Feasibility Study of Using Hydrophobic Geopolymer-Based as Aggregate Substitution in Asphalt Mixture

Abstract

:1. Introduction

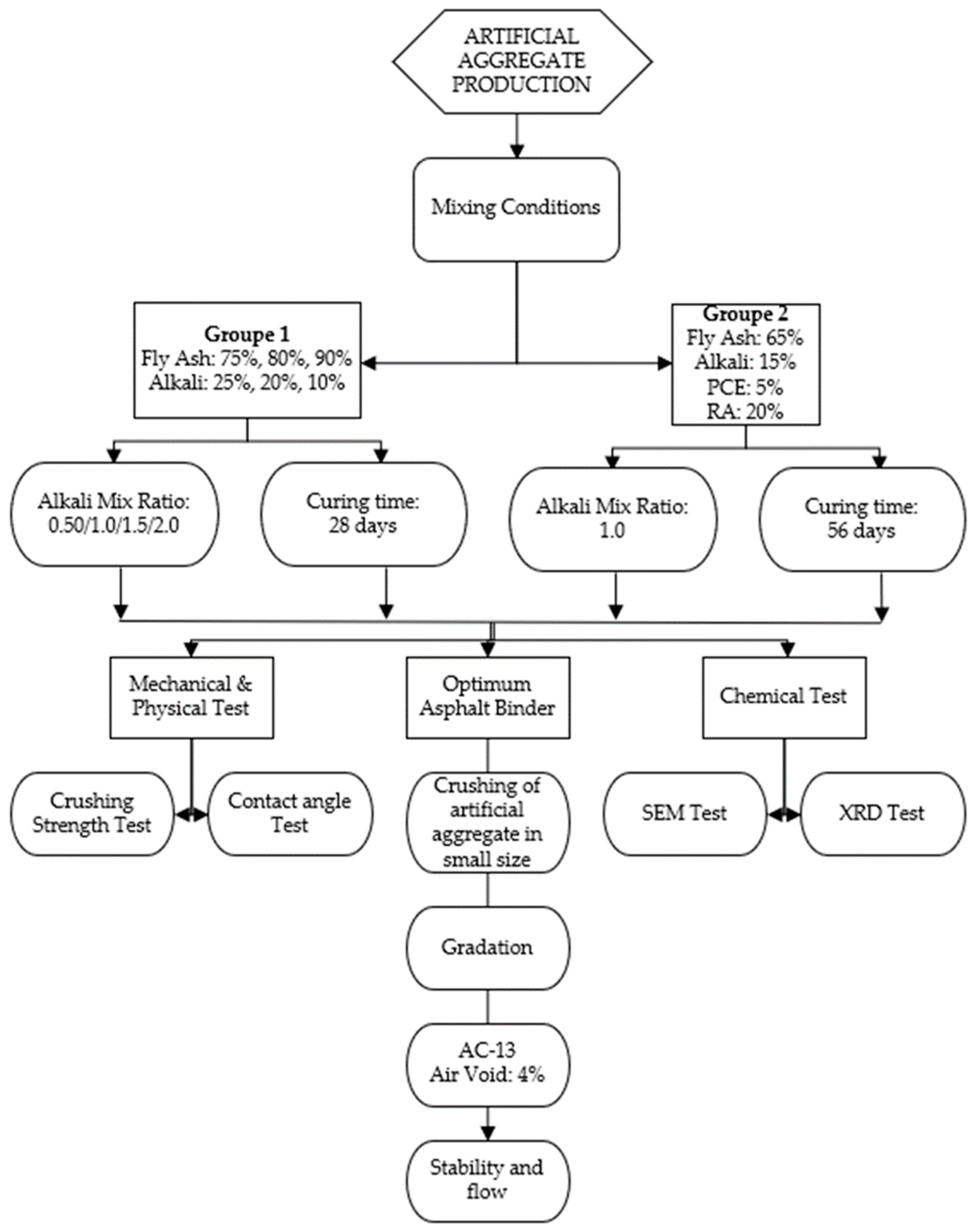

