Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach

Abstract

1. Introduction

2. Materials and Methods

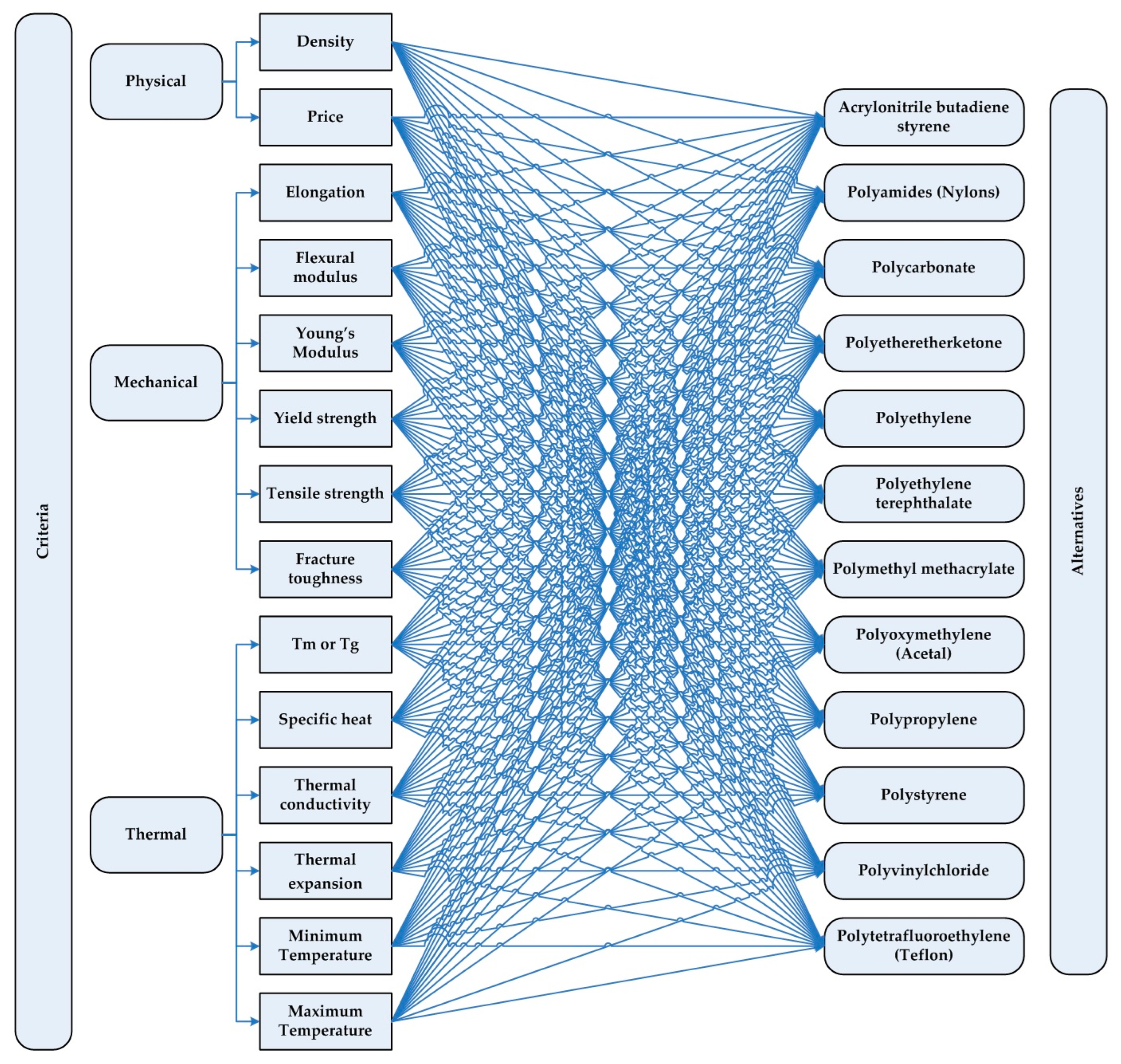

2.1. Material Alternatives

2.2. Criteria

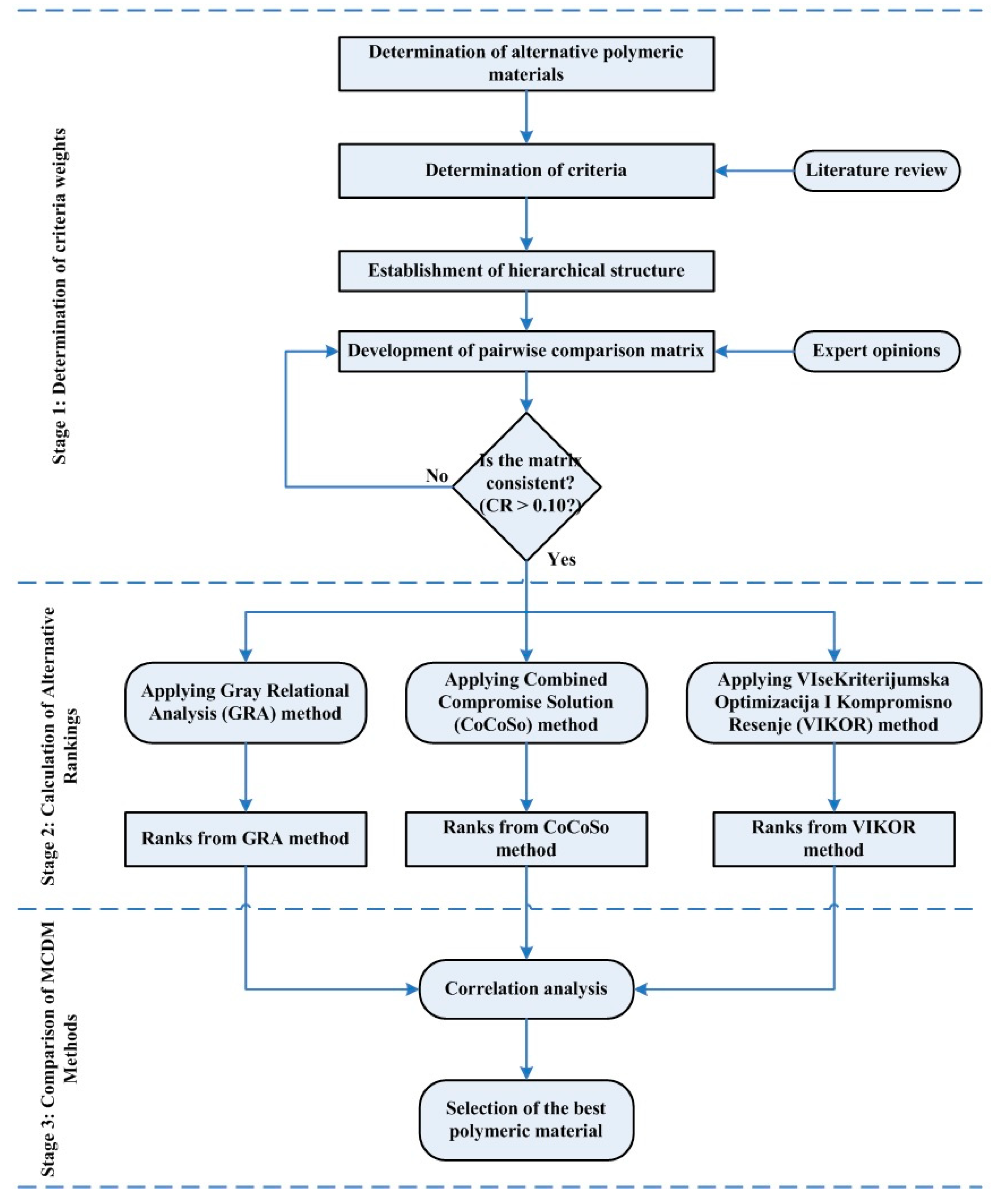

2.3. Comparative Hybrid MCDM Approach

2.3.1. Determination of the Criterion Weights by Analytical Hierarchy Proses (AHP) Method

2.3.2. Gray Relational Analysis (GRA) Method

2.3.3. CoCoSo Method

2.3.4. VIKOR Method

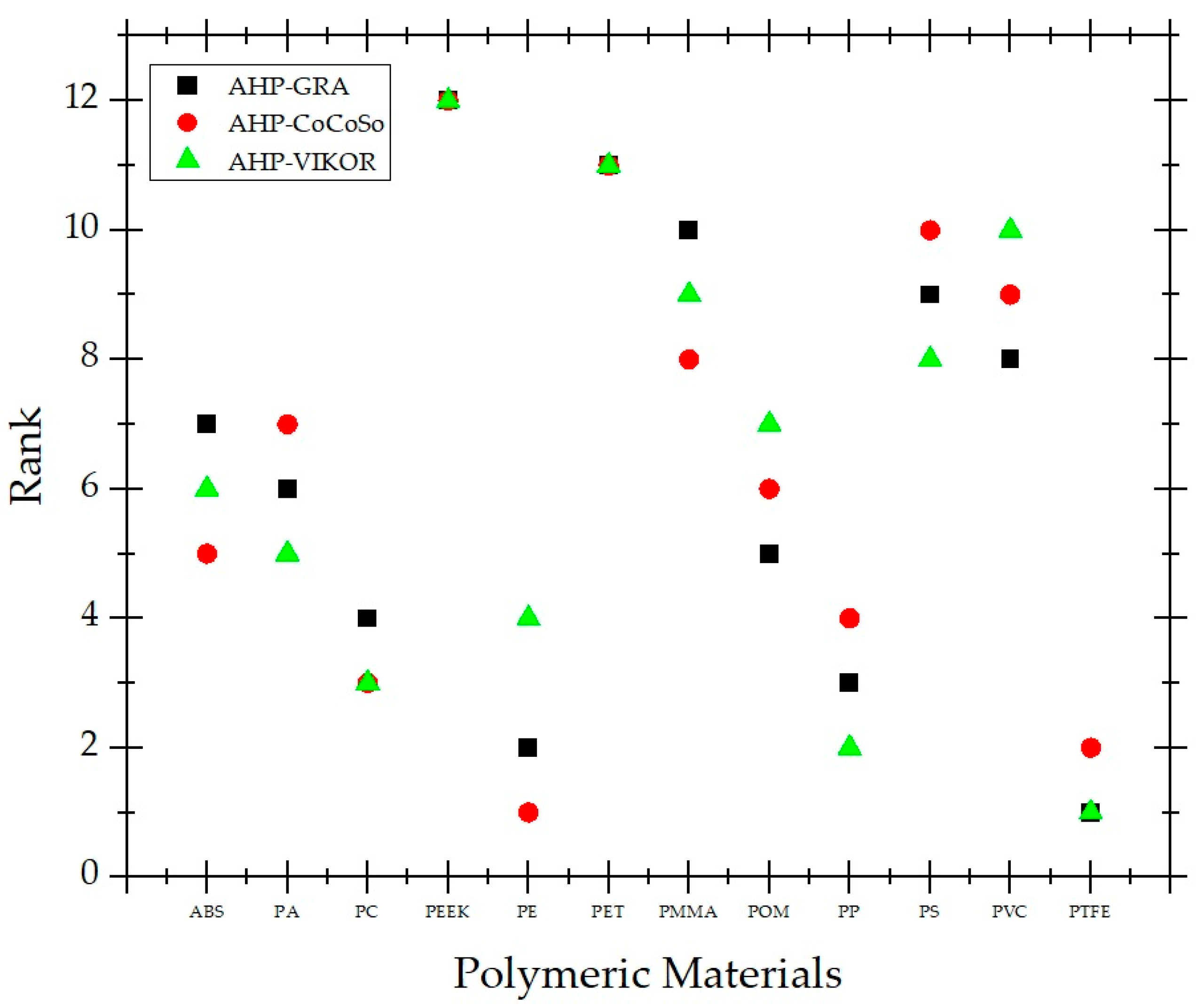

3. Results and Discussion

Criterion Weights

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruch, P.; Brunschwiler, T.; Escher, W.; Paredes, S.; Michel, B. Toward five-dimensional scaling: How density improves efficiency in future computers. IBM J. Res. Dev. 2011, 55, 1–13. [Google Scholar] [CrossRef]

- Vasiliev, L. Heat pipes in modern heat exchangers. Appl. Therm. Eng. 2005, 25, 1–19. [Google Scholar] [CrossRef]

- Ma, H. Oscillating Heat Pipes; Springer: New York, NY, USA, 2015. [Google Scholar]

