Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen

Abstract

:1. Introduction

2. Raw Materials and Experimental Methods

2.1. Raw Materials

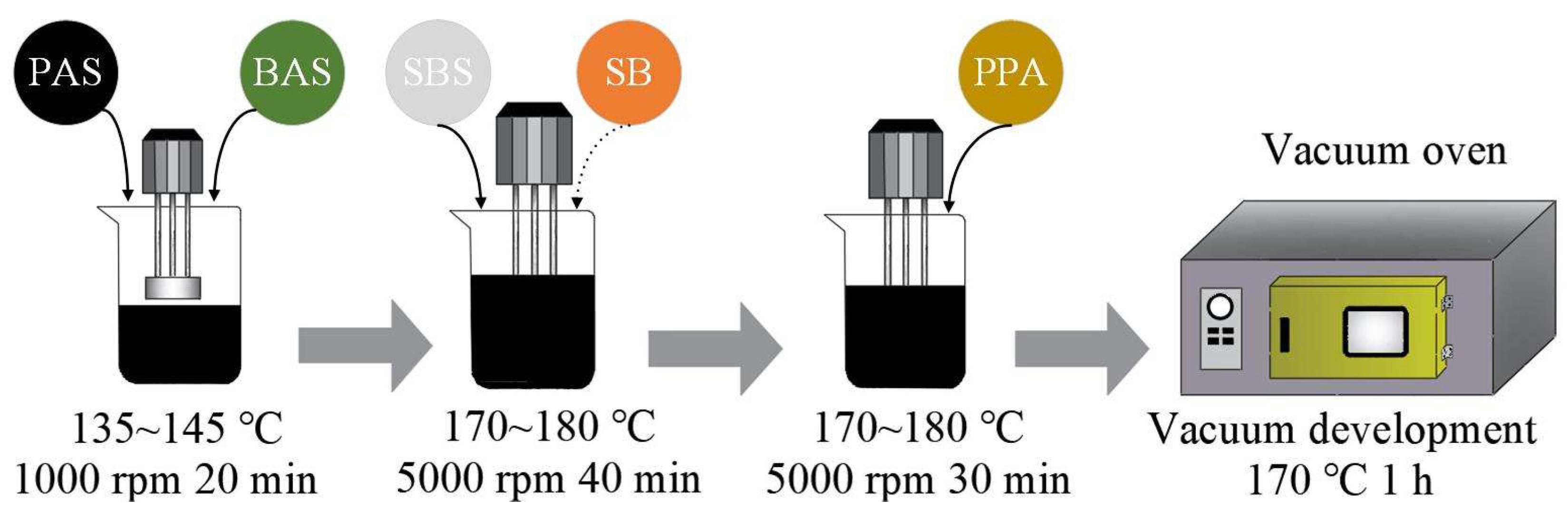

2.2. Sample Preparation

2.3. Experimental Methods

2.3.1. Long-Term Aging Process

2.3.2. Dynamic Shear Frequency Sweep Test

2.3.3. Amplitude Strain Sweep Test

2.3.4. Fatigue Properties Based on the VECD Model

- Performance parameter α was used to evaluate the stress sensitivity of the undamaged sample. Firstly, the energy storage modulus was calculated according to Equation (1) through the phase angle and complex modulus recorded during the frequency sweep test. Then, the slope m-value and intercept b-value were obtained by fitting Equation (2). Finally, α was calculated by Equation (3).

- The damage intensity D(t) was used to evaluate the accumulated damage of the bitumens during the oscillating stress. And it was calculated according to Equation (4).where is the integrity index of the specimen over time; is the strain applied; t is the time over the test; and is the initial complex modulus of the material.

- 3.

- Damage accumulation (Df) was used to evaluate bearing capacity of fatigue damage of the bitumens.

- 4.

- Finally, the loading cycles to failure (Nf) of each specimen were calculated according to Equation (9).where f is the frequency, 10 Hz.

