Gamma, E-Beam and X-ray Irradiations on PE/EVOH/PE Multilayer Film: An Industrial Point of View Regarding the Impact on Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

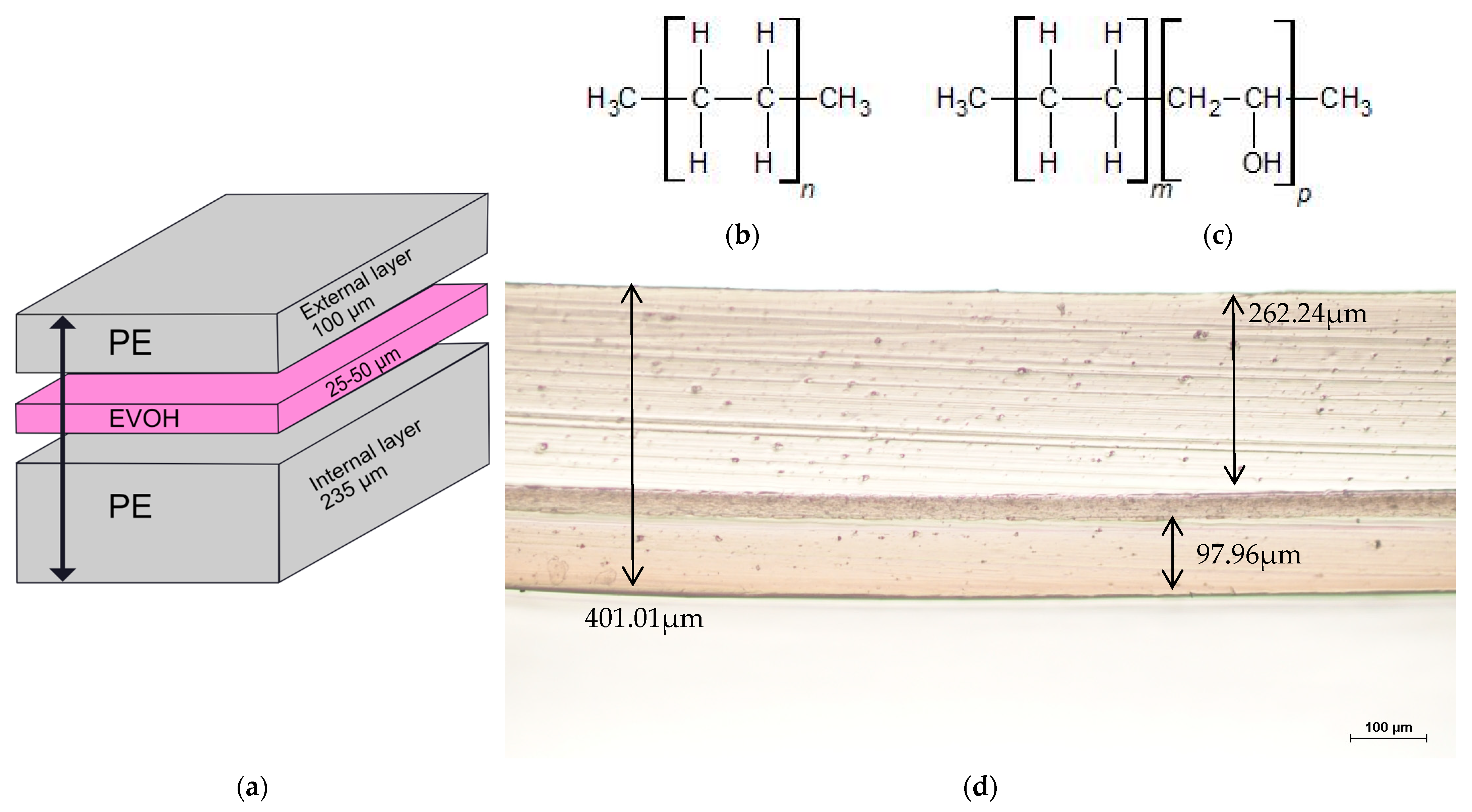

2.1. PE/EVOH/PE Multilayer Film

2.2. Storage Conditions

2.3. Irradiation Methods

- Gamma

- Electron beam

- X-ray

2.4. Tensile Strength Measurement

2.5. DMA (Dynamic Mechanical Analysis)

2.6. Statistical Analyses

2.6.1. Equivalency Assessment

2.6.2. Tensile Strength EAC

2.6.3. Thermal Properties EAC

3. Results

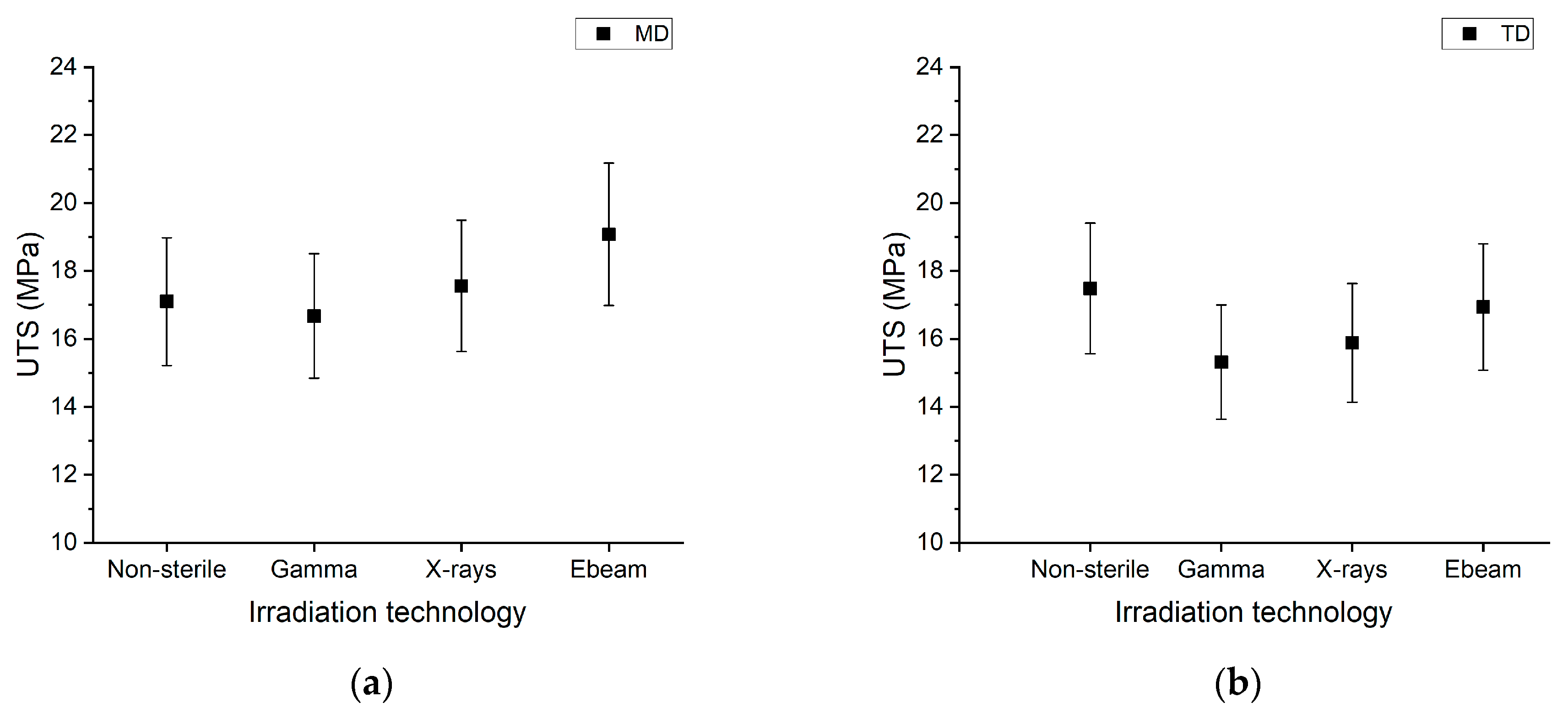

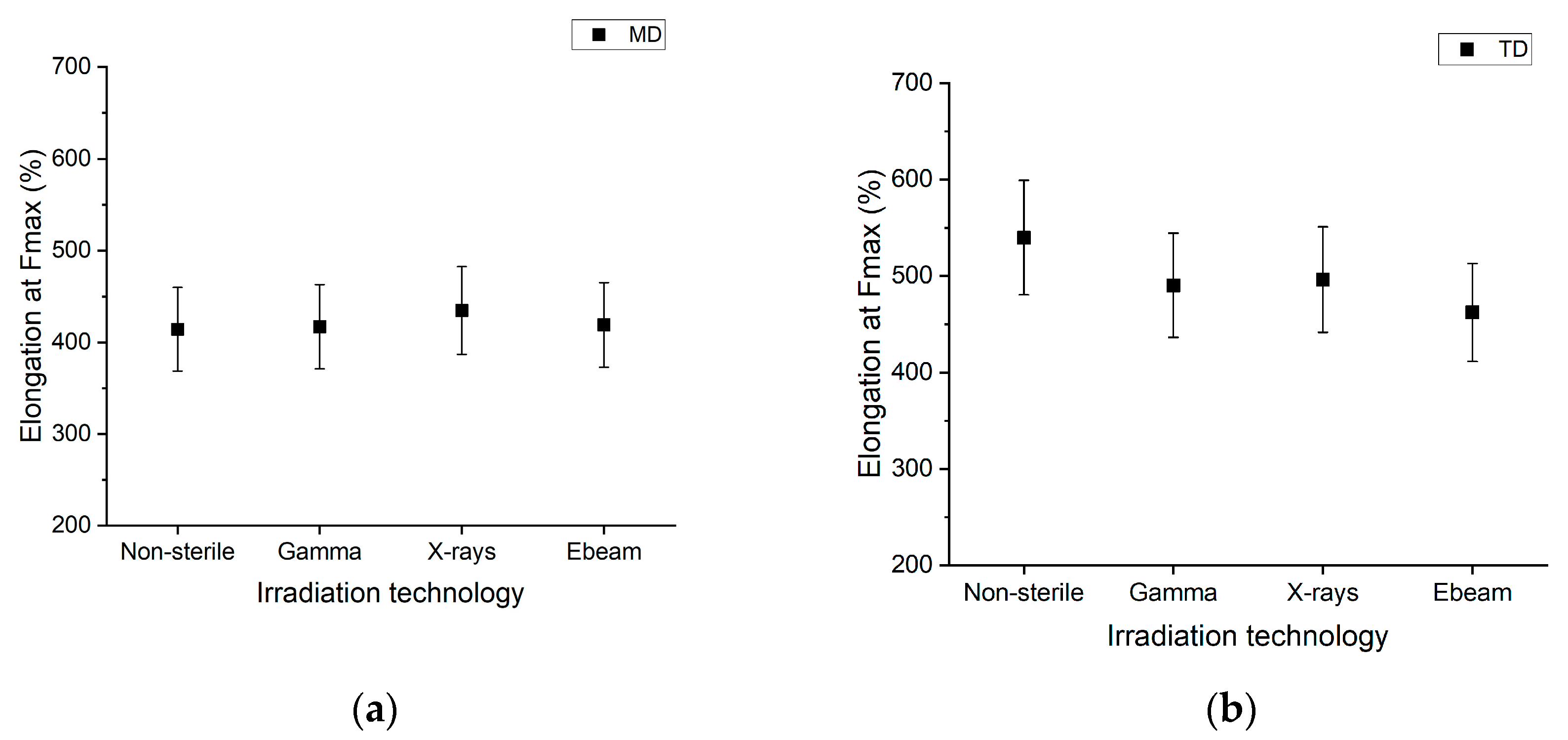

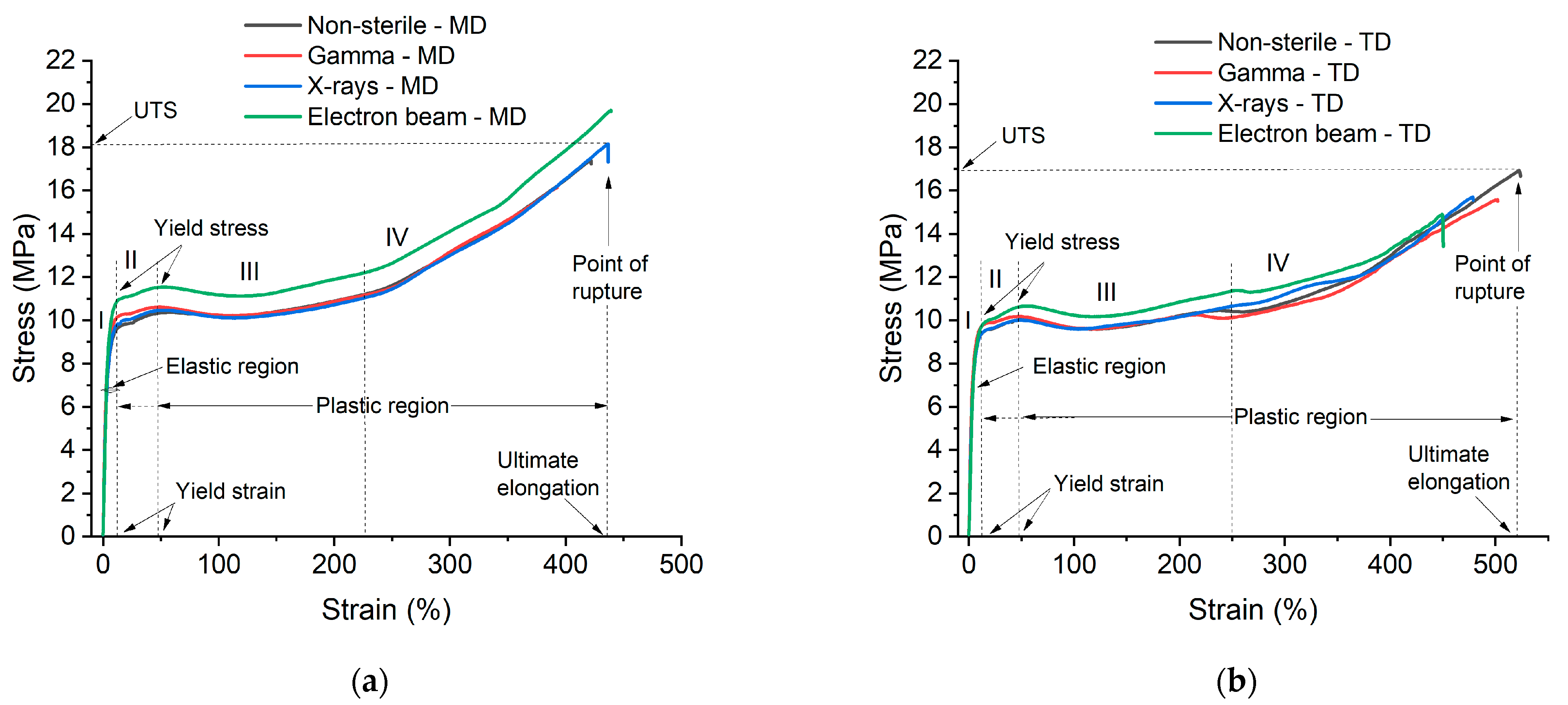

