Combined Effect of Citric Acid and Polyphenol-Rich Grape Seed Extract towards Bioactive Smart Food Packaging Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GSE Filtrates

2.3. Preparation of Film-Forming Solutions

2.4. Preparation of Films

2.5. Mechanical Properties

2.6. FTIR

2.7. Barrier Properties

2.8. Total Phenolic Content

2.9. Antioxidant Properties

2.10. Antimicrobial Properties

2.11. Colour Characteristics

2.12. Statistical Analyses

3. Results

3.1. Citric Acid Concentration

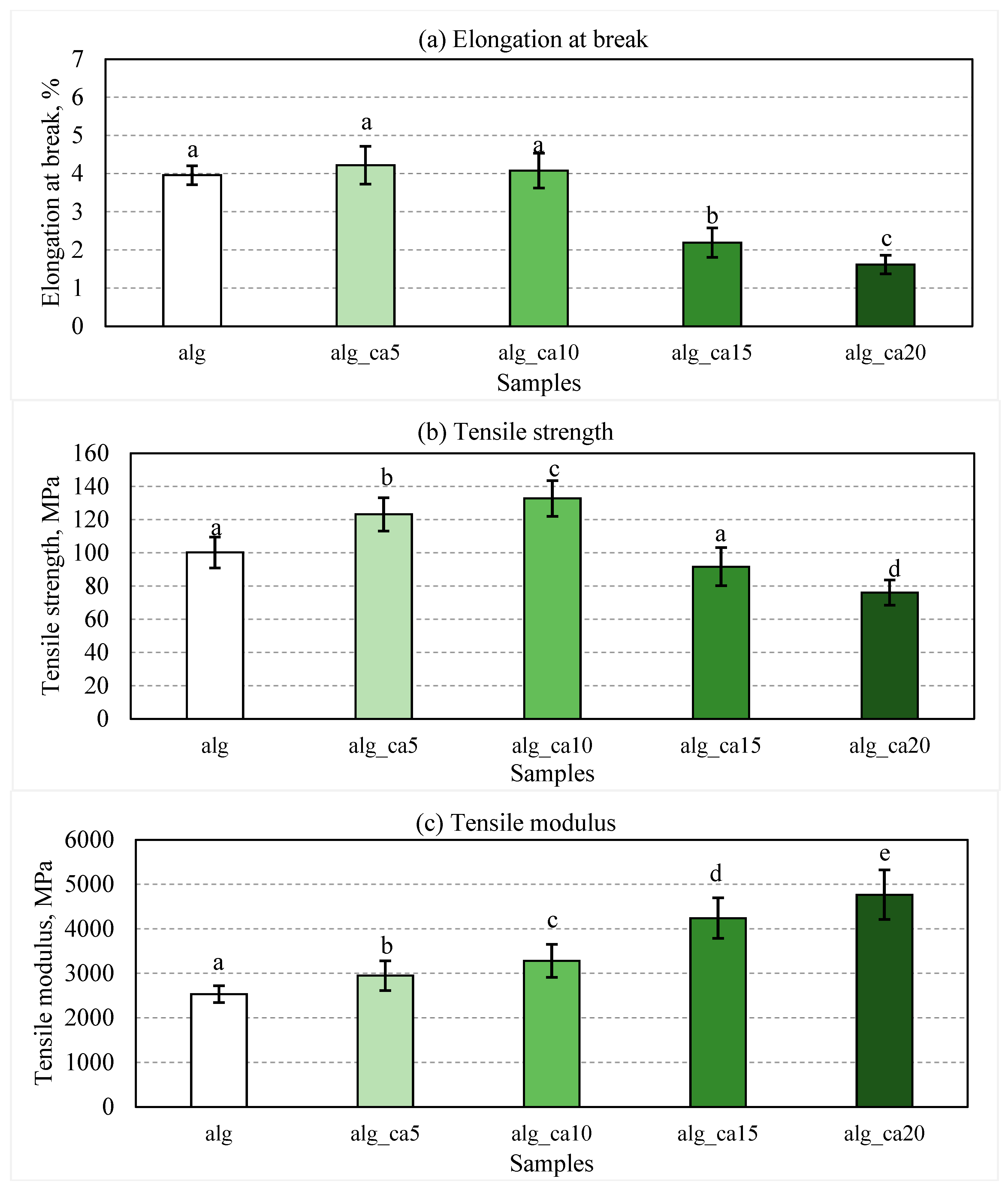

3.1.1. Effect of Citric Acid Concentration on Mechanical Properties

3.1.2. FTIR and the Effect of Citric Acid

3.1.3. Effect of Citric Acid on Barrier Properties

3.2. GSE

3.2.1. Effect of GSE on Mechanical Properties

3.2.2. FTIR and the Effect of GSE

3.2.3. Effect of GSE on Barrier Properties

3.2.4. Effect of GSE on Antioxidant Properties

3.2.5. Effect of GSE on Antimicrobial Properties

3.2.6. Effect of pH on the Colour of GSE-Based Film-Forming Solutions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Abdul Khalil, H.P.S.; Chong, E.W.N.; Owolabi, F.A.T.; Asniza, M.; Tye, Y.Y.; Rizal, S.; Nurul Fazita, M.R.; Mohamad Haafiz, M.K.; Nurmiati, Z.; Paridah, M.T. Enhancement of Basic Properties of Polysaccharide-Based Composites with Organic and Inorganic Fillers: A Review. J. Appl. Polym. Sci. 2019, 136, 47251. [Google Scholar] [CrossRef] [Green Version]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-Based Films and Coatings for Food Packaging: A Review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Cha, D.S.; Chinnan, M.S. Biopolymer-Based Antimicrobial Packaging: A Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 223–237. [Google Scholar] [CrossRef] [PubMed]

