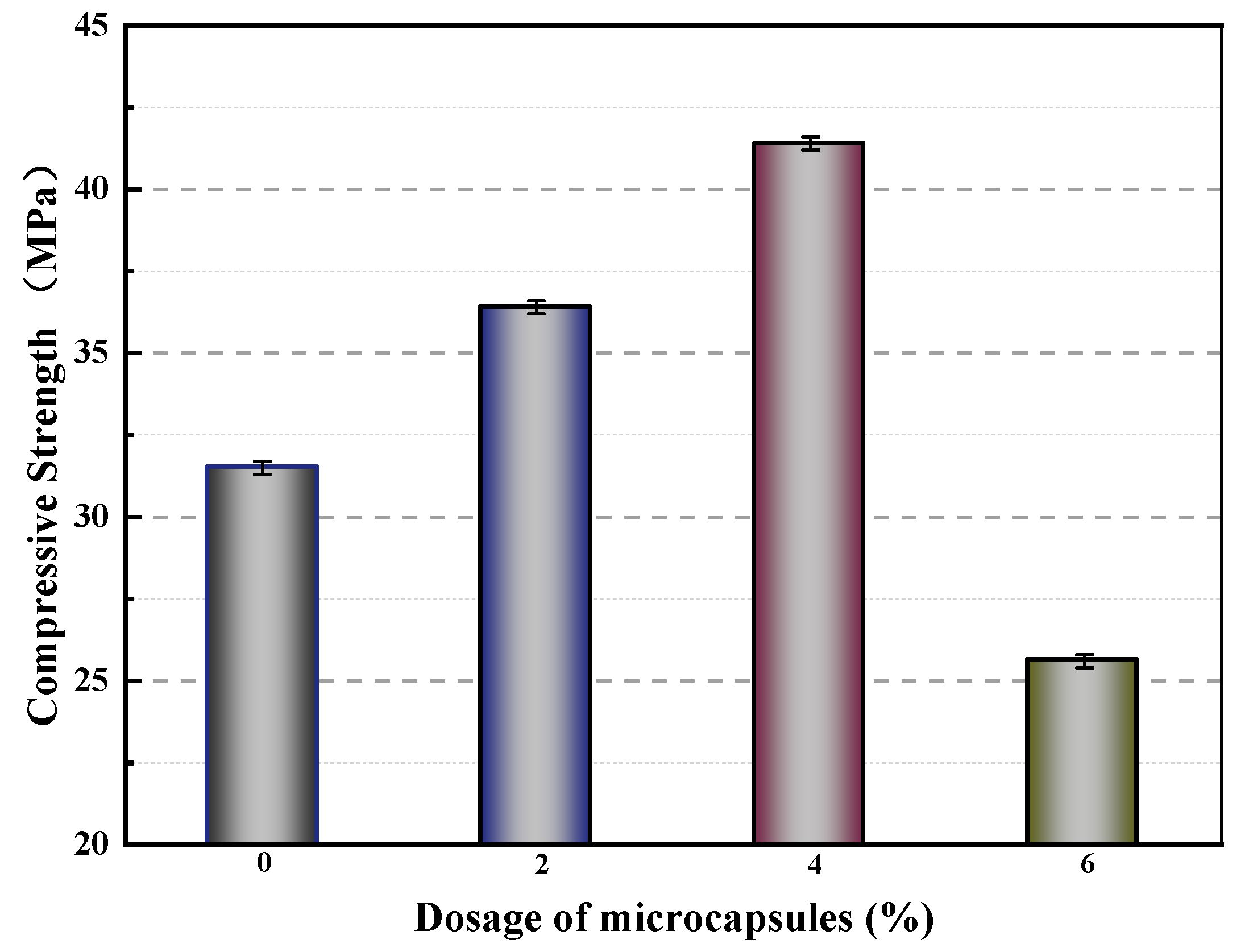

4.1. Mechanical Properties

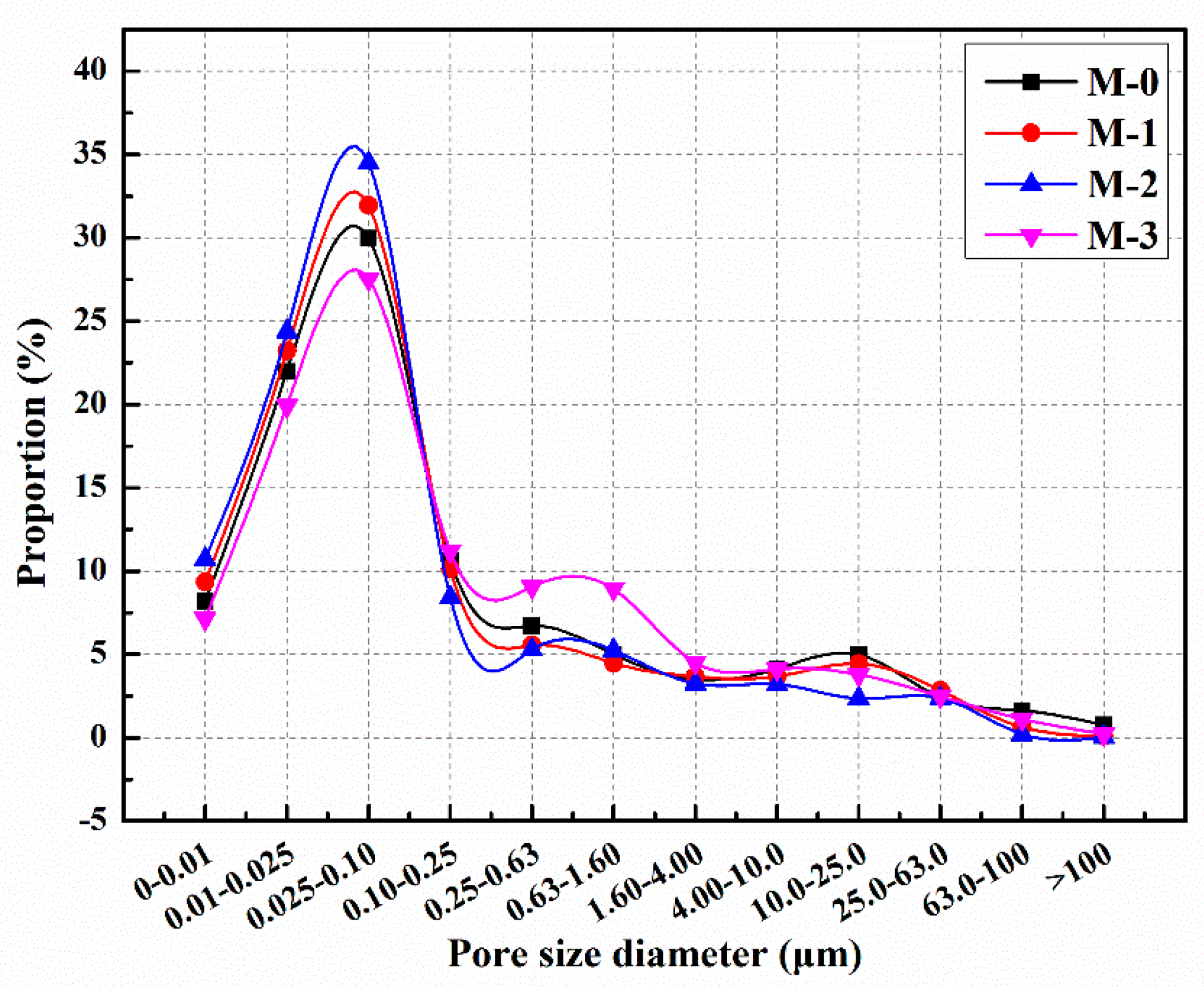

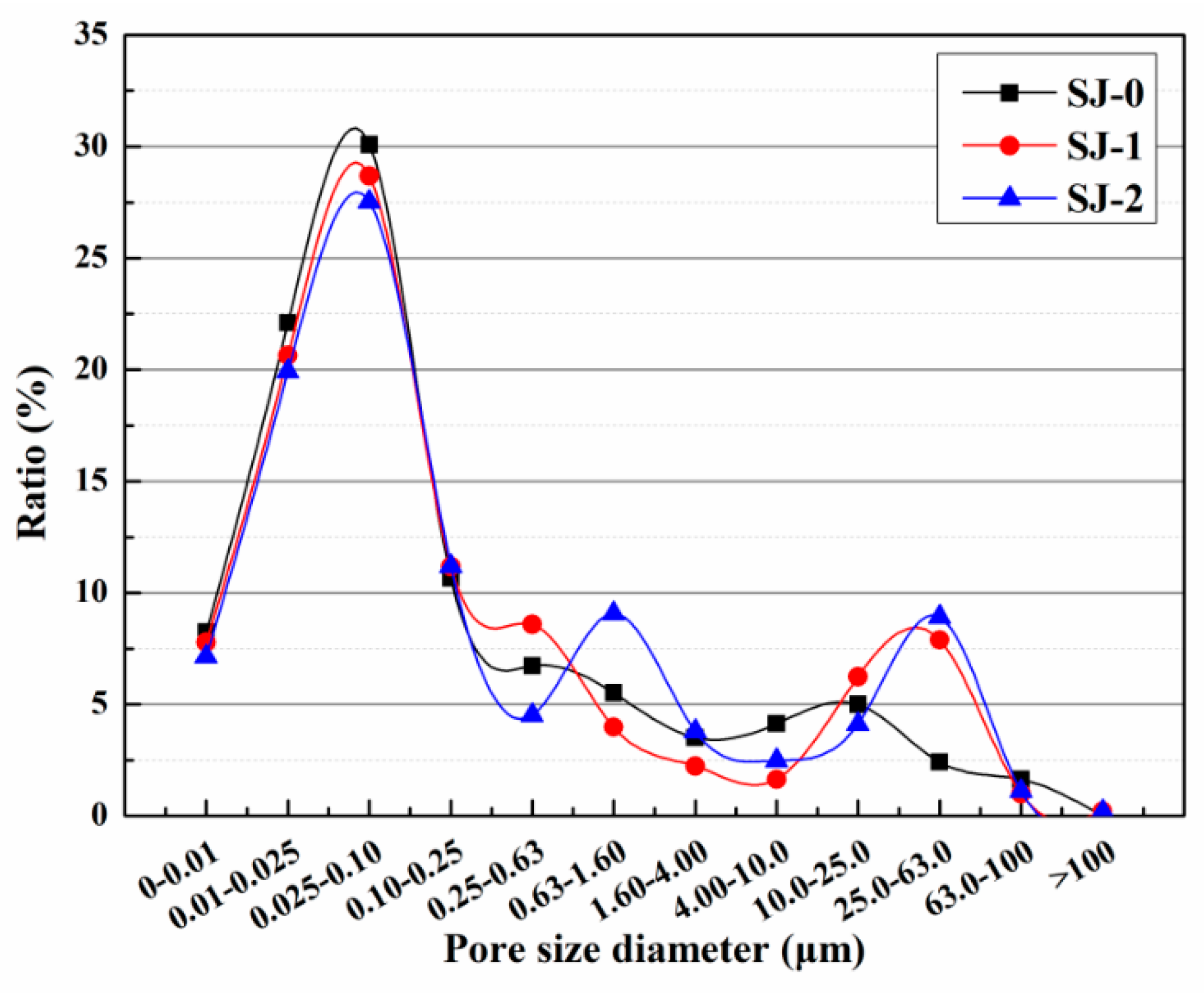

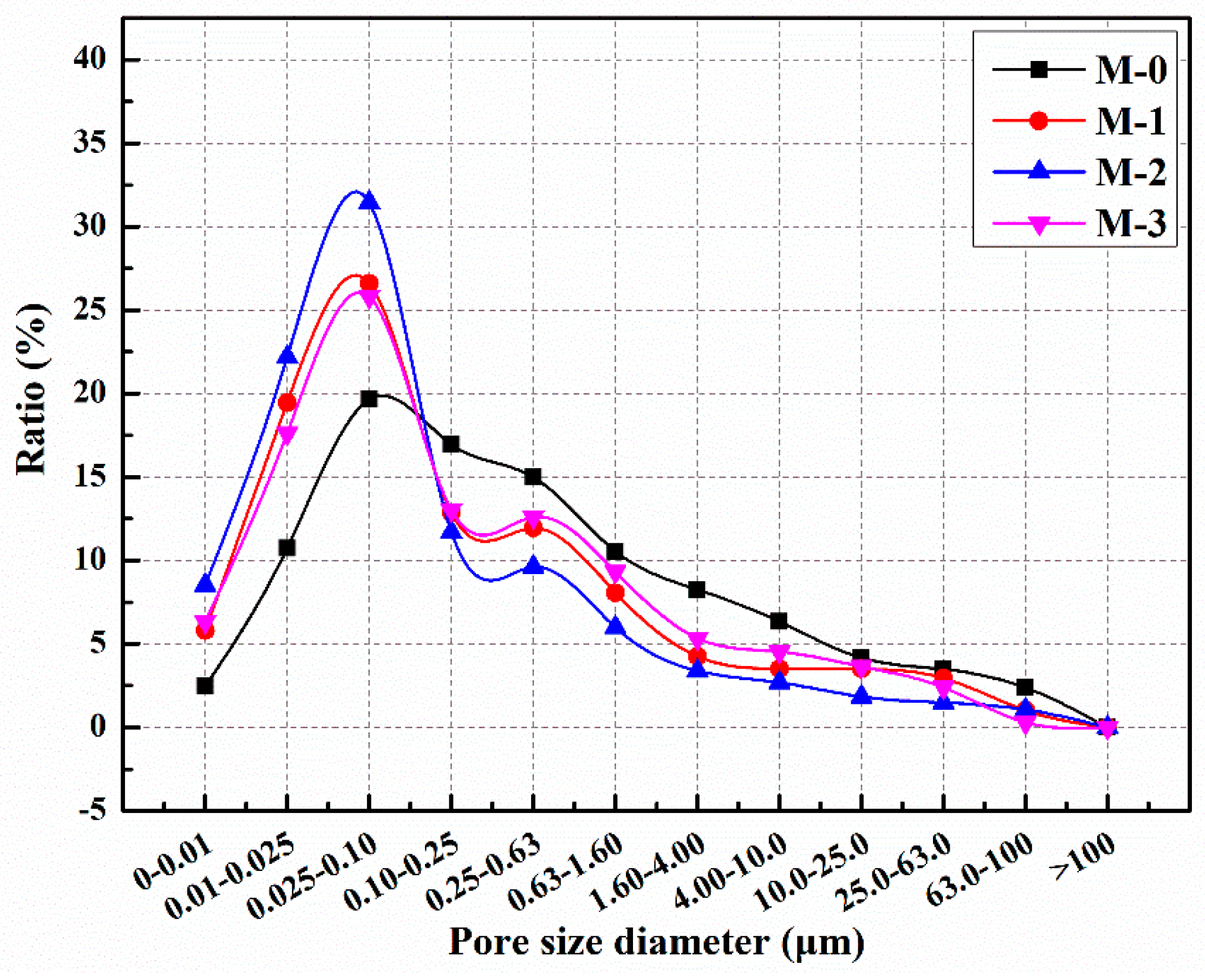

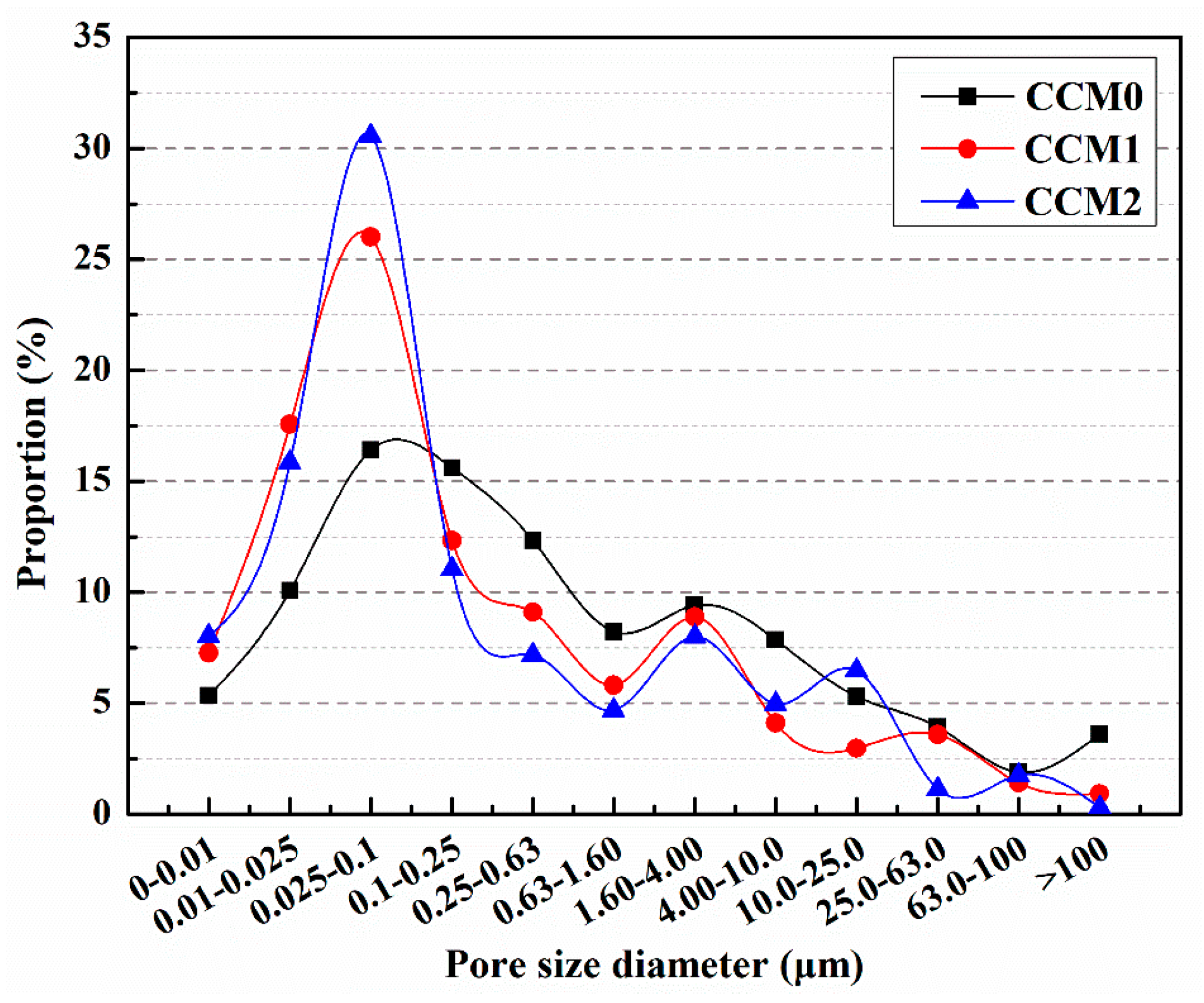

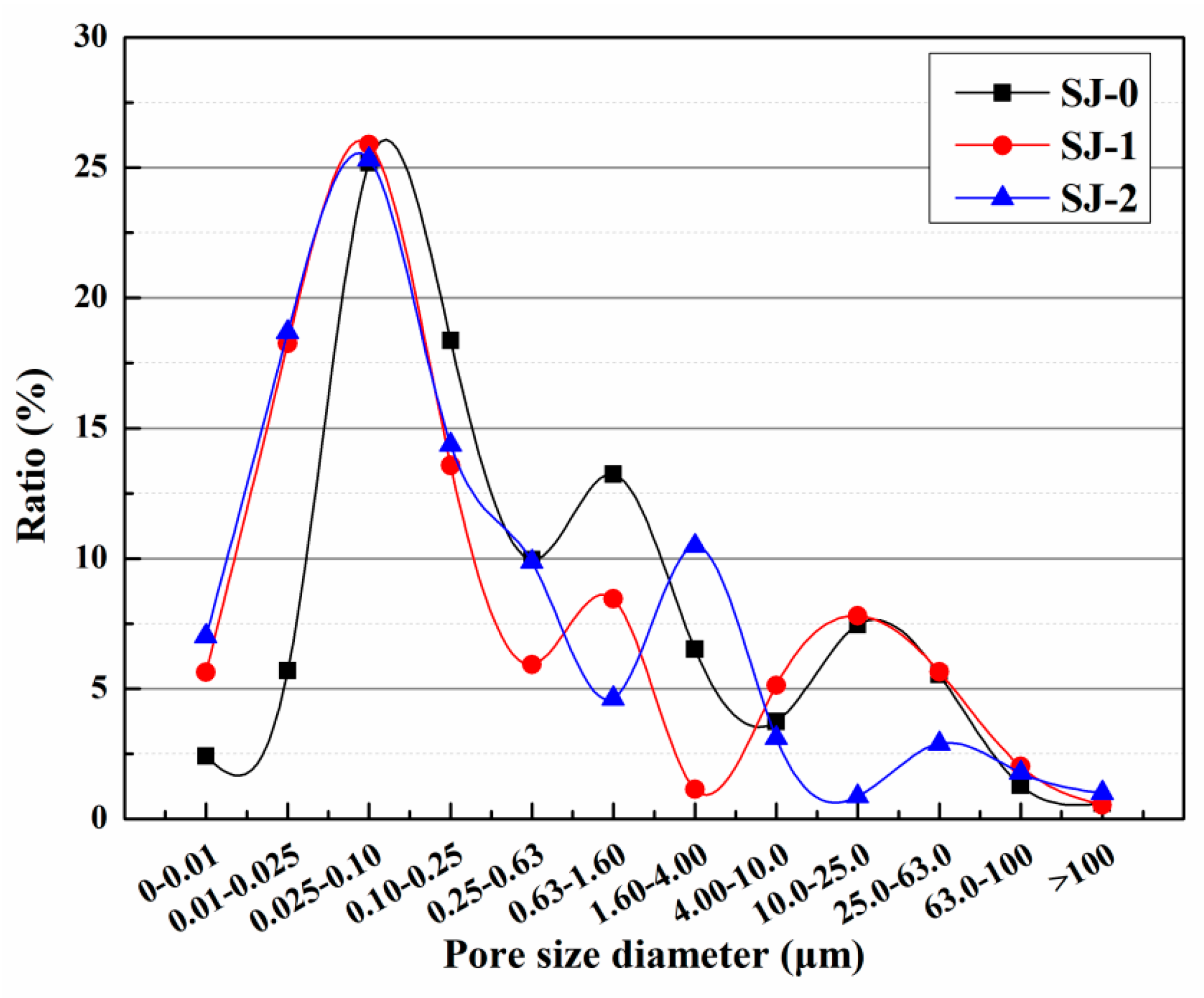

4.2. Pore Size Distribution

5. The Self-Healing Mechanism and Effect of Microcapsules

5.1. Physical Trigger

5.1.1. Mechanical Fracture Trigger

5.1.2. Temperature Trigger

5.1.3. Light Trigger

5.2. Chemical Trigger

5.2.1. pH Trigger

5.2.2. Ion Trigger

5.3. The Self-Healing Effect of Microcapsules on Cement-Based Materials

5.3.1. Pore Size Distribution

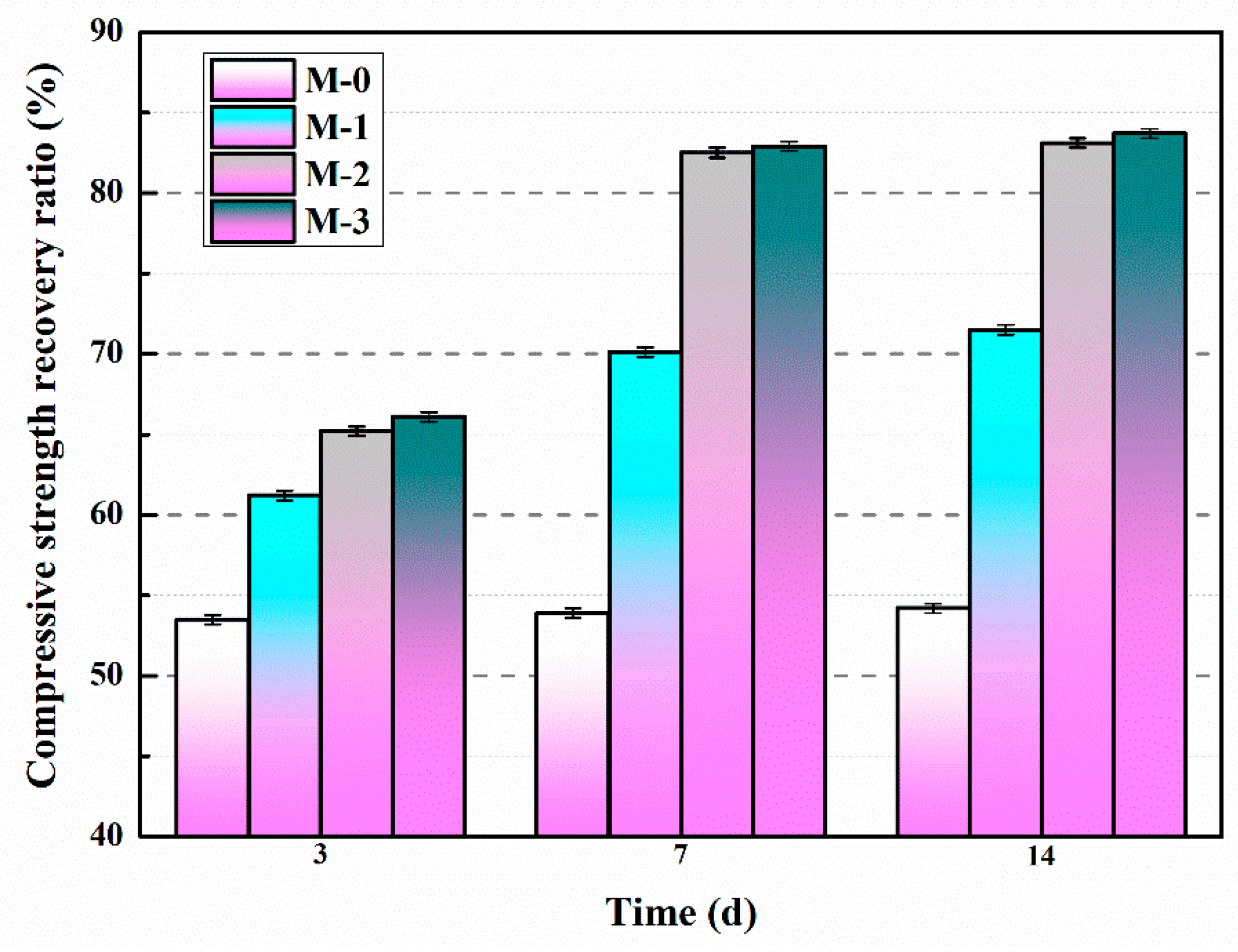

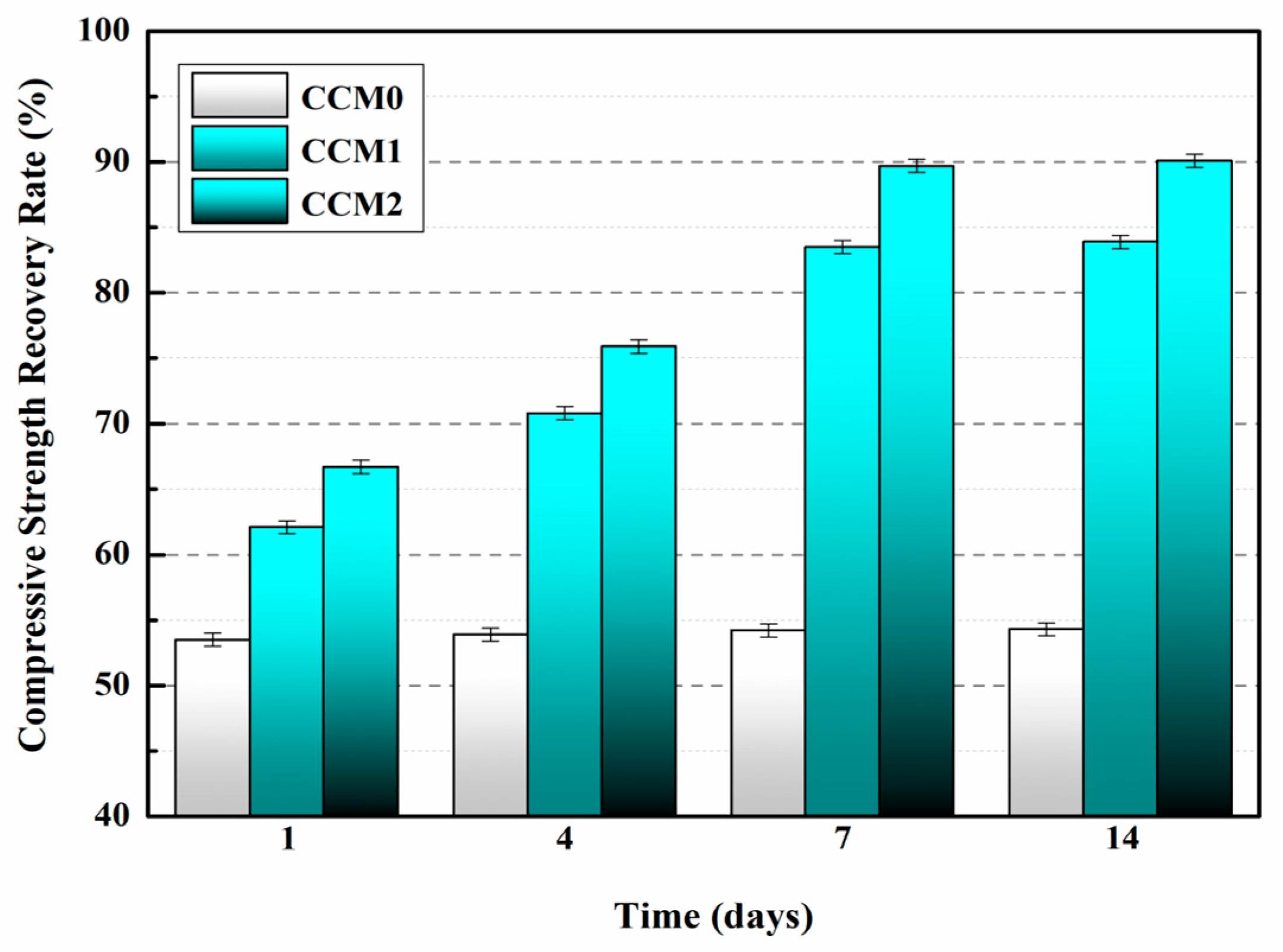

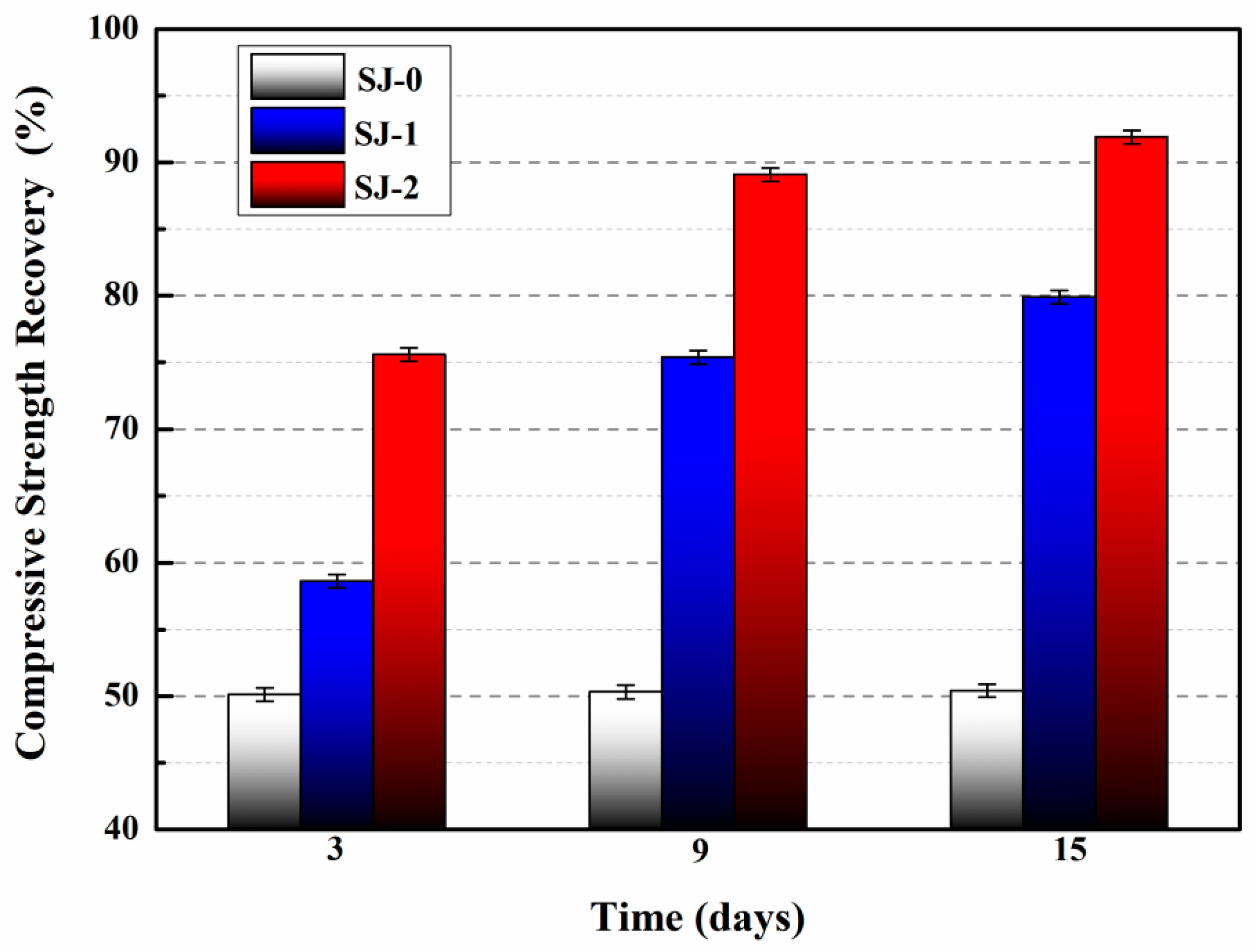

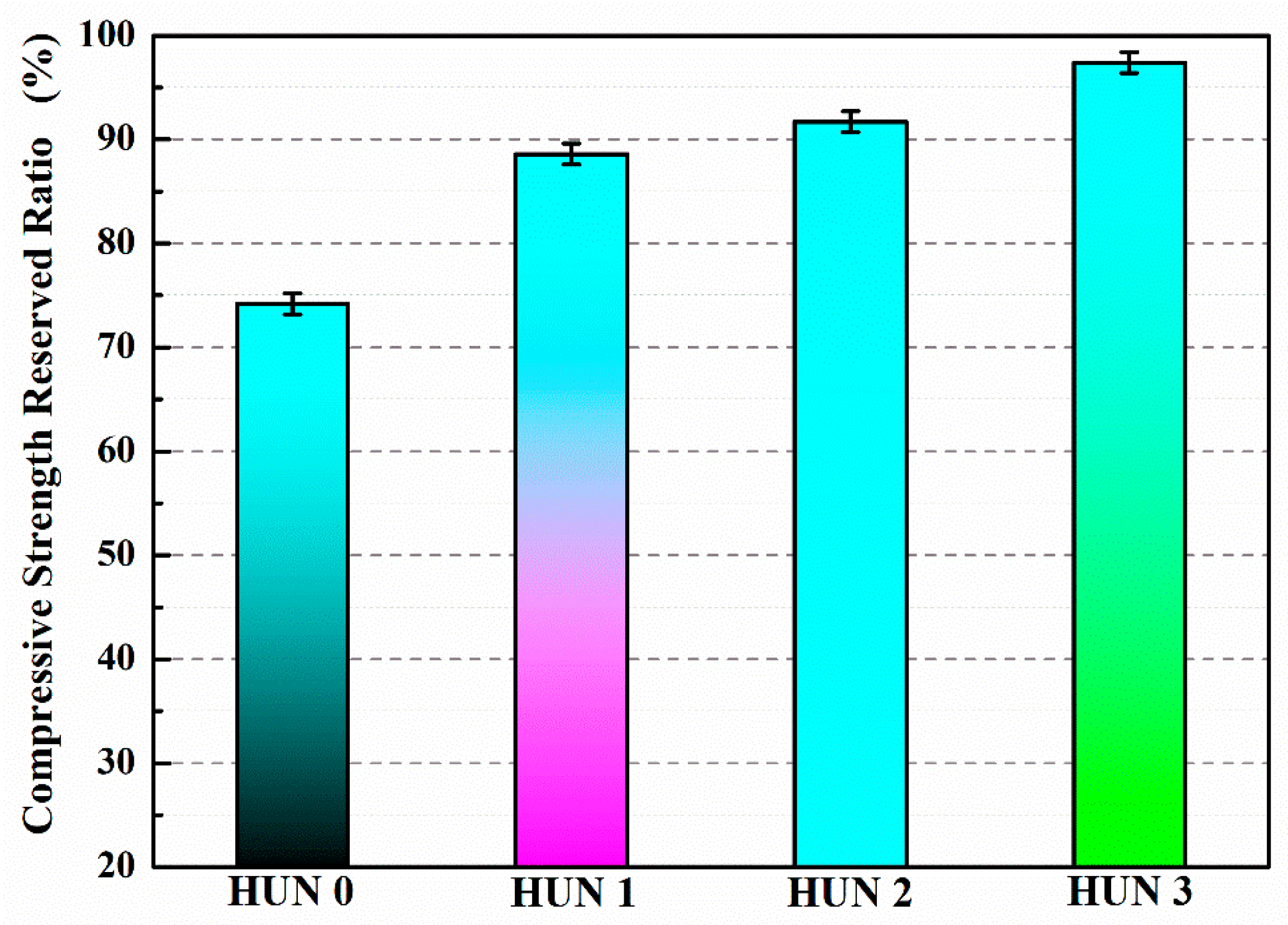

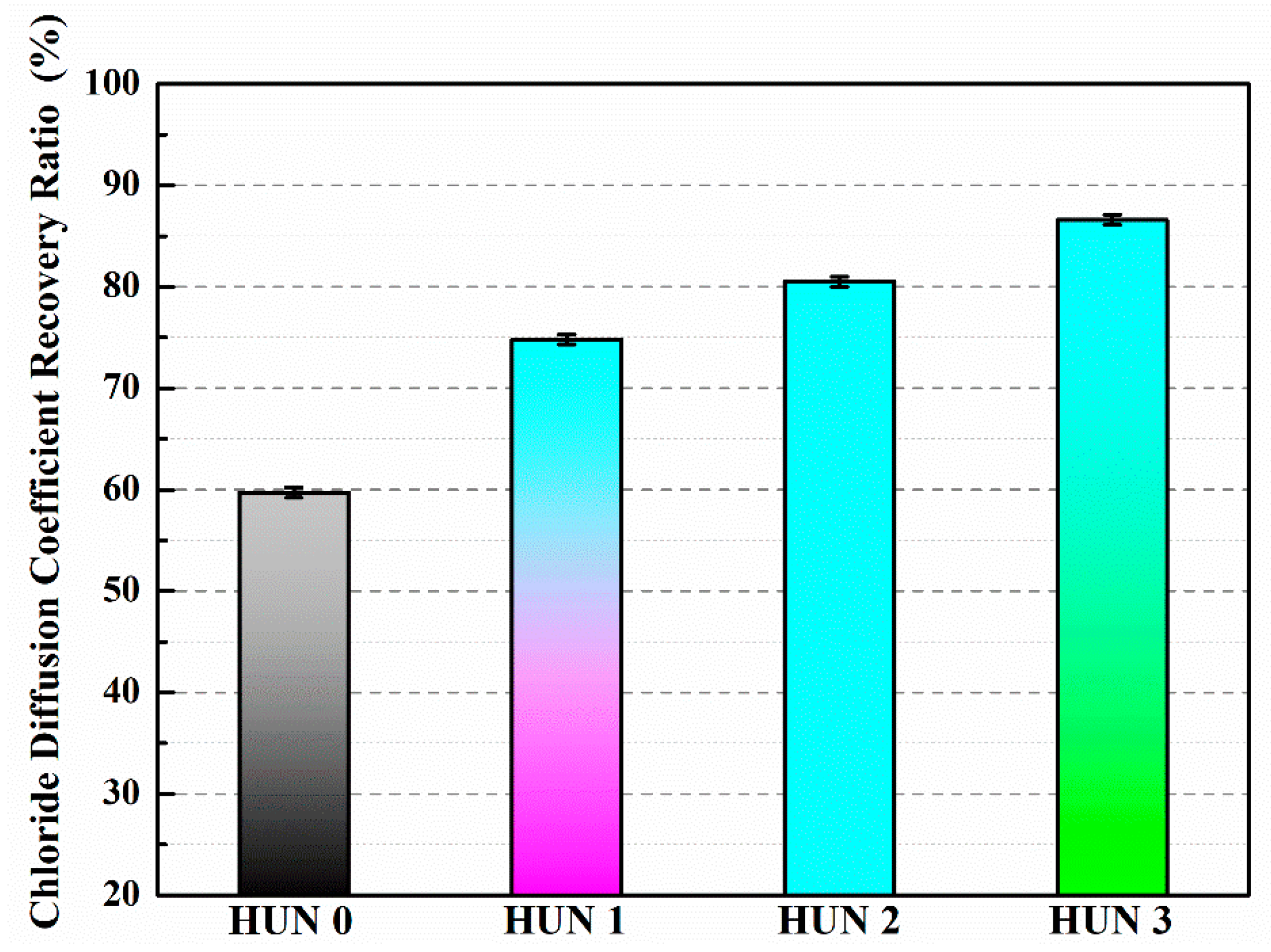

5.3.2. Compressive Strength Recovery Ratio

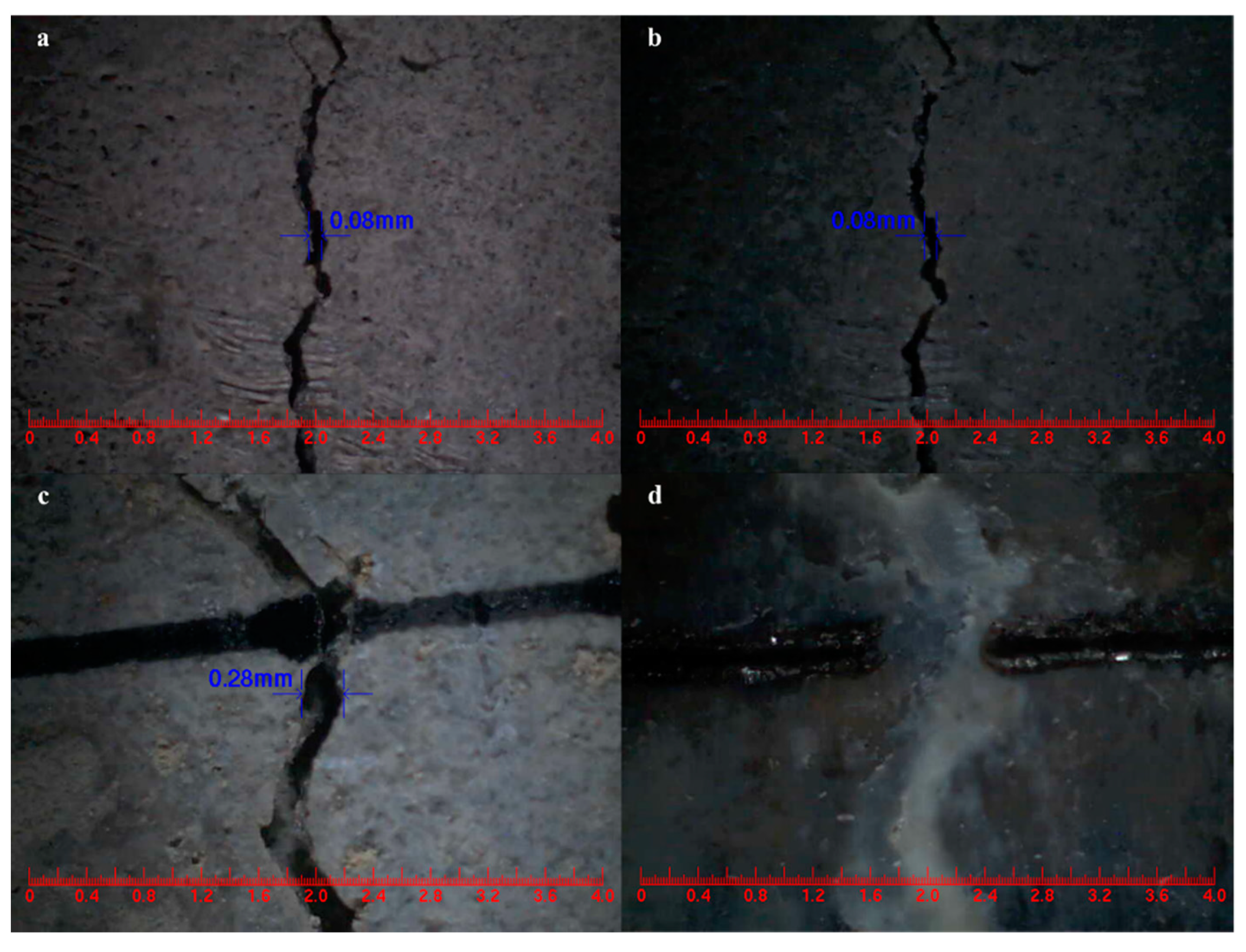

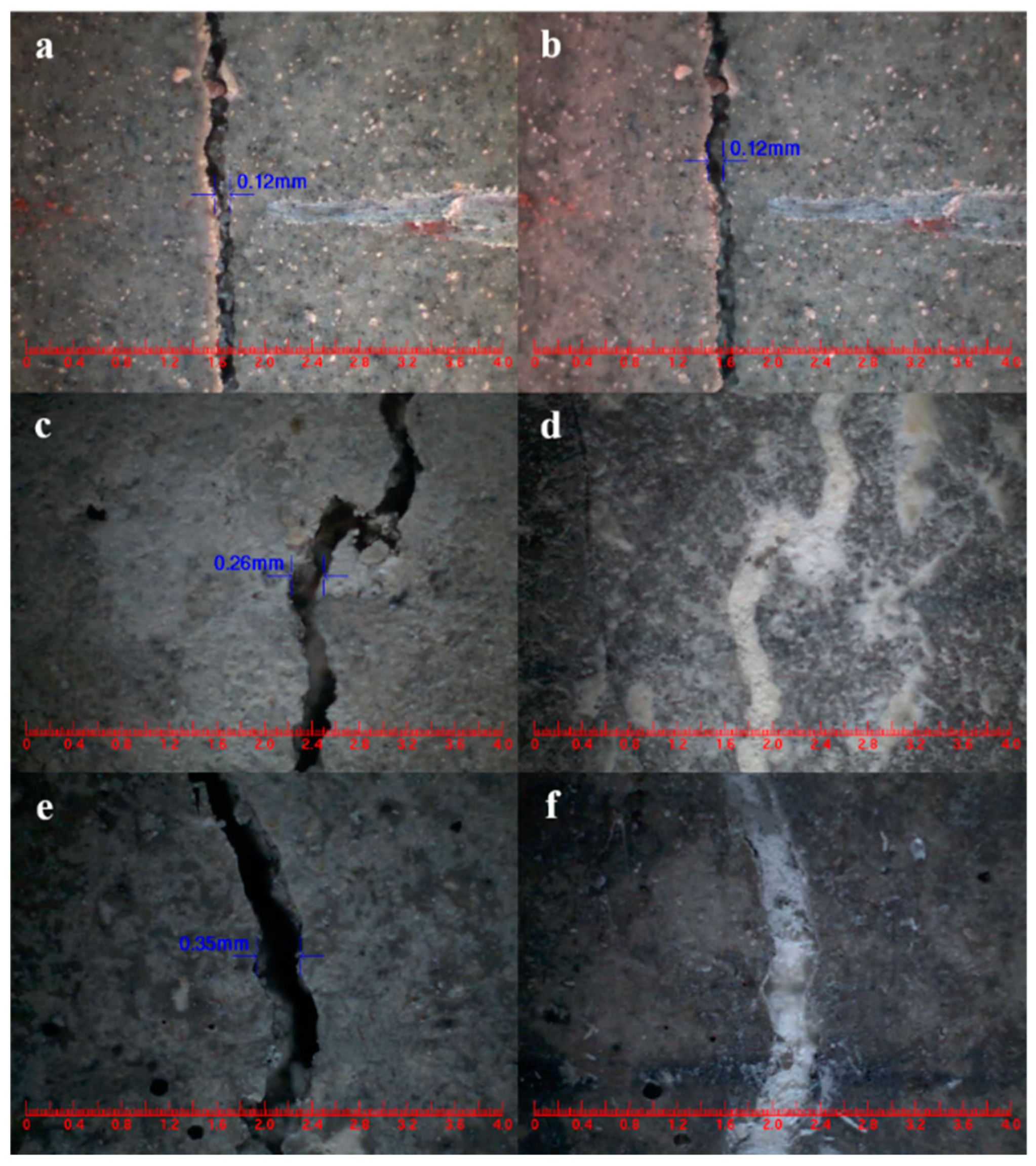

5.3.3. Surface Cracks Self-Healing

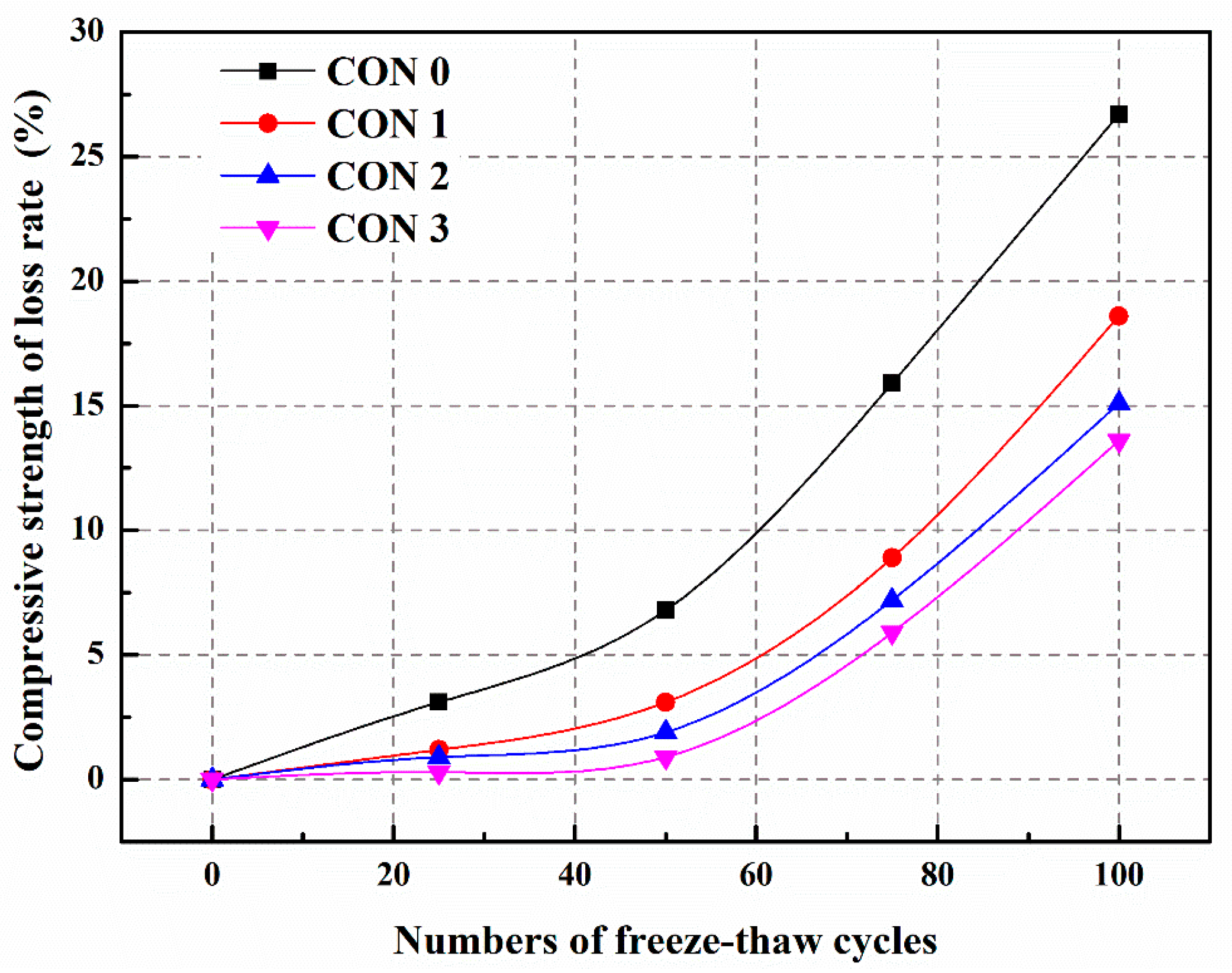