3.1. Tensile Strength Evaluation

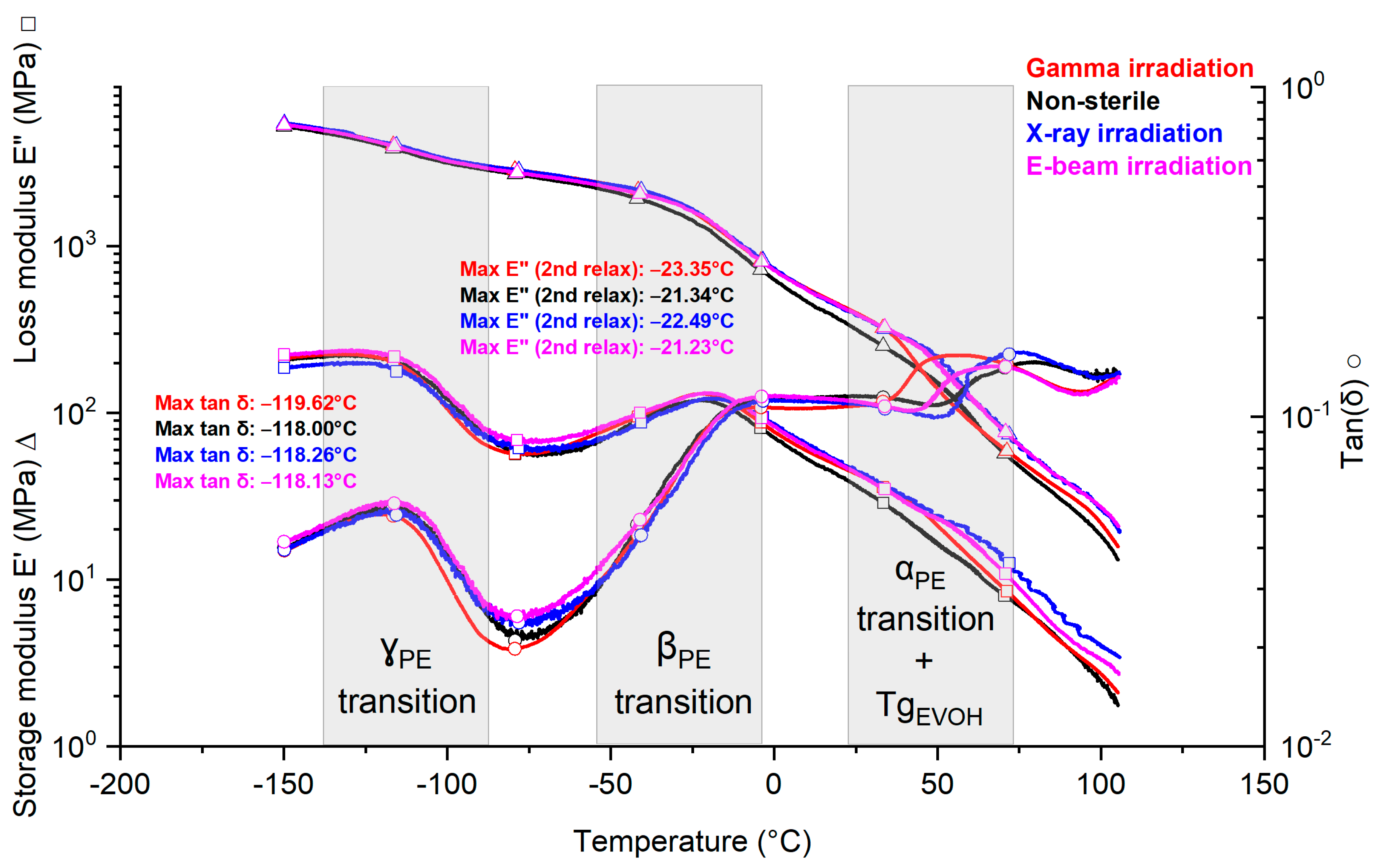

3.2. Thermal Relaxations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vogel, J.D. The Maturation of Single-Use Applications. BioProcess Int. 2012, 10 (Suppl. 5), 10–19. [Google Scholar]

- Mahajan, E.; Lye, G.; Eibl-Schindler, R. Bridging Polymer Science to Biotechnology Applications: A Single-Use Technology Conference Report. BioProcess Int. 2018. Available online: https://bioprocessintl.com/manufacturing/single-use/bridging-polymer-science-to-biotechnology-applications-a-single-use-technology-conference-report/ (accessed on 1 March 2023).