- Iversen, L.J.L.; Rovina, K.; Vonnie, J.M.; Matanjun, P.; Erna, K.H.; ‘Aqilah, N.M.N.; Felicia, W.X.L.; Funk, A.A. The Emergence of Edible and Food-Application Coatings for Food Packaging: A Review. Molecules 2022, 27, 5604. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xiao, J.; Li, F.; Shi, Y.; Li, D.; Huang, Q. Chitosan-Sodium Alginate Nanoparticle as a Delivery System for ε-Polylysine: Preparation, Characterization and Antimicrobial Activity. Food Control 2018, 91, 302–310. [Google Scholar] [CrossRef]

- Vieira, T.M.; Moldão-Martins, M.; Alves, V.D. Design of Chitosan and Alginate Emulsion-Based Formulations for the Production of Monolayer Crosslinked Edible Films and Coatings. Foods 2021, 10, 1654. [Google Scholar] [CrossRef]

- Zhao, X.; Xia, Y.; Li, Q.; Ma, X.; Quan, F.; Geng, C.; Han, Z. Microwave-Assisted Synthesis of Silver Nanoparticles Using Sodium Alginate and Their Antibacterial Activity. Colloids Surf. A Physicochem. Eng. Asp. 2014, 444, 180–188. [Google Scholar] [CrossRef]

- Abdullah, N.A.S.; Mohamad, Z.; Khan, Z.I.; Jusoh, M.; Zakaria, Z.Y.; Ngadi, N. Alginate Based Sustainable Films and Composites for Packaging: A Review. Chem. Eng. Trans. 2021, 83, 271–276. [Google Scholar] [CrossRef]

- Draget, K.I.; Smidsrød, O.; Skjåk-Bræk, G. Algintes from Algae. In Polysaccharides and Polyamides in the Food Industry: Properties, Production, and Patents; Wiley-VCH: Weinheim, Germany, 2005; pp. 1–30. ISBN 978-3-527-31345-7. [Google Scholar]