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

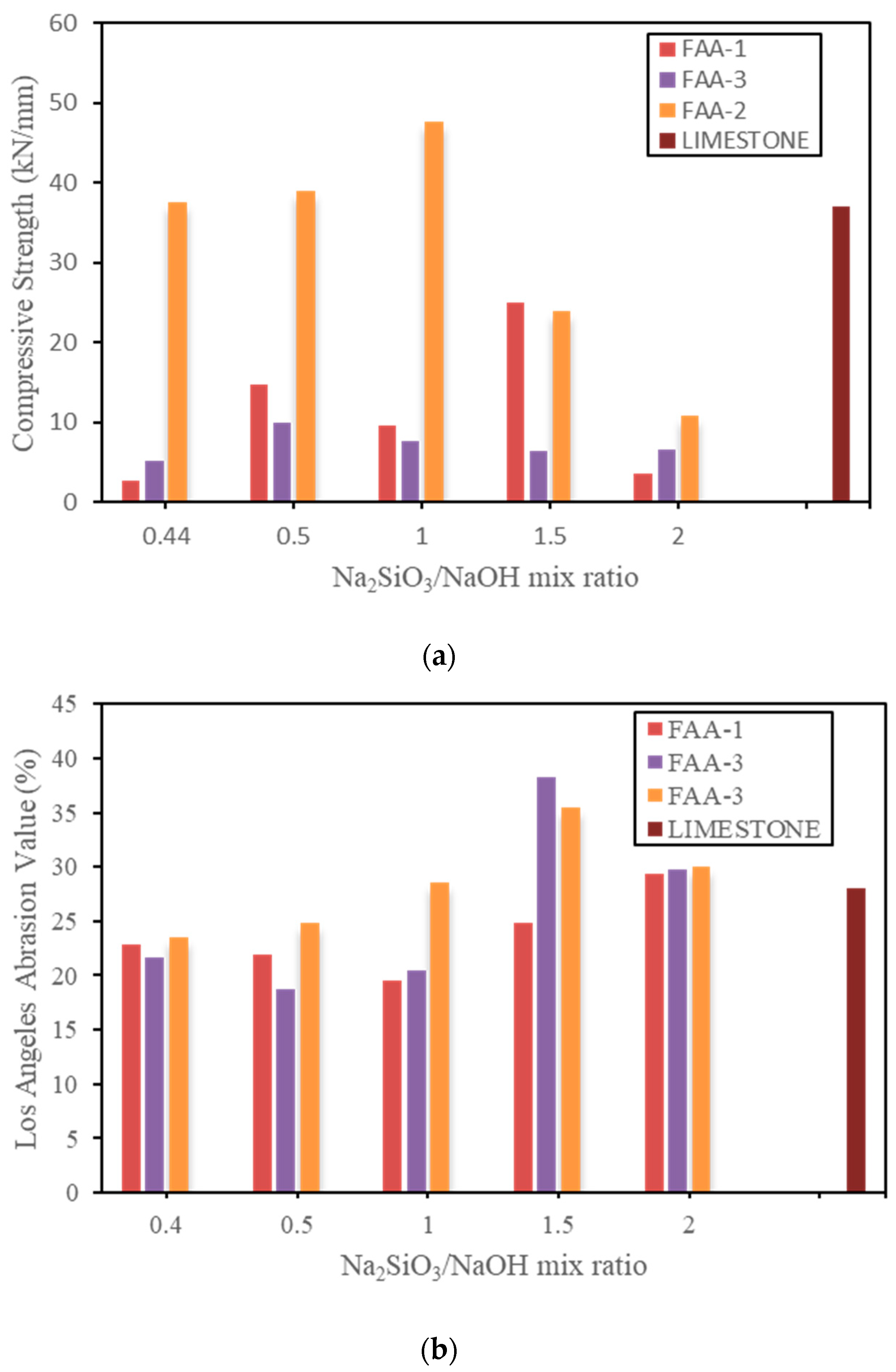

3.1. Mechanical Performance

3.2. Hydrophobic Properties

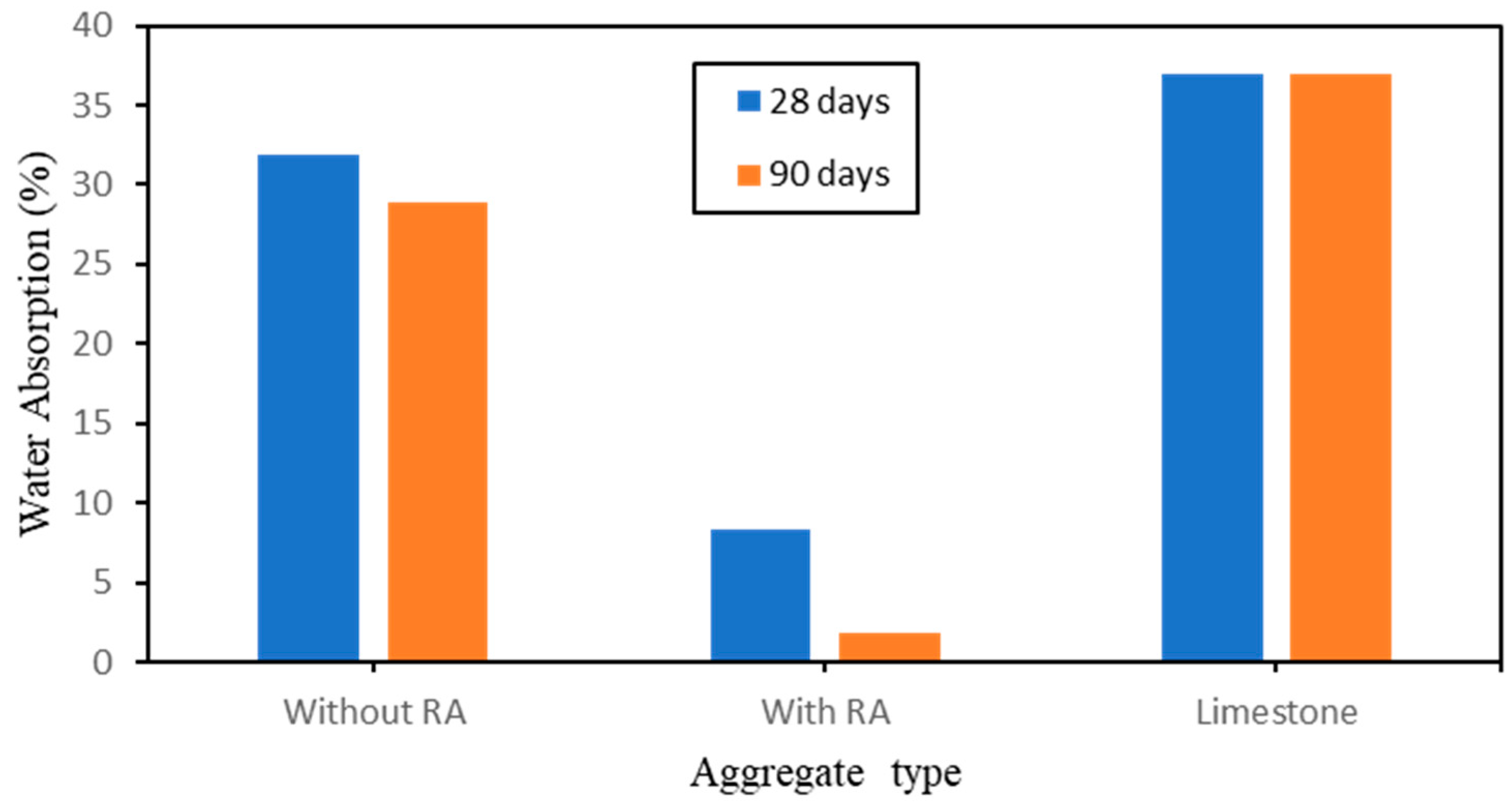

3.2.1. Water Absorption