- Das, S.P.; Nikolayev, V.S.; Lefevre, F.; Pottier, B.; Khandekar, S.; Bonjour, J. Thermally induced two-phase oscillating flow inside a capillary tube. Int. J. Heat Mass Transf. 2010, 53, 3905–3913. [Google Scholar] [CrossRef]

- Nine, M.J.; Tanshen, M.R.; Munkhbayar, B.; Chung, H.; Jeong, H. Analysis of pressure fluctuations to evaluate thermal performance of oscillating heat pipe. Energy 2014, 70, 135–142. [Google Scholar] [CrossRef]

- Yang, H.; Khandekar, S.; Groll, M. Operational limit of closed loop pulsating heat pipes. Appl. Therm. Eng. 2008, 28, 49–59. [Google Scholar] [CrossRef]

- Pagliarini, L.; Iwata, N.; Bozzoli, F. Pulsating Heat Pipes: Critical review on different experimental techniques. Exp. Therm. Fluid Sci. 2023, 148, 110980. [Google Scholar] [CrossRef]

- Alqahtani, A.; Bertola, V. Polymer and composite materials in two-phase passive thermal management systems: A review. Materials 2023, 16, 893. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.H.; Kang, S.; Wu, T.Y. Fabrication of polydimethylsiloxane (PDMS) pulsating heat pipe. Appl. Therm. Eng. 2009, 29, 573–580. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, G.; Ma, H.; Li, G.; Sun, Y. An experimental investigation of heat transfer performance in a polydimethylsiloxane (PDMS) oscillating heat pipe. Appl. Therm. Eng. 2013, 61, 690–697. [Google Scholar] [CrossRef]

- Ogata, S.; Sukegawa, E.; Kimura, T. Performance evaluation of ultra-thin polymer pulsating heat pipes. In Proceedings of the Fourteenth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 27–30 May 2014. [Google Scholar]

- Lim, J.; Kim, S. Fabrication and experimental evaluation of a polymer-based flexible pulsating heat pipe. Energy Convers. Manag. 2018, 156, 358–364. [Google Scholar] [CrossRef]

- Der, O.; Alqahtani, A.; Marengo, M.; Bertola, V. Characterization of polypropylene pulsating heat stripes: Effects of orientation, heat transfer fluid, and loop geometry. Appl. Therm. Eng. 2021, 184, 116304. [Google Scholar] [CrossRef]

- Ordu, M.; Fedai, Y. A novel decision support system based on fuzzy multi criteria decision making for optimizing machining parameters. J. Eng. Res. 2021, 53, 1–17. [Google Scholar] [CrossRef]