- Scott, C. Downstream Disposables: The Latest Single-Use Solutions for Downstream Processing. BioProcess Int. 2017. Available online: https://bioprocessintl.com/downstream-processing/downstream-single-use-technologies/downstream-processing-single-use-solutions/ (accessed on 1 March 2023).

- Guide to Irradiation and Sterilization Validation of Single-Use Bioprocess Systems. BioProcess Int. 2008. Available online: https://bioprocessintl.com/upstream-processing/upstream-single-use-technologies/guide-to-irradiation-and-sterilization-validation-of-single-use-bioprocess-systems-183975/ (accessed on 1 March 2023).

- ISO 11137-1; Sterilization of HealthCare Products-Radiation-Part 1: Requirements for Development, Validation and Routine Control of a Sterilization Process for MedicalDevices. ISO: Geneva, Switzerland, 2006.

- BPSA. X-ray Sterilization of Single-Use BioProcess Equipment, Part 1: Industry Need, Requirements & Risk Evaluation; BPSA: Washington, WA, USA, 2021. [Google Scholar]

- Dutta, A.; Ghosh, A.K. Investigation on γ-irradiated PP/ethylene acrylic elastomer TPVs by rheological and thermal approaches. Radiat. Phys. Chem. 2018, 144, 149–158. [Google Scholar] [CrossRef]

- Abdel Tawab, K.; Ibrahim, S.M.; Magida, M.M. The effect of gamma irradiation on mechanical, and thermal properties of recycling polyethylene terephthalate and low density polyethylene (R-PET/LDPE) blend compatibilized by ethylene vinyl acetate (EVA). J. Radioanal. Nucl. Chem. 2013, 295, 1313–1319. [Google Scholar] [CrossRef]

- Buttafava, A.; Consolati, G.; Mariani, M.; Quasso, F.; Ravasio, U. Effects induced by gamma irradiation of different polyesters studied by viscometry, thermal analysis and positron annihilation spectroscopy. Polym. Degrad. Stab. 2005, 89, 133–139. [Google Scholar] [CrossRef]

- Hyun Kang, P. The effect of γ-irradiation on ultra-high molecular weight polyethylene recrystallized under different cooling conditions. Radiat. Phys. Chem. 2001, 60, 79–87. [Google Scholar] [CrossRef]