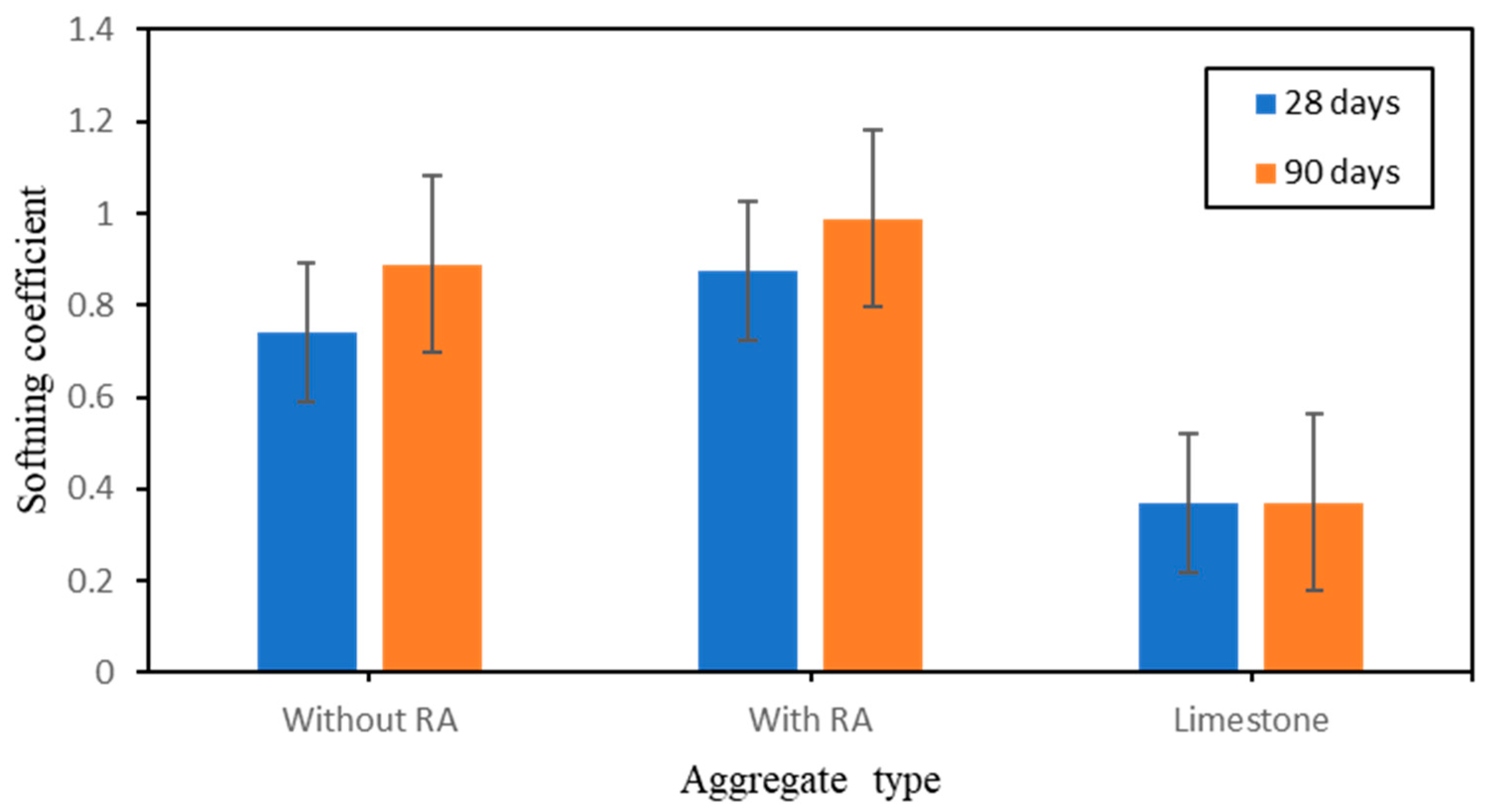

3.2.2. Softening Coefficient

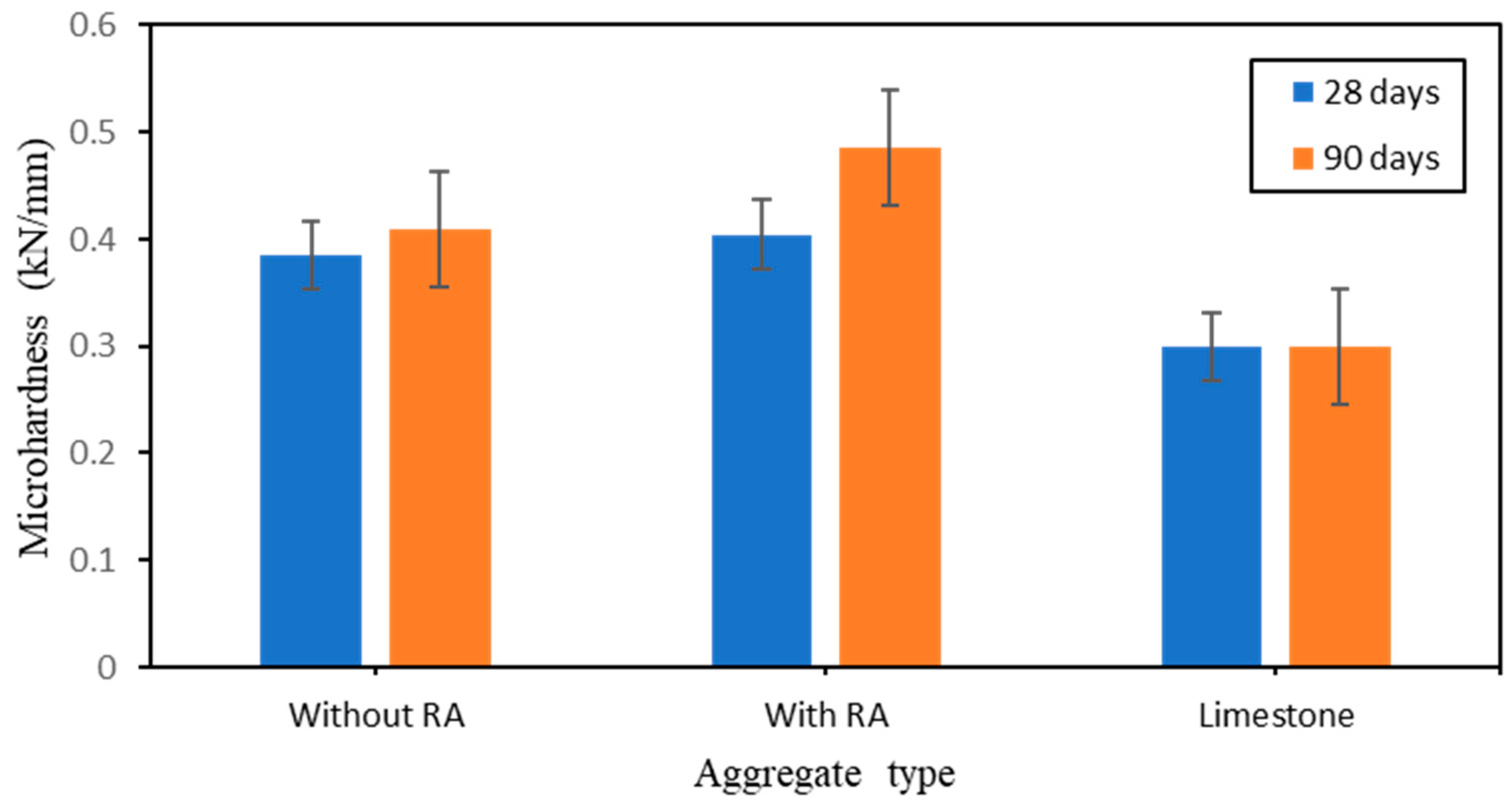

3.2.3. Microhardness Value

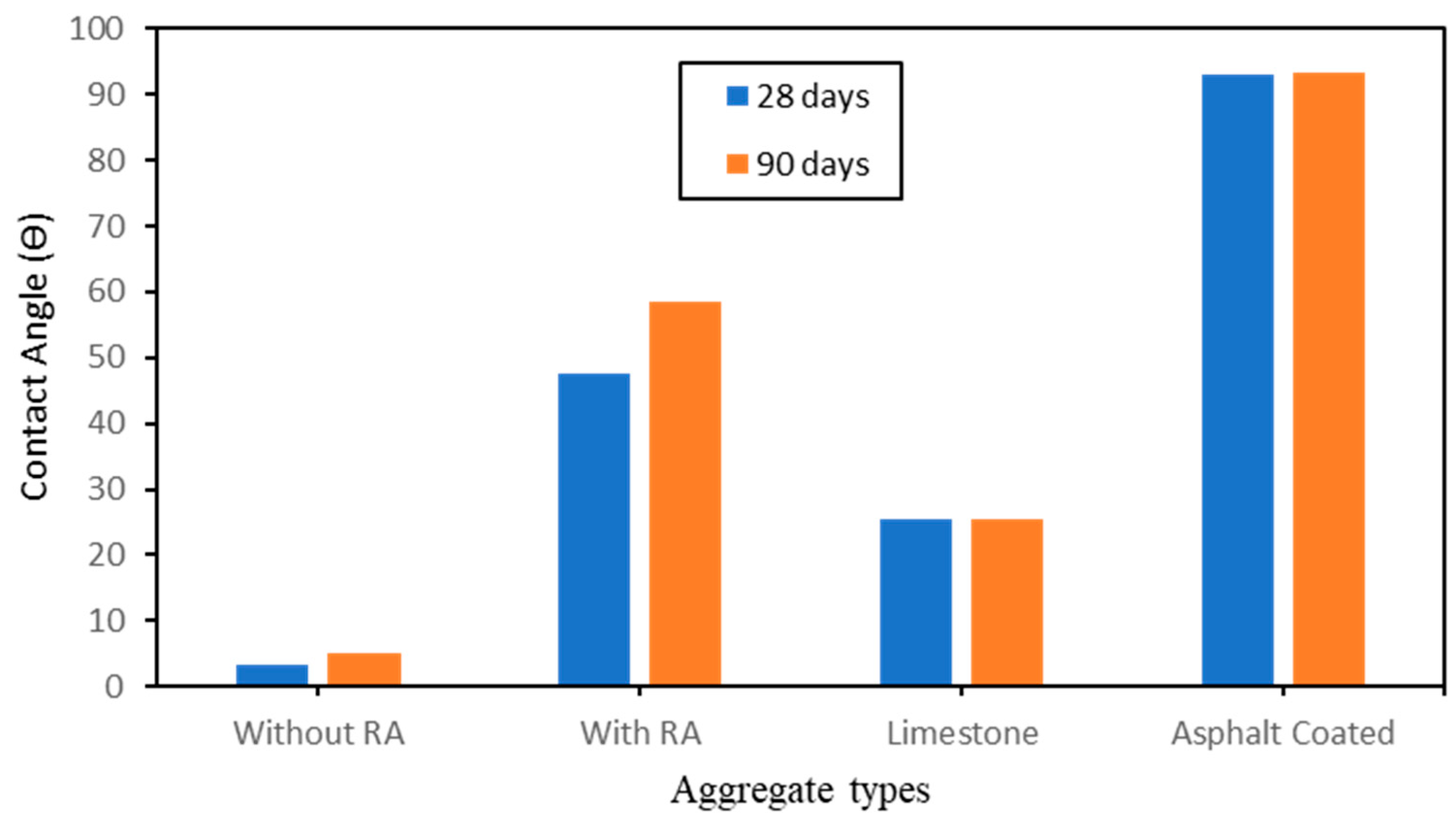