5.3.4. Frost Resistance and Self-Healing Ability of Concrete (Freeze–Thaw Cycle)

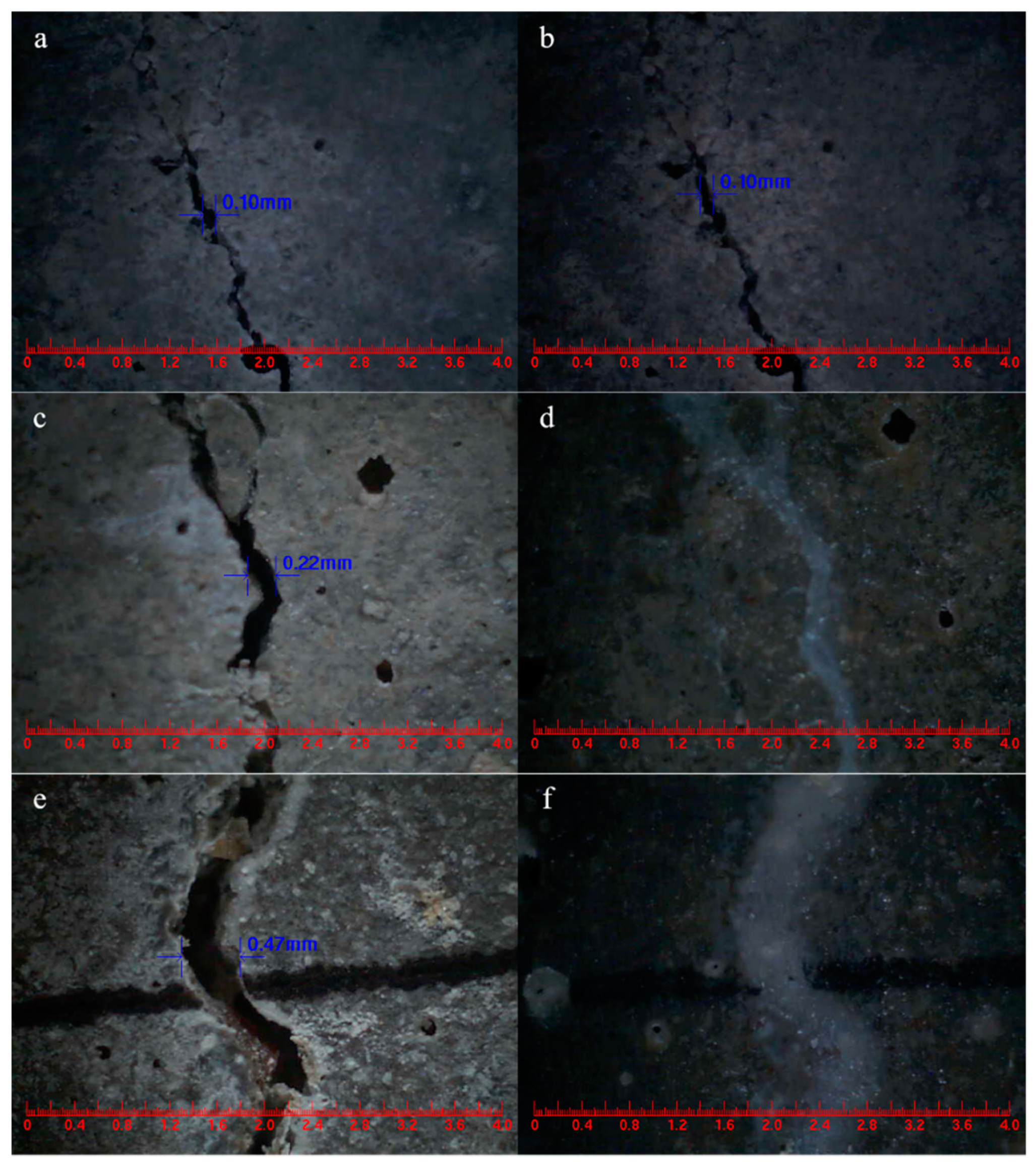

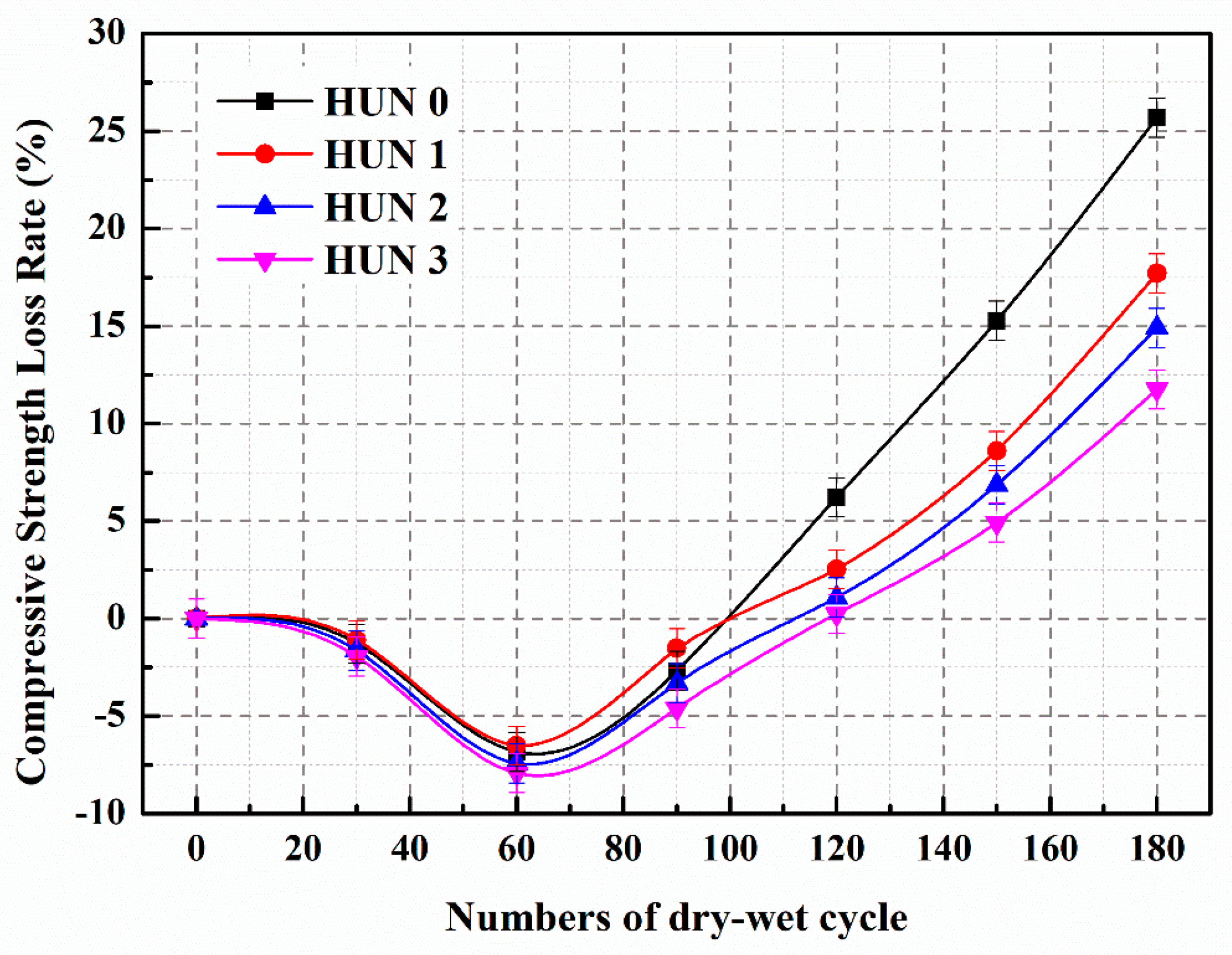

5.3.5. Sulfate Resistance and Self-Healing Ability of Concrete (Sulfate Dry–Wet Cycle)

5.3.6. Effect of Microcapsules on the Steel Corrosion in Cement-Based Materials

6. Future Development Prospects

- (1)

- Optimization of microcapsule design: future research can focus on optimizing the design of microcapsules, including the selection of core materials, improvement of shell materials, and control of microcapsule size and distribution. By designing the structure and properties of microcapsules in a rational manner, the effectiveness and durability of self-healing materials can be further improved.

- (2)

- Enhancement of microcapsule self-healing ability: further research can delve into the self-healing mechanisms of microcapsules, such as introducing new self-healing components or modifying the internal structure of microcapsules to enhance their self-healing efficiency and capability. Additionally, the combination of microcapsules with other functional materials can be investigated to achieve multifunctional self-healing effects.