2.3.5. Bending Beam Rheometer (BBR)

2.3.6. Atomic Force Microscopic (AFM)

3. Results and Discussion

3.1. Analysis of Frequency Sweep Test

3.2. Analysis of Stress–Strain Relationship in Amplitude Strain Sweep Test

3.3. Analysis of Fatigue Properties in VECD Theory

3.3.1. Analysis of VECD Curve

3.3.2. Analysis of Damage Accumulation

3.3.3. Analysis of the Strain Sensitivity Parameter

3.3.4. Analysis of Fatigue Life

3.4. Analysis of the BBR Test

3.5. Analysis of AFM Topography

4. Conclusions

- Under the action of esterification crosslinking of PPA and bio-bitumen, the compound-modified bitumen can bear more damage. In addition, the fatigue damages of A2 and A3 are greater than that of the control bitumen at the failure point, but after long-term aging, the damage-bearing capacity of the compound-modified bitumen is significantly reduced;

- The Nf-value of unaged A2 and A3 at 2.5%, 5%, 7.5%, and 10% strains are higher than that of the control bitumen, which shows that the esterification produced by the reaction of PPA and bio-bitumen can effectively improve the fatigue life of the unaged bitumen. However, after long-term aging, the fatigue life of bitumens is only improved under the condition of small applied strain (2.5%);

- The low-temperature performance of the compound-modified bitumen does not deteriorate further with the decrease in SBS content. Therefore, the esterification and crosslinking of PPA and bio-bitumen have positive effects on the low-temperature properties. The variation rate of the S-value for the compound-modified bitumen after PAV aging is significantly below that of the control bitumen, which means the compound-modified bitumen has better anti-aging performance in the BBR test;

- After long-term aging, the surface morphology of the control bitumen is rough, which shows that the intermolecular heterogeneity increases significantly. In contrast, the surface topography of the compound-modified bitumen is relatively flat, but the number of its bee-like structure is increased. In addition, combined with the results of the medium linear amplitude test, it can be posited that PPA and bio-bitumen can delay the influence of aging on the fatigue life of compound-modified bitumen;

- The esterified crosslinking provided by PPA and bio-bitumen has a benefit on the mechanical properties of bitumen, and it has been justified. However, the modification mechanism that we currently understand is superficial. Therefore, subsequent research should focus on the underlying mechanism and model establishment of the compound-modified bitumen.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, D.; Kong, L. Laboratory evaluation of carbon nanotubes modified bio-asphalt. Case Stud. Constr. Mater. 2023, 18, e01944. [Google Scholar] [CrossRef]

- Wang, J.; Lv, S.; Liu, J.; Peng, X.; Lu, W.; Wang, Z.; Xie, N. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- Ju, Z.; Ge, D.; Wu, Z.; Xue, Y.; Lv, S.; Li, Y.; Fan, X. The performance evaluation of high content bio-asphalt modified with polyphosphoric acid. Constr. Build. Mater. 2022, 361, 129593. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, Y.; Yang, J.; Li, X. A comprehensive review of bio-oil, bio-binder and bio-asphalt materials: Their source, composition, preparation and performance. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 151–166. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Bitumen improvement with bio-oil and natural or organomodified montmorillonite: Structure, rheology, and adhesion of composite asphalt binders. Constr. Build. Mater. 2023, 364, 129919. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Sun, B.; Zhou, X. Diffusion and Rheological Properties of Asphalt Modified by Bio-Oil Regenerant Derived from Waste Wood. J. Mater. Civ. Eng. 2018, 30, 04017274. [Google Scholar] [CrossRef]

- Mohamed, R.; Williams, R. Temperature and Shear Susceptibility of a Nonpetroleum Binder as a Pavement Material. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 9–18. [Google Scholar]

- Mills-Beale, J.; You, Z.; Fini, E.; Zada, B.; Lee, C.H.; Yap, Y.K. Aging Influence on Rheology Properties of Petroleum-Based Asphalt Modified with Biobinder. J. Mater. Civ. Eng. 2014, 26, 358–366. [Google Scholar] [CrossRef]

- Yang, X.; Liu, G.; Zhang, H.; Meng, Y.; Peng, C.; He, X.; Liang, J. Aging behavior of polyphosphoric acid/styrene-butadiene-styrene-modified bio-mixed asphalt based on high-temperature rheological properties and microscopic mechanism. Constr. Build. Mater. 2023, 389, 131691. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, W.; Yang, X.; Ning, Z. Study on the Conventional Performance and Microscopic Properties of PPA/SBS-Modified Bio-Mixed Asphalt. Materials 2022, 15, 4101. [Google Scholar] [CrossRef]