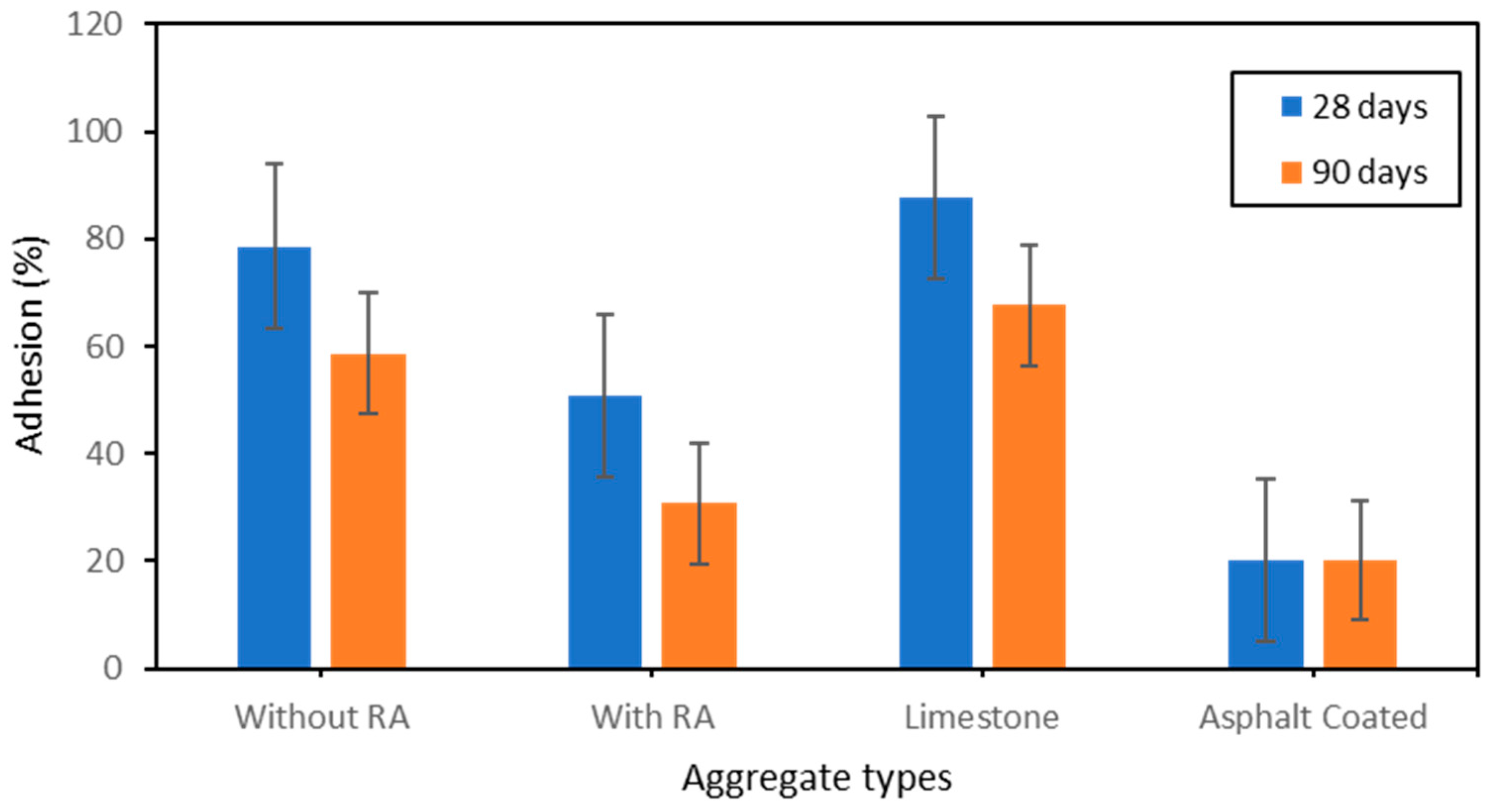

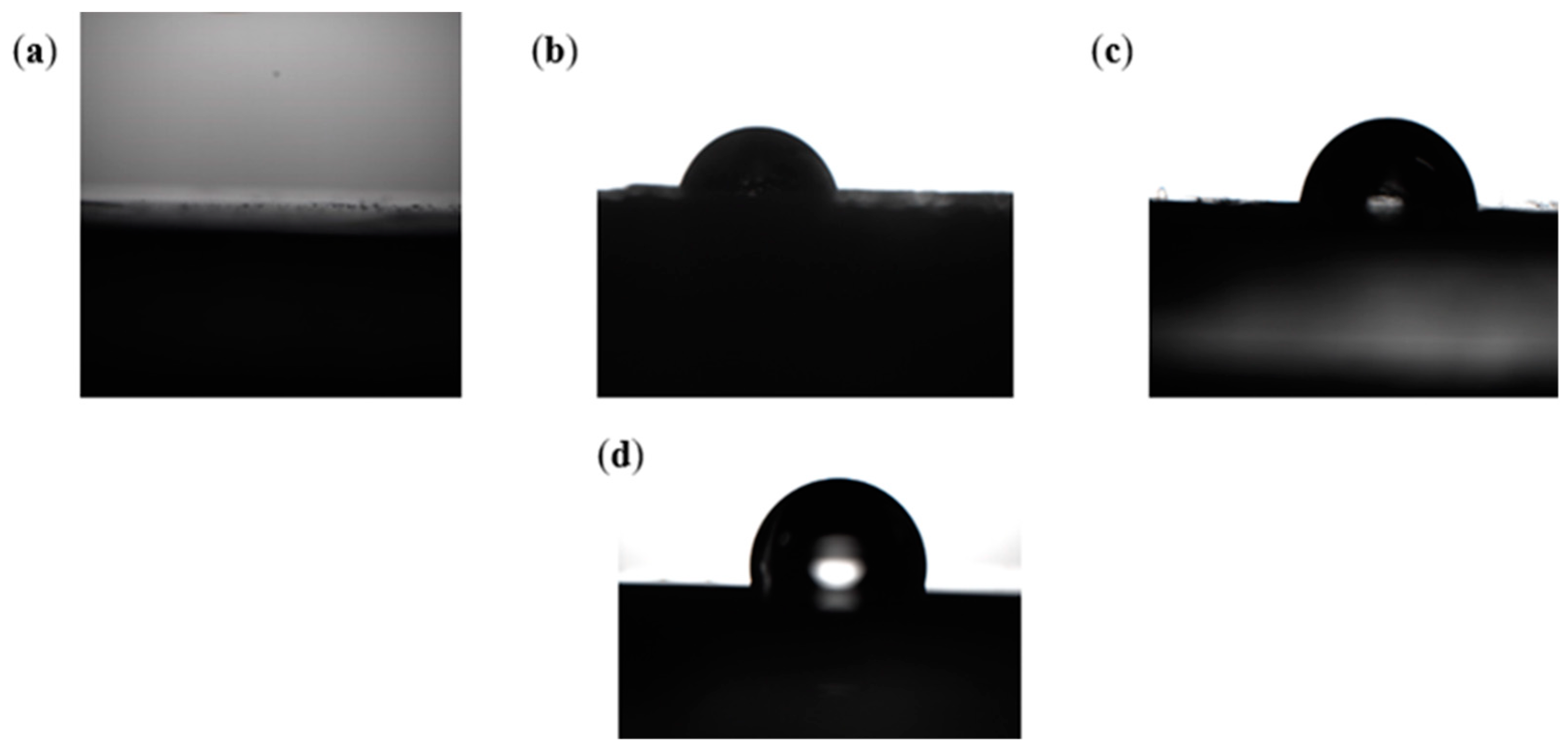

3.2.4. Contact Angle and Adhesion

3.3. Morphology and Mineralogical Composition

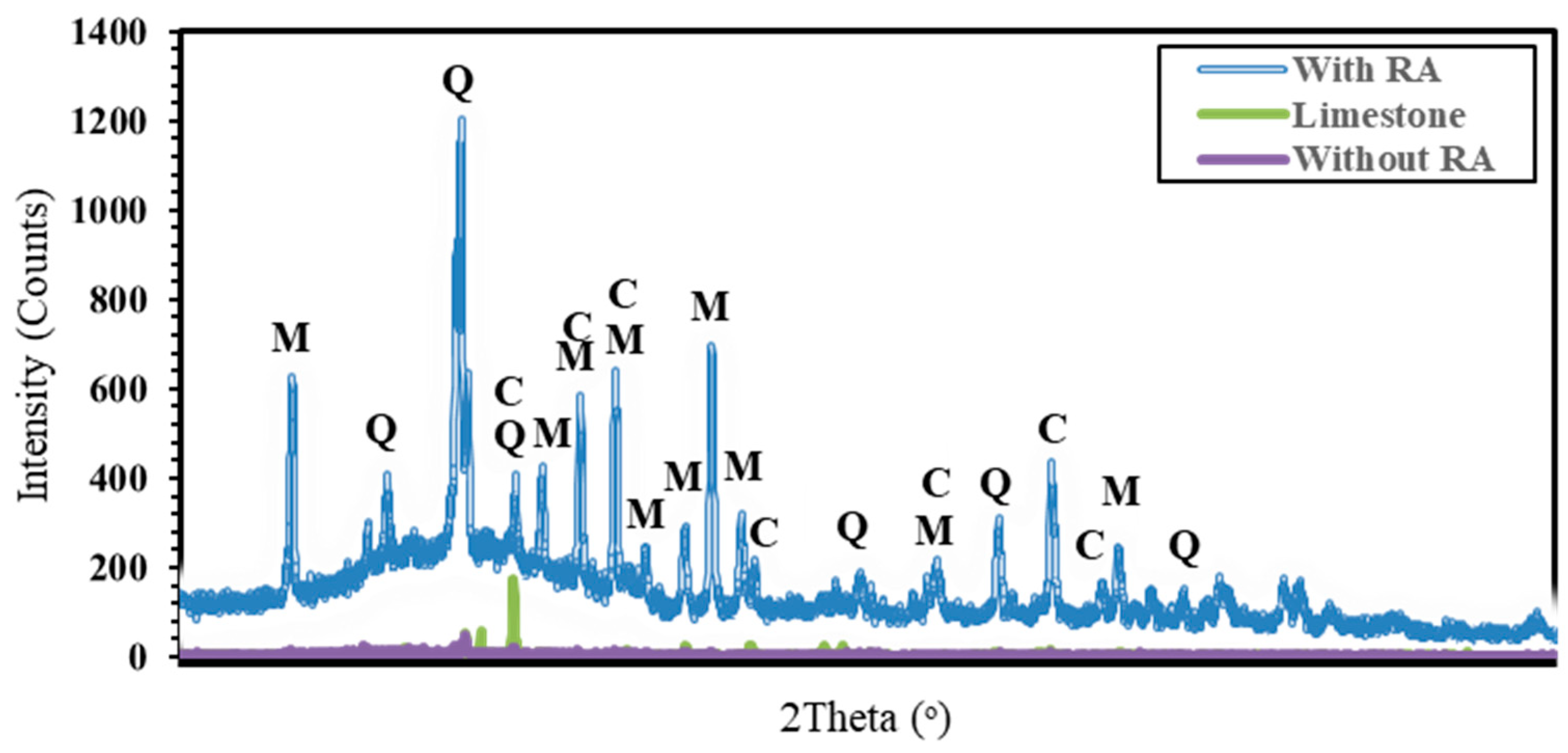