- Chowdhury, S.; Das, P.; Chakraborty, S. Optimization of CNC turning of aluminium 6082-T6 alloy using fuzzy multi-criteria decision making methods: A comparative study. Int. J. Interact. Des. Manuf. 2022, 17, 1047–1066. [Google Scholar] [CrossRef]

- Kharwar, P.; Verma, R. Machining performance optimization in drilling of multiwall carbon nano tube/epoxy nanocomposites using GRA-PCA hybrid approach. Measurement 2020, 158, 107701. [Google Scholar] [CrossRef]

- Jadhav, P.; Mohanty, C.; Hotta, T.; Gupta, M. An optimal approach for improving the machinability of Nimonic C-263 superalloy during cryogenic assisted turning. J. Manuf. Process. 2020, 58, 693–705. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Analysis and optimization of sustainable machining of AISI O1 tool steel by the wire-EDM process. Adv. Manuf. 2021, 9, 304–317. [Google Scholar] [CrossRef]

- Das, P.; Tiwary, A.; Chakraborty, S. A hybrid MCDM approach for parametric optimization of a micro-EDM process. Int. J. Interact. Des. Manuf. 2022, 16, 1739–1759. [Google Scholar] [CrossRef]

- Fedai, Y.; Basar, G.; Kirli Akin, H. Multi-response optimization in drilling of MWCNTs reinforced GFRP using grey relational analysis. Tech. Gaz. 2022, 29, 742–751. [Google Scholar]

- Sun, W.; Zhang, Y.; Luo, M.; Zhang, Z.; Zhang, D. A multi-criteria decision-making system for selecting cutting parameters in milling process. J. Manuf. Syst. 2022, 65, 498–509. [Google Scholar] [CrossRef]

- Kalita, K.; Madhu, S.; Ramachandran, M.; Chakraborty, S.; Ghadai, R. Experimental investigation and parametric optimization of a milling process using multi-criteria decision making methods: A comparative analysis. Int. J. Interact. Des. Manuf. 2023, 17, 453–467. [Google Scholar] [CrossRef]

- Bhowmik, C.; Gangwar, S.; Bhowmik, S.; Ray, A. Optimum selection of energy-efficient material: A MCDM-based distance approach. In Soft Computing Applications; Ray, K., Pant, M., Bandyopadhyay, A., Eds.; Springer Nature: Singapore, 2018; Volume 761, pp. 59–79. [Google Scholar]

- Moradian, M.; Modanloo, V.; Aghaiee, S. Comparative analysis of multi criteria decision making techniques for material selection of brake booster valve body. J. Traffic Transp. Eng. 2019, 6, 526–534. [Google Scholar] [CrossRef]

- Agrawal, R. Sustainable material selection for additive manufacturing technologies: A critical analysis of rank reversal approach. J. Clean. Prod. 2021, 296, 126500. [Google Scholar] [CrossRef]

- Wang, K.; Xie, G.; Xiang, J.; Li, T.; Peng, Y.; Wang, J.; Zhang, H. Materials selection of 3D printed polyamide-based composites at different strain rates: A case study of automobile front bumpers. J. Manuf. Process. 2022, 84, 1449–1462. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Lee, R.; Ghazi, A. Experimental polymeric nanocomposite material selection for automotive bumper beam using multi-criteria decision making methods. Iran. J. Mater. Sci. Eng. 2017, 14, 1–10. [Google Scholar]

- Roy, M.; Shivakoti, I.; Phipon, R.; Sharma, A. A holistic Approach to polymeric material selection for laser beam machining using methods of DEA and TOPSIS. Found. Comput. Decis. Sci. 2020, 45, 339–357. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S. A comprehensive review on material selection for polymer matrix composites subjected to impact load. Def. Technol. 2021, 17, 257–277. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Liu, H.; Sun, G.; Li, Y.; Lang, T.; Wang, R.; Cui, B. A method for manufacturing flexible microfluidic chip based on soluble material. J. Nanomater. 2021, 2021, 1280338. [Google Scholar] [CrossRef]

- Choudhury, I.; Shirley, S. Laser cutting of polymeric materials: An experimental investigation. Opt. Laser Technol. 2010, 42, 503–508. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, G.; Tian, C.; Li, Z.; Shao, J.; Li, S.; He, X. Hole morphology and keyhole evolution during single pulse laser drilling on polyether-ether-ketone (PEEK). Materials 2022, 15, 2457. [Google Scholar] [CrossRef]

- Eltawahni, H.; Olabi, A.; Benyounis, K. Effect of process parameters and optimization of CO2 laser cutting of ultra high-performance polyethylene. Mater. Des. 2010, 31, 4029–4038. [Google Scholar] [CrossRef]

- Li, H.; Fan, Y.; Kodzius, R.; Foulds, I. Fabrication of polystyrene microfluidic devices using a pulsed CO2 laser system. Microsyst. Technol. 2012, 18, 373–379. [Google Scholar] [CrossRef]

- Wu, C.; Rong, Y.; Huang, Y.; Li, M.; Zhang, G.; Liu, W. Precision cutting of polyvinyl chloride film by ultraviolet nanosecond laser. Mater. Manuf. Process. 2021, 36, 1650–1657. [Google Scholar] [CrossRef]