- (3)

- Controlled release of microcapsules: researchers can explore more precise mechanisms for the release of microcapsules, such as electromagnetic, chemical, or biological stimuli, to control the release behavior of microcapsules. This will help achieve precise control and regulation of the self-healing process, thereby improving the performance and applicability of self-healing materials.

- (4)

- Material performance evaluation and standardization: future research can focus on developing comprehensive evaluation methods and standards to assess the performance and durability of microcapsule self-heal materials. Establishing unified testing methods and evaluation criteria will promote the development of the field and facilitate the practical application and industrialization of self-healing materials.

- (5)

- Application expansion and engineering practice: further application of microcapsule self-heal technology in practical engineering projects and conducting long-term usage and environmental adaptation studies are encouraged. Through experiments and monitoring under different environmental and load conditions, the feasibility and reliability of microcapsule self-heal materials can be verified, promoting their practical application in engineering.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tittelboom, K.V.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [Green Version]

- Meharie, M.G.; Kaluli, J.W.; Abiero-Gariy, Z.; Kumar, N.D. Factors Affecting the Self-Healing Efficiency of Cracked Concrete Structures. Am. J. Appl. Sci. Res. 2017, 3, 80. [Google Scholar] [CrossRef] [Green Version]

- Aïtcin, P.-C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Mehta, P.K. Concrete technology for sustainable development. Concr. Int. 1999, 21, 47–53. [Google Scholar]

- Maddalena, R.; Bonanno, L.; Balzano, B.; Tuinea-Bobe, C.; Sweeney, J.; Mihai, I. A crack closure system for cementitious composite materials using knotted shape memory polymer (k-SMP) fibres. Cem. Concr. Compos. 2020, 114, 103757. [Google Scholar] [CrossRef]