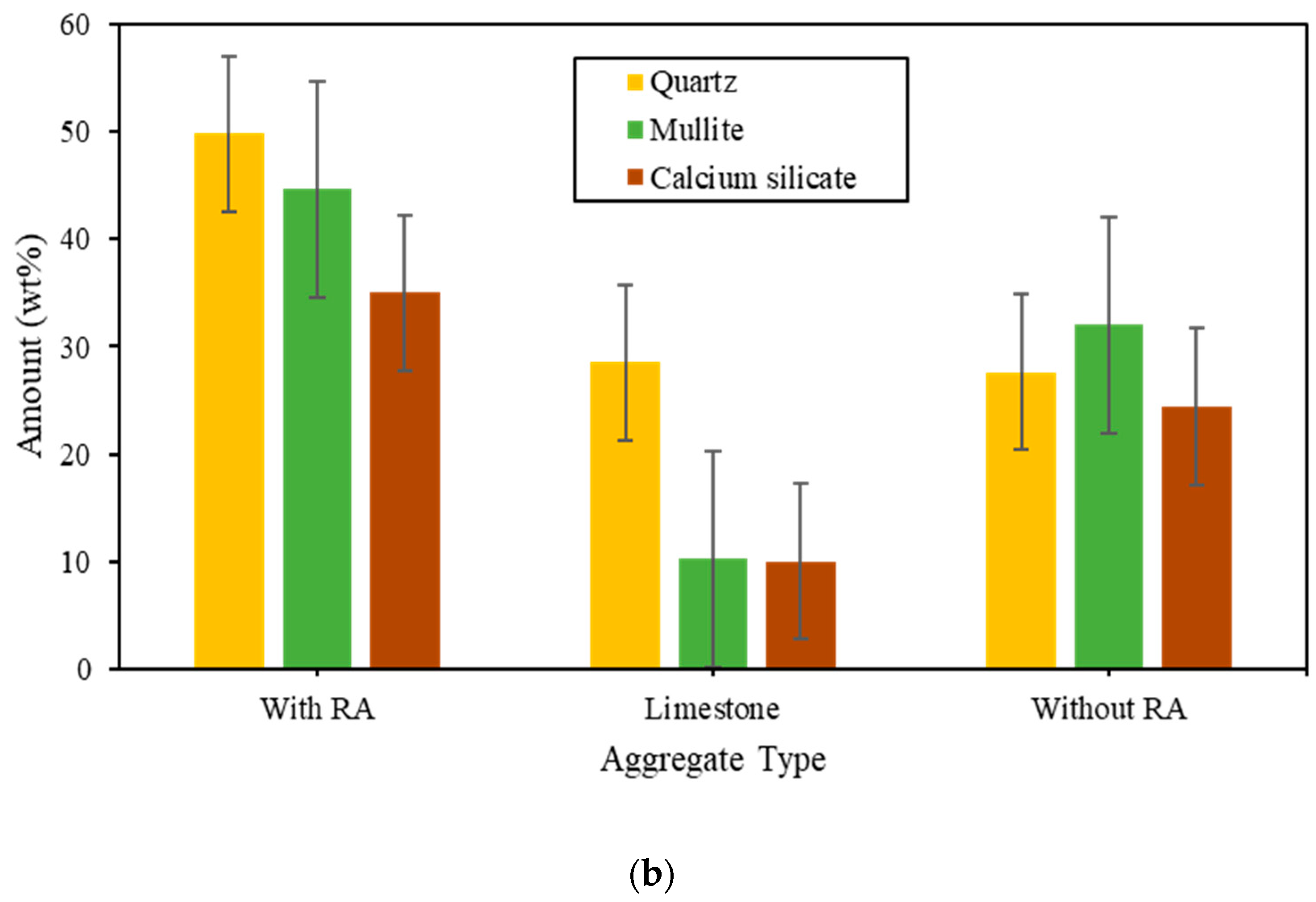

3.3.1. X-ray Diffraction (XRD)

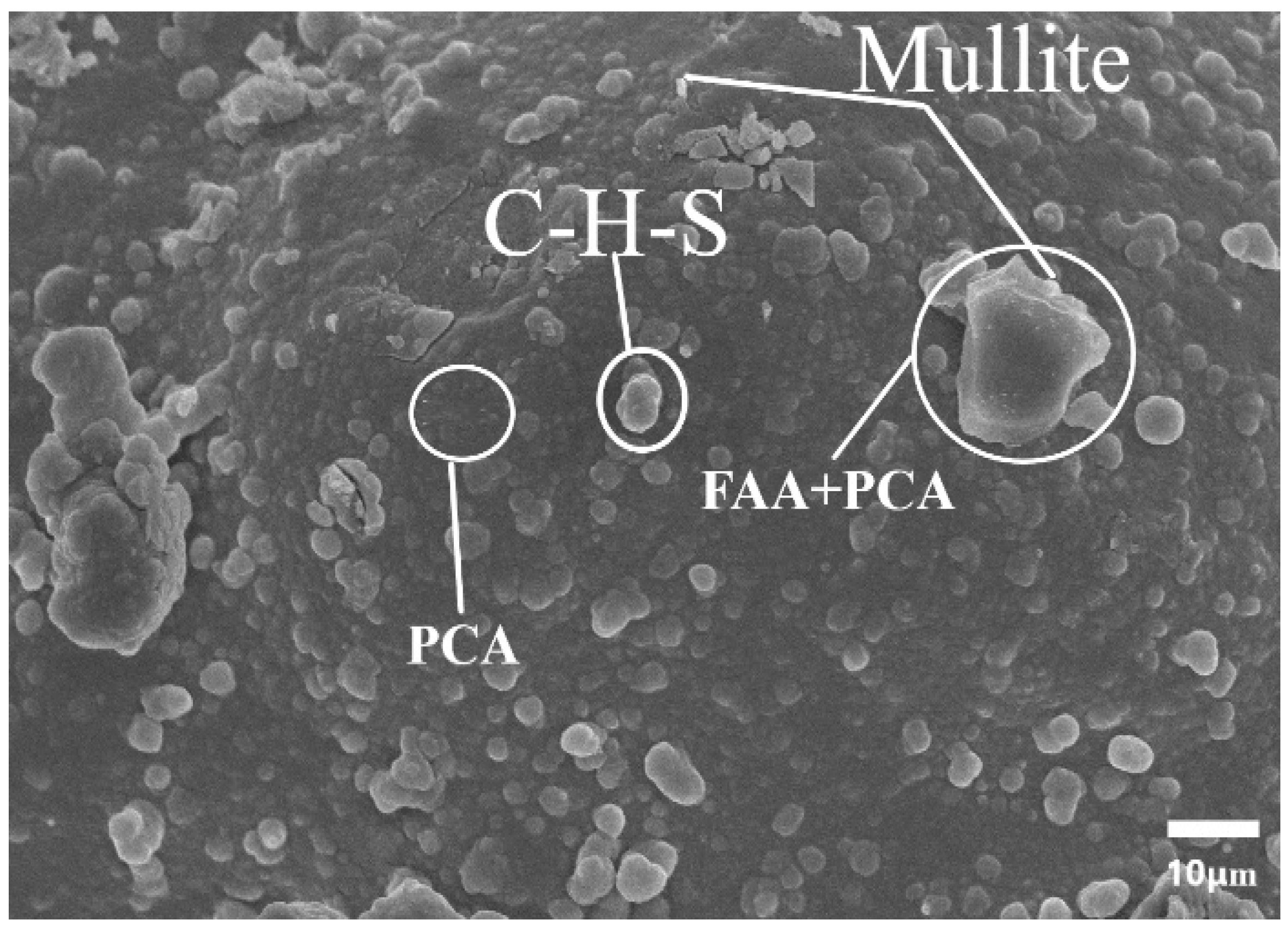

3.3.2. Scanning Electron Microscopy (SEM)

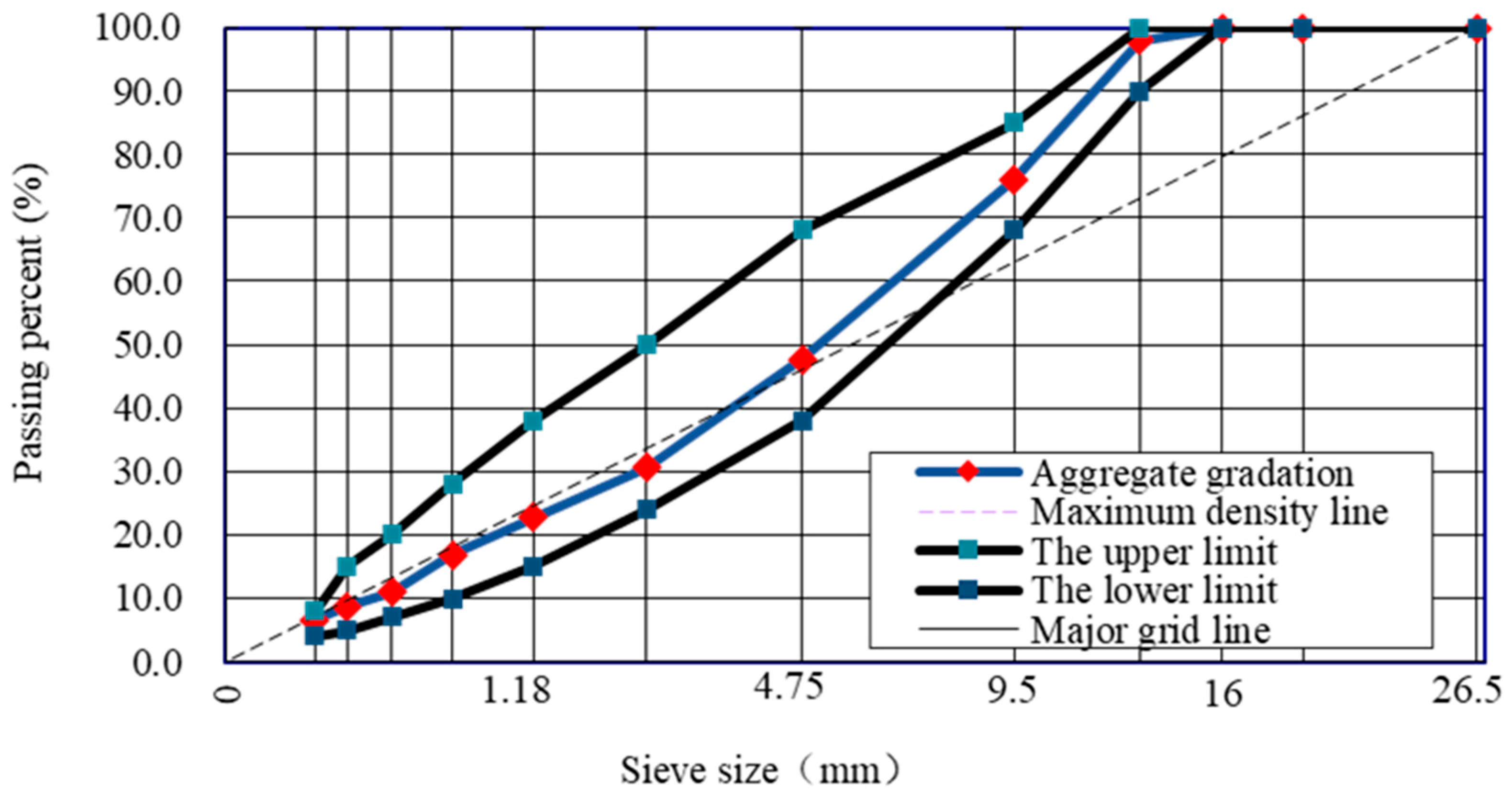