- Ashby, M.; Johnson, K. Materials and the Environment; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Kurt, M.; Kaynak, Y.; Bagci, E.; Demirer, H.; Kurt, M. Dimensional analyses and surface quality of the laser cutting. Int. J. Adv. Manuf. Technol. 2009, 41, 259–267. [Google Scholar] [CrossRef]

- Der, O.; Bertola, V. An experimental investigation of oil-water flow in a serpentine channel. Int. J. Multiph. Flow 2020, 129, 103327. [Google Scholar] [CrossRef]

- Strobl, G. The Physics of Polymers; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Maqbool, M.; Aftab, W.; Bashir, A.; Usman, A.; Guo, H.; Bai, S. Engineering of polymer-based materials for thermal management solutions. Compos. Commun. 2022, 29, 101048. [Google Scholar] [CrossRef]

- Lakes, R. Viscoelastic Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Callister Jr, W.; Rethwisch, D. Fundamentals of Materials Science and Engineering: An Integrated Approach, 5th ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Chae, H.; Kumar, S. Making Strong Fibers. Science 2008, 319, 908–909. [Google Scholar] [CrossRef]

- Tarannum, F.; Muthaiah, R.; Annam, R.; Gu, T.; Garg, J. Effect of alignment on enhancement of thermal conductivity of polyethylene–graphene nanocomposites and comparison with effective medium theory. Nanomaterials 2020, 10, 1291. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering; Prentice Hall: London, UK, 2009. [Google Scholar]

- Rodrigues, R.O.; Lima, R.; Gomes, H.T.; Silva, A.M.T. Polymer microfluidic devices: An overview of fabrication methods. U. Porto J. Eng. 2015, 1, 67–79. [Google Scholar] [CrossRef]

- Ashby, M. Material Property Data for Engineering Materials; Cambridge Press: Cambridge, UK, 2016. [Google Scholar]

- Höfer, T.; Sunak, Y.; Siddique, H.; Madlener, R. Wind farm siting using a spatial analytic hierarchy process approach: A case study of the Städteregion Aachen. Appl. Energy 2016, 163, 222–243. [Google Scholar] [CrossRef]

- Xu, H.; Romagnoli, A.; Sze, J.; Py, X. Application of material assessment methodology in latent heat thermal energy storage for waste heat recovery. Appl. Energy 2017, 187, 281–290. [Google Scholar] [CrossRef]

- Saaty, T. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Sánchez-Lozano, J.; García-Cascales, M.; Lamata, M. GIS-based onshore wind farm site selection using fuzzy multi-criteria decision making methods. Evaluating the case of Southeastern Spain. Appl. Energy 2016, 171, 86–102. [Google Scholar] [CrossRef]

- Shyamprasad, V.; Kousalya, P. Role of Consistency and Random Index in Analytic Hierarchy Process—A New Measure. In Numerical Optimization in Engineering and Sciences; Dutta, D., Mahanty, B., Eds.; Springer Nature: Singapore, 2020; Volume 979, pp. 233–239. [Google Scholar]

- Yang, K.; Zhu, N.; Chang, C.; Wang, D.; Yang, S.; Ma, S. A methodological concept for phase change material selection based on multi-criteria decision making (MCDM): A case study. Energy 2018, 165, 1085–1096. [Google Scholar] [CrossRef]

- Julong, D. Introduction to grey system theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Wu, J.; Wen, K.; You, M. A multi-decision making based on grey relational grade. J. Grey Syst. 1999, 11, 381–386. [Google Scholar]

- Wu, H.H. A comparative study of using grey relational analysis in multiple attribute decision making problems. Qual. Eng. 2002, 15, 209–217. [Google Scholar] [CrossRef]

- Hsu, Y.; Yeh, J.; Chang, H. Grey relational analysis for image compression. J. Grey Syst. 2000, 12, 131–138. [Google Scholar]

- Tong, L.; Wang, C. Optimizing multi-response problems in a dynamic system by grey relational grade analysis. J.-Chin. Inst. Ind. Eng. 2000, 17, 147–156. [Google Scholar]

- Yazdani, M.; Torkayesh, A.; Chatterjee, P. An integrated decision-making model for supplier evaluation in public healthcare system: The case study of a Spanish hospital. J. Enterp. Inf. Manag. 2020, 33, 965–989. [Google Scholar] [CrossRef]

- Torkayesh, A.; Pamucar, D.; Ecer, F.; Chatterjee, P. An integrated BWM-LBWA-CoCoSo framework for evaluation of healthcare sectors in Eastern Europe. Socio-Econ. Plan. Sci. 2021, 78, 101052. [Google Scholar] [CrossRef]

- Muravev, D.; Mijic, N. A novel integrated provider selection multicriteria model: The BWM-MABAC model. Decis. Mak. Appl. Manag. Eng. 2020, 3, 60–78. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D.; Zolfani, S.; Eshkalag, M. Sustainability assessment of OPEC countries: Application of a multiple attribute decision making tool. J. Clean. Prod. 2019, 241, 118324. [Google Scholar] [CrossRef]