- Garavand, F.; Rouhi, M.; Razavi, S.H.; Cacciotti, I.; Mohammadi, R. Improving the Integrity of Natural Biopolymer Films Used in Food Packaging by Crosslinking Approach: A Review. Int. J. Biol. Macromol. 2017, 104, 687–707. [Google Scholar] [CrossRef]

- Sharmin, N.; Sone, I.; Walsh, J.L.; Sivertsvik, M.; Fernández, E.N. Effect of Citric Acid and Plasma Activated Water on the Functional Properties of Sodium Alginate for Potential Food Packaging Applications. Food Packag. Shelf Life 2021, 29, 100733. [Google Scholar] [CrossRef]

- Azevedo, V.M.; Dias, M.V.; de Siqueira Elias, H.H.; Fukushima, K.L.; Silva, E.K.; de Deus Souza Carneiro, J.; de Fátima Ferreira Soares, N.; Borges, S.V. Effect of Whey Protein Isolate Films Incorporated with Montmorillonite and Citric Acid on the Preservation of Fresh-Cut Apples. Food Res. Int. 2018, 107, 306–313. [Google Scholar] [CrossRef]

- Menzel, C. Improvement of Starch Films for Food Packaging through a Three-Principle Approach: Antioxidants, Cross-Linking and Reinforcement. Carbohydr. Polym. 2020, 250, 116828. [Google Scholar] [CrossRef]

- Eliuz, E. Antimicrobial Activity of Citric Acid against Escherichia coli, Staphylococcus aureus and Candida albicans as a Sanitizer Agent. Eurasian J. For. Sci. 2020, 8, 295–301. [Google Scholar] [CrossRef]

- In, Y.-W.; Kim, J.-J.; Kim, H.-J.; Oh, S.-W. Antimicrobial Activities of Acetic Acid, Citric Acid and Lactic Acid against Shigella Species: Organic Acids on Shigella. J. Food Saf. 2013, 33, 79–85. [Google Scholar] [CrossRef]

- Ounkaew, A.; Kasemsiri, P.; Kamwilaisak, K.; Saengprachatanarug, K.; Mongkolthanaruk, W.; Souvanh, M.; Pongsa, U.; Chindaprasirt, P. Polyvinyl Alcohol (PVA)/Starch Bioactive Packaging Film Enriched with Antioxidants from Spent Coffee Ground and Citric Acid. J. Polym. Environ. 2018, 26, 3762–3772. [Google Scholar] [CrossRef]

- Skřivanová, E.; Marounek, M.; Benda, V.; Brezina, P. Susceptibility of Escherichia coli, Salmonella sp. and Clostridium perfringens to Organic Acids and Monolaurin. Vet. Med. 2006, 51, 81–88. [Google Scholar] [CrossRef] [Green Version]

- Abdullah; Cai, J.; Hafeez, M.A.; Wang, Q.; Farooq, S.; Huang, Q.; Tian, W.; Xiao, J. Biopolymer-Based Functional Films for Packaging Applications: A Review. Front. Nutr. 2022, 9, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Han, J.H.; Ho, C.H.L.; Rodrigues, E.T. Intelligent Packaging. In Innovations in Food Packaging; Food Science and Technology International Series; Academic Press: Amsterdam, The Netherlands, 2014; pp. 138–155. ISBN 978-0-12-311632-1. [Google Scholar]

- Aljerf, L. High-Efficiency Extraction of Bromocresol Purple Dye and Heavy Metals as Chromium from Industrial Effluent by Adsorption onto a Modified Surface of Zeolite: Kinetics and Equilibrium Study. J. Environ. Manag. 2018, 225, 120–132. [Google Scholar] [CrossRef] [PubMed]