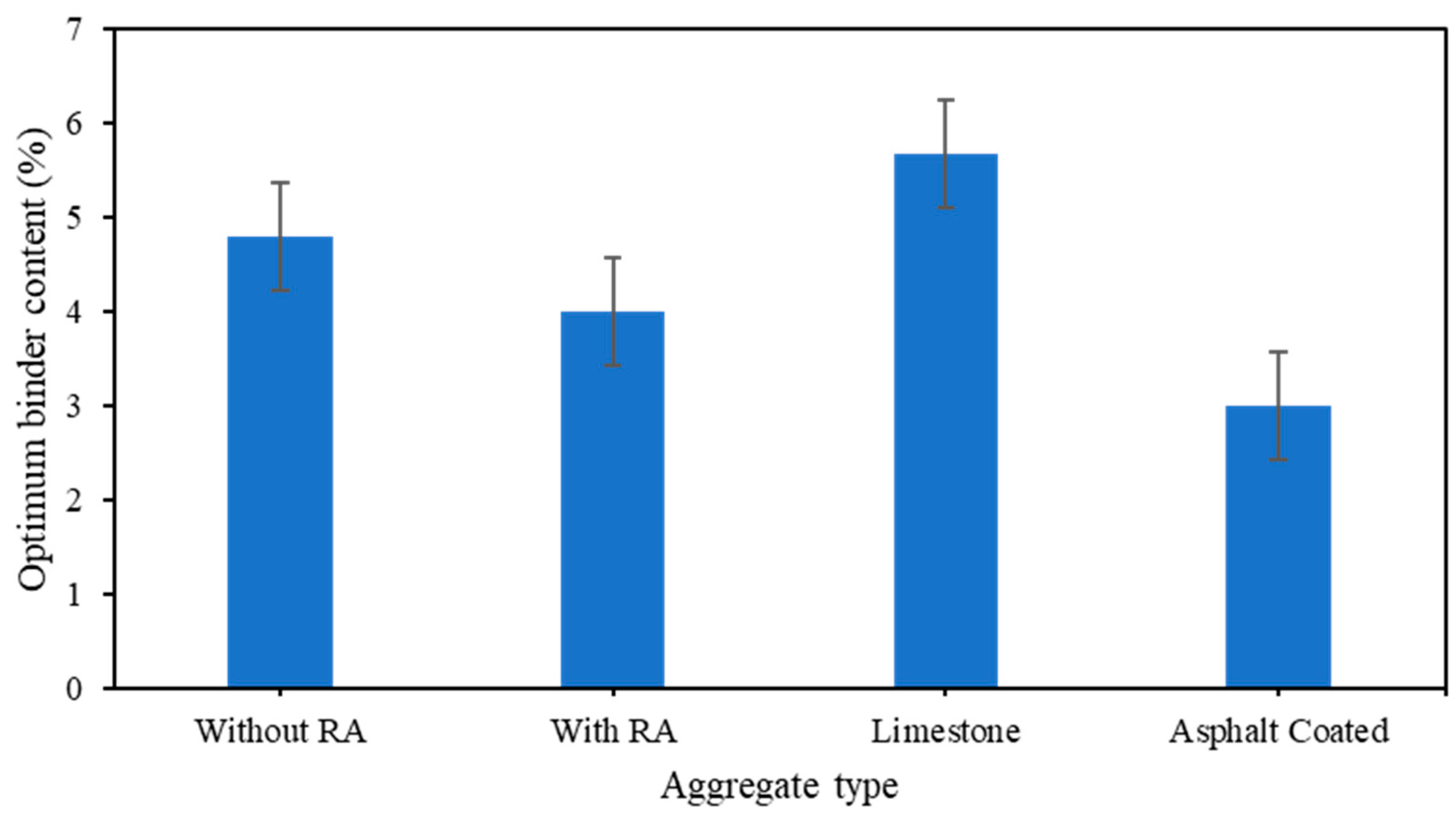

3.4. Optimum Asphalt Binder Content

4. Conclusions

- (1)

- Na2SiO3/NaOH mix ratio 1 gives a better balance and control of the overall activating reaction.

- (2)

- Sodium hydroxide (NaOH) is the solid part of the activators, hence, a quantity of 7.5–10% of alkali-silicate solution’s total weight leads to the reduction of pores.