- Montanari, L.; Costantini, M.; Signoretti, E.C.; Valvo, L.; Santucci, M.; Bartolomei, M.; Fattibene, P.; Onori, S.; Faucitano, A.; Conti, B.; et al. Gamma irradiation effects on poly(dl-lactictide-co-glycolide) microspheres. J. Control. Release 1998, 56, 219–229. [Google Scholar] [CrossRef] [PubMed]

- Hemmerich, K.J. Medical Device and Diagnostic Industry. 2000. Available online: https://www.mddionline.com/materials/polymer-materials-selection-radiation-sterilized-products (accessed on 1 March 2023).

- Şen, M.; Çopuroğlu, M. A comparative study of gamma irradiation of poly(ethylene-co-vinyl acetate) and poly(ethylene-co-vinyl acetate)/carbon black mixture. Mater. Chem. Phys. 2005, 93, 154–158. [Google Scholar] [CrossRef]

- Stoffers, N.H.; Linssen, J.P.H.; Franz, R.; Welle, F. Migration and sensory evaluation of irradiated polymers. Radiat. Phys. Chem. 2004, 71, 205–208. [Google Scholar] [CrossRef]

- Dutta, S.K.; Bhowmick, A.K.; Mukunda, P.G.; Chaki, T.K. Thermal degradation studies of electron beam cured ethylene-vinyl acetate copolymer. Polym. Degrad. Stab. 1995, 50, 75–82. [Google Scholar] [CrossRef]

- Demertzis, P.G.; Franz, R.; Welle, F. The effects of γ-irradiation on compositional changes in plastic packaging films. Packag. Technol. Sci. 1999, 12, 119–130. [Google Scholar] [CrossRef]

- Milosavljevic, B.H.; Thomas, J.K. Effects of the degree of hydrolysis on radiation induced reactions in the poly(vinyl alcohol)–poly(vinyl acetate) system. Radiat. Phys. Chem. 2001, 62, 3–10. [Google Scholar] [CrossRef]

- Zainuddin, Z.; Hill, D.J.T.; Le, T.T. An ESR study on γ-irradiated poly(vinyl alcohol). Radiat. Phys. Chem. 2001, 62, 283–291. [Google Scholar] [CrossRef]

- Rao, B.S.; Murthy, M.R. Electron spin resonance and UV absorption of irradiated poly(vinyl alcohol). J. Polym. Sci. Part B Polym. Phys. 1987, 25, 1897–1902. [Google Scholar] [CrossRef]

- Suarez, J.C.M.; Mano, E.B. Characterization of degradation on gamma-irradiated recycled polyethylene blends by scanning electron microscopy. Polym. Degrad. Stab. 2001, 72, 217–221. [Google Scholar] [CrossRef]

- Chapiro, A. Radiation chemistry of polymers. Radiat. Res. 1964, 4, 179–191. [Google Scholar] [CrossRef]

- Fifield, L.S.; Pharr, M.; Staack, D.; Pillai, S.D.; Nichols, L.; McCoy, J.; Faucette, T.; Bisel, T.T.; Huang, M.; Hasan, M.K.; et al. Direct comparison of gamma, electron beam and X-ray irradiation effects on single-use blood collection devices with plastic components. Radiat. Phys. Chem. 2021, 180, 109282. [Google Scholar] [CrossRef]

- Brouwer, H.D. Comparison of the effects of X-ray and gamma irradiation on engineering thermoplastics. Radiat. Phys. Chem. 2022, 193, 109999. [Google Scholar] [CrossRef]

- Manfredini, M.; Atzei, D.; Elsener, B.; Marchetti, A.; Rossi, A. Degradation of plasticized PVC for biomedical disposable device under soft X-ray irradiation. Surf. Interface Anal. 2003, 35, 294–300. [Google Scholar] [CrossRef]

- Nouh, S.A.; El-Nabarawy, H.A.; Abutalib, M.M.; Bahareth, R.A. Effect of X-ray irradiation on the structure, thermal and mechanical properties of polyester. Eur. Phys. J. Appl. Phys. 2013, 62, 30201. [Google Scholar] [CrossRef]

- Fintzou, A.T.; Kontominas, M.G.; Badeka, A.V.; Stahl, M.R.; Riganakos, K.A. Effect of electron-beam and gamma-irradiation on physicochemical and mechanical properties of polypropylene syringes as a function of irradiation dose: Study under vacuum. Radiat. Phys. Chem. 2007, 76, 1147–1155. [Google Scholar] [CrossRef]