- Igbinosa, E.O.; Odjadjare, E.E.; Chigor, V.N.; Igbinosa, I.H.; Emoghene, A.O.; Ekhaise, F.O.; Igiehon, N.O.; Idemudia, O.G. Toxicological Profile of Chlorophenols and Their Derivatives in the Environment: The Public Health Perspective. Sci. World J. 2013, 2013, 460215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nor, N.M.; Hadibarata, T.; Zubir, M.M.F.A.; Lazim, Z.M.; Adnan, L.A.; Fulazzaky, M.A. Mechanism of Triphenylmethane Cresol Red Degradation by Trichoderma harzianum M06. Bioprocess Biosyst. Eng. 2015, 38, 2167–2175. [Google Scholar] [CrossRef]

- Balbinot-Alfaro, E.; Craveiro, D.V.; Lima, K.O.; Costa, H.L.G.; Lopes, D.R.; Prentice, C. Intelligent Packaging with PH Indicator Potential. Food Eng. Rev. 2019, 11, 235–244. [Google Scholar] [CrossRef]

- Li, J.-H.; Miao, J.; Wu, J.-L.; Chen, S.-F.; Zhang, Q.-Q. Preparation and Characterization of Active Gelatin-Based Films Incorporated with Natural Antioxidants. Food Hydrocoll. 2014, 37, 166–173. [Google Scholar] [CrossRef]

- Perumalla, A.V.S.; Hettiarachchy, N.S. Green Tea and Grape Seed Extracts—Potential Applications in Food Safety and Quality. Food Res. Int. 2011, 44, 827–839. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Riahi, Z.; Rhim, J.-W. Antioxidant Pectin/Pullulan Edible Coating Incorporated with Vitis vinifera Grape Seed Extract for Extending the Shelf Life of Peanuts. Postharvest Biol. Technol. 2022, 183, 111740. [Google Scholar] [CrossRef]

- Corrales, M.; Han, J.H.; Tauscher, B. Antimicrobial Properties of Grape Seed Extracts and Their Effectiveness after Incorporation into Pea Starch Films. Int. J. Food Sci. Technol. 2009, 44, 425–433. [Google Scholar] [CrossRef]

- Shahbazi, Y. The Properties of Chitosan and Gelatin Films Incorporated with Ethanolic Red Grape Seed Extract and Ziziphora clinopodioides Essential Oil as Biodegradable Materials for Active Food Packaging. Int. J. Biol. Macromol. 2017, 99, 746–753. [Google Scholar] [CrossRef] [PubMed]

- Sivarooban, T.; Hettiarachchy, N.S.; Johnson, M.G. Physical and Antimicrobial Properties of Grape Seed Extract, Nisin, and EDTA Incorporated Soy Protein Edible Films. Food Res. Int. 2008, 41, 781–785. [Google Scholar] [CrossRef]

- Sogut, E.; Seydim, A.C. The Effects of Chitosan and Grape Seed Extract-Based Edible Films on the Quality of Vacuum Packaged Chicken Breast Fillets. Food Packag. Shelf Life 2018, 18, 13–20. [Google Scholar] [CrossRef]

- Guo, B.; Lv, K.; Hu, Y.; Du, J.; Lv, Y. Study on Optical Properties and Biological Activity of Proanthocyanidins at Different PH and Alkalinit. IOP Conf. Ser. Earth Environ. Sci. 2021, 706, 012040. [Google Scholar] [CrossRef]

- Guo, L.; Yang, Z.-Y.; Tang, R.-C.; Yuan, H.-B. Preliminary Studies on the Application of Grape Seed Extract in the Dyeing and Functional Modification of Cotton Fabric. Biomolecules 2020, 10, 220. [Google Scholar] [CrossRef] [Green Version]

- Silván, J.M.; Mingo, E.; Hidalgo, M.; de Pascual-Teresa, S.; Carrascosa, A.V.; Martinez-Rodriguez, A.J. Antibacterial Activity of a Grape Seed Extract and Its Fractions against Campylobacter spp. Food Control 2013, 29, 25–31. [Google Scholar] [CrossRef]

- ASTM D638-99; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 1999. Available online: https://www.astm.org/d0638-99.html (accessed on 15 March 2022).