- (3)

- 90 days of curing has a great impact in both the compressive strength and the absorption; the longer time the aggregate is given to cure, the more solid mineral compound is produced.

- (4)

- High quantity of rice ash can improve the compressive strength and, accelerate the production of mullite which is a great component for the hydrophobic nature of the aggregate.

- (5)

- Asphalt coated aggregates improves the surface hydrophobicity of the artificial aggregate, hence, can be used as aggregate replacement in asphalt pavement mixtures.

- (6)

- An optimum asphalt binder content ranges from 3–4.2% of asphalt content is required for a good wearing course and binder course coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S.; Yusoff, N.I.M. Utilisation of waste-based geopolymer in asphalt pavement modification and construction—A review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Mo, L.; Lv, L.; Deng, M.; Qian, J. Influence of fly ash and metakaolin on the microstructure and compressive strength of magnesium potassium phosphate cement paste. Cem. Concr. Res. 2018, 111, 116–129. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Shadnia, R.; Zhang, L.; Li, P. Experimental study of geopolymer mortar with incorporated PCM. Constr. Build. Mater. 2015, 84, 95–102. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Abdullah, M.M.A.B.; Vizureanu, P.; Tahir, M.F.M. Geopolymers and their uses. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012019. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Ibrahim, W.M.W. Mechanism and chemical reaction of fly ash geopolymer cement-a review. Int. J. Pure Appl. Sci. Technol. 2011, 6, 35–44. [Google Scholar]

- Navarro, F.J.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified asphalts. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Guo, J.; Guo, J.; Wang, S.; Xu, Z. Asphalt modified with nonmetals separated from pulverized waste printed circuit boards. Environ. Sci. Technol. 2009, 43, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Dayal, S.; Soundarapandian, N. Effect of fly-ash based geopolymer coated aggregate on bituminous mixtures. Gra Devinar 2018, 70, 187–199. [Google Scholar]

- Ruan, S.; Chen, S.; Lu, J.; Zeng, Q.; Liu, Y.; Yan, D. Waterproof geopolymer composites modified by hydrophobic particles and polydimethylsiloxane. Compos. Part B Eng. 2022, 237, 109865. [Google Scholar] [CrossRef]

- Rosyidi, S.A.P.; Rahmad, S.; Yusoff, N.I.; Shahrir, A.H.; Ibrahim, A.N.H.; Ismail, N.F.N.; Badri, K.H. Investigation of the chemical, strength, adhesion and morphological properties of fly ash based geopolymer-modified asphalt. Constr. Build. Mater. 2020, 255, 119364. [Google Scholar] [CrossRef]

- Bittencourt, S.V.; Magalhães, M.D.S.; Tavares, M.E.D.N. Mechanical behavior and water infiltration of pervious concrete incorporating recycled asphalt pavement aggregate. Case Stud. Constr. Mater. 2021, 14, e00473. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Yang, S.; Oeser, M.; Ago, C. Study of migration and diffusion during the mixing process of asphalt mixtures with RAP. Road Mater. Pavement Des. 2020, 22, 1578–1593. [Google Scholar] [CrossRef]

- Siswanto, H. Improving of Water Resistance of Asphalt Concrete Wearing Course Using Latex-Asphalt Binder. MATEC Web Conf. 2017, 97, 01033. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D36; Standard Test Method for Softening Point of Asphalt (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D113; Standard Test Method for Ductility of Bituminous Materials. Annual Book of Standards. ASTM International: West Conshohocken, PA, USA, 2007.

- BS EN 1097-1:1996; Tests for Mechanical and Physical Properties of Aggregates. British Standard: British Standard Institution: London, UK, 2004.

- Wu, Q.; Ma, H.; Chen, Q.; Gu, B.; Li, S.; Zhu, H. Effect of silane modified styrene-acrylic emulsion on the waterproof properties of flue gas desulfurization gypsum. Constr. Build. Mater. 2019, 197, 506–512. [Google Scholar] [CrossRef]

- Gao, J.; Qian, C.; Wang, B.; Morino, K. Experimental study on properties of polymer-modified cement mortars with silica fume. Cem. Concr. Res. 2002, 32, 41–45. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W. A novel waterproof, fast setting and high early strength repair material derived from metakaolin geopolymer. Constr. Build. Mater. 2016, 124, 69–73. [Google Scholar] [CrossRef]

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- Rudawska, A.; Jacniacka, E. Analysis for determining surface free energy uncertainty by the Owen–Wendt method. Int. J. Adhes. Adhes. 2009, 29, 451–457. [Google Scholar] [CrossRef]

- Sharma, V.; Chandra, S.; Choudhary, R. Characterization of Fly Ash Bituminous Concrete Mixes. J. Mater. Civ. Eng. 2010, 22, 1209–1216. [Google Scholar] [CrossRef]

| Chemical Formula | Mineral Crystals | Type of Aggregate (wt%) | ||

|---|---|---|---|---|

| With RA | Without RA | Limestone | ||

| SiO2 | Quartz | 27.64 | 43.6 | 49.76 |

| 3Al2O3·2SiO2 | Mullite | 44.64 | 31.98 | 10.24 |

| Ca2O4Si | Calcium silicate | 27.72 | 24.42 | 40 |

| Properties | Value | Method |

|---|---|---|

| Penetration @25 °C (dmm) | 68 | ASTM D 5-20 [18] |

| R&B Softening Point (°C) | 49.2 | ASTM D 36-14 [19] |

| Ductility @15 °C (cm) | 158.4 | ASTM D 113-17 [20] |

| Description | Picture |

|---|---|

| Step 1: 15 cm × 15 cm × 15 cm cubic artificial aggregate based geopolymer specimen. |  |

| Step 2: crushing and sieving of specimens in different coarse and fine aggregate sizes in order to design the required aggregate gradation size. |  |

| Step 3: coating of the sieved (coarse and fine) artificial aggregate based geopolymer with asphalt in order to reduce the pores present on the aggregates. |  |

| Step 4: use of the coated artificial aggregate based geopolymer with asphalt to make Marshall test specimens in order to determine the optimum asphalt binder content and hence, reduce the absorption of asphalt by the aggregates. |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ago, C.; Li, G.; Wu, J.; Md Yusoff, N.I. Feasibility Study of Using Hydrophobic Geopolymer-Based as Aggregate Substitution in Asphalt Mixture. Polymers 2023, 15, 3077. https://doi.org/10.3390/polym15143077

Ago C, Li G, Wu J, Md Yusoff NI. Feasibility Study of Using Hydrophobic Geopolymer-Based as Aggregate Substitution in Asphalt Mixture. Polymers. 2023; 15(14):3077. https://doi.org/10.3390/polym15143077

Chicago/Turabian StyleAgo, Cadnel, Guowei Li, Jiantao Wu, and Nur Izzi Md Yusoff. 2023. "Feasibility Study of Using Hydrophobic Geopolymer-Based as Aggregate Substitution in Asphalt Mixture" Polymers 15, no. 14: 3077. https://doi.org/10.3390/polym15143077

APA StyleAgo, C., Li, G., Wu, J., & Md Yusoff, N. I. (2023). Feasibility Study of Using Hydrophobic Geopolymer-Based as Aggregate Substitution in Asphalt Mixture. Polymers, 15(14), 3077. https://doi.org/10.3390/polym15143077