- Yazdani, M.; Torkayesh, A.; Santibanez-Gonzalez, E.; Otaghsara, S. Evaluation of renewable energy resources using integrated Shannon Entropy—EDAS model. Sustain. Oper. Comput. 2020, 1, 35–42. [Google Scholar] [CrossRef]

- Zolfani, S.; Ecer, F.; Pamučar, D.; Raslanas, S. Neighborhood selection for a newcomer via a novel BWM-based revised MAIRCA integrated model: A case from the Coquimbo-La Serena conurbation, Chile. Int. J. Strateg. Prop. Manag. 2020, 24, 102–118. [Google Scholar] [CrossRef]

- Zhang, M.; Peng, X. Detection and filling of pseudo-hole in complex curved surface objects. Int. J. Inf. Commun. Technol. 2019, 14, 1–15. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D. Sustainable supplier selection: A novel integrated fuzzy best worst method (F-BWM) and fuzzy CoCoSo with Bonferroni (CoCoSo’B) multi-criteria model. J. Clean. Prod. 2020, 266, 121981. [Google Scholar] [CrossRef]

- Ulutaş, A.; Karakuş, C. Location selection for logistics center with fuzzy SWARA and CoCoSo methods. J. Intell. Fuzzy Syst. 2020, 38, 4693–4709. [Google Scholar] [CrossRef]

- Wen, Z.; Liao, H.; Zavadskas, E.; Al-Barakati, A. Selection third-party logistics service providers in supply chain finance by a hesitant fuzzy linguistic combined compromise solution method. Econ. Res.-Ekon. Istraživanja 2019, 32, 4033–4058. [Google Scholar] [CrossRef]

- Yazdani, M.; Zarate, P.; Zavadskas, E.K.; Turskis, Z. A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems. Manag. Decis. 2019, 57, 2501–2519. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Yu, P.L. A class of solutions for group decision problems. Manag. Sci. 1973, 19, 936–946. [Google Scholar] [CrossRef]

- Zeleny, M. Multiple Criteria Decision Making; Mc-Graw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Hao, T.; Ma, H.; Ma, X. Heat transfer performance of polytetrafluoroethylene oscillating heat pipe with water, ethanol, and acetone as working fluids. Int. J. Heat Mass Transf. 2019, 131, 109–120. [Google Scholar] [CrossRef]

- Der, O.; Marengo, M.; Bertola, V. Thermal performance of pulsating heat stripes built with plastic materials. J. Heat Transf. 2019, 141, 091808. [Google Scholar] [CrossRef]

- Gurgen, S.; Çakır, F.; Sofuoglu, M.; Orak, S.; Kushan, M.; Li, H. Multi-criteria decision-making analysis of different non-traditional machining operations of Ti6Al4V. Soft Comput. 2019, 23, 5259–5272. [Google Scholar] [CrossRef]

- Lukic, D.; Cep, R.; Vukman, J.; Antic, A.; Djurdjev, M.; Milosevic, M. Multi-criteria selection of the optimal parameters for high-speed machining of aluminum alloy Al7075 thin-walled parts. Metals 2020, 10, 1570. [Google Scholar] [CrossRef]

- Goswami, S.; Behera, D.; Afzal, A.; Kaladgi, A.; Khan, S.; Rajendran, P.; Subbiah, R.; Asif, M. Analysis of a robot selection problem using two newly developed hybrid MCDM models of TOPSIS-ARAS and COPRAS-ARAS. Symmetry 2021, 13, 1331. [Google Scholar] [CrossRef]

| Thermoplastics | Abbreviation |

|---|---|

| Acrylonitrile butadiene styrene | ABS |

| Polyamides (Nylons) | PA |

| Polycarbonate | PC |

| Polyetheretherketone | PEEK |

| Polyethylene | PE |

| Polyethylene terephthalate | PET |

| Polymethyl methacrylate | PMMA |

| Polyoxymethylene (Acetal) | POM |

| Polypropylene | PP |

| Polystyrene | PS |

| Polyvinylchloride | PVC |

| Polytetrafluoroethylene (Teflon) | PTFE |

| Thermoplastics | D | P | E | FM | YM | YS | TS | FT | TM | SH | TC | TE | MINT | MAXT |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ABS | 1100 | 2.55 | 50.00 | 2.50 | 2.00 | 35.00 | 42.00 | 2.80 | 110.00 | 1650 | 0.27 | 160.00 | −20 | 80 |