- Sarwar, M.S.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Hussain, A. Preparation and Characterization of PVA/Nanocellulose/Ag Nanocomposite Films for Antimicrobial Food Packaging. Carbohydr. Polym. 2018, 184, 453–464. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144. [Google Scholar] [CrossRef]

- Dysjaland, H.; Sone, I.; Noriega Fernández, E.; Sivertsvik, M.; Sharmin, N. Mechanical, Barrier, Antioxidant and Antimicrobial Properties of Alginate Films: Effect of Seaweed Powder and Plasma-Activated Water. Molecules 2022, 27, 8356. [Google Scholar] [CrossRef]

- Sharmin, N.; Pang, C.; Sone, I.; Walsh, J.L.; Fernández, C.G.; Sivertsvik, M.; Fernández, E.N. Synthesis of Sodium Alginate–Silver Nanocomposites Using Plasma Activated Water and Cold Atmospheric Plasma Treatment. Nanomaterials 2021, 11, 2306. [Google Scholar] [CrossRef]

- Olivato, J.B.; Grossmann, M.V.E.; Bilck, A.P.; Yamashita, F. Effect of Organic Acids as Additives on the Performance of Thermoplastic Starch/Polyester Blown Films. Carbohydr. Polym. 2012, 90, 159–164. [Google Scholar] [CrossRef]

- Reddy, N.; Jiang, Q.; Yang, Y. Preparation and Properties of Peanut Protein Films Crosslinked with Citric Acid. Ind. Crop. Prod. 2012, 39, 26–30. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Citric Acid Cross-Linking of Starch Films. Food Chem. 2010, 118, 702–711. [Google Scholar] [CrossRef] [Green Version]

- Shi, R.; Bi, J.; Zhang, Z.; Zhu, A.; Chen, D.; Zhou, X.; Zhang, L.; Tian, W. The Effect of Citric Acid on the Structural Properties and Cytotoxicity of the Polyvinyl Alcohol/Starch Films When Molding at High Temperature. Carbohydr. Polym. 2008, 74, 763–770. [Google Scholar] [CrossRef]

- Wang, S.; Ren, J.; Li, W.; Sun, R.; Liu, S. Properties of Polyvinyl Alcohol/Xylan Composite Films with Citric Acid. Carbohydr. Polym. 2014, 103, 94–99. [Google Scholar] [CrossRef]

- Wu, H.; Lei, Y.; Lu, J.; Zhu, R.; Xiao, D.; Jiao, C.; Xia, R.; Zhang, Z.; Shen, G.; Liu, Y.; et al. Effect of Citric Acid Induced Crosslinking on the Structure and Properties of Potato Starch/Chitosan Composite Films. Food Hydrocoll. 2019, 97, 105208. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Kontou-Vrettou, C.; Moates, G.K.; Wellner, N.; Cross, K.; Pereira, P.H.F.; Waldron, K.W. Wheat Straw Hemicellulose Films as Affected by Citric Acid. Food Hydrocoll. 2015, 50, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Priyadarshi, R.; Sauraj; Kumar, B.; Negi, Y.S. Chitosan Film Incorporated with Citric Acid and Glycerol as an Active Packaging Material for Extension of Green Chilli Shelf Life. Carbohydr. Polym. 2018, 195, 329–338. [Google Scholar] [CrossRef]

- Costa, M.J.; Marques, A.M.; Pastrana, L.M.; Teixeira, J.A.; Sillankorva, S.M.; Cerqueira, M.A. Physicochemical Properties of Alginate-Based Films: Effect of Ionic Crosslinking and Mannuronic and Guluronic Acid Ratio. Food Hydrocoll. 2018, 81, 442–448. [Google Scholar] [CrossRef] [Green Version]