- Hassan, M.M.; El-kelesh, N.A.; Dessouki, A.M. The effect of gamma and electron beam irradiation on the thermal and mechanical properties of injection-moulded high crystallinity poly(propylene). Polym. Compos. 2008, 29, 883–889. [Google Scholar] [CrossRef]

- Badia, A.; Duplâtre, G. Electron beam and gamma irradiation effects on high density polyethylene studied via positron annihilation lifetime spectroscopy. Radiat. Phys. Chem. 1999, 54, 151–158. [Google Scholar] [CrossRef]

- Croonenborghs, B.; Smith, M.A.; Strain, P. X-ray versus gamma irradiation effects on polymers. Radiat. Phys. Chem. 2007, 76, 1676–1678. [Google Scholar] [CrossRef]

- Audran, G.; Dorey, S.; Dupuy, N.; Gaston, F.; Marque, S.R.A. Degradation of γ-irradiated polyethylene-ethylene vinyl alcohol-polyethylene multilayer films: An ESR study. Polym. Degrad. Stab. 2015, 122, 169–179. [Google Scholar] [CrossRef]

- Girard-Perier, N.; Claeys-Bruno, M.; Marque, S.R.A.; Dupuy, N.; Gaston, F.; Dorey, S. Monitoring of peroxide in gamma irradiated PE/EVOH/PE multilayer film using methionine probe. Food Bioprod. Process. 2022, 132, 226–232. [Google Scholar] [CrossRef]

- Dorey, S.; Gaston, F.; Marque, S.R.A.; Bortolotti, B.; Dupuy, N. XPS analysis of PE and EVA samples irradiated at different γ-doses. Appl. Surf. Sci. 2018, 427, 966–972. [Google Scholar] [CrossRef]

- Dorey, S.; Gaston, F.; Girard-Perier, N.; Dupuy, N.; Marque, S.R.A.; Delaunay, L. Generation of O 2 -Permeation Barrier during the Gamma-Irradiation of Polyethylene/Ethylene-Vinyl Alcohol/Polyethylene Multilayer Film. Ind. Eng. Chem. Res. 2019, 58, 14115–14123. [Google Scholar] [CrossRef]

- Saito, O. On the Effect of High Energy Radiation to Polymers I. Cross-linking and Degradation. J. Phys. Soc. Jpn. 1958, 13, 198–206. [Google Scholar] [CrossRef]

- Saito, O. Effects of High Energy Radiation on Polymers II. End-linking and Gel Fraction. J. Phys. Soc. Jpn. 1958, 13, 1451–1464. [Google Scholar] [CrossRef]

- Yassouridis, C.; Dürauer, A.; Scharl, T.; Leisch, F.; Brocard, C.; Tscheliessnig, A.-L. Strategy to equivalence testing for development and scale up of biopharmaceutical downstream processes. Chem. Eng. Sci. 2021, 235, 116497. [Google Scholar] [CrossRef]

- Schuirmann, D.J. A comparison of the two one-sided tests procedure and the power approach for assessing the equivalence of average bioavailability. J. Pharmacokinet. Biopharm. 1987, 15, 657–680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Food and Drug Administration. Statistical Approaches to Establishing Bioequivalence: Guidance for Industry; Food and Drug Administration: Silver Spring, MD, USA, 2001. [Google Scholar]

- Limentani, G.B.; Ringo, M.C.; Ye, F.; Berquist, M.L.; McSorley, E.O. Beyond the t-test: Statistical equivalence testing. Anal. Chem. 2005, 77, 221A–226A. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lakens, D. Equivalence Tests: A Practical Primer for t Tests, Correlations, and Meta-Analyses. Soc. Psychol. Personal. Sci. 2017, 8, 355–362. [Google Scholar] [CrossRef] [Green Version]

- ISO527-3:1995; Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Sheets. ISO: Geneva, Switzerla, 1995.