| PA | 1100 | 4.30 | 65.00 | 2.30 | 2.90 | 72.00 | 130.00 | 3.90 | 50.00 | 1650 | 0.24 | 145.00 | −30 | 95 |

| PC | 1150 | 4.85 | 100.0 | 2.30 | 2.20 | 65.00 | 66.00 | 3.40 | 170.00 | 1550 | 0.21 | 130.00 | −30 | 120 |

| PEEK | 1300 | 97.0 | 90.00 | 3.80 | 3.90 | 80.00 | 85.00 | 3.50 | 170.00 | 1450 | 0.25 | 130.00 | −65 | 70 |

| PE | 950 | 2.20 | 15.00 | 0.80 | 0.76 | 23.50 | 33.00 | 1.60 | 125.00 | 1850 | 0.42 | 165.00 | −40 | 130 |

| PET | 1350 | 2.20 | 20.00 | 3.30 | 3.45 | 59.50 | 60.00 | 5.00 | 75.00 | 1450 | 0.15 | 115.00 | −30 | 60 |

| PMMA | 1200 | 2.85 | 2.50 | 2.90 | 3.00 | 63.00 | 64.00 | 1.20 | 125.00 | 1550 | 0.17 | 115.00 | −70 | 70 |

| POM | 1400 | 3.15 | 40.00 | 2.83 | 3.75 | 61.00 | 75.00 | 2.90 | 170.00 | 1400 | 0.29 | 140.00 | −30 | 80 |

| PP | 900 | 2.25 | 120.0 | 1.50 | 1.25 | 29.00 | 35.00 | 3.80 | 160.00 | 1950 | 0.14 | 150.00 | −20 | 160 |

| PS | 1050 | 3.15 | 30.00 | 2.50 | 1.90 | 43.00 | 47.00 | 0.90 | 90.00 | 1750 | 0.13 | 120.00 | −50 | 70 |

| PVC | 1450 | 2.10 | 1.60 | 3.00 | 3.10 | 43.00 | 53.00 | 3.30 | 88.00 | 1400 | 0.22 | 125.00 | −20 | 60 |

| PTFE | 2150 | 16.0 | 300.0 | 0.60 | 0.48 | 20.00 | 25.00 | 1.60 | 115.00 | 1100 | 0.25 | 175.00 | −100 | 260 |

| Thermoplastics | Units | Abbreviation |

|---|---|---|

| Density | kg/m3 | D |

| Price | US $/kg | P |

| Elongation | % | E |

| Flexural modulus | GPa | FM |

| Young’s modulus | GPa | YM |

| Yield strength | MPa | YS |

| Tensile strength | MPa | TS |

| Fracture toughness | MPa.m1/2 | FT |

| Melting temperature or glass transition | °C | TM |

| Specific heat capacity | J/kg. °C | SH |

| Thermal conductivity | W/m/K | TC |

| Thermal expansion | 10−6/°C | TE |

| Minimum temperature | °C | MINT |

| Maximum temperature | °C | MAXT |

| D | P | E | FM | YM | YS | TS | FT | TM | SH | TC | TE | MINT | MAXT | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | 1 | 1/9 | 1/6 | 1/4 | 1/9 | 1/6 | 1/6 | 1/3 | 1/7 | 1/6 | 1/8 | 1/6 | 1/7 | 1/9 |

| P | 9 | 1 | 3 | 5 | 1 | 3 | 3 | 6 | 2 | 3 | 2 | 3 | 2 | 1 |

| E | 6 | 1/3 | 1 | 2 | 1/3 | 1 | 1 | 3 | 2 | 1 | 1/2 | 1 | 2 | 1/3 |

| FM | 4 | 1/5 | 1/2 | 1 | 1/5 | 1/2 | 1/2 | 2 | 1/3 | 1/2 | 1/4 | 1/2 | 1/3 | 1/5 |

| YM | 9 | 1 | 3 | 5 | 1 | 3 | 3 | 6 | 2 | 3 | 2 | 3 | 2 | 1 |

| YS | 6 | 1/3 | 1 | 2 | 1/3 | 1 | 1 | 3 | 1/2 | 1 | 1/2 | 1 | 1/2 | 1/3 |

| TS | 6 | 1/3 | 1 | 2 | 1/3 | 1 | 1 | 3 | 1/2 | 1 | 1/2 | 1 | 1/2 | 1/3 |

| FT | 3 | 1/6 | 1/3 | 1/2 | 1/6 | 1/3 | 1/3 | 1 | 1/4 | 1/3 | 1/5 | 1/3 | 1/4 | 1/6 |

| TM | 7 | 1/2 | 1/2 | 3 | 1/2 | 2 | 2 | 4 | 1 | 2 | 1/2 | 2 | 1 | 1/2 |

| SH | 6 | 1/3 | 1 | 2 | 1/3 | 1 | 1 | 3 | 1/2 | 1 | 1/2 | 1 | 1/2 | 1/3 |

| TC | 8 | 1/2 | 2 | 4 | 1/2 | 2 | 2 | 5 | 2 | 2 | 1 | 2 | 2 | 1/2 |

| TE | 6 | 1/3 | 1 | 2 | 1/3 | 1 | 1 | 3 | 1/2 | 1 | 1/2 | 1 | 1/2 | 1/3 |

| MINT | 7 | 1/2 | 1/2 | 3 | 1/2 | 2 | 2 | 4 | 1 | 2 | 1/2 | 2 | 1 | 1/2 |

| MAXT | 9 | 1 | 3 | 5 | 1 | 3 | 3 | 6 | 2 | 3 | 2 | 3 | 2 | 1 |

| D | P | E | FM | YM | YS | TS | FT | TM | SH | TC | TE | MINT | MAXT | Weights (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | 0.01 | 0.02 | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 1.05 |