- Kaygusuz, H.; Evingür, G.A.; Pekcan, Ö.; von Klitzing, R.; Erim, F.B. Surfactant and Metal Ion Effects on the Mechanical Properties of Alginate Hydrogels. Int. J. Biol. Macromol. 2016, 92, 220–224. [Google Scholar] [CrossRef]

- Shitrit, Y.; Davidovich-Pinhas, M.; Bianco-Peled, H. Shear Thinning Pectin Hydrogels Physically Cross-Linked with Chitosan Nanogels. Carbohydr. Polym. 2019, 225, 115249. [Google Scholar] [CrossRef] [PubMed]

- Sinha-Ray, S.; Khansari, S.; Yarin, A.L.; Pourdeyhimi, B. Effect of Chemical and Physical Cross-Linking on Tensile Characteristics of Solution-Blown Soy Protein Nanofiber Mats. Ind. Eng. Chem. Res. 2012, 51, 15109–15121. [Google Scholar] [CrossRef]

- Singh, P.; Baisthakur, P.; Yemul, O.S. Synthesis, Characterization and Application of Crosslinked Alginate as Green Packaging Material. Heliyon 2020, 6, e03026. [Google Scholar] [CrossRef] [Green Version]

- Kanatt, S.R.; Makwana, S.H. Development of Active, Water-Resistant Carboxymethyl Cellulose-Poly Vinyl Alcohol-Aloe vera Packaging Film. Carbohydr. Polym. 2020, 227, 115303. [Google Scholar] [CrossRef]

- Niazi, M.B.K.; Broekhuis, A.A. Surface Photo-Crosslinking of Plasticized Thermoplastic Starch Films. Eur. Polym. J. 2015, 64, 229–243. [Google Scholar] [CrossRef]

- Awadhiya, A.; Kumar, D.; Verma, V. Crosslinking of Agarose Bioplastic Using Citric Acid. Carbohydr. Polym. 2016, 151, 60–67. [Google Scholar] [CrossRef]

- Liang, H.-F.; Hong, M.-H.; Ho, R.-M.; Chung, C.-K.; Lin, Y.-H.; Chen, C.-H.; Sung, H.-W. Novel Method Using a Temperature-Sensitive Polymer (Methylcellulose) to Thermally Gel Aqueous Alginate as a PH-Sensitive Hydrogel. Biomacromolecules 2004, 5, 1917–1925. [Google Scholar] [CrossRef]

- Kazayawoko, M.; Balatinecz, J.J.; Woodhams, R.T. Diffuse Reflectance Fourier Transform Infrared Spectra of Wood Fibers Treated with Maleated Polypropylenes. J. Appl. Polym. Sci. 1997, 66, 1163–1173. [Google Scholar] [CrossRef]

- Leal, D.; Matsuhiro, B.; Rossi, M.; Caruso, F. FT-IR Spectra of Alginic Acid Block Fractions in Three Species of Brown Seaweeds. Carbohydr. Res. 2008, 343, 308–316. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.; Yang, C.Q. FTIR Spectroscopy Study of the Formation of Cyclic Anhydride Intermediates of Polycarboxylic Acids Catalyzed by Sodium Hypophosphite. Text. Res. J. 2000, 70, 64–70. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H.; Entezami, A.A. Improving the Barrier and Mechanical Properties of Corn Starch-Based Edible Films: Effect of Citric Acid and Carboxymethyl Cellulose. Ind. Crop. Prod. 2011, 33, 229–235. [Google Scholar] [CrossRef]

- Moradi, M.; Tajik, H.; Razavi Rohani, S.M.; Oromiehie, A.R.; Malekinejad, H.; Aliakbarlu, J.; Hadian, M. Characterization of Antioxidant Chitosan Film Incorporated with Zataria multiflora Boiss Essential Oil and Grape Seed Extract. LWT 2012, 46, 477–484. [Google Scholar] [CrossRef]