- Ismail, M.; Toumi, A.; François, R.; Gagné, R. Effect of crack opening on the local diffusion of chloride in cracked mortar samples. Cem. Concr. Res. 2008, 38, 1106–1111. [Google Scholar] [CrossRef]

- Picandet, V.; Khelidj, A.; Bellegou, H. Crack effects on gas and water permeability of concretes. Cem. Concr. Res. 2009, 39, 537–547. [Google Scholar] [CrossRef] [Green Version]

- Hoseini, M.; Bindiganavile, V.; Banthia, N. The effect of mechanical stress on permeability of concrete: A review. Cem. Concr. Compos. 2009, 31, 213–220. [Google Scholar] [CrossRef]

- Dry, C. Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices. Smart Mater. Struct. 1994, 3, 118–123. [Google Scholar] [CrossRef]

- Carpinteri, A. Size-Scale Effects on the Brittleness of Concrete Structures: Dimensional Analysis and Snap-Back Instability. Spec. Publ. 1990, 118, 198–236. [Google Scholar] [CrossRef]

- Sidiq, A.; Gravina, R.; Giustozzi, F. Is concrete healing really efficient? A review. Constr. Build. Mater. 2019, 205, 257–273. [Google Scholar] [CrossRef]

- Li, W.; Liu, W.; Wang, S. The Effect of Crack Width on Chloride-Induced Corrosion of Steel in Concrete. Adv. Mater. Sci. Eng. 2017, 2017, 3968578. [Google Scholar] [CrossRef] [Green Version]

- Sideris, K.K.; Anagnostopoulos, N.S. Durability of normal strength self-compacting concretes and their impact on service life of reinforced concrete structures. Constr. Build. Mater. 2013, 41, 491–497. [Google Scholar] [CrossRef]

- Li, V.C.; Herbert, E. Robust Self-Healing Concrete for Sustainable Infrastructure. J. Adv. Concr. Technol. 2012, 10, 207–218. [Google Scholar] [CrossRef] [Green Version]

- Trask, R.; Williams, H.; Bond, I. Self-repairing polymer composites: Mimicking nature to enhance performance. Bioinspiration Biomim. 2007, 2, 1–9. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Van Tittelboom, K.; De Belie, N. Efficiency of self-healing cementitious materials with encapsulated polyurethane to reduce water ingress through cracks. Mater. Des. Constr. 2018, 68, e159. [Google Scholar] [CrossRef]

- Pattanaik, S.C. Causes, Evaluation and repair of cracks in concrete structures. ACI Mater. J. 2011, 81, 211–230. [Google Scholar]