- Yang, X.; Liu, G.; Rong, H.; Meng, Y.; Peng, C.; Pan, M.; Ning, Z.; Wang, G. Investigation on mechanism and rheological properties of Bio-asphalt/PPA/SBS modified asphalt. Constr. Build. Mater. 2022, 347, 128599. [Google Scholar] [CrossRef]

- de Oliveira, L.S.; da Silva, L.S.V.; Lucas Júnior, J.L.O.; Babadopulos, L.F.d.A.L.; Soares, J.B. Linear viscoelasticity and fatigue life: Relationships between properties of asphalt binders and corresponding mixtures. Constr. Build. Mater. 2023, 372, 130685. [Google Scholar] [CrossRef]

- Cao, W.; Wang, Y.; Wang, C. Fatigue characterization of bio-modified asphalt binders under various laboratory aging conditions. Constr. Build. Mater. 2019, 208, 686–696. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.R. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 160, 786–793. [Google Scholar] [CrossRef]

- Ramón, R.; Anton, S.; Juan, J.P.; Maria, E.M.; Marisol, B.; Esteban, G.; Victorio, J. Rheological aspects of the rejuvenation of aged bitumen. Rheol. Acta Int. J. Rheol. 2006, 45, 474–478. [Google Scholar]

- Sabouri, M.; Mirzaiyan, D.; Moniri, A. Effectiveness of Linear Amplitude Sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 2018, 171, 281–290. [Google Scholar] [CrossRef]

- Yue, M.; Yue, J.; Wang, R.; Xiong, Y. Evaluating the fatigue characteristics and healing potential of asphalt binder modified with Sasobit® and polymers using linear amplitude sweep test. Constr. Build. Mater. 2021, 289, 123054. [Google Scholar] [CrossRef]

- Nan, H.; Sun, Y.; Chen, J.; Gong, M. Investigation of fatigue performance of asphalt binders containing SBS and CR through TS and LAS tests. Constr. Build. Mater. 2022, 361, 129651. [Google Scholar] [CrossRef]

- Wang, C. Rheological Characterization on Paving Performance of Asphalt Binder. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2015. (In Chinese). [Google Scholar]

- Liu, Z.; Li, S.; Wang, Y. Waste engine oil and polyphosphoric acid enhanced the sustainable self-healing of asphalt binder and its fatigue behavior. J. Clean. Prod. 2022, 339, 130767. [Google Scholar] [CrossRef]

- Yan, C.; Yuan, L.; Yu, X.; Ji, S.; Zhou, Z. Characterizing the fatigue resistance of multiple modified asphalts using time sweep test, LAS test and elastic recovery test. Constr. Build. Mater. 2022, 322, 125806. [Google Scholar] [CrossRef]

- Singh, D.; Ashish, P.K.; Kataware, A.; Habal, A. Evaluating Performance of PPA-and-Elvaloy-Modified Binder Containing WMA Additives and Lime Using MSCR and LAS Tests. J. Mater. Civ. Eng. 2017, 29, 04017064. [Google Scholar] [CrossRef]

- Johnson, C.M. Estimating Asphalt Binder Fatigue Resistance Using an Accelerated Test Method. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 2010. [Google Scholar]

- Bahia, H.; Motamed, A.; Delgadillo, R. Field Validation of Wisconsin Modified Binder Selection Guidelines; Wisconsin Highway Research Program: Madison, WI, USA, 2007. [Google Scholar]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Yang, J.; Gong, M.; Troy, P.; Wei, J.; Wang, X. Study on micro-structures of asphalt by using atomic force microscopy. Acta Pet. Sin. (Pet. Process. Sect.) 2015, 31, 959–965. [Google Scholar]

- Yang, J.; Wang, X.; Gong, M.; Chen, X.; Jiao, L. Analysis of the microscopic image of asphalt getting from atomic force microscopy. Acta Pet. Sin. (Pet. Process. Sect.) 2015, 31, 1110–1115. [Google Scholar]

- Guo, B.; Jia, X.; Zhang, H.; Liu, L. Effect of solid waste filler on fatigue property of modified asphalt during aging process. Bull. Chin. Ceram. Soc. 2021, 40, 2822–2830. (In Chinese) [Google Scholar]

- Zhang, X.; Tong, P.; Lin, X.; Li, J.; Li, B. Fatigue characterization of hard petroleum asphalt based on the linear amplitude sweep test. Mater. Rep. 2021, 35, 18083–18089. (In Chinese) [Google Scholar]