- Borges-Vilches, J. Graphene Oxide/Polyethylene Glycol Aerogel Reinforced with Grape Seed Extracts as Wound Dressing. J. Mater. Sci. 2021, 56, 16082–16096. [Google Scholar] [CrossRef]

- Xu, Y.; Tian, Y.; Ma, R.; Liu, Q.; Zhang, J. Effect of Plasma Activated Water on the Postharvest Quality of Button Mushrooms, Agaricus bisporus. Food Chem. 2016, 197, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Fabra, M.J.; Falcó, I.; Randazzo, W.; Sánchez, G.; López-Rubio, A. Antiviral and Antioxidant Properties of Active Alginate Edible Films Containing Phenolic Extracts. Food Hydrocoll. 2018, 81, 96–103. [Google Scholar] [CrossRef]

- Li, A.-N.; Li, S.; Zhang, Y.-J.; Xu, X.-R.; Chen, Y.-M.; Li, H.-B. Resources and Biological Activities of Natural Polyphenols. Nutrients 2014, 6, 6020–6047. [Google Scholar] [CrossRef] [Green Version]

- Yeo, J.; Shahidi, F. Revisiting DPPH (2,2-Diphenyl-1-Picrylhydrazyl) Assay as a Useful Tool in Antioxidant Evaluation: A New IC100 Concept to Address Its Limitations. JFB 2019, 7, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Akaranta, O.; Akaho, A.A. Synergic Effect of Citric Acid and Peanut Skin Extract on the Oxidative Stability of Vegetable Oil. J. Appl. Sci. Environ. Manag. 2013, 16, 345–351. Available online: https://hdl.handle.net/1807/51939 (accessed on 4 April 2022).

- Hraš, A.R.; Hadolin, M.; Knez, Ž.; Bauman, D. Comparison of Antioxidative and Synergistic Effects of Rosemary Extract with α-Tocopherol, Ascorbyl Palmitate and Citric Acid in Sunflower Oil. Food Chem. 2000, 71, 229–233. [Google Scholar] [CrossRef]

- Bintsis, T. Foodborne Pathogens. AIMS Microbiol. 2017, 3, 529–563. [Google Scholar] [CrossRef]

- Helander, I.M.; Mattila-Sandholm, T. Fluorometric Assessment of Gram-Negative Bacterial Permeabilization. J. Appl. Microbiol. 2000, 88, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.-W.; Lee, H.-Y.; Kang, D.-H. Synergistic Bactericidal Effect of Hot Water with Citric Acid against Escherichia coli O157:H7 Biofilm Formed on Stainless Steel. Food Microbiol. 2021, 95, 103676. [Google Scholar] [CrossRef] [PubMed]

- Raftari, M.; Jalilian, F.A.; Abdulamir, A.S.; Son, R.; Sekawi, Z.; Fatimah, A.B. Effect of Organic Acids on Escherichia coli O157:H7 and Staphylococcus aureus Contaminated Meat. Open Microbiol. J. 2009, 3, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Chedea, V.S.; Echim, C.; Braicu, C.; Andjelkovic, M.; Verhe, R.; Socaciu, C. Composition in Polyphenols and Stability of the Aqueous Grape Seed Extract from the Romanian Variety “Merlot Recas”: Polyphenols from the “Merlot Recas” Grape Seeds. J. Food Biochem. 2011, 35, 92–108. [Google Scholar] [CrossRef]

- Gadang, V.P.; Hettiarachchy, N.S.; Johnson, M.G.; Owens, C. Evaluation of Antibacterial Activity of Whey Protein Isolate Coating Incorporated with Nisin, Grape Seed Extract, Malic Acid, and EDTA on a Turkey Frankfurter System. J. Food Sci. 2008, 73, M389–M394. [Google Scholar] [CrossRef]