| P | 0.10 | 0.15 | 0.17 | 0.14 | 0.15 | 0.14 | 0.14 | 0.12 | 0.14 | 0.14 | 0.18 | 0.14 | 0.14 | 0.15 | 14.35 |

| E | 0.07 | 0.05 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.14 | 0.05 | 0.05 | 0.05 | 0.14 | 0.05 | 6.43 |

| FM | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | 0.04 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | 2.83 |

| YM | 0.10 | 0.15 | 0.17 | 0.14 | 0.15 | 0.14 | 0.14 | 0.12 | 0.14 | 0.14 | 0.18 | 0.14 | 0.14 | 0.15 | 14.35 |

| YS | 0.07 | 0.05 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 4.98 |

| TS | 0.07 | 0.05 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 4.98 |

| FT | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | 1.99 |

| TM | 0.08 | 0.08 | 0.03 | 0.08 | 0.08 | 0.10 | 0.10 | 0.08 | 0.07 | 0.10 | 0.05 | 0.10 | 0.07 | 0.08 | 7.59 |

| SH | 0.07 | 0.05 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 4.98 |

| TC | 0.09 | 0.08 | 0.11 | 0.11 | 0.08 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | 0.09 | 0.10 | 0.14 | 0.08 | 9.72 |

| TE | 0.07 | 0.05 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 4.98 |

| MINT | 0.08 | 0.08 | 0.03 | 0.08 | 0.08 | 0.10 | 0.10 | 0.08 | 0.07 | 0.10 | 0.05 | 0.10 | 0.07 | 0.08 | 7.42 |

| MAXT | 0.10 | 0.15 | 0.17 | 0.14 | 0.15 | 0.14 | 0.14 | 0.12 | 0.14 | 0.14 | 0.18 | 0.14 | 0.14 | 0.15 | 14.35 |

| Parameters | Values |

|---|---|

| Number of comparisons | 14 |

| Average consistency (λmax) | 14.33 |

| Consistency index (CI) | 0.025 |

| Random consistency index (RI) | 1.57 |

| Consistency ratio (CR) | 0.02 |

| Thermoplastics | AHP-GRA | AHP-CoCoSo | AHP-VIKOR | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Γ0i | Rank | ka | kb | kc | k | Rank | Si | Ri | Q0 | Rank | |

| ABS | 0.034 | 7 | 0.091 | 2.879 | 0.968 | 1.946 | 5 | 0.547 | 0.129 | 0.704 | 6 |

| PA | 0.035 | 6 | 0.086 | 2.795 | 1.017 | 1.924 | 7 | 0.548 | 0.118 | 0.643 | 5 |

| PC | 0.037 | 4 | 0.093 | 3.112 | 1.021 | 2.075 | 3 | 0.486 | 0.101 | 0.457 | 3 |

| PEEK | 0.030 | 12 | 0.072 | 2.053 | 1.004 | 1.572 | 12 | 0.707 | 0.144 | 1.000 | 12 |

| PE | 0.044 | 2 | 0.092 | 3.321 | 1.026 | 2.160 | 1 | 0.419 | 0.136 | 0.576 | 4 |

| PET | 0.031 | 11 | 0.076 | 2.134 | 1.005 | 1.618 | 11 | 0.703 | 0.144 | 0.995 | 11 |

| PMMA | 0.032 | 10 | 0.087 | 2.530 | 1.010 | 1.816 | 8 | 0.635 | 0.136 | 0.862 | 9 |

| POM | 0.035 | 5 | 0.090 | 2.775 | 1.015 | 1.926 | 6 | 0.573 | 0.137 | 0.785 | 7 |

| PP | 0.041 | 3 | 0.087 | 3.097 | 1.023 | 2.053 | 4 | 0.461 | 0.094 | 0.386 | 2 |

| PS | 0.032 | 9 | 0.077 | 2.392 | 1.010 | 1.730 | 10 | 0.630 | 0.136 | 0.855 | 8 |

| PVC | 0.033 | 8 | 0.079 | 2.383 | 1.010 | 1.731 | 9 | 0.639 | 0.144 | 0.910 | 10 |

| PTFE | 0.049 | 1 | 0.071 | 3.285 | 1.033 | 2.084 | 2 | 0.331 | 0.057 | 0.0000 | 1 |

| AHP-GRA | AHP-CoCoSo | AHP-VIKOR | |

|---|---|---|---|

| AHP-GRA | 1.0000 | 0.9441 | 0.9371 |

| AHP-CoCoSo | 1.0000 | 0.9091 | |

| AHP-VIKOR | 1.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ordu, M.; Der, O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers 2023, 15, 2933. https://doi.org/10.3390/polym15132933

Ordu M, Der O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers. 2023; 15(13):2933. https://doi.org/10.3390/polym15132933

Chicago/Turabian StyleOrdu, Muhammed, and Oguzhan Der. 2023. "Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach" Polymers 15, no. 13: 2933. https://doi.org/10.3390/polym15132933

APA StyleOrdu, M., & Der, O. (2023). Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers, 15(13), 2933. https://doi.org/10.3390/polym15132933