- Herrington, P.R.; James, B.; Henning, T.F.P. Effect of concentration on the rate of formation of carbonyl compounds during oxidation of roading bitumen. Fuel 2022, 322, 124133. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Z.; Yuan, G.; Zheng, Y.; Qian, G.; You, Z.; Zhang, H. Research on the anti-aging mechanism of SBS-modified asphalt compounded with multidimensional nanomaterials based on atomic force microscopy. Constr. Build. Mater. 2022, 317, 125808. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Oliviero Rossi, C.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, T.; Ma, J.; Liu, W.; Li, Y. Alcohol modified animal glue binder and its modification mechanism. Foundry 2022, 71, 351–356. (In Chinese) [Google Scholar]

- Ma, W.; Huang, T.; Guo, S.; Yang, C.; Ding, Y.; Hu, C. Atomic force microscope study of the aging/rejuvenating effect on asphalt morphology and adhesion performance. Constr. Build. Mater. 2019, 205, 642–655. [Google Scholar] [CrossRef]

| Bitumen Type | Applied Strain (%) | Nf (Times) | Predicting Equation | |

|---|---|---|---|---|

| A1 | Original | 2.5 | 11,832 | |

| 5 | 1364 | |||

| 7.5 | 386 | |||

| 10 | 157 | |||

| After PAV | 2.5 | 16,900 | ||

| 5 | 1490 | |||

| 7.5 | 361 | |||

| 10 | 132 | |||

| A2 | Original | 2.5 | 12,366 | |

| 5 | 1625 | |||

| 7.5 | 496 | |||

| 10 | 214 | |||

| After PAV | 2.5 | 17,018 | ||

| 5 | 1238 | |||

| 7.5 | 267 | |||

| 10 | 90 | |||

| A3 | Original | 2.5 | 12,249 | |

| 5 | 1572 | |||

| 7.5 | 473 | |||

| 10 | 202 | |||

| After PAV | 2.5 | 16,706 | ||

| 5 | 1206 | |||

| 7.5 | 259 | |||

| 10 | 87 | |||

| A4 | Original | 2.5 | 7093 | |

| 5 | 937 | |||

| 7.5 | 287 | |||

| 10 | 124 | |||

| After PAV | 2.5 | 14,190 | ||

| 5 | 1065 | |||

| 7.5 | 234 | |||

| 10 | 80 | |||

| Bitumen Type | −12 °C | −18 °C | −24 °C | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S/MPa | Variation/% | m | S/MPa | Variation/% | m | S/MPa | Variation/% | m | ||

| A1 | Original | 48.411 | ↑ 113 | 0.448 | 212.224 | ↑ 138 | 0.331 | 492.217 | ↑ 92 | 0.240 |

| PAV | 102.341 | 0.351 | 505.445 | 0.243 | 942.766 | 0.118 | ||||

| A2 | Original | 96.512 | ↑ 64 | 0.436 | 262.598 | ↑ 103 | 0.315 | 605.456 | ↑ 63 | 0.237 |

| PAV | 158.152 | 0.314 | 532.166 | 0.221 | 988.145 | 0.104 | ||||

| A3 | Original | 98.902 | ↑ 45 | 0.442 | 296.726 | ↑ 91 | 0.323 | 623.775 | ↑ 59 | 0.232 |

| PAV | 143.226 | 0.321 | 565.731 | 0.218 | 993.771 | 0.101 | ||||

| A4 | Original | 109.287 | ↑ 90 | 0.433 | 329.757 | ↑ 135 | 0.324 | 652.306 | - | 0.229 |

| PAV | 207.851 | 0.291 | 774.167 | 0.197 | 1000+ | - | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Du, Z.; Liu, G.; Luo, X.; Yang, C. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers 2023, 15, 2911. https://doi.org/10.3390/polym15132911

Wang H, Du Z, Liu G, Luo X, Yang C. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers. 2023; 15(13):2911. https://doi.org/10.3390/polym15132911

Chicago/Turabian StyleWang, Haitao, Zhongming Du, Guiyong Liu, Xiaofeng Luo, and Chunlu Yang. 2023. "Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen" Polymers 15, no. 13: 2911. https://doi.org/10.3390/polym15132911

APA StyleWang, H., Du, Z., Liu, G., Luo, X., & Yang, C. (2023). Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers, 15(13), 2911. https://doi.org/10.3390/polym15132911