- Emmons, P.H.; Sordyl, D.J. The state of the concrete repair industry, and a vision for its future. Concr. Repair Bull. 2006, 19, 7–14. [Google Scholar]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Stocks-Fischer, S.; Galinat, J.K.; Bang, S.S. Microbiological precipitation of CaCO3. Soil Biol. Biochem. 1999, 31, 1563–1571. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Issa, M.A.; Tsui, S.; Yousif, A. Application of knowledge-based expert systems for rating highway bridges. Eng. Fract. Mech. 1995, 50, 923–934. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; Van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Carsana, M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr. Build. Mater. 2014, 68, 535–551. [Google Scholar] [CrossRef]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Gupta, S.; Pang, S.D.; Kua, H.W. Autonomous healing in concrete by bio-based healing agents—A review. Constr. Build. Mater. 2017, 146, 419–428. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Nathaniel, O.; Sam, A.R.M.; Lim, N.H.A.S.; Adebisi, O.; Abdulkareem, M. Biogenic approach for concrete durability and sustainability using effective microorganisms: A review. Constr. Build. Mater. 2020, 261, 119664. [Google Scholar] [CrossRef]

- Norris, C.J.; Bond, I.P.; Trask, R.S. Interactions between propagating cracks and bioinspired self-healing vascular embedded in glass fiber reinforced composites. Compos. Sci. Technol. 2011, 71, 847–853. [Google Scholar] [CrossRef] [Green Version]

- Han, T.; Wang, X.; Li, D.; Li, D.; Xing, F.; Han, N.; Li, Z. Uniaxial deformation characteristics and mechanical model of microcapsule-based self-healing cementitious composite. Constr. Build. Mater. 2021, 274, 121227. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Han, R.; Han, N.; Xing, F. Evaluation of damage and repair rate of self-healing microcapsule-based cementitious materials using electrochemical impedance spectroscopy. J. Clean. Prod. 2019, 235, 966–976. [Google Scholar] [CrossRef]

- Xu, N.; Song, Z.; Guo, M.-Z.; Jiang, L.; Chu, H.; Pei, C.; Yu, P.; Liu, Q.; Li, Z. Employing ultrasonic wave as a novel trigger of microcapsule self-healing cementitious materials. Cem. Concr. Compos. 2021, 118, 103951. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R.; Yu, J. Influence of external environment on self-repairing ability of the cement-based materials containing paraffin/toluene-di-isocyanate microcapsules. Constr. Build. Mater. 2021, 281, 122584. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R. Effects of toluene-di-isocyanate microcapsules on the frost resistance and self-repairing capability of concrete under freeze-thaw cycles. J. Build. Eng. 2021, 44, 102880. [Google Scholar] [CrossRef]

- Tsuda, N.; Ohtsubo, T.; Fuji, M. Preparation of self-bursting microcapsules by interfacial polymerization. Adv. Powder Technol. 2012, 23, 724–730. [Google Scholar] [CrossRef]

- Yang, J.; Keller, M.W.; Moore, J.S.; White, S.R.; Sottos, N.R. Microencapsulation of Isocyanates for Self-Healing Polymers. Macromolecules 2008, 41, 9650–9655. [Google Scholar] [CrossRef]

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Influence of process parameters on microcapsules loaded with n-hexadecane prepared by in situ polymerization. Chem. Eng. J. 2009, 155, 457–465. [Google Scholar] [CrossRef]

- Huang, Q.; Gong, S.; Han, W.; Chen, Y.; Shu, X. Preparation of TTO/UF resin microcapsule via in situ polymerisation and modelling of its slow release. J. Microencapsul. 2020, 37, 297–304. [Google Scholar] [CrossRef] [PubMed]

- Muhoza, B.; Yuyang, H.; Uriho, A.; Harindintwali, J.D.; Qian, L.; Li, Y. Spray-and freeze-drying of microcapsules prepared by complex coacervation method: A review. Food Hydrocoll. 2023, 140, 108650. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Ding, W.J.; Dong, P.; Han, S.W.; Li, H.F.; Chen, S.S.; Hong, S.X.; Dong, B.Q.; Xing, F. Preparation and anti-corrosion performances of chemical self-healing system for steel in concrete. J. Funct. Mater. 2017, 48, 7006–7011. [Google Scholar]

- Du, W.; Yu, J.; Gu, Y.; Li, Y.; Zhang, C.; Liu, Q. Preparation and application of microcapsules containing toluene-di-isocyanate for self-healing of concrete. Constr. Build. Mater. 2019, 202, 762–769. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; He, P.; Liu, Q.; Han, X.; Wan, Y. Preparation and application of novel microcapsules ruptured by microwave for self-healing concrete. Constr. Build. Mater. 2021, 304, 124616. [Google Scholar] [CrossRef]

- Xue, B.; Wang, H.; Pei, J.; Li, R.; Zhang, J.; Fan, Z. Study on self-healing microcapsule containing rejuvenator for asphalt. Constr. Build. Mater. 2017, 135, 641–649. [Google Scholar] [CrossRef]

- Tao, Y.; Yan, X. Influence of HLB Value of Emulsifier on the Properties of Microcapsules and Self-Healing Properties of Waterborne Coatings. Polymers 2022, 14, 1304. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, X. Preparation of Thermochromic Microcapsules of Bisphenol A and Crystal Violet Lactone and Their Effect on Coating Properties. Polymers 2022, 14, 1393. [Google Scholar] [CrossRef] [PubMed]

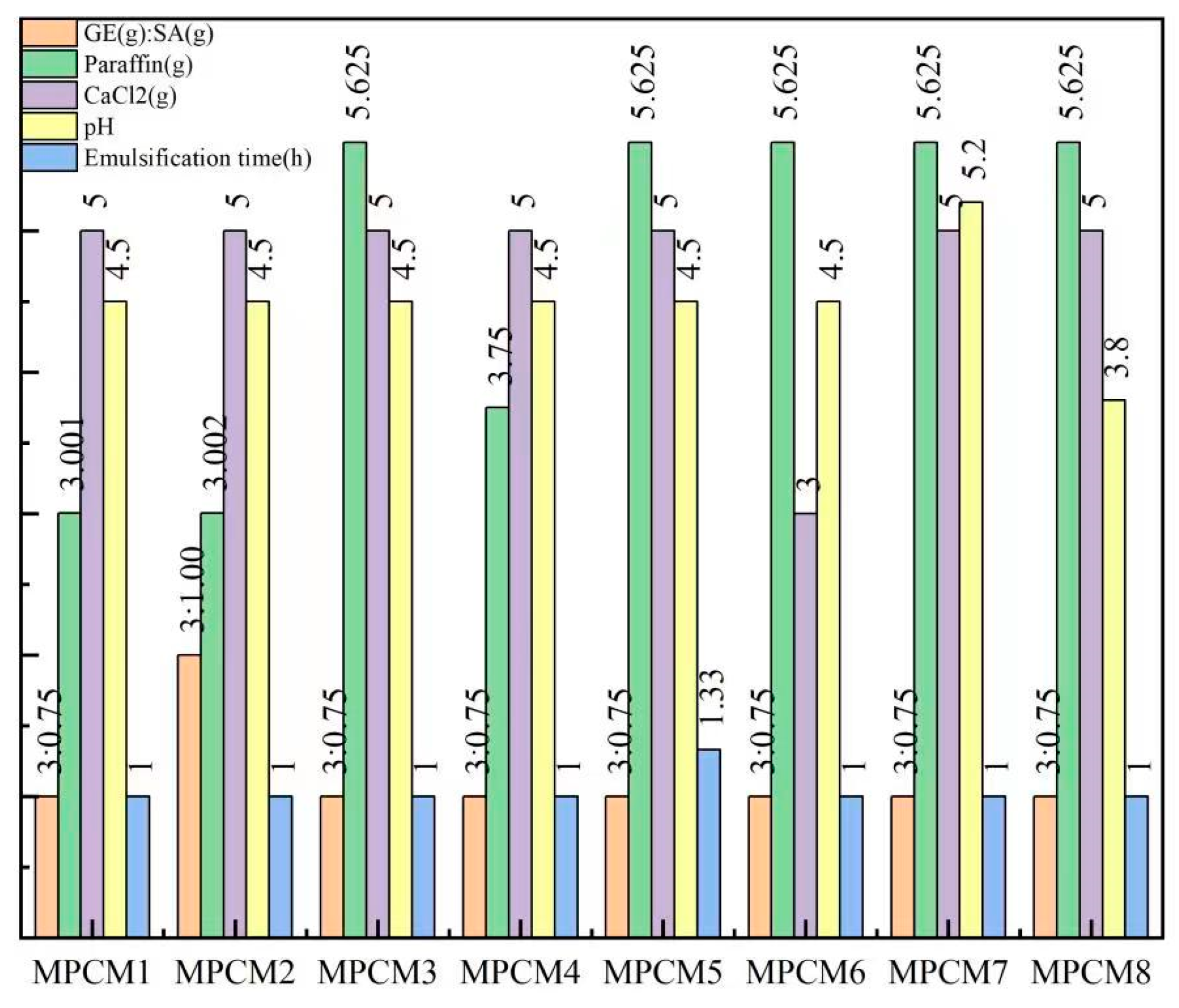

- Tian, Y.; Liu, Y.; Zhang, L.; Hua, Q.; Liu, L.; Wang, B.; Tang, J. Preparation and characterization of gelatin-sodium alginate/paraffin phase change microcapsules. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 586, 124216. [Google Scholar] [CrossRef]

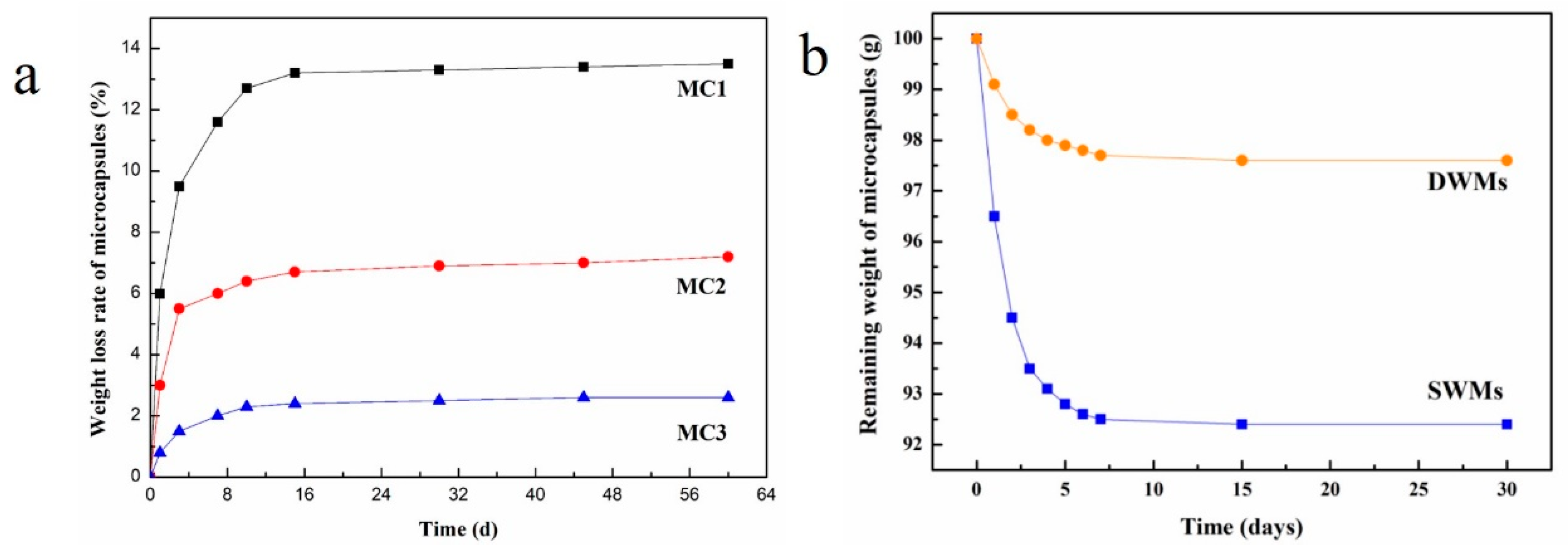

- Du, W.; Yu, J.; He, B.; He, Y.; He, P.; Li, Y.; Liu, Q. Preparation and characterization of nano-SiO2/paraffin/PE wax composite shell microcapsules containing TDI for self-healing of cementitious materials. Constr. Build. Mater. 2020, 231, 117060. [Google Scholar] [CrossRef]