- Memar, M.Y.; Adibkia, K.; Farajnia, S.; Kafil, H.S.; Yekani, M.; Alizadeh, N.; Ghotaslou, R. The Grape Seed Extract: A Natural Antimicrobial Agent against Different Pathogens. Rev. Med. Microbiol. 2019, 30, 173–182. [Google Scholar] [CrossRef]

- Shi, J.; Yu, J.; Pohorly, J.E.; Kakuda, Y. Polyphenolics in Grape Seeds—Biochemistry and Functionality. J. Med. Food 2003, 6, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Nopwinyuwong, A.; Trevanich, S.; Suppakul, P. Development of a Novel Colorimetric Indicator Label for Monitoring Freshness of Intermediate-Moisture Dessert Spoilage. Talanta 2010, 81, 1126–1132. [Google Scholar] [CrossRef] [PubMed]

- Wahyuningsih, S.; Wulandari, L.; Wartono, M.W.; Munawaroh, H.; Ramelan, A.H. The Effect of PH and Color Stability of Anthocyanin on Food Colorant. IOP Conf. Ser. Mater. Sci. Eng. 2017, 193, 012047. [Google Scholar] [CrossRef]

| Sample Code | Composition (%w·v−1) | pH | Thickness (mm) | WVTR, (g/m2h) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Solvent | alg | SHP | CA | ||||||

| alg | DW | 2.00 | - | - | 5.9 ± | 0.1 a | 0.04 ± 0.01 a | 138.56 ± | 4.87 a |

| alg_ca5 | DW | 2.00 | 0.05 | 0.10 | 4.4 ± | 0.2 b | 0.04 ± 0.00 a | 98.49 ± | 9.46 c |

| alg_ca10 | DW | 2.00 | 0.10 | 0.20 | 4.0 ± | 0.1 c | 0.04 ± 0.00 a | 91.99 ± | 4.41 c |

| alg_ca15 | DW | 2.00 | 0.15 | 0.30 | 3.8 ± | 0.1 d | 0.05 ± 0.00 a | 89.66 ± | 9.74 c |

| alg_ca20 | DW | 2.00 | 0.20 | 0.40 | 3.7 ± | 0.1 e | 0.05 ± 0.00 a | 78.04 ± | 3.17 d |

| GSE_alg | GSE | 2.00 | - | - | 5.9 ± | 0.2 a | 0.06 ± 0.01 b | 116.02 ± | 5.16 b |

| GSE_alg_ca10 | GSE | 2.00 | 0.10 | 0.20 | 4.2 ± | 0.2 b | 0.07 ± 0.00 b | 91.49 ± | 5.00 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pažarauskaitė, A.; Noriega Fernández, E.; Sone, I.; Sivertsvik, M.; Sharmin, N. Combined Effect of Citric Acid and Polyphenol-Rich Grape Seed Extract towards Bioactive Smart Food Packaging Systems. Polymers 2023, 15, 3118. https://doi.org/10.3390/polym15143118

Pažarauskaitė A, Noriega Fernández E, Sone I, Sivertsvik M, Sharmin N. Combined Effect of Citric Acid and Polyphenol-Rich Grape Seed Extract towards Bioactive Smart Food Packaging Systems. Polymers. 2023; 15(14):3118. https://doi.org/10.3390/polym15143118

Chicago/Turabian StylePažarauskaitė, Akvilė, Estefanía Noriega Fernández, Izumi Sone, Morten Sivertsvik, and Nusrat Sharmin. 2023. "Combined Effect of Citric Acid and Polyphenol-Rich Grape Seed Extract towards Bioactive Smart Food Packaging Systems" Polymers 15, no. 14: 3118. https://doi.org/10.3390/polym15143118

APA StylePažarauskaitė, A., Noriega Fernández, E., Sone, I., Sivertsvik, M., & Sharmin, N. (2023). Combined Effect of Citric Acid and Polyphenol-Rich Grape Seed Extract towards Bioactive Smart Food Packaging Systems. Polymers, 15(14), 3118. https://doi.org/10.3390/polym15143118