- Menczel, J.D.; Prime, R.B. (Eds.) Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 978-0-471-76917-0. [Google Scholar]

- AAMI: Association for the Advancement of Medical Instrumentation. Compatibility of Materials Subject to Sterilization; AAMI: Arlington, VA, USA, 2017. [Google Scholar]

- Denardin, E.L.G.; Tokumoto, S.; Samios, D. Stress–strain behaviour of poly(ethylene terephthalate) (PET) during large plastic deformation by plane strain compression: The relation between stress–strain curve and thermal history, temperature and strain rate. Rheol Acta 2005, 45, 142–150. [Google Scholar] [CrossRef]

- Nitta, K.-h.; Uchida, Y.; Tanaka, A. Analysis of Stress-Strain Curve of Polyethylene Films by Toda-Lattice Model. Polym. J. 1991, 23, 895–901. [Google Scholar] [CrossRef] [Green Version]

- Greene, J.P. Microstructures of Polymers. In Automotive Plastics and Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 27–37. ISBN 9780128180082. [Google Scholar]

- Munaro, M.; Akcelrud, L. Correlations between composition and crystallinity of LDPE/HDPE blends. J. Polym. Res. 2008, 15, 83–88. [Google Scholar] [CrossRef]

- Nitta, K.-H.; Tanaka, A. Dynamic mechanical properties of metallocene catalyzed linear polyethylenes. Polymer 2001, 42, 1219–1226. [Google Scholar] [CrossRef]

- Matsuo, M.; Bin, Y.; Xu, C.; Ma, L.; Nakaoki, T.; Suzuki, T. Relaxation mechanism in several kinds of polyethylene estimated by dynamic mechanical measurements, positron annihilation, X-ray and 13C solid-state NMR. Polymer 2003, 44, 4325–4340. [Google Scholar] [CrossRef]

- Girard-Perier, N.; Claeys-Bruno, M.; Marque, S.R.A.; Dupuy, N.; Gaston, F.; Dorey, S. Effects of X-ray, electron beam and gamma irradiation on PE/EVOH/PE multilayer film properties. Chem. Commun. 2021, 57, 11049–11051. [Google Scholar] [CrossRef]

| Tensile Test | DMA | |||||

|---|---|---|---|---|---|---|

| Batch # | Dose (kGy) | Ageing (Months) | Batch # | Dose (kGy) | Ageing (Months) | |

| Gamma | Batch 1 | 54.3 ± 2.7 | 2 | Batch 3 | 55.2 ± 2.8 | 6 |

| Batch 2 | 48.2 ± 2.1 | 2 | Batch 2 | 48.2 ± 2.1 | 4 | |

| X-rays | Batch 3 | 55.2 ± 2.8 | 2 | Batch 6 | 50.8 ± 1.4 | 6 |

| Batch 2 | 54.7 ± 2.5 | 2 | Batch 2 | 53.1 ± 1.7 | 4 | |

| E-beam | Batch 4 | 52.0 ± 2.6 | 2 | Batch 7 | 54.1 ± 9.5 | 12 |

| Batch 5 | 54.8 ± 2.8 | 2 | n.a. | n.a. | n.a. | |

| Non-sterile | Batch 2 | 0 | n.a. a | Batch 7 | 0 | n.a. |

| UTS (Ultimate Tensile Stress) | Elongation | |

|---|---|---|

| Six-sigma variation | 22% | 21% |

| Criteria δ | 35% | 25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Girard-Perier, N.; Marque, S.R.A.; Dupuy, N.; Krieguer, B.; Dorey, S. Gamma, E-Beam and X-ray Irradiations on PE/EVOH/PE Multilayer Film: An Industrial Point of View Regarding the Impact on Mechanical Properties. Polymers 2023, 15, 2799. https://doi.org/10.3390/polym15132799

Girard-Perier N, Marque SRA, Dupuy N, Krieguer B, Dorey S. Gamma, E-Beam and X-ray Irradiations on PE/EVOH/PE Multilayer Film: An Industrial Point of View Regarding the Impact on Mechanical Properties. Polymers. 2023; 15(13):2799. https://doi.org/10.3390/polym15132799

Chicago/Turabian StyleGirard-Perier, Nina, Sylvain R. A. Marque, Nathalie Dupuy, Blanche Krieguer, and Samuel Dorey. 2023. "Gamma, E-Beam and X-ray Irradiations on PE/EVOH/PE Multilayer Film: An Industrial Point of View Regarding the Impact on Mechanical Properties" Polymers 15, no. 13: 2799. https://doi.org/10.3390/polym15132799

APA StyleGirard-Perier, N., Marque, S. R. A., Dupuy, N., Krieguer, B., & Dorey, S. (2023). Gamma, E-Beam and X-ray Irradiations on PE/EVOH/PE Multilayer Film: An Industrial Point of View Regarding the Impact on Mechanical Properties. Polymers, 15(13), 2799. https://doi.org/10.3390/polym15132799