- Li, E.; Du, W.; Zhuang, R.; Ba, M.; Yuan, L.; Zhang, Q.; Zhang, Y. Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars. Materials 2022, 15, 3608. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Chen, W.; Fan, X. Experimental investigation of particle size effect on the self-healing performance of microcapsule for cemented coral sand. Constr. Build. Mater. 2020, 256, 119343. [Google Scholar] [CrossRef]

- Yao, J.L.; Yang, C.P.; Zhu, C.F.; Hou, B.Q. Preparation process of epoxy resin microcapsules for self-healing coatings. Prog. Org. Coat. 2019, 132, 440–444. [Google Scholar]

- Zotiadis, C.; Patrikalos, I.; Loukaidou, V.; Korres, D.M.; Karantonis, A.; Vouyiouka, S. Self-healing coatings based on poly(urea-formaldehyde) microcapsules: In situ polymerization, capsule properties and application. Prog. Org. Coat. 2021, 161, 106475. [Google Scholar] [CrossRef]

- Du, W.; Li, E.W.; Lin, R.S. Preparation and characterization of nano-CaCO3/ceresine wax composite shell microcapsules containing E-44 epoxy resin for self-healing of cement-based materials. Nanomaterials 2022, 12, 197. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S.; Fei, X.; Zhao, H.; Lou, X. Enhanced mechanical properties and thermal conductivity of paraffin microcapsules shelled by hydrophobic-silicon carbide modified melamine-formaldehyde resin. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 603, 125219. [Google Scholar] [CrossRef]

- Li, M.; Chen, M.; Wu, Z. Enhancement in thermal property and mechanical property of phase change microcapsule with modified carbon nanotube. Appl. Energy 2014, 127, 166–171. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R.; Su, X. Preparation and Characterization of Microcrystalline Wax/Epoxy Resin Microcapsules for Self-Healing of Cementitious Materials. Materials 2021, 14, 1725. [Google Scholar] [CrossRef]

- Ji, X.; Wang, S.; Yao, B.; Si, W.; Wang, C.; Wu, T.; Zhang, X. Preparation and properties of nano-SiO2 modified microcapsules for asphalt pavement. Mater. Des. 2023, 229, 111871. [Google Scholar] [CrossRef]

- Ahangaran, F.; Hayaty, M.; Navarchian, A.H.; Picchioni, F. Micromechanical assessment of PMMA microcapsules containing epoxy and mercaptan as self-healing agents. Polym. Test. 2017, 64, 330–336. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797, Correction in Nature 2002, 415, 817. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.A.; Hwang, Y.-H.; Oh, H.; Jeon, K.; Lee, J.H.; Yoon, J.; Lee, J.B.; Lee, H. Biocompatible Wax-Based Microcapsules with Hermetic Sealing for Thermally Triggered Release of Actives. ACS Appl. Mater. Interfaces 2021, 13, 36380–36387. [Google Scholar] [CrossRef] [PubMed]

- Tylkowski, B.; Giamberini, M.; Underiner, T.; Prieto, S.F.; Smets, J. Photo-Triggered Microcapsules. Macromol. Symp. 2016, 360, 192–198. [Google Scholar] [CrossRef]

- Wang, H.C.; Grolman, J.M.; Rizvi, A.; Hisao, G.S.; Rienstra, C.M.; Zimmerman, S.C. pH-triggered release from polyamide microcapsules prepared by interfacial polymerization of a simple diester monomer. ACS Macro Lett. 2017, 6, 321–325. [Google Scholar] [CrossRef]

- Xiong, W.; Tang, J.; Zhu, G.; Han, N.; Schlangen, E.; Dong, B.; Wang, X.; Xing, F. A novel capsule-based self-recovery system with a chloride ion trigger. Sci. Rep. 2015, 5, 10866. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Lin, R.; Liu, Q. Investigation of isophorone diisocyanate microcapsules to improve self-healing properties and sulfate resistance of concrete. Constr. Build. Mater. 2021, 300, 124438. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Ding, W.; Li, S.; Han, N.; Xing, F.; Lu, Y. Electrochemical impedance study on steel corrosion in the simulated concrete system with a novel self-healing microcapsule. Constr. Build. Mater. 2014, 56, 1–6. [Google Scholar] [CrossRef]

- Xu, N.; Ji, X.P.; Wang, W.Y. Effect of epoxy/urea-formaldehyde microcapsules on corrosion performance of reinforcing steel in cement mortars. J. Corros. Sci. Eng. 2020, 23, 1–12. [Google Scholar]

| Microcapsule | D10 Values/μm | D50 Values/μm | D90 Values/μm |

|---|---|---|---|

| WM1 | 10 | 23 | 50 |

| WM2 | 25 | 52 | 115 |

| Microcapsules | Elastic Modulus (GPa) | Hardness (MPa) |

|---|---|---|

| WM1 | 0.55 | 4.89 |

| WM2 | 2.02 | 72.54 |

| Mortars * | Flexural Strength | Compressive Strength |

|---|---|---|

| SJ-0 | 8.2 MPa | 33.4 MPa |

| SJ-1 | 7.9 MPa | 32.6 MPa |

| SJ-2 | 7.5 MPa | 30.9 MPa |

| Mortars * | Compressive Strength (after 28 Days of Standard Curing) |

|---|---|

| CCM0 | 31.2 MPa |

| CCM1 | 40.6 MPa |

| CCM2 | 35.5 MPa |

| TM1 * | TM2 * | TM3 * | |

|---|---|---|---|

| Mass Ratio of Raw Materials (%) | Paraffin 33 TDI 67 | Paraffin 16.5 PE Wax 16.5 TDI 67 | Paraffin 15 PE Wax 15 Nano-SiO2 3 TDI 67 |

| Preparation Temperature (°C) | 75 | 120 | 120 |

| Agitation Rate (rpm) | 600 | 800 | 800 |

| Softening Point (°C) | 58 | 95 | 100 |

| Average Particle Size (μm) | 100 | 320 | 480 |

| Core Fraction (%) | 66.5 | 68.8 | 72.6 |

| Elastic Modulus (GPa) | 0.48 | 0.83 | 1.87 |

| Hardness (MPa) | 4.06 | 5.90 | 61.67 |

| Weight Loss Rate in 60 d (%) | 13.5 | 7.2 | 2.6 |

| Specimens | Cement | River Sand | Gravel | FA | Water | Superplasticizer | Microcapsules |

|---|---|---|---|---|---|---|---|

| CON0 | 280 | 850 | 1080 | 60 | 160 | 5.5 | 0 |

| CON1 | 280 | 850 | 1080 | 60 | 160 | 5.5 | 8.4 (TM1) |

| CON2 | 280 | 850 | 1080 | 60 | 160 | 5.5 | 8.4 (TM2) |

| CON3 | 280 | 850 | 1080 | 60 | 160 | 5.5 | 8.4 (TM3) |

| Specimens | CON0 | CON1 | CON2 | CON3 |

|---|---|---|---|---|

| Compressive Strength Recovery Rate (%) | 73.5 | 86.5 | 91.3 | 96.9 |

| Specimens | CON0 | CON1 | CON2 | CON3 |

|---|---|---|---|---|

| Chloride Diffusion Coefficient Recovery Rate (%) | 59.3 | 72.8 | 77.2 | 84.6 |

| MS1 * | MS2 * | MS3 * | |

|---|---|---|---|

| Mass Ratio of Raw Materials (%) | Paraffin Wax 33 IPDI 67 | Paraffin Wax 16.5 Polyethylene Wax 16.5 IPDI 67 | Paraffin Wax 15 Polyethylene Wax 15 Nano Silica 3 IPDI 67 |

| Temperature (°C) | 80 | 130 | 140 |

| Stirring Speed (rpm) | 800 | 900 | 1000 |

| Average Particle Size (μm) | 90 | 300 | 500 |

| Core Content (%) | 69.7 | 73.5 | 77.8 |

| Elastic Modulus (GPa) | 0.52 | 0.96 | 2.01 |

| Hardness (MPa) | 4.33 | 6.12 | 65.99 |

| Weight Loss Rate in 60 Days (%) | 12.1 | 6.5 | 1.9 |

| Constituent | HUN0 | HUN1 | HUN2 | HUN3 |

|---|---|---|---|---|

| Cement | 260 | 260 | 260 | 260 |

| Mineral Powder | 120 | 120 | 120 | 120 |

| Fly Ash | 140 | 140 | 140 | 140 |

| Sand | 816 | 816 | 816 | 816 |

| Crushed Stone | 850 | 850 | 850 | 850 |

| Water | 180 | 180 | 180 | 180 |

| Superplasticizer | 13 | 13 | 13 | 13 |

| Microcapsules | 0 | 8.4 (MS1) | 8.4 (MS2) | 8.4 (MS3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Wu, M.; Du, W.; Jiang, L.; Li, H.; Wang, L.; Li, J.; Zuo, D.; Ding, Q. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers 2023, 15, 2718. https://doi.org/10.3390/polym15122718

Liu B, Wu M, Du W, Jiang L, Li H, Wang L, Li J, Zuo D, Ding Q. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers. 2023; 15(12):2718. https://doi.org/10.3390/polym15122718

Chicago/Turabian StyleLiu, Bo, Mingli Wu, Wei Du, Lu Jiang, Hongjun Li, Luoxin Wang, Jinhui Li, Danying Zuo, and Qingjun Ding. 2023. "The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect" Polymers 15, no. 12: 2718. https://doi.org/10.3390/polym15122718

APA StyleLiu, B., Wu, M., Du, W., Jiang, L., Li, H., Wang, L., Li, J., Zuo, D., & Ding, Q. (2023). The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers, 15(12), 2718. https://doi.org/10.3390/polym15122718